Corn pulverization device with thorough pulverization function

A crushing device, corn technology, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of not being able to circulate the crushing, not having a material control device, and incomplete crushing, so as to achieve safe use and avoid excessive feeding , The effect of convenient material control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

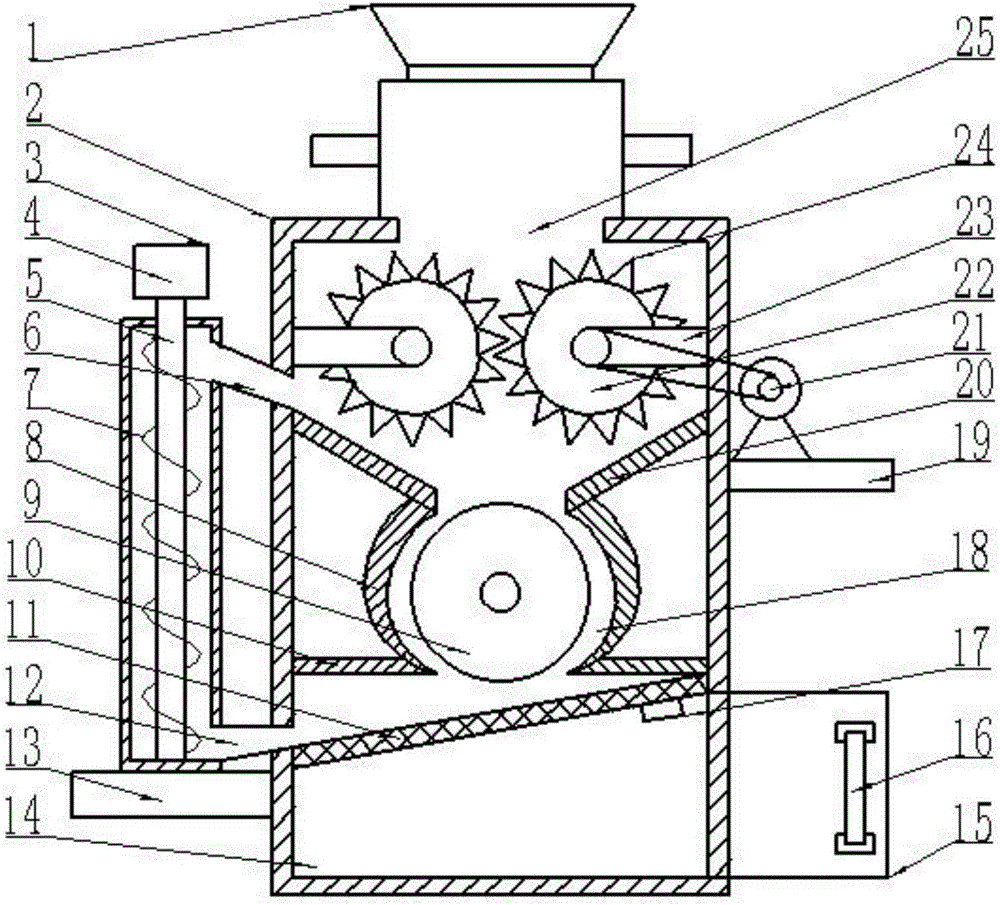

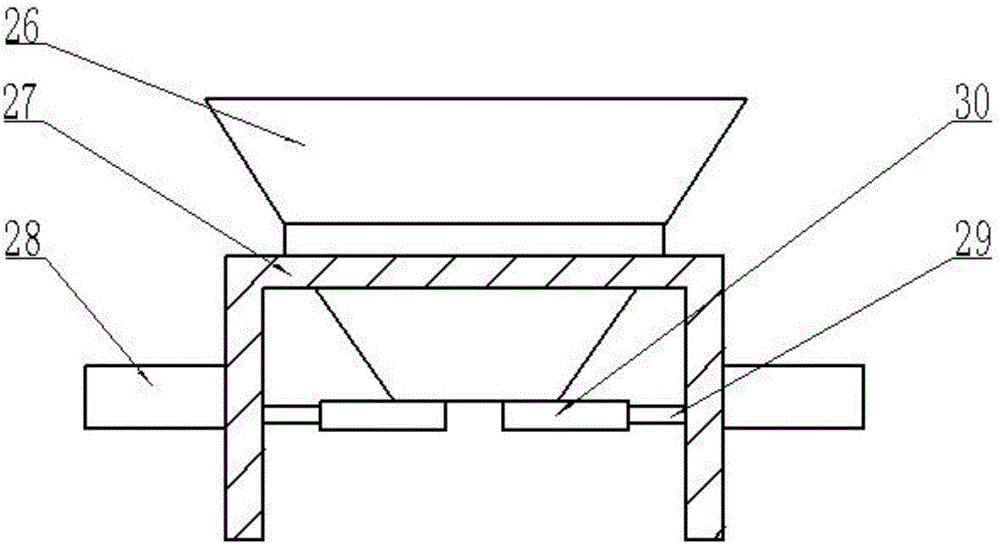

[0016] see Figure 1-2 , the present embodiment provides a corn crushing device that can be thoroughly crushed, including a material control device 1 and a casing 2; the material control device 1 includes a feed hopper 26 and a frame 27, and the material control device 1 is fixed on the casing 2 upper ends; the feed hopper 26 is arranged on the upper end of the frame 27, and the feed hopper 26 is conical; the frame 27 is provided with a cylinder 28, a telescopic shaft 29 and a block 30; the cylinder 28 is provided with Two, the telescopic shaft 29 is driven by the cylinder 28 to move telescopically; the telescopic shaft 29 is connected to the block 30 and the cylinder 28; the box 2 is provided with a screen 11, a placement plate 13, a storage bin 14, and a rolling bin 18. Motor base 19 and support rod 23; the screen 11 is set in the storage bin 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com