Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Control nitrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

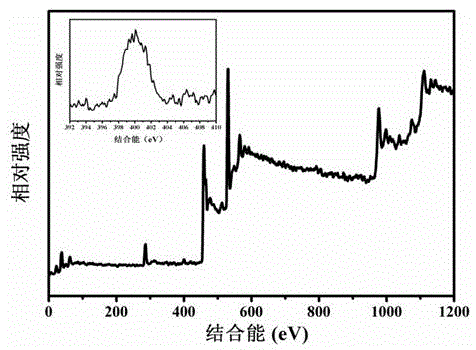

Method for preparing nitrogen-doped graphene material with hydrothermal process

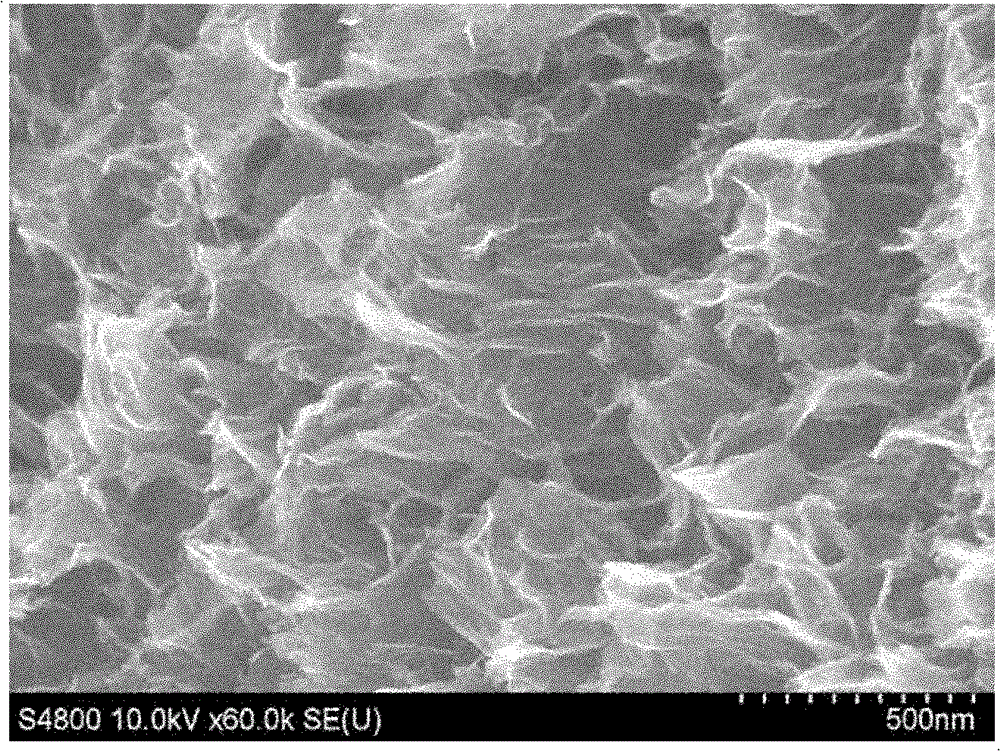

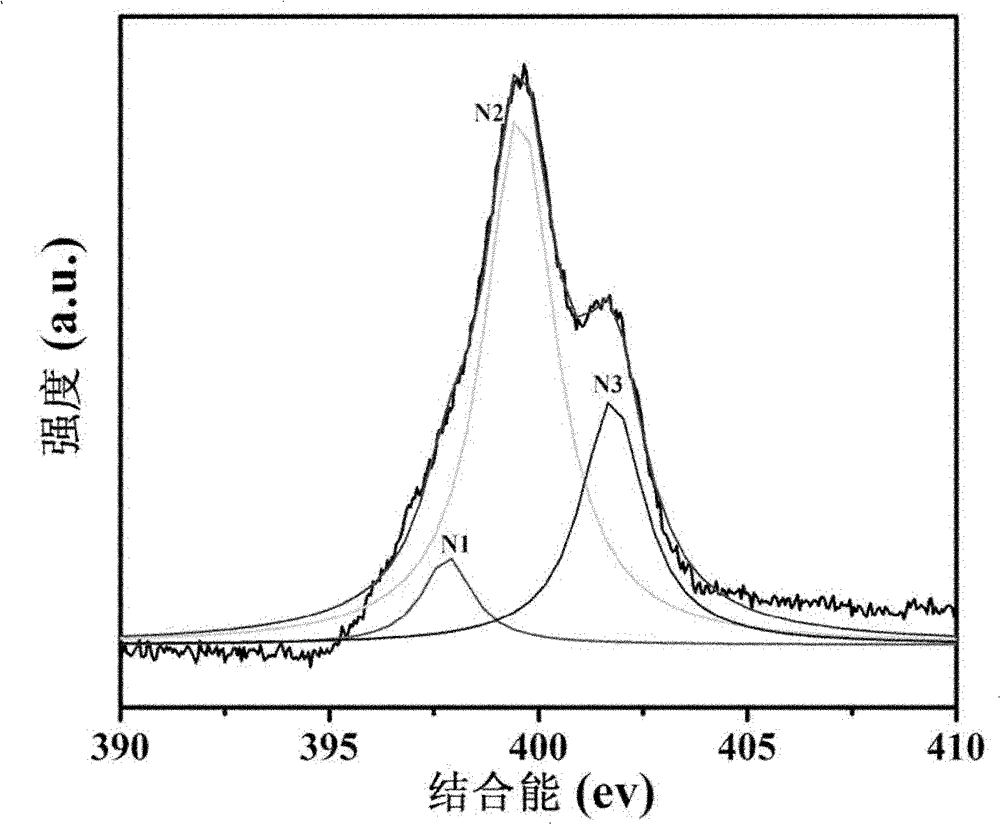

The invention discloses a method for preparing a nitrogen-doped graphene material with a hydrothermal process, relating to a method for preparing the nitrogen-doped graphene material. The technical problems of lower nitrogen content, difficulty in control of nitrogen content, high production cost, complex structure of equipment required by reaction, rigorous reaction conditions, low yield, difficulty in industrialized production and the like in the traditional method for preparing the nitrogen-doped graphene material are solved in the invention. The method comprises the steps of: 1, dissolving graphite oxide in a solvent, adding a surfactant and uniformly mixing; 2, adding a nitrogen-containing compound, and uniformly mixing; and 3, after a hydro-thermal reaction, washing and drying to obtain the nitrogen-doped graphene material. The nitrogen-doped graphene material prepared in the invention has the advantages of higher nitrogen content, controllable nitrogen content, low production cost, simple structure of required equipment, high yield and easiness in realizing industrialized production.

