Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

116results about How to "Realize intelligent production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

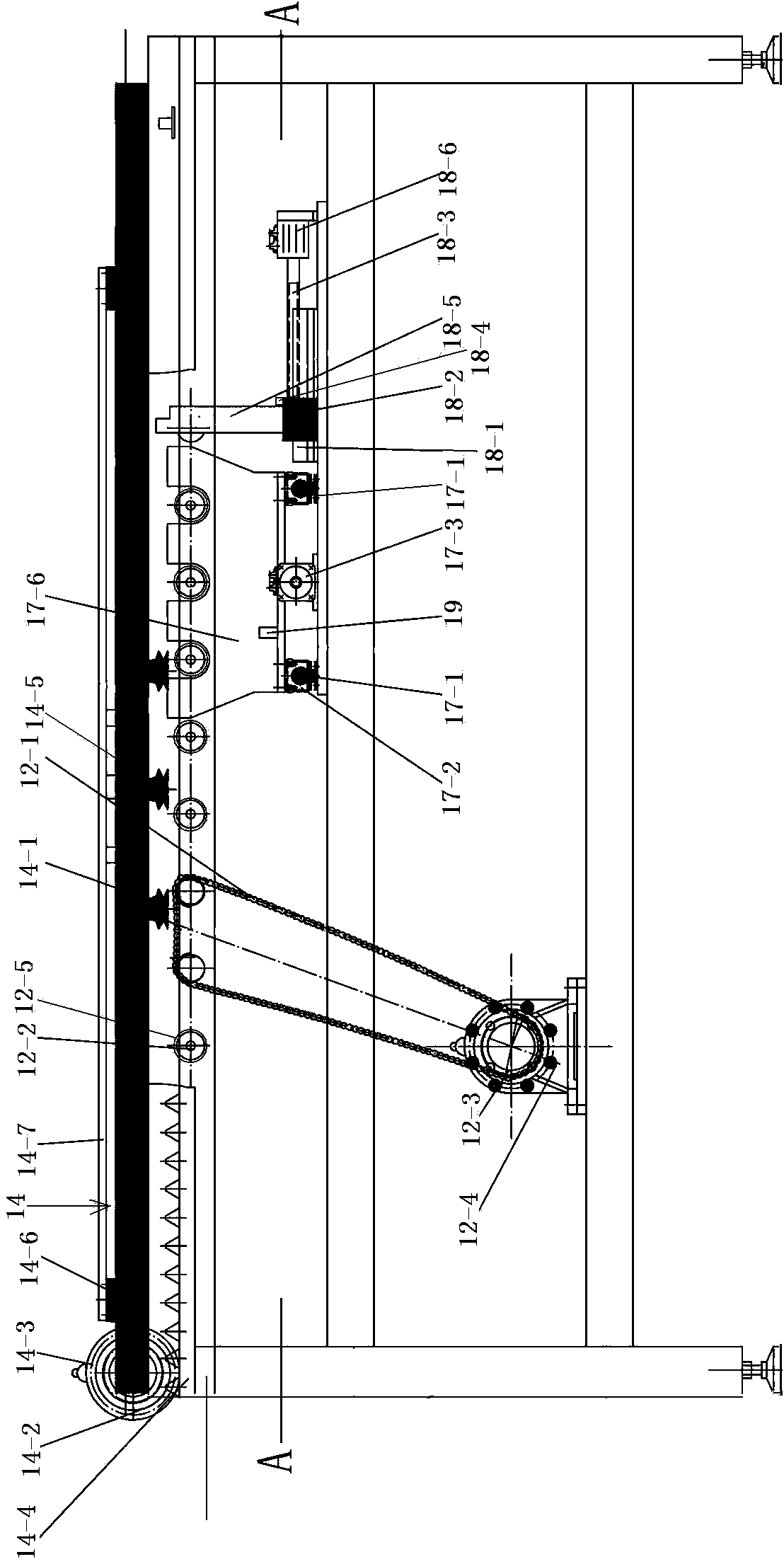

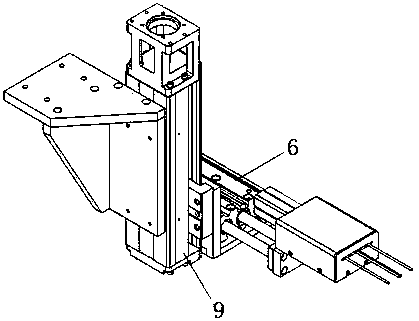

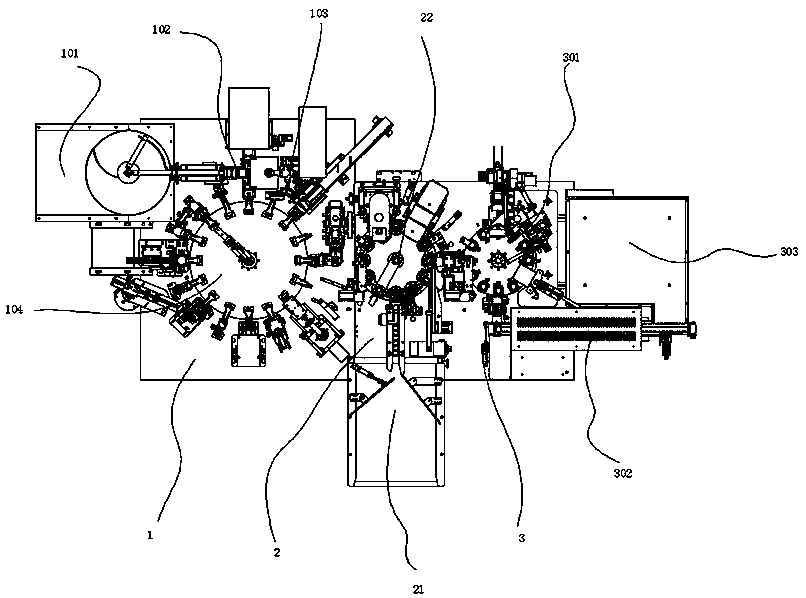

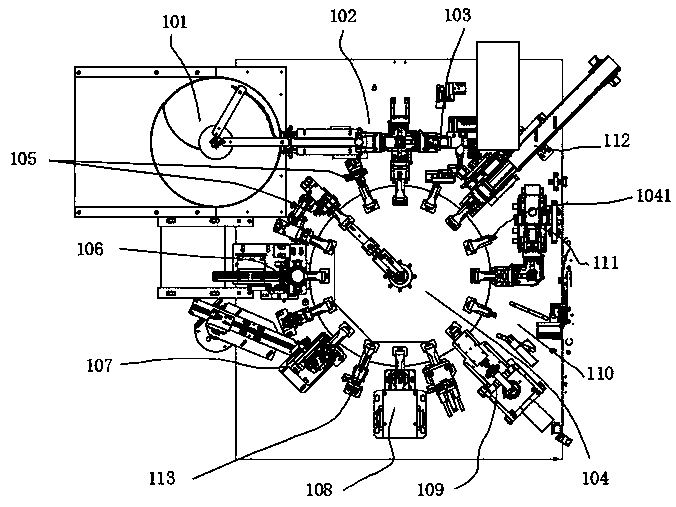

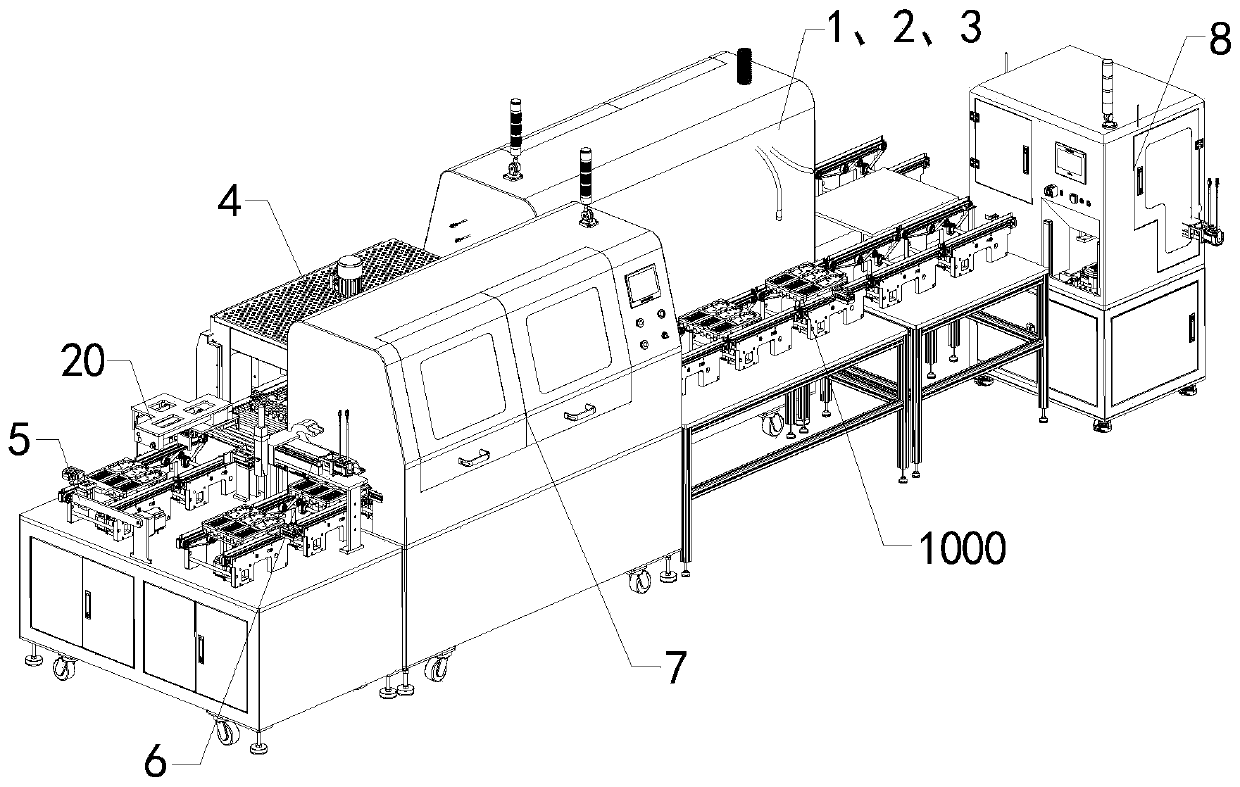

Automatic stator core production line

ActiveCN104810992ARealize intelligent productionIncrease productivityOther manufacturing equipments/toolsManufacturing stator/rotor bodiesWinding machineProduction line

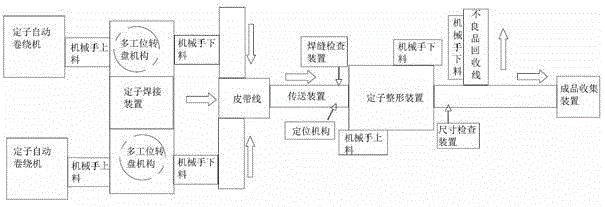

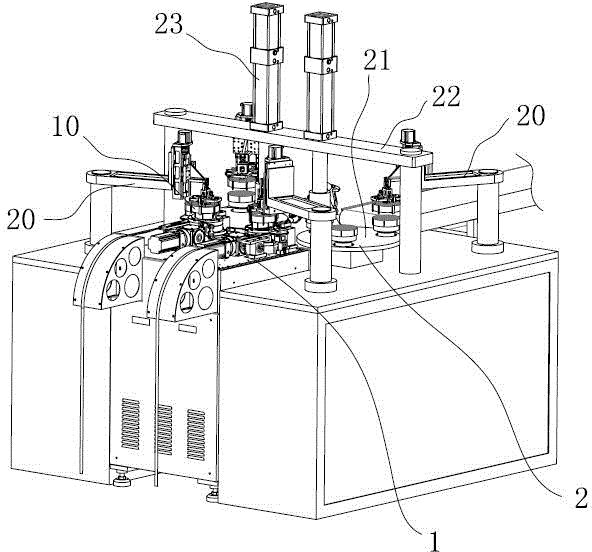

The invention discloses an automatic stator core production line. The automatic stator core production line comprises an automatic stator winding machine, a stator welding device, a conveying device, a weld joint detecting device, a stator reshaping device, a size detecting device and a finished product collecting device, mechanical arm systems are arranged among the devices, and working instructions among the devices are achieved via an instruction system. The automatic stator core production line has the advantages that in the full process, mechanical arms are adopted, automatic pipeline operation is achieved, unqualified stator cores generated in working procedures during production can be removed automatically, intelligent production is achieved, production efficiency is improved, and production cost is reduced.

Owner:CHANGYING XINZHI TECH CO LTD

Ceramic large plate of anhydrous glaze line all-digital jet printing process and manufacturing method thereof

InactiveCN108394008AHigh transparencyLabor savingSpecial ornamental structuresCeramic shaping apparatusSurface patternEngineering

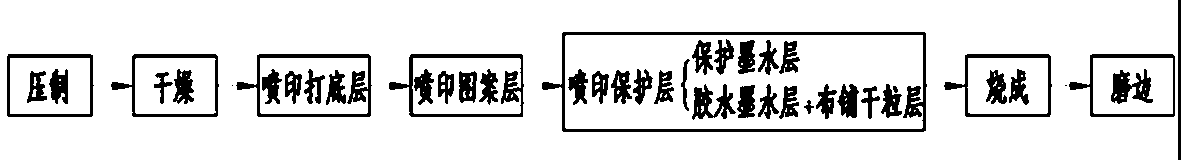

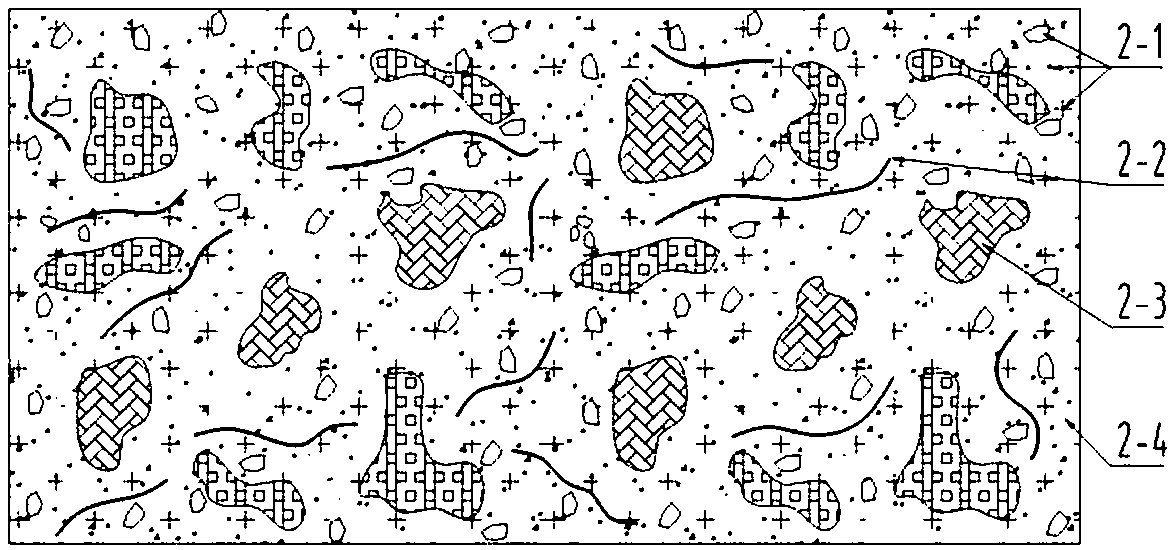

The invention discloses a ceramic large plate of an anhydrous glaze line all-digital jet printing process. The large plate comprises a bottom blank layer and a surface pattern layer; the surface pattern layer consists of a jet printing bottoming layer, a jet printing pattern layer, a jet printing protection layer / or a jet printing glue layer bonded with a dry particle layer in sequence from bottomto top; and the bottoming layer, the pattern layer, the protection layer / or the glue layer are formed by digital jet printing through a ceramic ink jet printer. The ceramic large plate and a manufacturing method thereof on a glaze line hardly need manual operation in the whole process for all-digital jet printing of the ceramic large plate and a sheet thereof; the texture is rich; the yield is increased; and anhydrous scene production environment is more accordant with modern green and intelligent manufacturing.

Owner:GUANGDONG SUMMIT CERAMIC CO LTD +1

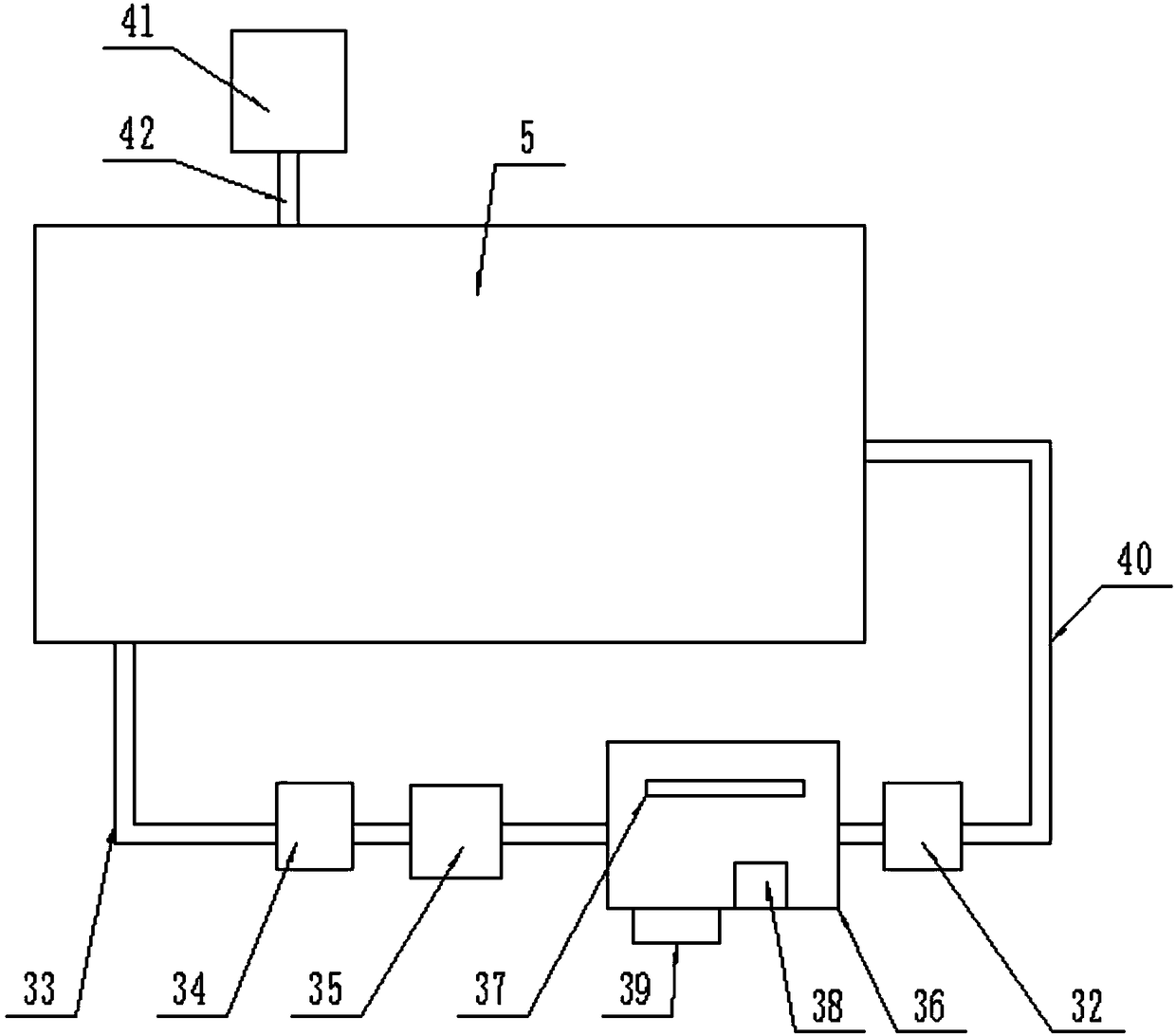

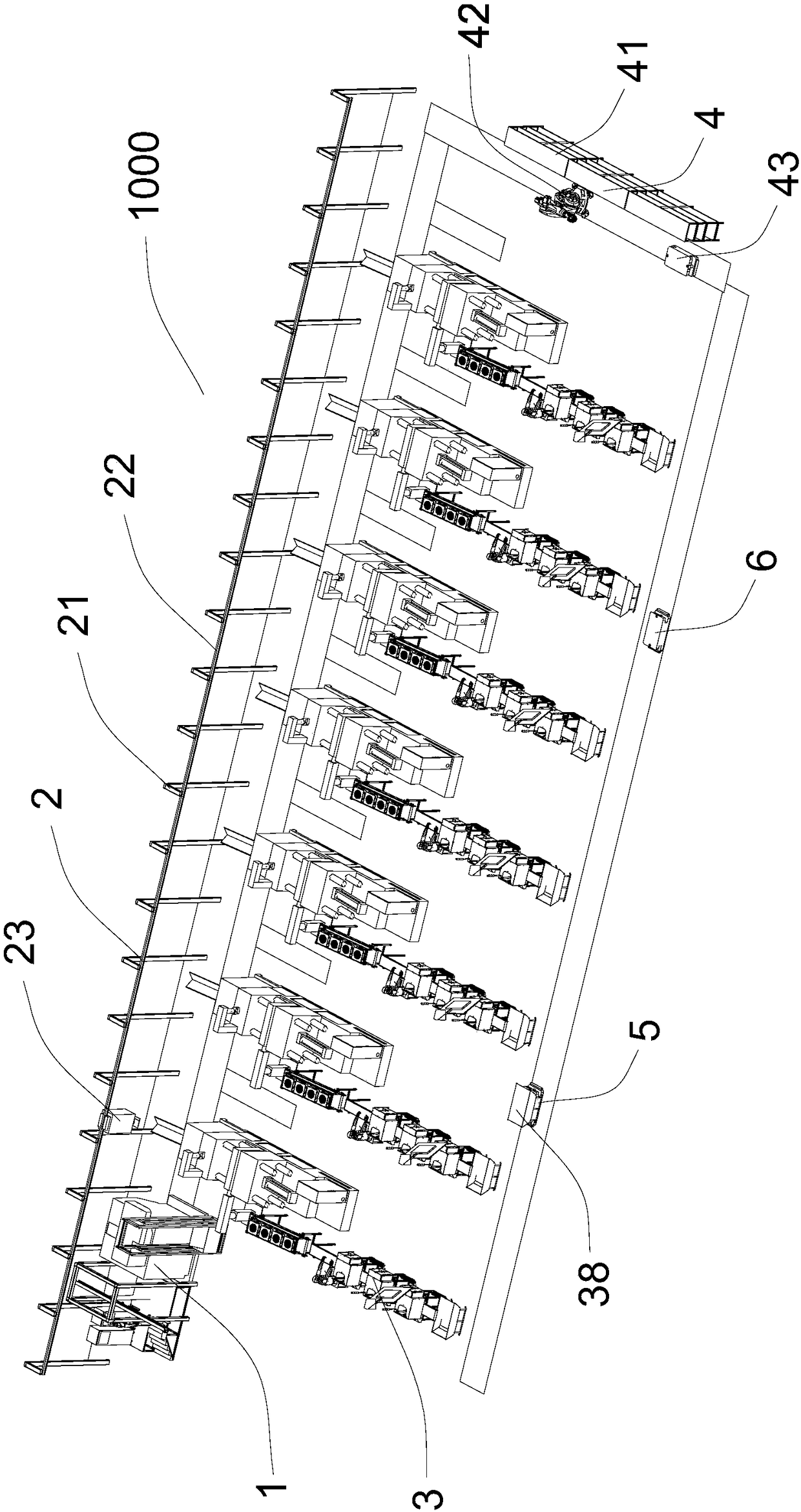

Panel furniture flexible production line

PendingCN109531757AFully automatedRealize intelligent productionOther plywood/veneer working apparatusConveyorsProduction lineStack machine

The invention discloses a panel furniture flexible production line. The panel furniture flexible production line comprises a panel storage mechanism, a rail trolley for conveying and a plate banding mechanism, and further comprises a power roller conveying line used for conveying panels, an electronic saw discharging machine used for discharging materials, a rotary lifting table used for transferring the panels, a vertical rotary sorting machine used for sorting the panels, a box sealing machine used for sealing and casing finished-products of panel furniture and a roadway stacking machine used for stereoscopic storage and automatic warehouse outlet of the finished-products of the panel furniture. By adopting the panel furniture flexible production line, customized production in the furniture industry is realized; the panel furniture flexible production line is applicable to both large-scale standard product production and small-scale customized production; labor cost is reduced; and automatic and intelligent production of the furniture is realized.

