Quantitative filling frame for constructional engineering

A technology for construction engineering and packing racks, applied in the field of packing racks, can solve the problems of uncontrolled blanking of packing racks, etc., and achieve the effects of saving manpower, facilitating material collection, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

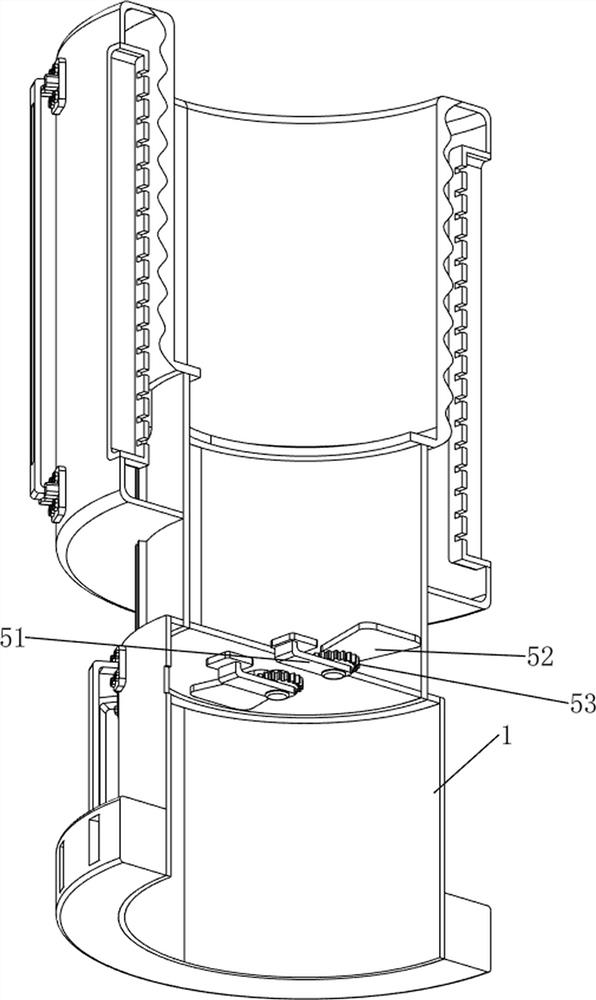

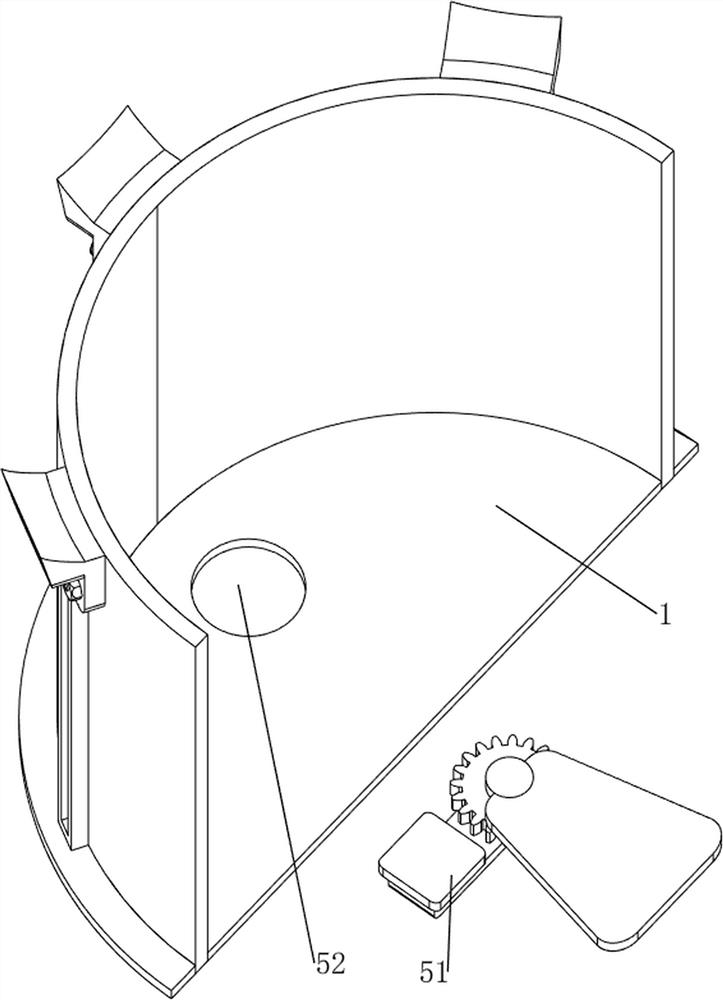

[0039] A quantitative filler frame for construction engineering, such as Figure 1-17 As shown, it includes a connecting barrel 1, a charging barrel 2, a discharging mechanism 3 and a stirring intermittent feeding mechanism 4. The upper side of the connecting barrel 1 is welded with a charging barrel 2, and the lower side of the charging barrel 2 is provided with a discharging mechanism. 3. A stirring intermittent feeding mechanism 4 is connected between the connecting barrel 1 and the discharging mechanism 3 .

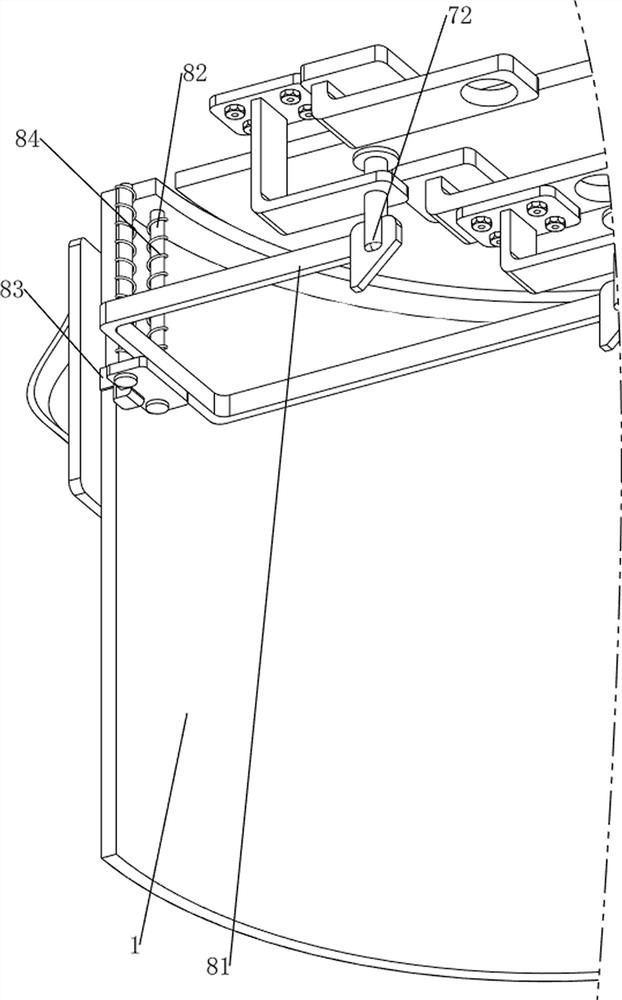

[0040] The discharge mechanism 3 includes a connecting frame 31, a first connecting rod 32, a sliding blocking plate 33 and a first spring 34. The lower side of the charging barrel 2 is provided with a connecting frame 31, and the lower side of the connecting frame 31 is uniformly welded with three third A connecting rod 32, between the three first connecting rods 32 is slidingly provided with a sliding blocking material plate 33, and three first springs 34 are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com