Owner:HEILONGJIANG UNIV

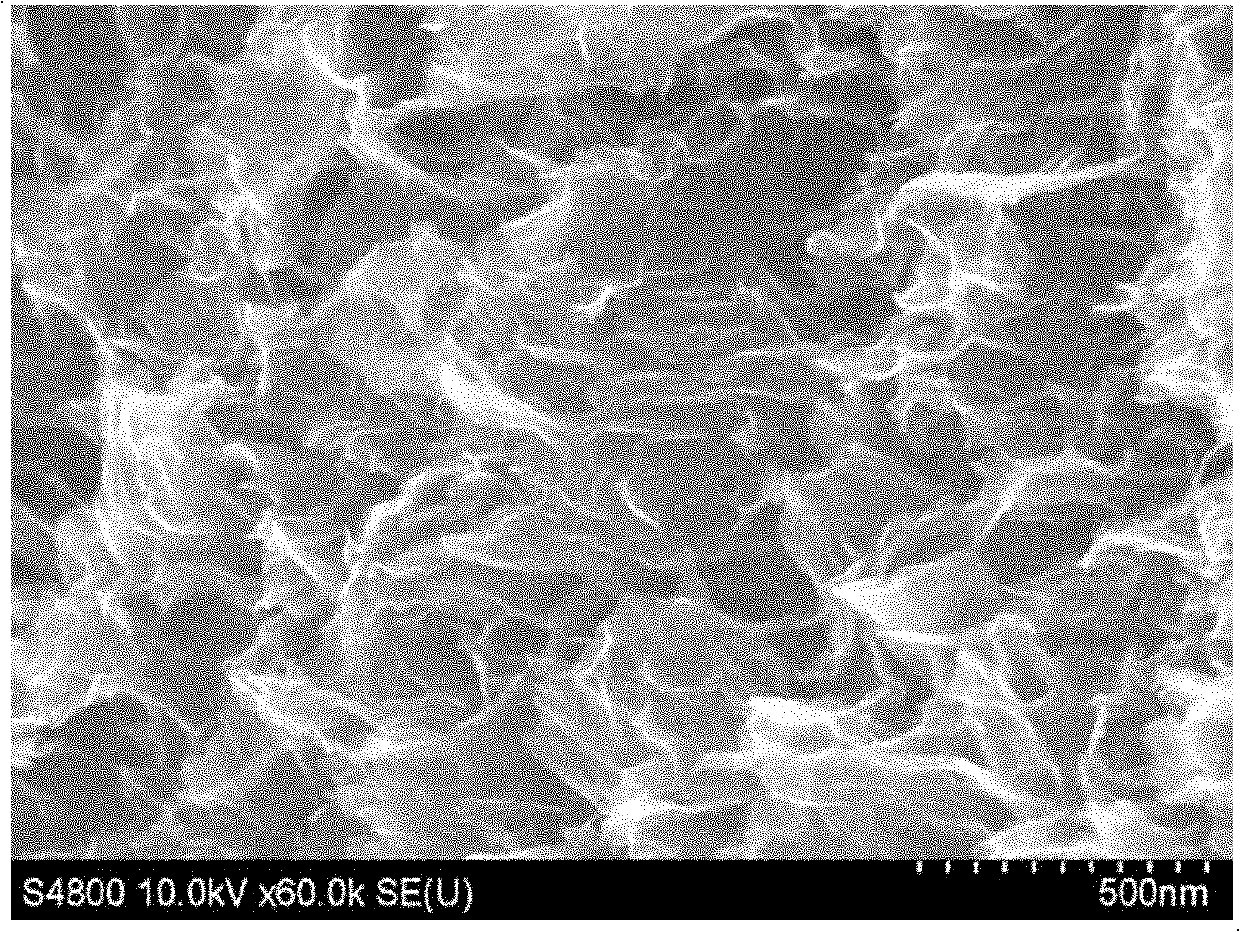

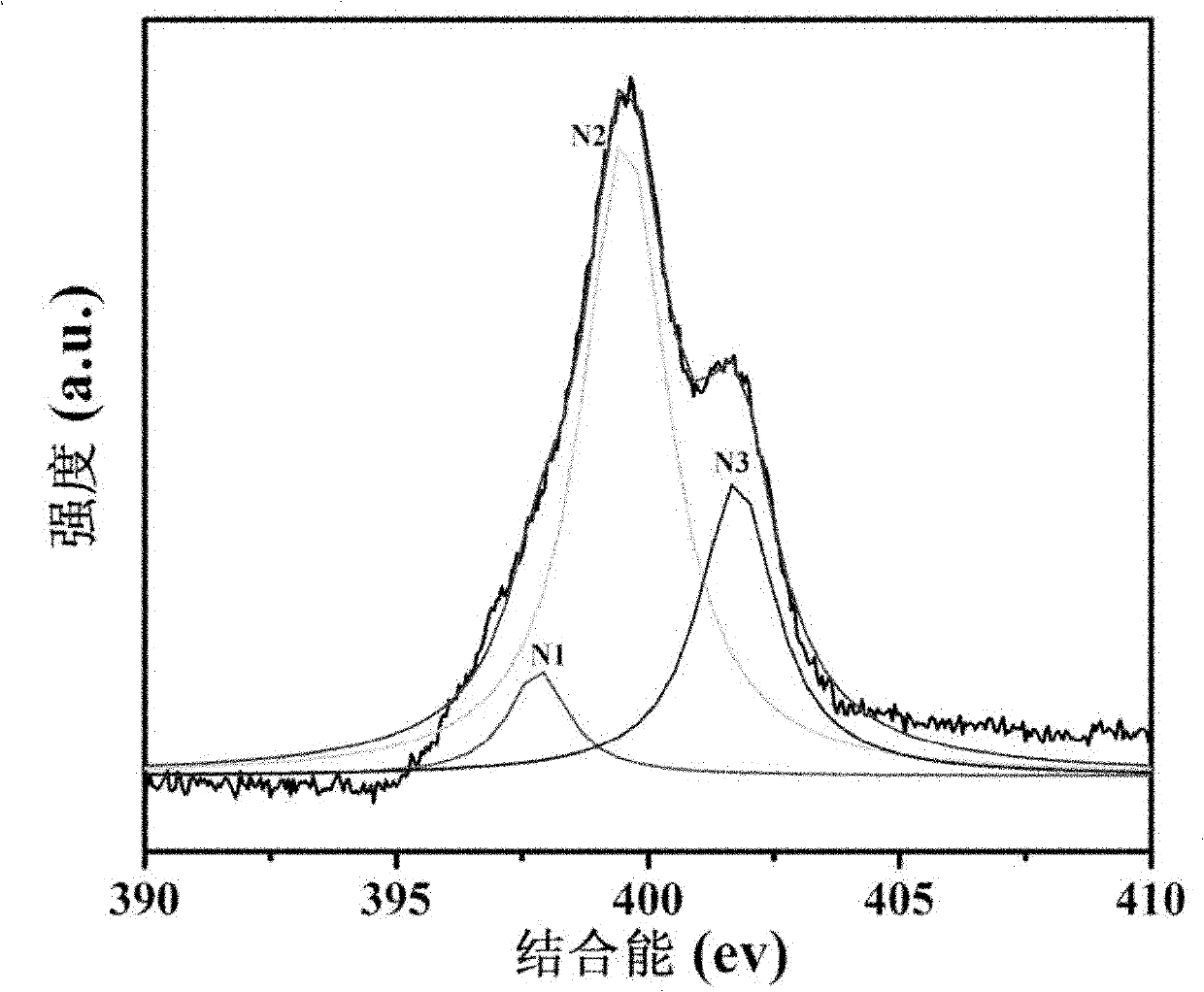

Preparation method of novel three-dimensional nitrogen doped graphene composite material system

ActiveCN105000548AEfficient preparationThe preparation process is easy to controlHybrid capacitor electrodesCell electrodesNitrogen doped grapheneBiomedicine

The invention discloses a preparation method of a novel three-dimensional nitrogen doped graphene composite material system. The method comprises the following steps: 1, uniformly dispersing graphene oxide in a solvent at room temperature, adding a selected material and a nitrogen-containing compound, and uniformly mixing to form a mixed solution; 2, reacting the mixed solution at a temperature from room temperature to 150DEG C for 0-8h; and 3, cooling the above obtained product to room temperature, centrifuging, collecting the obtained product, washing, and drying to obtain the nitrogen doped graphene composite material. The three-dimensional nitrogen doped graphene composite material system with the nitrogen content of 8-19% can be efficiently and controllably prepared through the method, and the nitrogen content of the system can be controlled by changing the kind and the amount of the added nitrogen-containing compound, the reaction temperature and the reaction time; and the method is simple, is easy to enforce, allows the yield to be greater than 98.9%, and can be widely used in fields of water treatment, biomedicines, energy generation, conversion and storage devices, electrostatic prevention, heat management, heat conduction and dissipation, sensors, electromagnetic shielding, wave absorption and catalysis.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

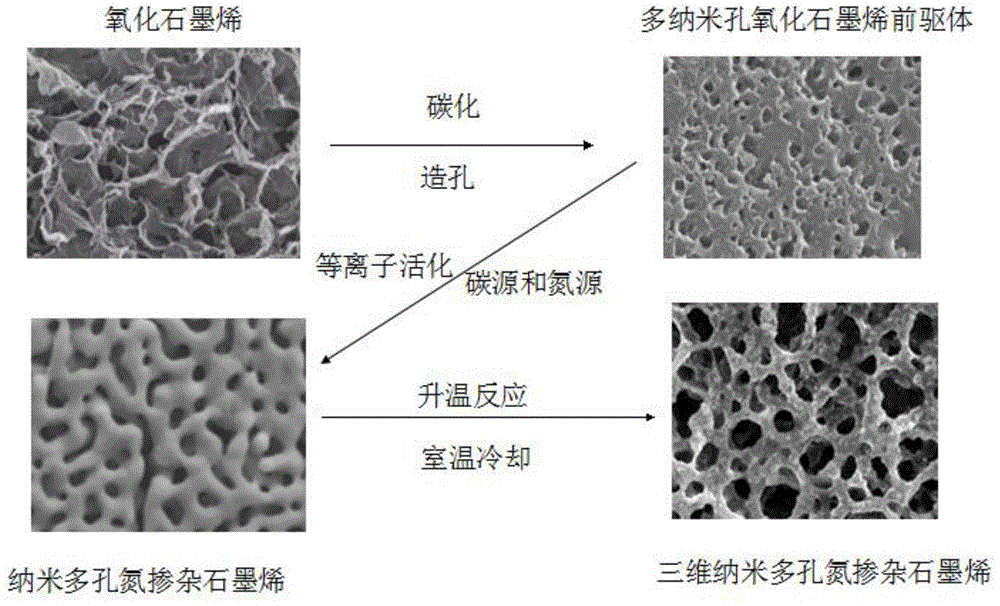

Method for growing three-dimensional nitrogen-doped graphene by taking nanoporous graphene as substrate

The invention provides a method for growing three-dimensional nitrogen-doped graphene by taking nanoporous graphene as a substrate. According to the method, oxidized graphene is taken as a precursor, a pore forming agent is added, nanometer micropores are formed in the surface of the oxidized graphene precursor through treatment, and the diameters of the pores are uniform and controllable; the precursor is combined with a silicon source and a nitrogen source through a plasma activation technology to realize the growth of porous nitrogen-doped graphene with different nitrogen contents, and a three-dimensional structure is obtained at a high temperature. According to the method, carbonized nanoporous oxidized graphene is taken as the substrate for the first time, the pore diameters of the nanometer pores of the prepared three-dimensional porous nitrogen-doped graphene are effectively controlled within 5-50 nm and are uniform, and the nanometer pores are distributed uniformly; the three-dimensional nitrogen-doped graphene with such pore diameters has more excellent electrochemical properties; since oxidized graphene is taken as the substrate, the use of a strong oxidant, which is used during an etching process when a metal substrate is used, is avoided, and the introduction of non-carbon impurity elements is also avoided, so that the nitrogen-doped graphene has higher purity.

Owner:QINGDAO UNIV

Device and method for producing synthesis gas through superheated steam, pure oxygen, high-temperature reheated pyrolyzed garbage and biomass

ActiveCN105349185AControl nitrogen contentImprove qualityEnergy inputGasification processes detailsChemistrySuperheater

The invention relates to a gas producing device, in particular to a device and method for producing synthesis gas through superheated steam, pure oxygen, high-temperature reheated pyrolyzed garbage and biomass. The device for producing the synthesis gas through the superheated steam, the pure oxygen, the high-temperature reheated pyrolyzed garbage and the biomass comprises a fluidized bed pyrolyzing furnace and a cyclone dust collector, a steam superheater is arranged on the outlet portion of the fluidized bed pyrolyzing furnace, a synthesis-gas high-temperature reheater is arranged on the rear portion of the cyclone dust collector, electric heating is adopted, and the temperature reaches up to 1200 DEG C or above. According to the device and method for producing the synthesis gas through the superheated steam, the pure oxygen, the high-temperature reheated pyrolyzed garbage and the biomass, the superheated steam is adopted to serve as part fluidizing air, a water gas reaction is fully utilized, the external oxygen supply of a reaction in the furnace is decreased, the nitrogen content in the synthesis gas is effectively controlled through the pure oxygen, the high quality of the synthesis gas is fully guaranteed, producing of tar and dioxin is thorough eradicated, and the difficult problem of garbage harmless treatment is solved.

