Feeding device and method for heat exchanger sheet forming

A feeding device and heat exchanger technology, applied in the field of mechanical processing, can solve the problems of restricting production efficiency and factory pass rate, and the work intensity of dangerous workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

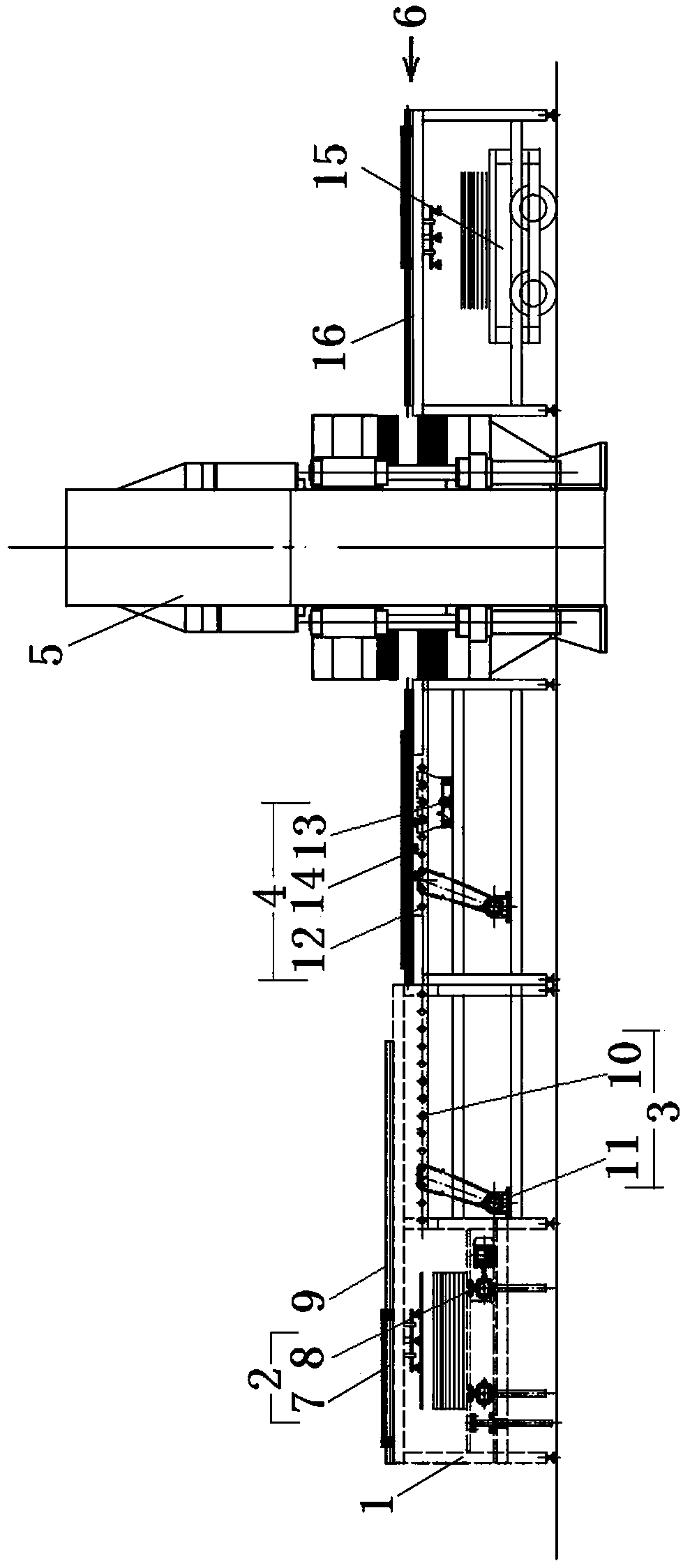

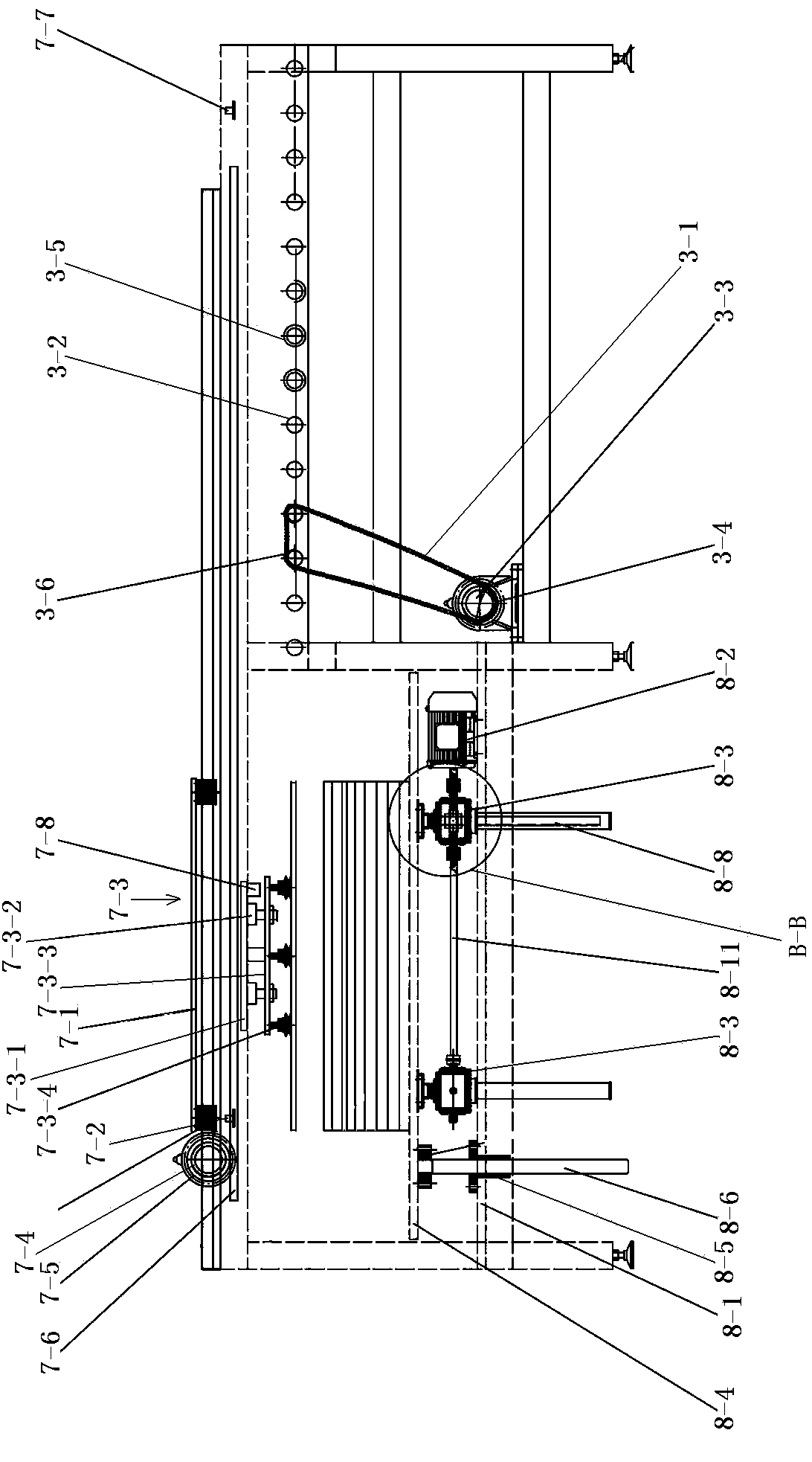

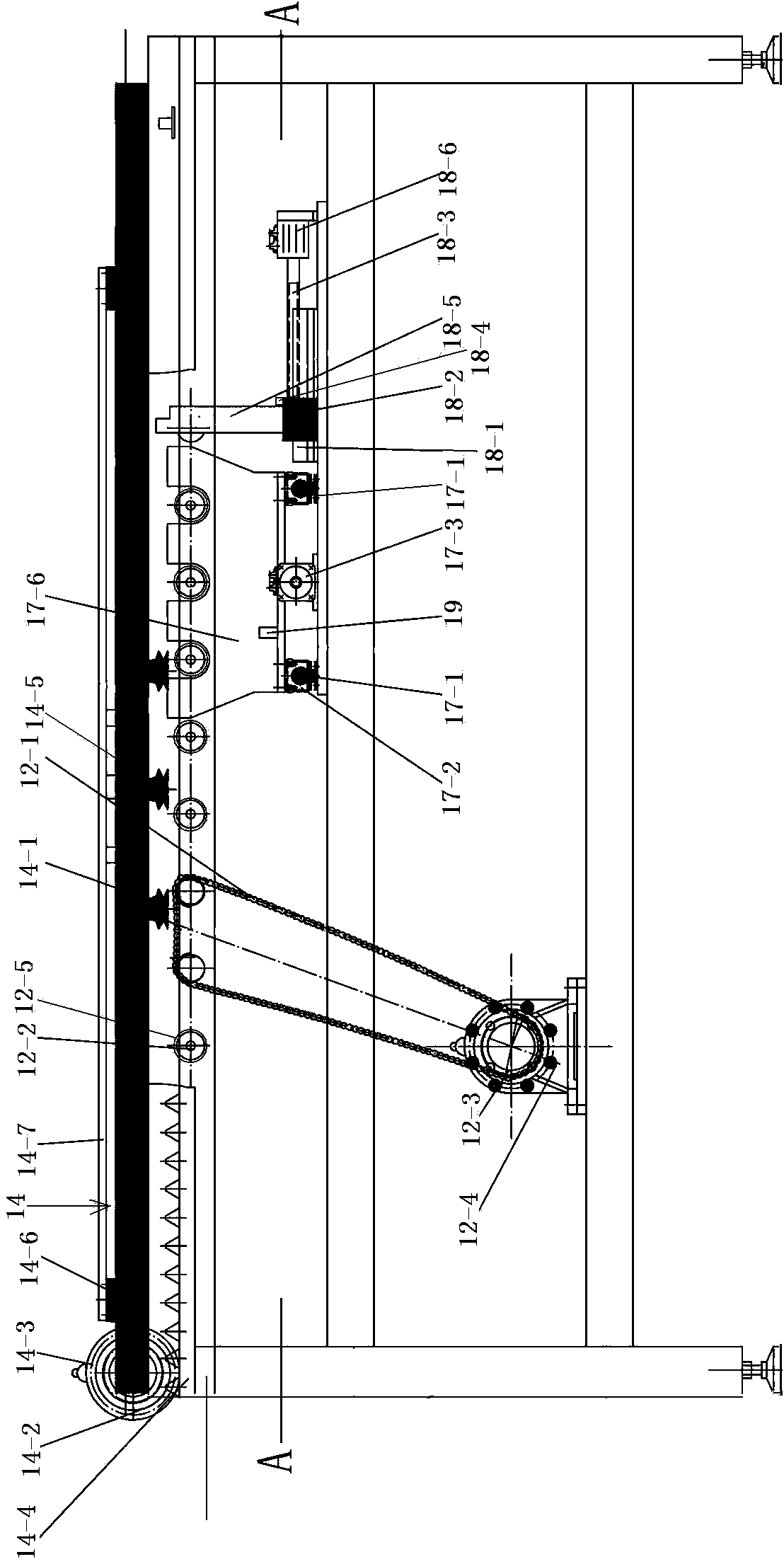

[0041] refer to figure 1 , the present invention comprises: a frame 1, a PLC controller installed on the electric control cabinet near the frame 1, an automatic feeding manipulator system 2, a conveying mechanism 3, and a conveying positioning system installed on the frame 1 in sequence from left to right 4. Sheet drawing die 5. Automatic picking and stacking system 6;

[0042] The automatic feeding manipulator system 2 includes: a first manipulator mechanism 7 for sucking the semi-finished heat exchanger plate and a plate lifting mechanism 8 for lifting the semi-finished heat exchanger plate to the suction range of the first manipulator mechanism 7, The first manipulator mechanism 7 is slidably connected to the frame 1 through the first guide rail 9, and the plate lifting mechanism 8 is installed on the frame 1 below the first manipulator mechanism 7;

[0043] The conveying system 3 includes: a first conveying track 10 for transporting semi-finished heat exchanger plates and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com