Automatic bending device of elevator door plates

A bending device and door panel technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, heavy quality, increased labor cost input, etc., and achieve the effect of realizing automation and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the technical solution of the present invention will be described in detail through specific examples.

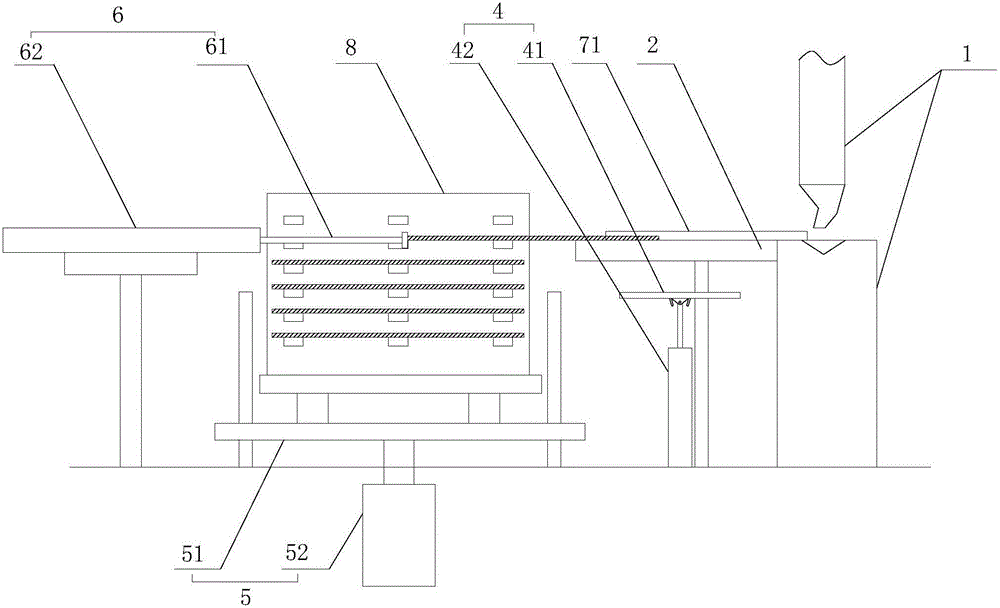

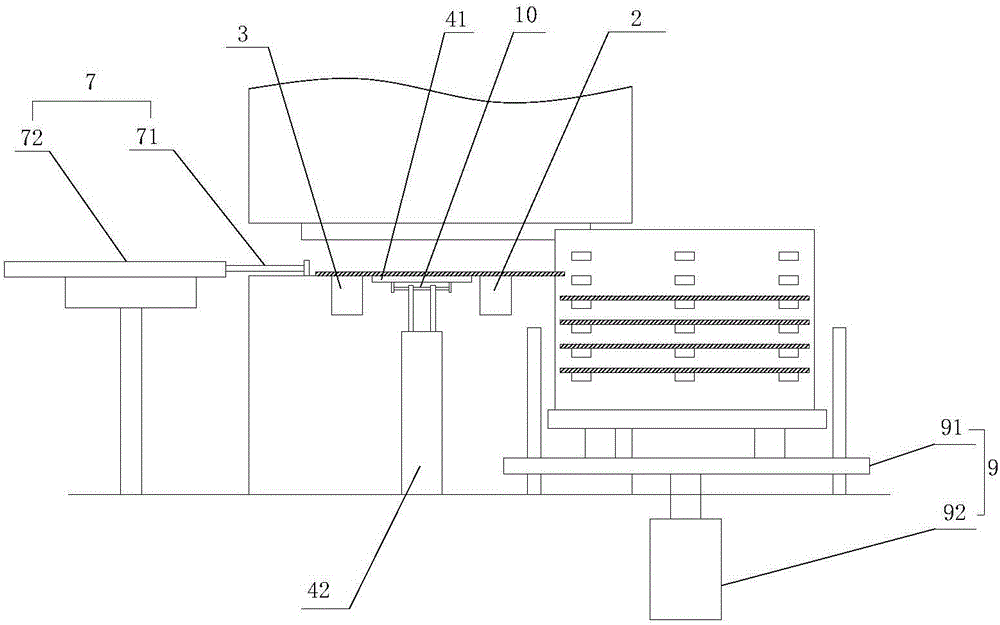

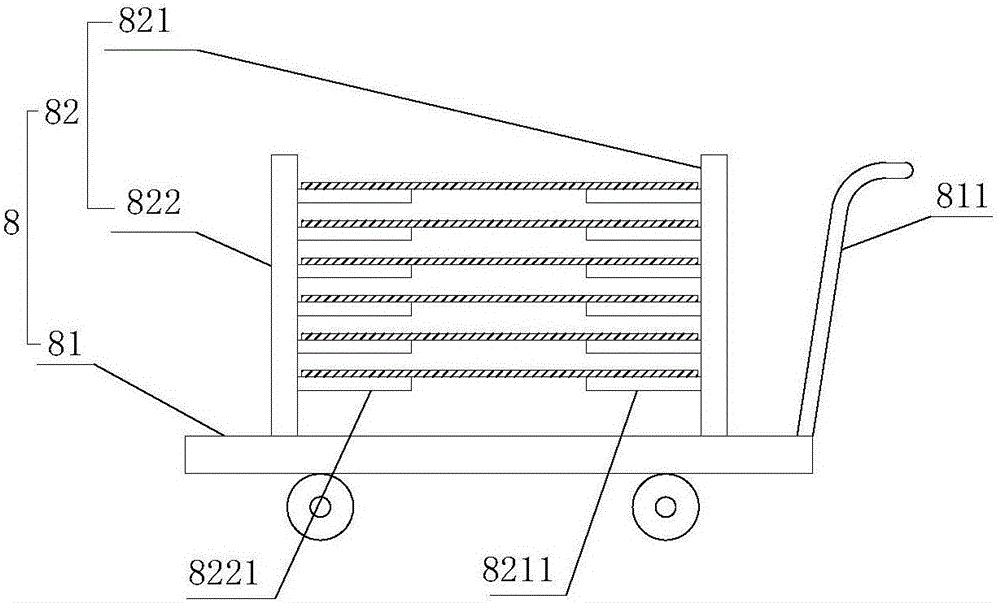

[0030] Such as Figure 1-4 as shown, figure 1 It is a structural schematic diagram of an elevator door panel automatic bending device proposed by the present invention; figure 2 It is a positional diagram of the second pushing mechanism, the first idler roller and the second idler roller in the elevator door panel automatic bending device proposed by the present invention; image 3 It is a structural schematic diagram of the material rack in an elevator door panel automatic bending device proposed by the present invention; Figure 4 It is a working schematic diagram of an elevator door panel automatic bending device proposed by the present invention.

[0031] refer to Figure 1-2 , an elevator door panel automatic bending device proposed by the embodiment of the present invention, comprising: a bending machine 1, a first idler roller 2, a second idler rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com