Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

503results about How to "Bright surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

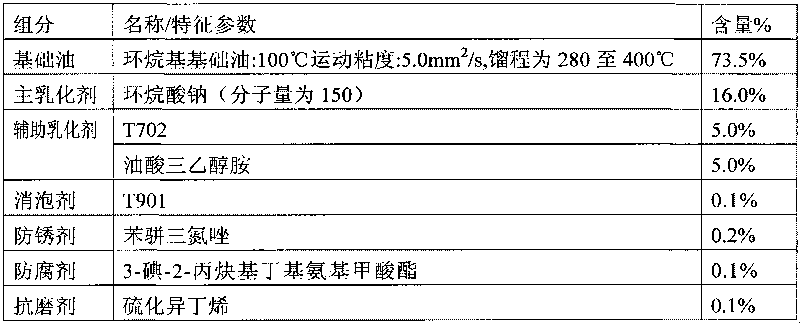

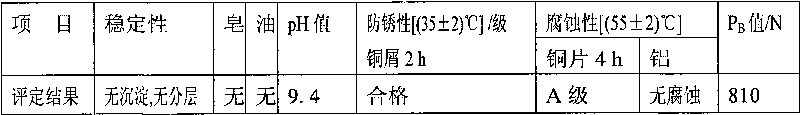

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

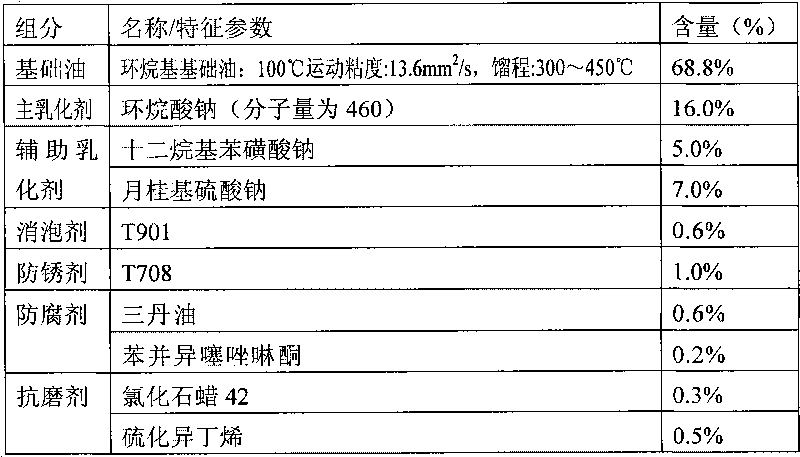

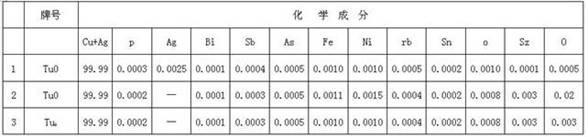

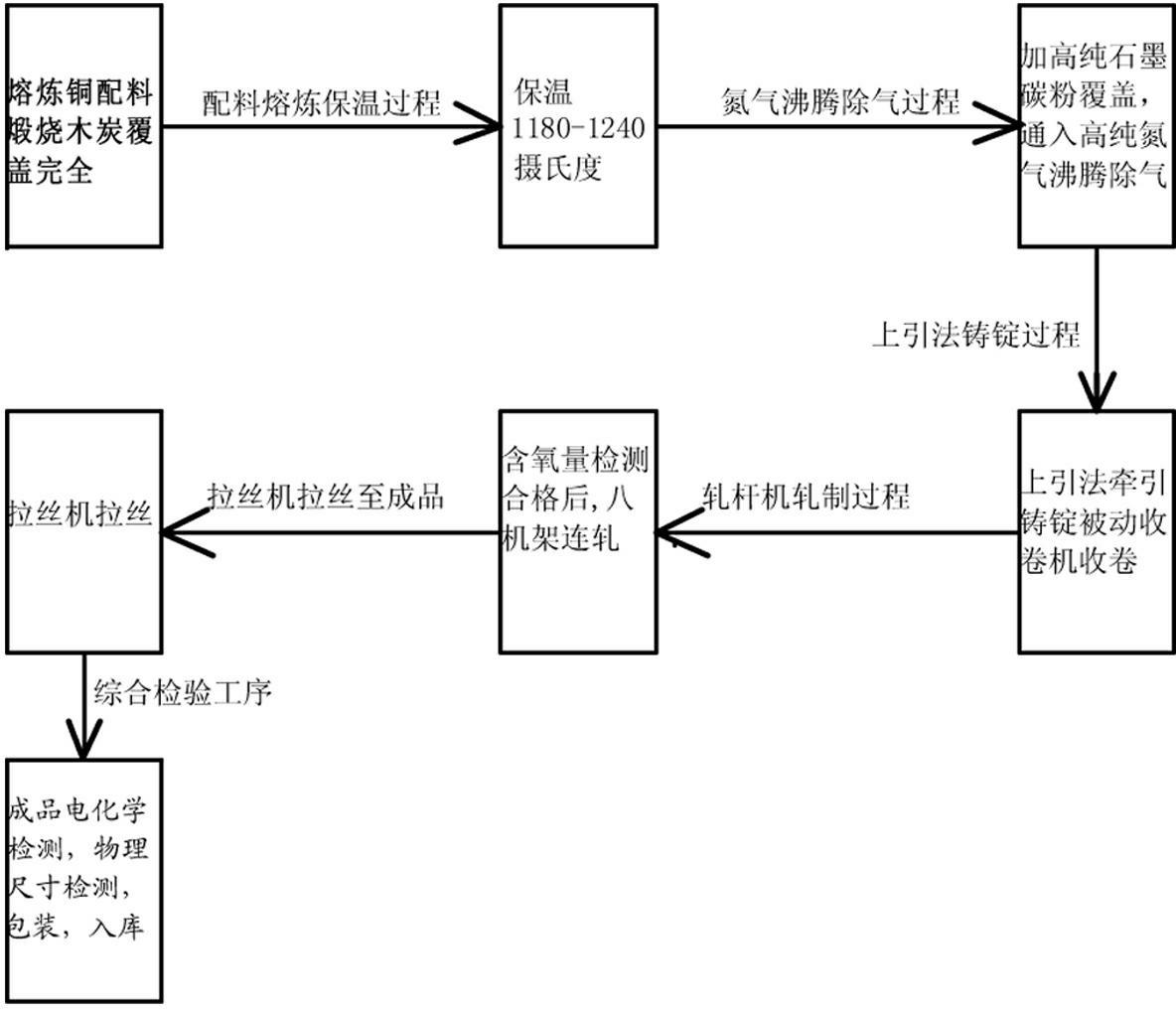

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

High-gloss, low-smell, reinforced nylon composite material and preparation method thereof

