Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

530 results about "Ultrasound test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

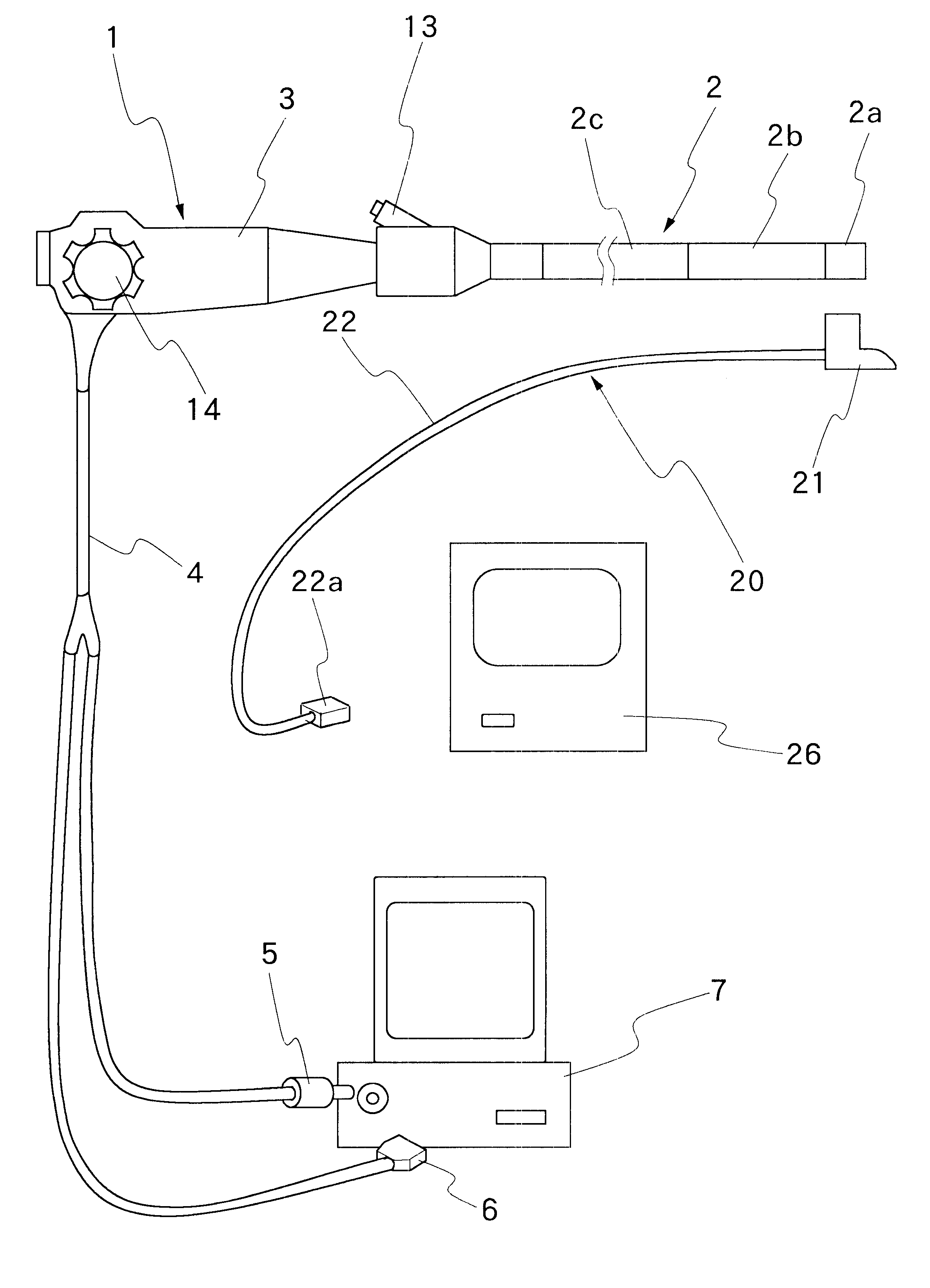

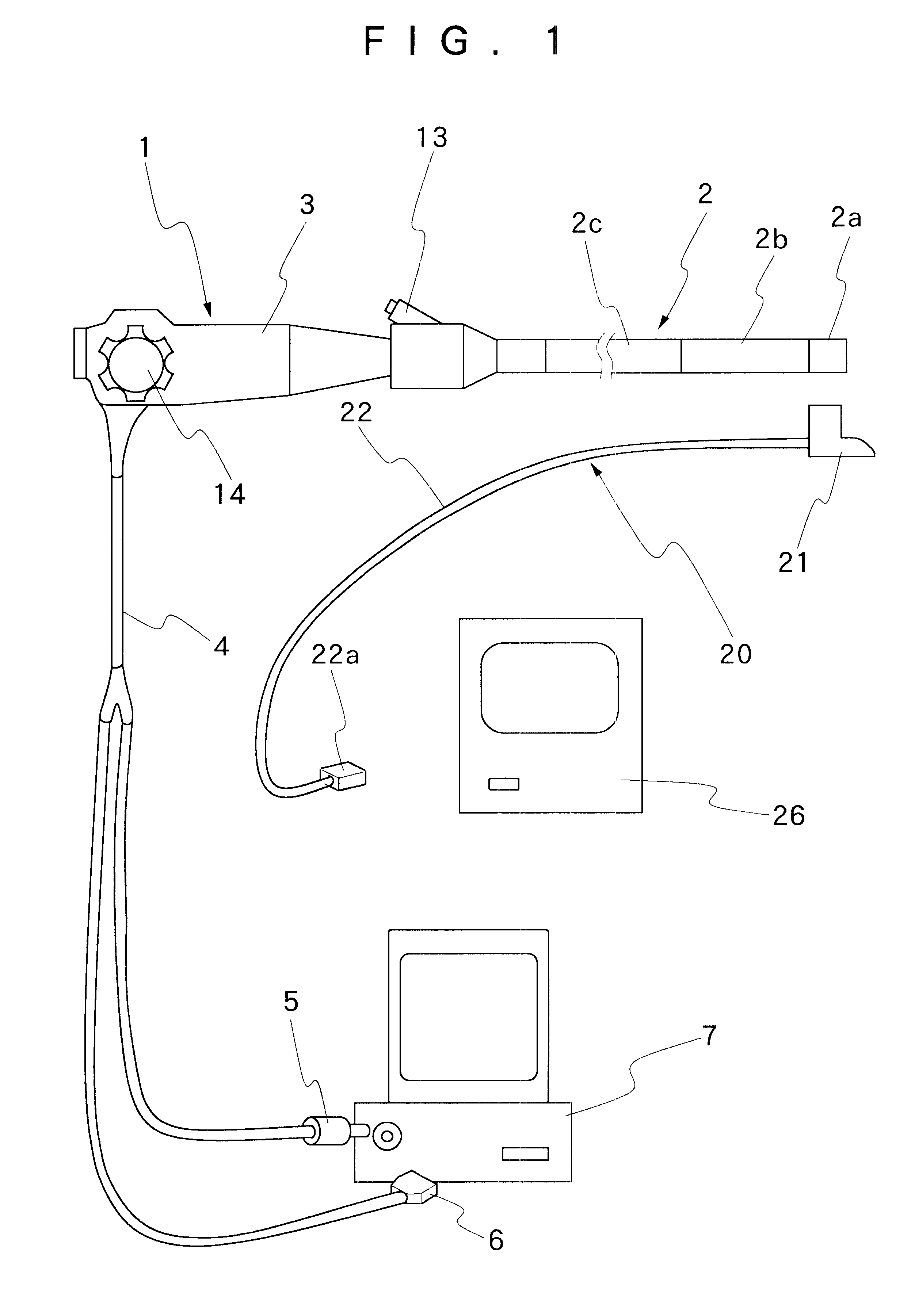

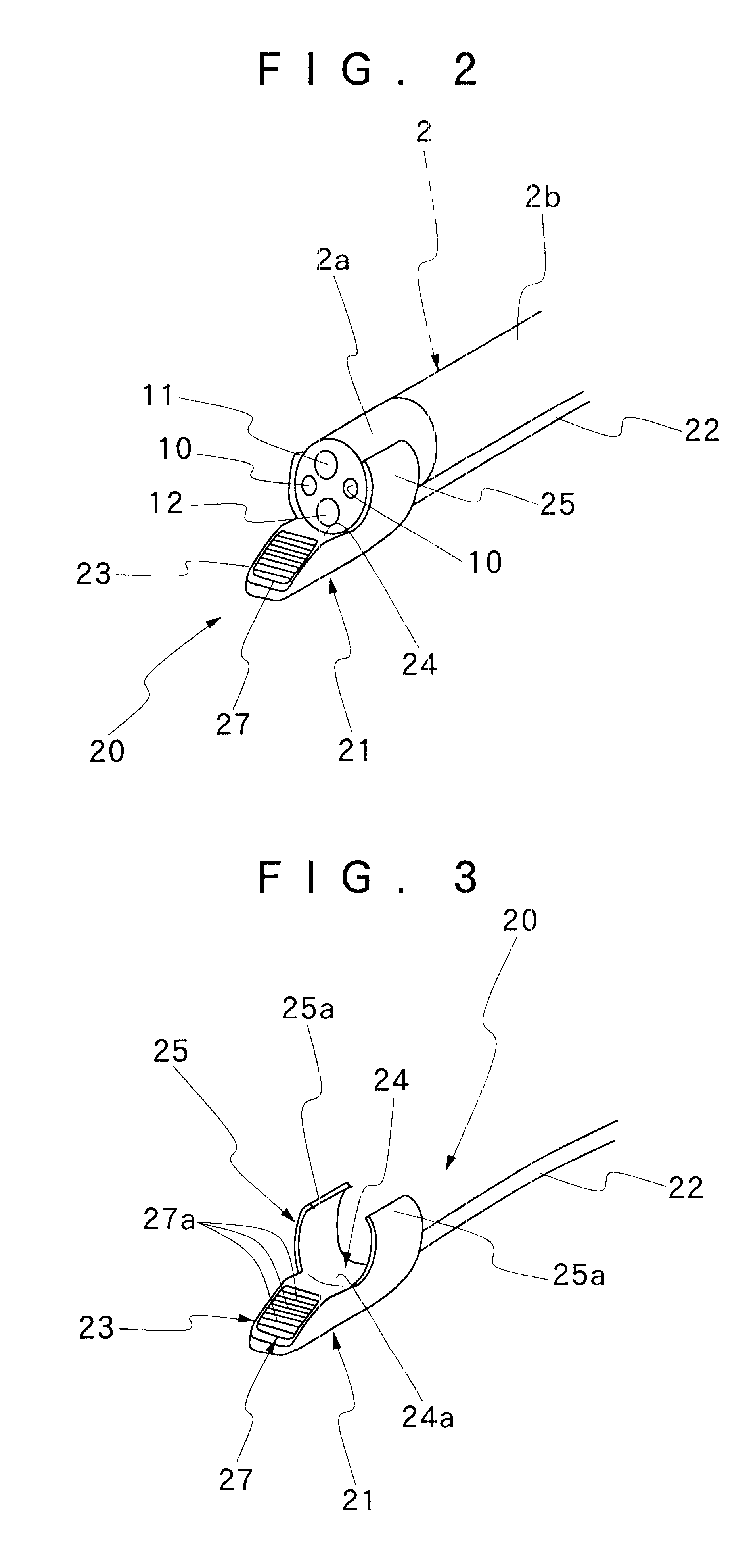

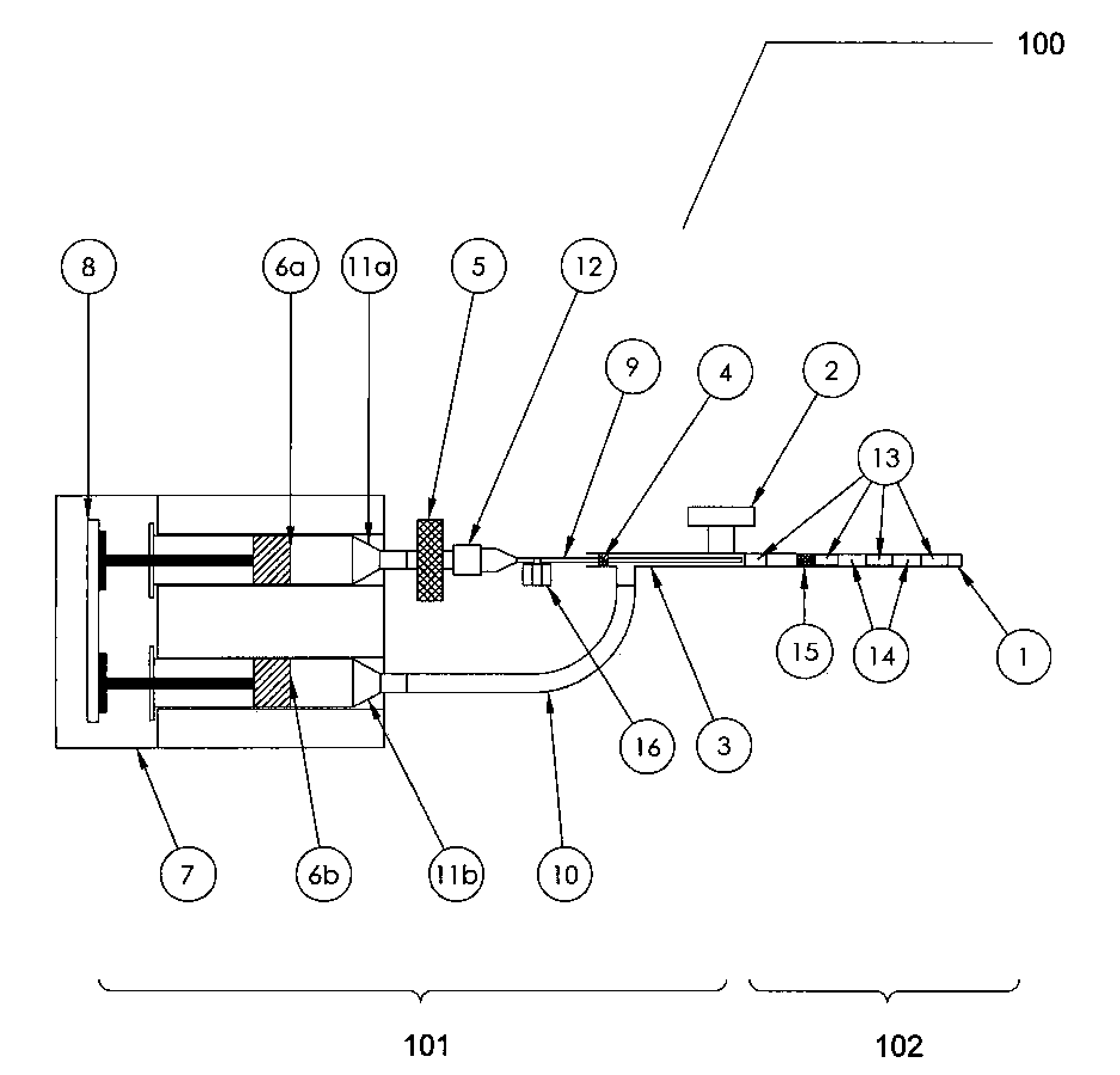

Ultrasound inspection apparatus detachably connected to an endoscope

InactiveUS6461304B1Increase profitSimpleness of the routingsUltrasonic/sonic/infrasonic diagnosticsSurgeryMedicineTransducer

An ultrasound inspection apparatus detachably connected to an endoscope comprises an ultrasonic scanning portion in the front-end side having an ultrasound transducer for performing ultrasonic scanning by arranging a number of transducer chips in a rectangular arrangement. The ultrasonic scanning portion is detachably attached to a distal end portion of an insertion unit in the endoscope so as to protrude ahead the distal end portion by a predetermined length. In order to hold the ultrasonic scanning portion in a fixed state, an endoscope-placing portion for placing the distal end portion is connected to the base end of the ultrasonic scanning portion, and an endoscope-fixing portion for detachably fixing the distal end portion thereto is arranged with the endoscope-placing portion. A predetermined number of wires connected to each transducer chip is inserted into a signal cable from a base end position of the endoscope-placing portion so as to bundle the wires.

Owner:FUJI PHOTO OPTICAL CO LTD

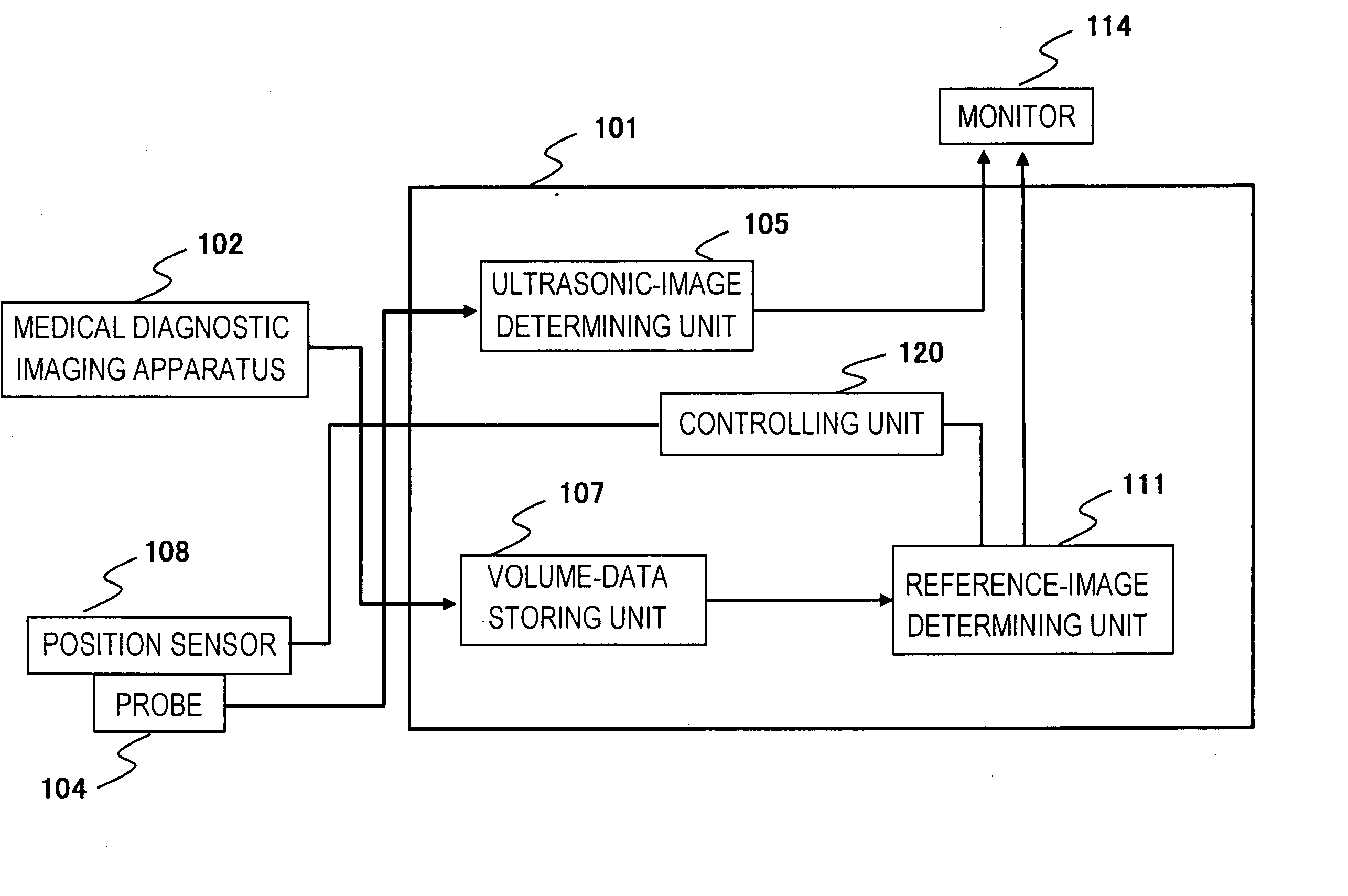

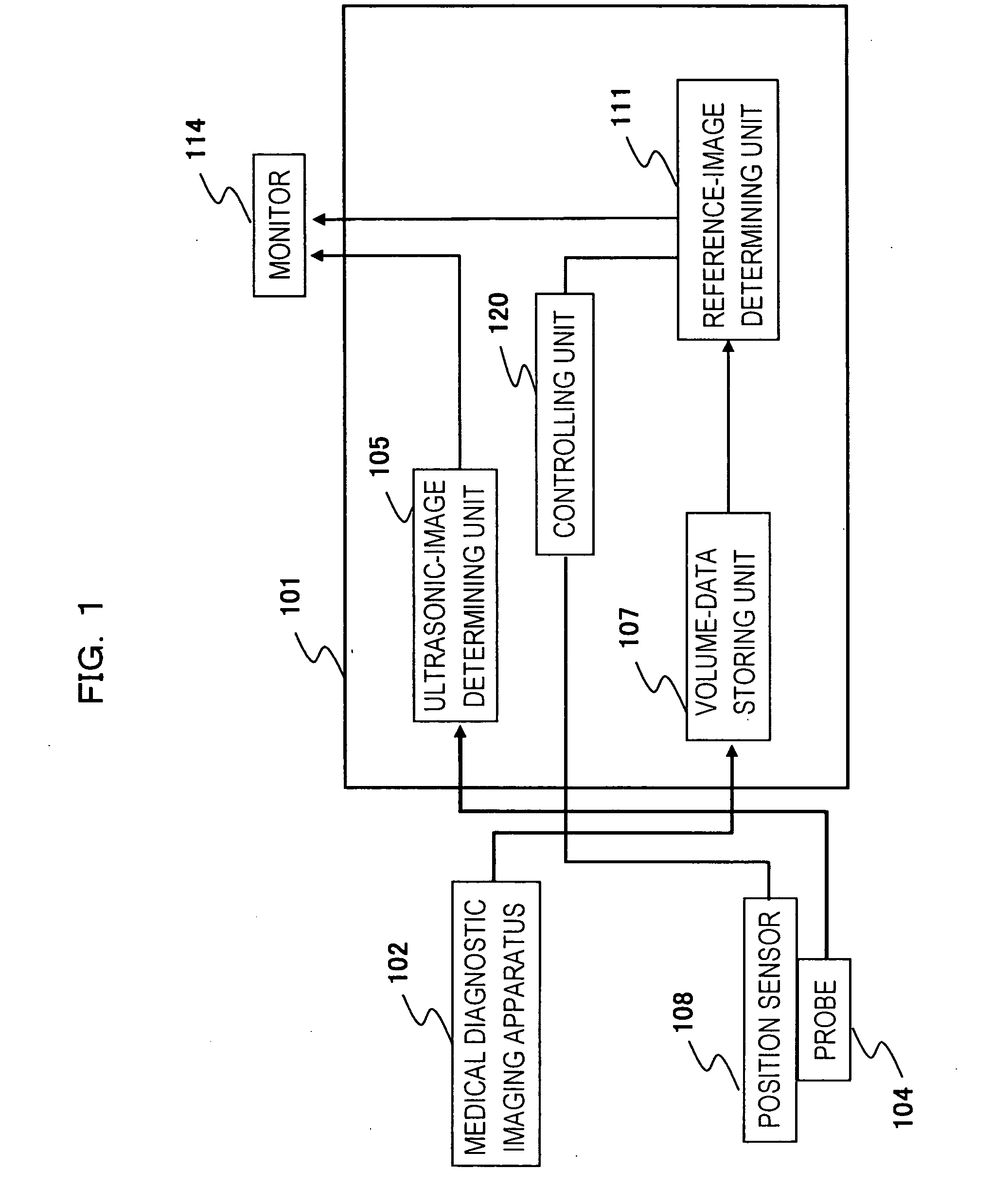

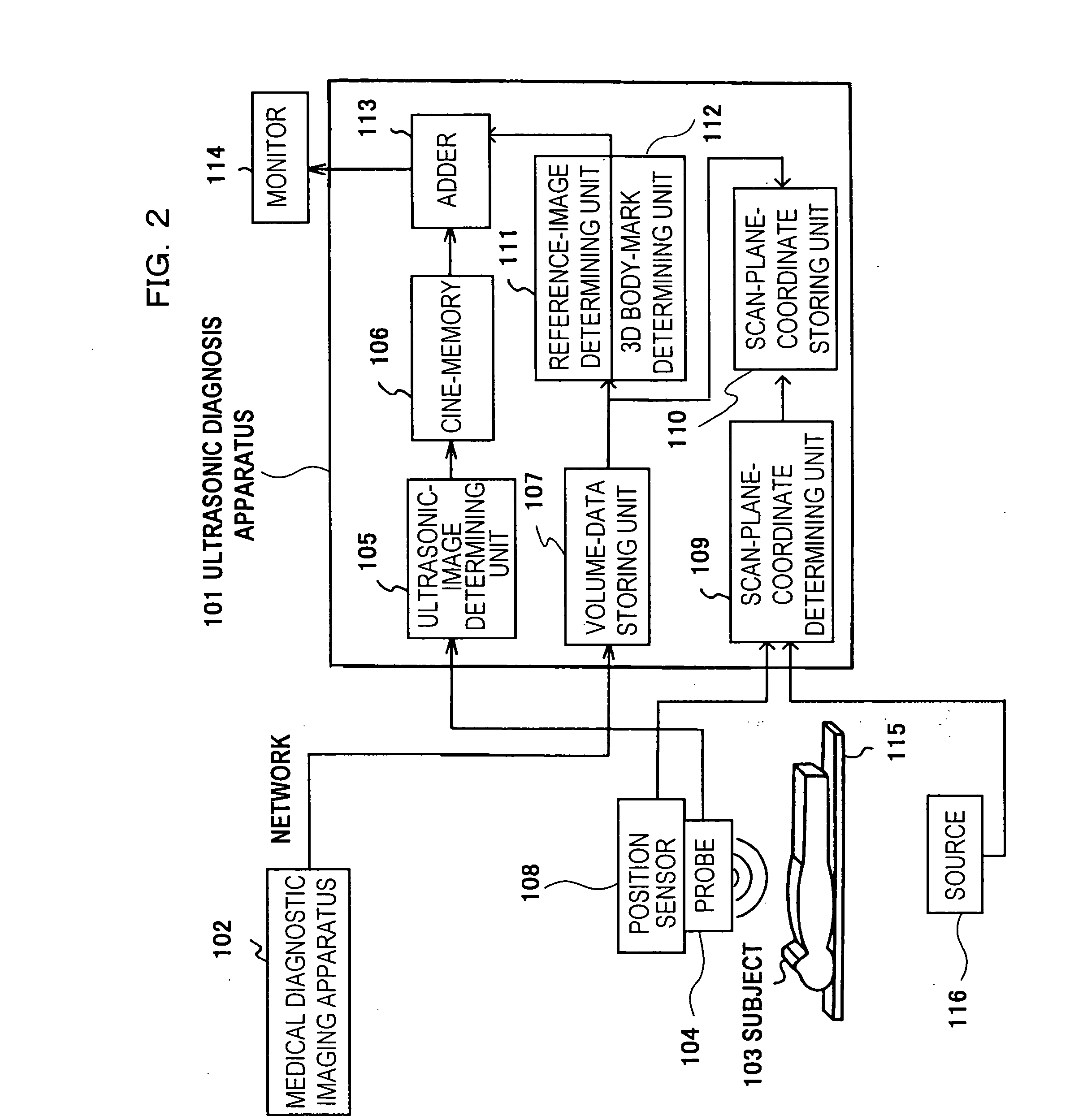

Reference image display method for ultrasonography and ultrasonograph

ActiveUS20070010743A1Increased freedom of settingImprove comparison accuracyUltrasonic/sonic/infrasonic diagnosticsImage enhancementReference imageTomographic image

An ultrasonic image 105, 106 is captured by an ultrasonic probe 104. A reference image 111 is obtained by extracting a tomographic image corresponding to the scan plane of the ultrasonic image from volume image data that is pre-obtained by a diagnostic imaging apparatus 102 and that is stored in a volume-data storing unit 107. The ultrasonic image and the reference image 111 are displayed on the same screen 114. In this case, of the reference image, a portion corresponding to the view area of the ultrasonic image is extracted and the resulting reference image having the same region as the ultrasonic image is displayed as a fan-shaped image.