Owner:广东友力智能科技有限公司

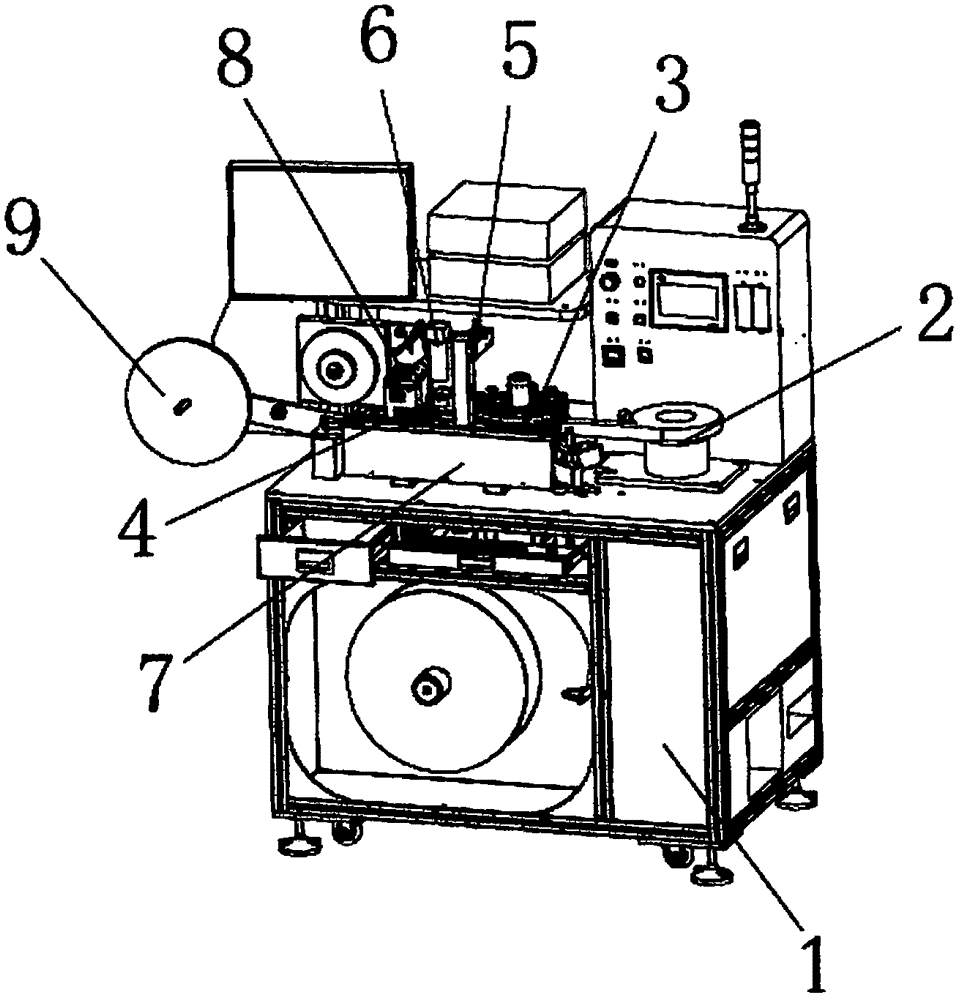

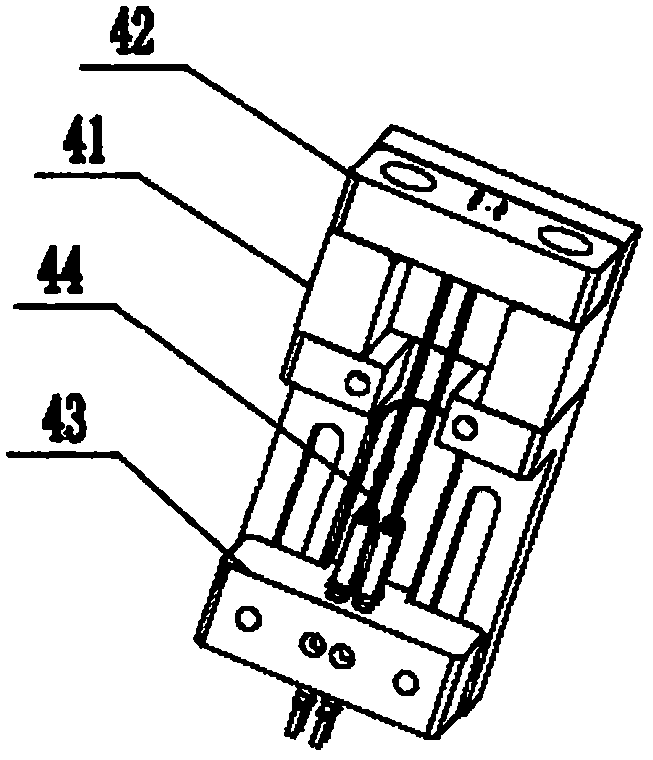

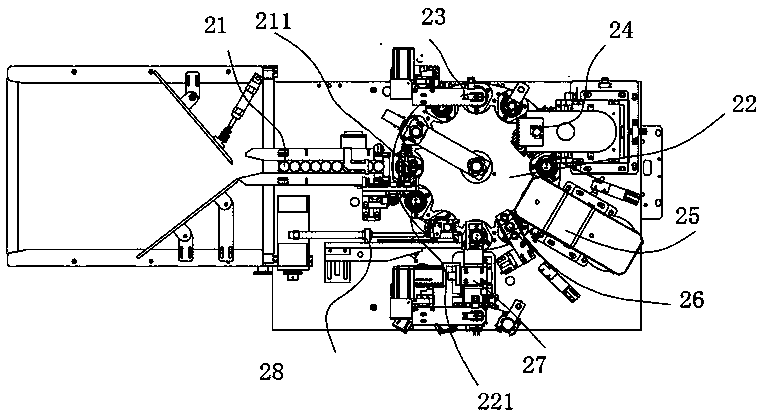

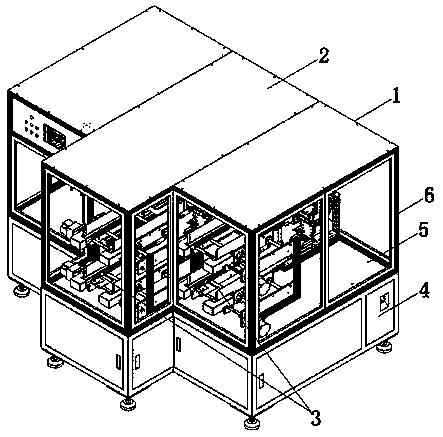

Intelligent taping machine with testing function

InactiveCN106005968ARealize intelligent productionIncrease productivityConveyorsControl devices for conveyorsEngineering

The invention discloses an intelligent taping machine with the testing function. The intelligent taping machine is characterized by comprising a machine frame, a feed mechanism, a 12-station division plate, a testing mechanism, a mark printing mechanism, an image detecting mechanism, a carrier tape mechanism, an adhesive sealing mechanism and a taping mechanism, and the feed mechanism, the 12-station division plate, the testing mechanism, the mark printing mechanism, the image detecting mechanism, the carrier tape mechanism, the adhesive sealing mechanism and the taping mechanism are arranged at the upper end of the machine frame and are sequentially connected; and the 12-station division plate comprises a rotary lifting divider and a rotating plate installed on the rotary lifting divider, 12 suction rods are uniformly arranged around the rotating plate, are movably installed on the rotating plate through linear bearings and are provided with springs for resetting, the upper ends of the suction rods are connected to a vacuum connection port through a pipeline, and a seal ring is installed at the bottom of each suction rod. According to the intelligent taping machine, printed mark surfaces of products can be easily confirmed, the production efficiency can be improved, and the effect is better because the automatic detection function and the supporting testing function are integrated.

