Pharmaceutical product manufacturing execution system and method

A manufacturing execution system and execution system technology, applied in general control systems, control/adjustment systems, program control, etc., can solve problems such as backward and chaotic material monitoring, achieve simplified material management, ensure accuracy, improve system development efficiency and The effect of maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

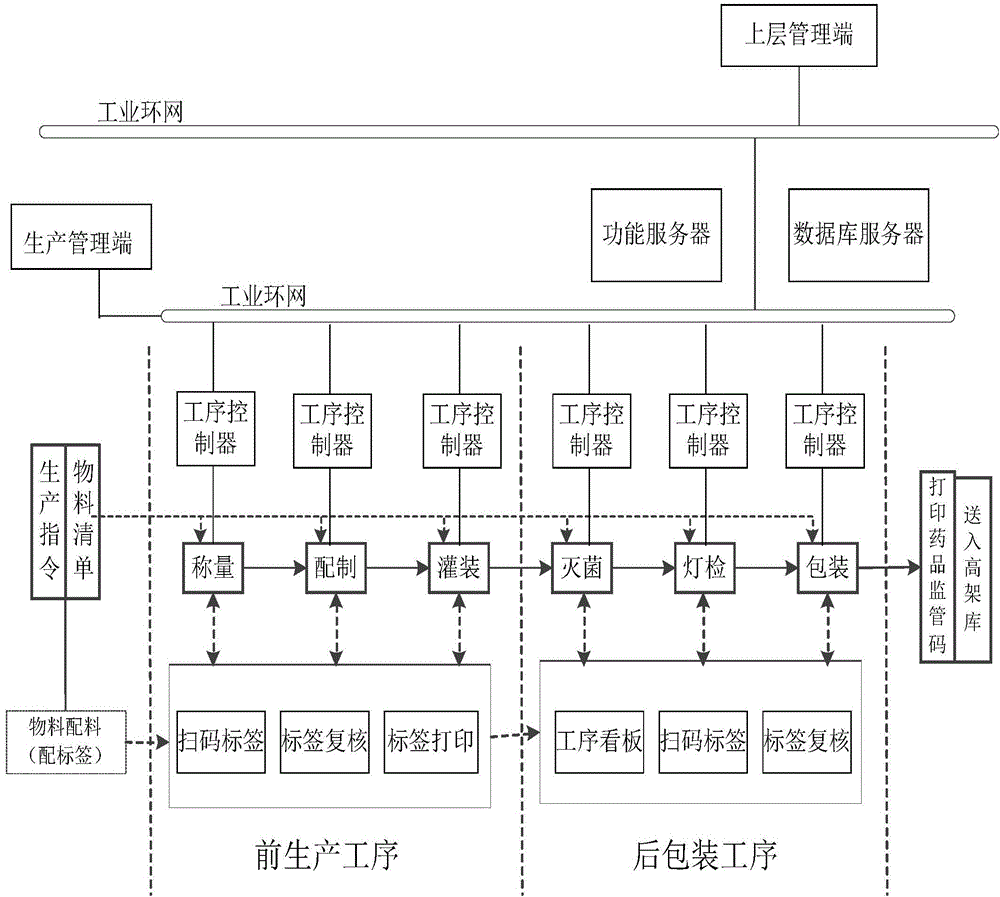

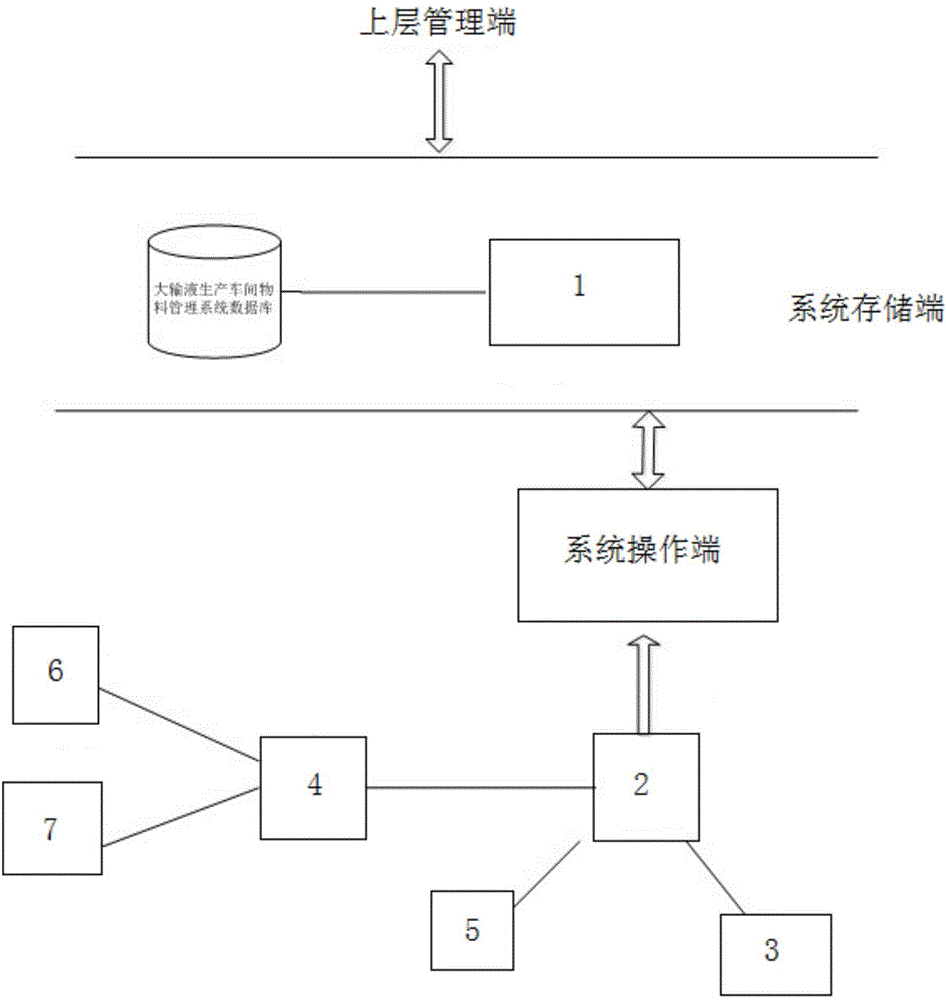

[0058] Such as figure 1 As shown, a manufacturing execution system for pharmaceutical products includes a manufacturing execution system function server, a manufacturing execution system data server, a production management terminal, a process controller, and the like. Each server has a redundancy mechanism, and each individual hardware device has a number of independent RJ45 interfaces, and each RJ45 interface is connected to the server through an industrial ring network.

[0059] Among them, the manufacturing execution system function server and the manufacturing execution system data server are connected with the upper management software or ERP system through the industrial ring network to realize the integration of network, data and applications. At the same time, do a good job of recording the server database data read and write operations and logs of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com