Owner:FUJIFILM HEALTHCARE CORP

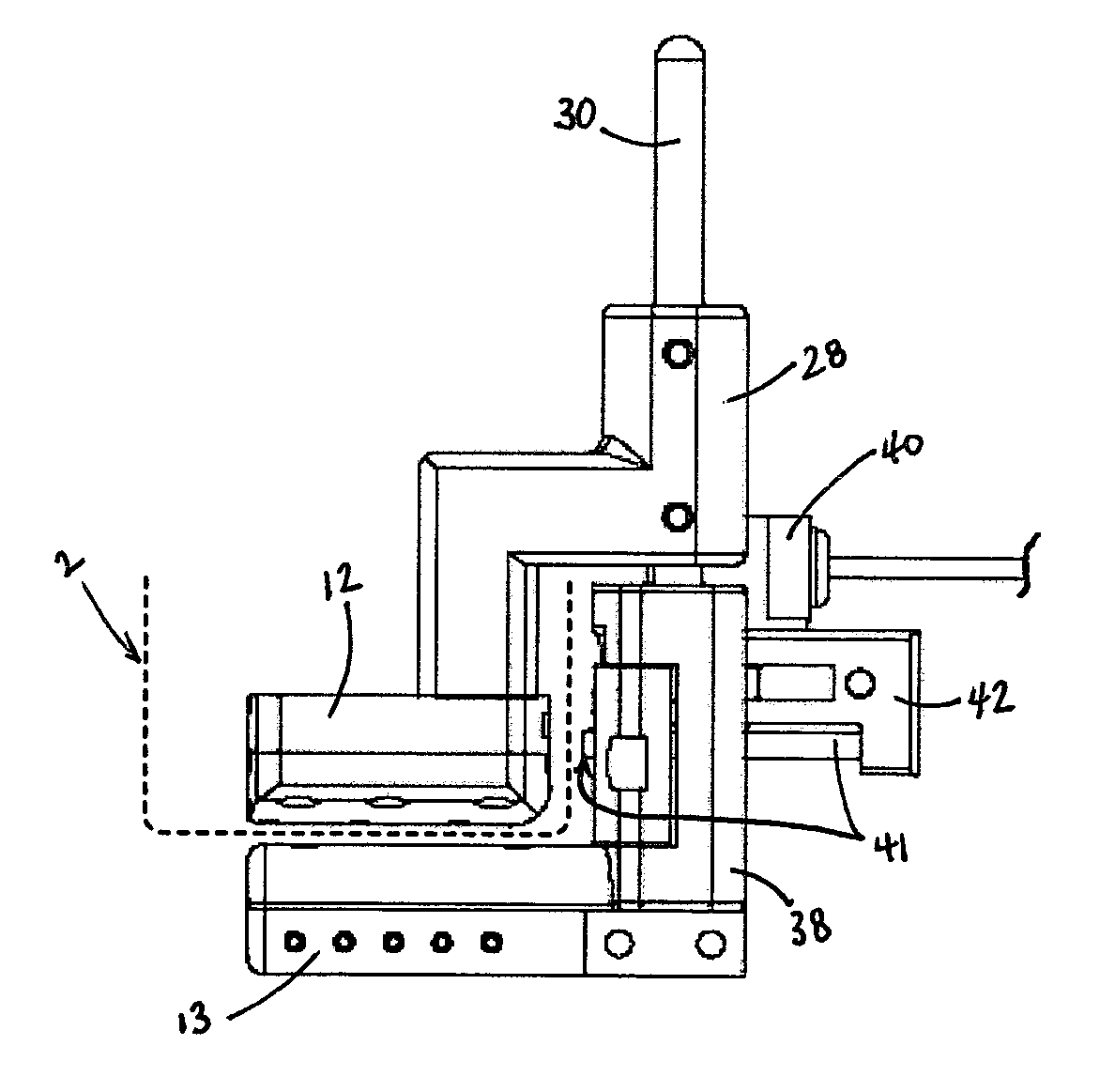

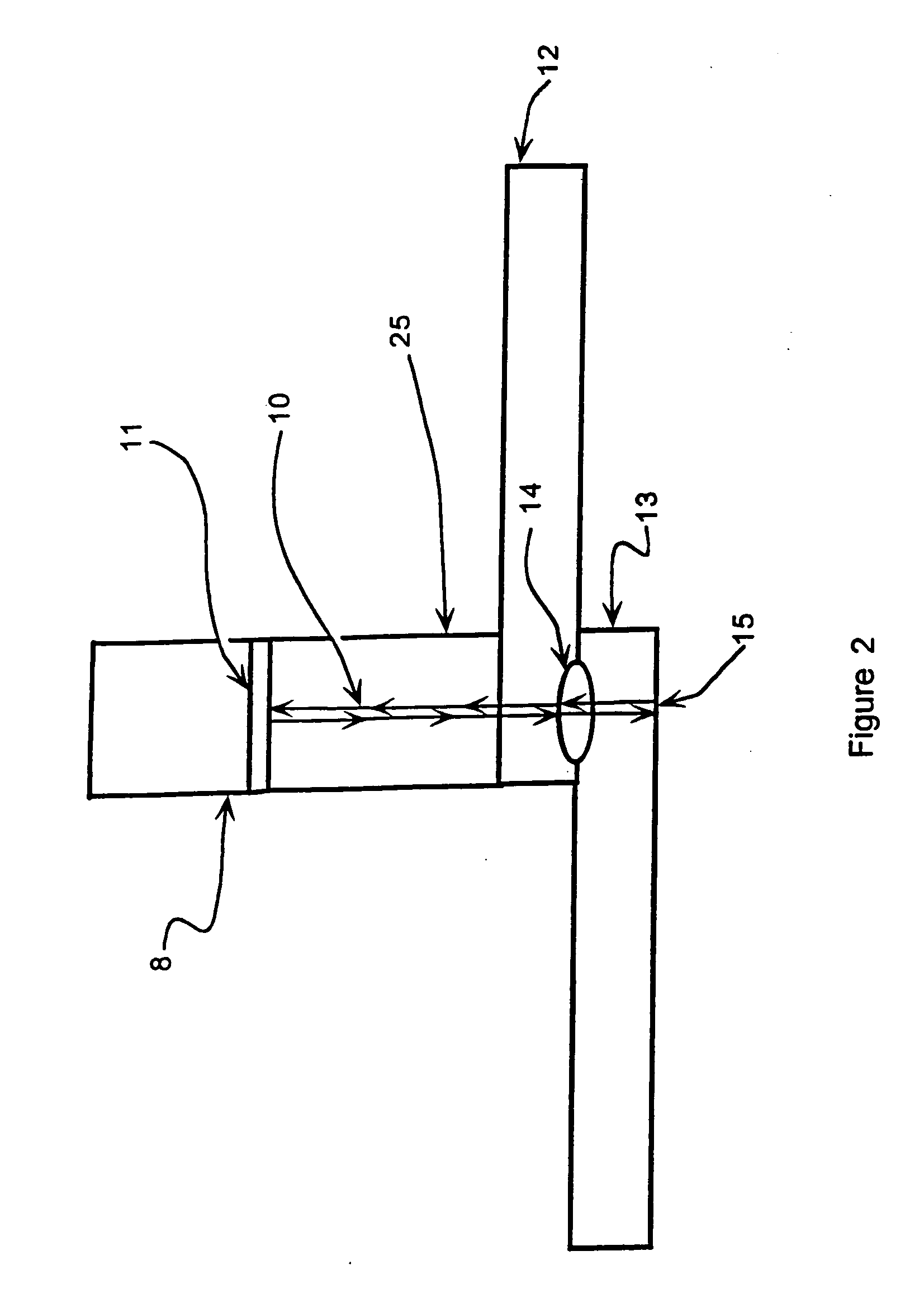

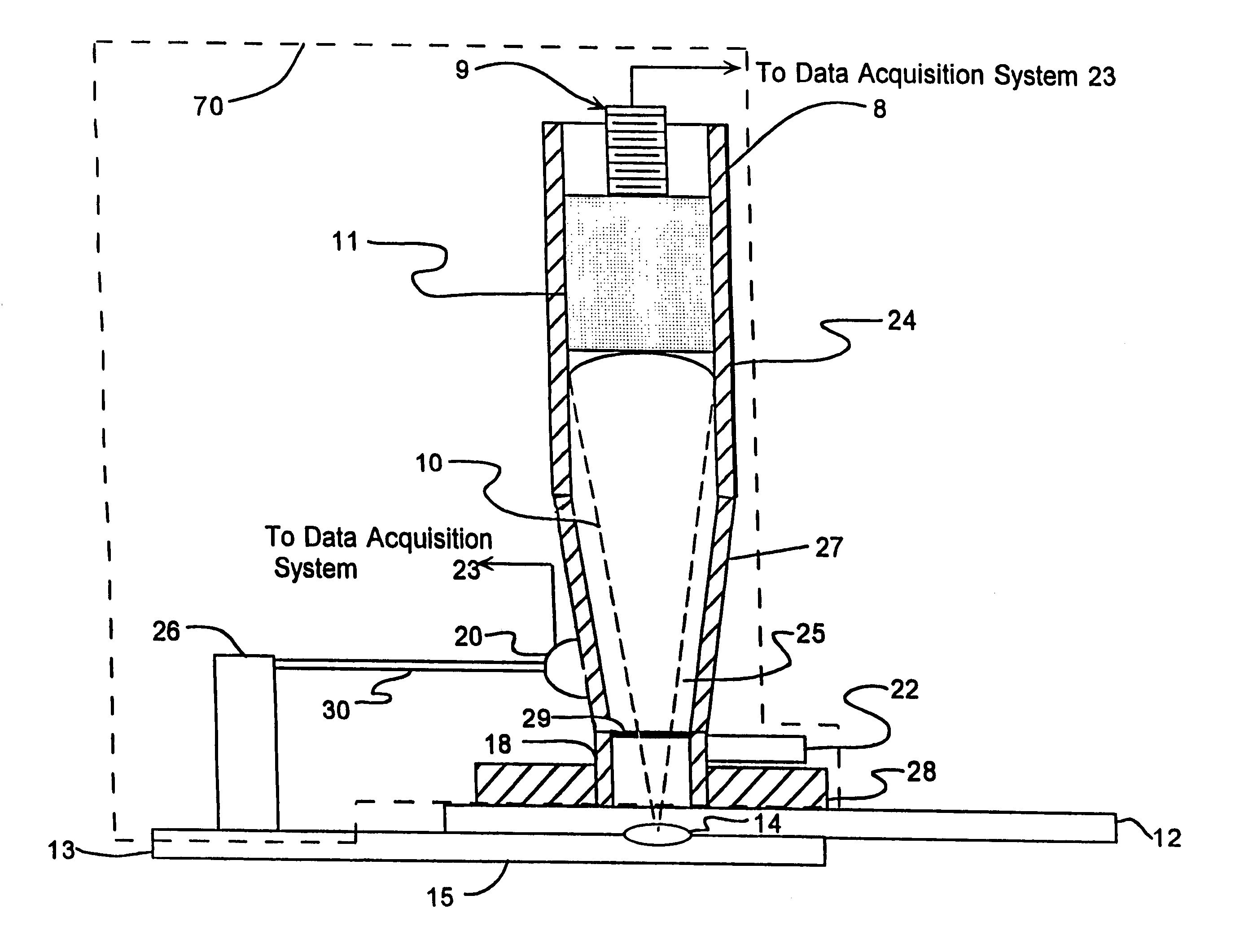

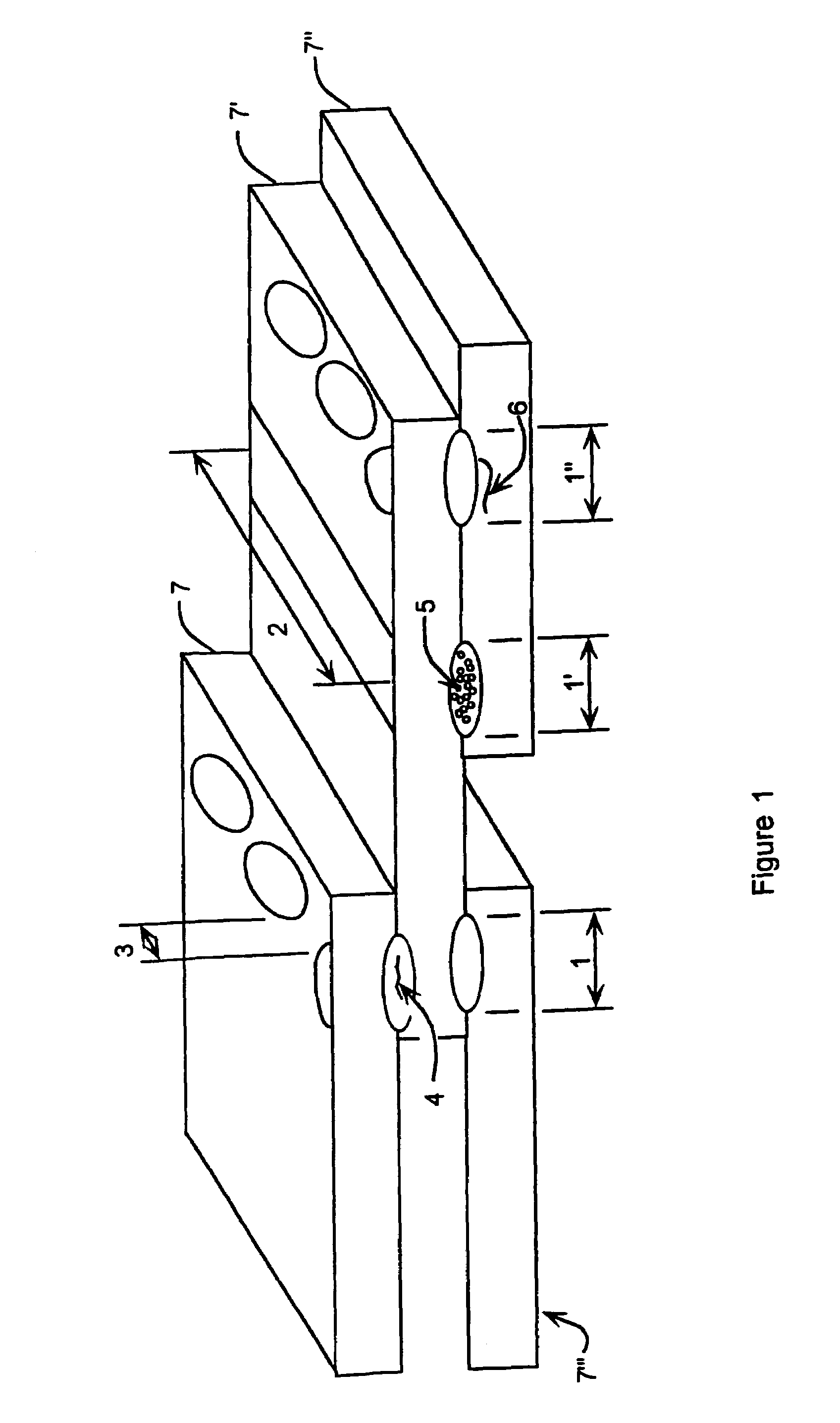

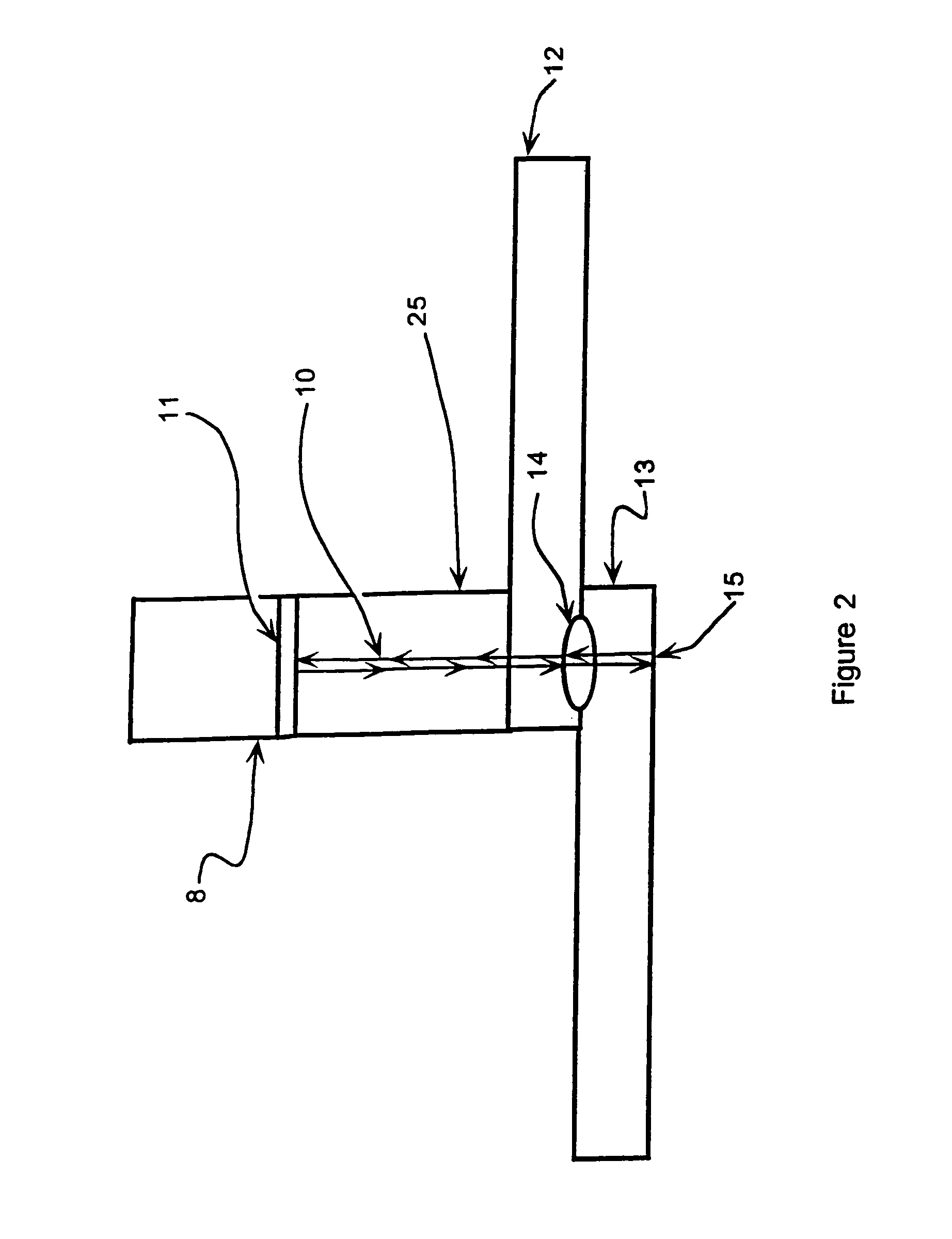

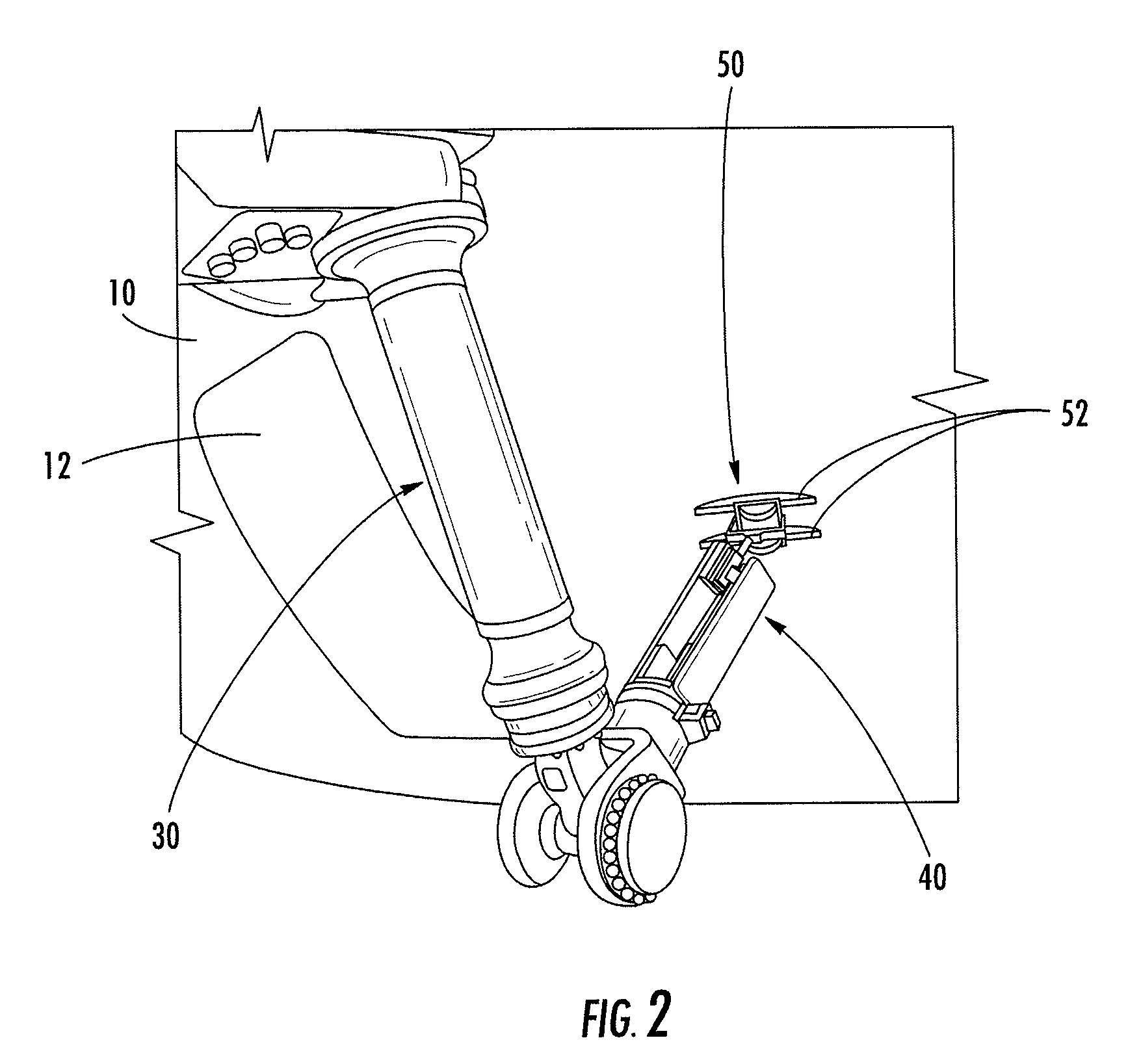

Method of and an apparatus for detecting, identifying and recording the location of defects in a railway rail

InactiveUS6055862AAccurate and repeatable flaw detectionAccurate detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationTransducerEngineering

Method and apparatus for ultrasonic inspection of an object. A tire is mounted for rolling along the surface of the object. It contains a liquid and a transducer assembly. The transducer assembly is positioned in the tire adjacent a portion of the surface of the tire in contact with the object. The liquid and the surface of the tire in contact with the object provide an acoustic bridge between the transducer assembly and the object. An electric signal processing system is connected to the transducer assembly. It generates electric signals which are converted to acoustic signals in the transducer assembly to place acoustic signals in the object. Acoustic signals returned from the object are converted to electric signals by the transducer assembly, and are processed in the electric signal processing system to indicate flaws in the object.