The invention relates to a high-gloss and low-odor reinforced nylon composite material and the preparation method thereof. The composite material is characterized in that the composite material contains, by weight percentage, PA66 resin, PA6 resin, glass fiber, inorganic minerals, micro-beads, compatibilizer, antioxidant, lubricant, etc. The preparation method comprises the following steps: mixing the above materials in a high-speed mixer; discharging, and extruding and granulating the mixed material in a screw extruder. Compared with common fiber glass reinforced PA and mineral reinforced PA, the PA composite material prepared by the method has the advantages of high gloss, high strength, low odor, etc., and can be widely used for exterior trimming parts such as electric tool housing and motor housing and for interior parts.

Owner:SHANGHAI SUNNY

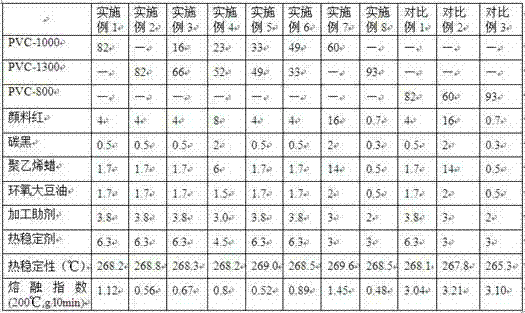

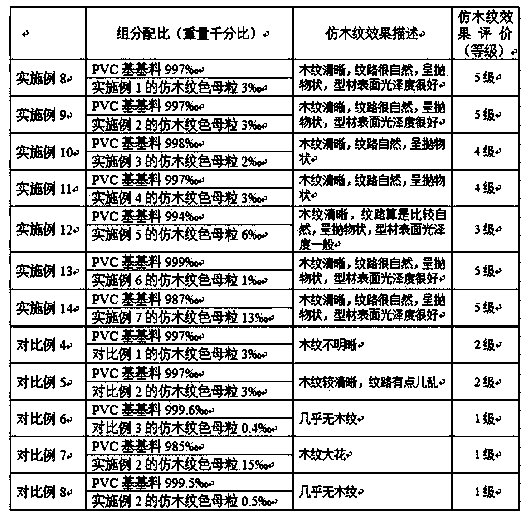

Wood-grain-like color master batch, and preparation method and application thereof

The invention discloses a wood-grain-like color master batch which comprises the following components in percentage by weight: 60-93% of PVC (polyvinyl chloride) resin, 1-18% of pigment, 0.5-14% of dispersant and 3-15% of other assistant. The preparation method comprises the following steps: a) proportionally mixing the components in a high-speed mixer; and b) carrying out melt blending extrusion on the mixture with a single screw extruder at the screw bolt speed of 14-27RPM at the melting temperature of 120-170 DEG C, uniformly dispersing the pigment in the carrier resin through the shearing and compounding of the screw bolt, naturally cooling, granulating, and airing to obtain the wood-grain-like color master batch. The wood-grain-like color master batch has the advantages of low toner consumption, favorable temperature tolerance and excellent dispersibility; when being used for preparing a wood-grain-like wood-plastic composite material, the wood-grain-like color master batch is easy to operate and control and has favorable compatibility with the PVC-based base material; the wood-grain-like wood-plastic composite material has highly simulated wood appearance, natural and clear grains, bright surface color and favorable wood-grain-like effect, and thus, is an ideal wood-like wood-plastic product.

Owner:KINGFA SCI & TECH CO LTD +2

Tartary buckwheat full-nutrition rice and preparation method

InactiveCN103704578AThe surface of whole nutritional rice grains is transparentBright surface of full nutritional rice grainsFood preparationBiotechnologyFagopyrum tataricum

The invention provides tartary buckwheat full-nutrition rice and a preparation method. The tartary buckwheat full-nutrition rice is prepared by the following steps: carrying out screening, winnowing, stone removing and magnetic separation cleaning on tartary buckwheat; then carrying out a heat-moisture treatment procedure; in the heat-moisture treatment procedure, finishing a three-in-one production process including a pressurizing and wheat moisturizing process, a normal-pressure steaming process and a low-temperature vacuum drying process in a container; and then, carrying out unshelling and separation on the tartary buckwheat, rolling rice, and polishing and grading. The tartary buckwheat full-nutrition rice prepared by the preparation method is transparent, bright, clean, sanitary and attractive in appearance; the shelf life is easy to prolong.

Owner:KUNMING WUGUWANG FOOD

Daylight-resisting heat insulation paint

A heat-insulative paint against sunlight. It comprises: 7-15 parts of phenylpropionic acid emulsion, 4-8 parts of an adhesive of trimerized cyanamide modified polyvinyl alcohol, 2-20 parts of polyvinyl acetate, 3-7 parts of silicasol (liquid),0.3-0.8 part of carbamideíó0.8-1.0 part of glycolíó3-7 parts of white titanium pigmentíó12-18 parts of light calcium carbonateíó3-7 parts of calcite powderíó2-4 parts of expanded perliteíó18-22 parts of sepioliteíó1-3 parts talcum powderíó0.8-1.2 parts of gray calcium powder,1-2 parts of powdery silcate fiber ,0.3-0.8 part of alumen, 0.4-0. 6 part of penetrating agent T, 0.1-0.2 part of sodium carbonateíó appropriate amount of thickening agentíó18-26 parts of wateríó0-0.5 of dyes with high optical stability, 0-0.8 g jellebekite powder. The paint could reflect sunlight and insulate heat, has a bright surface.