Owner:肇庆市宏华电子科技有限公司

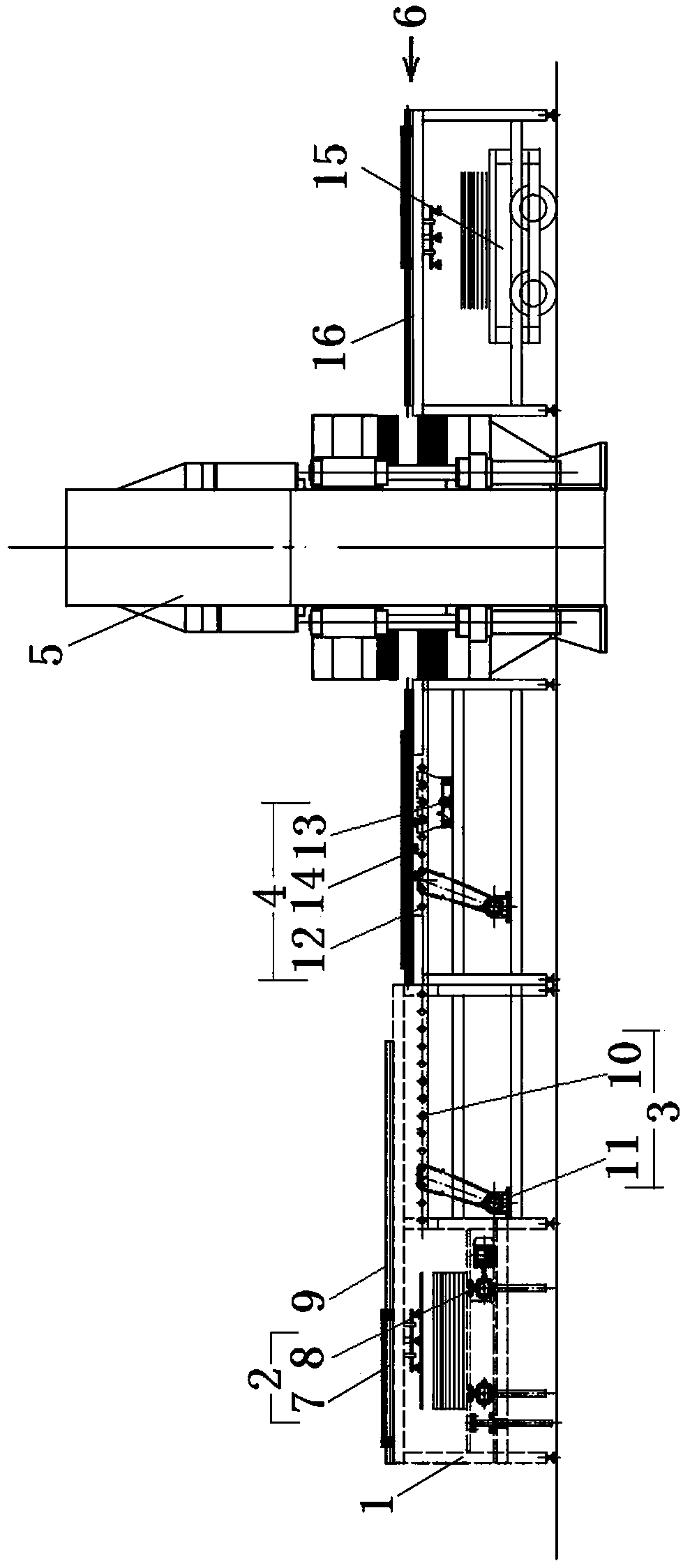

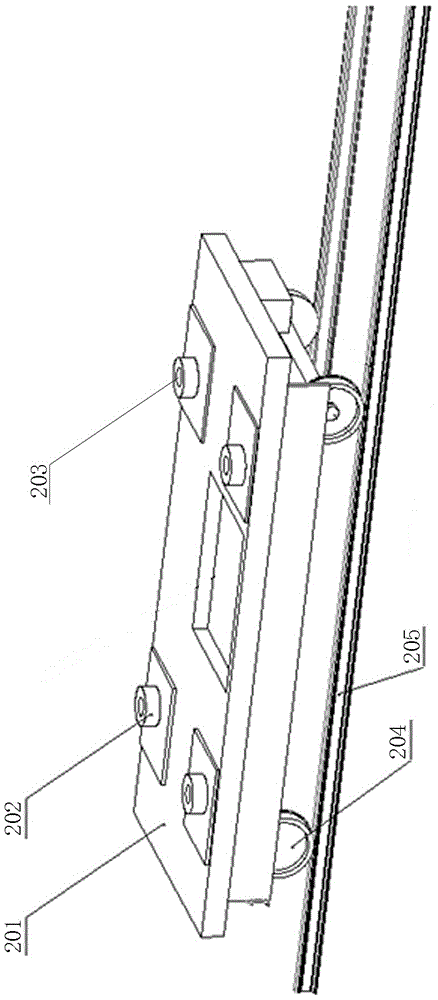

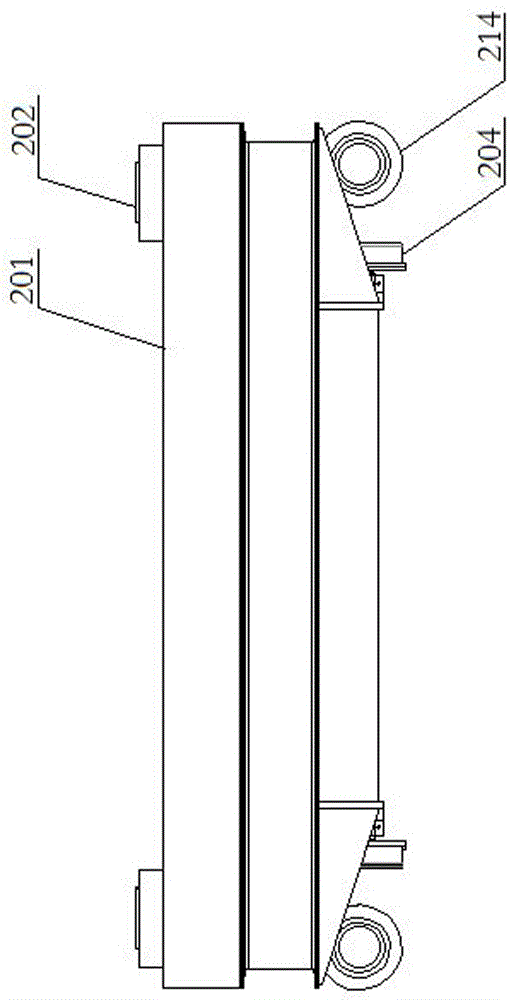

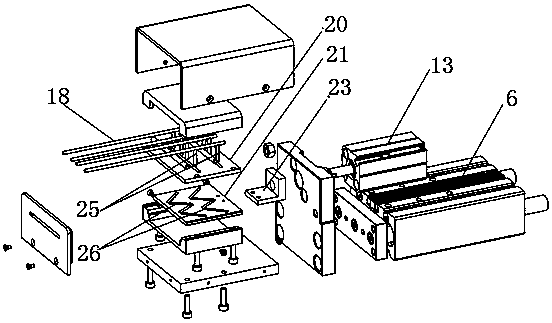

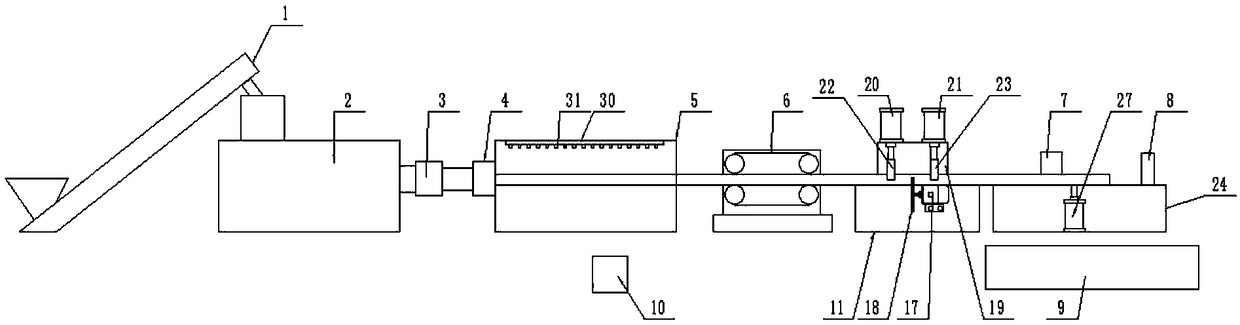

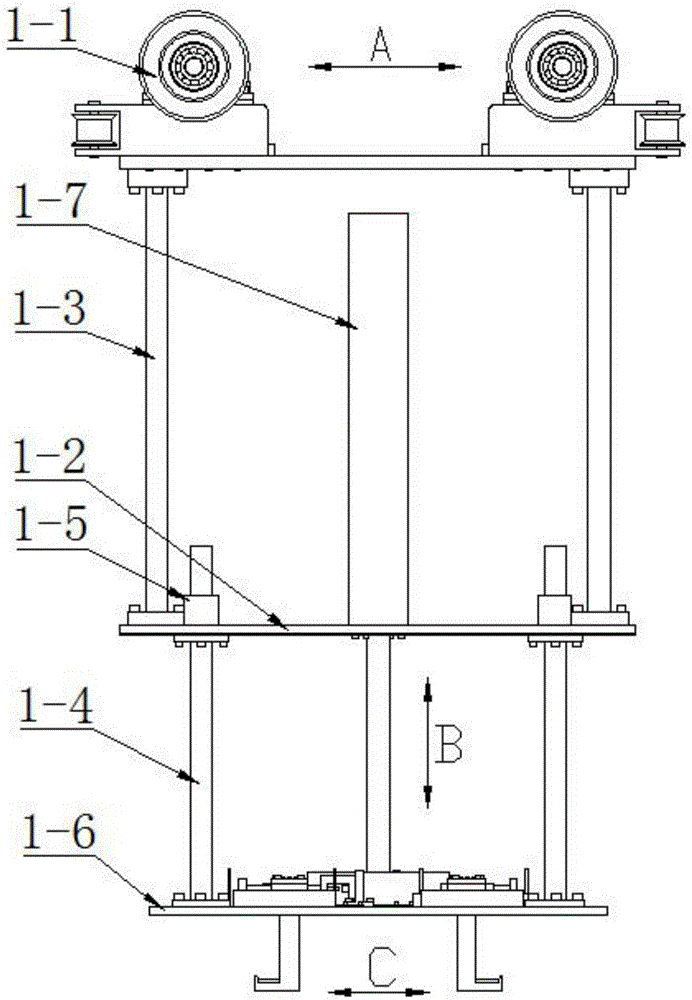

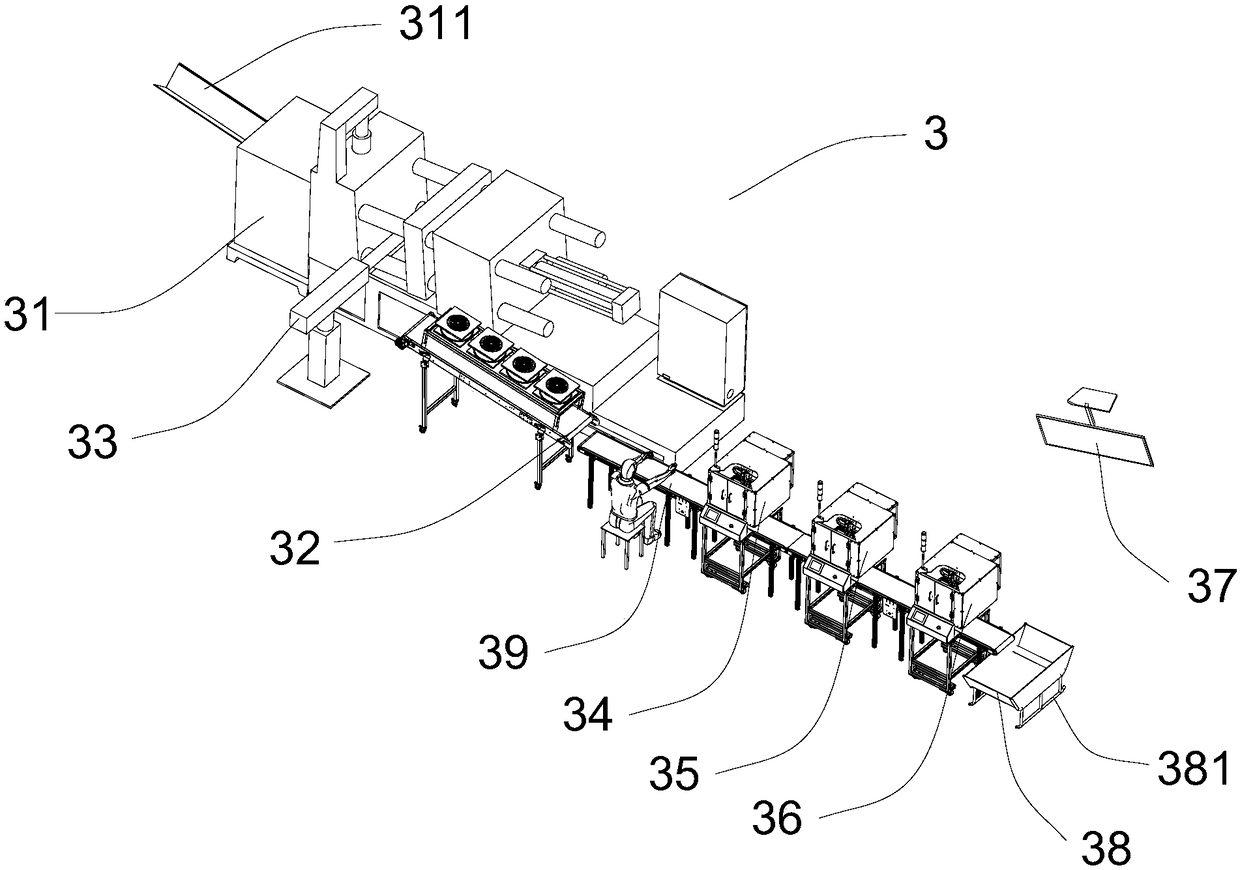

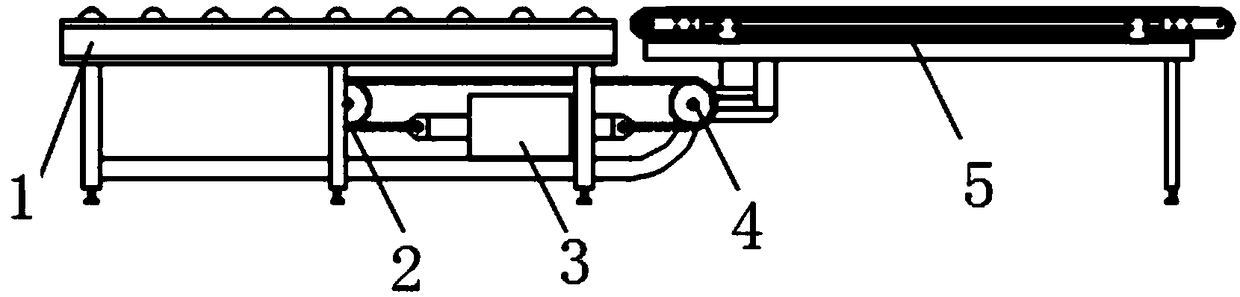

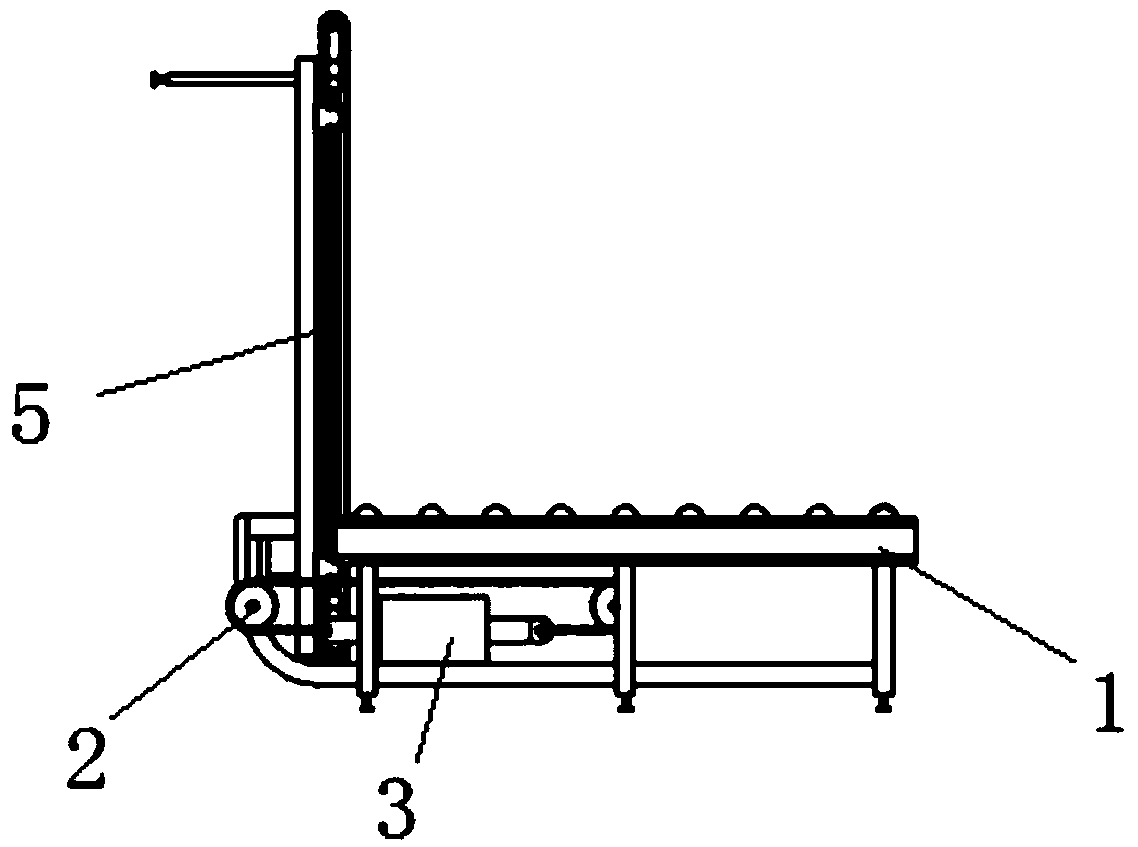

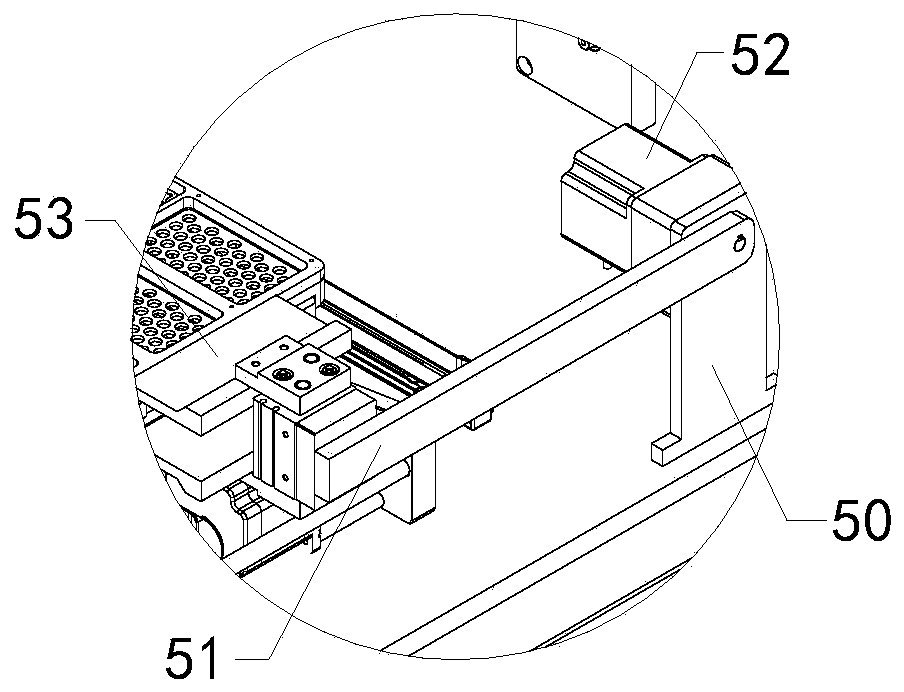

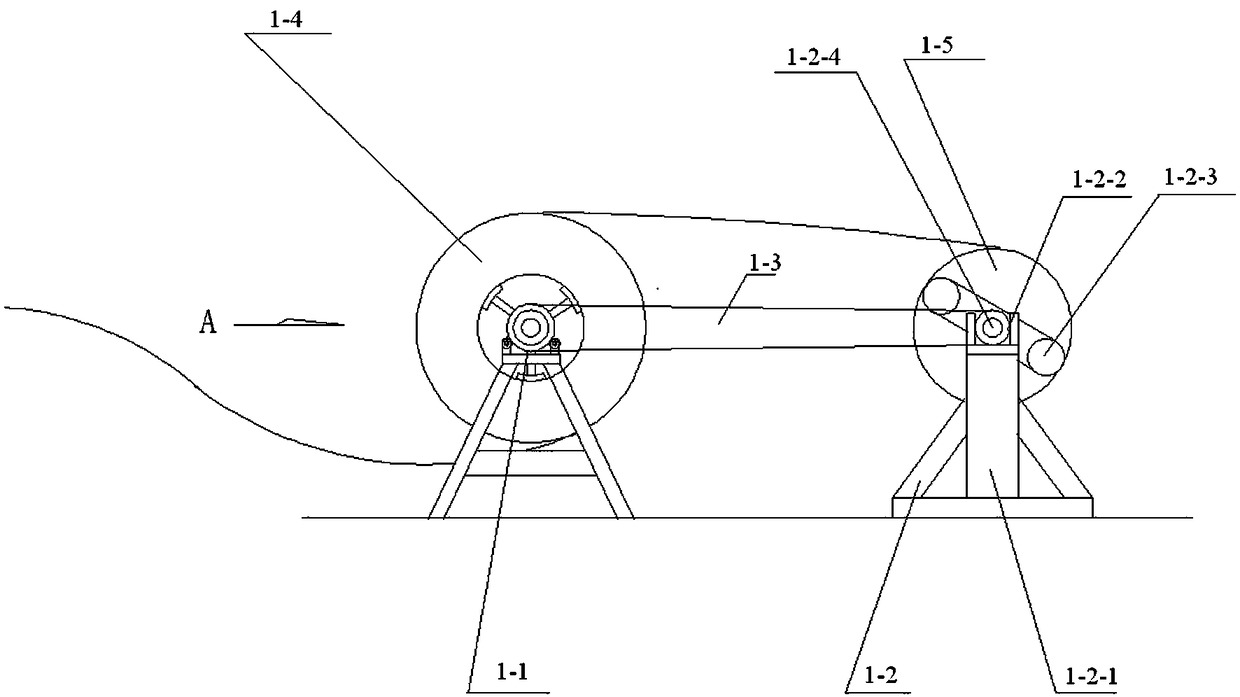

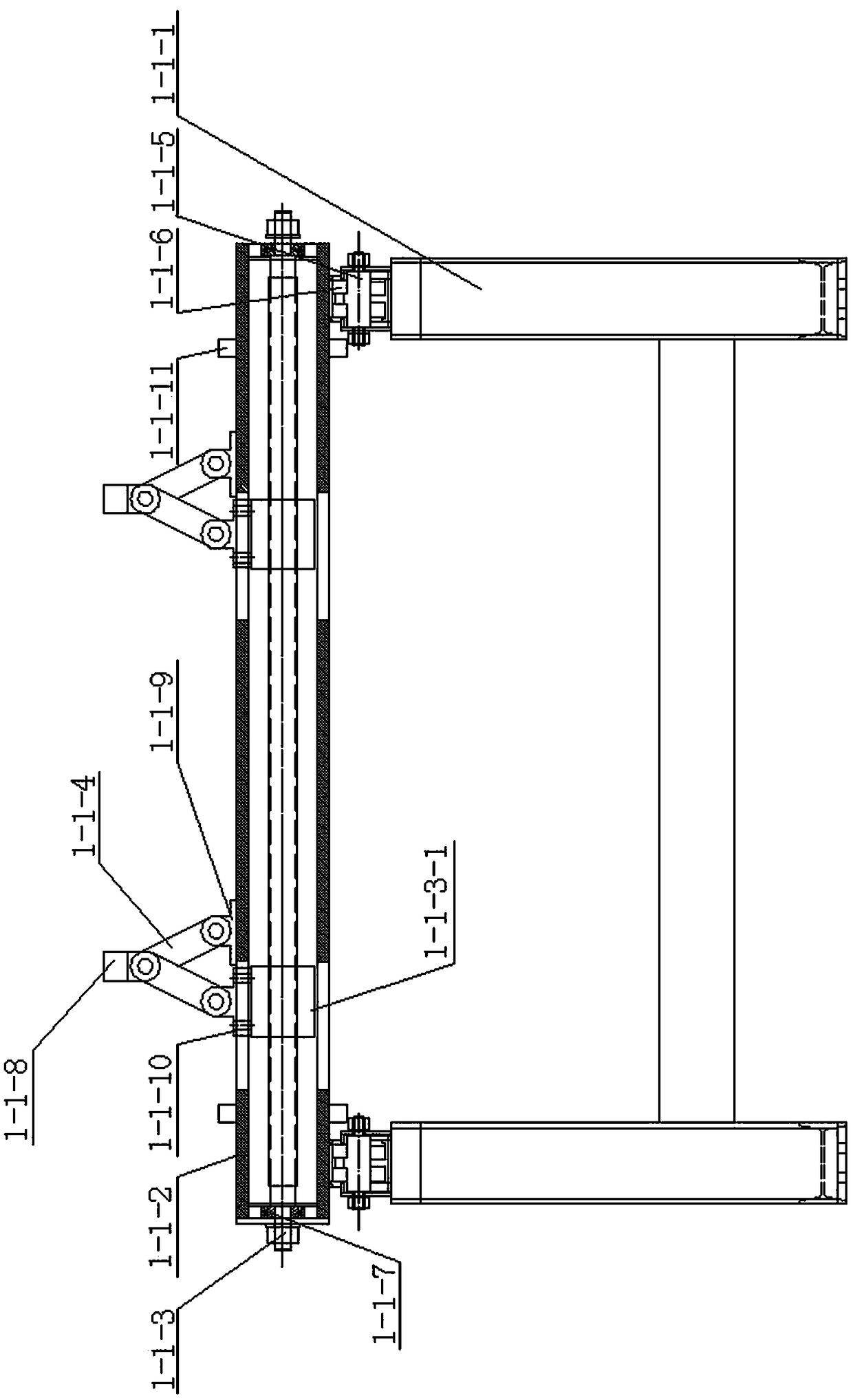

Feeding device and method for heat exchanger sheet forming

PendingCN108772502AFully automatedChange the way of productionMetal-working feeding devicesHeat exchange apparatusHigh volume manufacturingWork in process

The invention discloses a feeding device and method for heat exchanger sheet forming. The device comprises a PLC installed on an electric control cabinet near a machine frame, and an automatic feedingmechanical hand system, a conveying mechanism, a conveying positioning system, a sheet stretching die, an automatic taking stacking system which are installed on the machine frame in sequence from left to right. The automatic feeding mechanical hand system is used for sucking heat exchanger sheet semi-finished products and transferring the semi-finished products to the conveying mechanism, the conveying mechanism is used for transferring the heat exchanger sheet semi-finished products to the conveying positioning system, the conveying positioning system is used for aligning the heat exchangersheet semi-finished products and transferring the semi-finished products to the sheet stretching die, and the sheet stretching die is used for stretching the heat exchanger sheet semi-finished products. The feeding device and method have the advantages that automation of the feeding work procedure, the conveying work procedure, the positioning work procedure, the stacking work procedure and the like for the plate type heat exchanger stainless steel sheet semi-finished products is achieved, production efficiency is improved, the traditional labor intensive production way is changed, and a guarantee is provided for large-batch production and industrial production.

Owner:辽宁光阳换热设备制造有限公司

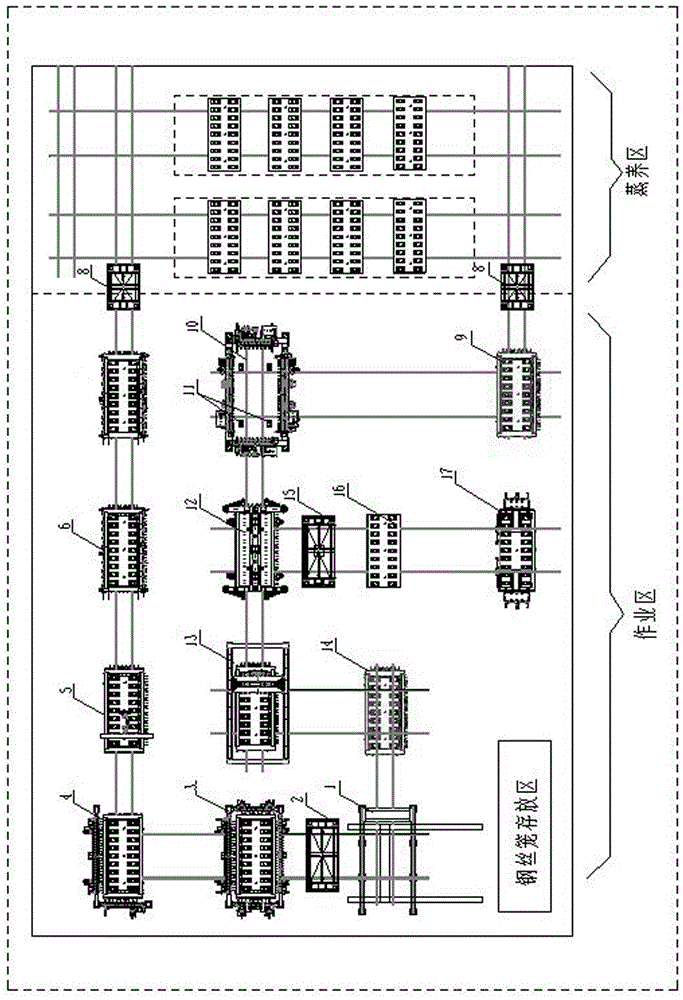

High speed railway ballastless track pre-tensioning method flow unit production line

ActiveCN106738283AFully automatedRealize intelligent productionCeramic shaping plantsMechanical conveyorsProduction linePower station

The invention provides a high speed railway ballastless track pre-tensioning method flow unit production line. The high speed railway ballastless track pre-tensioning method flow unit production line comprises a tension station, a vibration compaction station, a maintenance station, a relaxation station and a demolding station, wherein the tension station, the vibration compaction station, the maintenance station, the relaxation station and the demolding station are fixedly arranged in sequence, the production line is provided with track template molds which works in coordination with the stations, all the stations are fixed on the ground surface through a support in a suspended mode, and are coordinated with a mobile type transporting cart for transporting a track plate mold and / or a track plate to transport the track plate mold and / or the track plate to work stations. According to the high speed railway ballastless track pre-tensioning method flow unit production line, all the fixed stations are arranged in the production sequence and fixed on the ground surface in a suspended mode, and the transporting cart is arranged to move along center lines at the inner sides of all the work station and to transport the track plate mold and / or the track plate to the work stations, so that the stationary track plate mold and / or the track plate moves along the production line in the work sequence as the transporting cart moves; by the coordination of a specially arranged control system, the automatic and intelligent production of the track plate is achieved. The production cost is reduced, the product quality is guaranteed, and the working efficiency is greatly improved.

Owner:SHANXI GAOHANG HYDRAULIC

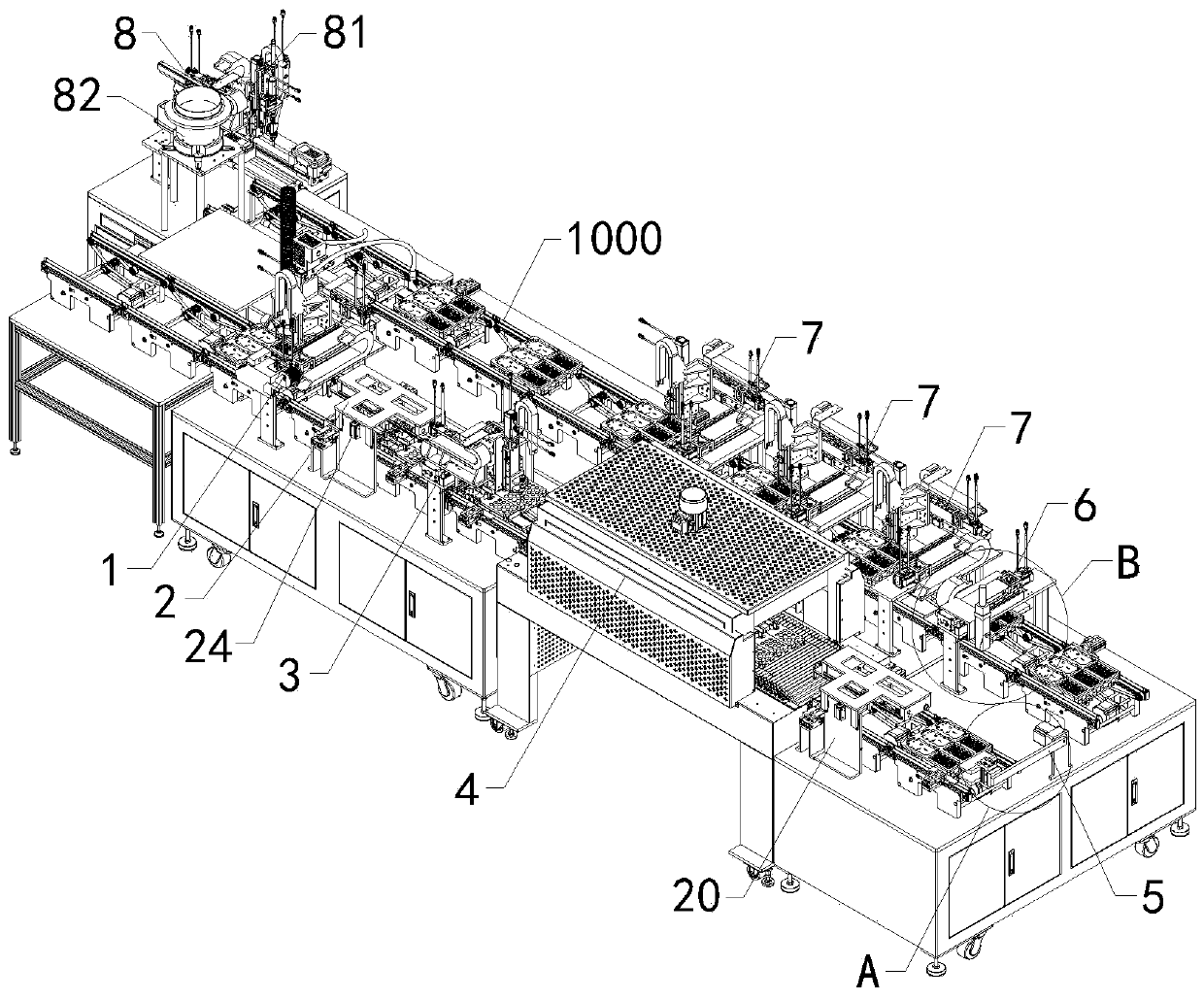

Intelligent assembly line of LED filament lamp

The invention provides an intelligent assembly line of an LED filament lamp. The intelligent assembly line comprises a filament fixing device, a ball lamp carrier for clamping and fixing the LED filament lamp, a first filament fixing guide device, a filament lead polarity testing device, a filament lead transparent casing pipe threading device, a PCB threading device and a filament lead and PCB welding device; the filament lead polarity testing device comprises a steering device and a testing device body; and the ball lamp carrier comprises a PCB positioning and rotating mechanism for clampingand positioning a PCB. By means of the intelligent assembly line, the problem that in an existing LED filament lamp production technology, various high-precision assembly operations (including a positioning guide station, a transparent casing pipe threading station, a threading station, a welding station and a cleaning station) need to be carried out on the LED filament lamp manually can be solved in a targeted mode, the intelligent assembly line of the LED filament lamp and an operation method of the intelligent assembly line have a high automatic operation function, and various assembly works required by the LED filament lamp can be well completed.

Owner:靳红梅

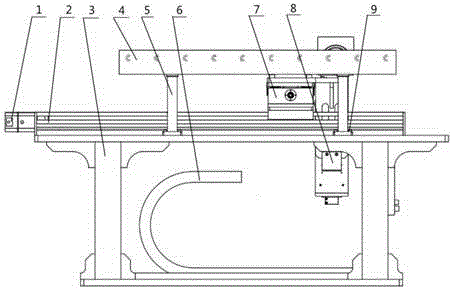

Full-automatic intelligent production line for PVC pipes

The invention discloses a full-automatic intelligent production line for PVC pipes. The production line comprises a feeding machine, an extruder, an extrusion die, a sizing sleeve, a spraying vacuum shaping box, a traction machine, a cutting device, a side turning device, an infrared scanning detector, a code spraying machine, a pipe stacking frame and an industrial personal computer, wherein a spraying device and a waste water recycling device are arranged in the spraying vacuum shaping box, and the cutting device is composed of a cutting machine frame, bearings, a screw, a first motor, a nutseat, a fixing rod, a second motor and a cutting knife; a pressing device is arranged on the cutting machine frame; and the side turning device is composed of a side turning machine frame, a connecting shaft, a side turning plate and a third air cylinder, a U-shaped groove is formed in the side turning plate, a weight sensor is arranged in the U-shaped groove, and the infrared scanning detector and the code spraying machine are arranged on the side turning machine frame. The full-automatic intelligent production line has the beneficial effects of being simple in structure and high in practicability.

Owner:阙宇凡

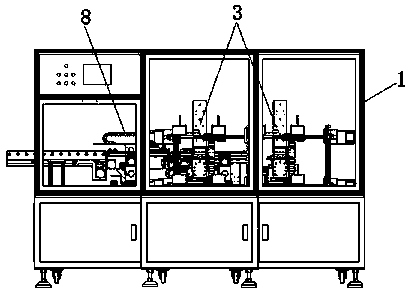

Full-automatic capacitor assembling system

PendingCN108581468AReduce in quantityReduce areaAssembly machinesMetal working apparatusElectricityCapacitor

The invention discloses a full-automatic capacitor assembling system and belongs to the field of capacitor manufacturing equipment. A machine table is provided with a cover plate riveting mechanism, an aluminum shell assembling mechanism and a sleeve mechanism, and a transmission mechanism is arranged in the machine table; a capacitor core cladding provided with a cover plate in a riveted manner is conveyed to the aluminum shell assembling mechanism by the cover plate riveting mechanism; the aluminum shell assembling mechanism conveys a capacitor subject to aluminum shell waist bundling and sealing to the sleeve mechanism; and the cover plate riveting mechanism, the aluminum shell assembling mechanism and the sleeve mechanism are driven by the transmission mechanism at the same time. According to the full-automatic capacitor assembling system, due to reasonable arrangement, the work procedure is simplified; full-automatic assembling is achieved in all process operation, and the intelligent degree is high; a unique optic, mechanic and electric detection integrated device is innovatively designed in a breakthrough manner, a plurality of detection stations are arranged, bad products are effectively eliminated, the product consistency is guaranteed, intelligent production is achieved, and the production quality is improved; and the problems that the labor intensity of personnel islarge, the production efficiency is low, the floor space of the equipment is large, the survival quality is low, and personnel shortage is caused are solved.