Owner:HERZOG SERVICES

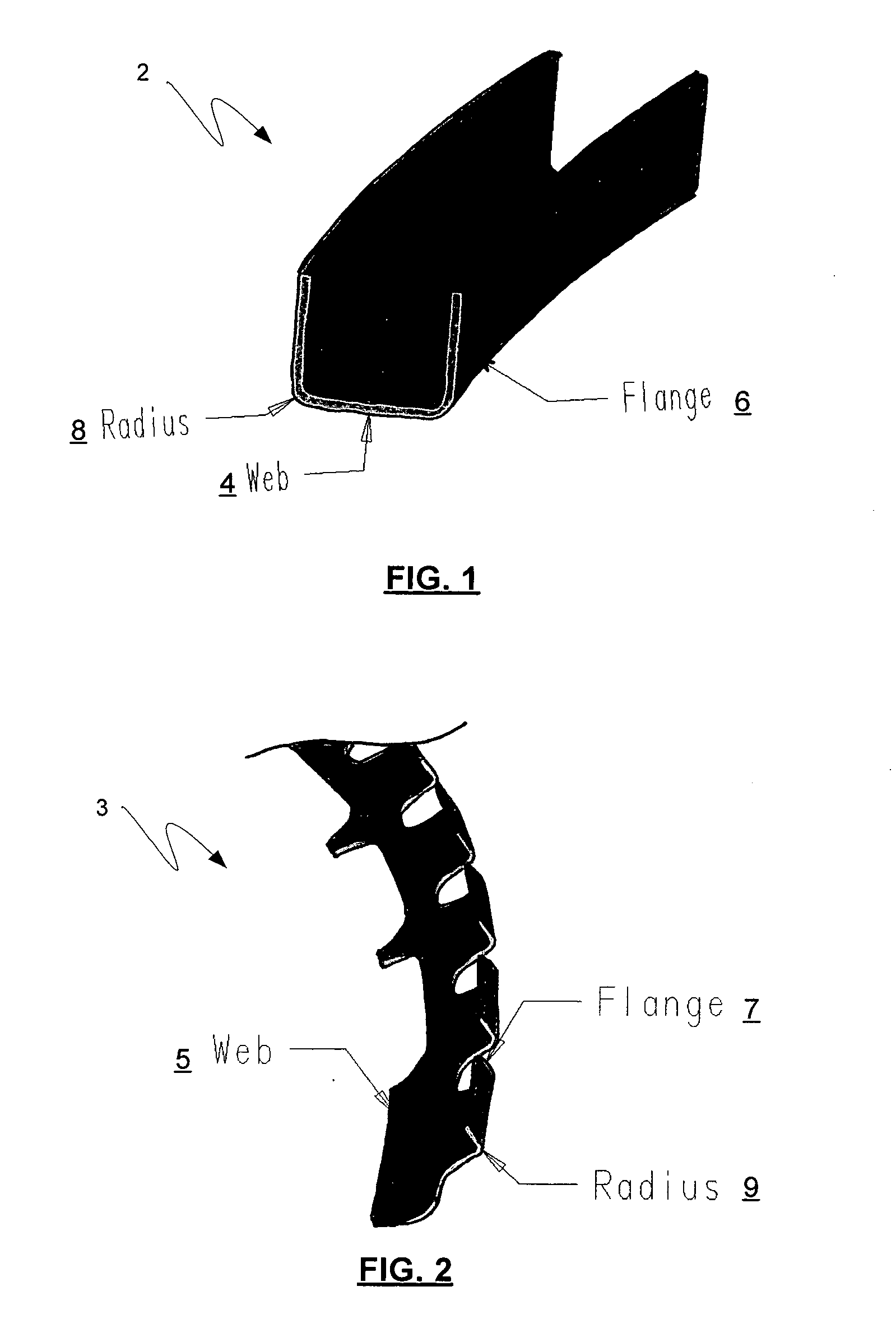

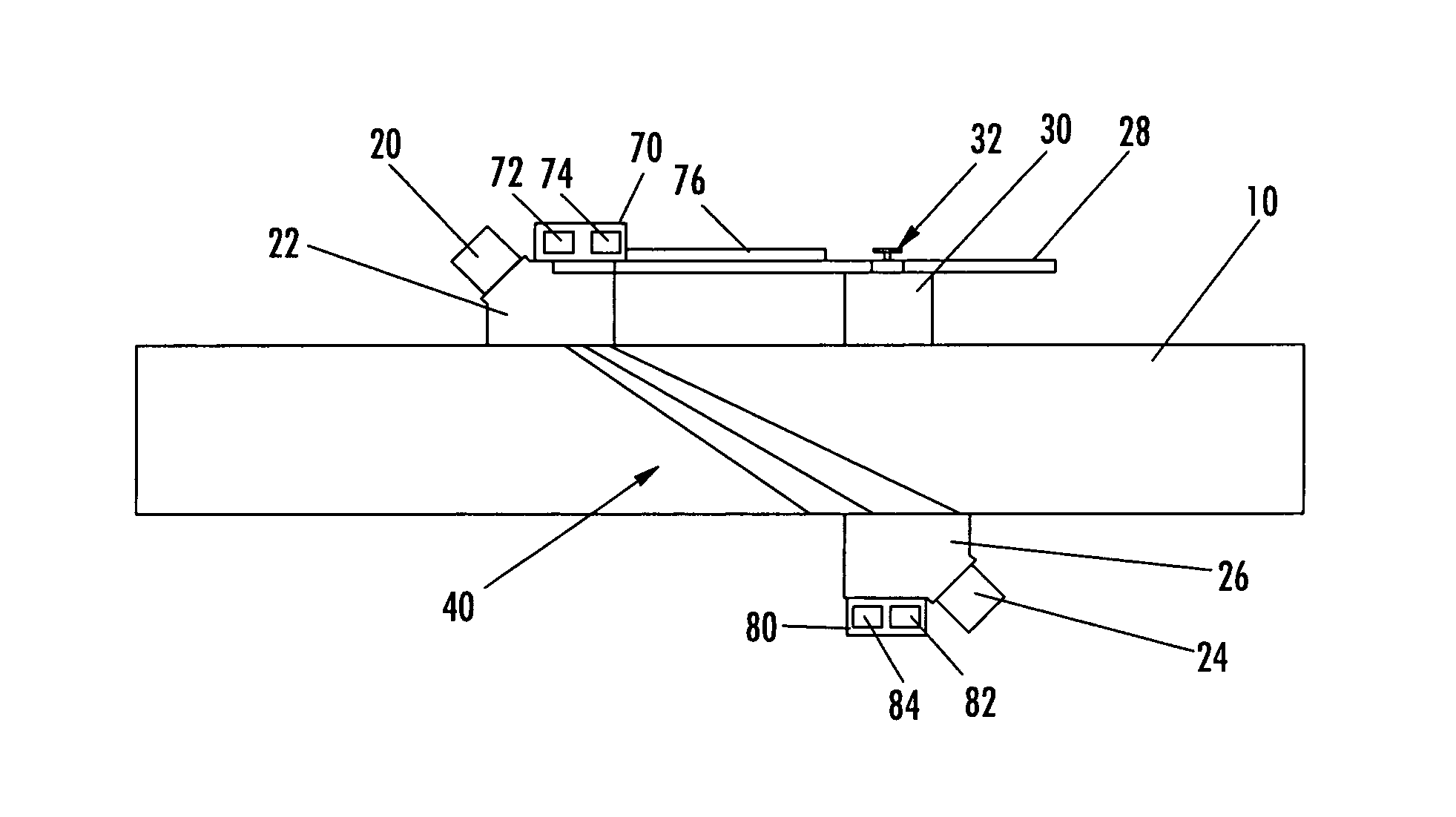

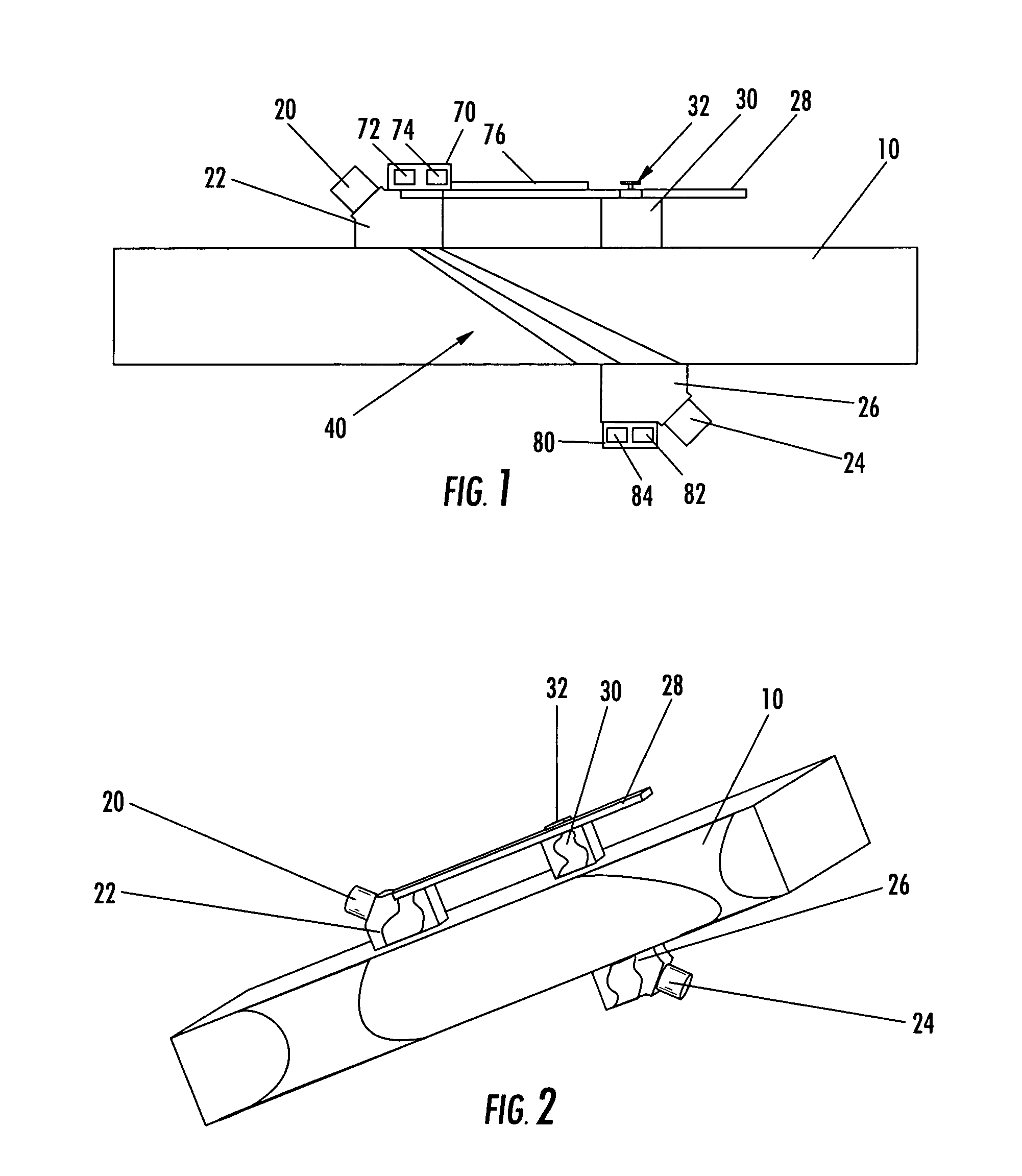

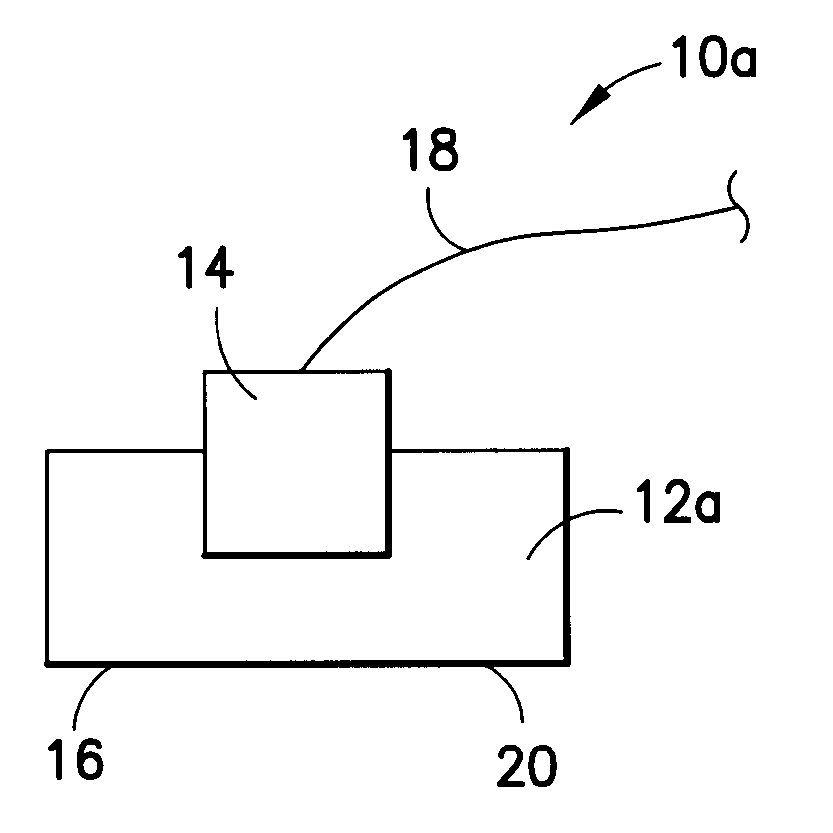

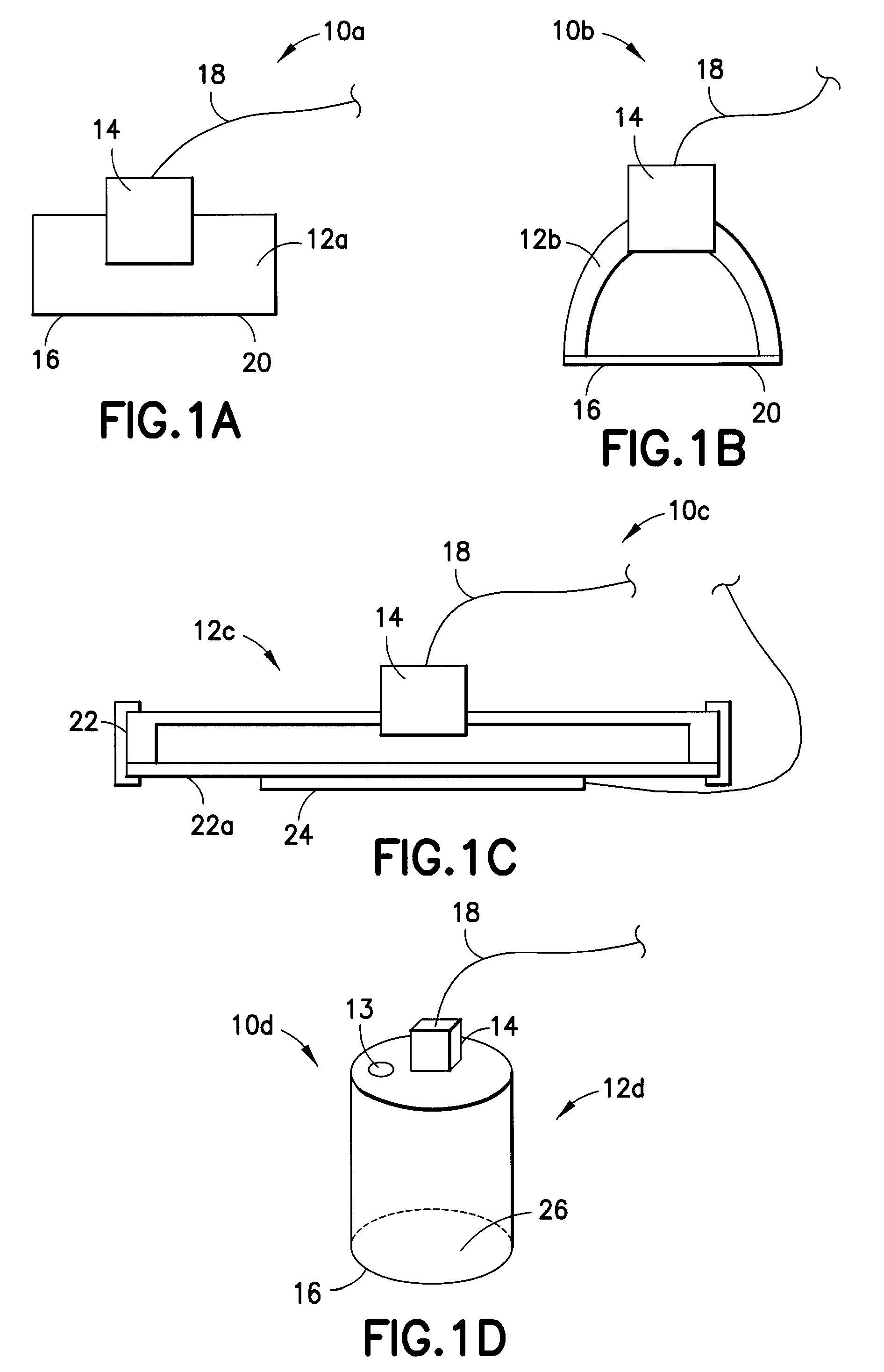

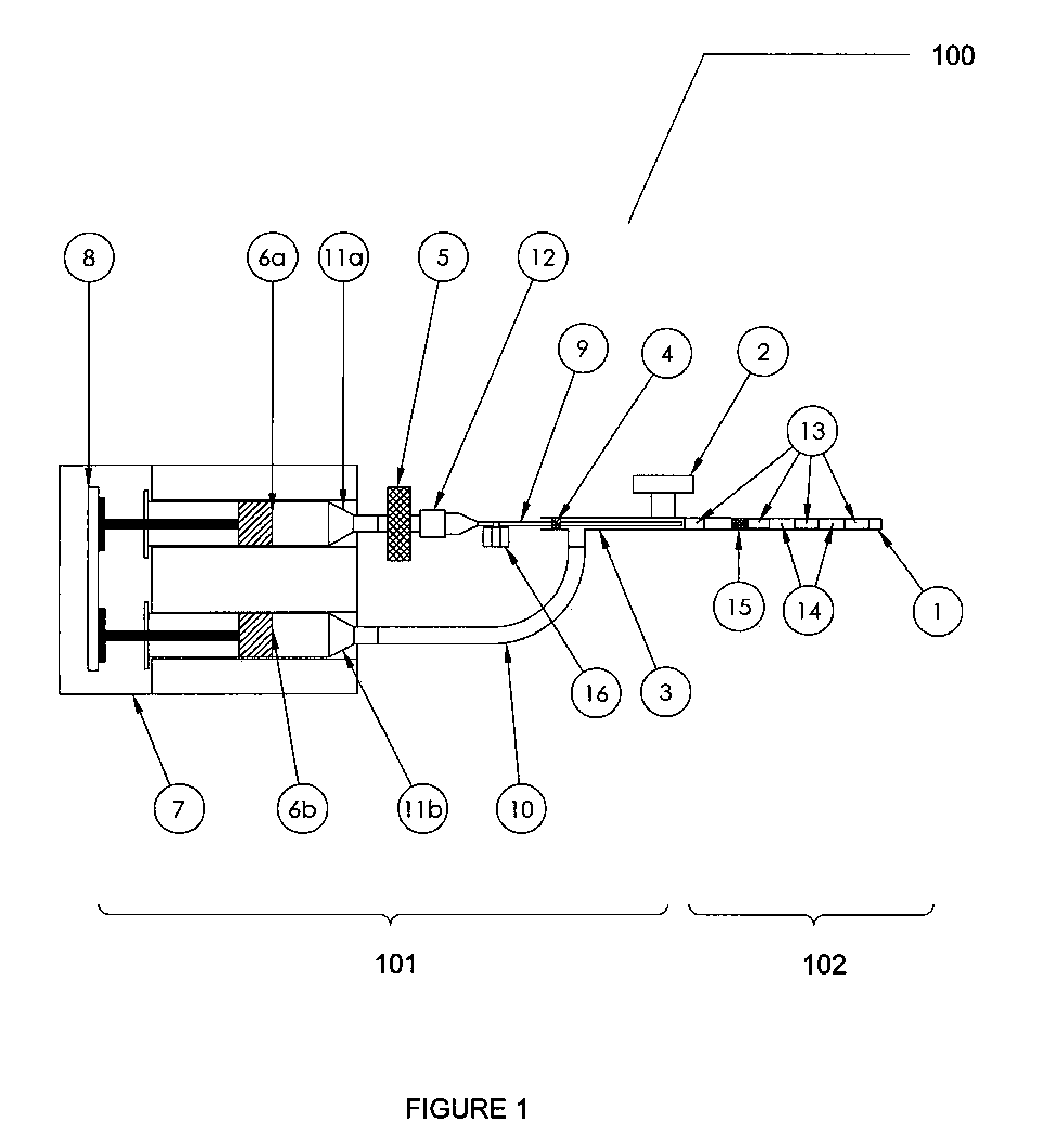

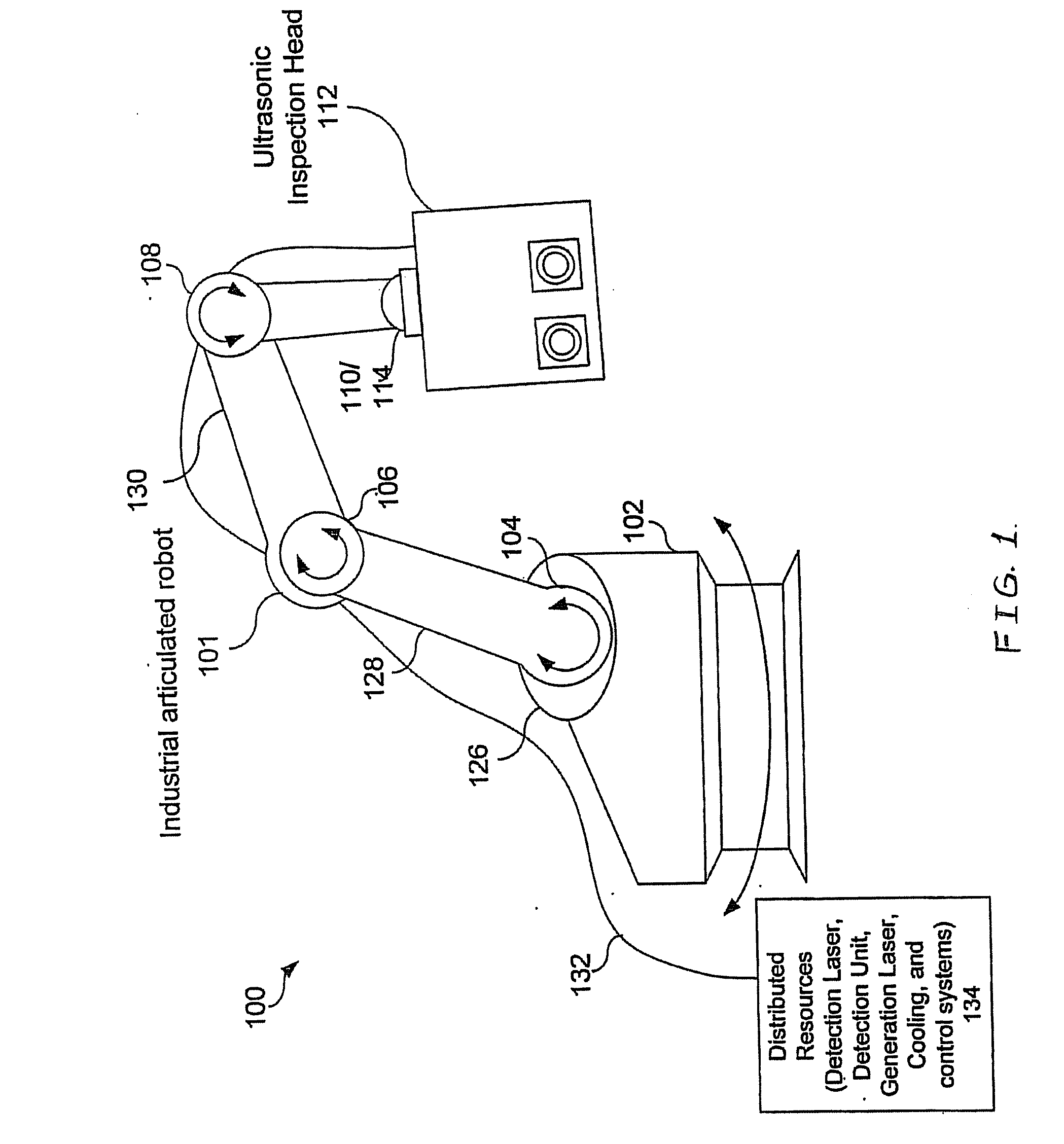

Integrated ultrasonic inspection probes, systems, and methods for inspection of composite assemblies

InactiveUS20060243051A1Fast wayEasy to checkAdditive manufacturing apparatusAnalysing solids using sonic/ultrasonic/infrasonic wavesSupporting systemEngineering

Apparatus, systems, and methods for inspecting a structure are provided which permit inspection of uniquely shaped structures such as fuselage frames and shear ties. Probes may be constructed from rapid prototyping. Inspection may be performed manually and may use a portable function support system for delivering fluid couplant, controlling transmit and receive functions of the inspection sensors, and delivering immediate visual analysis for an operator. Integrated ultrasonic inspection apparatus, systems, and methods facilitate fast and efficient custom inspection devices and inspecting otherwise difficult-to-inspect structures.

Owner:THE BOEING CO

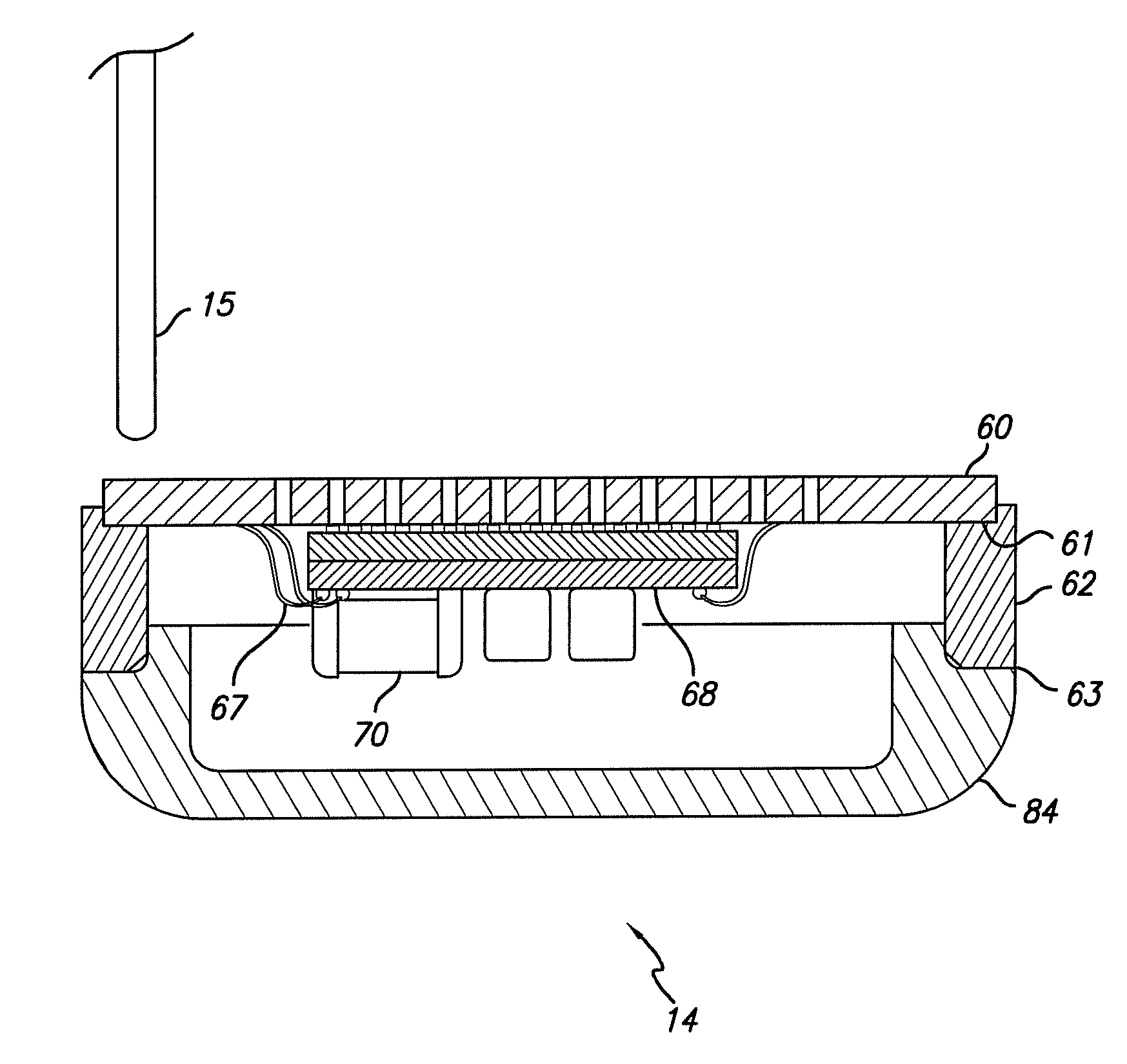

Method of inspection of materials for defects

ActiveUS8131376B1Material analysis using sonic/ultrasonic/infrasonic wavesHead electrodesNon destructiveVisual prosthesis

The present invention is a non-destructive method of inspecting a bond, particularly a braze bond, in a hermetic package. The invention involves a unique hermetic package design adapted for ultrasonic inspection and a method of inspecting the package. This package and non-destructive inspection process are particularly useful in implantable neural stimulators such as visual prostheses.

Owner:CORTIGENT INC

Method of ultrasonically inspecting turbine blade attachments

InactiveUS6082198AEasy to detectIncrease in sizeAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsTurbine bladeStraddle

A method of simultaneously reconstructing and testing a straddle-mount turbine blade hub with the turbine blades in place. The method employs a sector scan ultrasonic phased array mounted on one face of the hub to inspect the opposite face.

Owner:ELECTRIC POWER RES INST INC

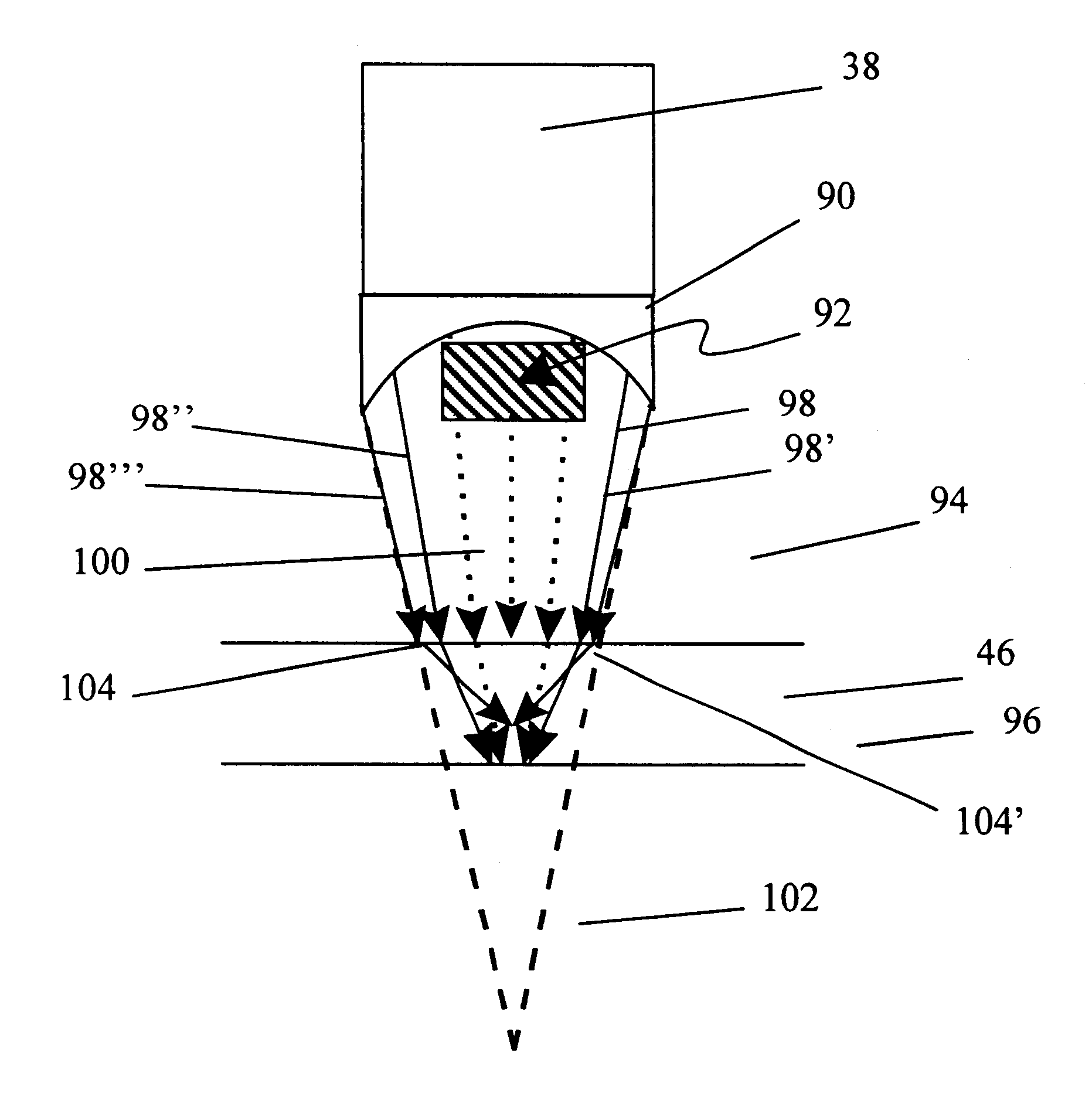

Ultrasonic inspection apparatus and method using a focused wave device

InactiveUS6234025B1Improving conventional ultrasonic inspectionIncrease total distance traveledAnalysing solids using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceSonificationSignal on

An ultrasonic pulse echo inspection apparatus and method for detecting structural failures. A focus lens is coupled to the transducer to focus the ultrasonic signal on an area to be inspected and a stop is placed in the focus lens to block selected ultrasonic waves. Other waves are not blocked and are transmitted through the structure to arrive at interfaces therein concurrently to produce an echo response with significantly less distortion.