Owner:黄维环

Method for processing metallic lithium belt

ActiveCN101497088BHigh dimensional accuracyBright surfaceExtrusion control devicesMetallic lithiumEngineering

The invention provides a method for a novel lithium ribbon by vacuum extrusion forming. The lithium ribbon produced by the method has high dimensional precision and bright surface, and a lithium battery made of the lithium ribbon produced by the method has uniform and stable performance.

Owner:CHINA ENERGY LITHIUM

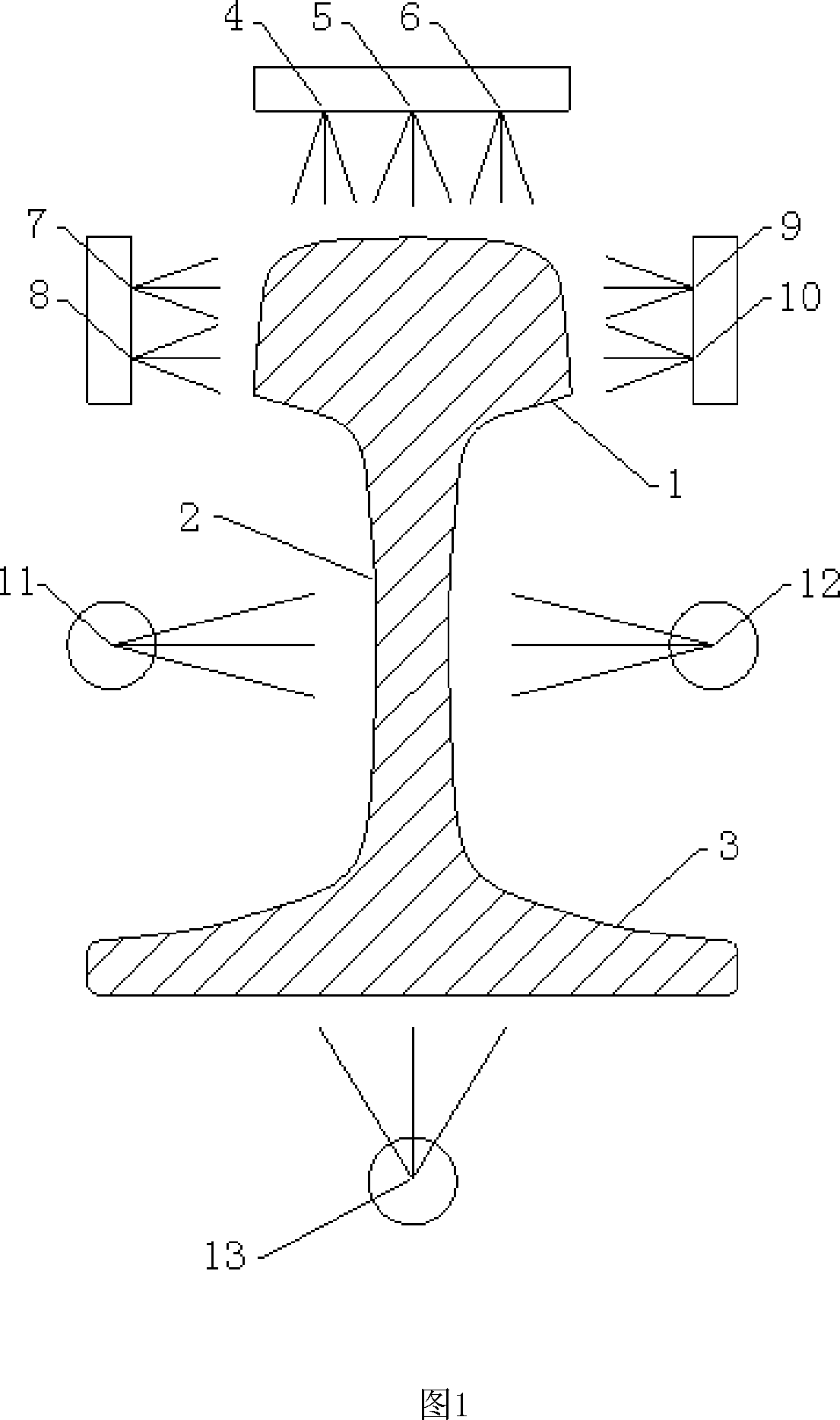

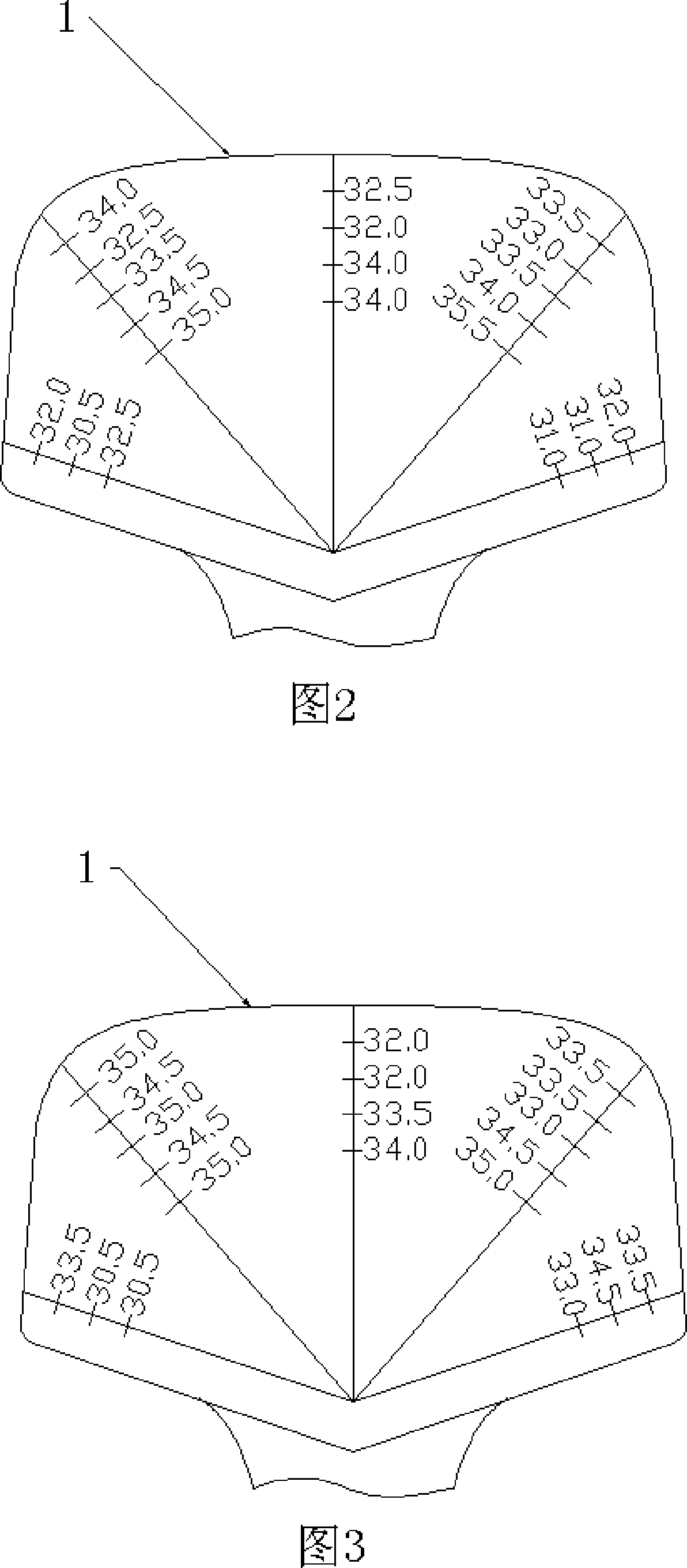

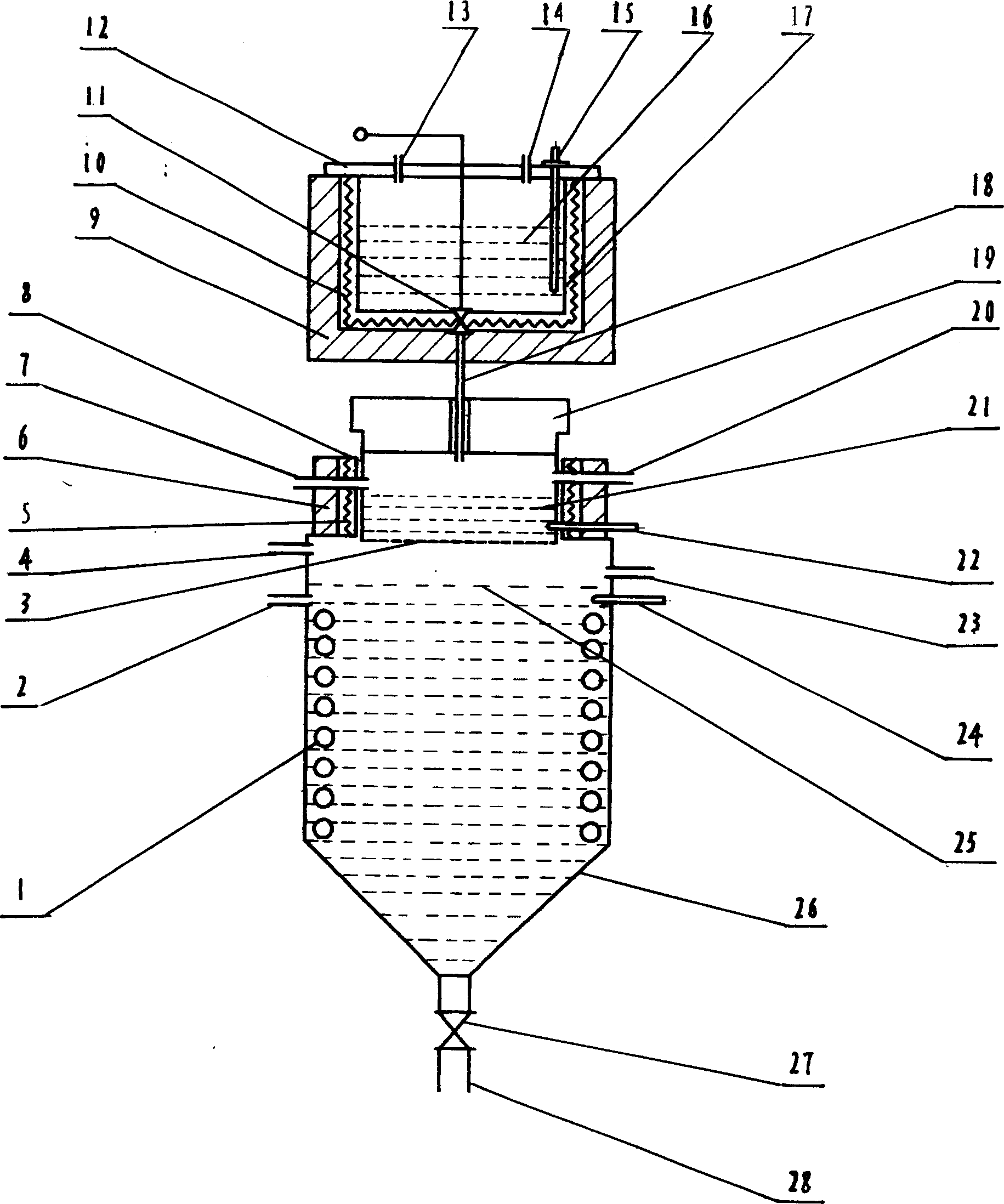

Steel rail and producing method thereof

InactiveCN101148736AReduce rateNo contact fatigue cracksFurnace typesHeat treatment process controlChemical compositionTrace element

The present invention relates to metallurgy technology, and is especially one kind of steel rail with high contact fatigue resistance and its production process. The steel rail has the chemical composition comprising C 0.61-0.73 %, Si 0.20-0.50 %, Mn 0.80-1.30 %, and Fe and other trace elements for the rest. It has tensile strength Rm over 1080 MPa, fracture toughness KIC over 45 MPa.m1 / 2, excellent contact fatigue resistance and high comprehensive use effect. Its production process includes the on-line treatment of rolled steel rail, including simultaneous quenching and cooling to the rail head, the rail web and the rail base.