Owner:郑必凤 +1

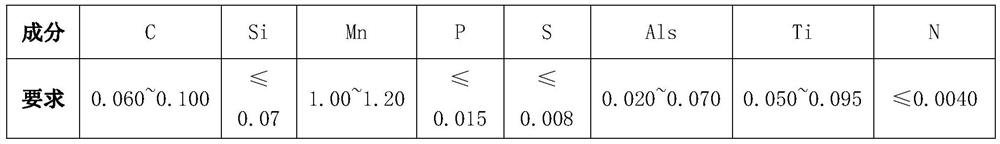

Method for controlling nitrogen content of steel grade in CV-LF-RH-CC process path

ActiveCN113403444AStable nitrogen contentBarrier contactManufacturing convertersSteelmakingRefining (metallurgy)

The invention discloses a method for controlling the nitrogen content of a steel grade in a CV-LF-RH-CC process path, and relates to the technical field of ferrous metallurgy. The method aims at achieving stable control over the nitrogen content and alloy components of the steel grade in the CV-LF-RH-CC process path. According to the method, stable control over the nitrogen content and the alloy components is achieved by strictly controlling the converter bottom blowing process, the steel tapping alloying process, the slag variety and adding amount, LF temperature rising, slagging and alloying process bottom blowing, the RH refining vacuum degree and time, the wire feeding speed, the casting process and other processes. According to the method, through strict control over the converter blowing process, the deoxidation alloying process of the primary molten steel, the LF and RH duplex refining process and the like, all alloy elements can stably reach target values, and the nitrogen content is stably controlled to be 30 ppm or below.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for controlling nitrogen content in N80 steel

ActiveCN101550473ALow costControl nitrogen contentProcess efficiency improvementQuenchingFlushing time

The invention relates to a method for controlling the nitrogen content in N80 steel. The method comprises the following steps: firstly, the LF slag smelting is stabilized and the deoxidation technology is perfected so that the weight and the components of the molten slag are controllable and the nitrogen flushing state during the process is stable; secondly, the proper nitrogen flushing flow, pressure and time are set in the VD packing process so that the nitrogen content after emptying is stable; and thirdly, the proper nitrogen flushing time, flow and pressure are set after the VD emptying so that the nitrogen content is stable and controllable. The method performs improvement to the non-quenching and tempering way, effectively controls the nitrogen content in the N80 level steel by taking measures, not only has low cost, but also effectively reduces the surface cracks of the casting billet and improves the quality of products.

Owner:ANGANG STEEL CO LTD

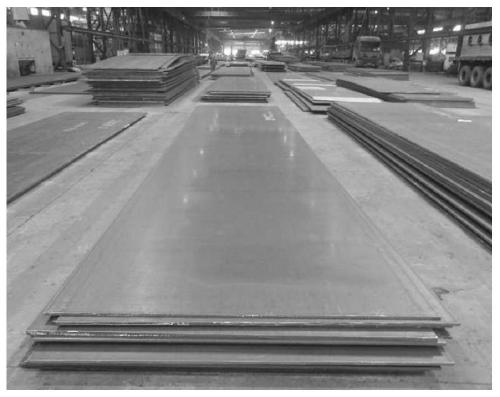

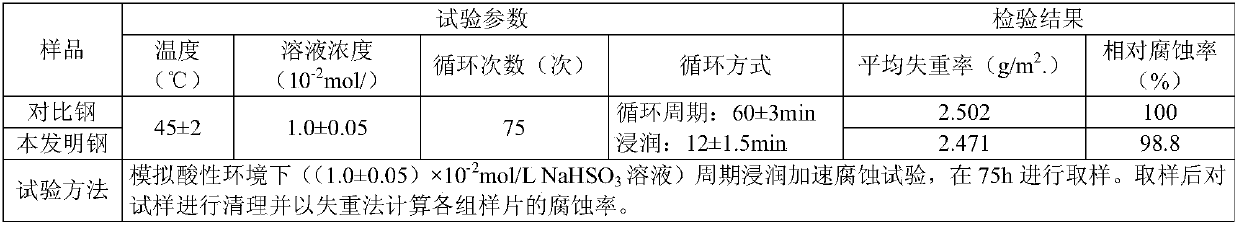

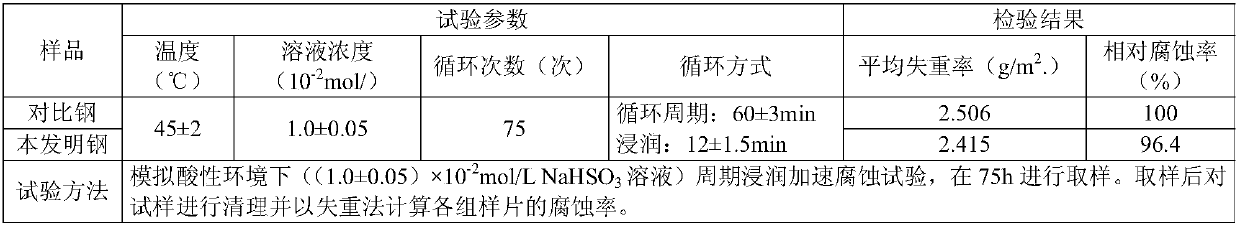

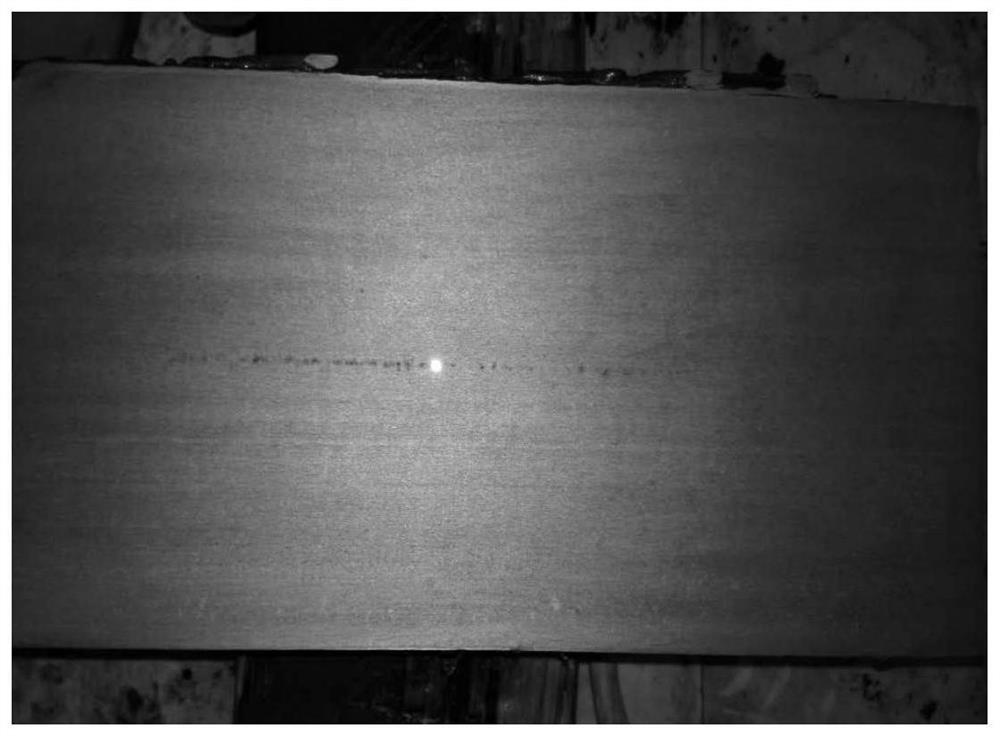

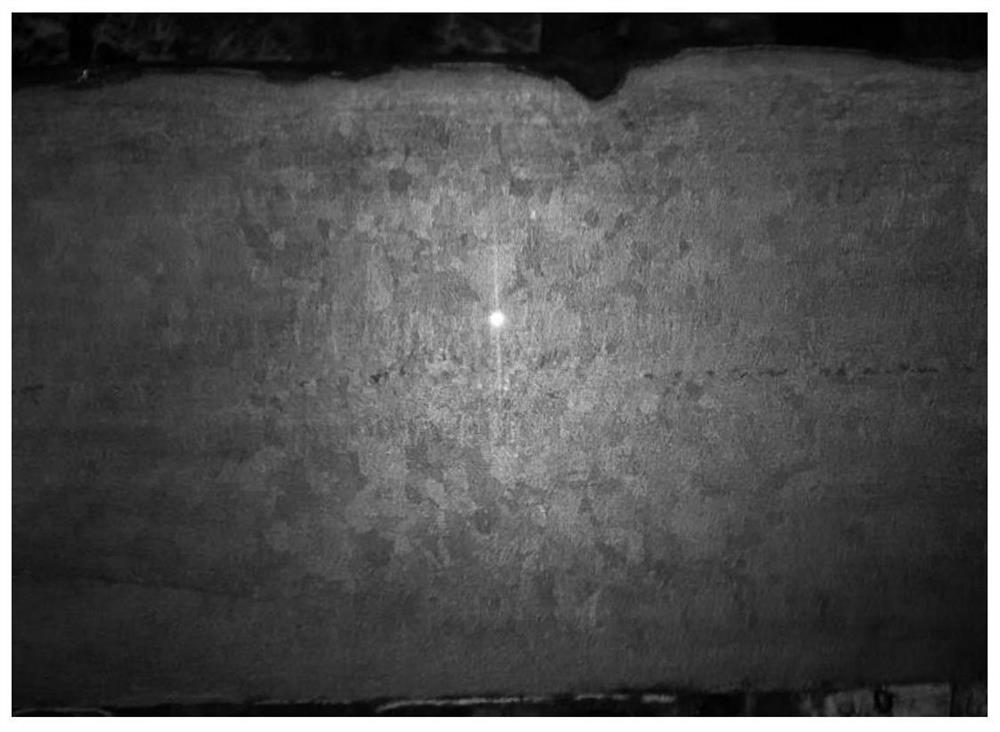

Smelting method for improving surface quality of steel plate

The invention discloses a smelting method for improving surface quality of a steel plate, and the chemical composition comprises by mass percent: 0.02%-0.60% of C, less than or qual to 0.20% of Si, 0.30%-2.20% of Mn, less than or equal to 0.030% of P, less than or equal to 0.0050% of S, less than or equal to 0.30 % of N, less than or equal to 0.070% of Nb, less than or equal to 0.50% of Cu, less than or equal to 0.0050% of N, 0.006%-0.020% of Ti, less than or equal to 0.30% of Cr, 0.015%-0.050% of Al and balance of Fe and impurities. The smelting method provided by the invention can achieve the purpose of optimizing the surface quality of a casting blank by rationally adjusting the smelting composition, high-purity steel smelting, low-oxygen nitrogen harmful element control, reasonable superheat control, covering slag selection, dynamic soft reduction adjustment and the like.