Owner:SANDIA NAT LAB

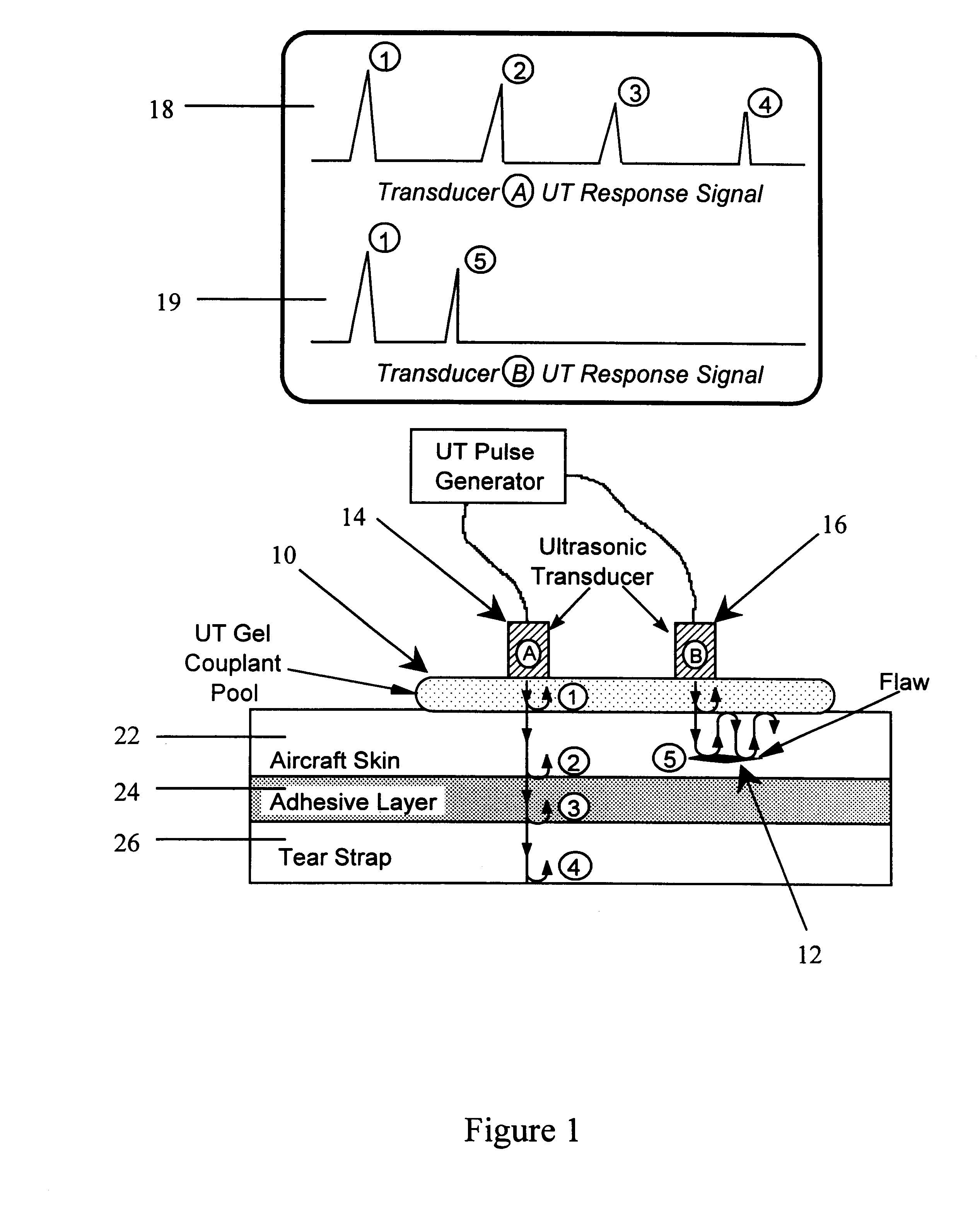

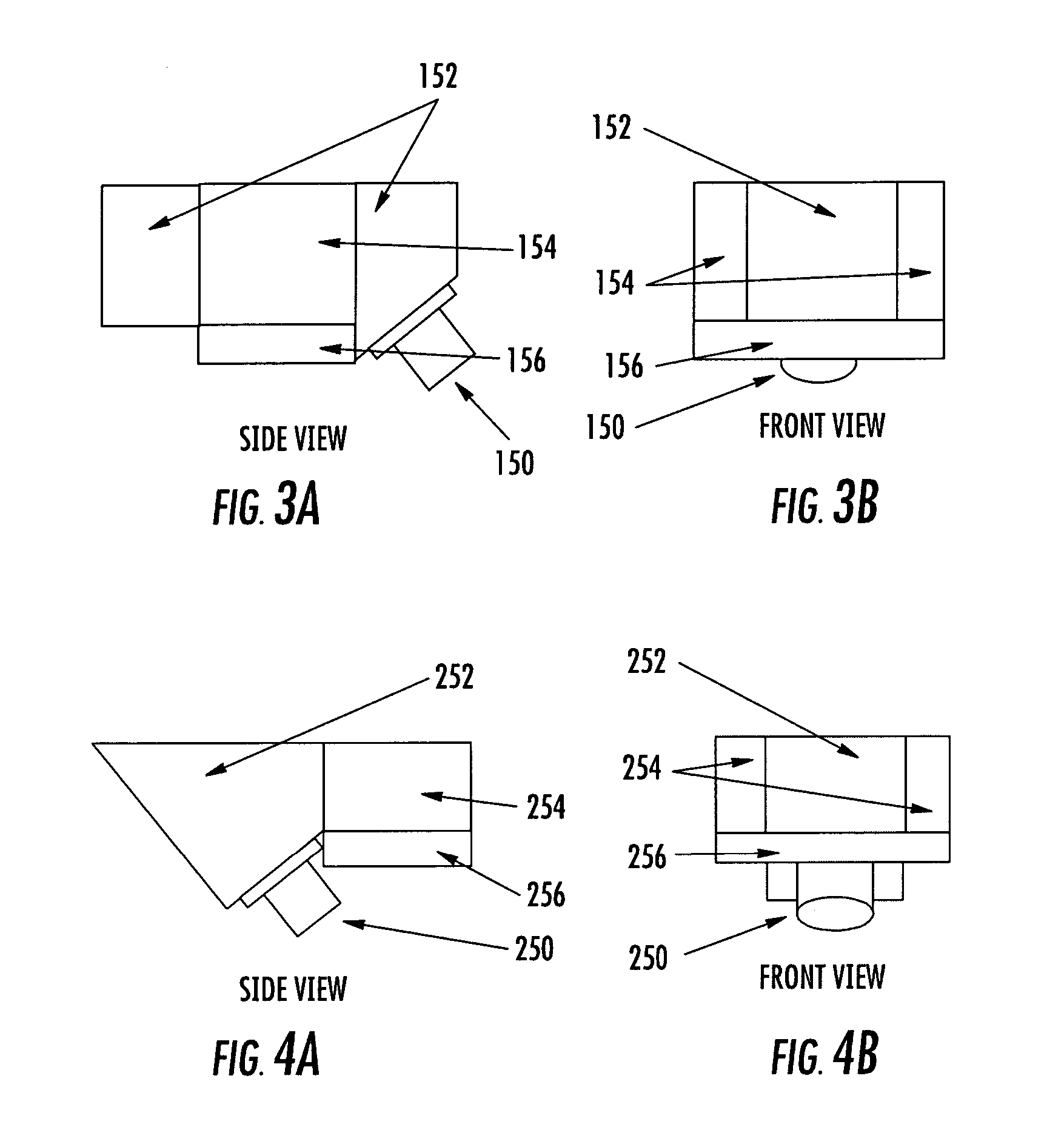

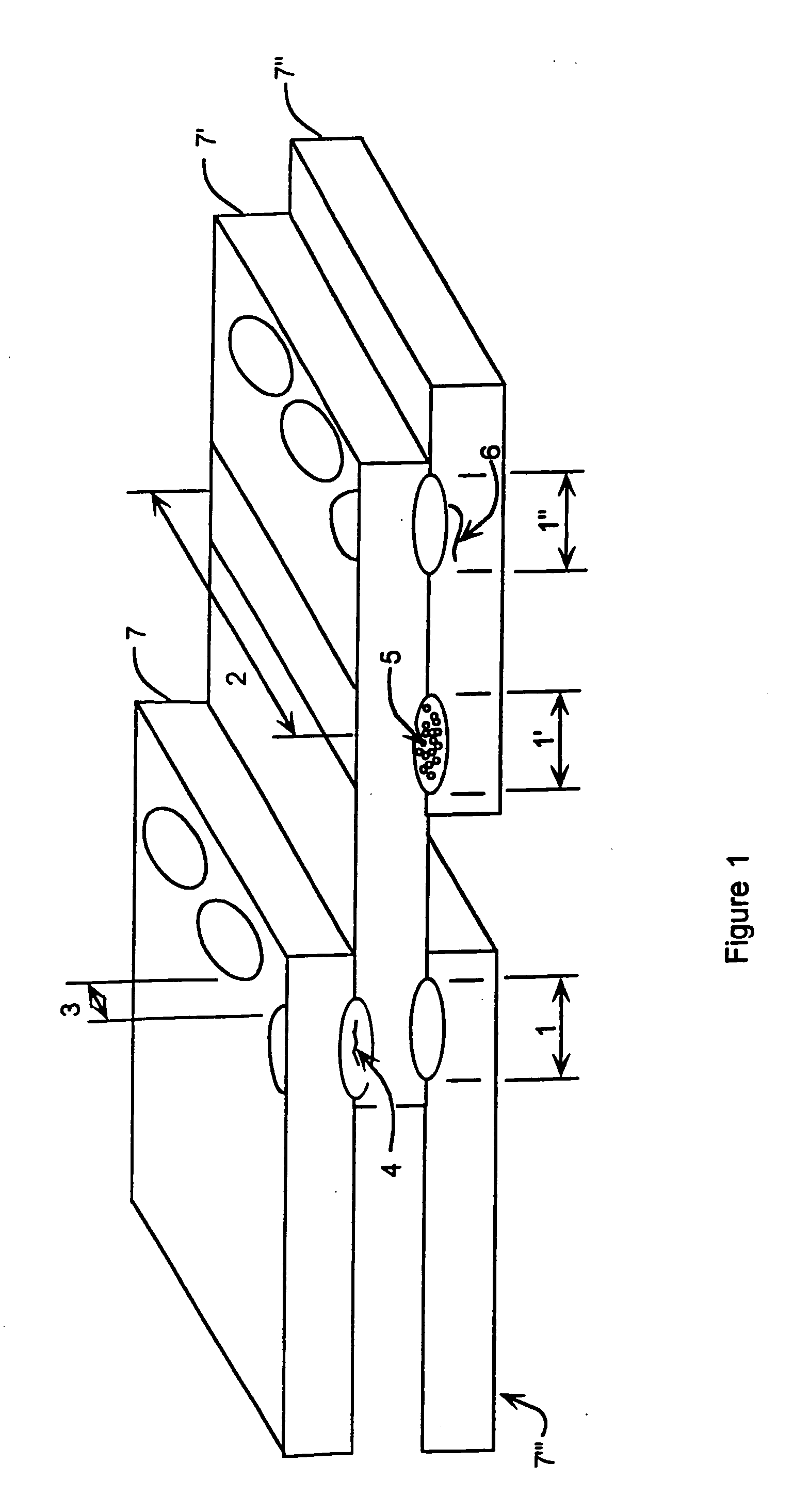

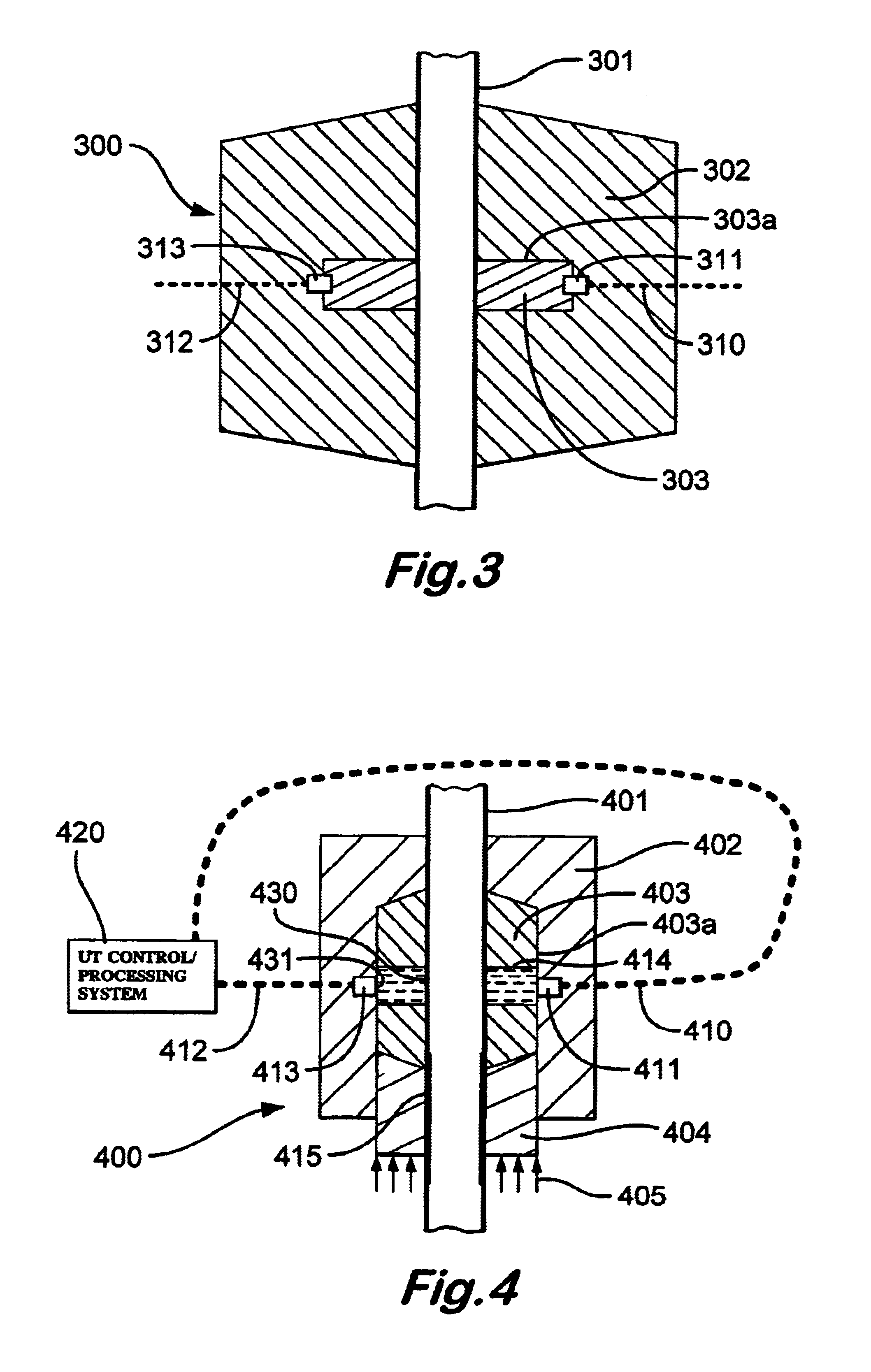

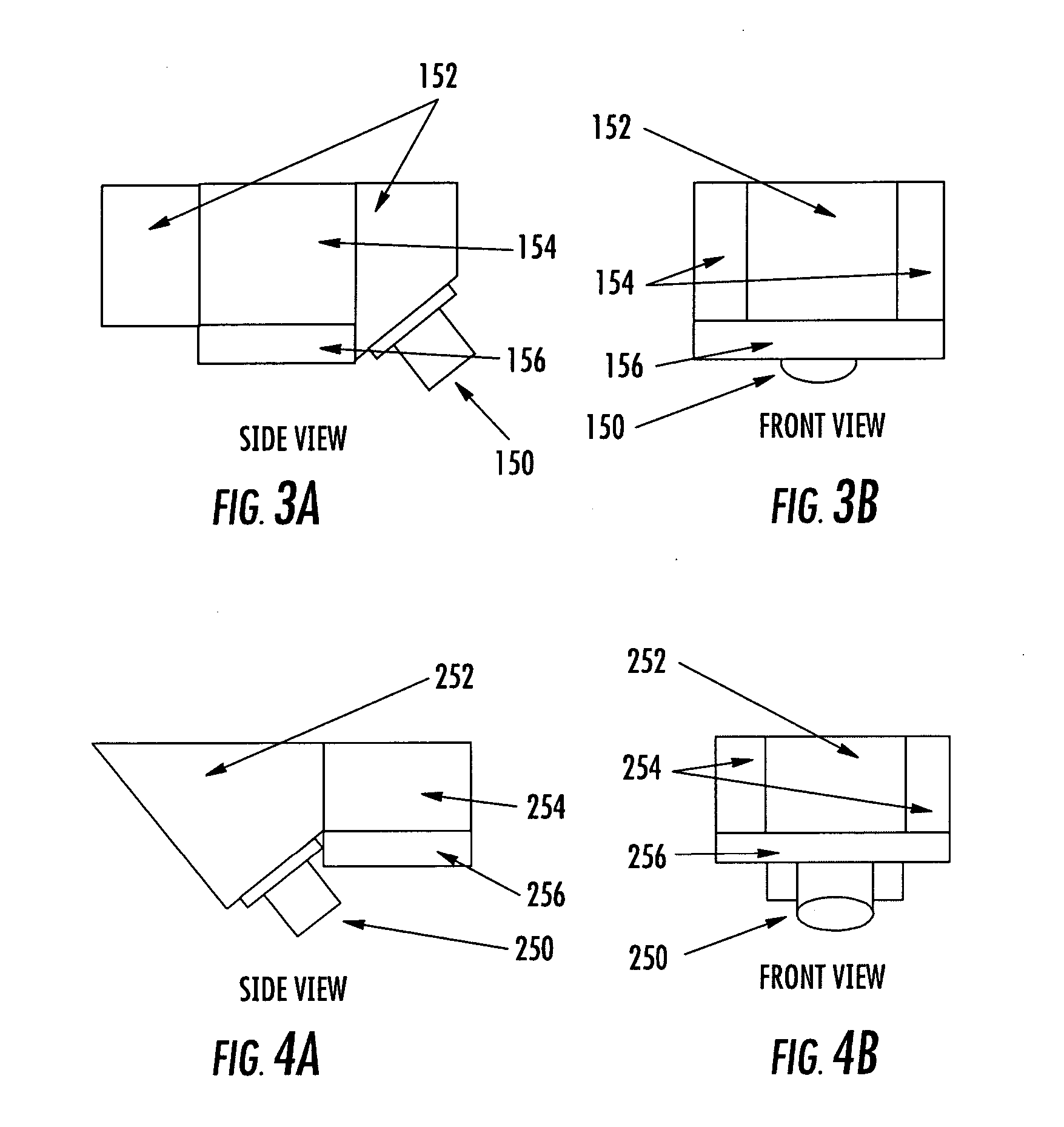

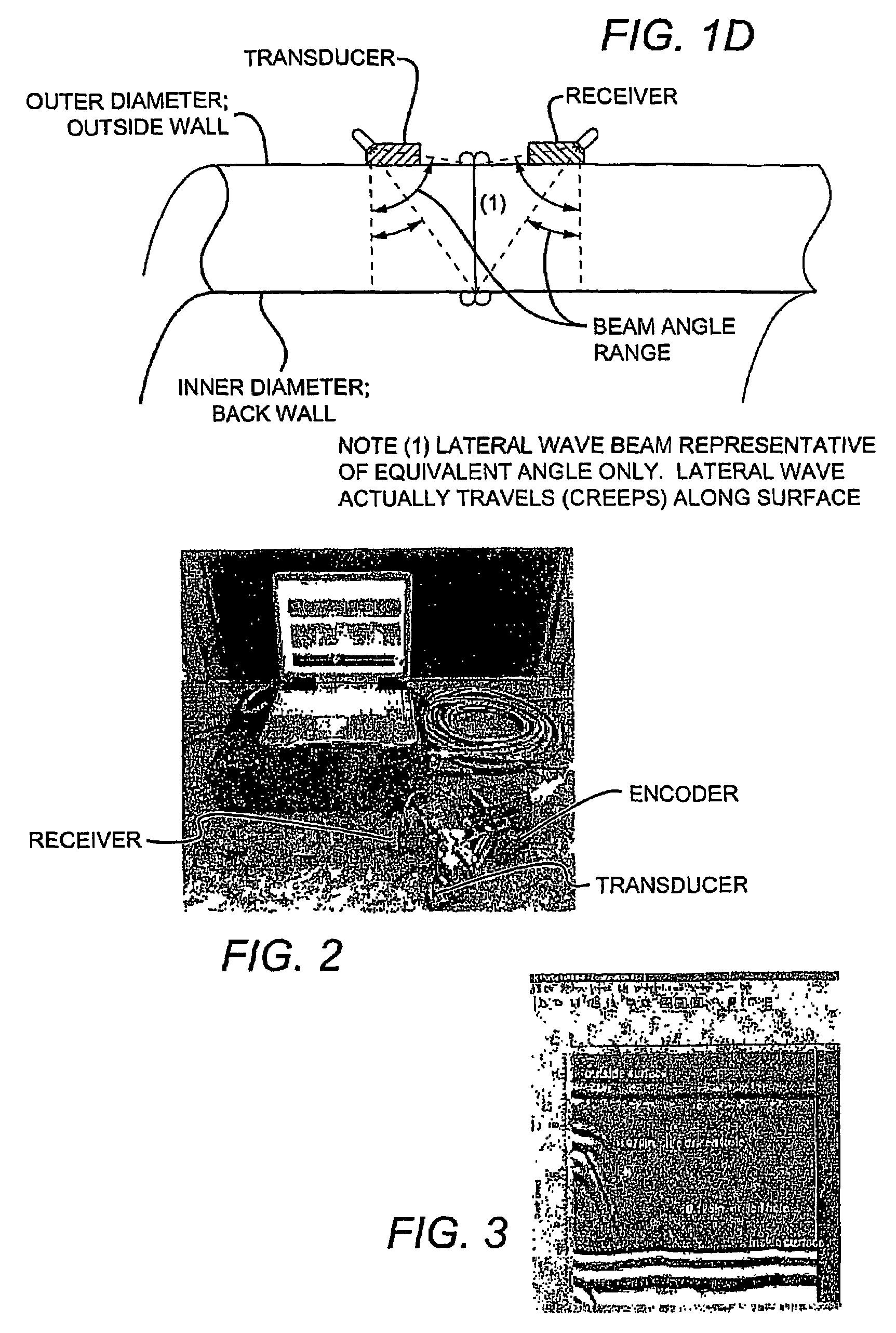

Angle beam shear wave through-transmission ultrasonic testing apparatus and method

InactiveUS7240556B2High resolutionPrevent and limit to regionAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationImage representation

Improved methods, systems, and apparatus for inspecting a structure using angle beam shear wave through-transmission ultrasonic signals involves positioning transducers at offset positions on opposing sides of the structure and permits inspection of the inside of the structure beneath surface defects and features. Magnetic coupling can be used for supporting a pair of leader-follower probes and defining offset positions between angle beam shear wave transducers carried by the probes. Inspection data can be collected for supporting real-time generation of three-dimensional image representations of the structure and of internal defects and features of the structure. Image generation and resolution using inspection data from angle beam shear wave ultrasonic signals can be supplemented using pulse-echo ultrasonic inspection data.

Owner:THE BOEING CO

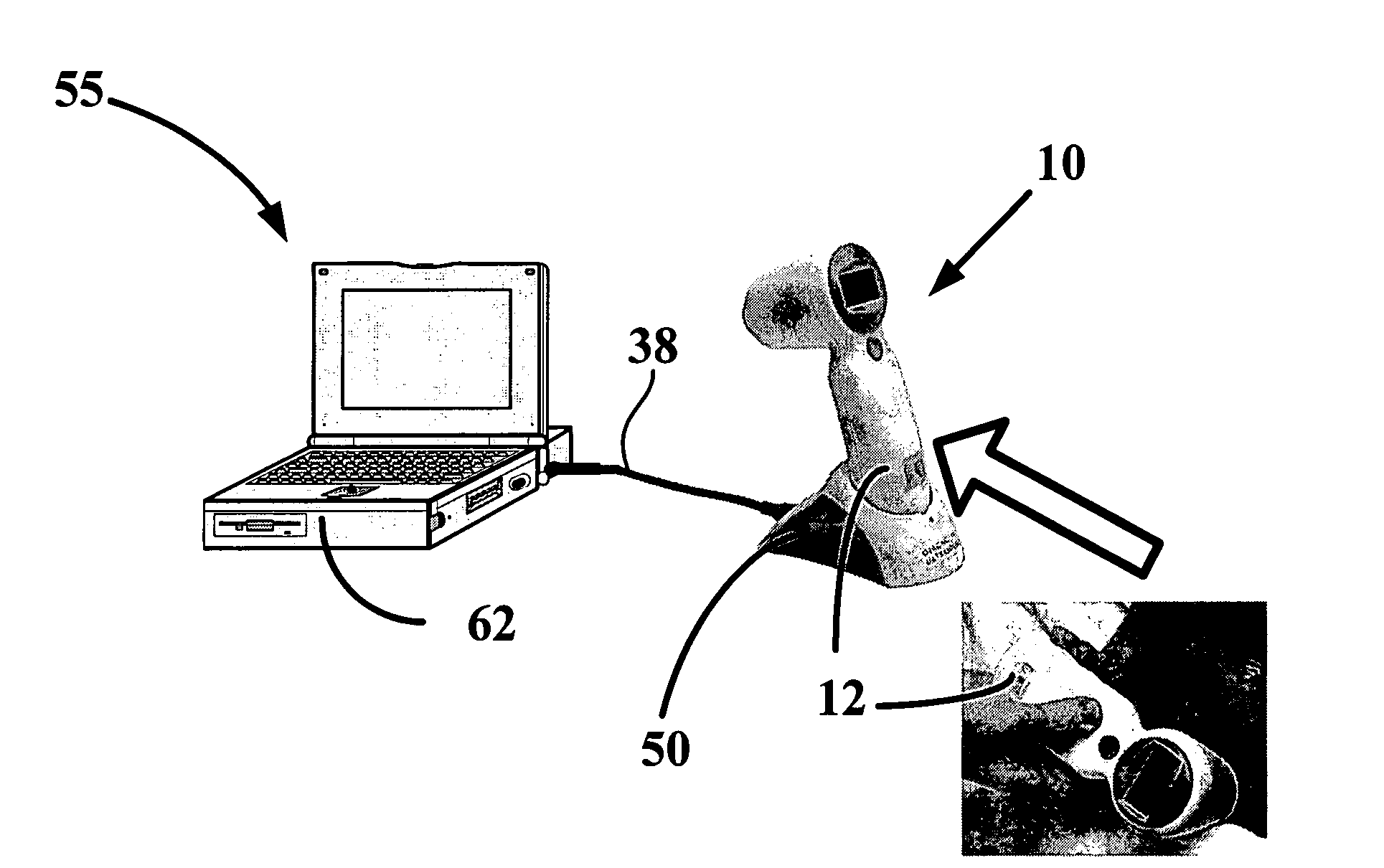

Electronic stethoscope system

InactiveUS20090316925A1Auxiliary diagnosisStethoscopeAcoustic sensorsAbnormal bowel soundsSonification

An electronic stethoscope head includes a head member having a contact surface for contact with a patient's body, a transducer in the head member, and an adhesive on the contact surface. A processing system for an electronic stethoscope includes a conditioning circuit configured to receive a transducer signal from a transducer and to be capable of amplifying and / or filtering the transducer signal, to yield a conditioned signal. There is also a signal processor system configured to subject the conditioned signal to an audio editing process. Bodily sounds are detected by applying an electronic stethoscope head a patient's body; generating a patient sonograph of the patient's bodily sounds; and comparing the patient sonograph to a reference sonograph. An electronic stethoscope system may include an accessory device and control circuitry to control the accessory device when abnormal bowel sounds are detected or no bowel sounds are detected for a predetermined interval.