Owner:PANZHIHUA IRON AND STEEL

Environment-friendly type insulated dope for cold rolling non-oriented silicon steel and preparation method for coat thereof

The invention relates to an environment-friendly insulating coating for cold-rolled non-oriented silicon steel and a preparation method thereof. The components of the insulating coating include: phosphate, molybdate, water, organic resin, silane coupling agent, and glycerol; the above-mentioned The weight ratio of each component is: phosphate 100, molybdate 3-20, water 800-1500, organic resin 20-50, silane coupling agent 0.5-5, glycerol 8-15. The steps of the coating preparation method are: (1) coating insulating paint on the surface of cold-rolled non-oriented silicon steel; (2) baking and drying, the baking temperature is 150-300 ° C; 600°C, the sintering time is 30-90 seconds; (4) Finished product. The insulating paint of the invention does not contain harmful elements, and the coating has good insulating performance, good adhesion and corrosion resistance, good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing. The method of the invention is simple to operate, and the coating prepared by the method has good punching and shearing processability and weldability, and can withstand heat resistance of stress-relieving annealing.

Owner:武钢集团有限公司

Processing method of high-strength titanium alloy thin-walled tube stock

The invention relates to a processing method of high-strength titanium alloy thin-walled tube stock, belonging to the field of material processing. The processing method comprises the following steps: 1) ingot casting titanium alloy at the temperature of 1100-1200 DEG C, cogging and forging, heating obtained bar stock to the temperature of 900-950 DEG C, conducting heat preservation for 30-50 minutes, and one-time hot-rolling on a rapid forging press to obtain titanium alloy forged bars; 2) finishing and drilling the titanium alloy forged bars to obtain tube blank; 3) preheating a central spindle to be spinned before hot spinning, with the preheating temperature not lower than the temperature of 350 DEG C; and conducting heat preservation on the tube blank at the temperature of 700-750 DEG C for 30-40 minutes, and multichannel hot spinning process; and 4) finishing the interior and exterior of the obtained hot spinned tube blank, and cold spinning and forming on a cold spinning machine to obtain finished products of the tube blank. The processing method adopts rapid forging blank making and spinning process for processing the titanium alloy thin-walled tube stock with higher requirements for room temperature strength and deformation resistance, has simple processing equipment and easy molding, and can effectively improve the quality and yield of alloy tube blank.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Galvanized steel sheet coating material and its production method

InactiveCN1807667AExtended service lifeImprove fatigue resistanceMetallic material coating processesSheet steelRare earth

The invention discloses a coating material and producing method of galvanized steel sheet, which comprises the following elements: Al 50%-60%, Zn 38%-47%, SiO 5%-3%, RE 0. 05%-0. 3%, wherein the producing method comprises the following steps: adding 50%-60%Al in founding furnace; heating-up to 795-805deg. c; adding in 0. 5-3 percent Si; mixing equably; heating-up to 845-855deg. c and joining 0. 05-0. 3% RE; stirring equably; heating-up to 860-880deg. c and adding in 38-47 percent Zn; mixing evenly and placing for 35min. The invention improves corrosion resistance and fire resistant property of coated rolled steel.

Owner:JIANGSU LINLONG NEW MATERIALS

Production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps

ActiveCN106319292ASolve the shortcomings of uneven online refinementEvenly meltedSmelting processDistribution system

The invention relates to a production method of aluminum plates and aluminum strips for cosmetic mirror surface aluminum caps. The manufacturing process comprises the steps of smelting, casting, homogenizing treatment, hot rolling, cold rolling, intermediate annealing and cold rolling of finished products. In the smelting process, a bottom-mounted electromagnetic stirring system is adopted; in the casting process, an automatic speed regulation system is adopted; in the hot rolling system, a hot rough rolling pass automatic distribution system is adopted; and in the intermediate annealing system, a large natural gas furnace is adopted for annealing. Through cooperation of all the procedures, product ingredients can be made uniform, and finished products are uniform in surface roughness, fine, smooth, good in smooth finish, free of surface defects such as stripes, black lines and color difference; the mirror surface effect is good after materials are subjected to anodic oxidation and electroplating, and the application requirements for deep drawing and tensile properties of the aluminum plates and the aluminum strips for the cosmetic mirror surface aluminum caps are met.