Owner:东莞士格电子集团有限公司

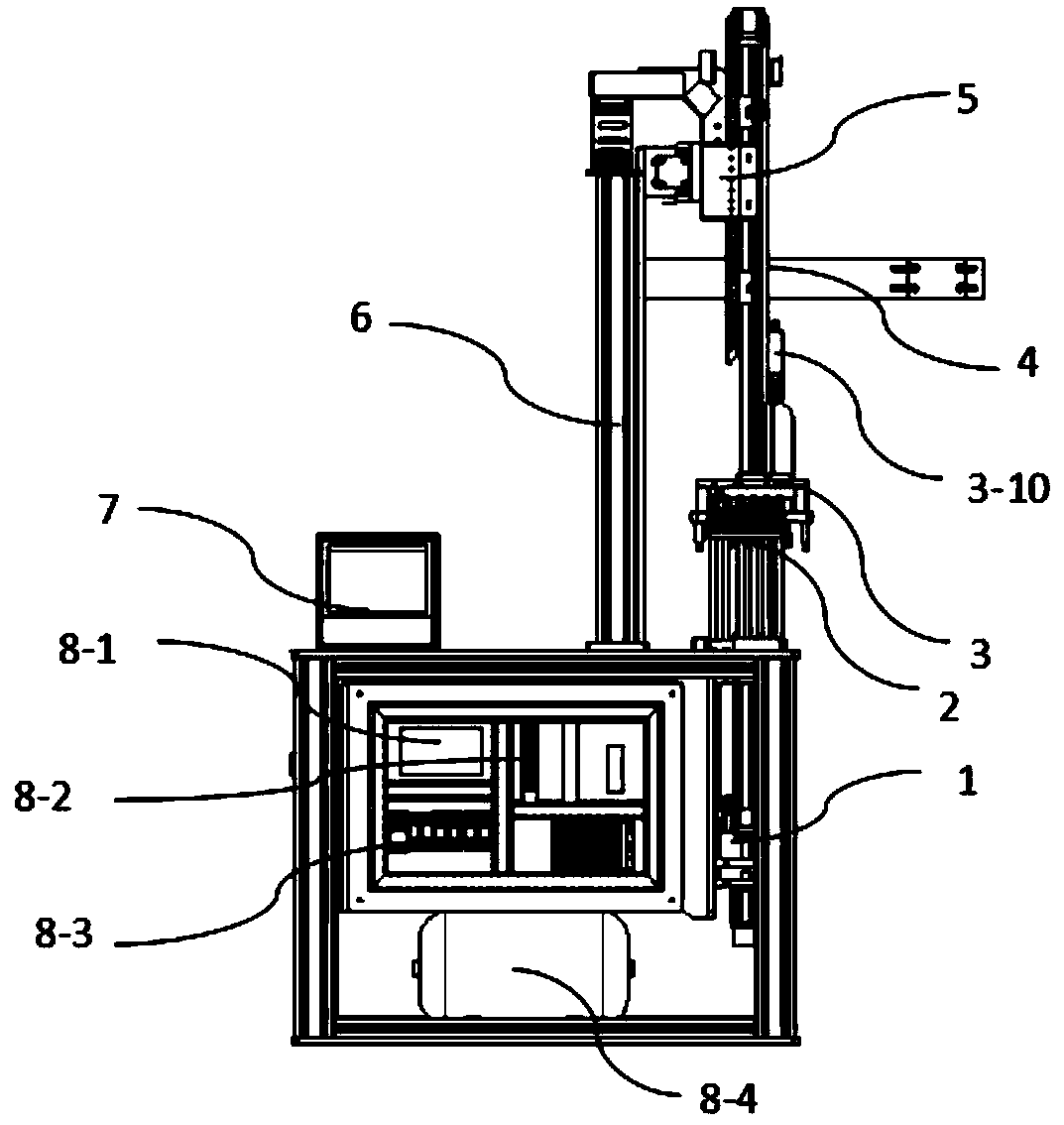

Full-automatic AGV battery replacing system

InactiveCN106629032AIncrease productivityReduce labor intensityConveyor partsMechanical conveyorsElectricityBattery charge

The invention discloses a full-automatic AGV (Automatic Guided Vehicle) battery replacing system which comprises a battery extracting mechanism, translation guide rails, a translation driving mechanism and a battery charging mechanism, wherein two translation guide rails are arranged; the two translation guide rails are arranged right above the battery charging mechanism in a parallel form; the top of the battery extracting mechanism is in rolling connection with the two translation guide rails; a claw device for hooking a lug on an AGV battery is arranged at the bottom of the battery extracting mechanism; the translation driving mechanism is arranged on the two translation guide rails and is used for driving the battery extracting mechanism to move on the two translation guide rails. The full-automatic AGV battery replacing system can be used for full-automatically taking out a depleted battery in an AGV, charging the depleted battery and replacing the depleted battery with a fully charged battery; the running time of the AGV is not occupied; the production efficiency of the enterprises can be greatly increased; the labor cost can be saved; the labor intensity of the workers can be reduced; the industry related to logistics can practically realize intelligent production; the full-automatic AGV battery replacing system has an ultrahigh practical value and a broad market prospect.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

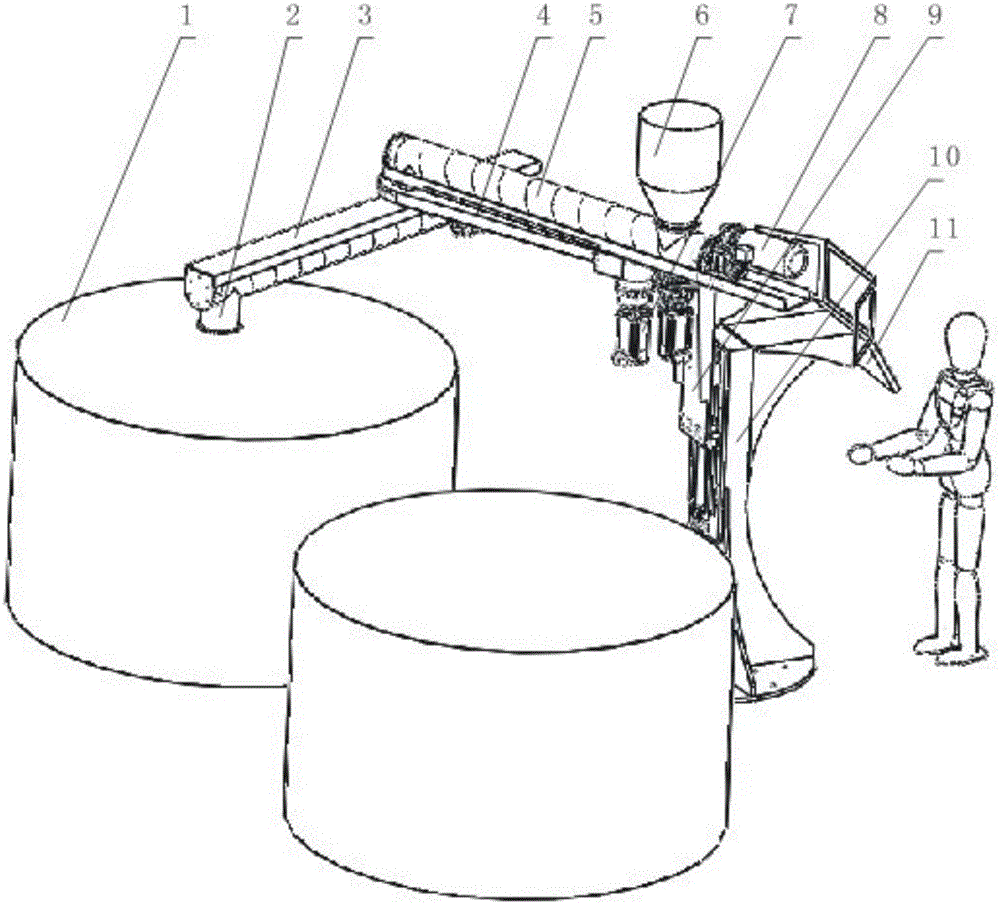

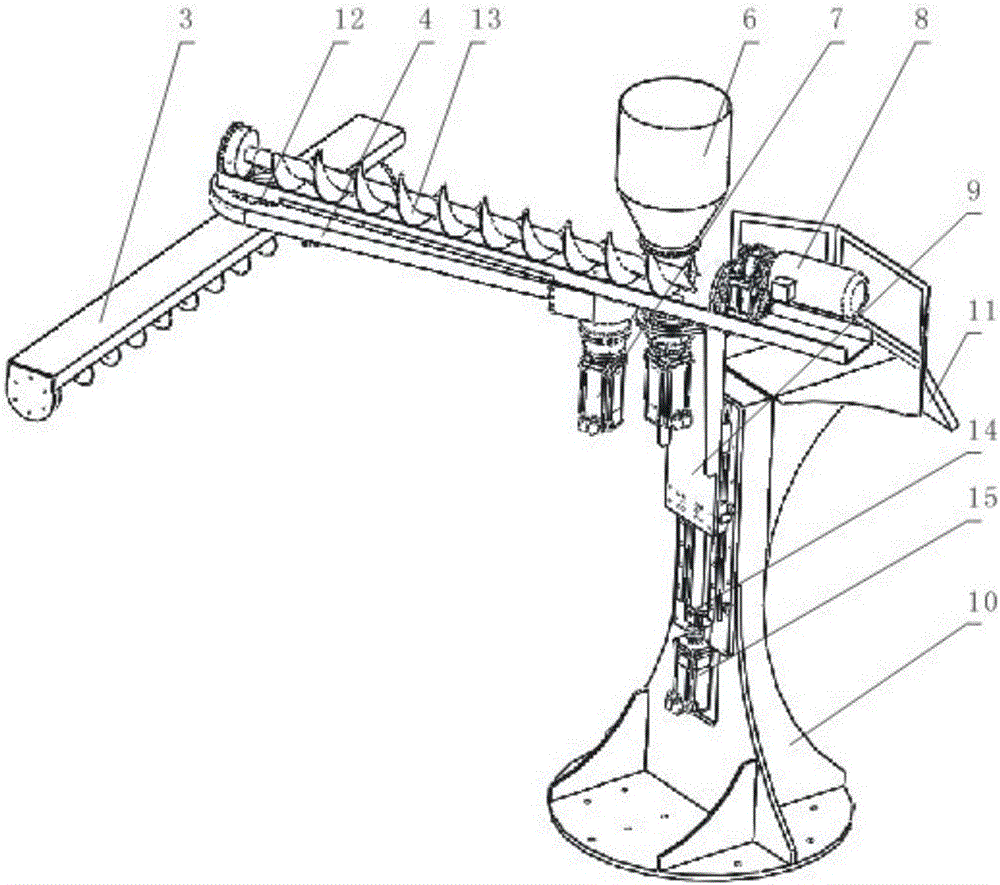

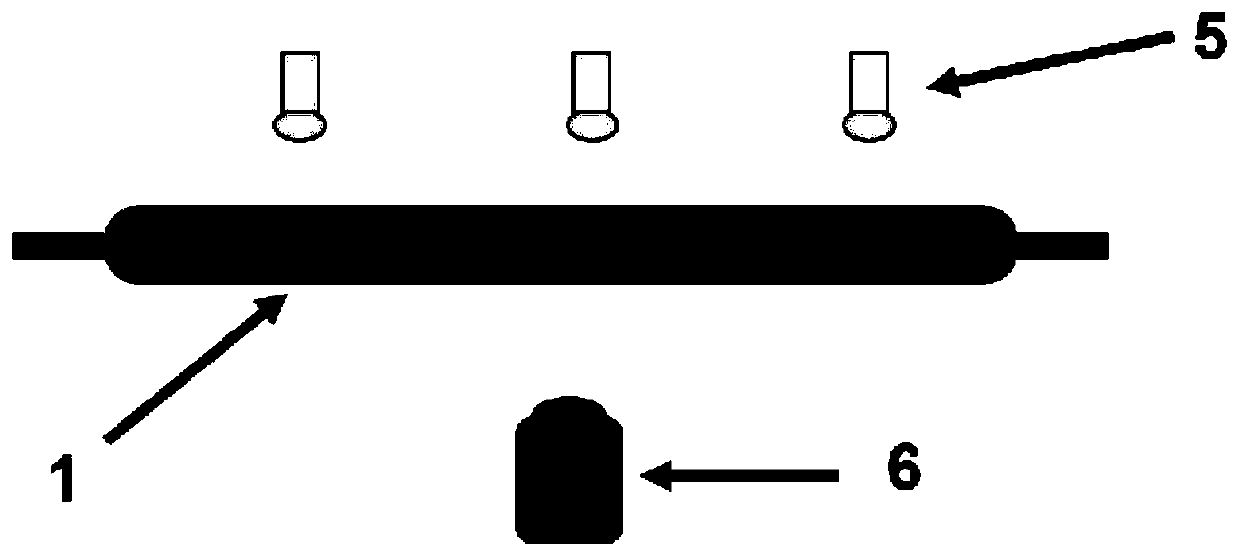

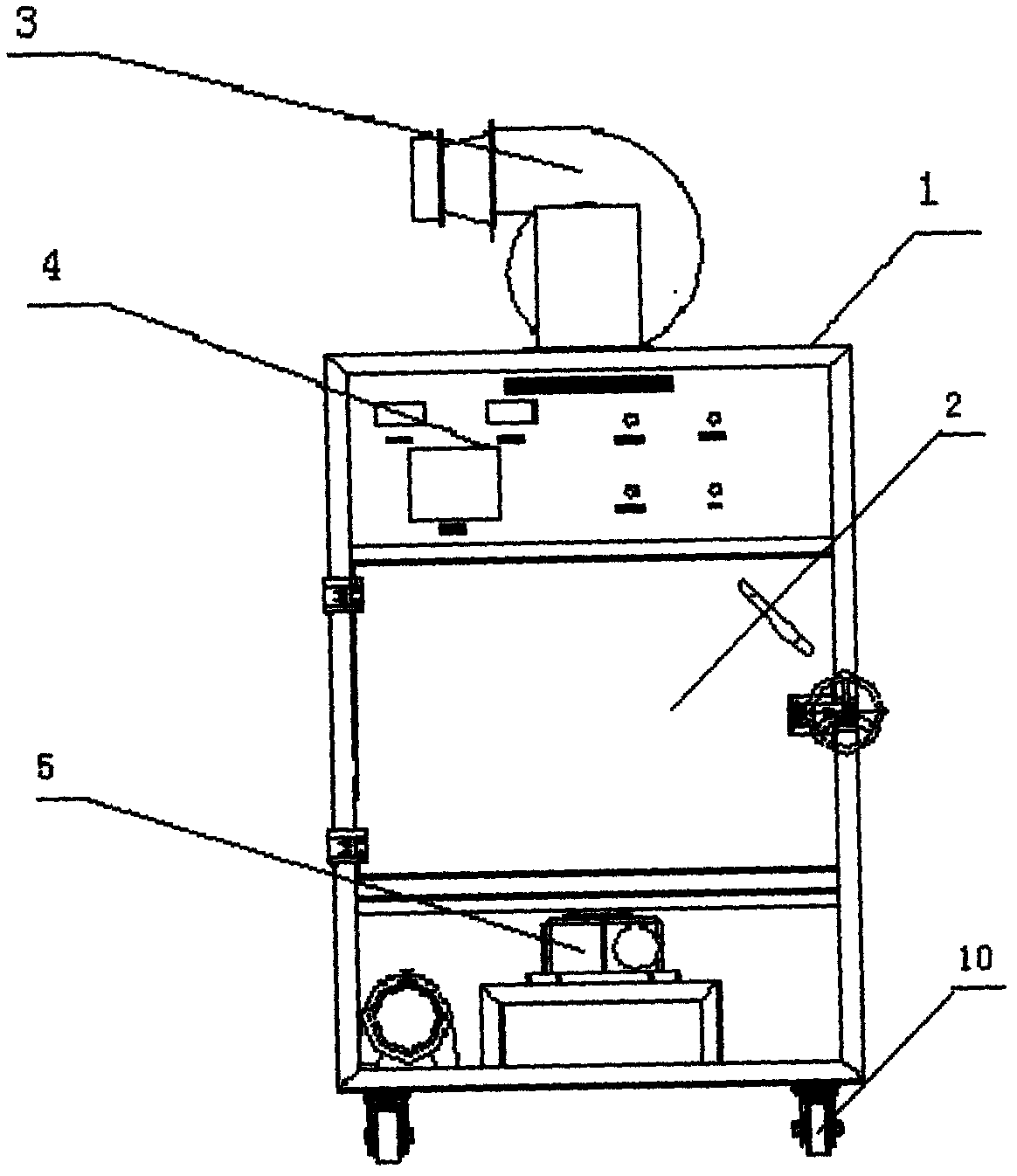

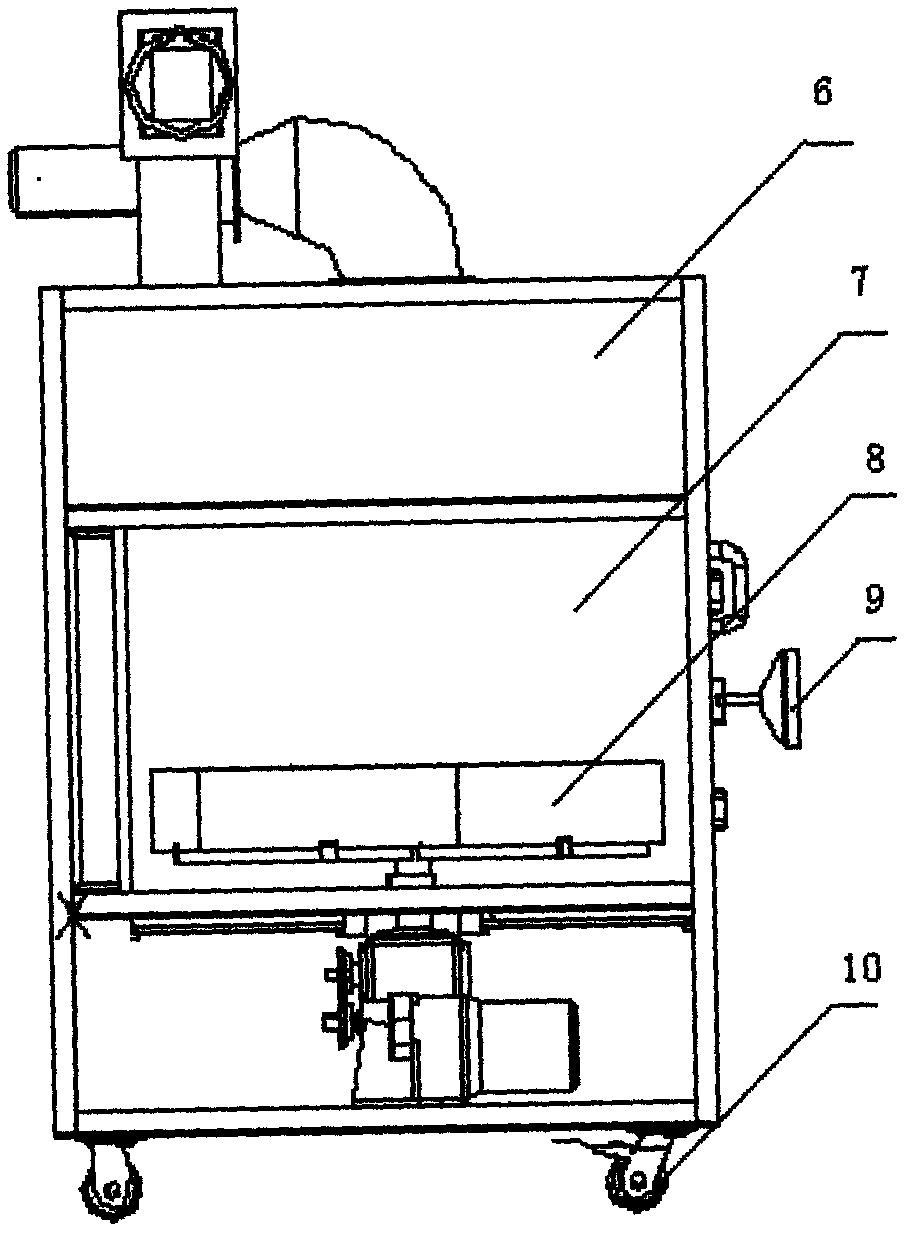

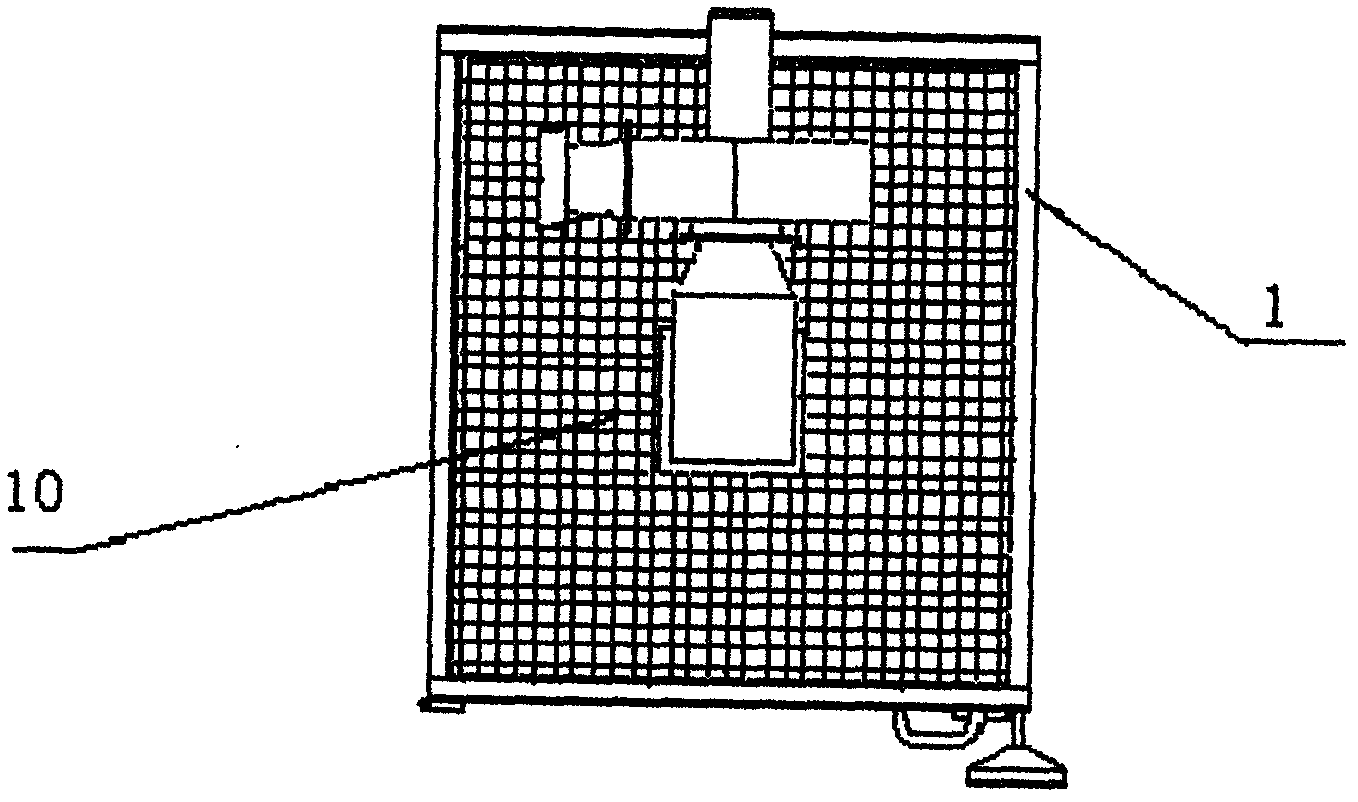

Intelligent steam stripping robot and work method thereof

InactiveCN105059959ASafety, Stability and SanitationGood distillationAlcoholic beverage preparationLoading/unloadingEngineeringDistillation

The invention relates to an intelligent steam stripping robot and a work method thereof. The robot comprises a stand column, a rear arm beam, a front arm beam, a conveying barrel and a material scattering head. The stand column is vertically and fixedly installed on the ground on the outer side of a steam barrel. One end of the rear arm beam is installed on the stand column. The other end of the rear arm beam is hinged to one end of the front arm beam. The front arm beam and the rear arm beam are driven by two rotation arm motors installed at the lower end of the rear arm beam respectively to horizontally swing and rotate. Raw material conveying and scattering can be carried out in a full-automatic manner. The material conveying safety, stability and sanitation can be guaranteed through an original inner arm material conveying mechanism, and the evenness of raw materials in the steam barrel can be guaranteed through vision detection. The distillation effect is good, intelligent production is completely achieved, efficiency is improved, and the machining quality is improved.