Owner:EISENFELD LEONARD

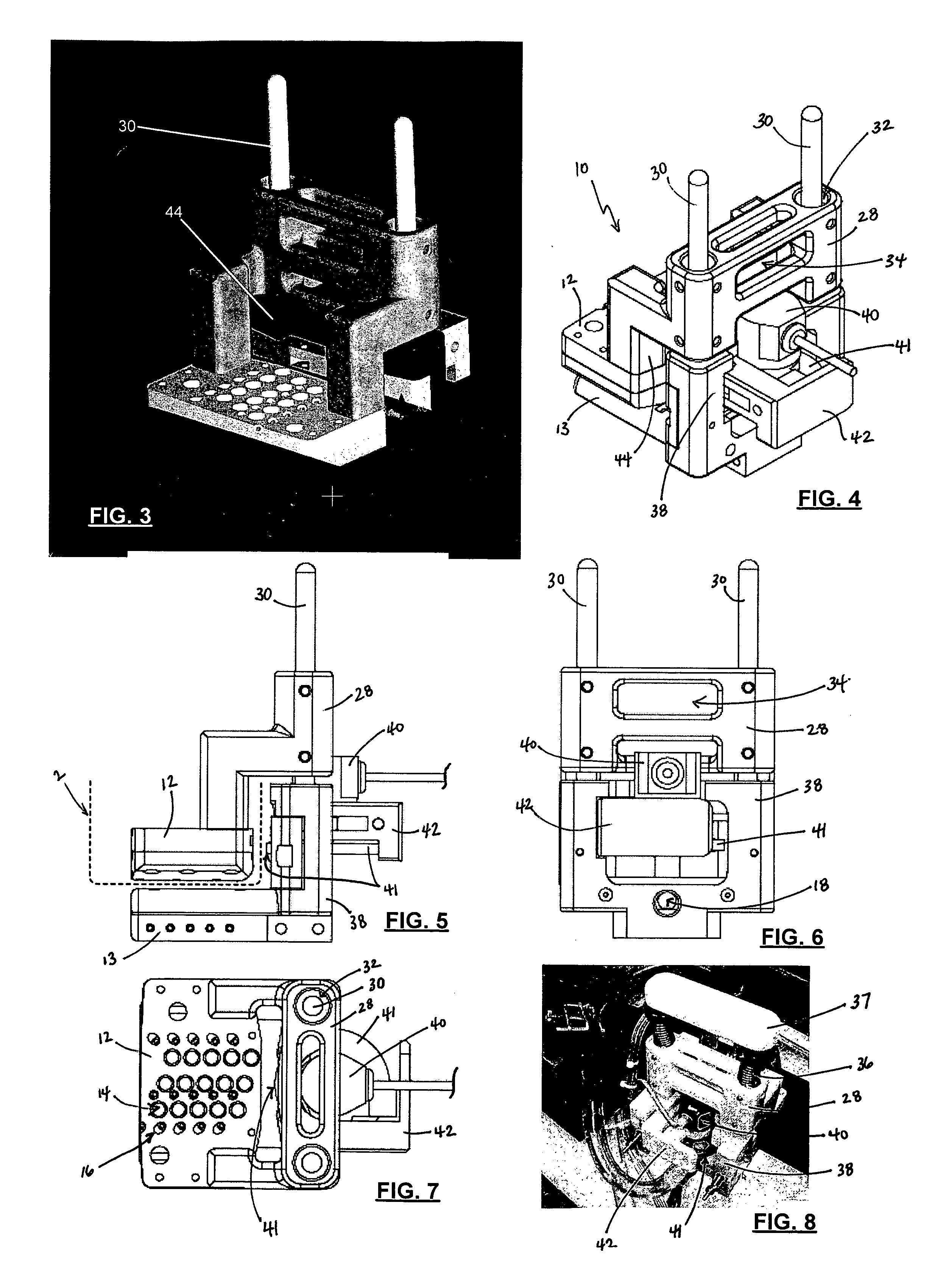

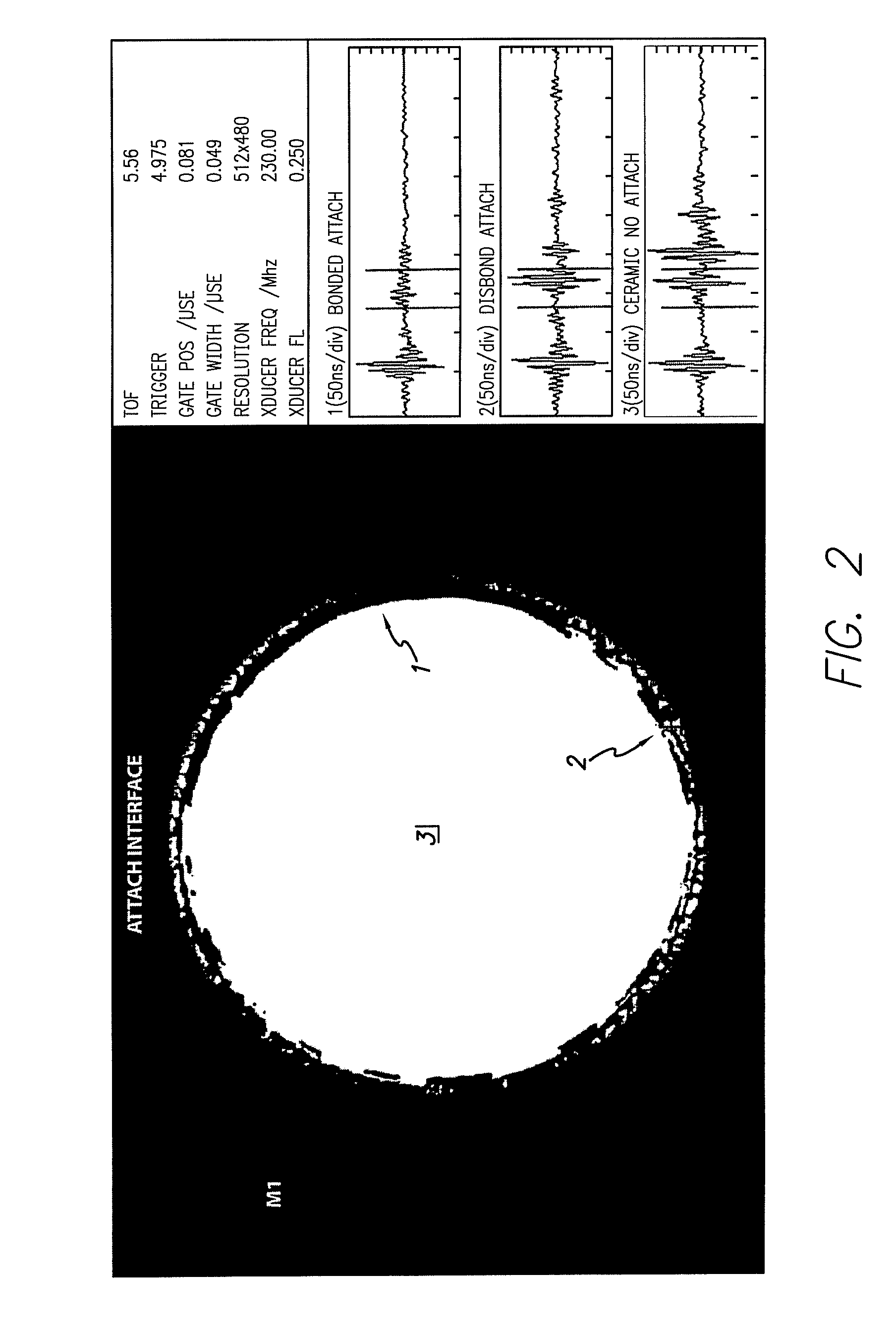

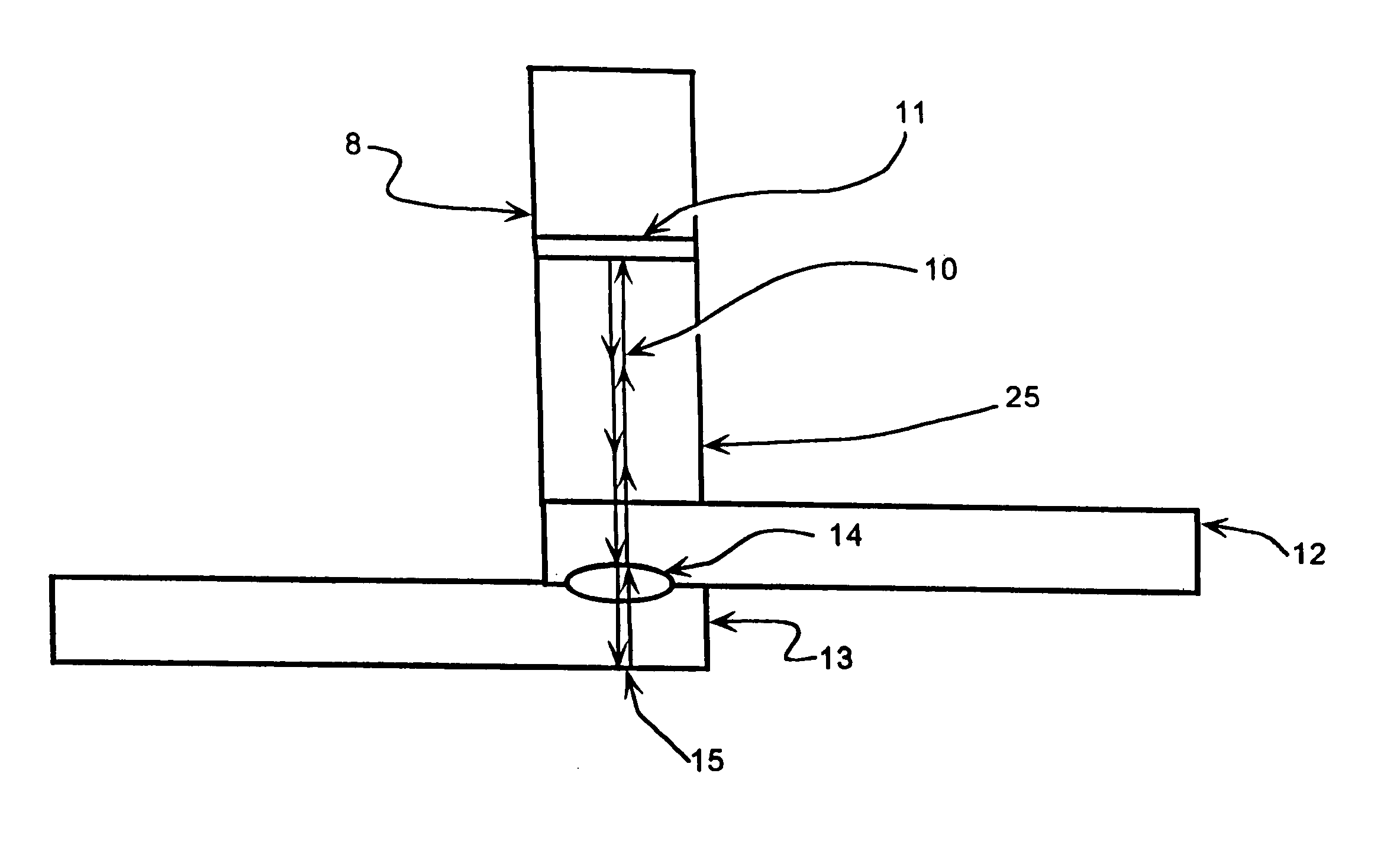

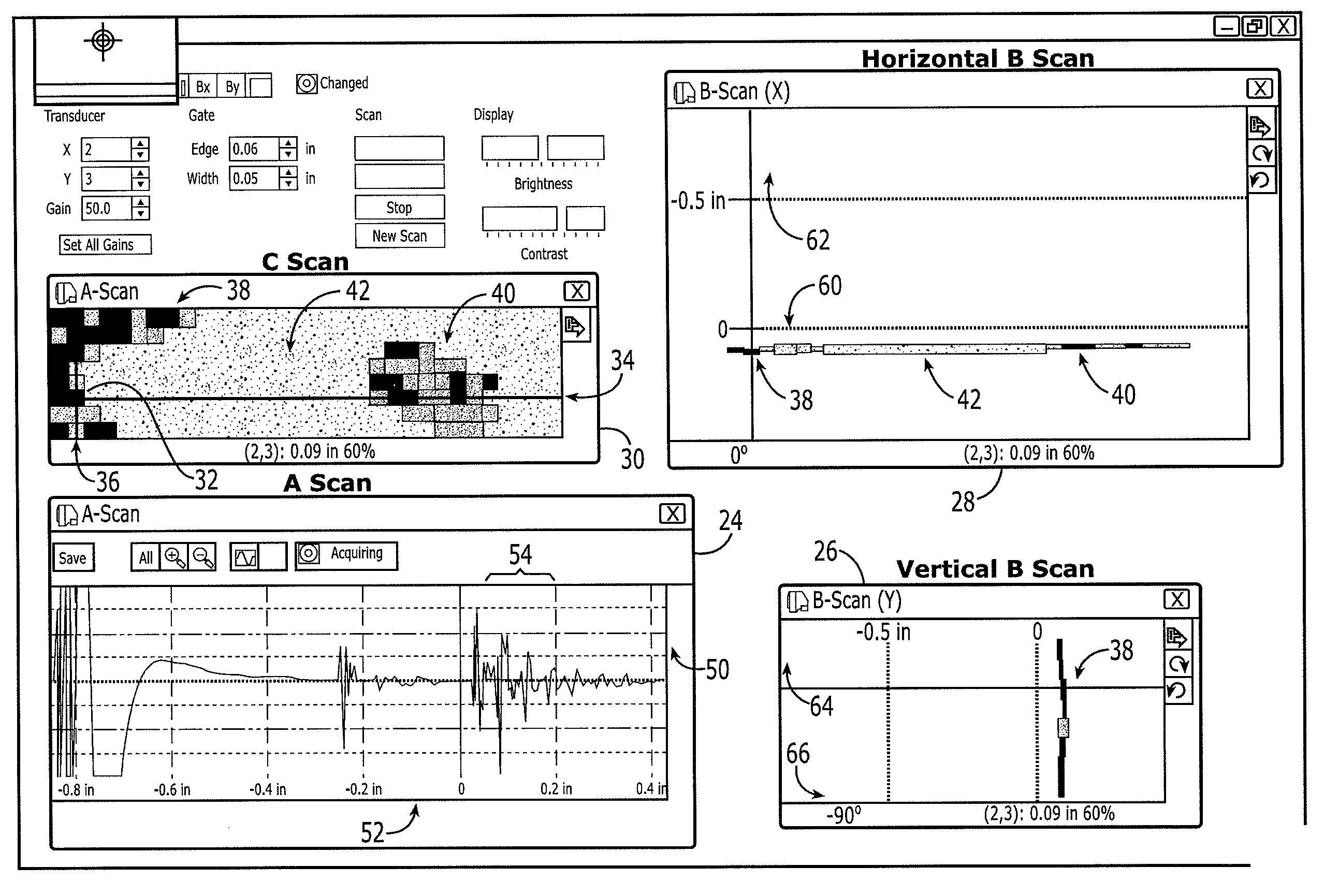

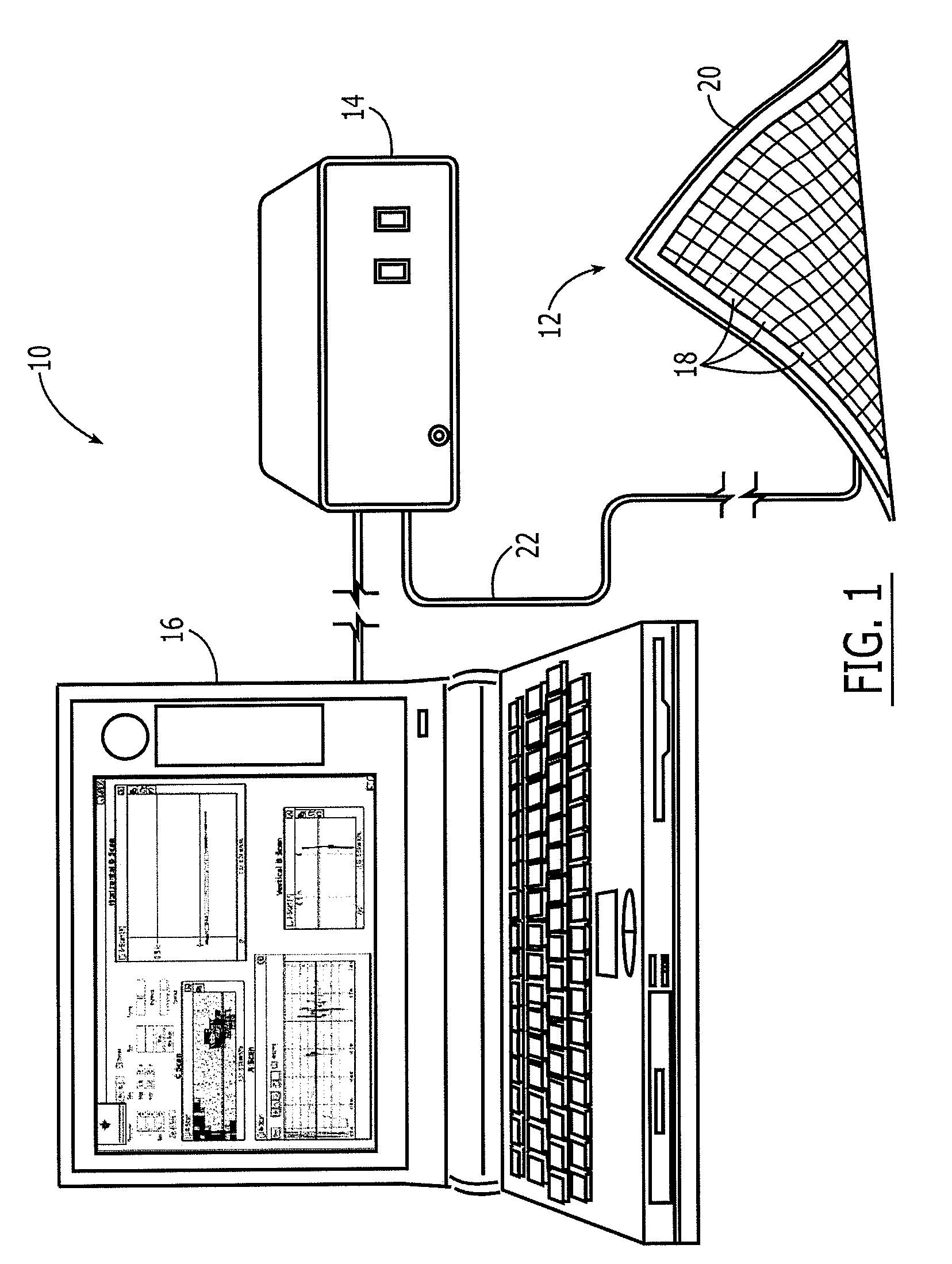

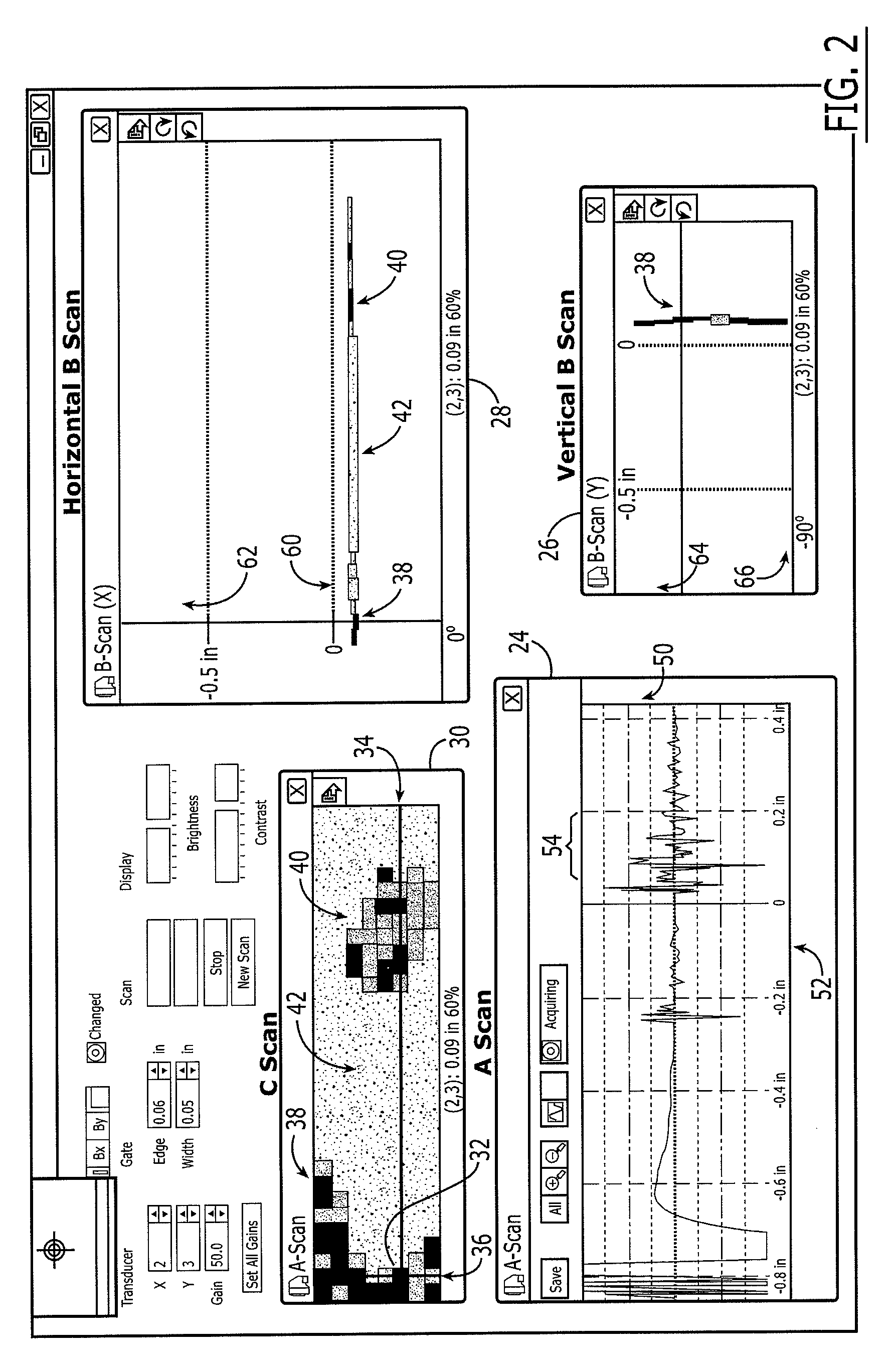

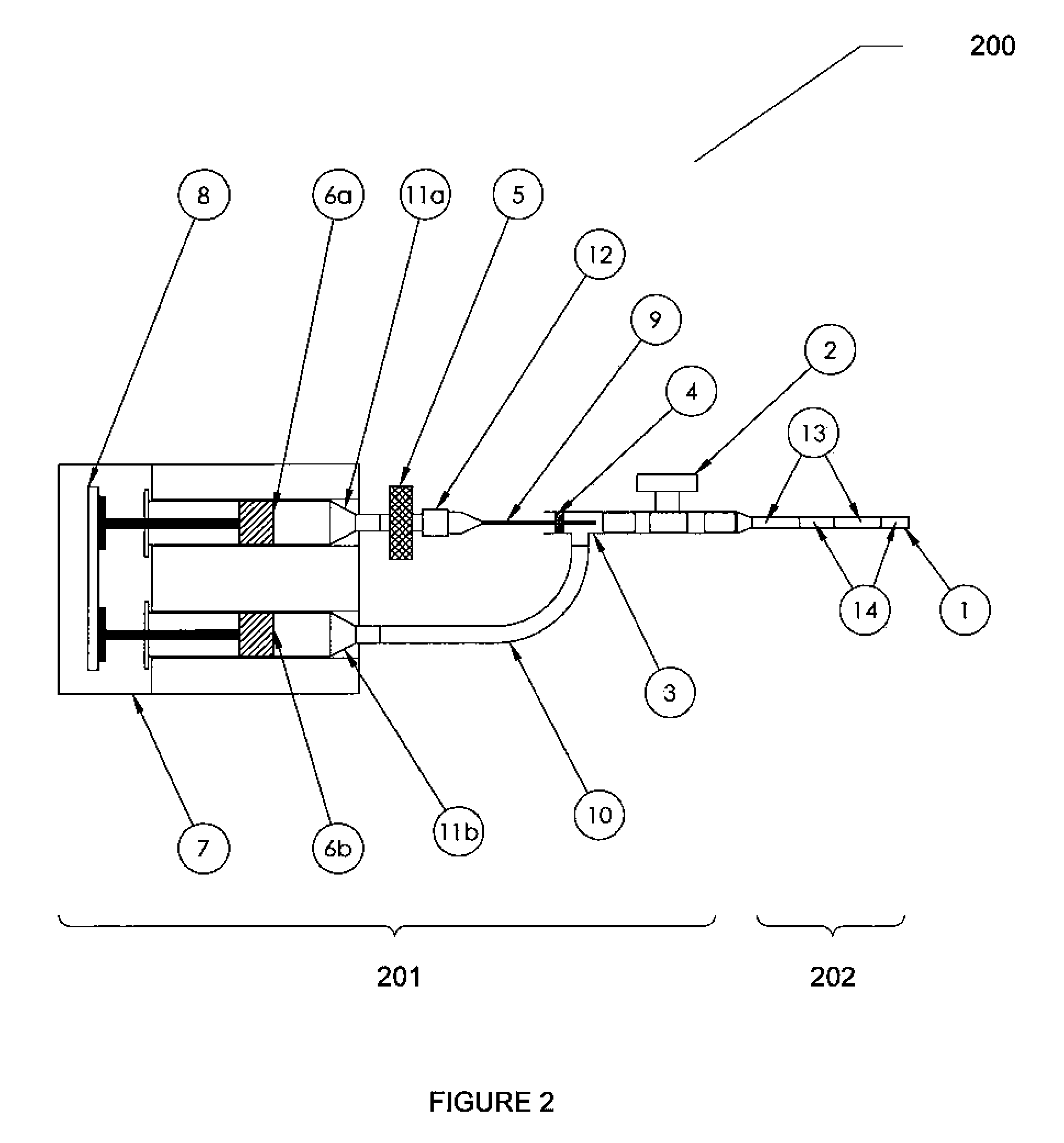

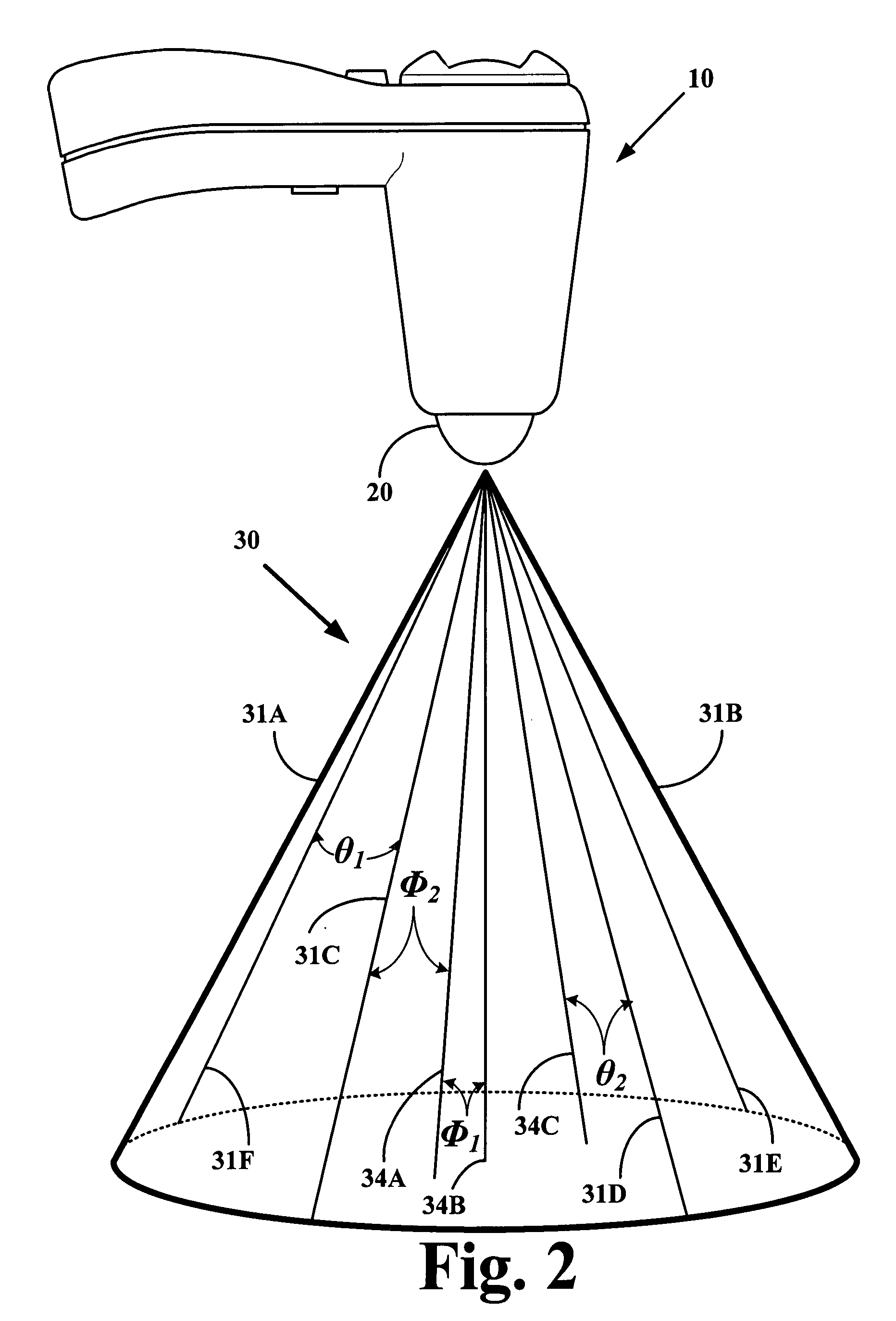

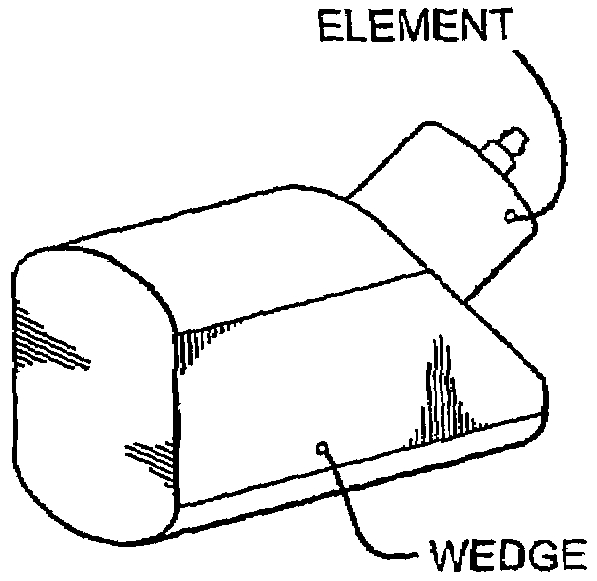

Methods for ultrasonic inspection of spot and seam resistance welds in metallic sheets and a spot weld examination probe system (SWEPS)

InactiveUS20050132809A1Allow flexibilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveElectrical resistance and conductance

An external focused ultrasonic beam, non-destructive, open-air, inspection method of sheet metal spot and seam weldments using a probe in combination with motion measurement of the probe over the weldments during inspection without immersion of the material. Reflected ultrasonic waves are received and signals produced and processed or displayed as A-scan, B-scan and C-scan images that are easily recognized. An A-Scan is based on the time-of-flight difference between the outer surface, the weldment and inner and opposite surfaces of the component. B-scan and C-scan indicate the degree of weld fusion and provide data relative to fused thickness and defects sheet metal or welds. A special purpose scanner that enables ultrasonic examination welds. Scanner is pencil like ultrasonic probe with bearing face and position sensing device disposed adjacent a weld position. Scanner collects data for method to determine various characteristics of welded items.

Owner:APPLIED METRICS

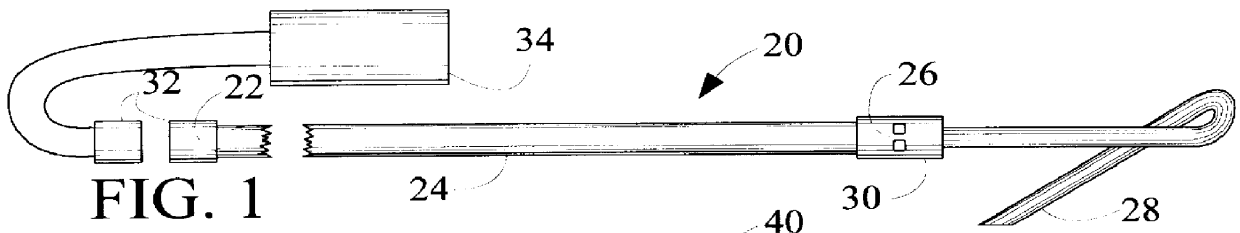

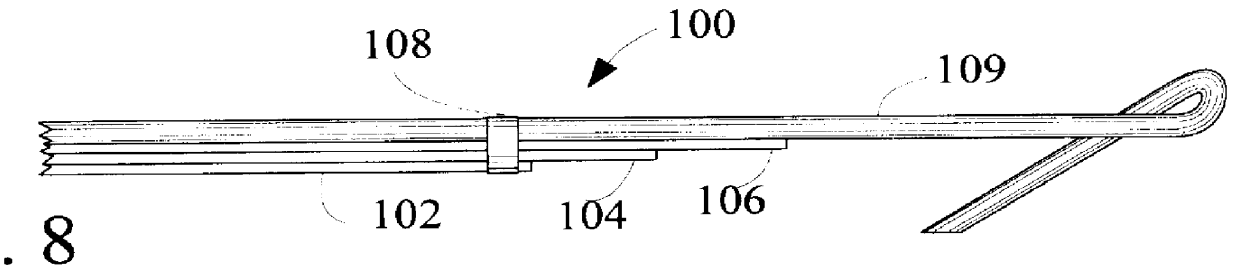

Optical localization fiber

An optical localization fiber 20 is provided suitable for preoperative localization of soft tissue lesions by x-ray mammography, CT, MRI, ultrasonography, or nuclear medicine. A hook 28 is carried by the optical fiber for retaining the fiber in soft tissue. The tip 26 of the optical fiber is visible through the soft tissue when the proximal end of the optical fiber is attached to a light source 170. Other embodiments include clad or coated 42 optical fibers, bundled optical fibers 156, hooks which are metallic 82, braided 66, and multiple 128, and a helix 162.