Owner:HENAN MINGTAI AL INDUSTRIAL CO LTD

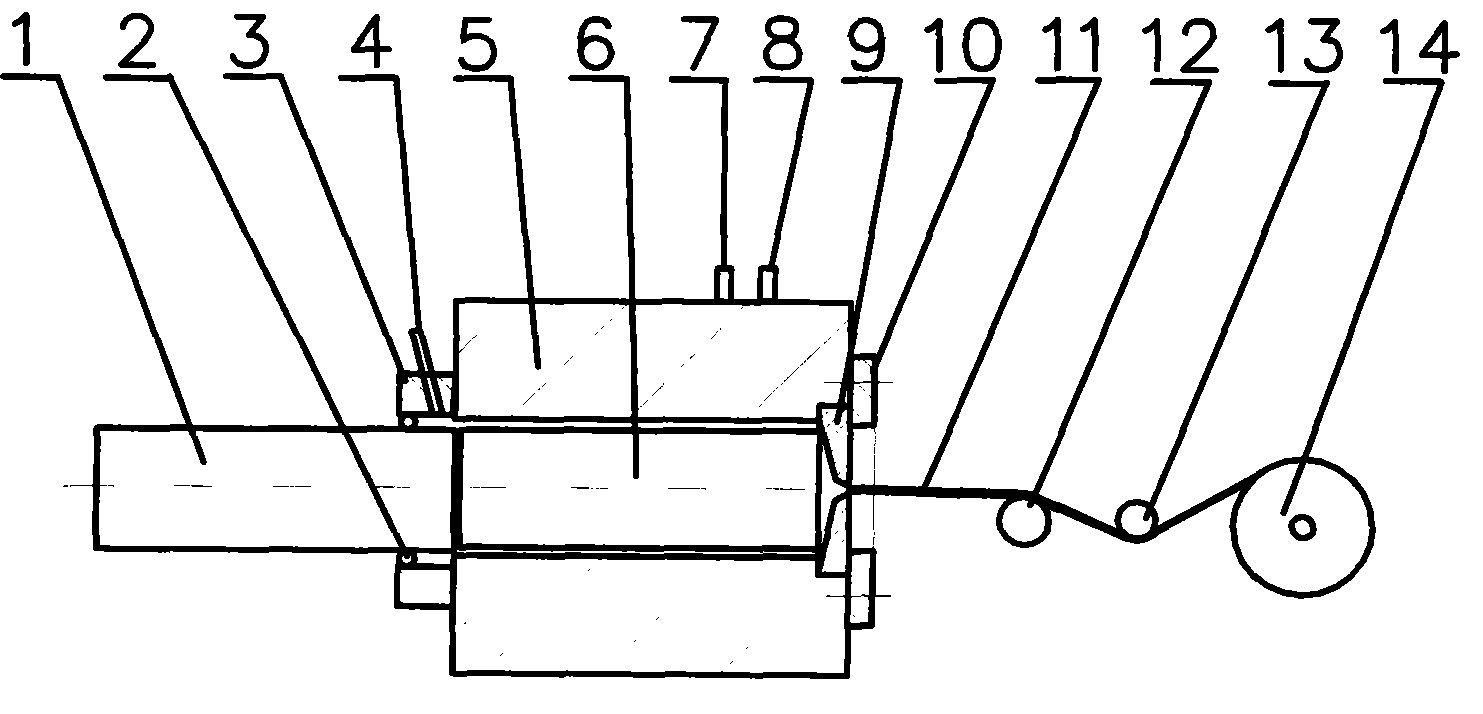

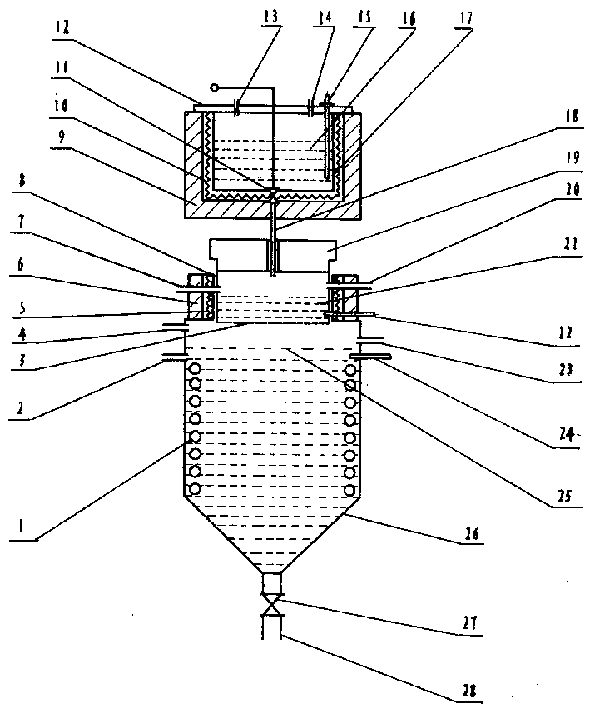

Method for preparing granules of nonoxidation stannic balls and forming machine used

A process for preparing unoxidized tin particles includes in the protecting atmosphere, introducing molten tin to a container whose bottom has uniform multiple fine holes, vertically vibrating the container to drop down in oil bath, cooling to form small balls, washing and drying. Its shaping machine is composed of smelting furnace, dropper, and sphericizing shaper. Its advantages are high productivity and high quality.

Owner:重庆工学院

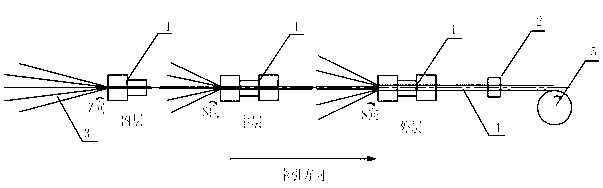

Method for manufacturing stainless steel wire for spectacle frame

ActiveCN102828122ABright surfaceNo defects in appearanceFoundry mouldsFoundry coresHardnessStainless steel wire

The invention discloses a method for manufacturing the stainless steel wire for a spectacle frame, comprising the following steps: (1) treating the skin film; (2) drying; (3) drawing for the first time and carrying out bright annealing on line for the first time, wherein the area-reduction rate during drawing for the first time is 40-60%, the temperature of carrying out bright annealing on line for the first time is 1,000-1,100 DEG C, and the speed is 3-9m / min; (4) drawing for the second time and carrying out bright annealing on line for the second time, wherein the area-reduction rate during drawing for the second time is 40-60%, the temperature of carrying out bright annealing on line for the second time is 1,000-1,100 DEG C, and the speed is 5-12m / min; and (5) drawing for the third time and carrying out bright annealing on line for the third time, wherein the area-reduction rate during drawing for the third time is 45-75%, the temperature of carrying out bright annealing on line for the third time is 1,000-1,100 DEG C, and the speed is 5-12m / min. The stainless steel wire manufactured by the method has a bright surface, is free from the surface defect, has high tensile strength temperature and good extensibility and has the following mechanical properties: the yield strength of 300-400N / mm<2>, the tensile strength of 550-650N / mm<2> or higher, the elongation of 50-60% and the hardness value (HV) of 200-300.

