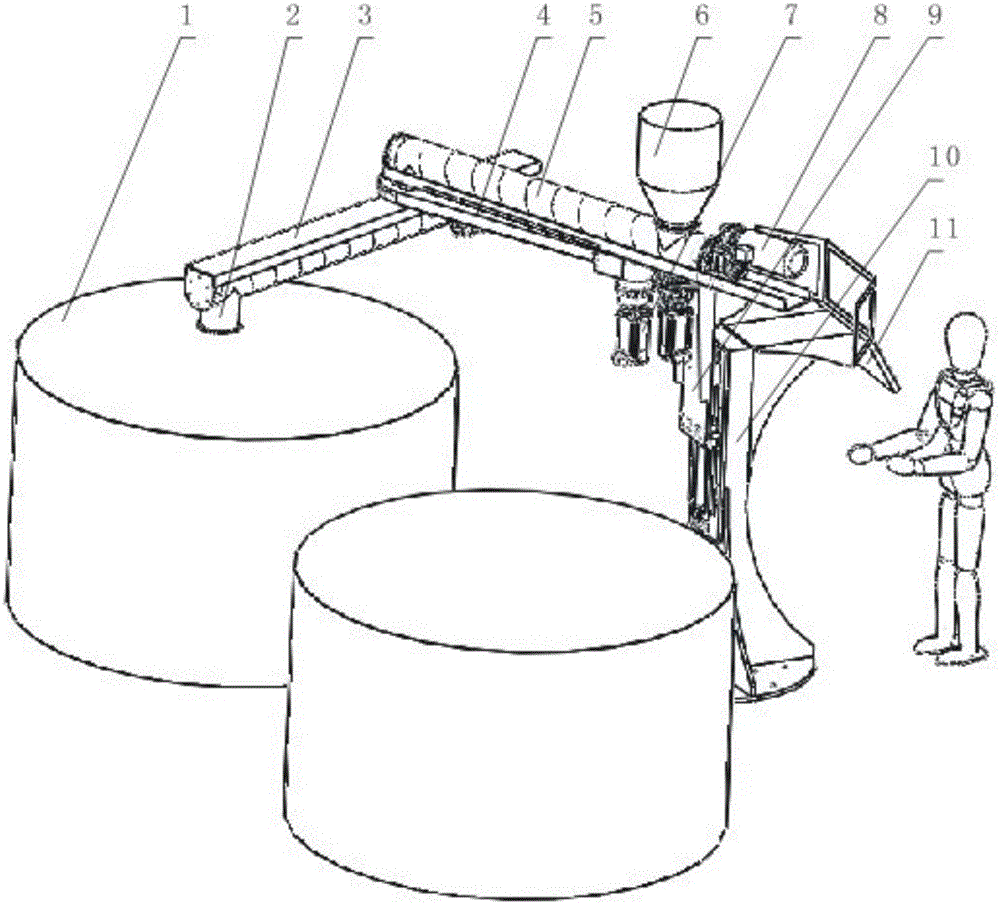

Intelligent steam stripping robot and work method thereof

A working method and robot technology, applied in the directions of loading/unloading, preparation, transportation and packaging of alcoholic beverages, can solve the problems of strong labor dependence, low production efficiency, high labor cost, and achieve good distillation effect, improve efficiency, The effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

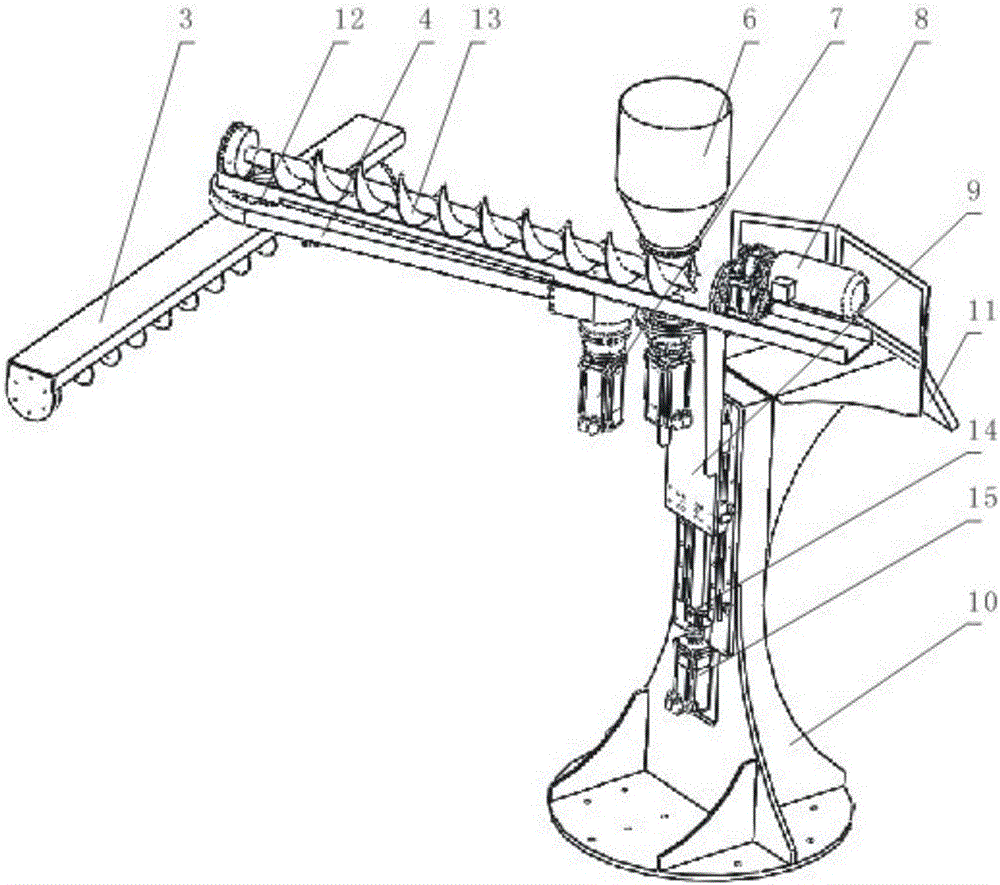

[0030] An intelligent upper-steaming robot, comprising a column 10, a rear arm beam 4, a forearm beam 3, a feeding cylinder 5 and a material spreading head 2, a column is fixed vertically on the ground outside the steaming barrel 1, and one side of the column is fixed There is a vertical track 14, on which the sliding guide is equipped with a lifting plate 9, and the lifting plate is driven by a lifting push cylinder 15 fixed on the column to move up and down along the track for adjustment;

[0031] One end of the rear arm beam 4 is hingedly mounted on the top of the lifting plate, and the other end of the rear arm beam is hinged with an end of the forearm beam 3. The motor 7 is driven to swing horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com