Owner:NANJING IRON & STEEL CO LTD

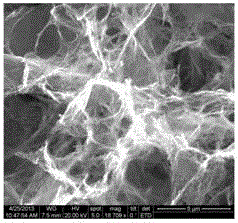

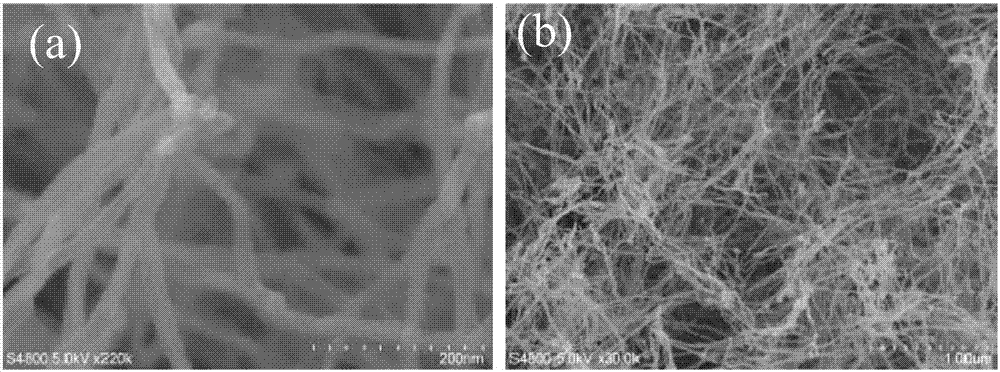

Large area nitrogen-doped carbon nano-tube paper preparation method

ActiveCN106082163AControl nitrogen contentControl mechanical strengthNanotechnologyNew energyCarbon nanotube

The invention provides a large area nitrogen-doped carbon nano-tube paper preparation method, which comprises: (1) weighing ferrocene powder, dissolving in dichlorobenzene to form a ferrocene / dichlorobenzene carbon source solution, weighing pyridine, and mixing the pyridine and the ferrocene / dichlorobenzene carbon source solution to form a ferrocene / dichlorobenzene / pyridine mixing carbon source solution; 2) coiling an iron sheet or copper sheet substrate into a cylindrical material, placing into the quartz reaction chamber of a reaction furnace, sealing the reaction chamber, introducing argon gas to completely discharge air, and heating the reaction furnace; 3) when the temperature of the reaction chamber achieves 750-900 DEG C, adjusting the argon flow rate while introducing hydrogen; 4) injecting the ferrocene / dichlorobenzene / pyridine mixing carbon source solution into the reaction chamber, and carrying out a reaction; and 5) stopping the heating of the tubular reaction furnace, closing the hydrogen, adjusting argon flow rate to make the product be cooled to a room temperature along with the furnace, and collecting the large area nitrogen-doped carbon nano-tube paper on the substrate. According to the present invention, the nitrogen-doped structure carbon nano-tube film two-dimensional structure and the simple, rapid and large-scale preparation method can be used for the fields of new energy sources, sensors, flexible electronic devices, and the like.

Owner:SUN YAT SEN UNIV

Smelting method for improving heavy rail steel cleanliness

InactiveCN108796173AImprove cleanlinessImprove fatigue performanceManufacturing convertersProcess efficiency improvementHigh magnesiumSocial benefits

The invention discloses a smelting method for improving the heavy rail steel cleanliness, and belongs to the technical field of iron and steel metallurgy. The invention solves the technical problem that the existing domestic heavy rail steel cleanliness is hard to meet the requirement of high-speed railways. The method comprises the steps of pretreating hot metal, smelting through a converter, LFrefining, RH refining and continuous casting, wherein during the process of smelting through the converter, hot metal is blown by adopting a double slag process, and the dosage of active lime of a first-time slag making material is 5 to 20kg / t of hot metal; the dosage of quartz sand is 5 to 10kg / t of hot metal; the dosage of high-magnesium lime is 5 to 10kg / t of hot metal; the dosage of active lime of a second-time slag making material is 5 to 10kg / t of hot metal; the dosage of quartz sand is 5 to 10kg / t of hot metal; and the dosage of high-magnesium lime is 5 to 10kg / t of hot metal. Accordingto the method provided by the invention, the (P+S+O+N+H) can be controlled to be less than or equal to 160ppm, the various grades of the occluded foreign substances are less than or equal to 1.0 grades, the heavy rail steel cleanliness is remarkably improved, and a certain social benefit is achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing nitrogen-doped graphene material with hydrothermal process

The invention discloses a method for preparing a nitrogen-doped graphene material with a hydrothermal process, relating to a method for preparing the nitrogen-doped graphene material. The technical problems of lower nitrogen content, difficulty in control of nitrogen content, high production cost, complex structure of equipment required by reaction, rigorous reaction conditions, low yield, difficulty in industrialized production and the like in the traditional method for preparing the nitrogen-doped graphene material are solved in the invention. The method comprises the steps of: 1, dissolving graphite oxide in a solvent, adding a surfactant and uniformly mixing; 2, adding a nitrogen-containing compound, and uniformly mixing; and 3, after a hydro-thermal reaction, washing and drying to obtain the nitrogen-doped graphene material. The nitrogen-doped graphene material prepared in the invention has the advantages of higher nitrogen content, controllable nitrogen content, low production cost, simple structure of required equipment, high yield and easiness in realizing industrialized production.

Owner:HEILONGJIANG UNIV

V and Cr containing microalloy building steel wire rod and production method thereof

The invention belongs to the field of ferrous metallurgy, and particularly relates to a V and Cr containing microalloy building steel wire rod and a production method thereof. The V and Cr containingmicroalloy building steel wire rod and the production method thereof are provided according to the problems that vanadium nitride alloys selected for preparing nitrogen containing alloy steel in the prior art are low in nitrogen content, few in kind and the like. The steel wire rod comprises, by weight percent, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, not larger than 0.040% of P, not larger than 0.040% of S, 0.010%-0.160% of V, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparation method of the steel wire rod is characterized in that an N containing cored wire is fed into a furnace rear small platform, and N is adjusted to the proper level. The method is simple in operation, the nitrogen yield is high and stable, the productioncost can be effectively reduced, and the method is worthy of use and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Microalloy building steel wire rod containing V, Ti and Cr and production method of microalloy building steel wire rod

The invention belongs to the field of steel metallurgy and particularly relates to a microalloy building steel wire rod containing V, Ti and Cr and a production method of the microalloy building steelwire rod. The microalloy building steel wire rod containing V, Ti and Cr and the production method of the microalloy building steel wire rod are provided for solving the problems that vanadium nitride alloys are adopted for preparing nitrogen-containing alloy steel at present, the nitrogen content is low, and kinds are few. The steel wire rod includes, by weight, 0.15%-0.30% of C, 0.30%-1.00% ofSi, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, smaller than or equal to 0.040% of P, smaller than or equal to 0.040% of S, 0.010%-0.100% of V, 0.010%-0.030% of Ti, 0.10%-0.60% of Cr and the balance Fe and inevitable impurities. The preparing method of the microalloy building steel wire rod containing V, Ti and Cr is characterized in that N-containing core spun yarn is fed into a small platform behind a furnace, and N is adjusted to the proper level. The method is easy to operate, the nitrogen yield is high and stable, the production cost can also be effectively reduced, and the method is worthyof application and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for remelting high-strength stainless steel

InactiveCN103484746AAddressing Insufficient Nitrogen Content for Recycling and RemeltingControl nitrogen contentProcess efficiency improvementAustenitic stainless steelMelt temperature

The invention relates to a method for remelting high-strength stainless steel. The method is characterized by including the steps that Fe-Mn-Cr nitrogen absorption alloy melt containing manganese and chromium is first smelted, then, high-nitrogen steel waste material is added to the nitrogen absorption alloy melt step by step at low melt temperature, nitrogen-containing alloy is added in proportion according to the designed composition proportion of high-nitrogen steel, and after being completely melted and homogenized, the nitrogen-containing alloy is discharged for pouring. The method solves the problem that the nitrogen content is insufficient in the recovering and remelting processes of the high-nitrogen steel waste material and can control the nitrogen content of new high-nitrogen steel smelted by the high-nitrogen steel waste material to be close to or not lower than that of the original high-nitrogen steel waste material.