Owner:HUSSMAN KARL L

Determining Material Stiffness Using Multiple Aperture Ultrasound

ActiveUS20130218012A1High resolutionHigh imagingOrgan movement/changes detectionInfrasonic diagnosticsDiseaseSonification

Changes in tissue stiffness have long been associated with disease. Systems and methods for determining the stiffness of tissues using ultrasonography may include a device for inducing a propagating shear wave in tissue and tracking the speed of propagation, which is directly related to tissue stiffness and density. The speed of a propagating shear wave may be detected by imaging a tissue at a high frame rate and detecting the propagating wave as a perturbance in successive image frames relative to a baseline image of the tissue in an undisturbed state. In some embodiments, sufficiently high frame rates may be achieved by using a ping-based ultrasound imaging technique in which unfocused omni-directional pings are transmitted (in an imaging plane or in a hemisphere) into a region of interest. Receiving echoes of the omnidirectional pings with multiple receive apertures allows for substantially improved lateral resolution.

Owner:MAUI IMAGING

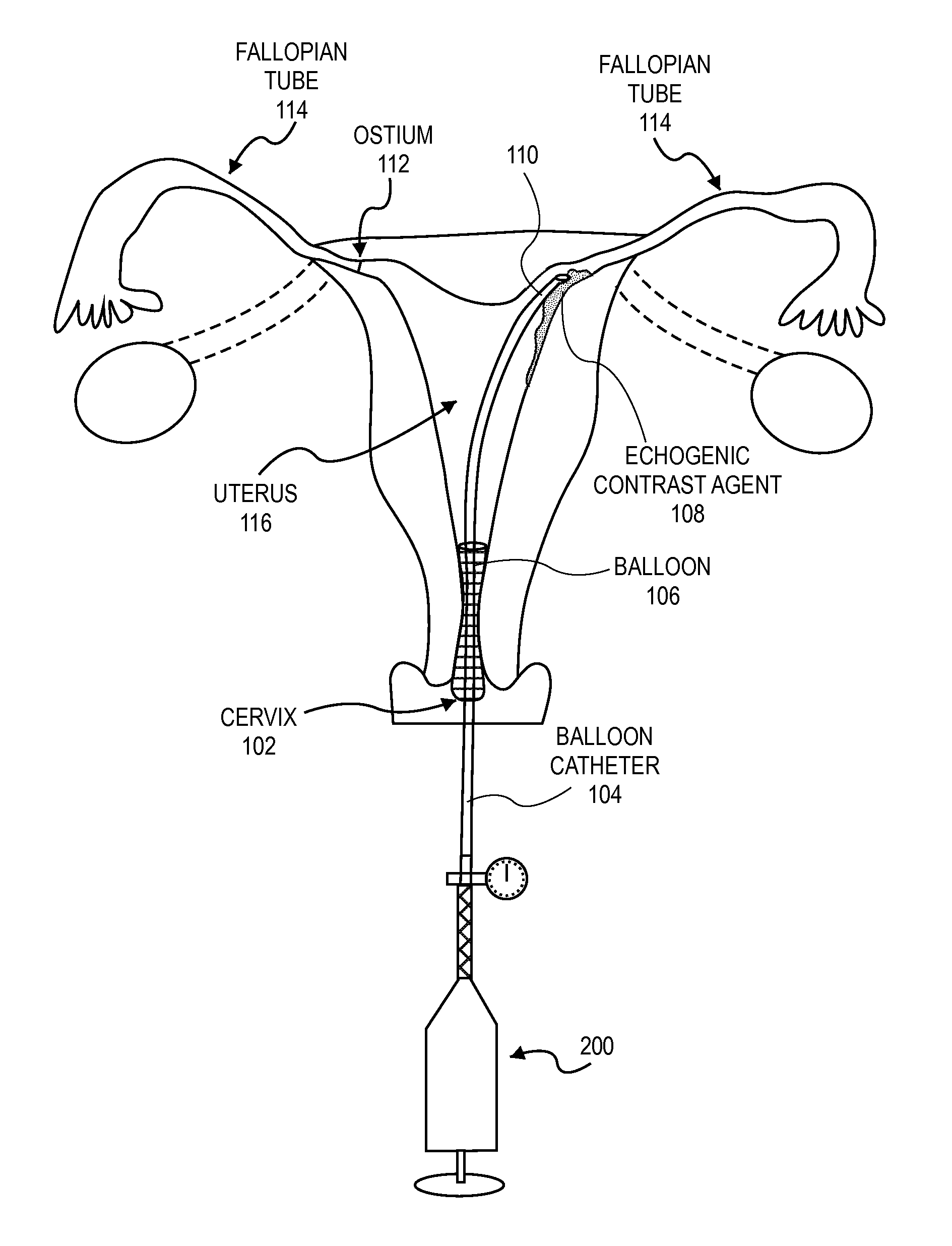

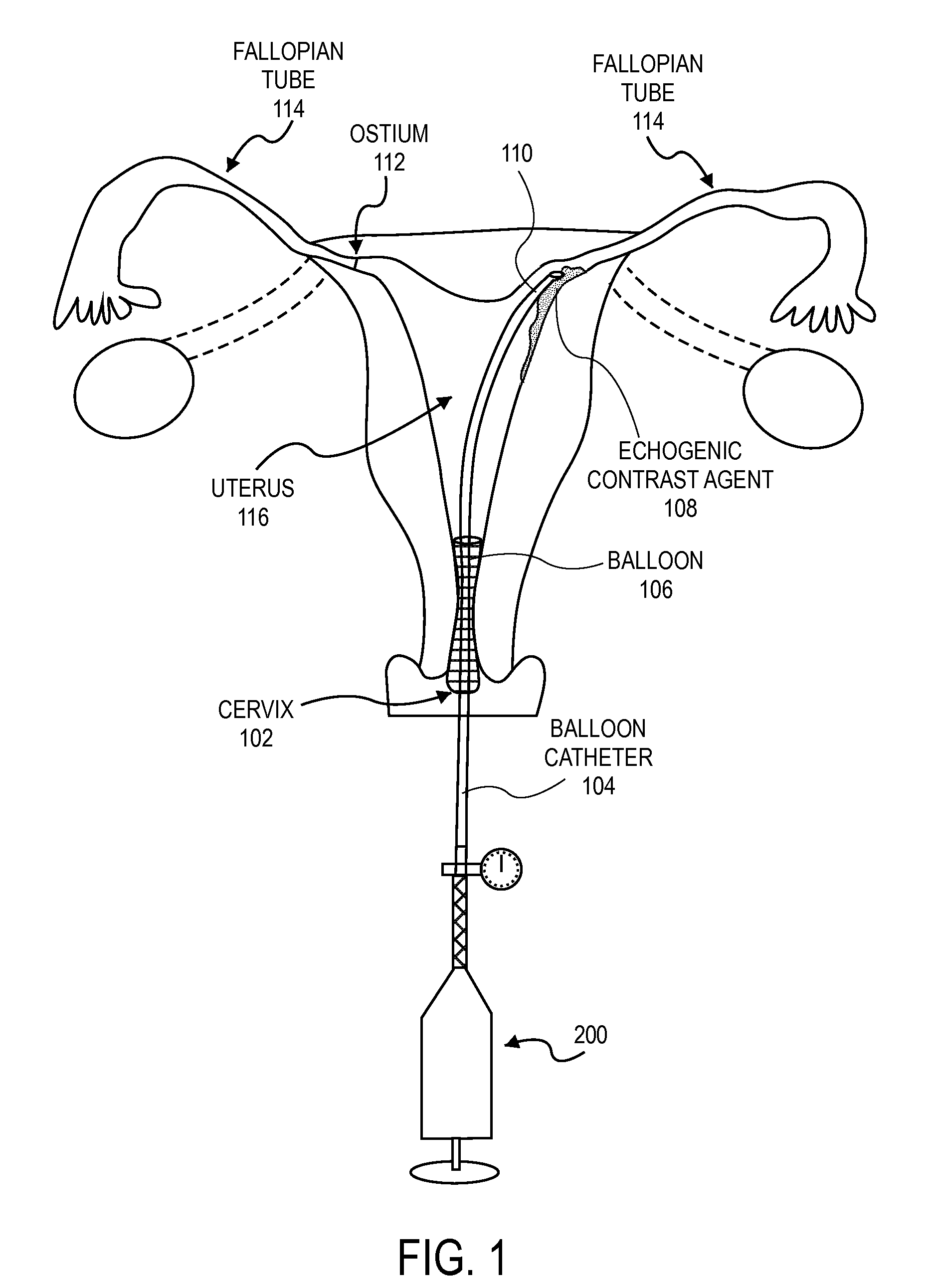

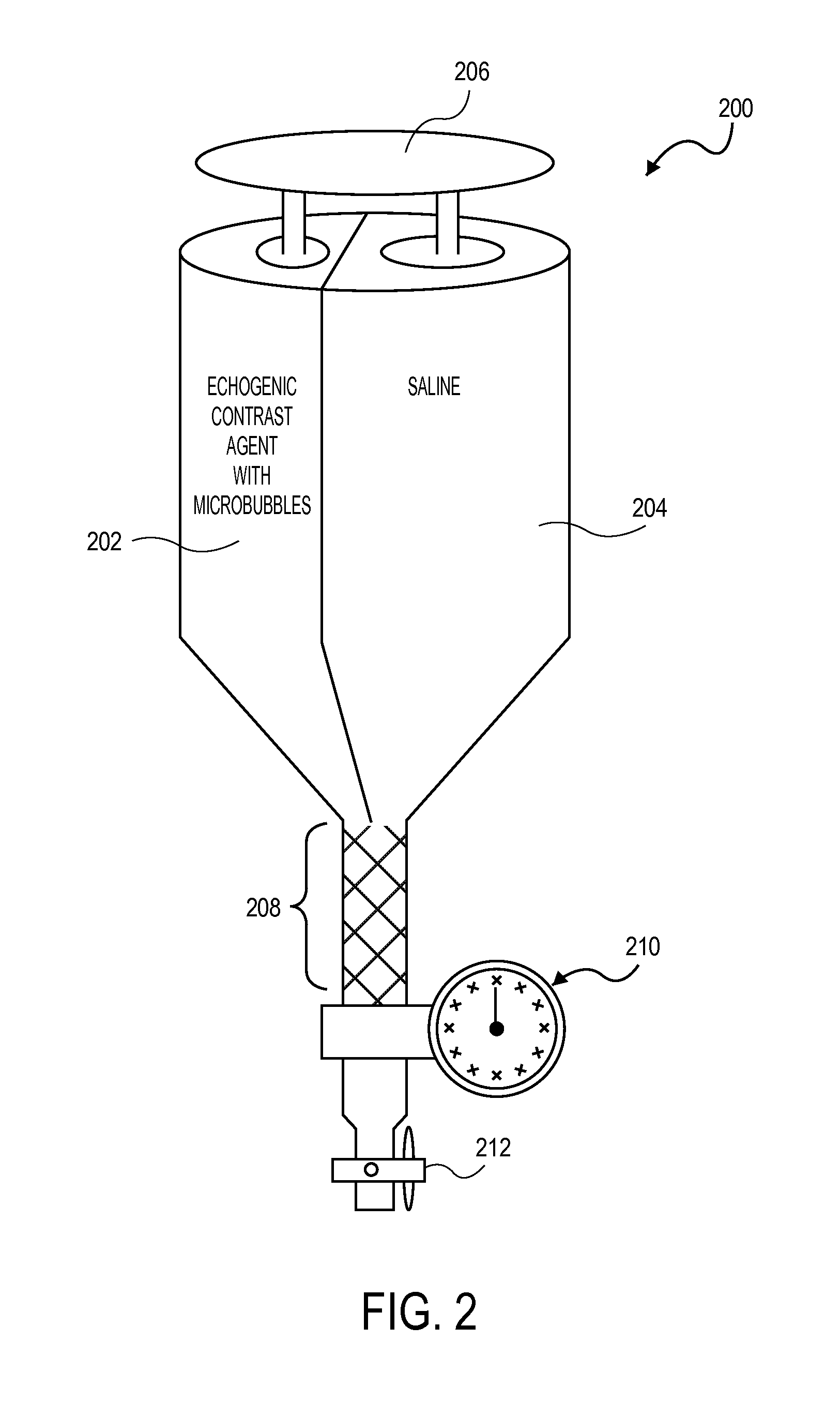

Methods and devices for determining lumen occlusion

InactiveUS20110137150A1Ultrasonic/sonic/infrasonic diagnosticsSurgeryMicrobubblesContrast enhance ultrasound

Embodiments of the present invention describe methods of determining the occlusion of body lumens and apparatuses for doing so. In one particular embodiment, the occlusion of the fallopian tubes by an intrafallopian contraceptive device may be confirmed by contrast enhanced ultrasonography (also known as stimulated acoustic emission hysterosalpingo-contrast sonography). In these embodiments a contrast agent containing microbubbles is used.

Owner:BAYER HEALTHCARE LLC

Method for manufacturing high-strength X80 steel spiral welded pipe

InactiveCN101205587AReduced dimensional accuracyImprove docking efficiencyArc welding apparatusWelding/cutting media/materialsUltrasound testSteel plates

The invention discloses a method for manufacturing a high-strength (X 80) steel spiral weld pipe. The weld pipe adopts a parent metal of X 80 rolled steel plate, and the chemical compositions of weld pipe are: 0.02 to 0.09 percent of C, 0.10 to 0.42 percent of Si, 1.50 to 1.85 percent of Mn, less than or equal to 0.022 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.45 percent of Cr, less than or equal to 0.50 percent of Ni, less than or equal to 0.30 percent of Cu, less than or equal to 0.35 percent of Mo, less than or equal to 0.025 percent of Ti, less than or equal to 0.11 percent of Nb, less than or equal to 0.06 percent of V, less than or equal to 0.06 percent of Al, less than or equal to 0.008 percent of N, less than or equal to 0.0005 percent of B, and less than or equal to 0.23 percent of Pcm. The manufacturing procedures includes: decoiling, leveling, edge milling, prebending, molding, internal welding, external welding, pipe end expending, hierarchical ultrasonic examination of parent metal, X-ray examination of welded seam, hydraulic pressure test, ultrasonic examination of welded seam, pipe end chamfering, finished product examination, etc. The (X 80) steel spiral weld pipe( ID: 1219mm, thickness:18.4mm) manufactured by the invention successfully solves the problem of poor stability and unsatisfactory welded seam performance, etc. in the manufacturing process of the high-strength (X 80) steel spiral weld pipe, thereby greatly improving the pass-rate and working efficiency.

Owner:CNPC BOHAI EQUIP MFG +1

Ultrasonic inspection and repair mode selection

ActiveUS20080000299A1Analysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansGraphicsSonification

In a method of inspecting a structure, a two-dimensional array of sensors is disposed onto a surface, ultrasonic pulses are sent into the surface, and echo signals are received. An image of damage within the structure is graphically displayed, a determination of whether the damage satisfies a predetermined criterion is made, and a mode of returning the structure to usage or service is selected. The predetermined criterion may define a length, a depth, and an area. A-scan, B-scan, and C-scan images of the damage may be displayed. Threshold images may be displayed wherein each pixel of a matrix of pixels is colored one of only two colors.

Owner:THE BOEING CO

Methods for ultrasonic inspection of spot and seam resistance welds in metallic sheets and a spot weld examination probe system (SWEPS)

InactiveUS6948369B2Allow flexibilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveElectrical resistance and conductance

An external focused ultrasonic beam, non-destructive, open-air, inspection method of sheet metal spot and seam weldments using a probe in combination with motion measurement of the probe over the weldments during inspection without immersion of the material. Reflected ultrasonic waves are received and signals produced and processed or displayed as A-scan, B-scan and C-scan images that are easily recognized. An A-Scan is based on the time-of-flight difference between the outer surface, the weldment and inner and opposite surfaces of the component. B-scan and C-scan indicate the degree of weld fusion and provide data relative to fused thickness and defects sheet metal or welds. A special purpose scanner that enables ultrasonic examination welds. Scanner is pencil like ultrasonic probe with bearing face and position sensing device disposed adjacent a weld position. Scanner collects data for method to determine various characteristics of welded items.

Owner:APPLIED METRICS

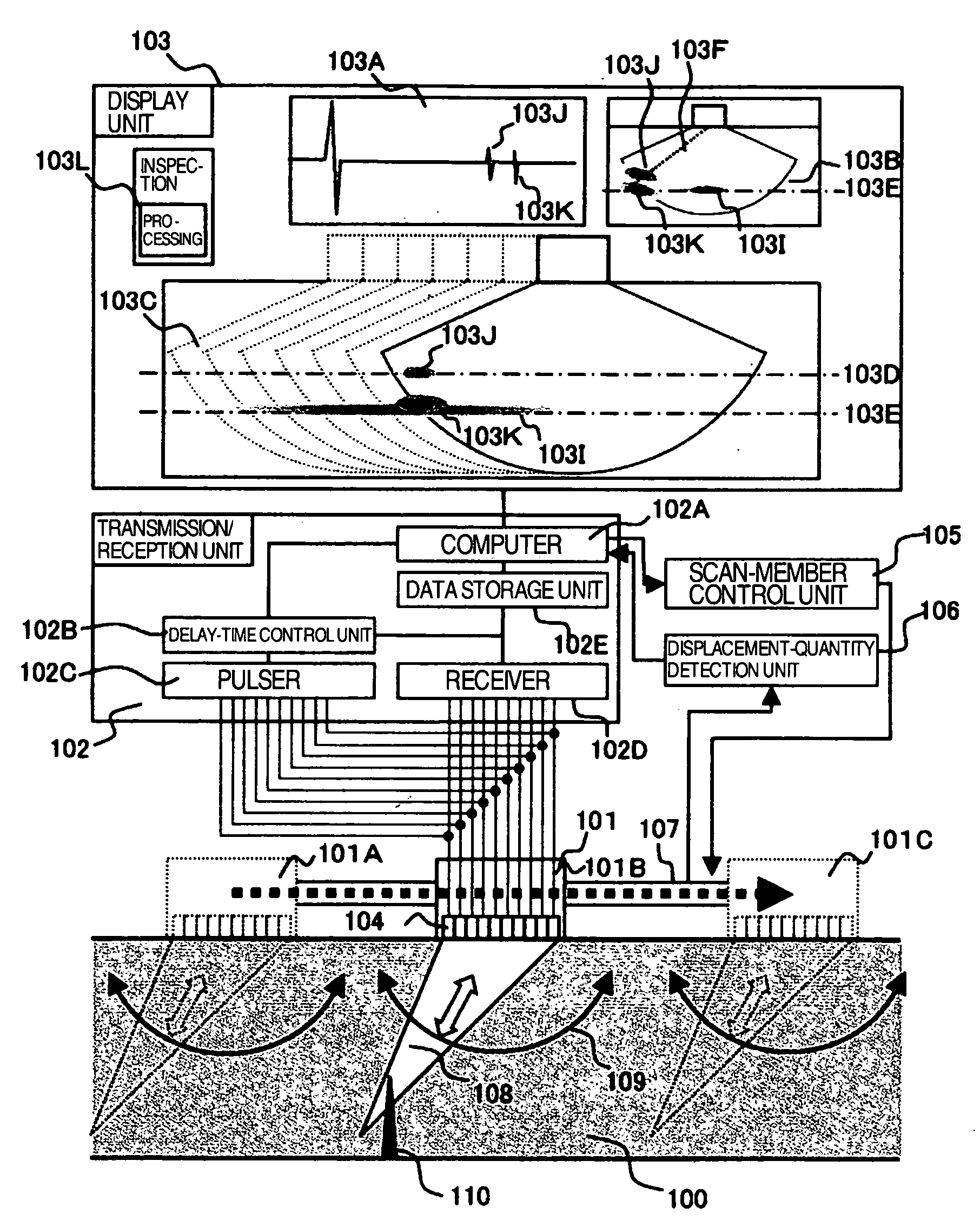

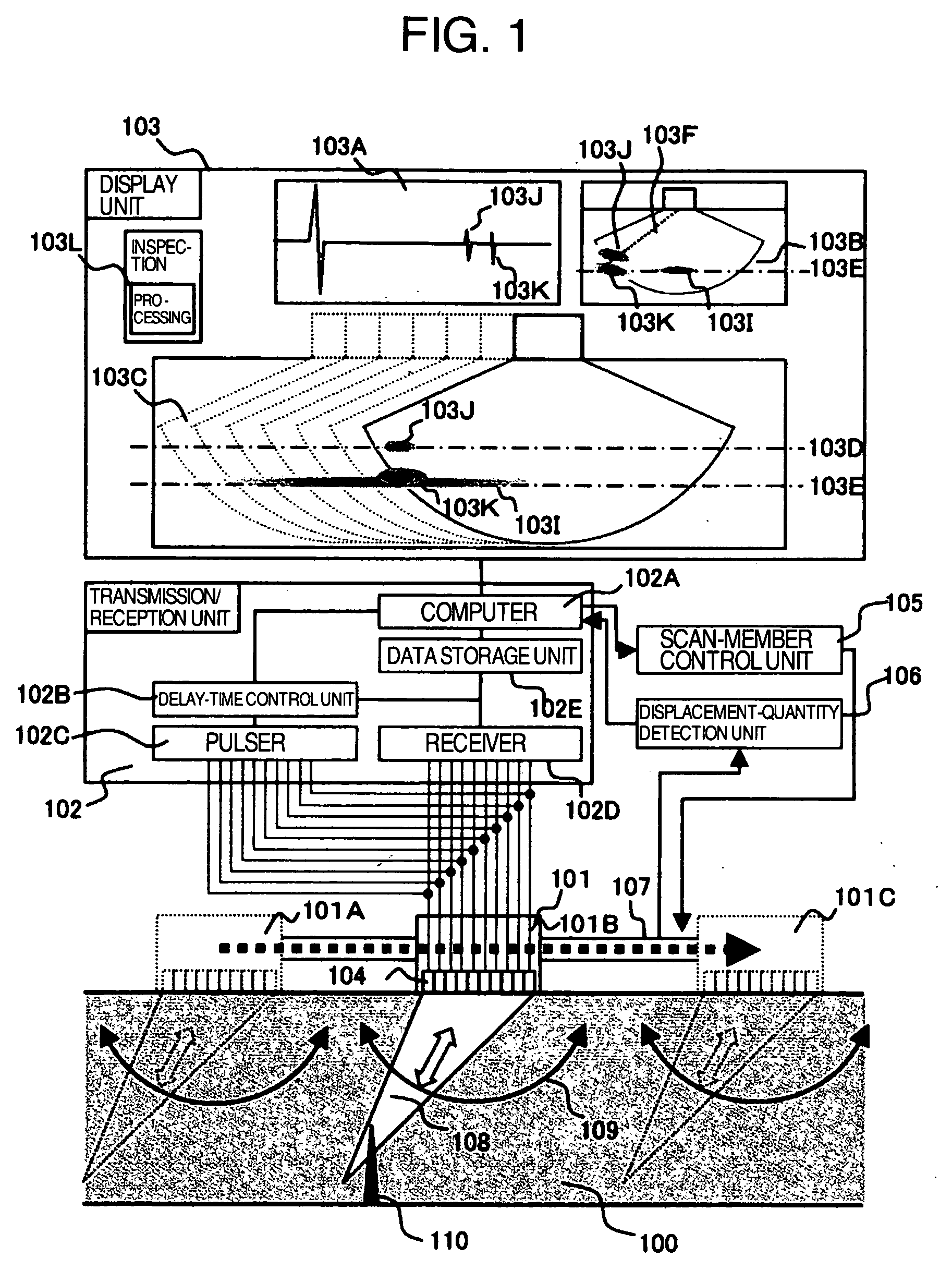

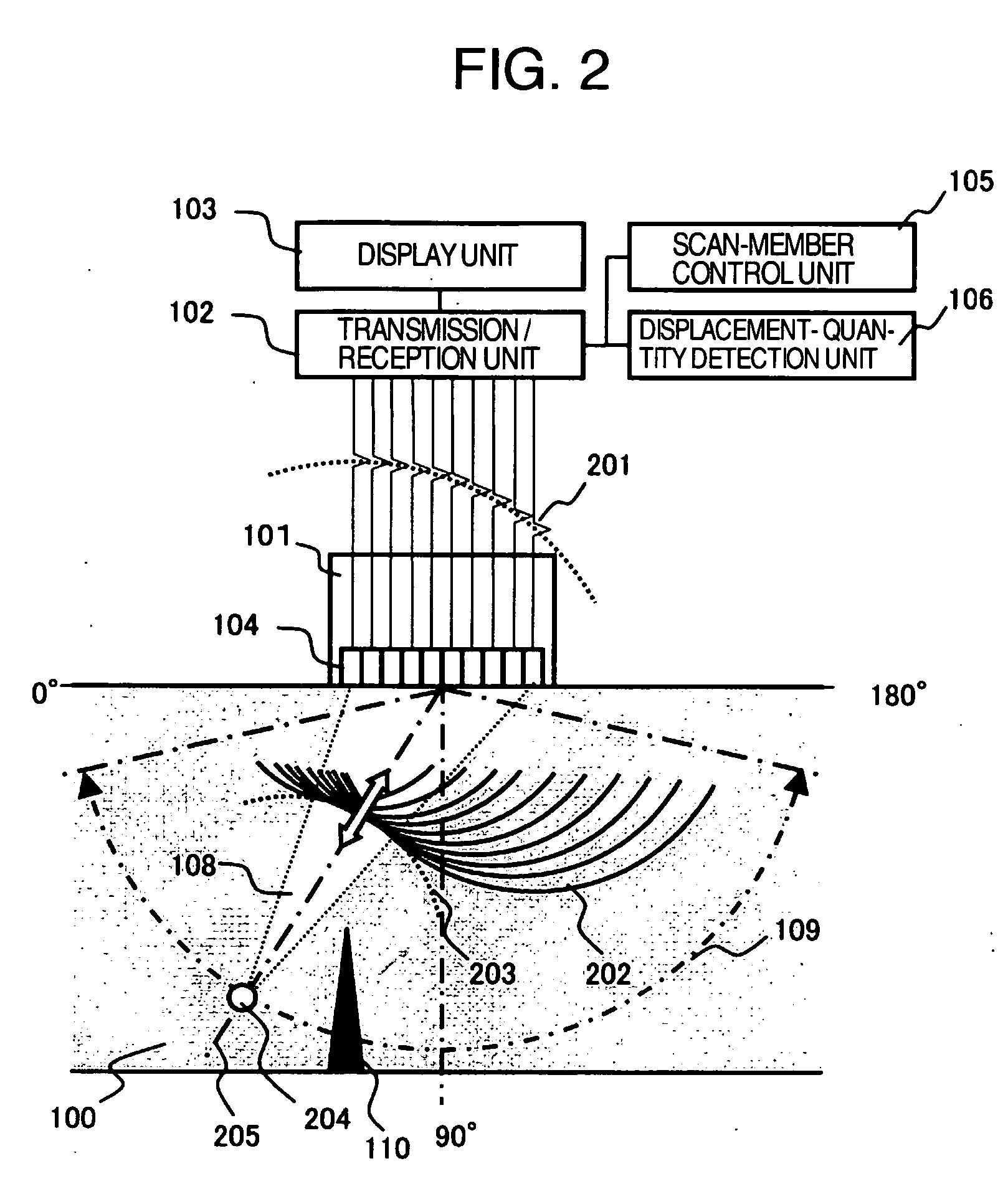

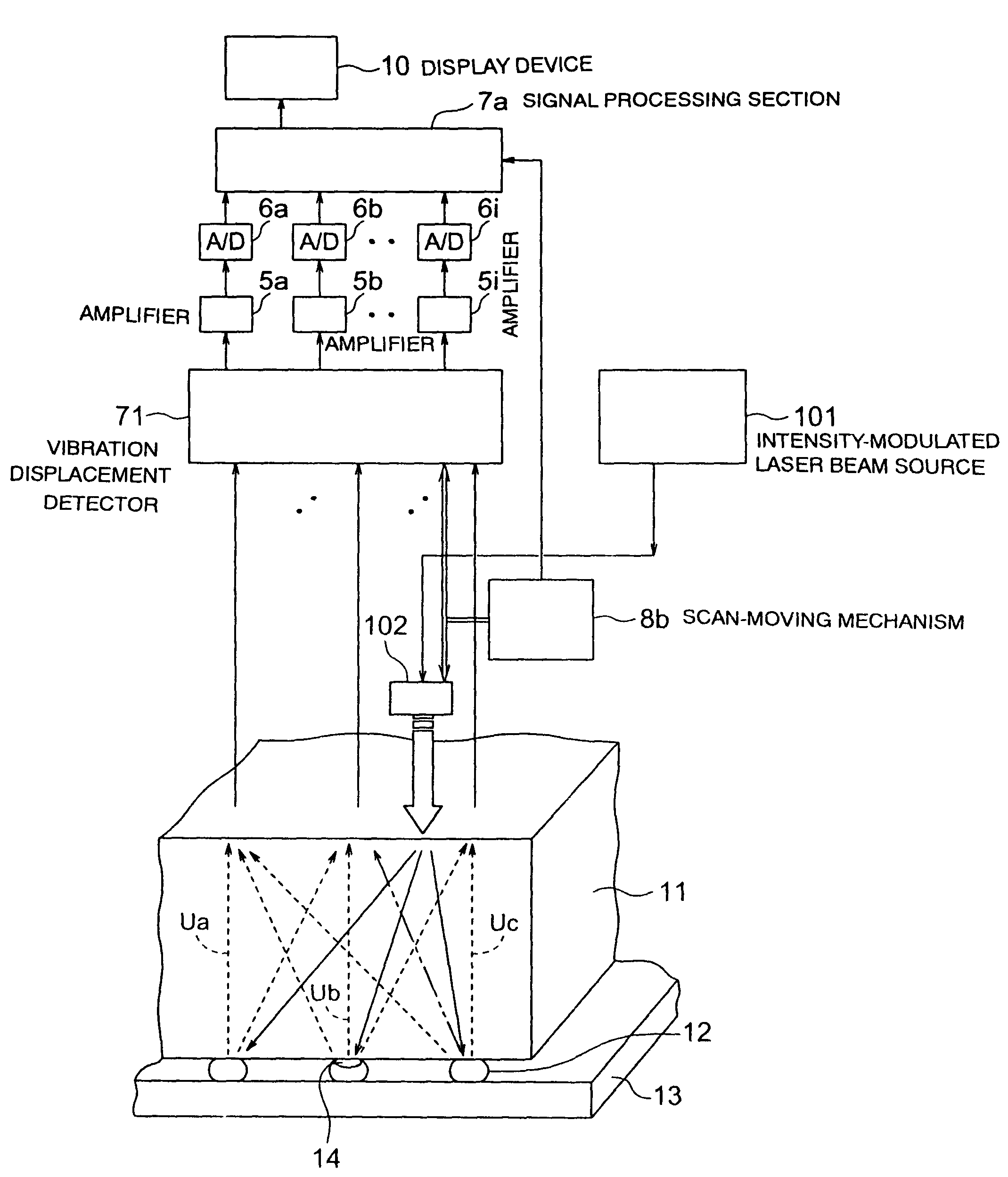

Ultrasonic inspection method and ultrasonic inspection equipment

ActiveUS20060219013A1Reduce random noiseImprove signal-to-noise ratioUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesOperabilityRapid acquisition

In the ultrasonic inspection method and equipment, a high-resolution and high-S / N-ratio inspection image can be speedily acquired with ease-of-operability. Inspection of the inside of the inspection target is performed by changing incident angle of the ultrasonic wave oscillated from the array-probe ultrasonic sensor. Then, while performing the inspection, the array-probe ultrasonic sensor is sequentially displaced from the position to the position via the position by using the displacement member. This displacement allows acquisition of inspection images on each position basis. Finally, the inspection images thus acquired are visualized as a processed image by adding or averaging the inspection images by shifting the images by displacement quantity of the array-probe ultrasonic sensor.