Owner:TIANJIN XINJINJIA TECH DEV CO LTD

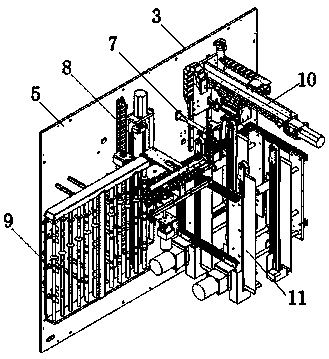

Double-blanking device through IC

PendingCN107716350AStrong process controllabilityReduce work intensitySortingAutomatic controlDrive motor

The invention discloses a double-blanking device through an IC and a blanking method thereof. The device comprises a double-blanking device body, a blanking mechanism, a material separation mechanism,a material box clamping mechanism and a material box storage mechanism. A rolling way connector, the material separation mechanism, a material conveying roller mechanism, the material box clamping mechanism, the material box storage mechanism, a material pushing sheet motor, a mobile base, a rail transmission motor, a rail width adjustment lead screw, a pushing rail, a baffle, a material pushingsheet air cylinder, a front-back mobile servo motor, a material pushing rail, a material pushing sheet, a straight-line module, a servo motor with a brake, a material clamping box air cylinder, a front-back mobile air cylinder, a straight-line guide rail, a baseplate, a material clamping box mechanism, a material box width adjustment mechanism, a material box conveying rail, a rolling-out motor, amaterial box width adjustment mechanism support and a mounting mechanism support are arranged on the double-blanking device body. According to the double-blanking device through the IC, automatic control is completely adopted in the whole blanking process, intelligent production is achieved, a double-blanking mechanism is adopted, accordingly, the productivity is greatly improved, and the workingintensity of workers is also lowered.

Owner:南通金泰科技有限公司

Die-casting workshop

PendingCN108326278ASave manpower and material resourcesIncrease productivityCasting plantsSite managementManufacturing line

The invention provides a die-casting workshop. The die-casting workshop comprises a control system, a central smelting furnace, a conveying device and a plurality of die-casting production lines arranged side by side, wherein the central smelting furnace and the conveying device are electrically connected with the control system. Each die-casting production line comprises a die-casting machine, aconveyor belt and a workpiece taking robot, wherein the part taking part is used for taking out workpieces die-cast by the die-casting machine and transferring the workpieces onto the conveyor belt. The die-casting machines can transmit melt demand signals to the control system. The control system can send a control instruction to drive the conveying device to convey melt of the central smelting furnace to the die-casting machines after receiving the melt demand signals. The die-casting workshop can achieve workshop automation and intelligent production through the control system, reduce the field management cost and improve the production efficiency.

Owner:广东顶固集创家居股份有限公司

Laser marking device for piston pins

InactiveCN106183439AShorten marking cycleImprove work efficiencyTypewritersOther printing apparatusElectric machineryEngineering

The invention discloses a laser marking device for piston pins. The laser marking device for the piston pins is structurally characterized in that locating mounting frames are installed on a fixed base through mounting screws, V-shaped locating blocks are installed on the locating mounting frames through locating block screws, the locating mounting frames are provided with a shield, and the shield covers the V-shaped locating blocks; a servo sliding platform is installed on the fixed base and arranged on one side of the locating mounting frames, and a servo motor is arranged at one end of the servo sliding platform; an adjusting seat is installed on the top of the servo sliding platform, the adjusting seat and a fixed plate are fastened together through fixed plate screws, and a laser marking machine is installed on the fixed plate; and one end of a drag chain is installed on the lower portion of the fixed base through a drag plate metal plate, the other end of the drag chain is fixedly connected with a fixing metal plate, and the fixing metal plate is installed on the laser marking machine and moves along with the laser marking machine. The laser marking device for the piston pins can conduct automatic online marking on end faces of the piston pins, marks the piston pins with production information in a laser marking manner, greatly shortens the marking period and improves the work efficiency.

Owner:FRIEDRICH MEASUREMENT INSTR CO LTD

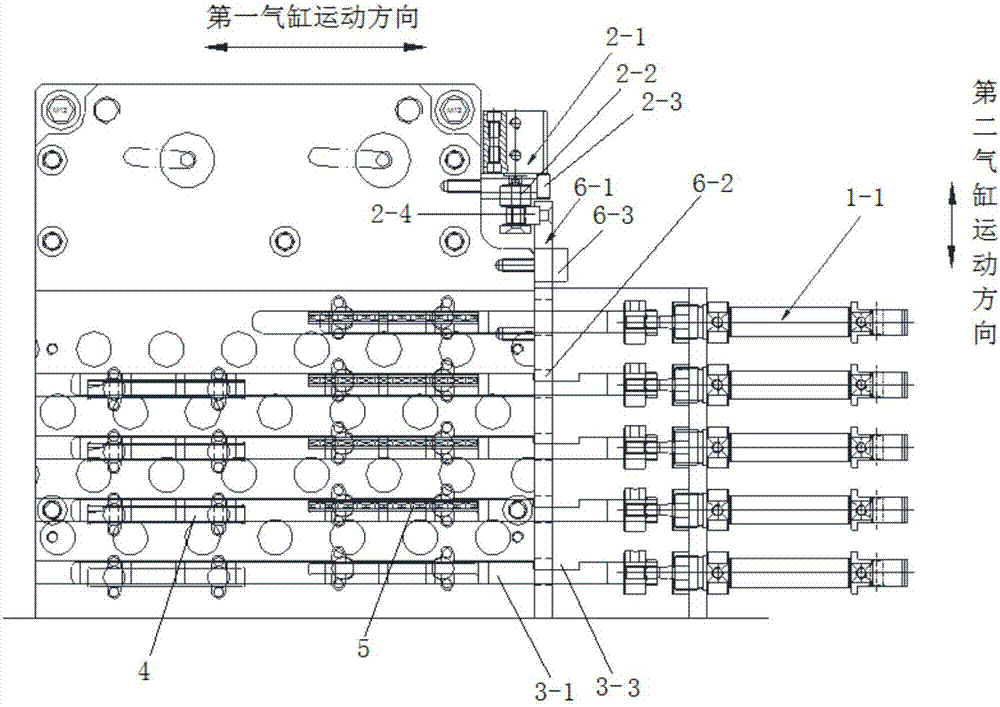

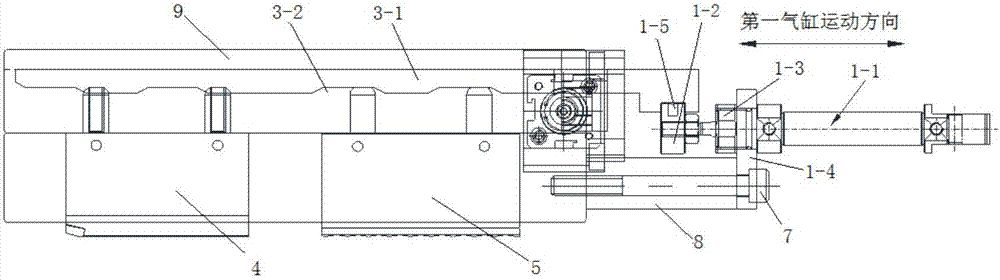

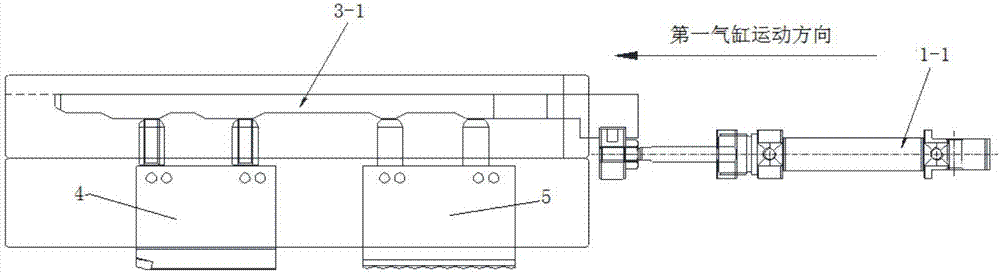

Rapid adjustment structure for conducting longitudinal cutting-apart and embossing molding on air conditioner fin mold

The invention provides a rapid adjustment structure for conducting longitudinal cutting-apart and embossing molding on an air conditioner fin mold. A first air cylinder assembly is fixed to a first air cylinder fixing plate through screw caps. A first limiting block is arranged on an upper cutter fixing plate and the first air cylinder fixing plate. The first air cylinder assembly is connected with drawing strips in a buckled manner. Straight cutter assemblies and cross cutter assemblies are arranged on the upper cutter fixing plate in an arrayed manner. A second air cylinder assembly is fixed to a machine body through a second air cylinder fixing plate and connected with one end of a limiting pillar. Through holes are formed in the limiting pillar. The drawing strips penetrate the through holes in the limiting pillar and are matched with the straight cutter assemblies and the cross cutter assemblies. According to the rapid adjustment structure, longitudinal cutting switching conducted among all states is adjusted through air cylinders; intelligentized production is achieved; production efficiency is improved; work of production workers can be reduced; manpower waste is avoided; and production efficiency is improved.

Owner:WUXI MICRO RES

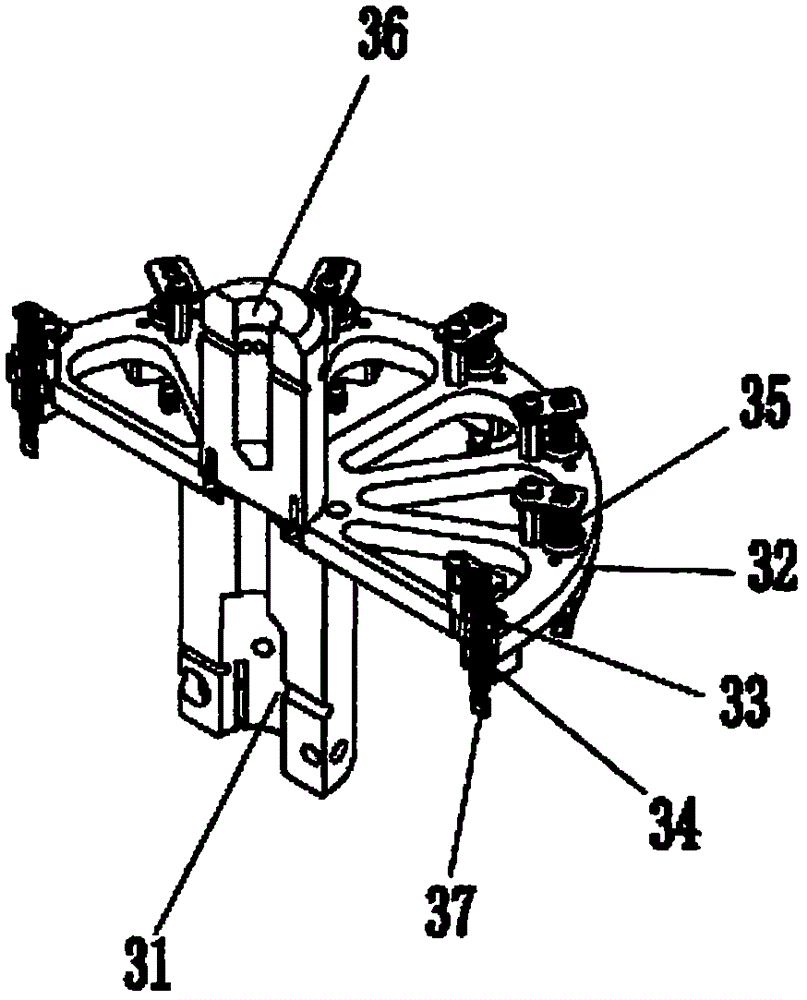

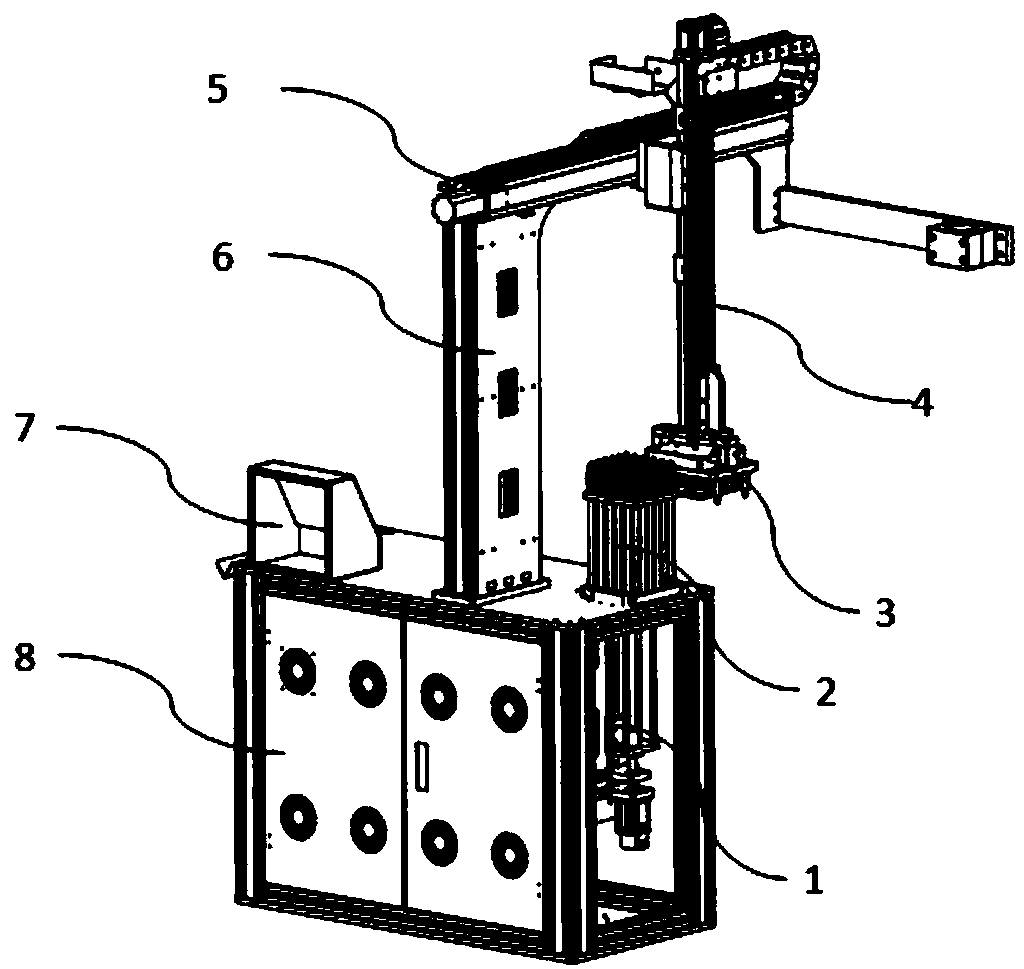

Intelligent placing device for seal ring frameworks

PendingCN108974933ALarge storage capacityRealize intelligent productionConveyor partsVulcanizationEngineering

The invention relates to an intelligent placing device for seal ring frameworks. The intelligent placing device comprises a jacking mechanism, a seal ring framework stringing mechanism, a seal ring framework sucker mechanism, a vertical guide rail, a horizontal guide rail, a fixing support, a touch control panel, a box base and a control module and is characterized in that the control module and the jacking mechanism are mounted in the box base, and the jacking mechanism is connected to the lifting plate of the seal ring framework stringing mechanism through jacking rods to allow the seal ringframework stringing mechanism to move vertically; the fixing base of the seal ring framework stringing mechanism is fixed on the box base, and the seal ring frameworks are placed on balancing washersthrough stringing rods; the sucker mechanism can vertically slide along the vertical guide rail, the vertical guide rail can horizontally move along the horizontal guide rail, sucking nozzles suck the seal ring frameworks through a vacuum gas circuit board, and the seal ring frameworks are intelligently placed into a vulcanization mold through the movement along the vertical guide rail and the horizontal guide rail.

Owner:浙江脉思科技有限公司

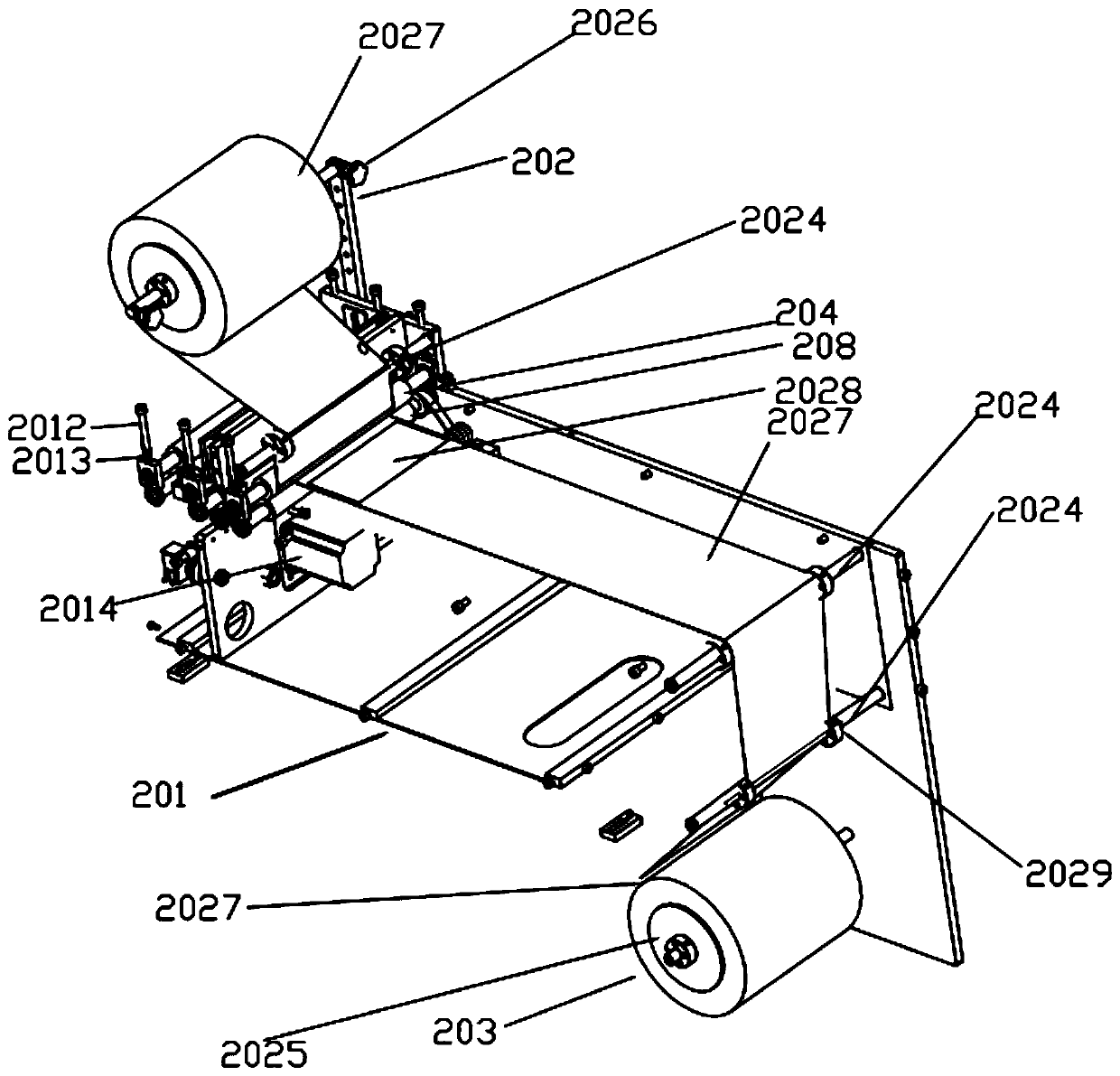

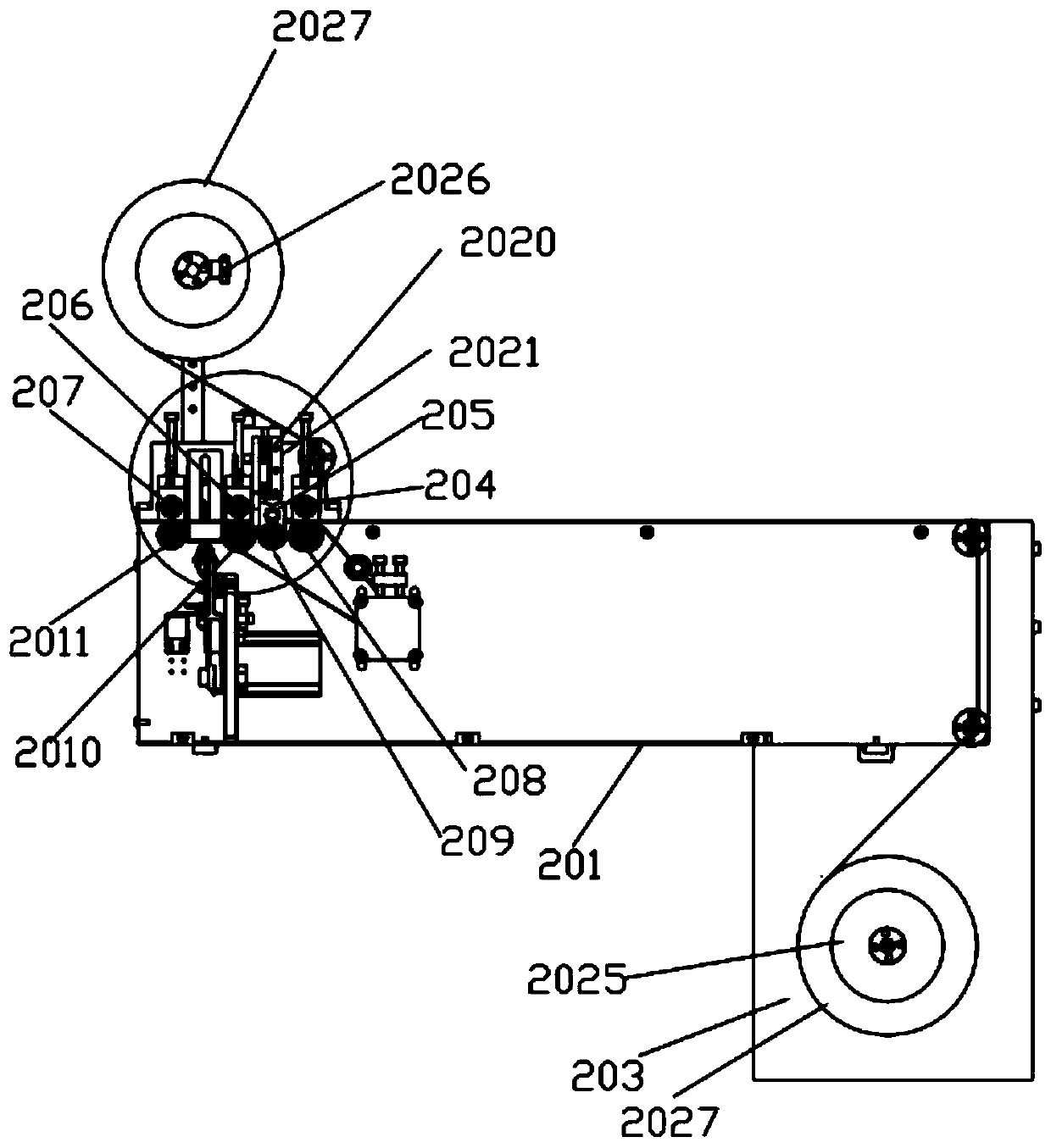

Automatic film-covering and film-cutting machine for glass

PendingCN110239080ARealize intelligent productionIncrease productivityGripping headsMetal working apparatusEngineeringManipulator

The invention discloses an automatic film-covering and film-cutting machine for glass. The automatic film-covering and film-cutting machine for the glass comprises a machine table, wherein at least one automatic film-covering and film-cutting device suitable for multi-specification glass, a connection line used for conveying the glass, and a three-axis manipulator used for placing the glass on the connection line onto the film-covering and film-cutting device are installed on the machine table, wherein a clamp used for clamping the glass is installed on the three-axis manipulator. The automatic film-covering and film-cutting machine for the glass is adaptive to the glass with different specifications, and supports simultaneous placement for any number of the glass; and the equipment is capable of realizing intelligent production according to whether the glass is automatically started and stopped or not. The number of clamping cylinders is equal to the incoming number of the glass on the connection line; the automatic film-covering and film-cutting machine for the glass is adaptive to machine tables with different dimensions; and the opening degree of a clamping jaw is adjusted by adjusting the position between the clamping jaw and a connection block, so that the automatic film-covering and film-cutting machine for the glass is compatible with the glass with different sizes. The automatic film-covering and film-cutting machine for the glass solves the problem that any-number placement and automatic cutting cannot be realized in a glass film-covering process, and increases the production efficiency.