Owner:CHANGCHUN UNIV OF TECH

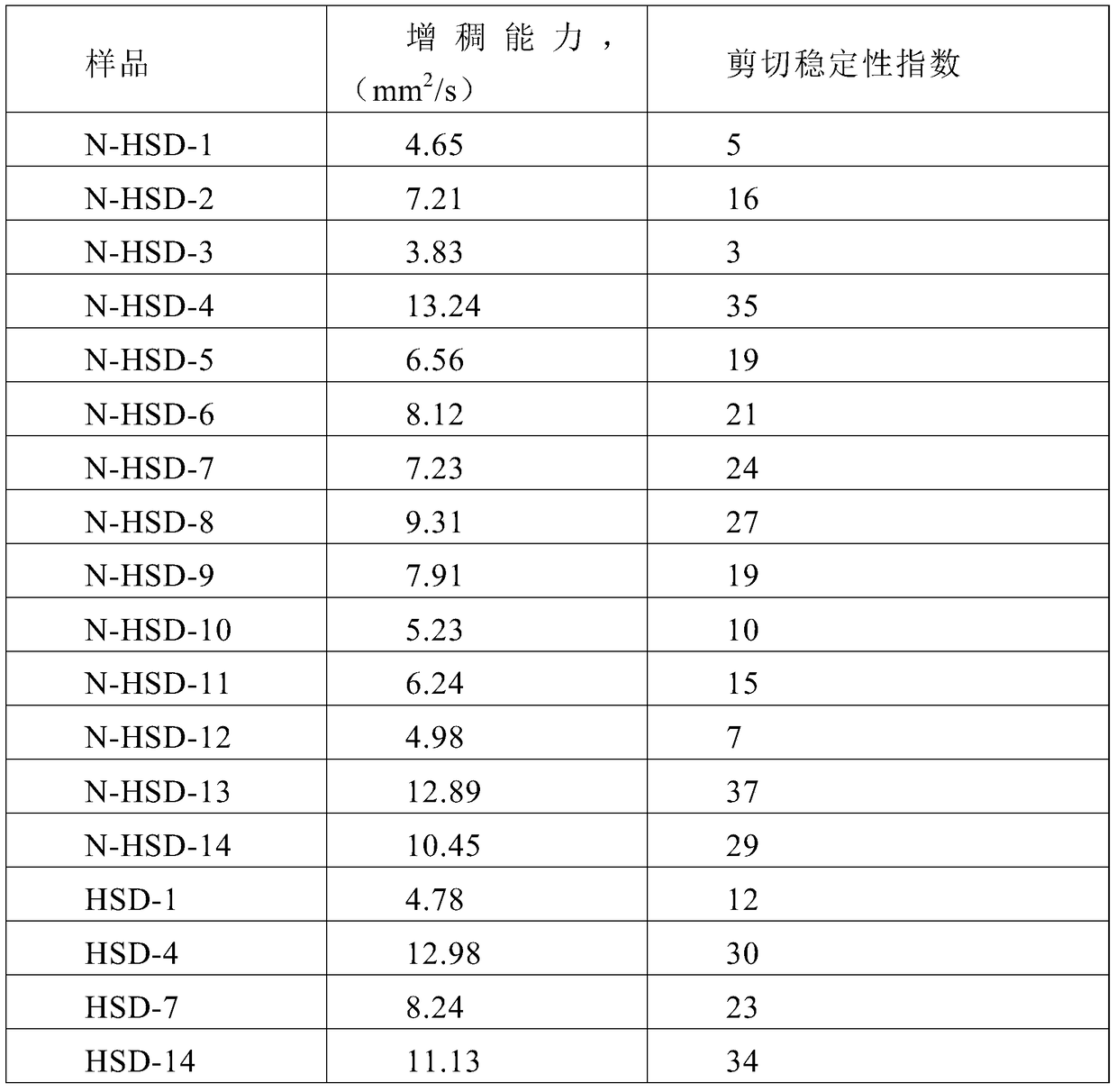

A kind of hydrogenated styrene diene copolymer viscosity index improver and preparation method thereof

ActiveCN106336490BGood thickening effectImprove antioxidant capacityAdditivesPolymer scienceDivinylbenzene

Owner:PETROCHINA CO LTD

Water quality improver for aquaculture and preparation method of water quality improver

InactiveCN107445309AImprove conversion rateStabilized Nitrite ContentWater treatment parameter controlWater/sewage treatment by irradiationOysterWater quality

The invention relates to a water quality improver and in particular to the water quality improver for aquaculture and a preparation method of the water quality improver. The quality improver is prepared from the following raw materials in parts by weight: 20 to 30 parts of bacillus subtilis, 20 to 30 parts of rhodobacter sphaeroides, 4 to 8 parts of liquid ozone, 3 to 7 parts of titanium dioxide powder, 5 to 9 parts of phosphoric acid, 1 to 5 parts of magnesium oxide powder, 2 to 6 parts of potassium chloride powder, 1 to 4 parts of vitamin and 3 to 7 parts of oyster shell powder. By using the technical scheme provided by the invention, the defects of incompletely removing ammonia nitrogen, hydrogen sulfide and nitrite in wastewater in the improver provided by the prior art can be made up to a certain degree.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

Preparation method of a novel three-dimensional nitrogen-doped graphene composite material system

ActiveCN105000548BControllable nitrogen contentControl nitrogen contentCell electrodesGrapheneDoped grapheneReaction temperature

The invention discloses a preparation method of a novel three-dimensional nitrogen doped graphene composite material system. The method comprises the following steps: 1, uniformly dispersing graphene oxide in a solvent at room temperature, adding a selected material and a nitrogen-containing compound, and uniformly mixing to form a mixed solution; 2, reacting the mixed solution at a temperature from room temperature to 150DEG C for 0-8h; and 3, cooling the above obtained product to room temperature, centrifuging, collecting the obtained product, washing, and drying to obtain the nitrogen doped graphene composite material. The three-dimensional nitrogen doped graphene composite material system with the nitrogen content of 8-19% can be efficiently and controllably prepared through the method, and the nitrogen content of the system can be controlled by changing the kind and the amount of the added nitrogen-containing compound, the reaction temperature and the reaction time; and the method is simple, is easy to enforce, allows the yield to be greater than 98.9%, and can be widely used in fields of water treatment, biomedicines, energy generation, conversion and storage devices, electrostatic prevention, heat management, heat conduction and dissipation, sensors, electromagnetic shielding, wave absorption and catalysis.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

LF furnace nitrogen-control refining method

InactiveCN109338032AHarm reductionControl nitrogen contentProcess efficiency improvementSlagNitrogen

The invention discloses an LF furnace nitrogen-control refining method. The method comprises the steps that firstly, slag is melted, specifically, slag is melted rapidly through short arc and high power; and secondly, temperature is rapidly increased, specifically, after slag is melted, arc is lengthened properly, and input power is increased. Through the LF furnace nitrogen-control refining method, the nitrogen content in steel can be effectively controlled, and the deep drawing performance of the steel is ensured.

Owner:WUHU XINXING DUCTILE IRON PIPES

Smelting method for improving heavy rail steel cleanliness

InactiveCN108754073AImprove cleanlinessImprove fatigue performanceManufacturing convertersSocial benefitsMolten steel

The invention discloses a smelting method for improving heavy rail steel cleanliness, and belongs to the technical field of iron and steel metallurgy. According to the smelting method for improving the heavy rail steel cleanliness, the technical problem that cleanliness of existing domestic heavy rail steel can difficultly meet the requirements of high-speed railways is solved. The smelting methodcomprises the steps of molten iron pretreatment, converter smelting, LF refining, RH refining and continuous casting, wherein calcium treatment is carried out by adopting an iron and calcium line with molten steel of 12-15 m / t in the step of LF refining. According to the smelting method for improving the heavy rail steel cleanliness, it is ensured that P is less than or equal to 0.0060%, S is less than or equal to 0.0030%, O is less than or equal to 0.0010%, N is less than or equal to 0.0050%, H is less than or equal to 0.00015%, the total amount of P and S and O and N and H is less than or equal to 160ppm, and various ratings of inclusions are less than or equal to 1.0 level in a steel rail, so that the heavy rail steel cleanliness is significantly improved, and the smelting method for improving the heavy rail steel cleanliness has certain social benefits and is worth popularizing and applying.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

V-containing microalloy building steel wire rod and LF furnace production method thereof

The invention belongs to the field of steel metallurgy and particularly relates to a V-containing microalloy building steel wire rod and an LF furnace production method of the V-containing microalloybuilding steel wire rod. The V-containing microalloy building steel wire rod and the LF furnace production method of the V-containing microalloy building steel wire rod are provided for solving the problems that vanadium nitride alloys are adopted for preparing nitrogen-containing alloy steel at present, the nitrogen content is low, and kinds are few. The steel wire rod includes, by weight, 0.15%-0.30% of C, 0.30%-1.00% of Si, 0.60%-1.30% of Mn, 0.0060%-0.0180% of N, smaller than or equal to 0.040% of P, smaller than or equal to 0.040% of S, 0.010%-0.160% of V and the balance Fe and inevitableimpurities. The preparing method of the V-containing microalloy building steel wire rod is characterized in that N-containing core spun yarn is fed into a LF furnace, and N is adjusted to the properlevel. The method is easy to operate, the nitrogen yield is high and stable, the production cost can also be effectively reduced, and the method is worthy of application and popularization.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