Owner:HITACHI LTD

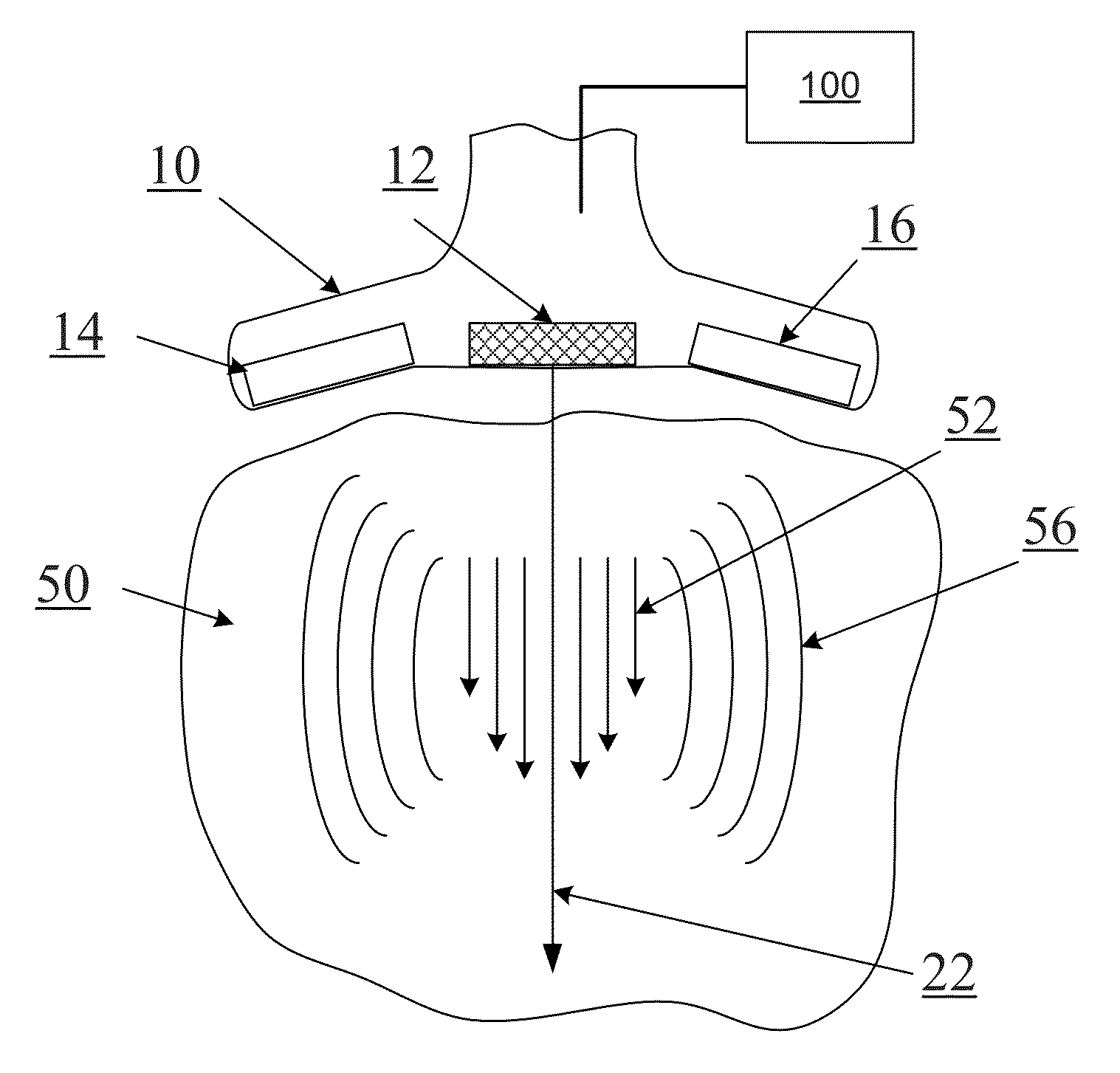

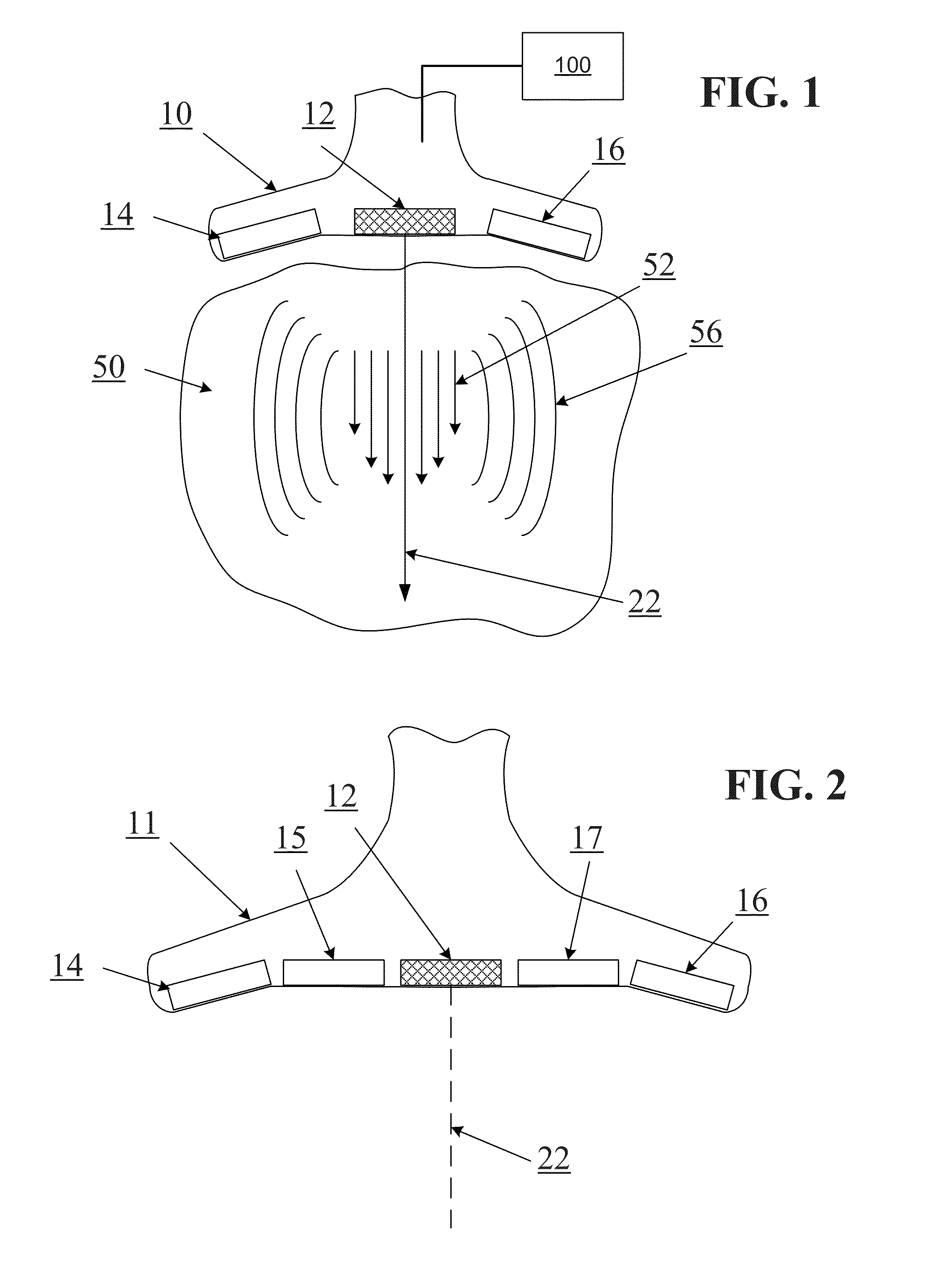

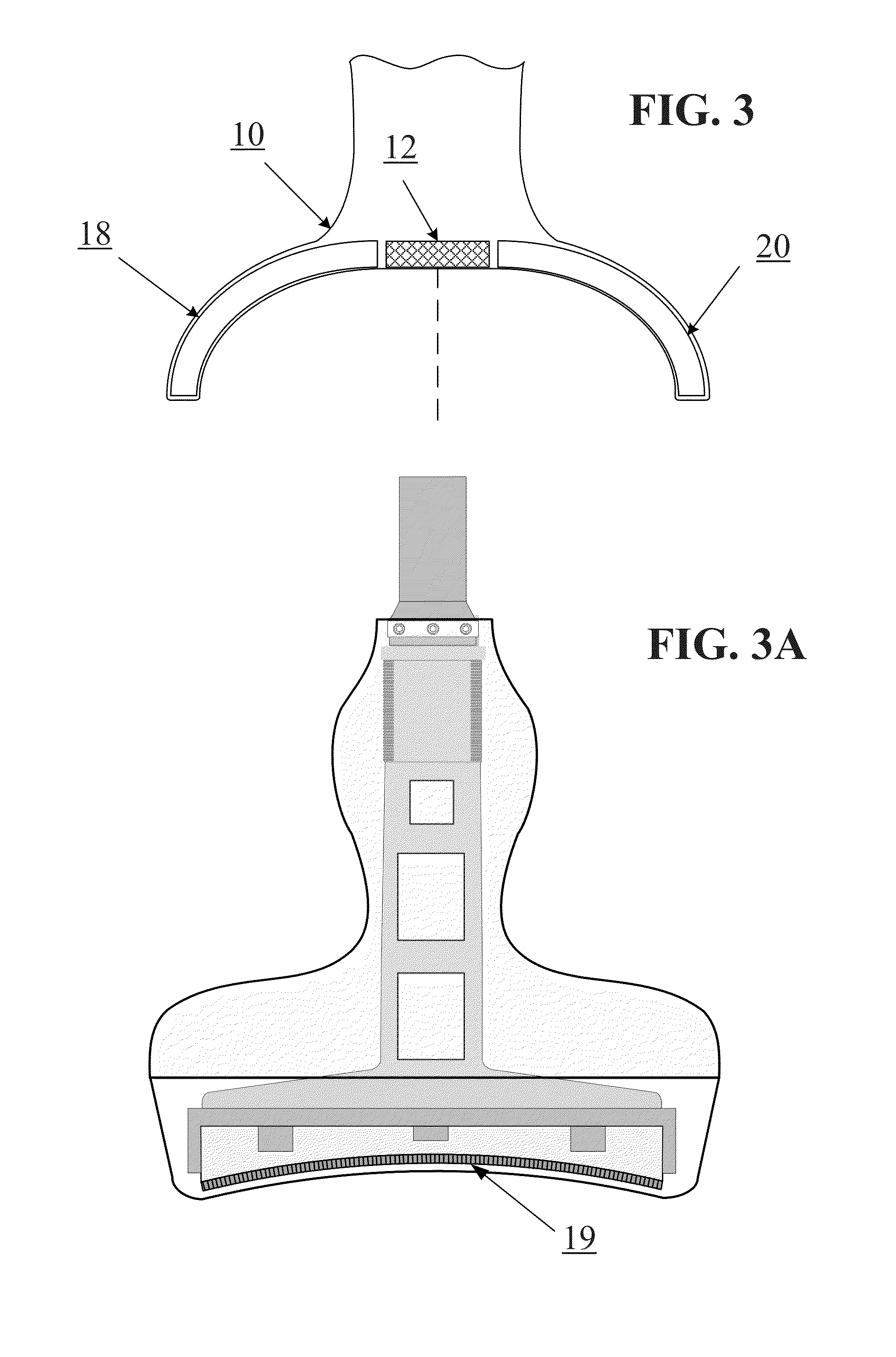

Methods and devices for sonographic imaging

ActiveUS20100086492A1Easy to observeUltrasonic/sonic/infrasonic diagnosticsBalloon catheterUltrasound imagingMedicine

The present invention comprises methods and devices for providing contrast medium for sonography of structures such as ducts and cavities. The invention provides for creation of detectable acoustic variations between two generated phases of a gas and a liquid to make a contrast medium. Sonography is the primary means of imaging but other conventional detection means may also be employed with the present invention.

Owner:FEMASYS INC

Systems and methods for quantification and classification of fluids in human cavities in ultrasound images

Ultrasound imaging systems and methods are disclosed. In one embodiment, an ultrasonography method includes creating a database that is representative of a tissue, a fluid, or a cavity of a body, and transmitting ultrasound pulses into a region-of-interest in a patient. Echoes are received from the region of interest, and based upon the received echoes, compiling an ultrasonic pattern of the region-of-interest is compiled. The pattern is processed by comparing the region-of-interest patterns to the pattern information stored in the database. A composition within the region-of-interest of the patient is then determined.

Owner:MCMORROW GERALD +6

Manufacture method of X80 pipeline JCOE direct sew submerged arc welding tube

The invention discloses a method for producing a JCOE longitudinal submerged arc welded pipe of an X80 pipeline steel. The invention is used for producing an oil and gas conveying tube with high intensity and high tenacity. The method includes using an HTP X80 controlled rolling steel pipe with a chemical composition of 0.03 to 0.05 percent of C, 0.20 to 0.30 percent of Si, 1.65 to 1.75 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.005 percent of S, 0.10 to 0.15 percent of Nb plus Ti and 0.5 to 0.7 percent of Ni plus Cr plus Cu. A steel plate is made into the oil and gas conveying tube with high intensity and high tenacity through the working procedures like edge milling, edge bending, a 'JCO' forming technique under multi-pass pressing, gas protection prewelding, inside welding, outside welding, diameter enlarging, ultrasonic checking, x-ray checking, hydraulic pressure testing, tube end to arris, ultrasonic checking and X-ray checking, etc. The inside welding and the outside welding of a steel tube adopt four-wire serial union melt welding and control the technical parameters of welding through selecting a suitable welding wire and a welding fluid; thereby controlling the components and organizations of a weld joint to lead the performance of the weld joint to reach the performance requirements of X80.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

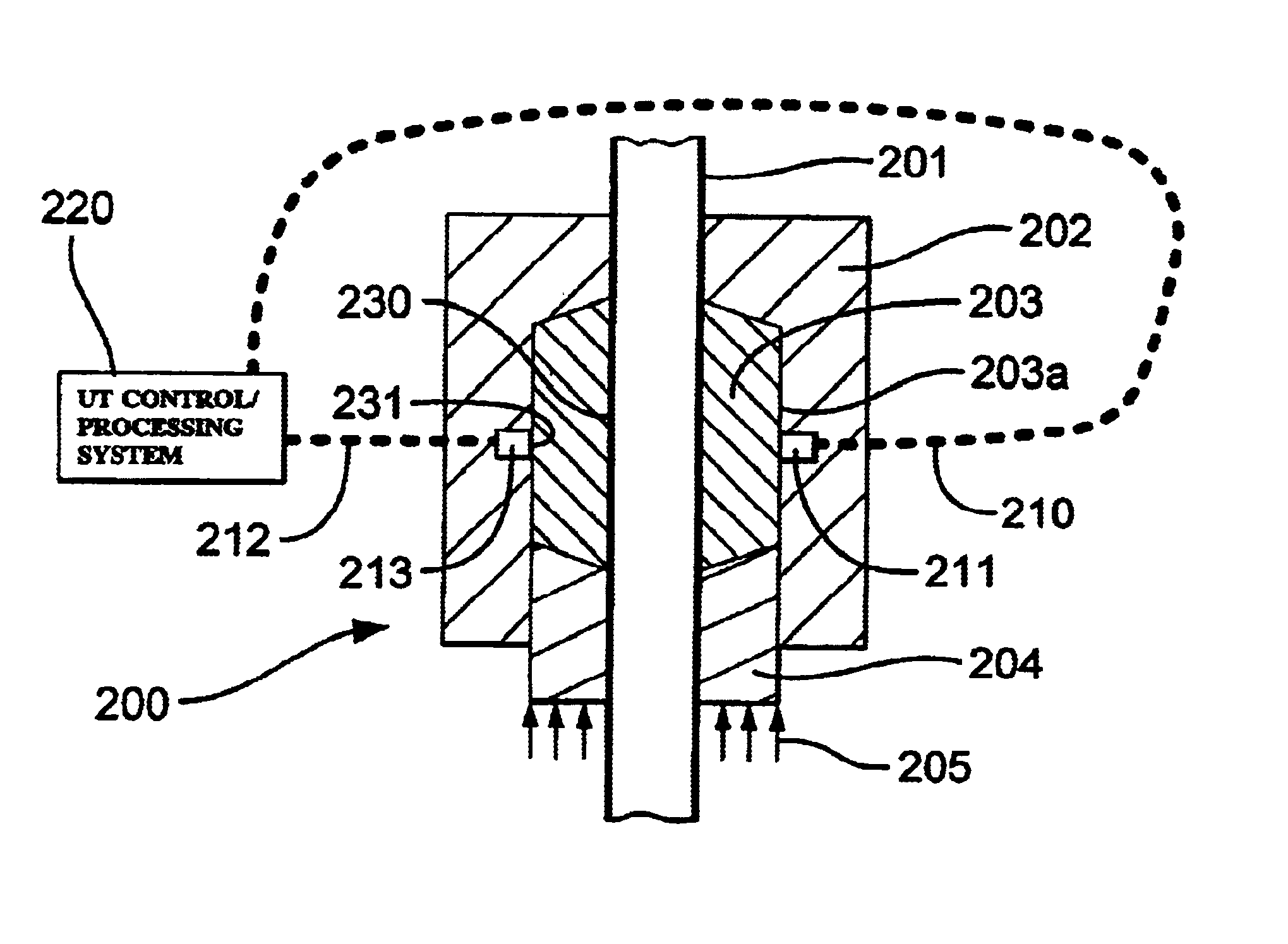

Pipe inspection systems and methods

InactiveUS6782751B2Analysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionElastomerUltrasound device

Systems and methods for ultrasonically inspecting pipe, the pipe having a longitudinal axis, the methods in certain aspects including compressing with a compressing force an elastomeric element between an ultrasonic probe of an ultrasonic pipe inspection system and a pipe to be inspected; and, in certain aspects, the systems and methods including placing a coupling between the elastomeric element and the pipe, wherein the elastomeric element surrounds the pipe; and, in certain aspects, a system for ultrasonically inspecting pipe, the system with a housing, a packer element in the housing with an opening through which a pipe to be inspected is passable, and at least one ultrasonic probe in or on the housing useful in conjunction with an ultrasonic apparatus for inspecting pipe.

Owner:COILED TUBING ENG SERVICES

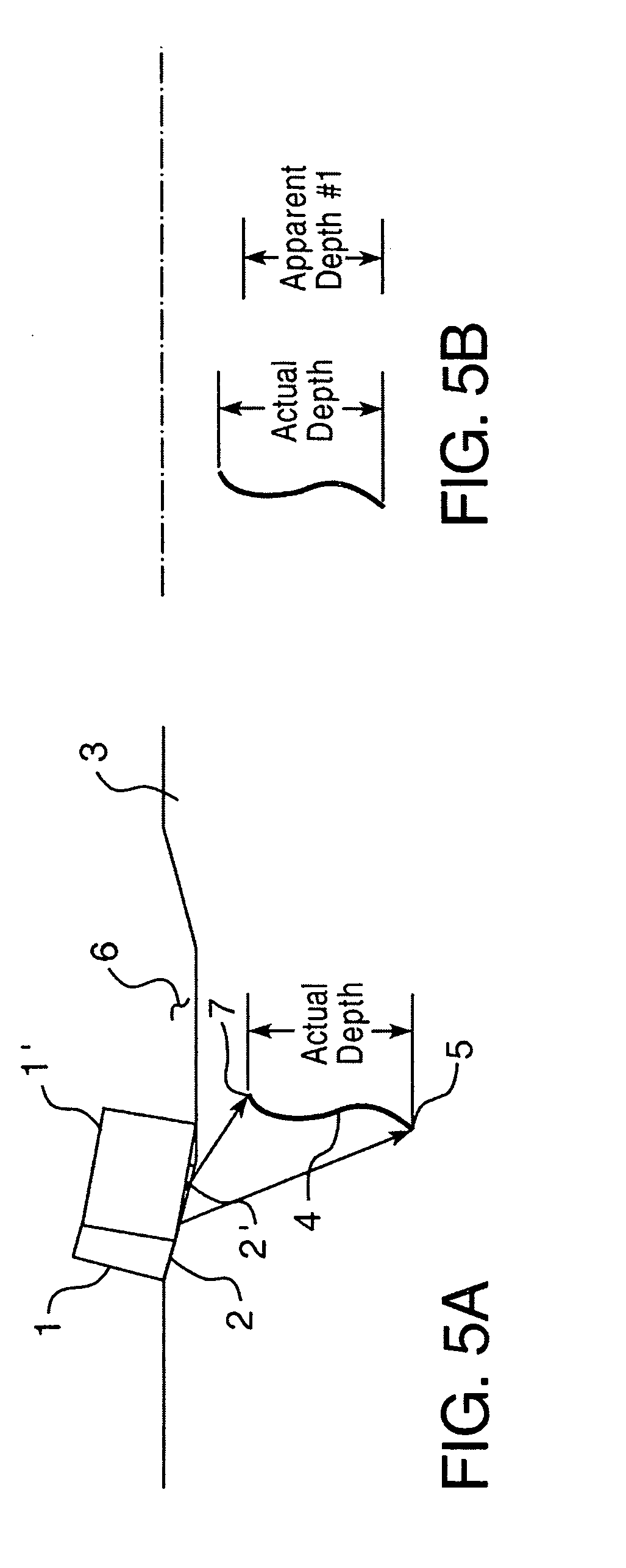

Device and method for ultrasonic inspection using profilometry data

ActiveUS20050150300A1Easy to determineAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationEngineering

An ultrasonic testing assembly structured to examine a test object, wherein the test object has a surface, and the examination examines the structure of the test object under the surface as well as the profile of the surface. The ultrasonic testing assembly includes a sled assembly structured to support a plurality of ultrasonic transducers, the sled assembly including at least one support member having a lower surface, at least one surface ultrasonic transducer coupled to the sled assembly and structured to extend below the support member lower surface and further structured to engage the test object surface, the surface ultrasonic transducer structured to examine internal structure of the test object and provide a first output, at least one profiling device coupled to the sled assembly, the profiling device structured to measure the profile of the test object surface and provide a second output, and a control device structured to correlate the first output and the second output and to calculate a corrected output.

Owner:WESTINGHOUSE ELECTRIC CORP

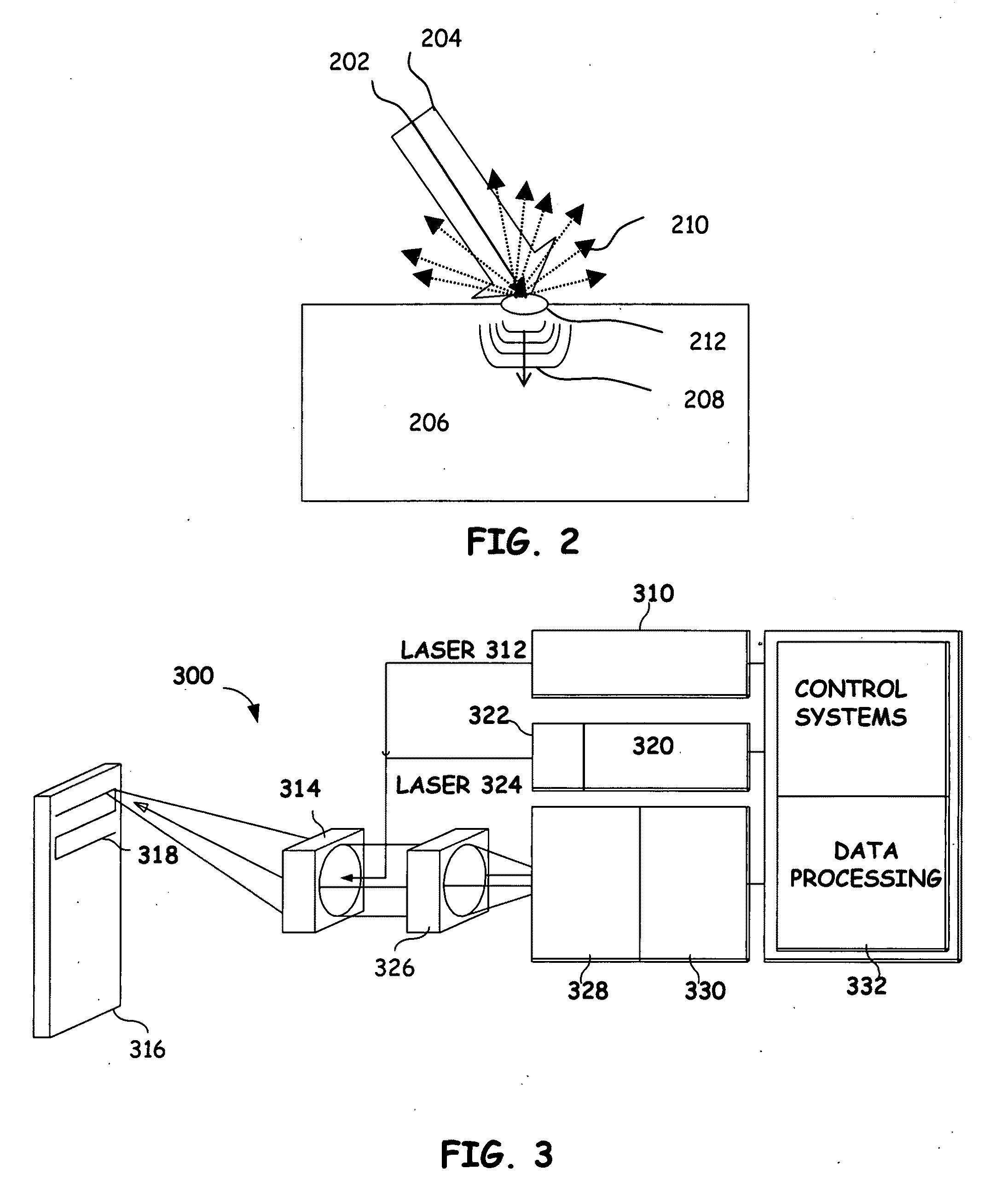

Laser-ultrasound inspection using infrared thermography

InactiveUS20080137105A1Complete understandingUnderstanding of internal structureMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansThermographic inspectionLaser

An inspection system is provided to examine internal structures of a target material. This inspection system combines an ultrasonic inspection system and a thermographic inspection system. The thermographic inspection system is attached to ultrasonic inspection and modified to enable thermographic inspection of target materials at distances compatible with laser ultrasonic inspection. Quantitative information is obtained using depth infrared (IR) imaging on the target material. The IR imaging and laser-ultrasound results are combined and projected on a 3D projection of complex shape composites. The thermographic results complement the laser-ultrasound results and yield information about the target material's internal structure that is more complete and more reliable, especially when the target materials are thin composite parts.

