Full-automatic intelligent production line for PVC pipes

A PVC pipe, fully automatic technology, applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of low automation, low speed, low intelligence, etc., achieve controllable water temperature, improve product quality, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

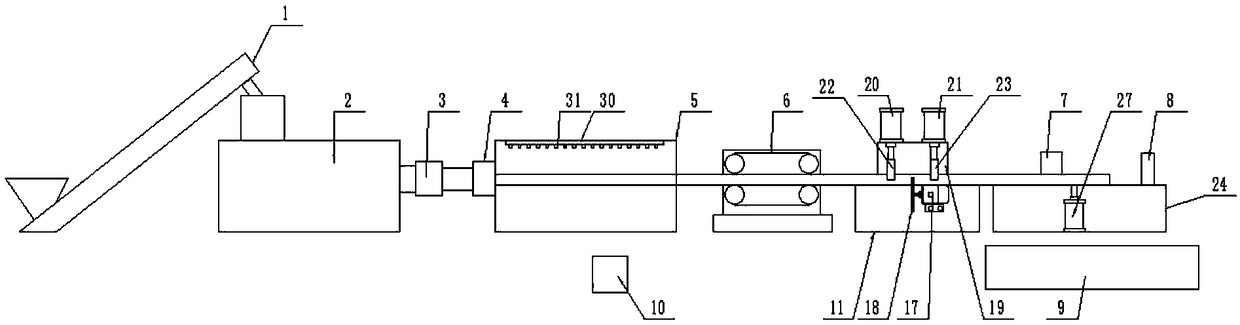

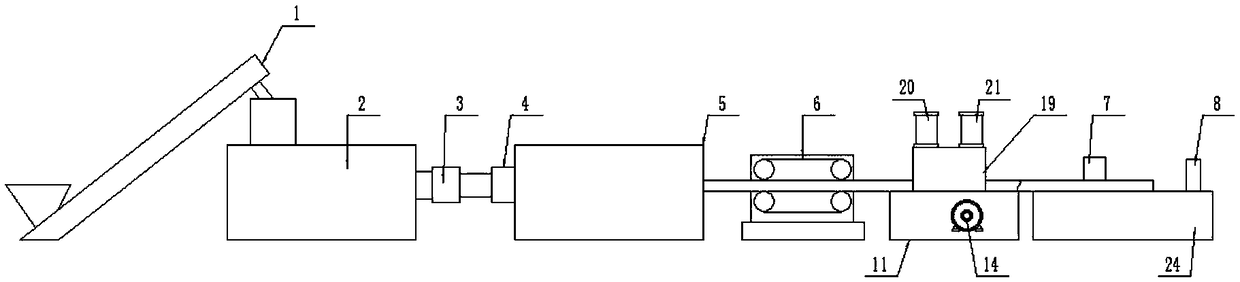

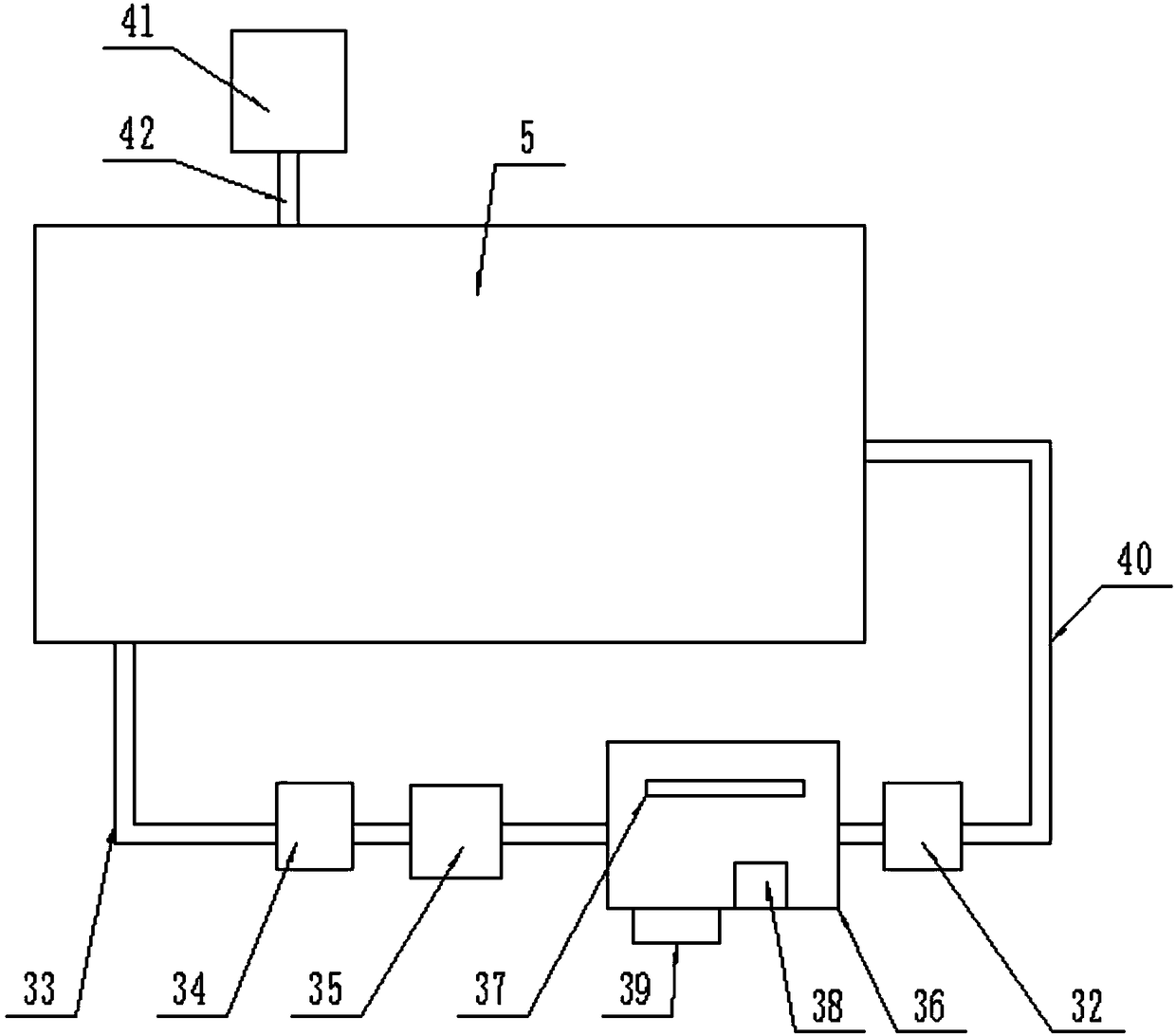

[0022] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 As shown, a fully automatic PVC pipe intelligent production line includes a feeder 1, an extruder 2, an extrusion die 3, a sizing sleeve 4, a spray vacuum calibrating box 5, a tractor 6, a cutting device, and a rollover device , infrared scanning detector 7, inkjet printer 8, pipe stacking rack 9 and industrial computer 10, the feeder 1, extruder 2, spray vacuum calibrating box 5, tractor 6, cutting device, rollover device , weighing device and pipe stacking rack 9 are arranged in sequence, the extrusion die 3 is located at the pipe outlet of the extruder 2, and the sizing sleeve 4 is located at the pipe inlet of the spray vacuum calibrating box 5 , the sizing sleeve 4 is connected to the extrusion port of the extrusion die 3, the spray vacuum setting box 5 is provided with a spray device and a waste water recovery device, and the cutting device is located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com