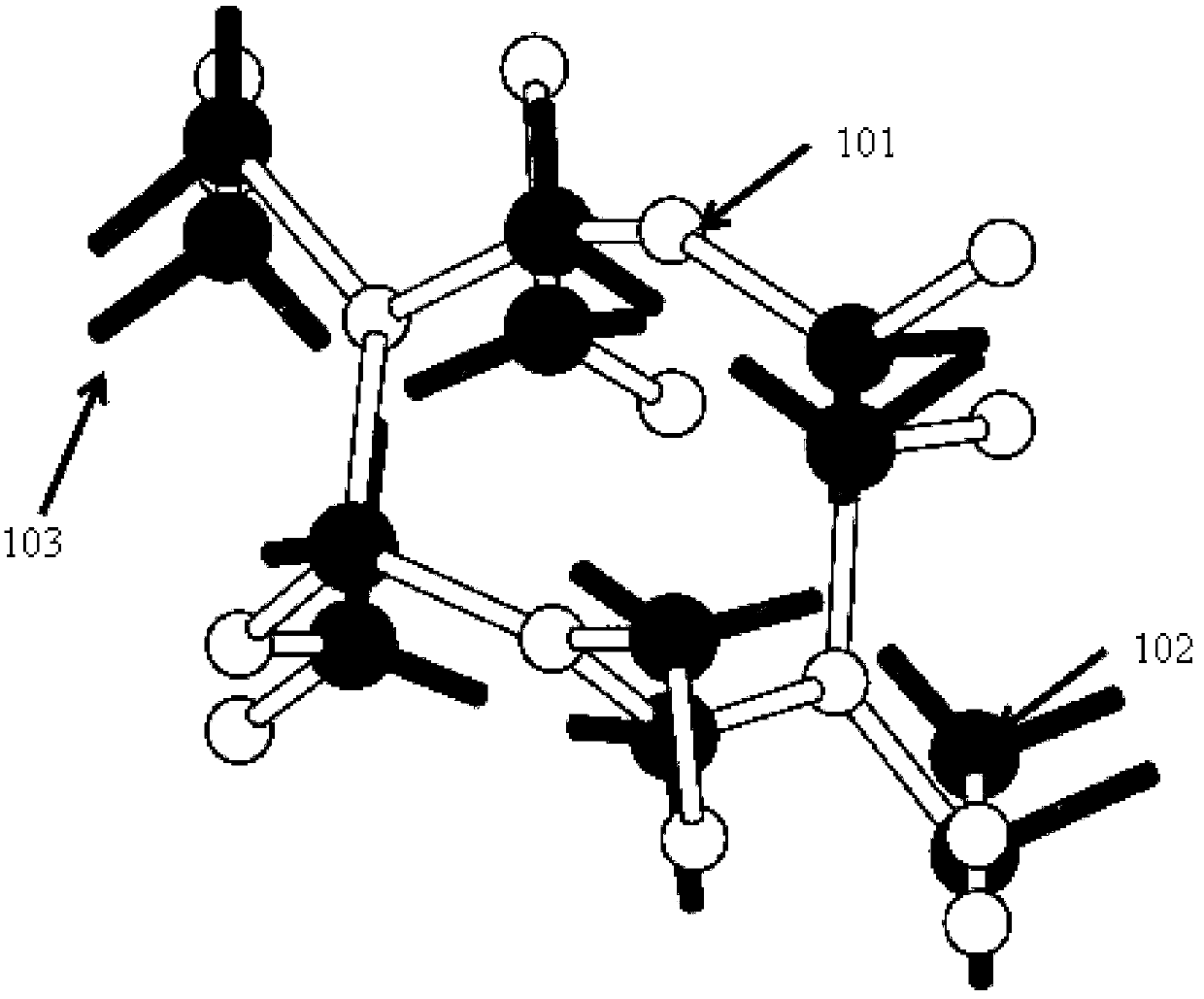

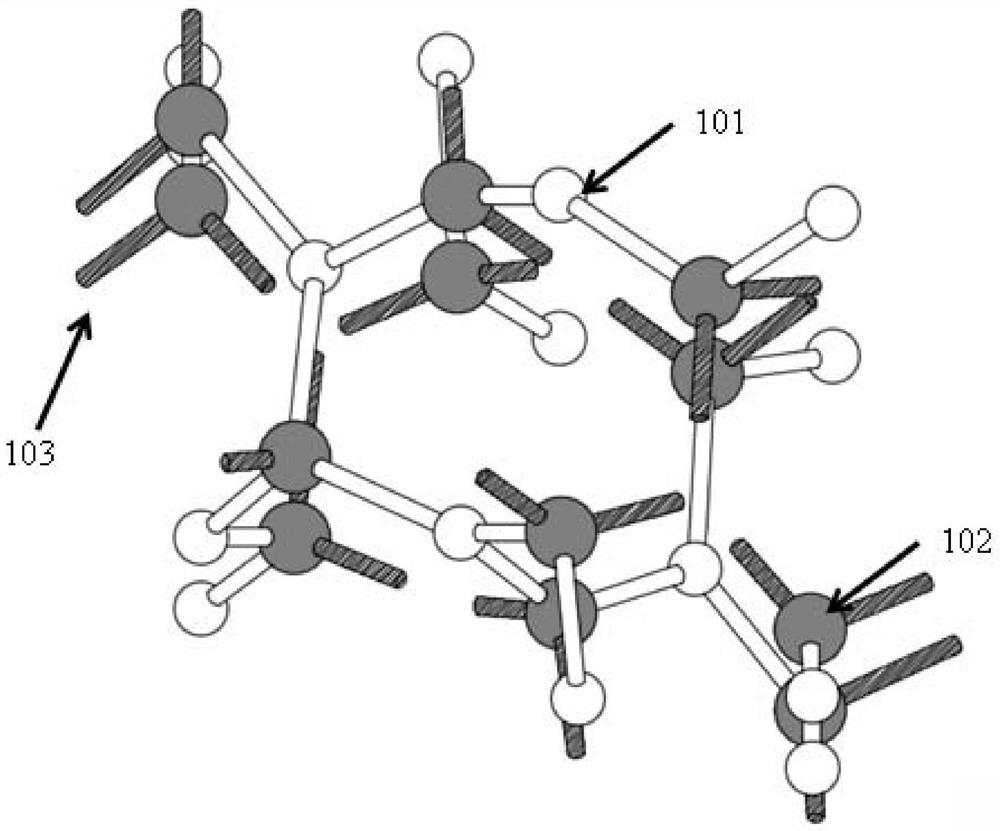

Lithium ion battery negative electrode material

ActiveCN109698327AHigh activityIncrease capacityCell electrodesSecondary cellsLow nitrogenElectric capacity

The invention provides a lithium ion battery negative electrode material. The negative electrode material includes a silicon nitride structure taking beta phase silicon nitride as a main body, and thesilicon nitride includes more than 50 wt% of the beta phase silicon nitride; the beta phase silicon nitride is a layered hexagonal system structure; the easy embedding and embedded of lithium ions can be achieved because of layered characteristics, so that a lithium dendrites structure generated by the unfavorable embedded of the lithium ions can be reduced, and as the size of the structure is stable during charging and discharging, the recession of electric capacity caused by the breaking and disintegrating of the material can be greatly reduced, so that the cycle life of the negative electrode material can be enhanced. The chemical formula of the disclosed beta phase silicon nitride is beta-Si3Nx, wherein 1 <= x <= 4; and the beta phase silicon nitride (beta-Si3Nx) can have unstable dangling bonds, unsaturated bonds and other unpaired bonds due to low nitrogen atom weight percentage, so that the activity and electric capacity of the negative electrode material can be enhanced.

Owner:SUPER ENERGY MATERIALS

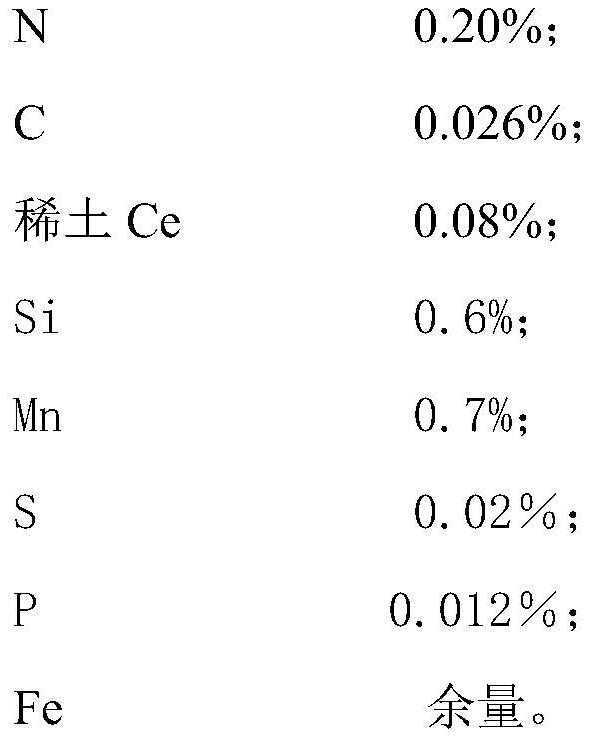

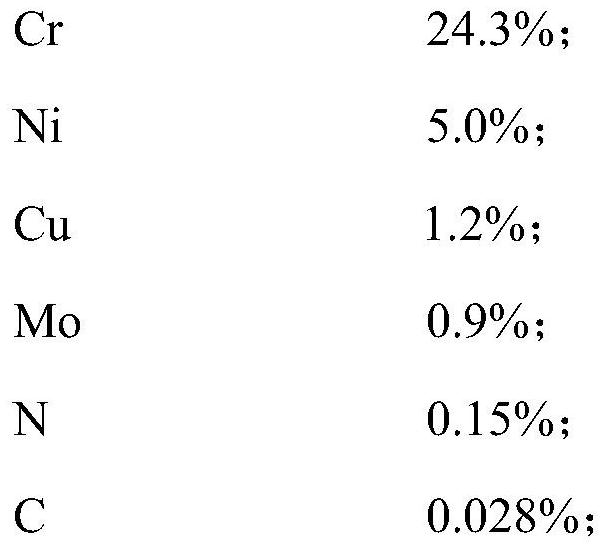

High-performance duplex stainless steel wire rope alloy material and preparation method thereof

PendingCN113652602AGood cold drawing performanceBright surfaceTextile cablesSmelting processCorrosion

The invention relates to a high-performance duplex stainless steel wire rope alloy material and a preparation method thereof, and belongs to the technical field of steel alloy materials. The duplex stainless steel wire rope comprises the following components in percentage by mass: less than or equal to 0.03% of C, less than or equal to 0.03% of S, less than or equal to 1.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 0.003% of P, 23.5-24.5% of Cr, 4.5-5.5% of Ni, 0.7-1.4% of Mo, 0.7-3.0% of Cu, 0.10-0.20% of N, 0.005-0.20% of rare earth Ce and the balance of iron and inevitable impurities. The preparation method comprises the following steps of preparing a steel billet by adopting a medium-frequency and AOD smelting process; the billets are subjected to a hot rolling process to prepare duplex stainless steel wire rods with different diameters, and the wire rods are subjected to processes such as acid pickling, repeated cold drawing and annealing to prepare semi-finished wire rods; and the semi-finished wire is subjected to stranding and rope combining, and the high-performance duplex stainless steel finished steel wire rope is obtained. The alloy material has excellent cold workability, strength, fatigue resistance and corrosion resistance, has remarkable popularization value, is particularly suitable for being used as maritime work steel, and can serve in moisture and salt corrosion environments.