Owner:ROBOT PHOENIX

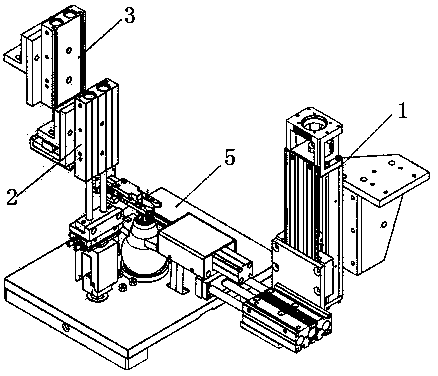

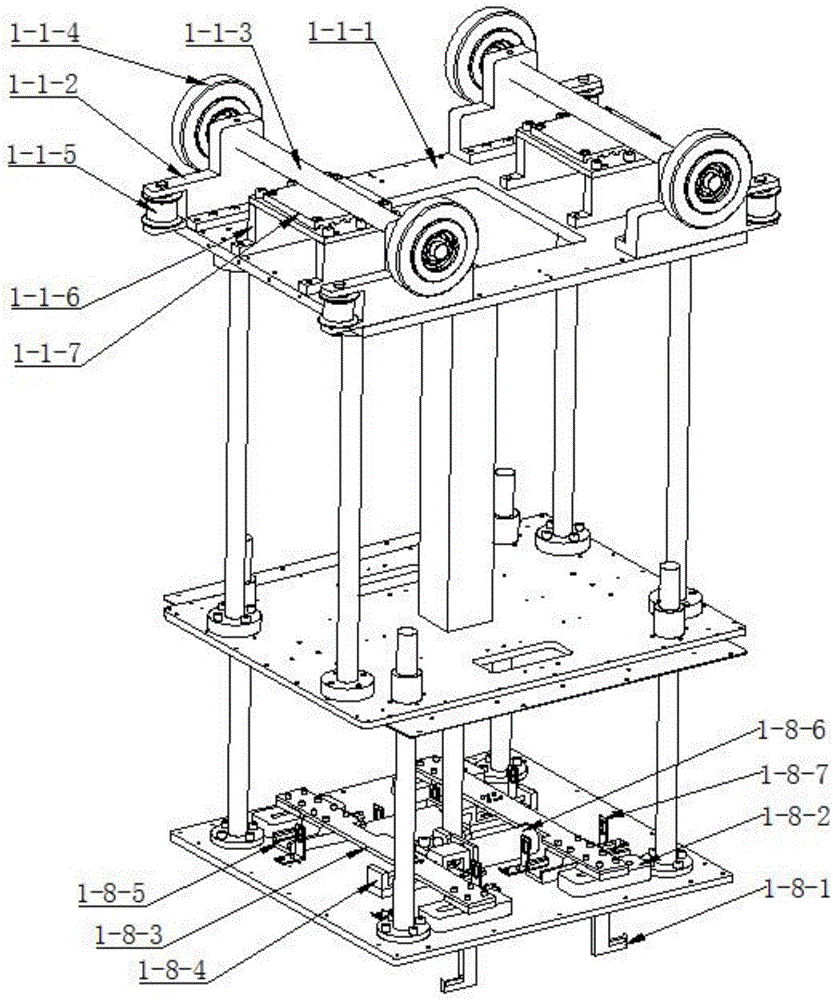

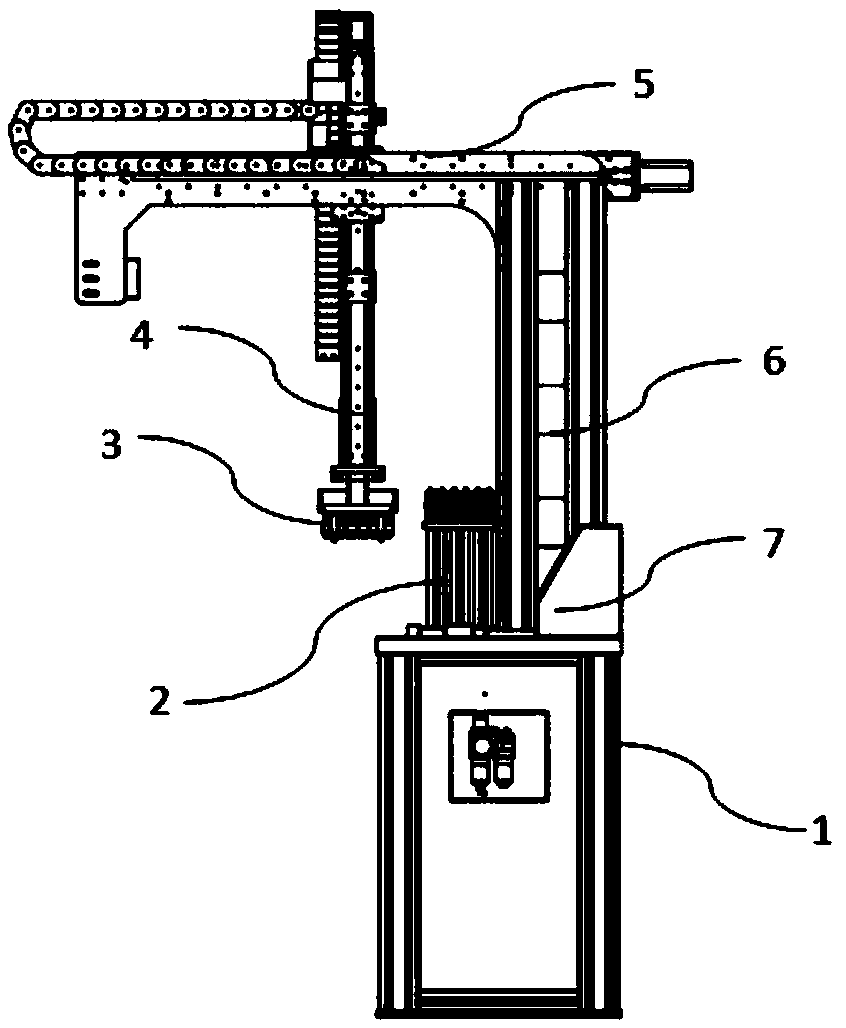

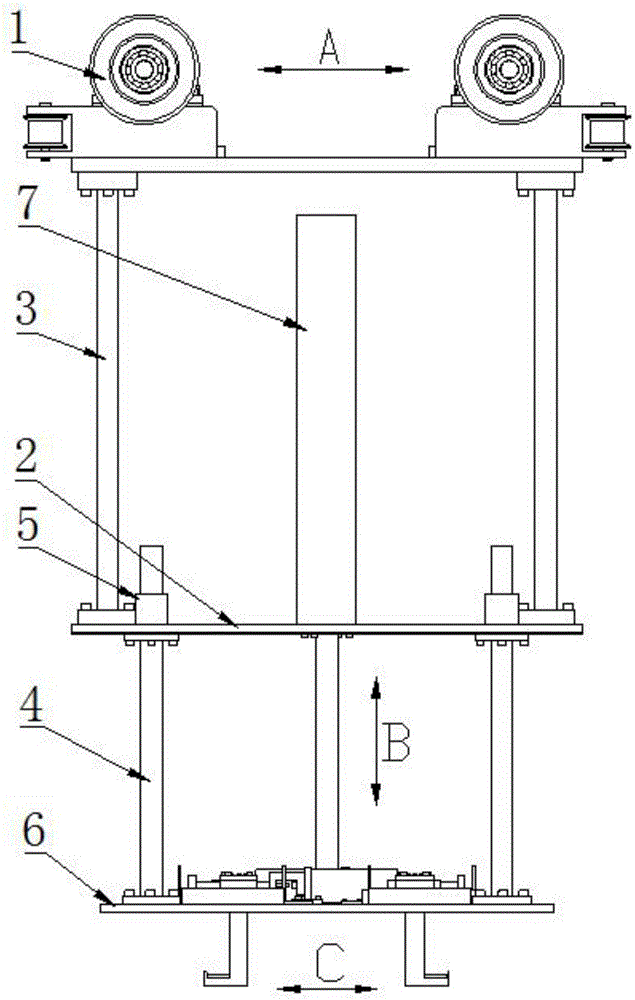

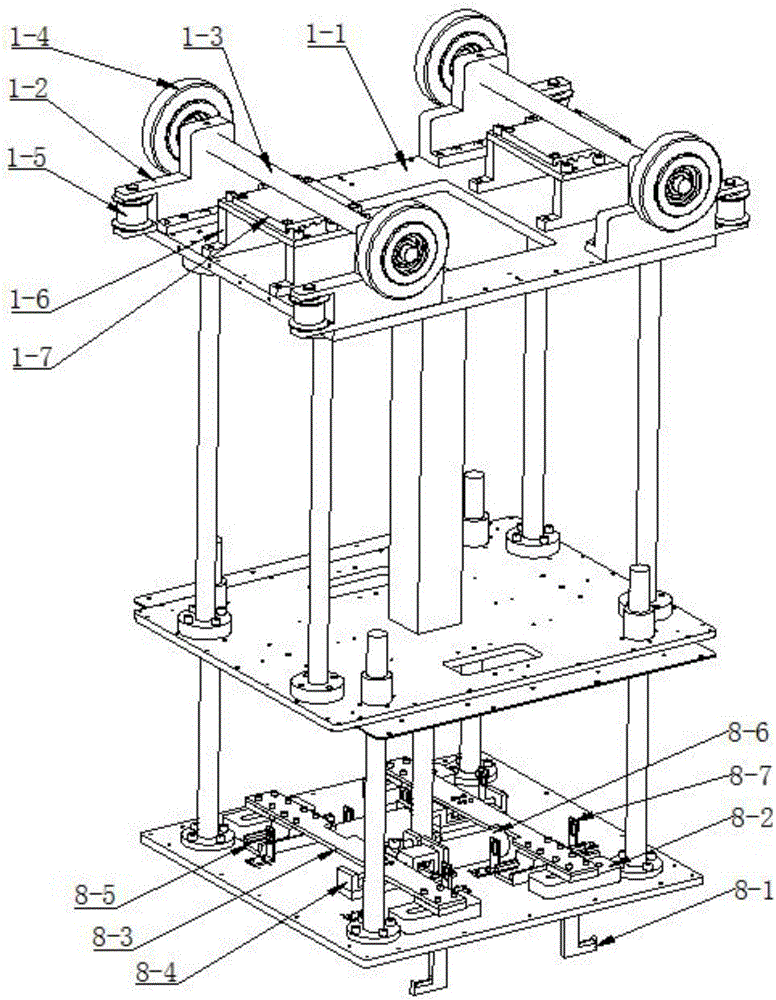

Battery extracting mechanism of full-automatic AGV battery replacement system

InactiveCN106740728AIncrease productivityReduce labor intensityElectric propulsion mountingVehicle servicing/repairingUltimate tensile strengthComputer engineering

The present invention discloses a battery extracting mechanism of a full-automatic AGV battery replacement system. The battery extracting mechanism includes a horizontal rolling device, a middle supporting plate, connecting rods, four guide columns, linear bearings, a lifting plate, a lifting driving device and a claw device; rolling wheels are arranged on the horizontal rolling device, and the four corners of the middle supporting plate are fixed to the four corners of the bottom of the horizontal rolling device through the four connecting rods respectively; each linear bearing is fixed at the corresponding corner of the middle supporting plate; the upper ends of the four guide columns are connected with the four linear bearings in a sliding mode respectively, and lower ends of the four guide columns are fixed at the four corners of the lifting plate; the lifting driving device is installed on the middle supporting plate and drives the lifting plate to ascend and descend; the claw device is arranged on the lifting plate. The mechanism can greatly improve the production efficiency, save labor cost, reduce the labor intensity of workers and make logistics-related industries truly achieve intelligent production and is very high in practical value and wide in market prospect.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Bridge type opening and closing bridge device of flat glass production line

InactiveCN108820881ASolve logistics problemsFix security issuesCharge manipulationConveyor partsRotational axisFlat glass

The invention discloses bridge type opening and closing bridge equipment of a flat glass production line. A flat glass main conveying roller way and a synchronous belt roller way are connected througha rotating shaft, a chain is pulled through a telescopic air cylinder arranged below the main conveying roller way, the chain drives a gear installed on the rotating shaft, and the gear rotates to drive the rotating shaft to rotate, so that the synchronous belt roller way is driven to rotate, and the horizontal and vertical 90-degree turnover of the synchronous belt roller way is realized. According to the equipment, intelligent production of the flat glass connecting line is realized, a pioneer which is produced by connecting the front end and the rear end of flat glass is opened up, the problem of product logistics at the front end and the rear end of the flat glass is solved, the loss of products in the transportation process is reduced, the labor cost caused by upper pieces and lowerpieces is greatly reduced, and benefits are brought to enterprises.

Owner:IRICO

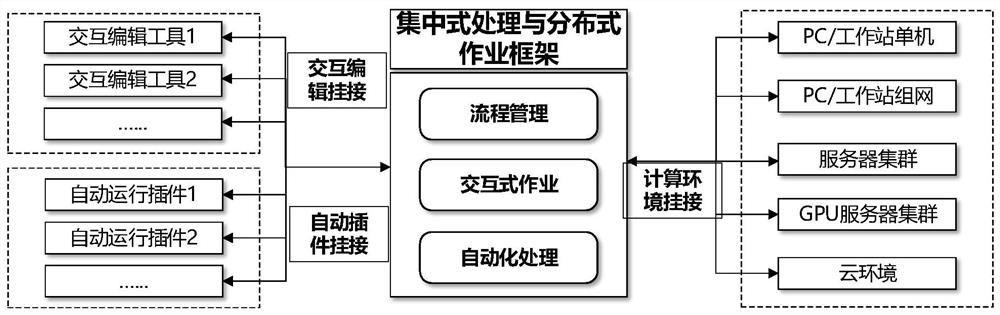

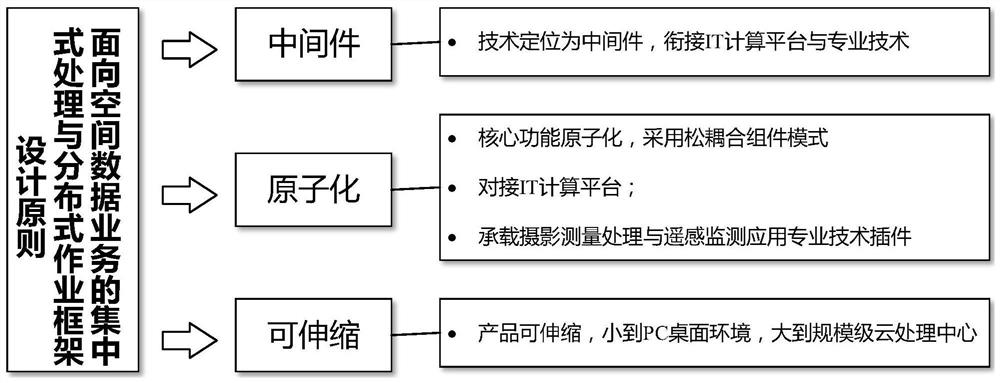

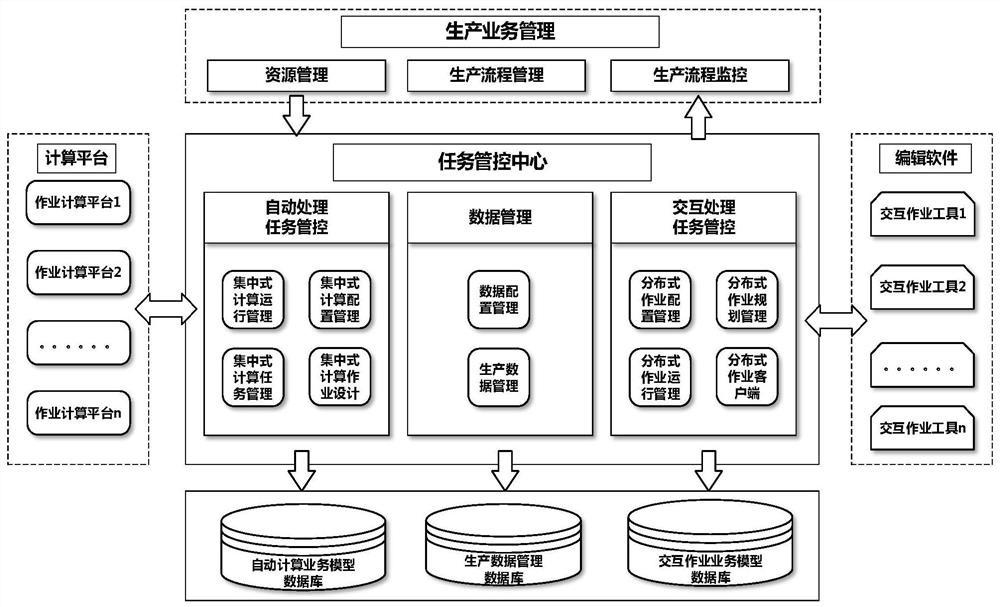

Centralized processing and distributed operation framework construction method for spatial data services

PendingCN111754073AReduce time redundancyImprove effective connectionPhotogrammetry/videogrammetryMaterial analysis by optical meansAutomatic processingAnalysis data

The invention discloses a centralized processing and distributed operation framework construction method for a spatial data service. The method comprises the following steps: deep analysis of data processing characteristics is performed, and standardized organization is carried out on spatial data and processing services; automatic processing services are integrated into a framework in a centralized parallel computing mode, and interactive editing services are integrated into the framework in a distributed operation mode, so unified regularization processing of spatial data is realized; and meanwhile, a spatial data processing framework is designed based on three principles of middleware, atomization and telescoping, so that the framework can be suitable for various operation scenes in thetechnical field of photogrammetry and remote sensing monitoring application. The invention has the advantages that intelligent production of large-data-volume spatial data is achieved, time redundancy caused by offline function circulation is reduced, connection between an automatic processing service and an interactive operation task is effectively improved, and centralized processing and distributed cooperative operation under various service scenes for spatial data processing are achieved.

Owner:BEIJING GEOWAY SOFTWARE

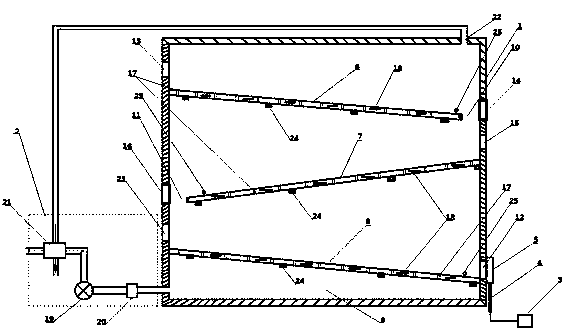

Novel drying device

InactiveCN108759433ASent out in timeQuality assuranceDrying gas arrangementsHeating arrangementEngineeringSingle chip

The invention discloses a novel drying device. The novel drying device comprises a drying box body, a hot air circulation device, a single chip microcomputer, an electric pushing rod, a baffle, an upper partition plate, a middle partition plate and a lower partition plate; the upper partition plate, the middle partition plate and the lower partition plate are obliquely installed in the drying boxbody from the top to bottom, so that the drying box body is divided into an upper drying space, a middle drying space, a lower drying space and a bottom heating space; material dryness degree sensorsare correspondingly arranged at the part, close to a first material channel, of the upper partition plate, the part, close to a second material channel, of the middle partition plate, and the part, close to a material outlet, of the lower partition plate; and the material dryness degree sensors, vibrators, a fan, a heater, a first electric door and a second electric door are electrically connectedwith the single chip microcomputer. Material inlets are formed in the parts corresponding to the different layers of the partition plates so as to dry multiple layers of materials simultaneously, andthe materials meeting the dryness degree requirement can be sent out in time through cooperation of the material dryness degree sensors, the electric doors, the baffle, the single chip microcomputerand the like, so that the drying efficiency is improved, the quality of drying products is ensured, and the intelligent production is achieved.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

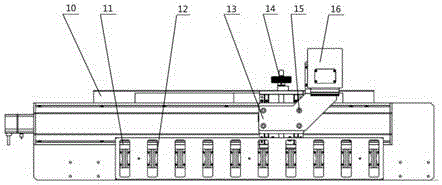

Circuit board assembling line

PendingCN110814775ARealize intelligent productionIncrease productivityOther manufacturing equipments/toolsEngineeringMechanical engineering

The invention provides a circuit board assembling line. The circuit board assembling line comprises a U-shaped conveying line, and a tin soldering device, a cover plate uncovering device, a glue spraying device, a baking device, a cover plate covering device, a turnover device, a code spraying device and a plurality of dispensing devices which are sequentially arranged in the conveying direction of the conveying line, and a screw locking device arranged at the tail of the conveying line. After a product enters the tin soldering device for tin soldering, a cover plate is taken down through thecover plate uncovering device, after the glue spraying device performs glue spraying on a circuit board, the product is dried through the baking device, the circuit board is covered with the cover plate through the cover plate covering device, then, the product is turned over by 180 degrees through the turnover device, after a code is sprayed to the product through the code spraying device, dispensing is performed on the product through the multiple dispensing devices, screw locking is performed on the product, and automatic tin soldering, cover plate uncovering, code spraying, drying, cover plate covering, overturning, code spraying, dispensing and screw locking of the circuit board are completed, intelligent production is achieved, the production efficiency is high, and manpower is saved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

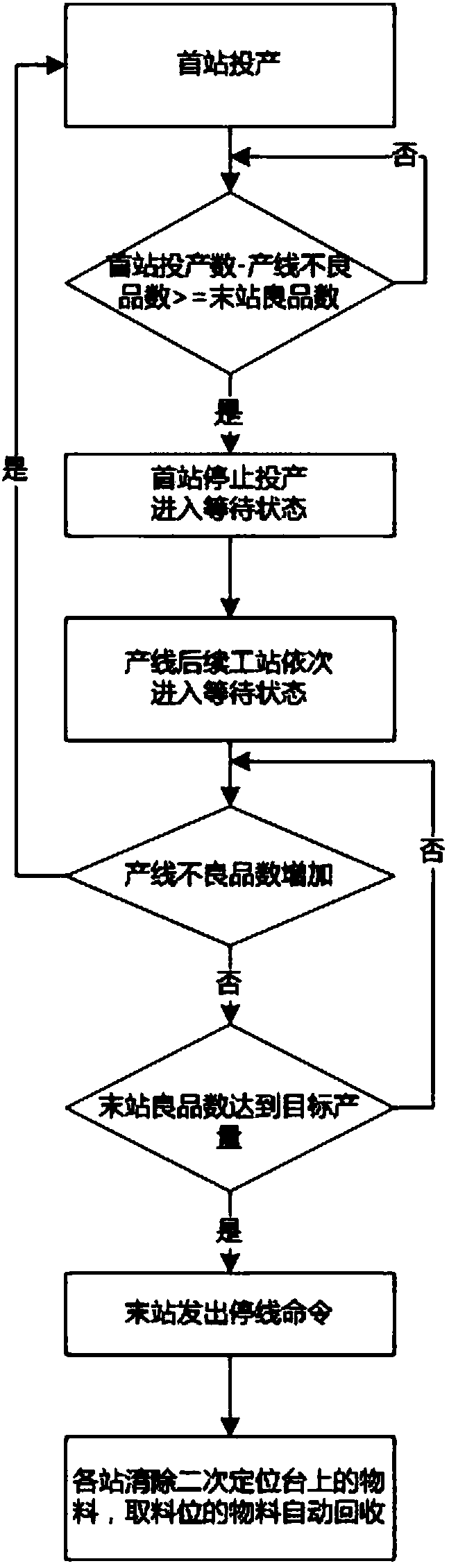

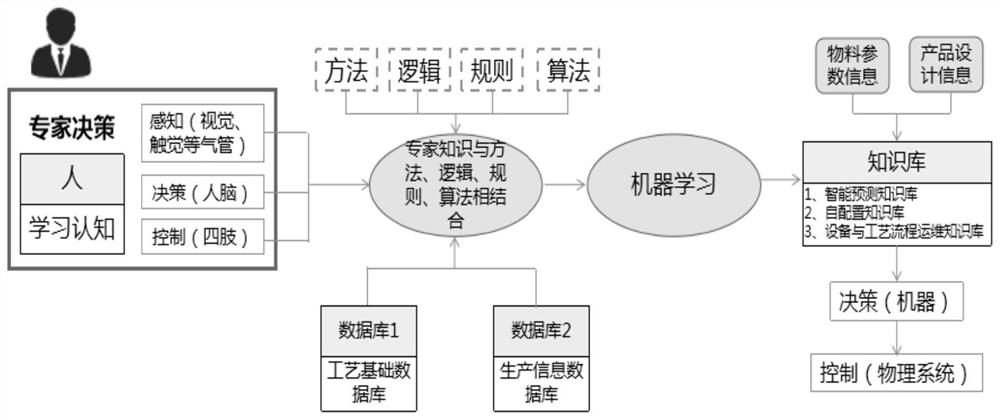

Output-based self-adaptive intelligent production method

ActiveCN105955229AShorten the timeIncrease productivityTotal factory controlProgramme total factory controlProduction lineSelf adaptive

The invention discloses an output-based self-adaptive intelligent production method. The method comprises the following steps: S1) monitoring production information of each station of a production line; S2) judging whether the production line needs to enter a waiting state; S3) judging whether an initial station needs supplement; S4) judging whether the production line needs stopping; and S5) when the production line stops, clearing materials automatically by each station. According to the provided output-based self-adaptive intelligent production method, operation of the production line is adjusted adaptively based on the preset target output, and thus production line quantitative product production and production line clearing operation can be realized simultaneously. The whole process does not need participation of workers and is highly automatic, thereby greatly reducing production line clearing time, improving production line production efficiency and realizing production line intelligent production.

