Four-side bending system

A four-sided, bending machine technology, applied in the field of sheet metal processing equipment, can solve the problems of inability to take into account production efficiency, product variety applicability, manufacturing cost, low manufacturing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: A four-sided bending system, the four-sided bending system is an L-type four-sided bending system, such as figure 1 As shown, it includes a first bending unit 1, a second bending unit 2 and a material transfer device 3. The first bending unit 1 is responsible for all bending processes of a group of opposite sides, and the second bending unit The bending unit 2 is responsible for all the bending processes of another group of opposite sides, and the material transfer device 3 is responsible for transferring the sheet material from the feeding station 4 to the first bending unit 1, and at the same time, the first bending unit 1. A group of parts with opposite sides folded is transferred to the second bending unit 2, and another group of parts with opposite sides folded by the second bending unit 2 is transferred to the unloading station 5. Complete the four-sided bending of the part.

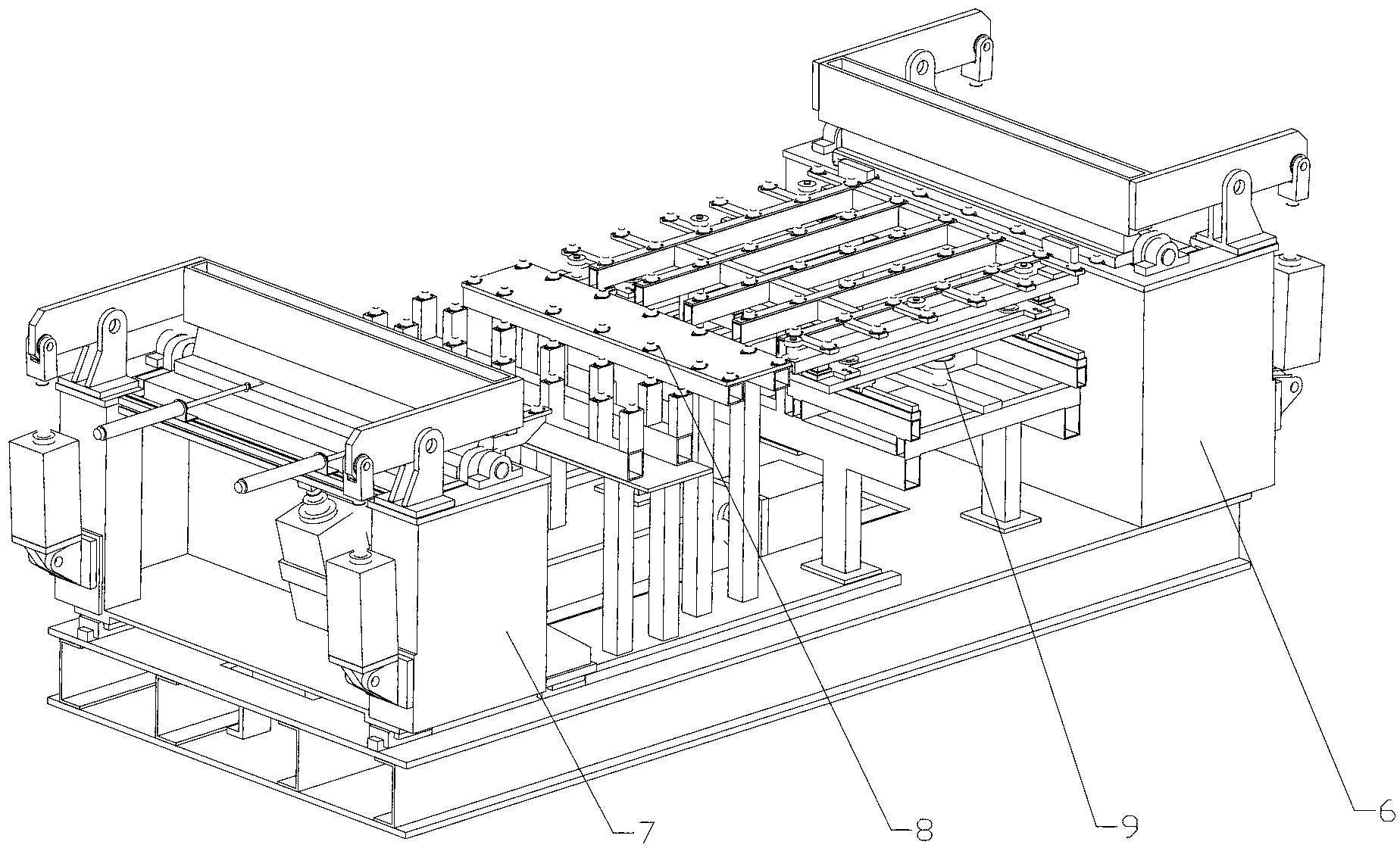

[0086] The first bending unit 1 is as image 3 , including a fixed bendi...

Embodiment 2

[0126] Embodiment 2: The four-side bending system of this embodiment adopts a straight-line four-side bending system, such as figure 2 As shown, the linear transfer device is as Figure 23 , comprising a frame 132, a loading station 133, a power unit 134, a first vacuum suction device 135, a second vacuum suction device 136, a pushing device 137 and a blanking station 138;

[0127] Described frame 132 is provided with power unit 134, the first vacuum suction device 135, the second vacuum suction device 136 and pushing device 137; Place on the workbench 8 of the first bending unit 1 from the loading station 133, while the second vacuum suction device 136 sucks up the processed sheet from the workbench 8 of the first bending unit 1 from being placed to On the workbench 50 of the second bending unit 2, at the same time, the pushing device 137 pushes the processed sheet material of the second bending unit 2 from the second bending unit 2 to the blanking station 138, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com