Numerical control pipe bending machine capable of dynamically correcting hole sites through visual inspection and pipe bending method

A dynamic correction and visual inspection technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of easy occurrence of eccentricity and inclination, circumferential position error of single hole, difficulty in pipe docking and assembly, etc., to achieve clamping The effect of large force, improving accuracy and avoiding pipe flange damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

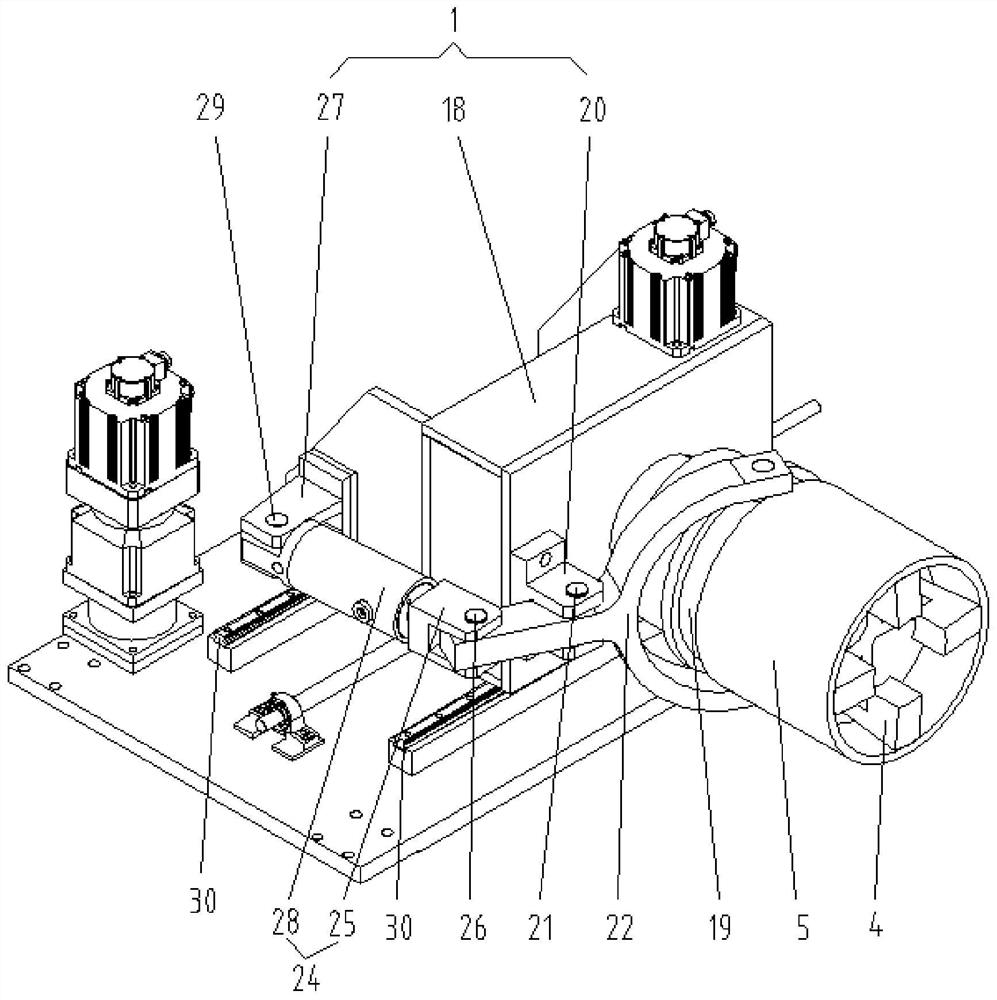

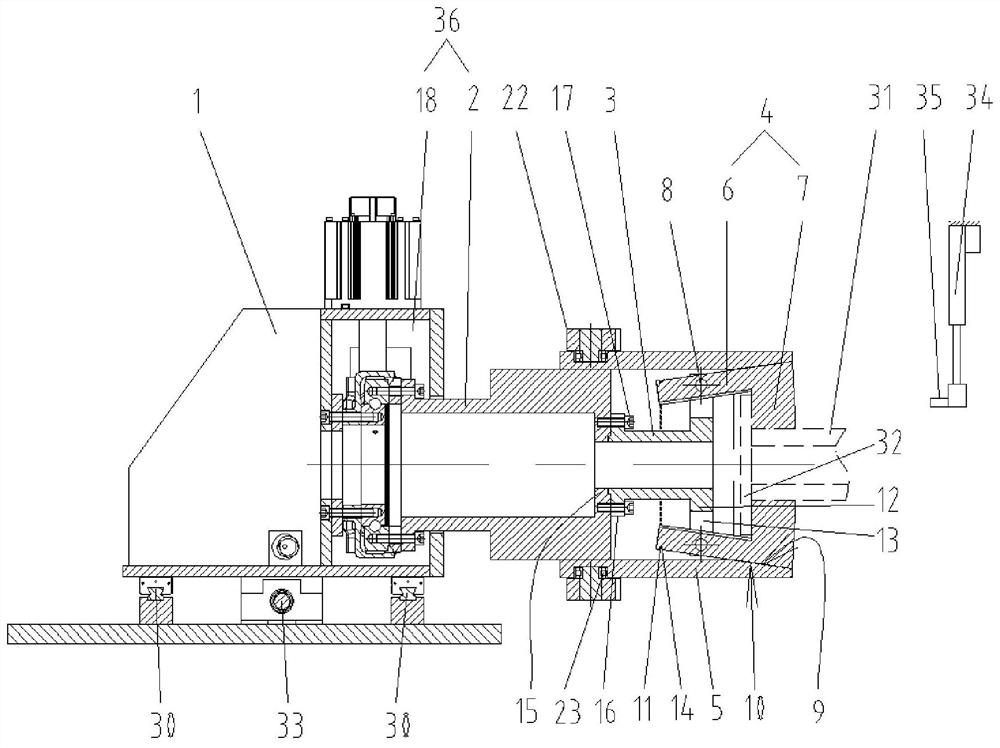

[0053] Such as Figures 1 to 4 Shown is an embodiment of a digitally controlled pipe bender of the present invention that dynamically corrects hole positions through visual inspection, including a pipe bender servo trolley 1, a trolley rotation mechanism 36 arranged on the pipe bender servo trolley 1, and a connecting The self-centering clamping mechanism 37 used to clamp the flanged pipeline on the trolley rotating mechanism 36 is arranged beside the self-centering clamping mechanism 37 for detecting the flanged pipeline A visual recognition device for flange holes; the visual recognition device includes a camera 35 and a visual recognition system connected to the camera 35, and the visual recognition system and the camera 35 are respectively connected to the control system of the numerically controlled pipe bender.