Owner:浙江腾龙不锈钢棒线有限公司

Corrosion inhibitor

The invention relates to a corrosion inhibitor, which is mainly used for corrosion inhibition in a continuous acid cleaning technology of a cold-rolled sheet. The corrosion inhibitor comprises the following components in percentage by weight: 10-25% of hexamine, 0-10% of vinylamine, 0-10% of ethanolamine, 0-3% of alkynol alkoxylate, 0-4% of oxalic acid, 2-5% of additive and 43%-88% of water. The corrosion inhibitor can effectively inhibit corrosion, improve the brightness of the surface of a sheet, prolong the use period of an acid liquid and has a certain rust-proof property.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

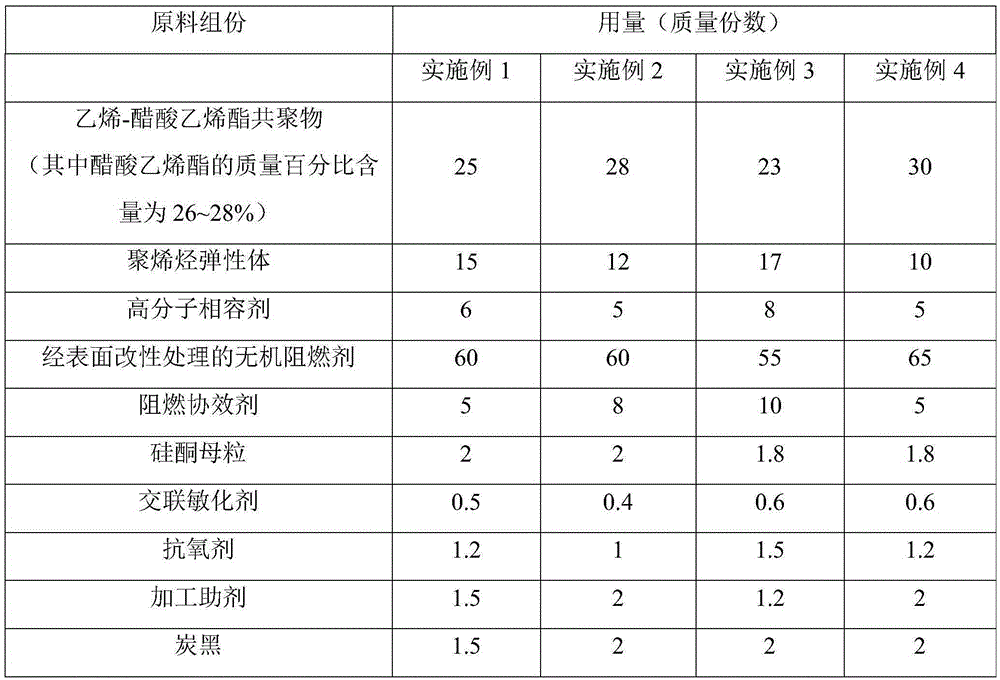

Irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and preparation method of irradiation crosslinking halogen-free flame retardant polyolefin material

InactiveCN105315541AAchieve oil resistanceAchieve high temperature resistancePlastic/resin/waxes insulatorsElastomerPolymer science

The invention belongs to the field of low-smoke halogen-free flame retardant materials, and particularly relates to an irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and a preparation method of the irradiation crosslinking halogen-free flame retardant polyolefin material. The polyolefin material comprises the following components in parts by mass: 20-30 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polyolefin elastomer, 5-10 parts of a macromolecular compatilizer, 45-65 parts of an inorganic flame retardant subjected to surface modification treatment, 5-10 parts of a flame retardant synergist, 0.8-1.5 parts of an antioxidant, 1.5-2.5 parts of silicone masterbatches, 0.3-0.6 part of a crosslinking sensitizer, 1.5-2 parts of carbon black and 1-2 parts of a processing aid. The preparation method comprises the technological steps of surface treatment of the inorganic flame retardant, proportioning, mixing, melting, extrusion for pelletization, and the like. Compared with the prior art, the polyolefin material has the characteristics of excellent flame retardation (capable of passing the D type group burning test), oil resistance (mineral oil and fuel oil resistant), high temperature resistance (the grade is 150 DEG C), ultraviolet resistance, scratch resistance, low corrosion, low toxicity, environment friendliness, excellent processing performance, extrusion speed capable of reaching 100-150 m / min, and bright surface.

Owner:SHANDONG UNIV OF TECH +1

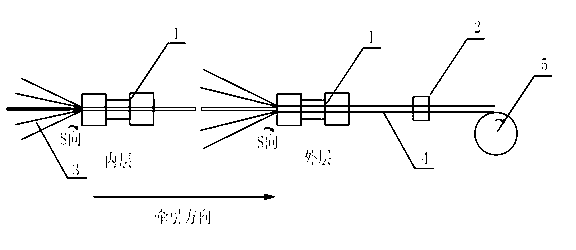

Aluminum or aluminum alloy conductor twisting and compressing process for cables

ActiveCN102800437AReduce resistanceReduce frictional resistanceCable/conductor manufactureSocial benefitsElectrical conductor

The invention provides an aluminum or aluminum alloy conductor twisting and compressing process for cables. The aluminum or aluminum alloy conductor twisting and compressing process comprises the following steps of: twisting aluminum or aluminum alloy single wires along the traction direction of the aluminum or aluminum alloy single wires; and compressing the twisted aluminum or aluminum alloy single wires by a compression roller, wherein a layer of twisting layer is formed after the aluminum or aluminum alloy single wires are twisted once and compressed by means of the compression roller, the subsequent twisting layer is twisted on the basis of the fore twisting layer, and the twisting direction of the last twisting layer is the same as that of the second last twisting layer. According to the aluminum or aluminum alloy conductor twisting and compressing process, the twisting directions of the outermost two layers of twisting layers are the same, the compression roller is combined with a nano diamond composite coating compression die, the phenomena of surface burrs of compressed round aluminum conductors, more aluminum scraps and wire fracture are prevented, the influence of alcohol which is continuously dripped for lubricating and cooling on the residual water inside or on the surface of the conductors is eliminated, the volume resistivity of the twisted and compressed cables is reduced by 0.5 to 2.0 percent, the production cost is saved, and the social benefit is higher.