Owner:BOZHON PRECISION IND TECH CO LTD

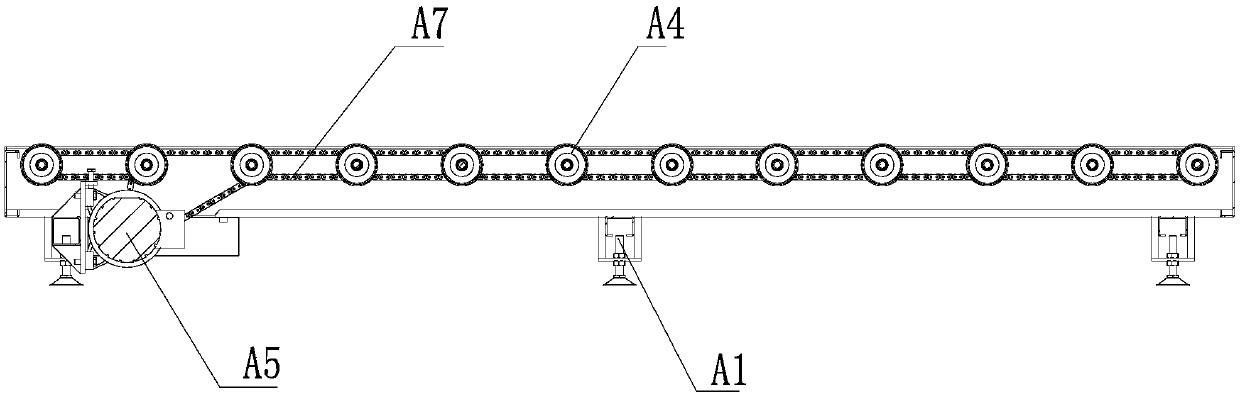

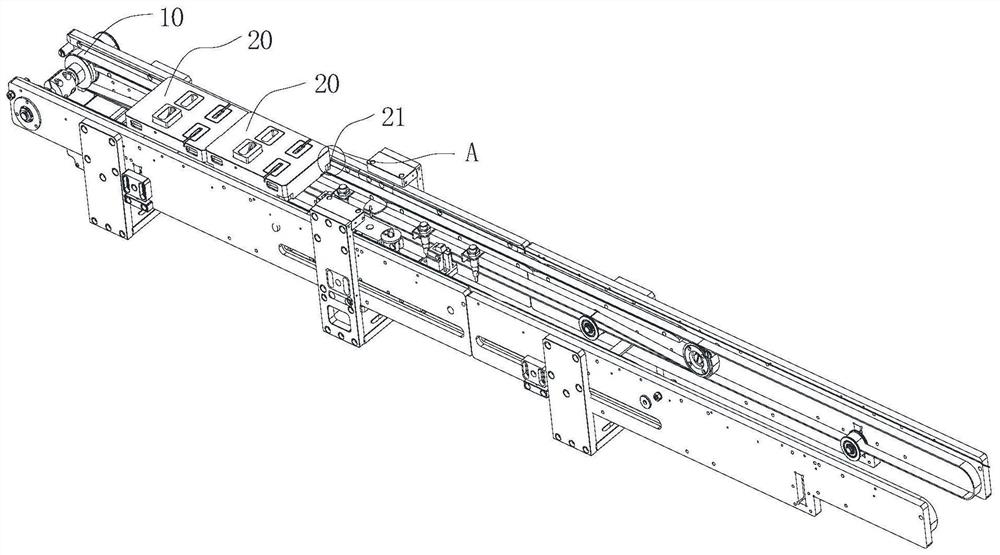

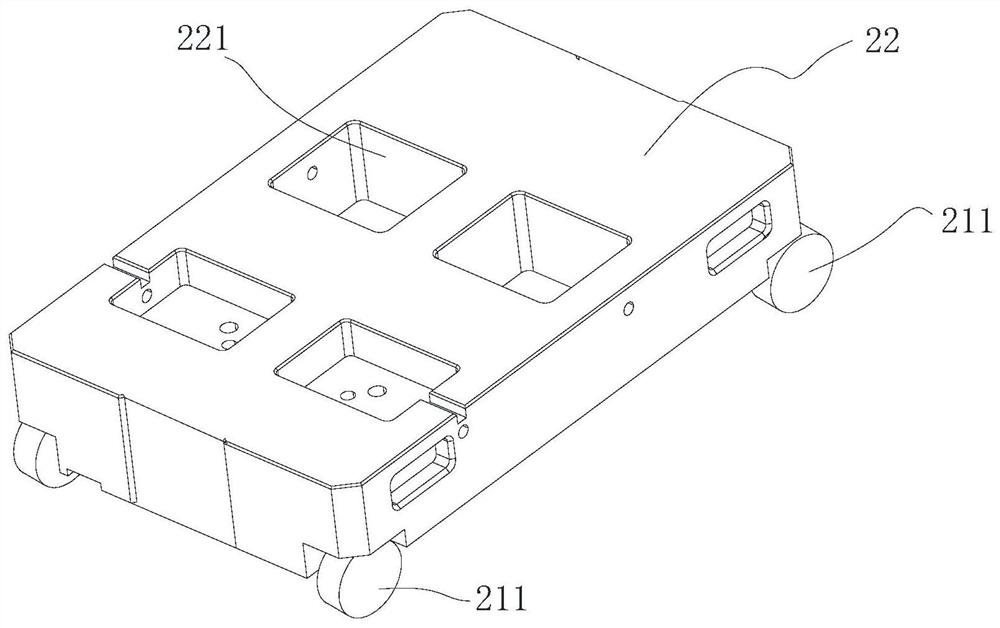

Conveyor belt system and conveyor belt control method

ActiveCN113173395APrevent falling offGood stabilityControl devices for conveyorsAutomotive engineeringSmart control

The invention is applicable to the technical field of intelligent adjustment control systems, and provides a conveyor belt system and a conveyor belt control method. The conveyor belt system comprises a control part, a conveyor belt assembly and carriers, wherein each carrier comprises a damping wheel set, a speed sensing part and a control module. When a certain carrier in a conveyor belt is in clamping stagnation, th said carrier converts sliding friction into rolling friction through the corresponding damping wheel set, so that sliding abrasion between the conveyor belt and the said carrier is avoided, carrier shaking caused by sliding friction force between the conveyor belt and the said carrier can also be prevented, a workpiece on the said carrier is effectively prevented from falling off, and better stability is achieved. According to the conveyor belt system, intelligent production is achieved through matching of the damping wheel sets and the speed sensing parts, the sliding friction between the carrier in clamping stagnation and the conveyor belt can be avoided, the workpiece is prevented from falling off, the running speed of the conveyor belt can be intelligently controlled, large-scale rear-end collision of the carriers is avoided, and system paralysis is prevented.

Owner:SHENZHEN YUANTONG ROBOT AUTOMATION CO LTD

Intelligent control system and method for manufacturing optical fiber prefabricated rod by using OVD (optical variable device)

InactiveCN110526573AImprove intelligent productionPromote OVD method to prepare optical fiber preform to realize intelligent productionGlass making apparatusEngineeringOptical variable device

The invention discloses an intelligent control system and a method for manufacturing an optical fiber prefabricated rod by using an OVD (optical variable device) and relates to the field of optical fiber manufacturing. The intelligent control system comprises a support device, at least one blowtorch, a diameter measuring device and a control device, wherein the support device is used for clampinga core rod to be processed; a weighing sensor is arranged on the support device; the weighing sensor is used for measuring the weight of a loosened body on the core rod in real time; the at least oneblowtorch is arranged on the support device; the diameter measuring device is used for measuring the outer diameter of the loosened body in real time; and the control device is used for receiving weight data transmitted from the weighing sensor and outer diameter data transmitted from the diameter measuring device, and used for adjusting the flow of the blowtorch according to the weight data and the outer diameter data, and thus the outer diameter and the density of the loosened body are both within preset ranges. By adopting the intelligent control system, the outer diameter size, the weightand the density of the loosened body can be precisely controlled.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

Equipment specially used for diamond drying

InactiveCN103162525AImprove drying efficiencyReduce energy consumptionDrying solid materialsHeating arrangementAutomatic controlMicrowave

The invention relates to equipment specially used for diamond drying. The equipment specially used for diamond drying is characterized by comprising a box body, a door body, a wet-pull-out system, an electronic control system, a rotating part, a microwave generating source and a microwave action cavity. According to the equipment specially used for diamond drying, microwave is used to conduct heating, and diamond micro powder enables materials to be heated evenly in a cavity body through a rotating mode. A temperature and humidity sensor is additionally arranged, and the equipment is controlled automatically through temperature and humidity. Therefore, intelligent production is achieved really, and the equipment specially used for diamond drying has broad market prospects.

Owner:HENAN BODA MICROWAVE EQUIP

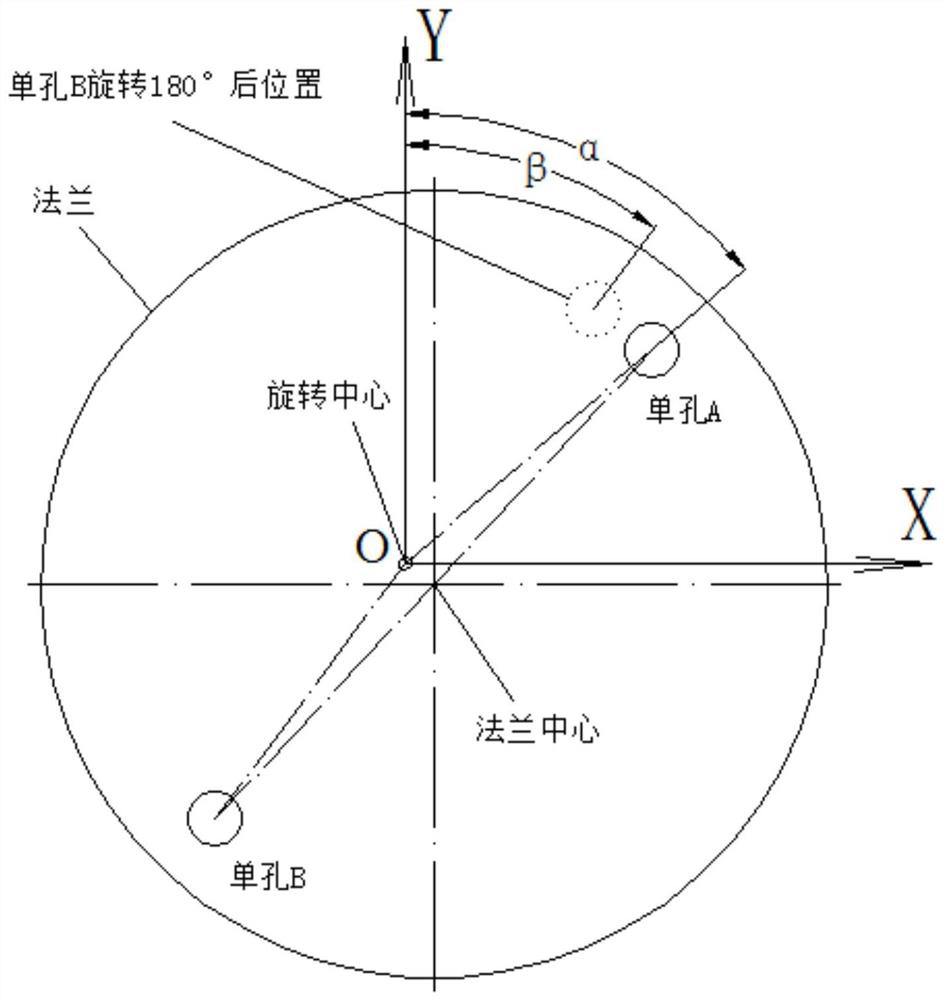

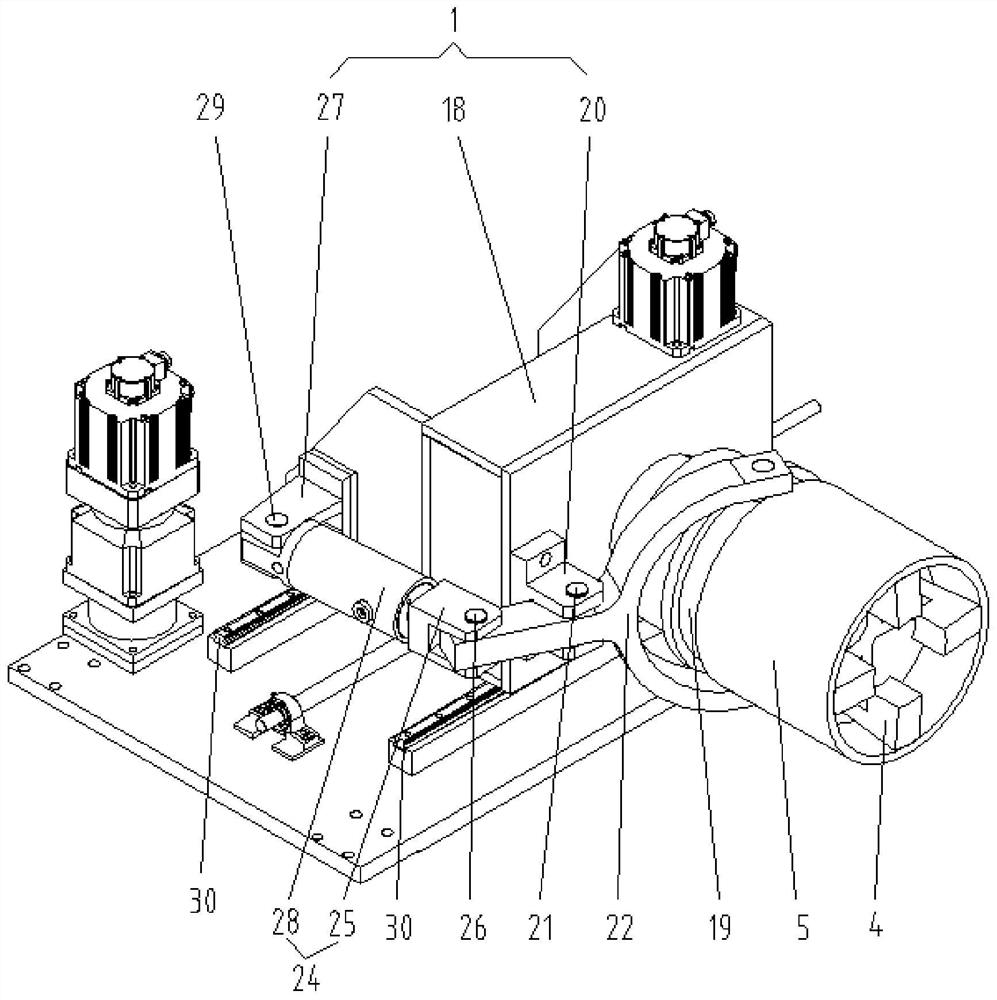

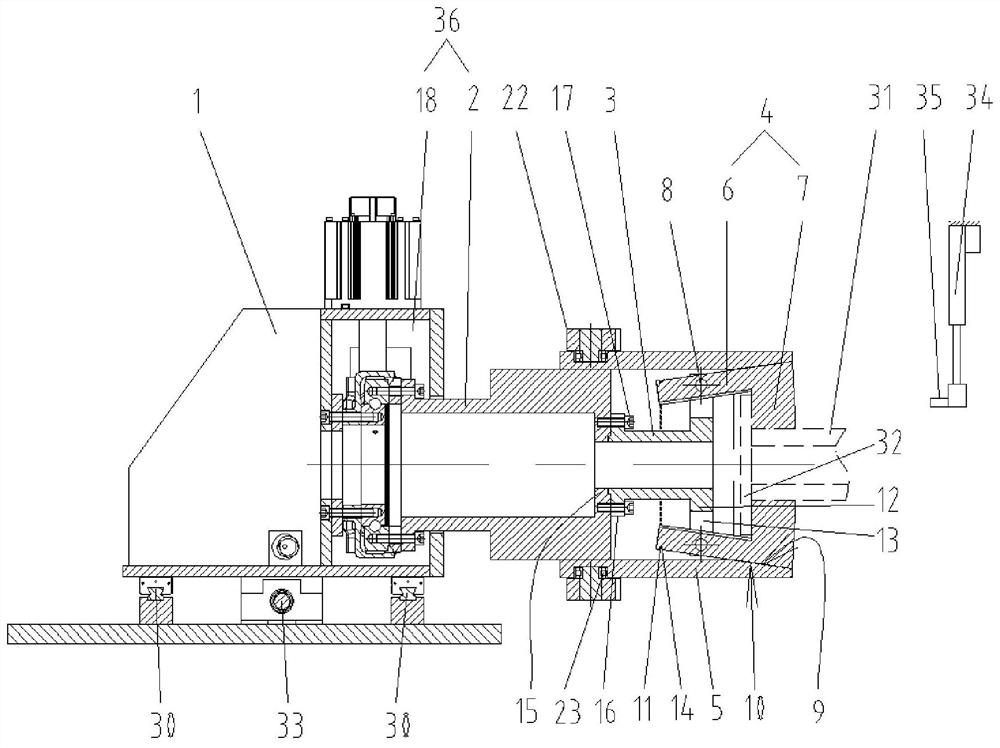

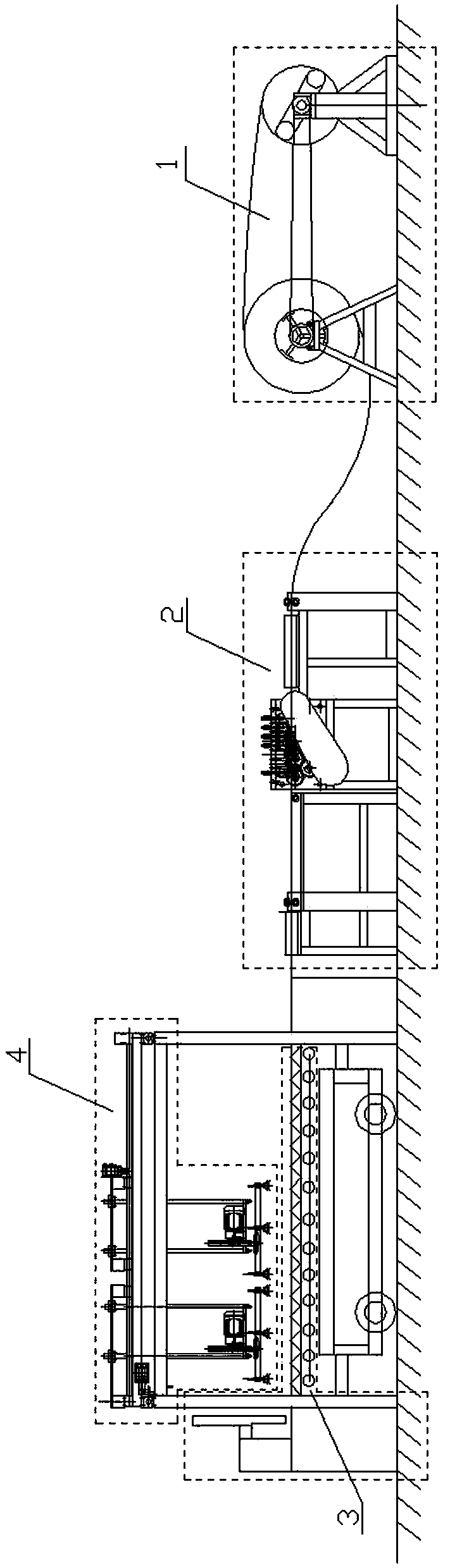

Numerical control pipe bending machine capable of dynamically correcting hole sites through visual inspection and pipe bending method

ActiveCN113118266AHigh precisionOvercoming the disadvantages of difficult installationMetal working apparatusNumerical controlControl system

The invention relates to the technical field of pipe bending machines, in particular to a numerical control pipe bending machine capable of dynamically correcting hole sites through visual inspection and a pipe bending method. The numerical control pipe bending machine comprises a pipe bending machine servo trolley, a trolley rotating mechanism arranged on the pipe bending machine servo trolley, a self-centering clamping mechanism connected to the trolley rotating mechanism and used for clamping a pipeline with a flange, and a visual identification device arranged beside the self-centering clamping mechanism and used for detecting the flange hole sites on the pipeline with the flange. The visual identification device comprises a camera and a visual identification system connected with the camera, and the visual identification system and the camera are respectively connected with a control system of the numerical control pipe bending machine. The bending precision of the pipeline with the flange is improved.