[0054] Preferably, the camera 35 is set on the lifting mechanism 34, and the lifting mechanism 34 is connected to the control system of the numerically controll...

Embodiment 2

[0056] A pipe bending method using a digitally controlled pipe bender for dynamically correcting hole positions through visual detection in Embodiment 1, comprising the following steps:

[0057] Step 1. Clamping of the flanged pipeline: the flanged pipeline 38 is clamped by the self-centering clamping mechanism 37 of the servo trolley 1 of the pipe bender;

[0058] Step 2. Dynamic correction of the initial position of the flange hole after clamping, which includes the following steps in turn:

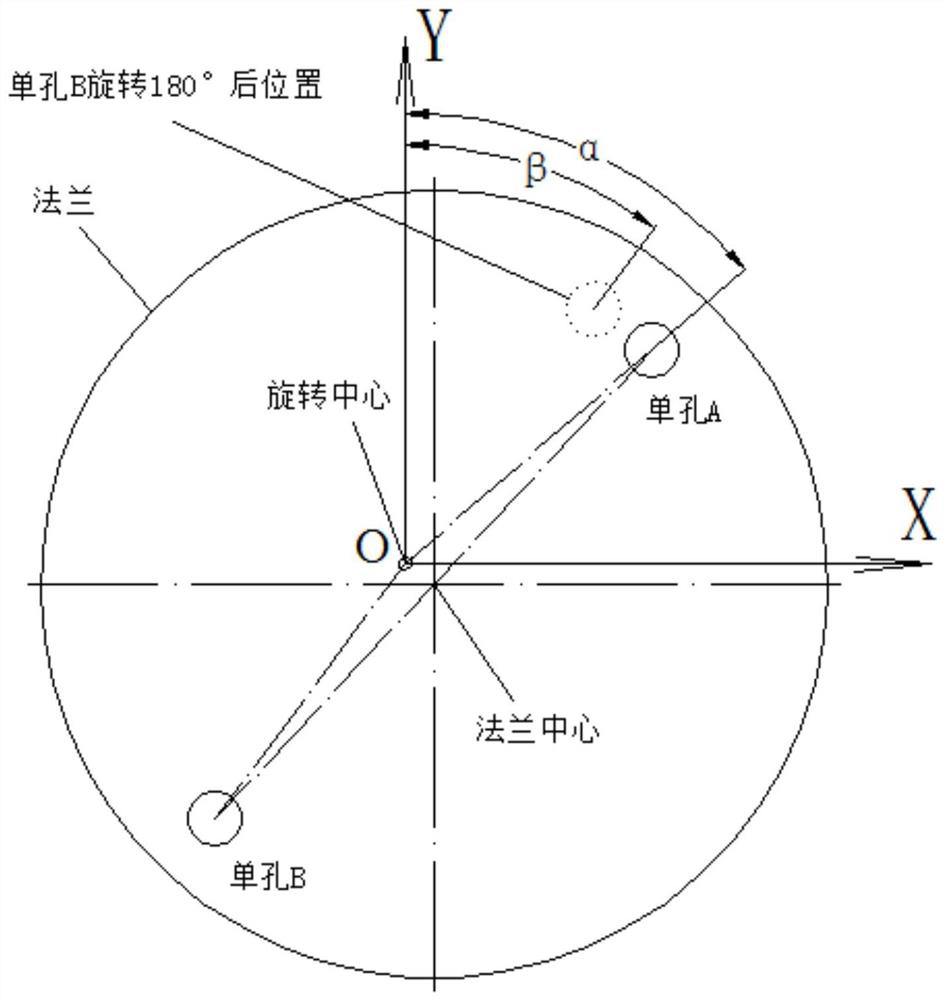

[0059] (1) Flange single hole identification: set the camera 35 coordinate system, and identify one of the single holes A and its position on the pipe flange 32 with the flanged pipeline 38 through the visual identification device;

[0060] (2) Rotation center position setting: the trolley rotation mechanism 36 rotates, drives the flanged pipeline 38 on the self-centering clamping mechanism 37 to rotate together, and rotates the single hole A on the pipe flange 32 to multiple At differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com