Owner:LOCKHEED MARTIN CORP

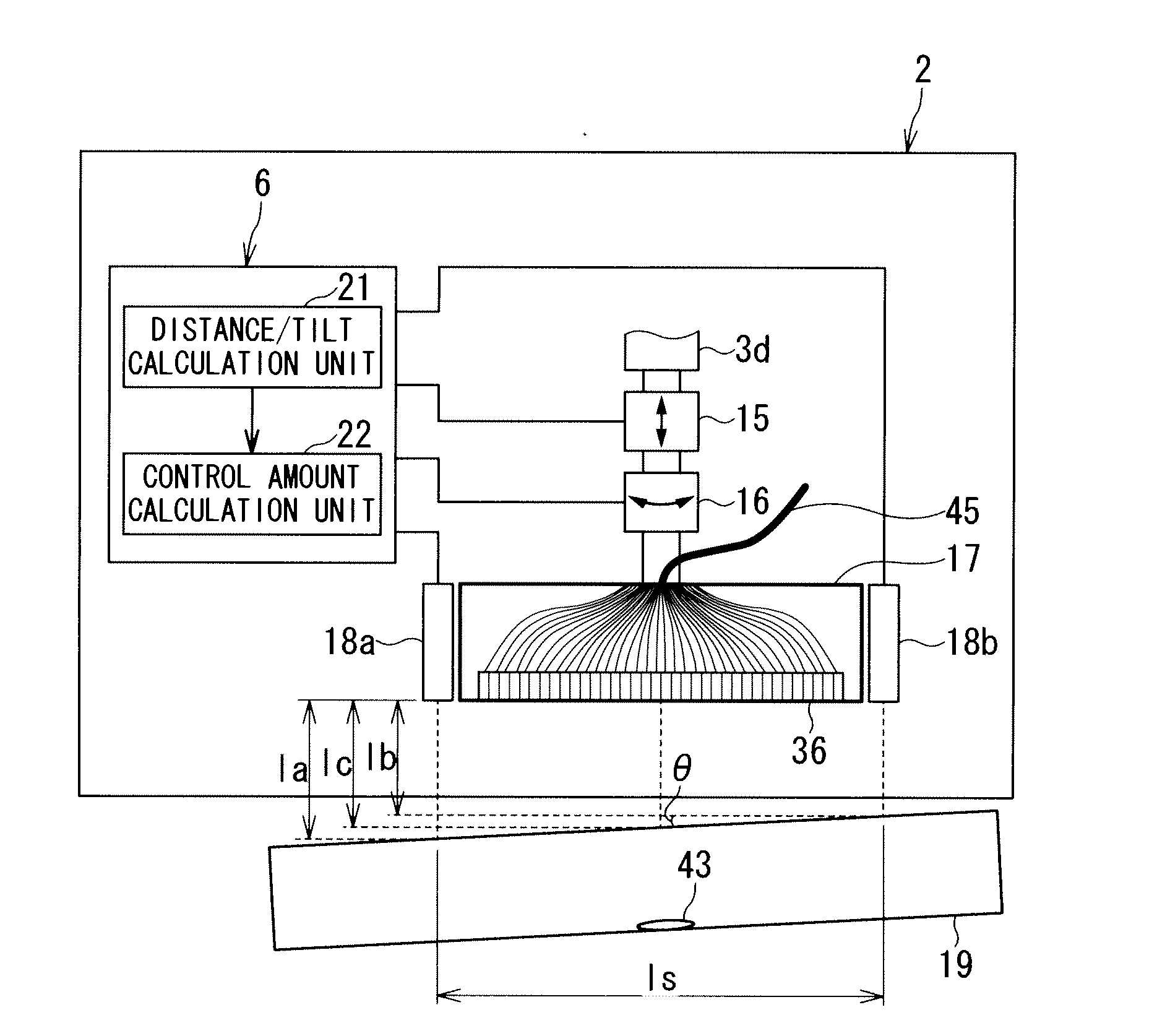

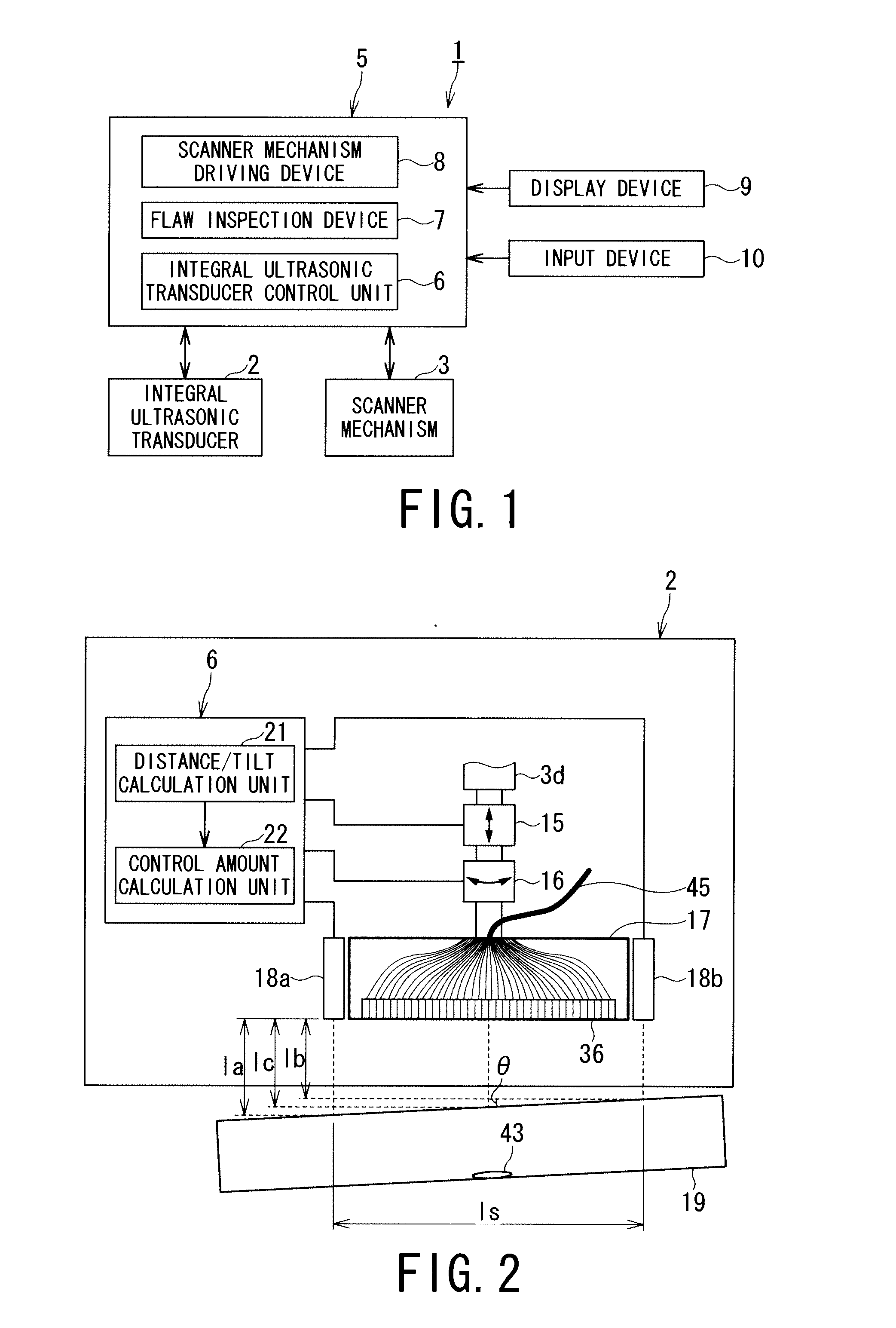

Ultrasonic inspection apparatus

InactiveUS20110000299A1Improve accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansTransducerEngineering

There is provided an ultrasonic inspection apparatus which detects various deviations with respect to an ideal scanning position and achieves, with high accuracy, an ultrasound flaw inspection by autonomously adjusting the deviations. The ultrasonic inspection apparatus according to the present invention is provided with an integrated type ultrasound transducer including an ultrasonic transducer, an integral type ultrasound transducer control unit, an actuator for distance adjustment, an actuator for tilt control, and a distance measuring sensor. The integrated type ultrasound transducer calculates a deviation between a scanning position based on a preliminarily generated scanning path information and an ideal scanning position, and performs a deviation correction processing by autonomously controlling a distance and a tilt between an opening surface of the ultrasound transducer and an inspection region of an object to be inspected in accordance with this deviation.

Owner:KK TOSHIBA

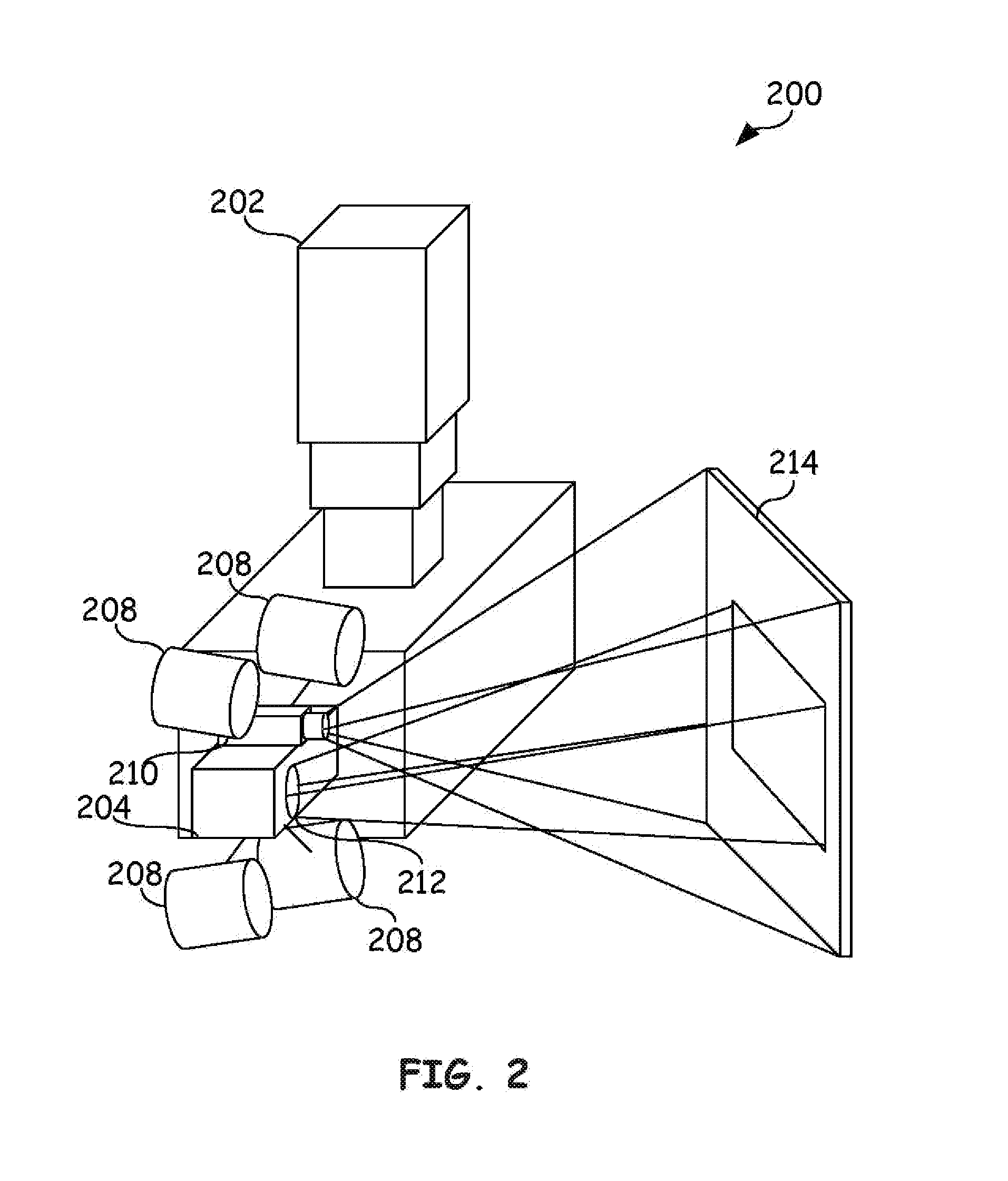

Articulated robot for laser ultrasonic inspection

ActiveUS20090010285A1Cost-effectiveMore compact robotsLaser using scattering effectsAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveUltrasound sonography

An ultrasonic non-destructive evaluation (NDE) system operable to inspect target materials is provided. This ultrasonic NDE system includes an articulated robot, an ultrasound inspection head, a processing module, and a control module. The ultrasound inspection head couples to or mounts on the articulated robot. The ultrasound inspection head is operable to deliver a generation laser beam, a detection laser beam, and collect phase modulated light scattered by the target materials. The processing module processes the phase modulated light and produces information about the internal structure of the target materials. The control module directs the articulated robot to position the ultrasound inspection head according to a pre-determined scan plan.

Owner:LOCKHEED MARTIN CORP

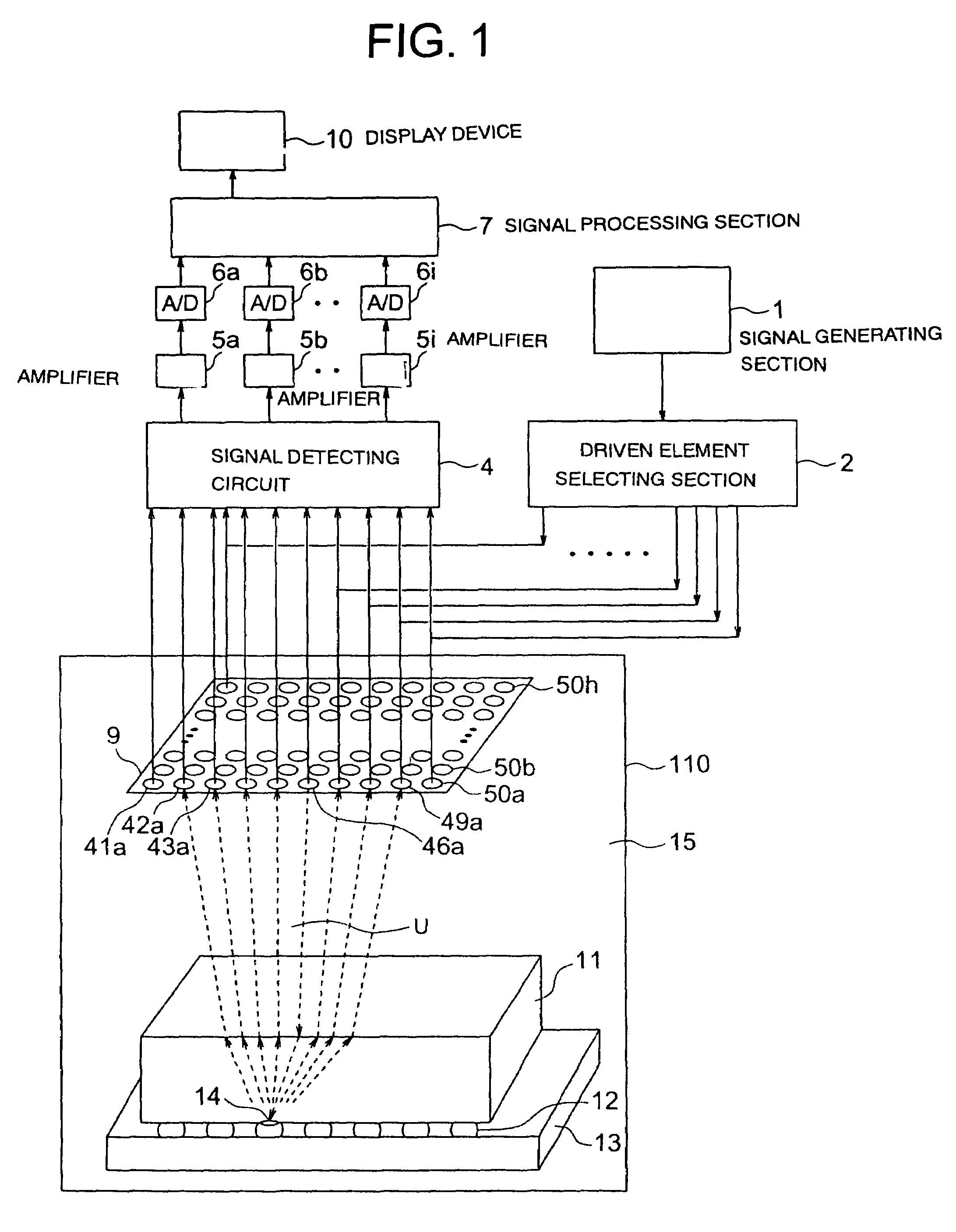

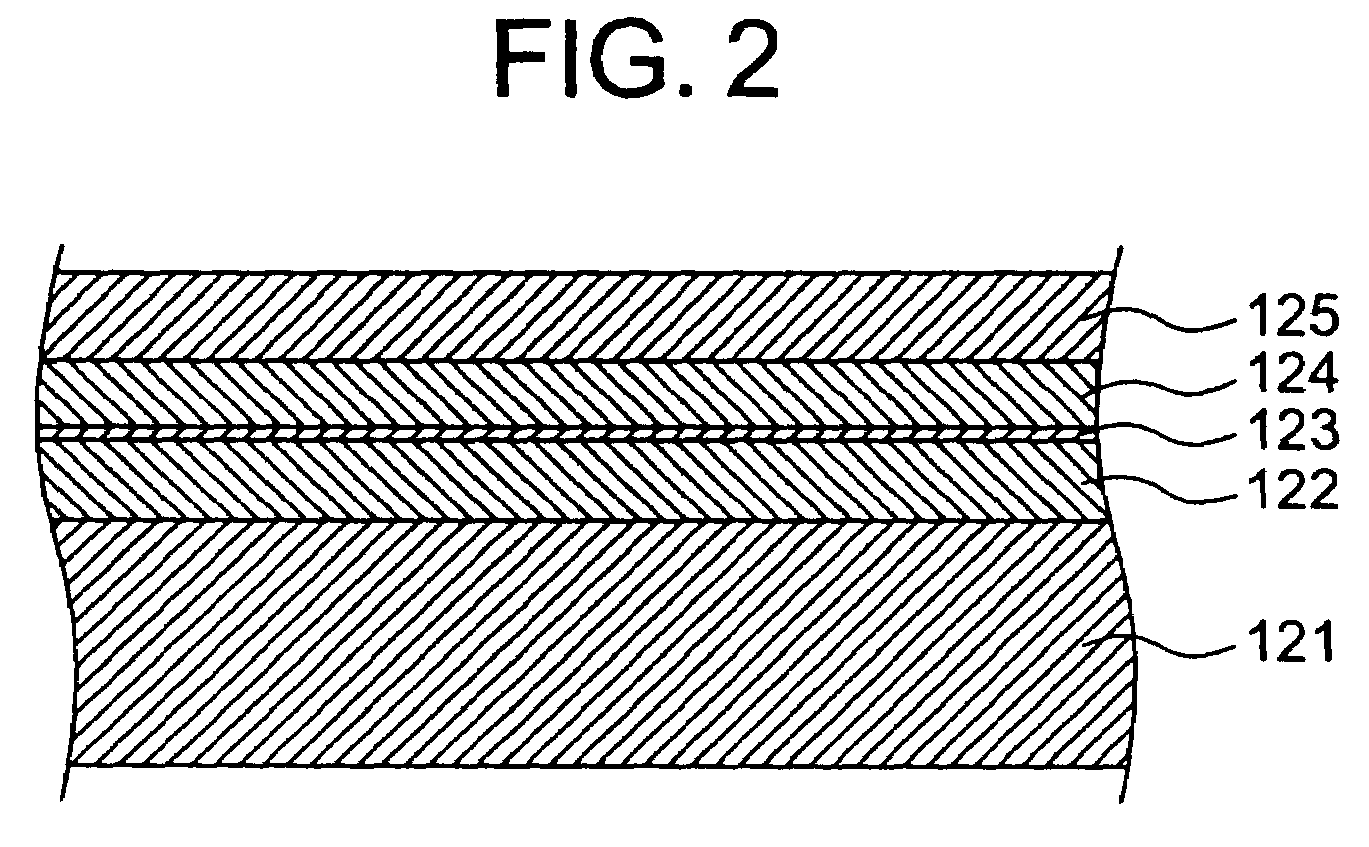

Ultrasonograph, ultrasonic transducer, examining instrument, and ultrasonographing device

ActiveUS7421900B2Transmission propertyUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesLead zirconate titanateElectricity

An ultrasonograph, an ultrasonic transducer, an inspection device, and an ultrasonic imaging device enabling easy and quick inspection and high-resolution or high-speed processing are provided. Barium titanate (BaTiO3) or lead zirconate titanate (PZT) is used for a piezoelectric material constituting the ultrasonic transducer, and the thickness thereof is 0.1 μm to 100 μm. Included therein are a drive section capable of driving an arbitrary one of piezoelectric layers, a detecting section detecting electrical signals generated by the plural piezoelectric layers based on echoes from an inspection object, the echoes being originated from an ultrasonic wave generated by the driven piezoelectric layer, and a processing section performing processing for visualizing a state of the inspection object based on the detected electrical signals.

Owner:KK TOSHIBA

Angle beam shear wave through-transmission ultrasonic testing apparatus and method

InactiveUS20060201252A1Improve three-dimensional defect resolutionImproving depth measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsSonificationImage representation

Improved methods, systems, and apparatus for inspecting a structure using angle beam shear wave through-transmission ultrasonic signals involves positioning transducers at offset positions on opposing sides of the structure and permits inspection of the inside of the structure beneath surface defects and features. Magnetic coupling can be used for supporting a pair of leader-follower probes and defining offset positions between angle beam shear wave transducers carried by the probes. Inspection data can be collected for supporting real-time generation of three-dimensional image representations of the structure and of internal defects and features of the structure. Image generation and resolution using inspection data from angle beam shear wave ultrasonic signals can be supplemented using pulse-echo ultrasonic inspection data.

Owner:THE BOEING CO

Ultrasonic inspection apparatus, system, and method

ActiveUS7640811B2Inspection speed is fastNon-destructively inspectedAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansHigh rateTransducer

Improved apparatus, systems, and methods for inspecting a structure are provided that use a pedestal robot mounted on a rail system, a probe extension coupler, and an inspection probe capable of performing pulse echo ultrasonic inspection. A probe may also include sled appendages and an axial braking system to inspect over holes and off edges. A probe may also include an ultrasonic pulse echo transducer array for high rate inspection; the transducer array may be mounted in a bubbler shoe for individually coupling each of the transducers in the array. A rail system may also include an optical encoder for providing location information for the robot and axial braking system. A probe extension coupler presses the inspection probe against the structure for adjusting to changes in surface contours.

Owner:THE BOEING CO

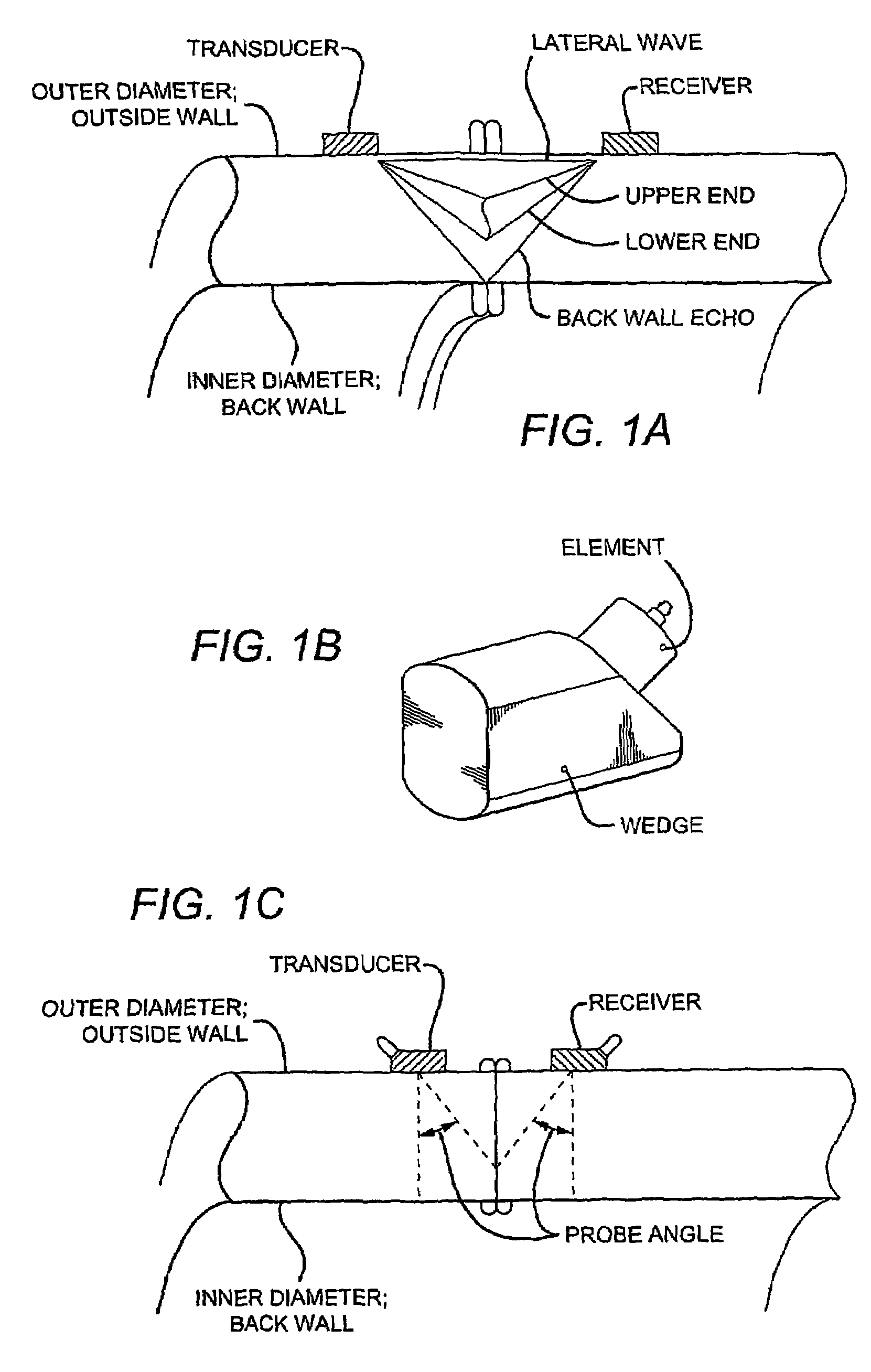

Configurations and methods for ultrasound time of flight diffraction analysis

InactiveUS7255007B2Flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesSonificationTime of flight

An ultrasound test apparatus for polymeric materials (e.g., plastic pipes) includes a low-absorption housing that at least partially encloses an ultrasound transducer, wherein the transducer emits a low frequency wide angle ultrasound beam with a narrow bandwidth. In especially preferred configurations and methods, the apparatus will detect flaws in polymeric pipes, and especially in welds or stressed zones of such pipes, wherein defects of less than 4% of the wall thickness (up to 4 inches) are detected. Further disclosed are configurations and methods for nondestructive detection of lack-of-fusion defects in polymeric pipes.

Owner:FLUOR ENTERPRISES

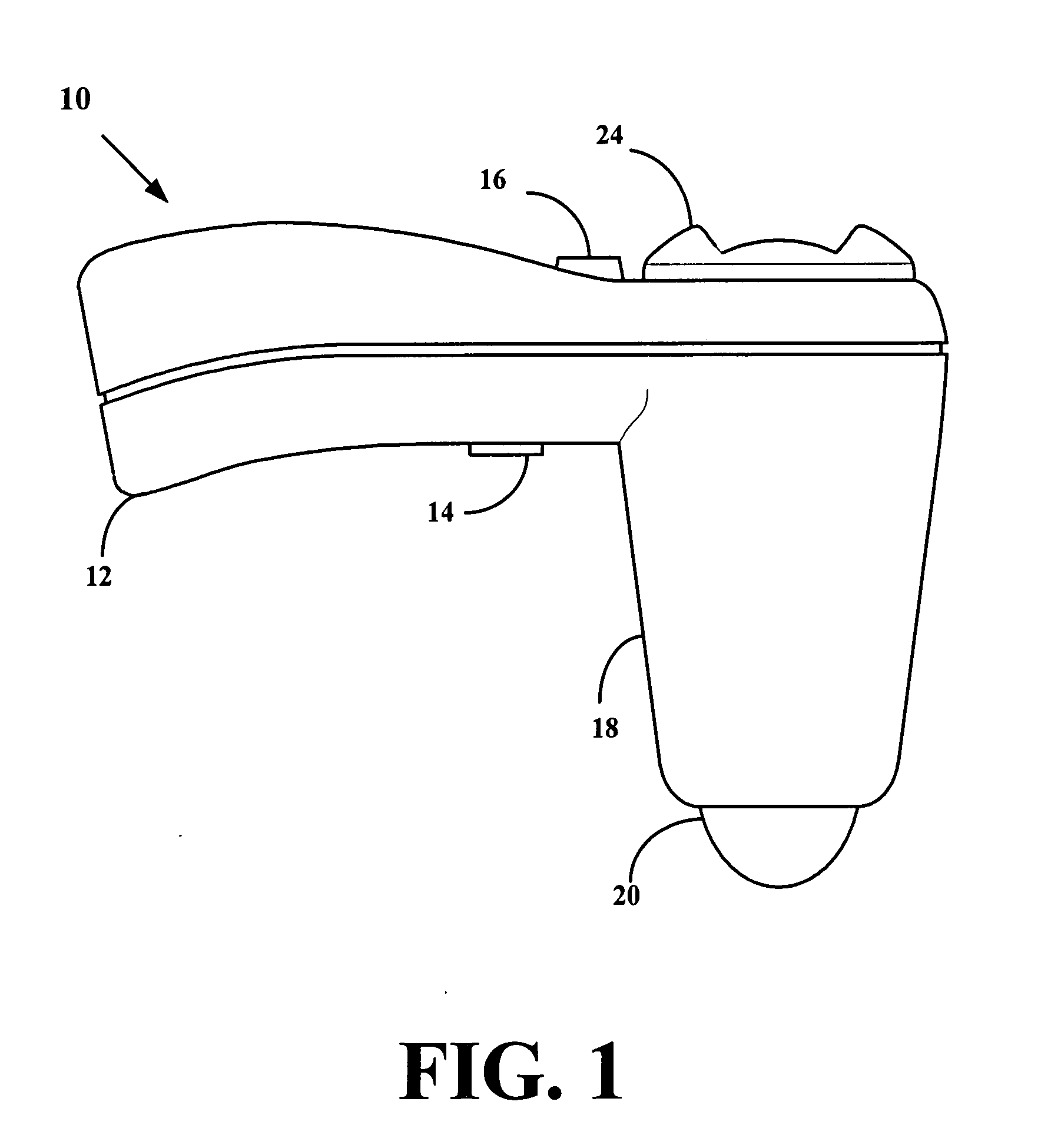

Automatic syringes

Owner:SIBBITT JR WILMER L +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com