Owner:SHANGHAI UNIV

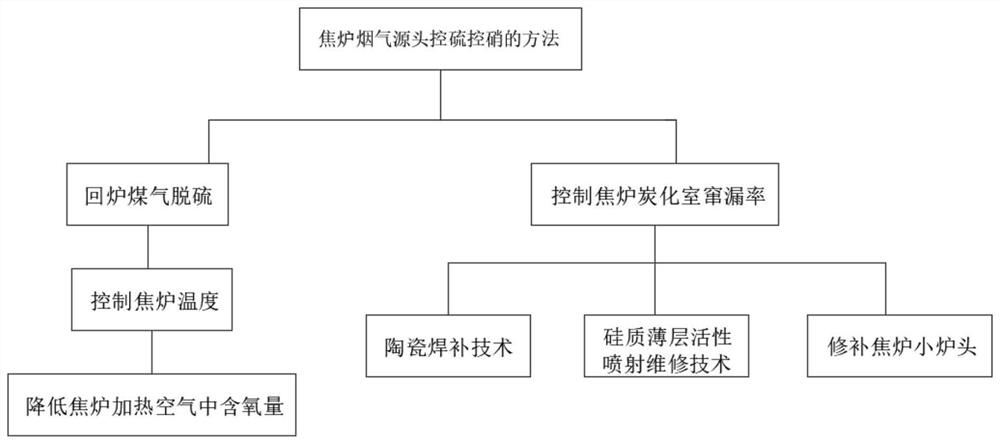

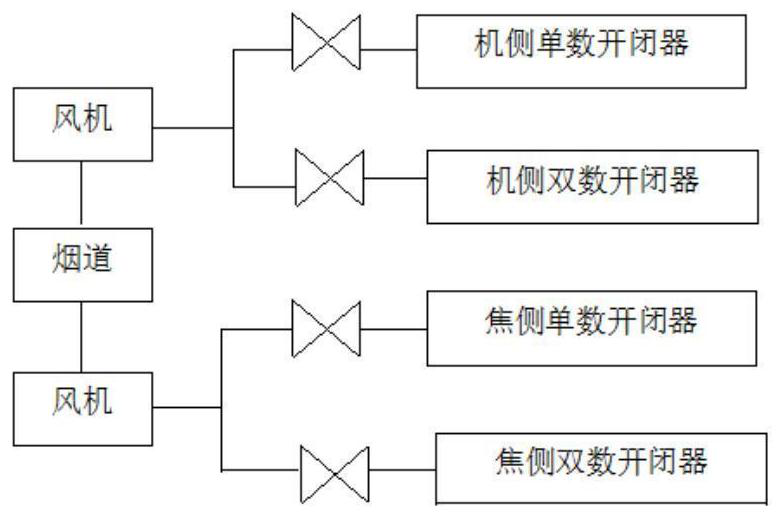

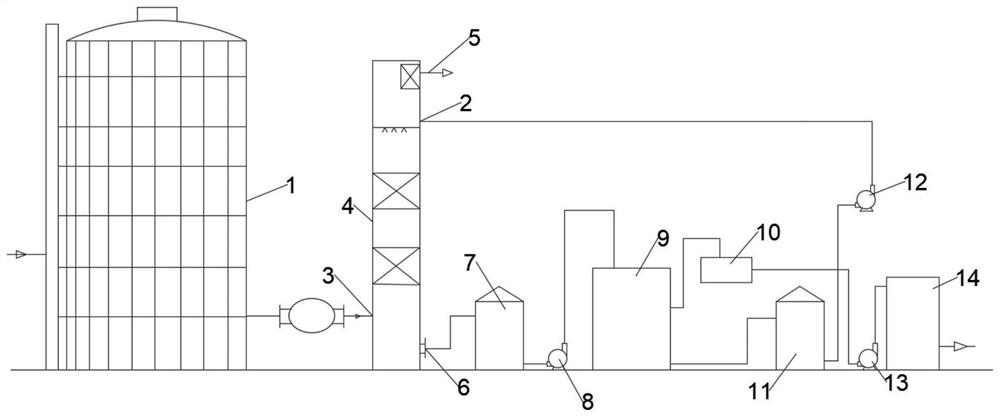

Method for controlling sulfur and nitrate from coke oven flue gas source

InactiveCN112280570AReduce contentEasy to controlCoke oven brickworkBrickwork leakage repair/preventionNitrateFlue gas

The invention relates to a method for controlling sulfur and nitrate from a coke oven flue gas source, and belongs to the technical field of coking. The method for controlling sulfur and nitrate fromthe coke oven flue gas source comprises the steps of 1, desulfurization, specifically, desulfurizing recirculated coal gas by adopting PDS wet desulfurization, wherein the content of hydrogen sulfidein the desulfurized recirculated coal gas is 20mg / m<3>; and 2, denitration, specifically, adjusting the temperature of the coke oven according to the relationship between the state parameters of the coke oven and a preset value in the denitration step. According to the method for controlling sulfur and nitrate from the coke oven flue gas source, the sulfur content and the nitrate content are controlled from the coke oven flue gas source, and the control effect is good.

Owner:TANGSHAN ZHONGRUN COAL CHEM CO LTD

A kind of preparation method of large-area nitrogen-doped carbon nanotube paper

ActiveCN106082163BEvenly distributedControl nitrogen contentCarbon nanotubesNanotechnologyNew energyFlexible electronics

Owner:SUN YAT SEN UNIV

Lithium-ion battery anode material

ActiveCN109698327BHigh activityIncrease capacityCell electrodesSecondary cellsMaterials scienceLithium electrode

Owner:SUPER ENERGY MATERIALS

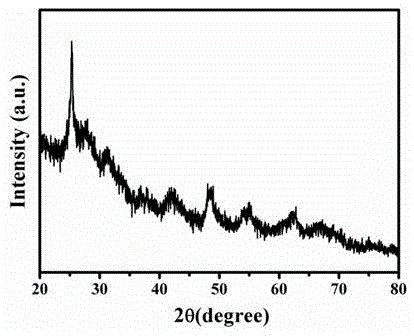

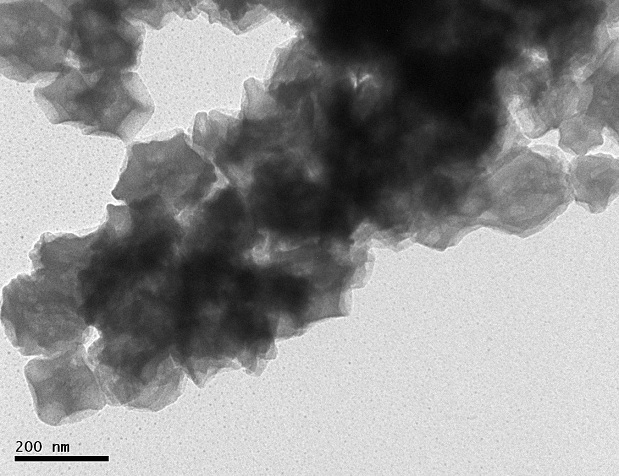

n-tio2/c and n-tio2 and preparation method thereof

InactiveCN104028292BHigh nitrogen contentVisible light photocatalytic activityCatalyst activation/preparationTetramethylammonium hydroxideTitanium tetraisopropoxide

The invention relates to N-TiO2 / C and N-TiO2 and a preparation method thereof, and specifically discloses a method for preparing nitrogen-doped titanium oxide and its nanocomposite with carbon by heat treatment in air. Its preparation method includes the following steps: (1) Mix 10wt% tetramethylammonium hydroxide aqueous solution with ethylene glycol, add titanium isopropoxide, stir well, and heat the obtained solution at 200°C for 8 hours; (2) Mix the step ( 1) The obtained hydrothermal product is centrifuged and washed in ethanol and deionized water, and dried in air at 70°C; (3) The dried product in step (2) is heat-treated in air at 250-550°C for 2 hours, that is A nitrogen-doped titanium oxide / carbon nanocomposite or nitrogen-doped titanium oxide is obtained. The nitrogen-doped titanium oxide / carbon nanocomposite and the nitrogen-doped titanium oxide obtained by the invention have the advantages of high nitrogen content, extended absorption spectrum to the light region, visible light photocatalytic activity and the like. The adopted preparation method has the advantages of simplicity, high safety factor, low cost and the like.

Owner:ZHEJIANG UNIV

A method of controlling nitrogen content in n80 steel

ActiveCN101550473BControl nitrogen contentImprovement of non-quenching and tempering treatmentProcess efficiency improvementFlushing timeNitrogen

The invention relates to a method for controlling the nitrogen content in N80 steel. The method comprises the following steps: firstly, the LF slag smelting is stabilized and the deoxidation technology is perfected so that the weight and the components of the molten slag are controllable and the nitrogen flushing state during the process is stable; secondly, the proper nitrogen flushing flow, pressure and time are set in the VD packing process so that the nitrogen content after emptying is stable; and thirdly, the proper nitrogen flushing time, flow and pressure are set after the VD emptying so that the nitrogen content is stable and controllable. The method performs improvement to the non-quenching and tempering way, effectively controls the nitrogen content in the N80 level steel by taking measures, not only has low cost, but also effectively reduces the surface cracks of the casting billet and improves the quality of products.