Owner:JIANGYIN HONGYE MECHANICAL

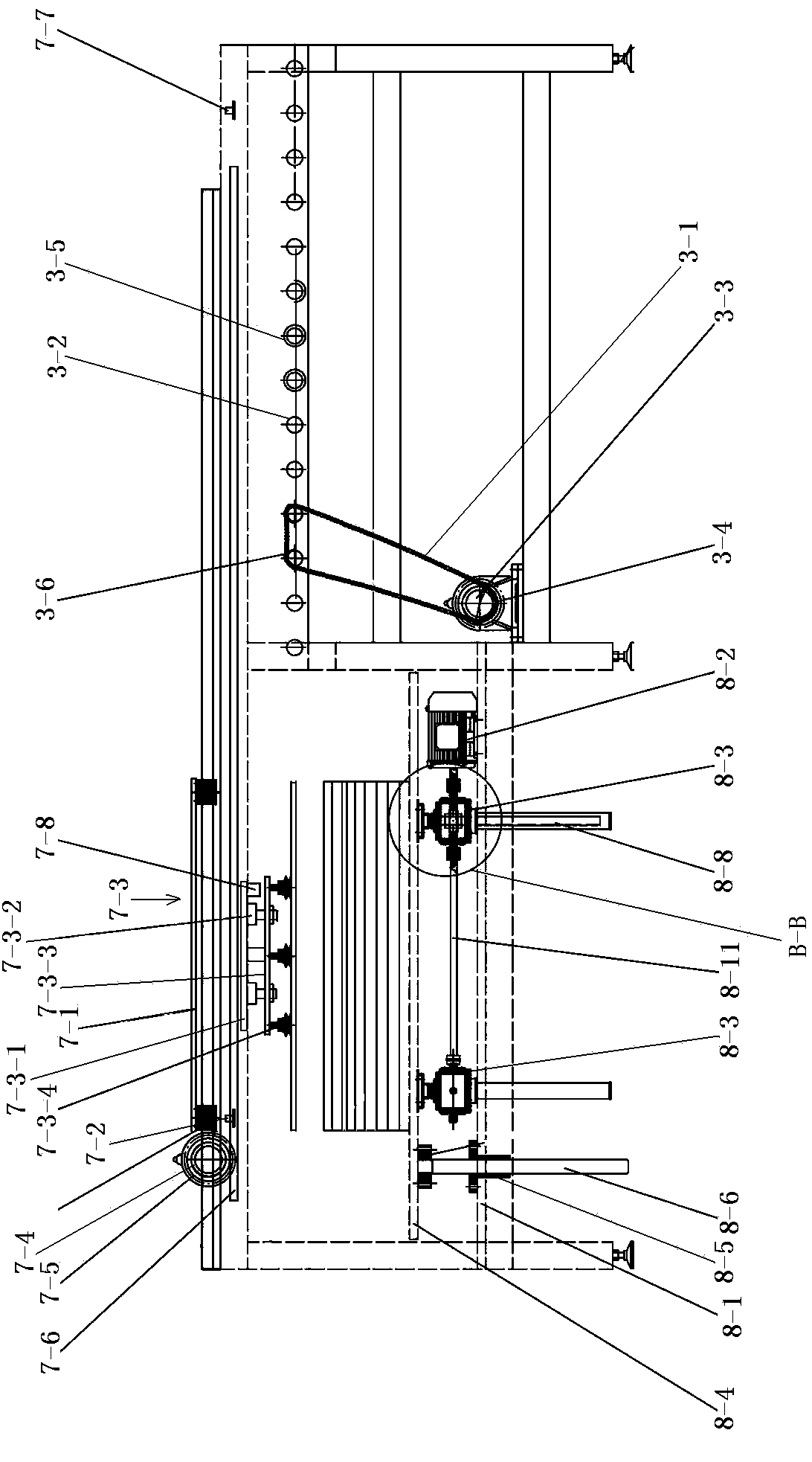

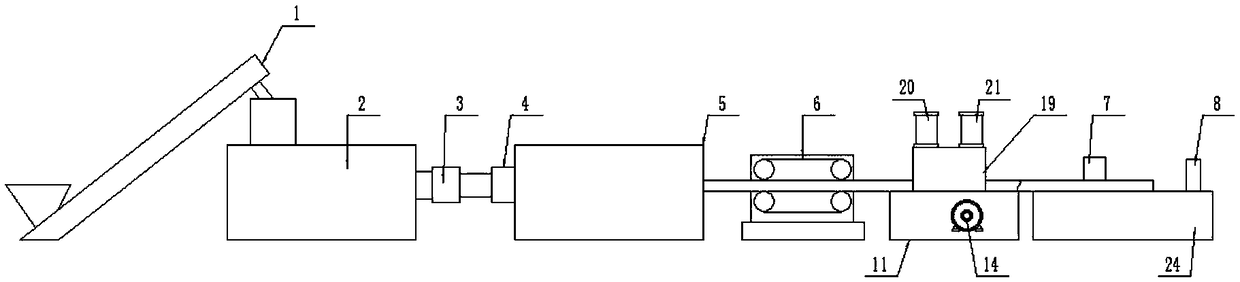

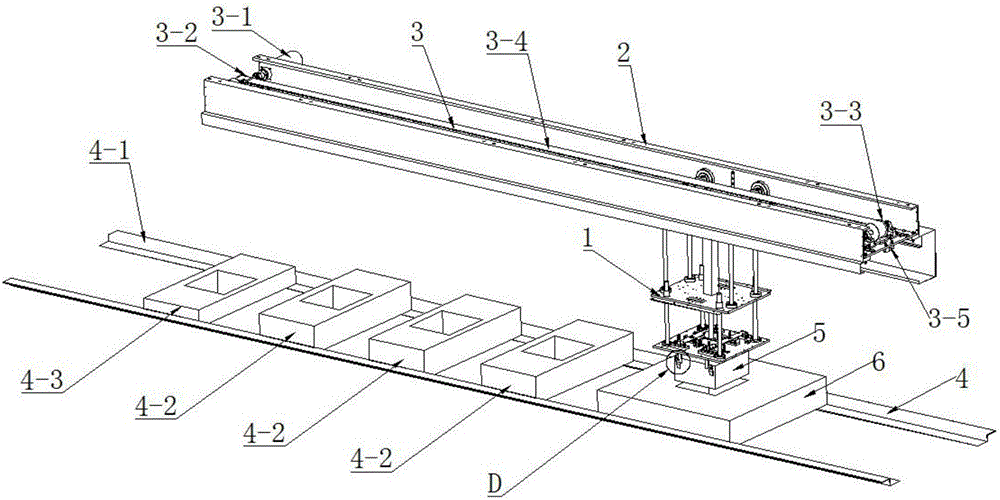

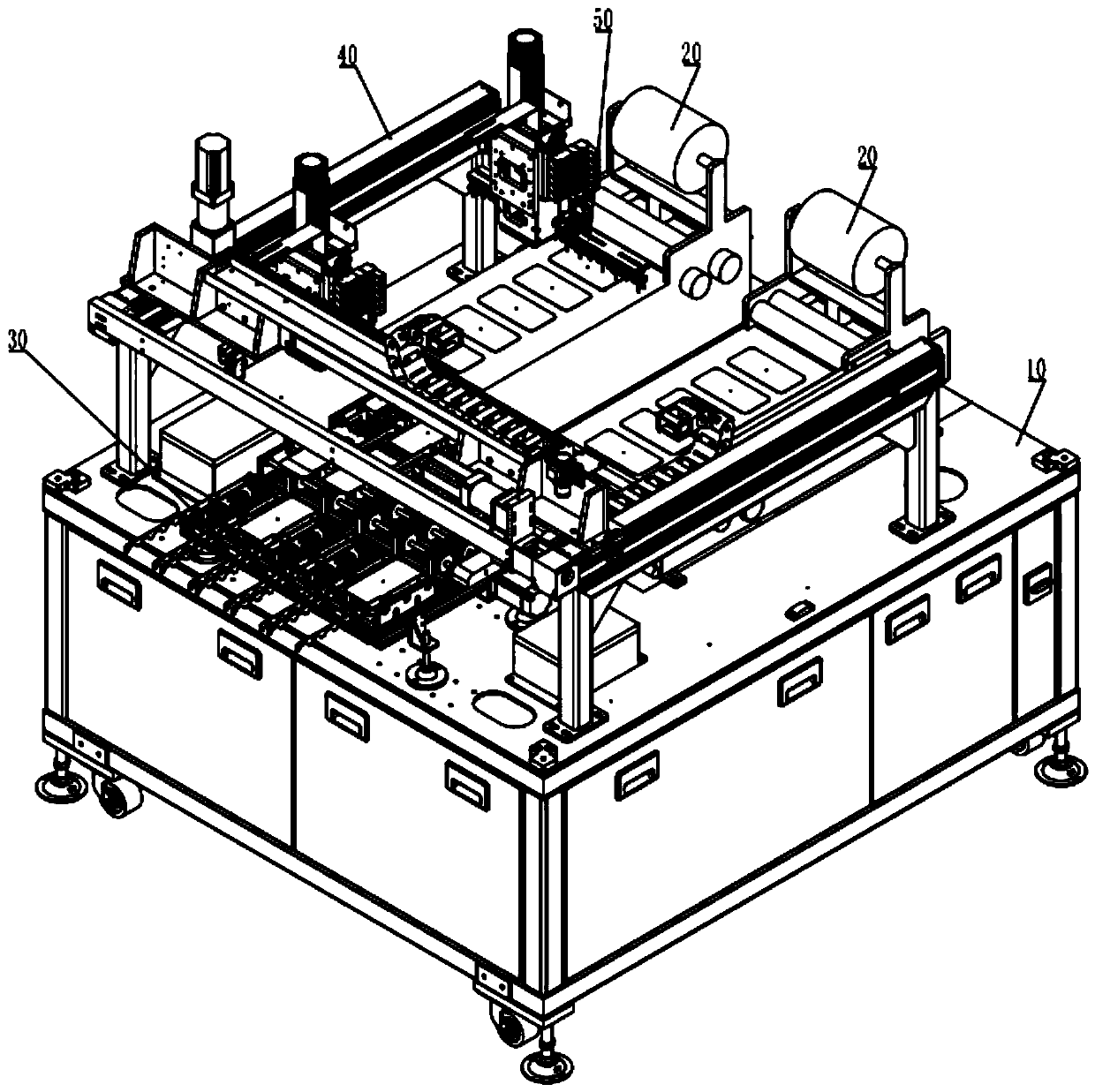

Automatic discharging system and discharging method of heat exchanger plate pieces

PendingCN108608112ARealize intelligent productionIncrease productivityOther manufacturing equipments/toolsLaser beam welding apparatusPunchingStack machine

The invention provides an automatic discharging system and method of heat exchanger plate pieces. The system comprises a stainless steel uncoiling device, a stainless steel coil flat plate device anda laser cutting device in sequence; an automatic stacking machine is arranged above the laser cutting device, the stainless steel uncoiling device is used for uncoiling the stainless steel coil, meanwhile, isolation paper on the stainless steel coil is coiled up, the stainless steel coil flat plate device is used for leveling the uncoiled stainless steel coil, the laser cutting device is used forcarrying out laser cutting on the leveled stainless steel coil, and the heat exchanger plate pieces are formed; the automatic stacking machine is used for stacking the heat exchanger plate pieces. Through automatic uncoiling, automatic leveling, automatic laser cutting and automatic stacking of the stainless steel plate pieces, intelligent production of the heat exchanger plate pieces can be achieved, traditional old processes of plate shearing machines, punching machines and punching molds are replaced, and production efficiency and precision are improved.

Owner:辽宁光阳换热设备制造有限公司

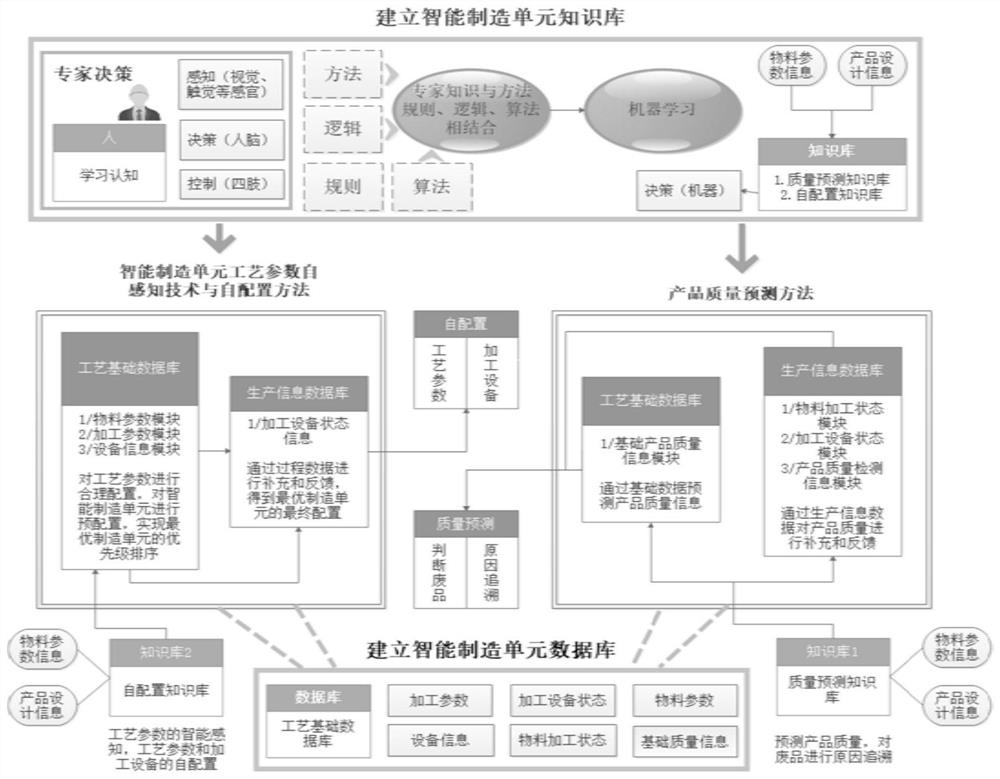

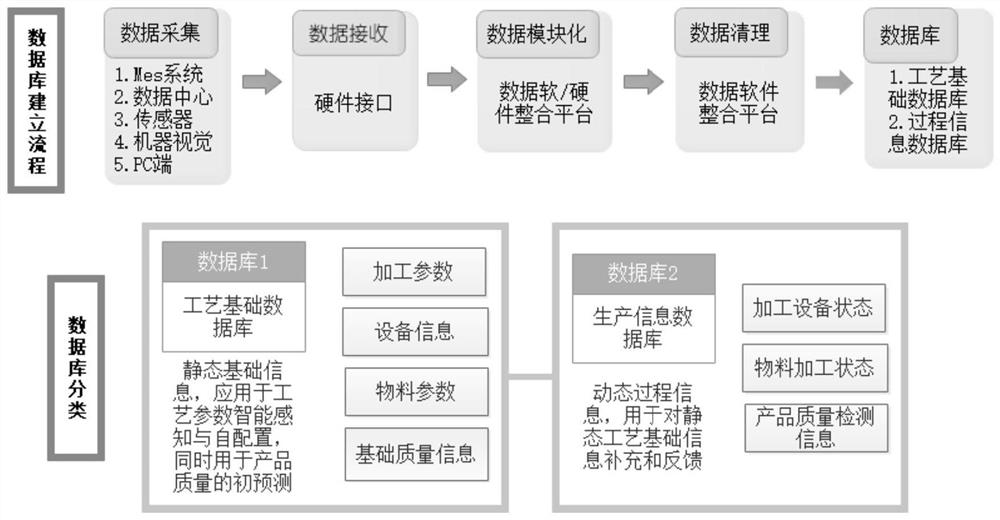

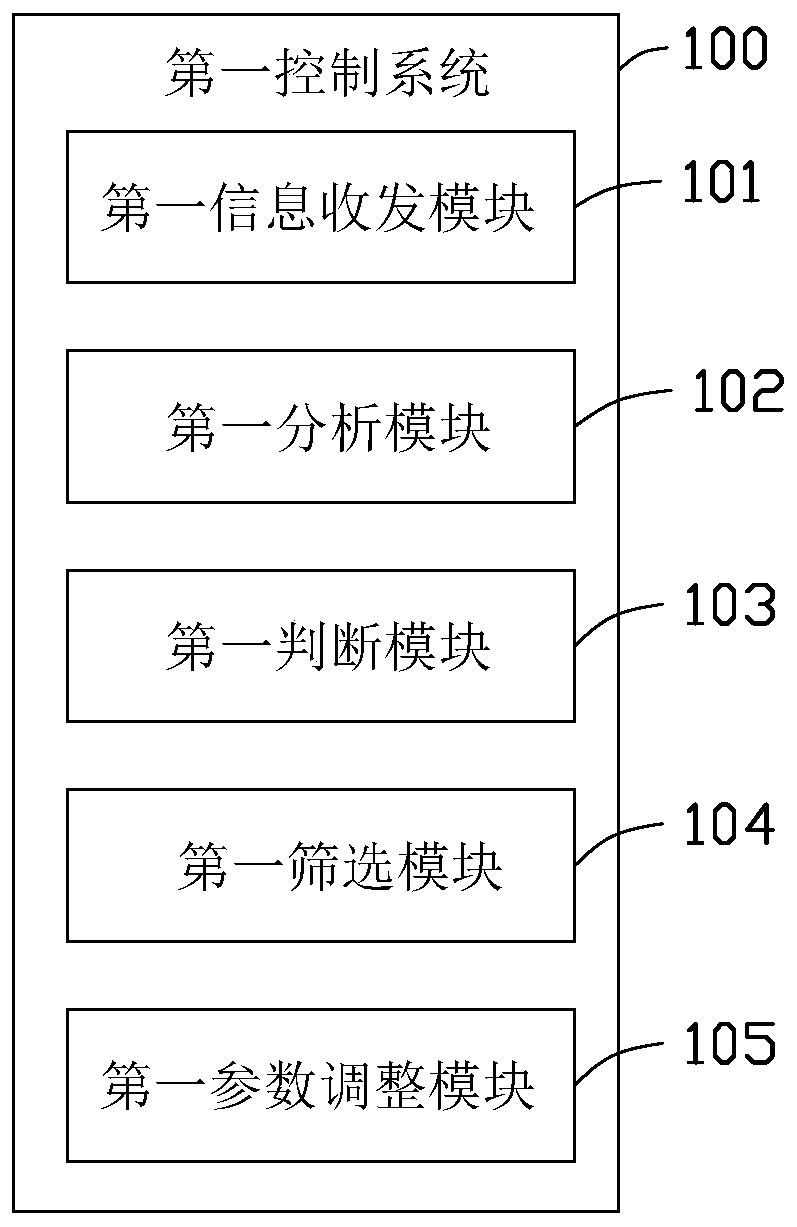

Intelligent manufacturing unit management and control system and device based on flexible circuit board SMT workshop

PendingCN113110345AImprove the level of intelligenceRealize intelligent productionTotal factory controlProgramme total factory controlFlexible circuitsControl system

The invention discloses an intelligent manufacturing unit management and control system and device based on a flexible circuit board SMT workshop. The system comprises an intelligent manufacturing unit knowledge base, an intelligent manufacturing unit database, an intelligent manufacturing unit technological parameter self-sensing and self-configuration unit and an intelligent manufacturing unit product quality information prediction unit. The intelligent manufacturing unit process parameter self-sensing and self-configuration unit is realized through the intelligent manufacturing unit database and the intelligent manufacturing unit knowledge base, and the intelligent manufacturing unit product quality information prediction unit is realized through the intelligent manufacturing unit database and the intelligent manufacturing unit knowledge base. Through the intelligent manufacturing unit management and control system based on the flexible circuit board SMT workshop, the intelligent level of the SMT workshop can be improved, the production efficiency is greatly improved, and intelligent production of the SMT workshop is realized.

Owner:SHENYANG INST OF AUTOMATION GUANGZHOU CHINESE ACAD OF SCI +2

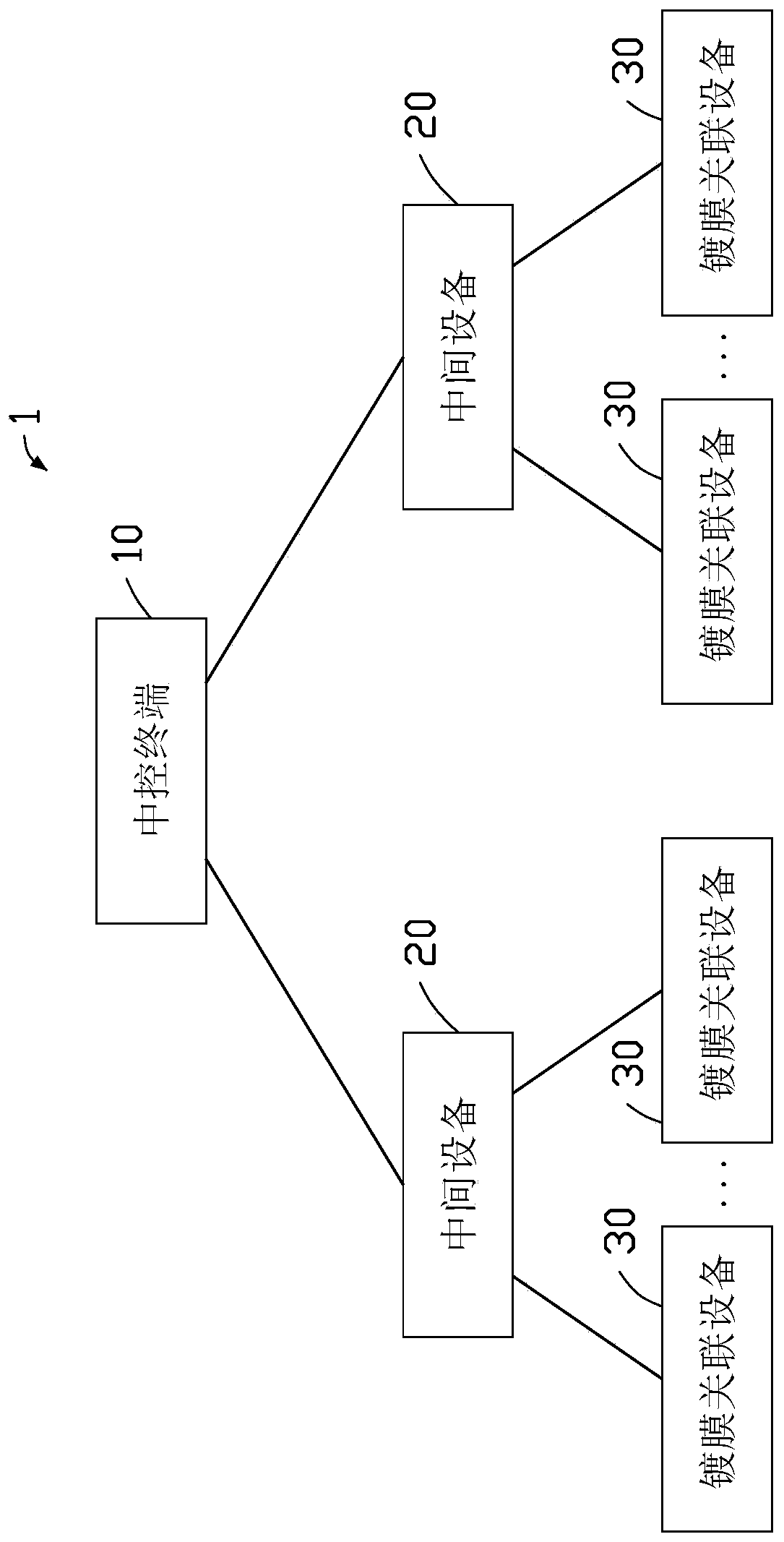

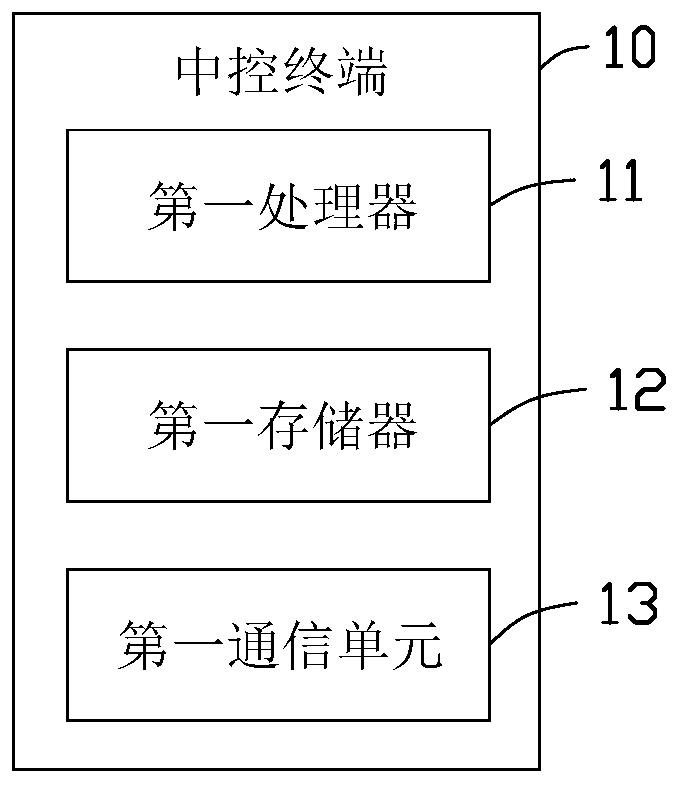

Central control terminal and control method thereof, intermediate equipment and computer storage medium

ActiveCN111045402ARealize intelligent productionImprove yield and efficiencyTotal factory controlProgramme total factory controlProcess engineeringSystems engineering

Provided in the invention is a control method of a central control terminal. The method comprises the steps: receiving production information that is sent by a conveying device and comprises a first processing parameter and product quality detection information; adjusting the first processing parameter into a second processing parameter according to the quality detection information; and sending the second processing parameter to coating associated equipment. The invention also provides a central control terminal, intermediate equipment and a computer readable storage medium. According to theinvention, the processing parameters of the coating associated equipment can be automatically adjusted, and the coating efficiency and yield are improved.

Owner:ZHENGZHOU FULIAN INTELLIGENT WORKSHOP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com