Intelligent grain loading robot for flexible spreading

A robot and intelligent technology, applied in the preparation of alcoholic beverages, conveyors, mechanical conveyors, etc., can solve the problems of feeding metering, poor speed and continuity, strong dependence on manual experience, and high labor costs, so as to improve processing quality , to ensure safety, stability and sanitation, and to improve the effect of wine yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

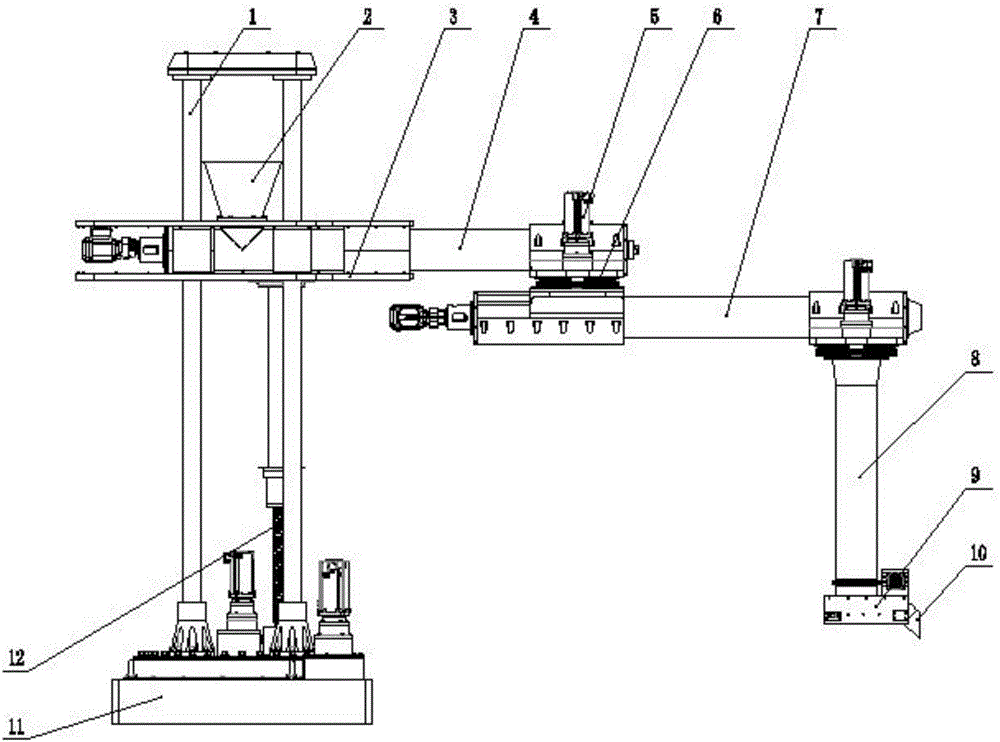

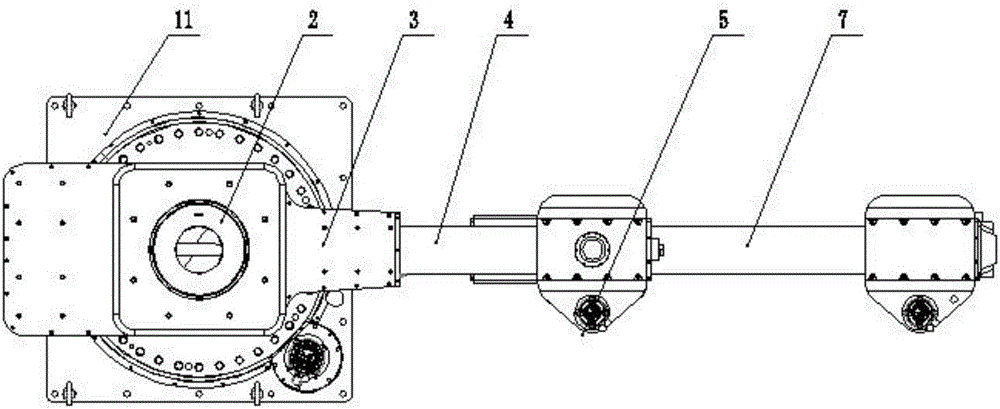

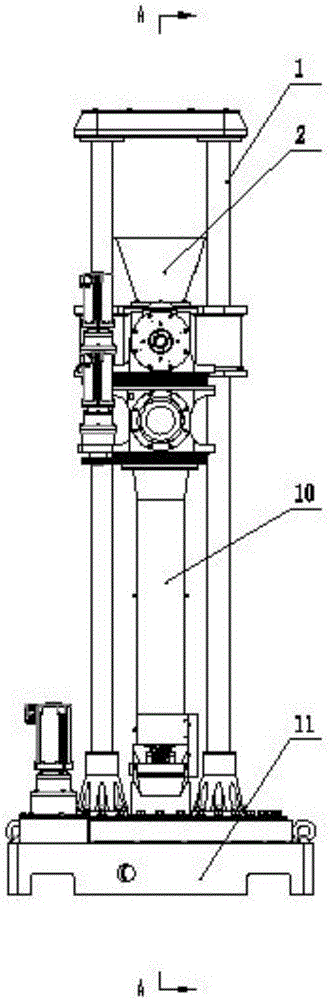

[0027] An intelligent steamer robot for flexible material spreading, comprising a base 11, a stand 1, a lifting frame 3, a primary feeding arm 4, a secondary feeding arm 7, a vertical feeding arm 8 and a buffer feeding arm 9,

[0028] There is a stand 1 in the vertical installation on the upper end of the base 11. The stand can rotate on the base with the vertical center axis of the stand as the axis. A lifting frame 3 is installed on the stand, and the lifting frame is driven by lifting. The device 12 is driven to move up and down along the vertical frame; a primary feeding arm 4 is installed in a horizontal cantilever type in the lifting frame, and the cantilever end of the primary feeding arm is ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com