Owner:ANGANG STEEL CO LTD

A kind of steelmaking production method of 600mpa grade peritectic high alumina trip steel

ActiveCN110724881BControl nitrogen contentImprove quality controlManufacturing convertersSteelmakingTRIP steel

The invention discloses a steelmaking production method of 600MPa peritectic high-alumina TRIP steel. The steelmaking production method comprises the steps of molten iron desulfurization, converter smelting, LF refining, RH treatment and medium slab continuous casting. The invention produces continuous casting slabs that meet the requirements by applying the rapid tapping process of the converter, the LF rapid slagging process, the RH degassing process, and the continuous casting slab control process. The production process is stable and can effectively control the full oxygen and Nitrogen content, O≤5ppm, N≤30ppm, the quality control of the steelmaking slab is good, the segregation grade of the slab is below C class 1.5, and the surface of the slab has no cracks; the slab can be used for hot rolling to produce high-quality hot-rolled coils , cold-rolled to produce high-quality cold-rolled products.

Owner:唐山钢铁集团高强汽车板有限公司 +2

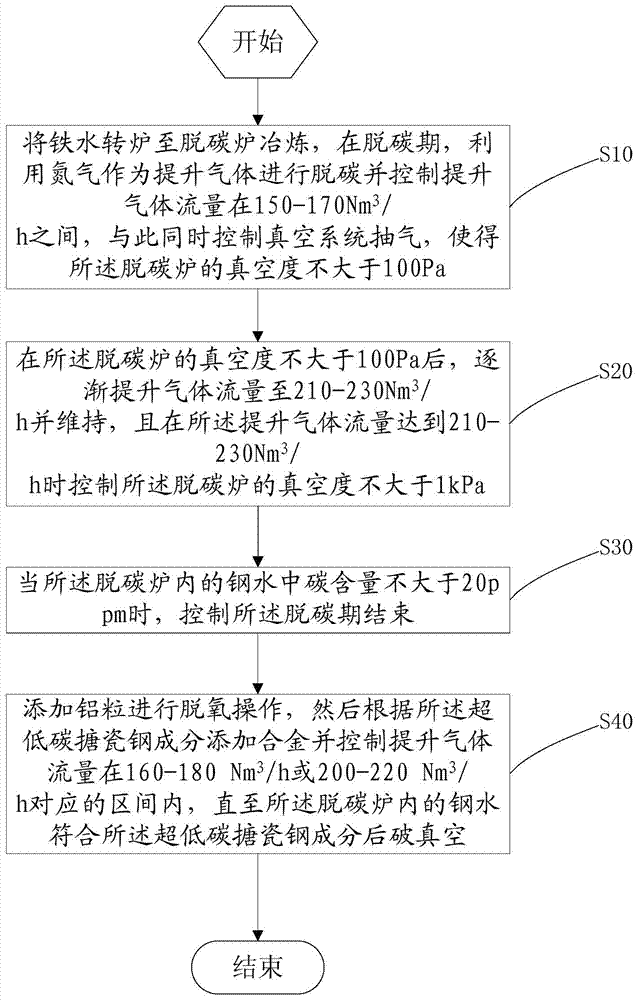

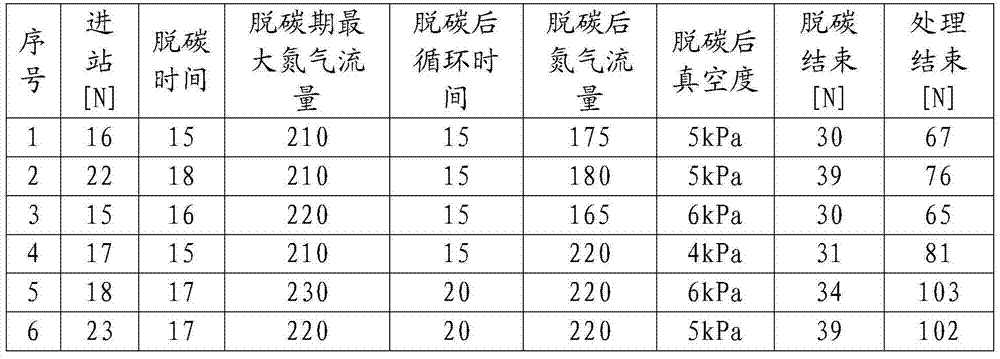

Nitrogen-increasing method for molten steel of ultra-low carbon enamel steel

ActiveCN103911490BControl nitrogen contentControlled Nitrogen Boosting Nitrogen Content in Decarburization and Deoxidation ProcessesNitrogenLifting gas

The invention belongs to the technical field of ferrous metallurgy, and particularly relates to a method for adding nitrogen to ultra-low carbon enamel molten steel. The method comprises the following steps: decarbonizing by utilizing nitrogen as a lift gas while controlling the flow of the lift gas at 150-170Nm<3> / h, and exhausting, so that the vacuum degree of a decarburization furnace is not greater than 100Pa; gradually lifting the flow of the lift gas to 210-230Nm<3> / h, and finishing the decarburization stage until the carbon content in the molten steel is not greater than 20ppm, wherein the vacuum degree of the decarburization furnace is not greater than 1kPa; carrying out a deoxidation operation; adding alloy and controlling the flow of the lift gas in an interval corresponding to 160-180Nm<3> / h or 200-220Nm<3> / h; breaking vacuum until the molten steel accords with the ultra-low carbon enamel molten steel ingredient. Nitrogen is added in decarburization by controlling the flow of the lift gas of nitrogen, the vacuum degree and the decarburization time of the decarburization furnace in the decarburization and deoxidation processes, so that the nitrogen content of a finished product can be accurately controlled, use of alloy is reduced, and the cost is reduced.

Owner:SHOUGANG CORPORATION

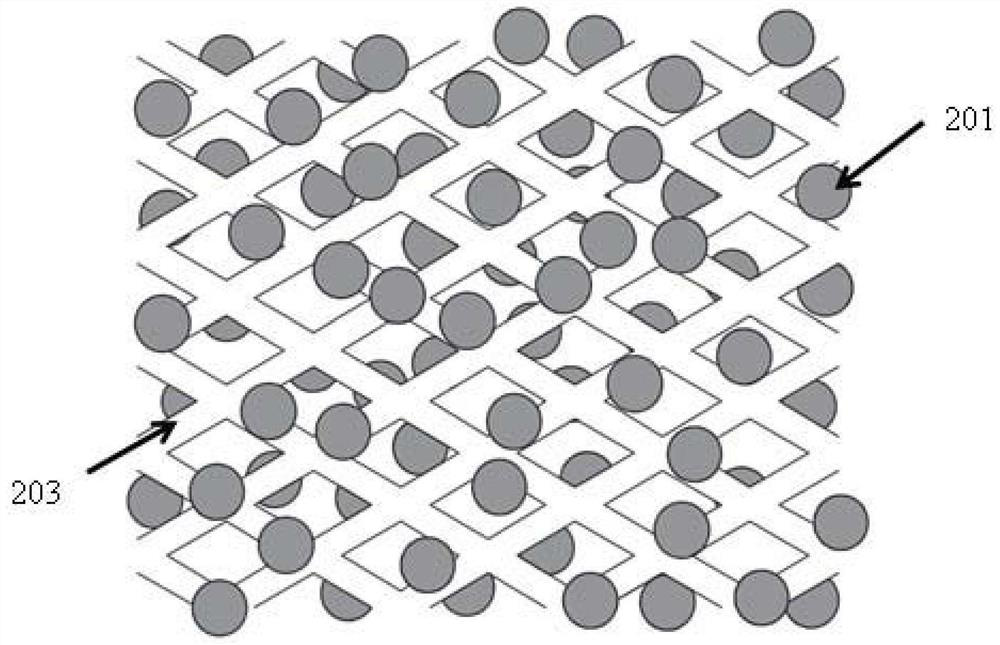

Three-dimensional graphene composite material with core-shell structure for capacitive desalination electrode and preparation method thereof

ActiveCN107089707BSuppress stackingControl nitrogen contentDispersed particle separationWater/sewage treatment apparatusCapacitanceElectrostatic interaction

The invention relates to a three-dimensional graphene composite material with a core-shell structure for a capacitive desalination electrode and a preparation method thereof. The method uses metal-organic framework as the core and graphene as the shell; through the electrostatic interaction between a certain concentration of graphite oxide solution and the metal-organic framework at a certain temperature, the precursor of the three-dimensional composite material with a core-shell structure is formed; further carbonization, pickling A three-dimensional graphene composite material is obtained; the composite material, acetylene black and polytetrafluoroethylene emulsion are evenly mixed, coated on graphite paper, and dried to obtain a capacitive desalination electrode. The process of the invention is fast, simple, low in cost and can be produced in batches. The obtained electrode has high specific surface area, good conductivity and wettability, and has potential application prospects in capacitive desalination.

Owner:SHANGHAI UNIV

A method for remelting high-strength stainless steel

InactiveCN103484746BAddressing Insufficient Nitrogen Content for Recycling and RemeltingControl nitrogen contentProcess efficiency improvementManganeseAlloy

The invention relates to a method for remelting high-strength stainless steel. The method is characterized by including the steps that Fe-Mn-Cr nitrogen absorption alloy melt containing manganese and chromium is first smelted, then, high-nitrogen steel waste material is added to the nitrogen absorption alloy melt step by step at low melt temperature, nitrogen-containing alloy is added in proportion according to the designed composition proportion of high-nitrogen steel, and after being completely melted and homogenized, the nitrogen-containing alloy is discharged for pouring. The method solves the problem that the nitrogen content is insufficient in the recovering and remelting processes of the high-nitrogen steel waste material and can control the nitrogen content of new high-nitrogen steel smelted by the high-nitrogen steel waste material to be close to or not lower than that of the original high-nitrogen steel waste material.

Owner:CHANGCHUN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com