Bridge type opening and closing bridge device of flat glass production line

A flat glass and production line technology, applied to lighting and heating equipment, conveyor objects, furnaces, etc., can solve the problems of unsafe hidden dangers in the flat glass connection production line, reduce product losses and unsafe hidden dangers, and reduce labor and energy cost, the effect of solving logistics problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

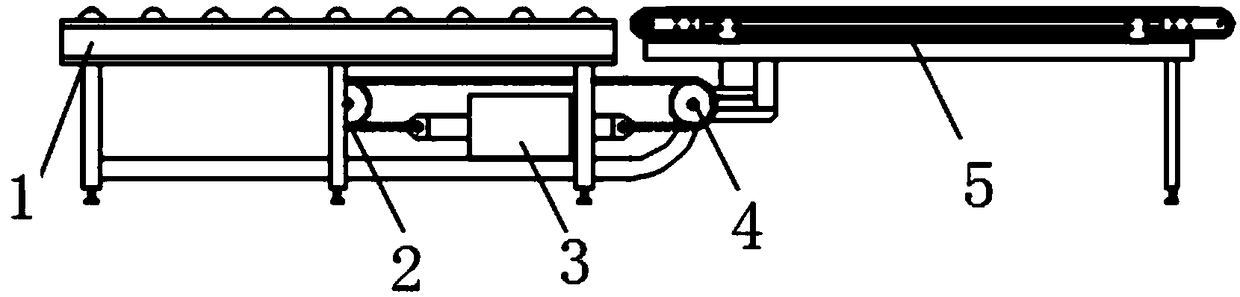

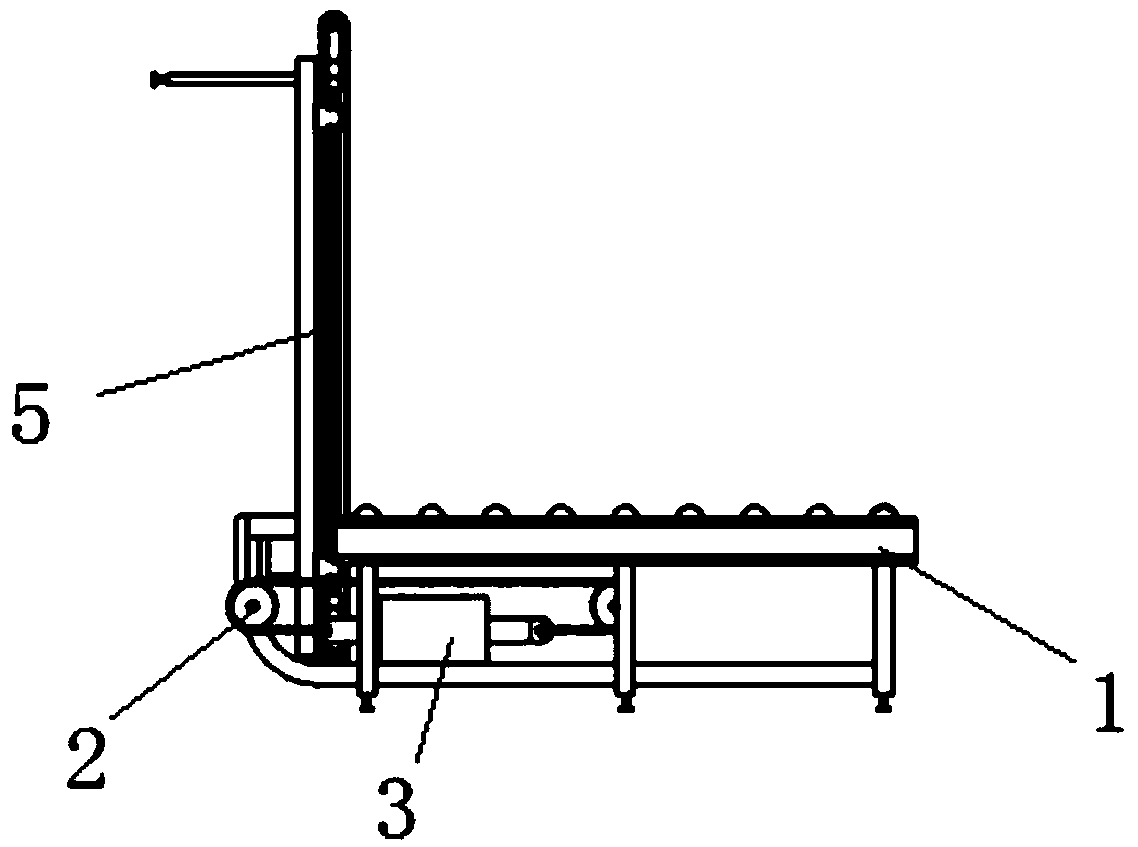

[0023] Such as figure 1 As shown, a bridge type opening and closing device for a flat glass production line includes a main conveying roller table 1, a sprocket 2, a cylinder 3, a rotating shaft 4, and a synchronous belt roller table 5.

[0024] Among them, the main conveyor roller table 1 is arranged at one end of the synchronous belt roller table 5, one end of the main conveyor roller table 1 is symmetrically provided with two support arms, and the support arms extend out of the end of the main conveyor roller table 1 and extend into the synchronous belt. In the lower part of the belt roller table 5, the rotating shaft 4 is horizontally arranged on the support arm and can be rotated freely. The bottom of the bracket of the synchronous belt roller table 5 is provided with an L-shaped bracket, and the horizontal end of the L-shaped bracket is fixedly connected with the rotating shaft 4.

[0025] The air cylinder 3 adopts a double-guide rod double-acting air cylinder. The air cylinde...

Embodiment 2

[0031] The structure of this embodiment is basically the same as that of the first embodiment, and the difference lies in the transmission mechanism, which is specifically as follows.

[0032] This embodiment adopts positive and negative motors for transmission. The motor is installed on the bracket of the main conveying roller table 1, and the end of the motor output shaft is equipped with a driving gear. The bracket of the main conveying roller table 1 is equipped with a track, which is installed in the track. There is a rack, a driven gear is installed on the rotating shaft, and the driving gear and the driven gear are matched with the rack.

[0033] The rack is provided with a stroke limit device to limit the turning angle of the synchronous belt roller table.

[0034] The starting motor rotates counterclockwise, the driving gear drives the rack to move to the right, and the rack drives the driven gear to rotate counterclockwise, thereby driving the timing belt roller to turn 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com