Owner:SICHUAN MINGXING CABLE

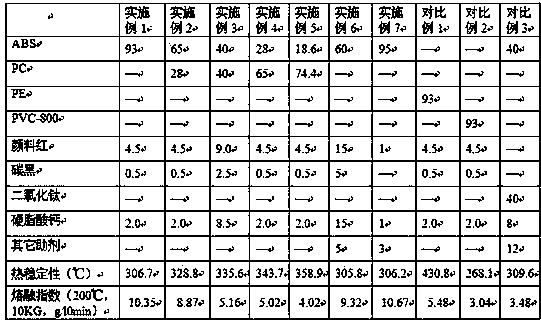

Imitation wood grain color master batch, preparation method, and applications thereof

The invention discloses an imitation wood grain color master batch, which comprises the following components in percentage by weight: 60 to 95% of carrier resin, 1 to 20% of pigment, 1 to 15% of dispersant, and 0 to 5% of other auxiliary agents; wherein the carrier resin is a mixture of PC and ABS, the PC accounts for 0 to 80% of the total weight of the carrier resin, and the ABS accounts for 20 to 100% of the total weight of the carrier resin. The preparation method comprises the following steps: (a) adding the components according to the ratios mentioned above into a high-speed mixer, and evenly mixing the components at the normal temperature and under the normal pressure; (b) melting, mixing and extruding the mixed materials mentioned above in a double-screw extruder, and at the same time subjecting the extruded materials to processes of water cooling, cutting, and wind drying so as to obtain the imitation wood grain color master batch. The imitation wood grain color master batch has the advantages of little color powder usage amount, good temperature toleration ability, and excellent dispersing ability; is easy to operate and control when the color master batch is applied to prepare imitation wood grain composite material of wood and plastic; has a good compatibility with PVC base basic materials and a high imitation wood appearance, thus the formed grains are natural and clear, the surface color is bright and beautiful, and the imitation wood grain effect is good.

Owner:KINGFA SCI & TECH CO LTD +2

Chamois leather gold-stamping method

ActiveCN102926243ABright surfaceTo achieve the effect of breathability and impermeabilityTextile decorationScreen printingRough surface

The invention relates to a cloth treatment method and especially relates to a chamois leather gold-stamping method. The chamois leather gold-stamping method is a chamois leather surface treatment technology. The chamois leather gold-stamping method solves the problem that in the existing gold-stamping method, gold-stamping slurry needs to be printed on a cloth by a 33T screen printing plate at least two times so that patterns are clear and bright-colored; gold-stamping processes are complex; and technical requirements are high. A chamois leather gold-stamped cloth obtained by the chamois leather gold-stamping method has beautiful patterns and a bright leather surface, and solves the problem that the existing chamois leather product is cleaned difficultly, has a rough surface and is maintained difficultly.

Owner:RUGAO XIDONG YARN DYED CO LTD

Wear-resistant material workpiece quenching medium

The invention discloses a wear-resistant material workpiece quenching medium, relating to the technical field of heat treatment quenching. The wear-resistant material workpiece quenching medium comprises following raw materials based on weight percentage: 6-12% of sodium hydroxide, 6-8% of zinc chloride, 0.01-0.03% of sulfonated castor oil, 1-5% of polyamide polyethylene glycol, 2-5% of acrylic acid, 5-10% of acrylic ester, 0.1-2% of additive and the balance of water. In the wear-resistant material workpiece quenching medium, formula is reasonable, a quenching piece can achieve high and uniform hardness and can be directly subjected to quenching, residual forging heat quenching and induced spraying quenching, and the medium is particularly applicable for quenching of a large workpiece; the sodium hydroxide used in the invention can mutually react with oxide skin on the surface of the quenching piece to generate oxygen, so that the oxide skin is rapidly stripped off, and the surface of the quenching piece shows shiny silver ; the zinc chloride and the sodium hydroxide react to generate strong zinc oxide, the scabbing speed of a high-temperature region is faster than that of water, the cooling speed of a low-temperature region is slower than that of the water, the quenching piece is slightly deformed, is not easy to crack and has a shiny surface.

Owner:安徽新马铸造科技有限公司

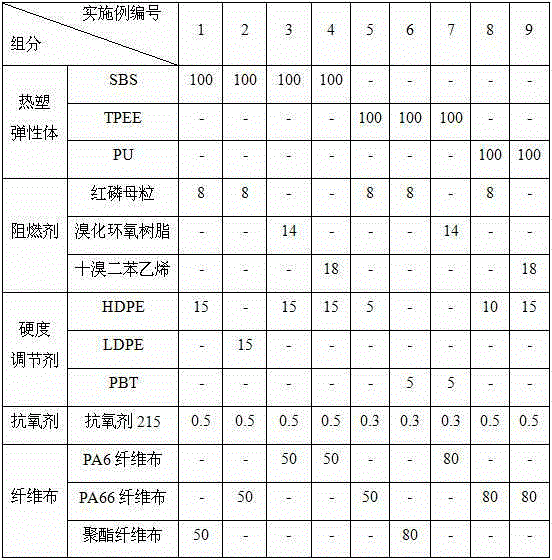

Flame-retarding composite floor leather resisting abrasion and skid and manufacturing technology and application thereof

The invention provides flame-retarding composite floor leather resisting abrasion and skid and a manufacturing technology and application thereof. The composite floor leather is formed by compositing fiber cloth serving as a framework material and a flame-retarding thermoplastic elastomer material serving as face adhesive, wherein the flame-retarding thermoplastic elastomer material is composed of, by weight, 100 parts of thermoplastic elastomer, 6-20 parts of flame retardants, 5-20 parts of hardness conditioning agents and 0.1-1.0 part of antioxidant. According to the manufacturing technology, the thermoplastic elastomer, the flame retardants, the hardness conditioning agents and the antioxidant are mixed together, and melted and extruded from a gap between bonding and heating guide rollers for winding the fiber cloth, the fiber cloth is coated, rolled and formed, and cooling, drawing, edge cutting, cutting and winding are carried out to obtain the composite floor leather. The composite floor leather has the advantages of being fireproof and comfortable, and resisting skid and abrasion, and can be applied to vehicles, indoor and outdoor decoration, sports places and the like.

Owner:长沙五犇新材料科技有限公司

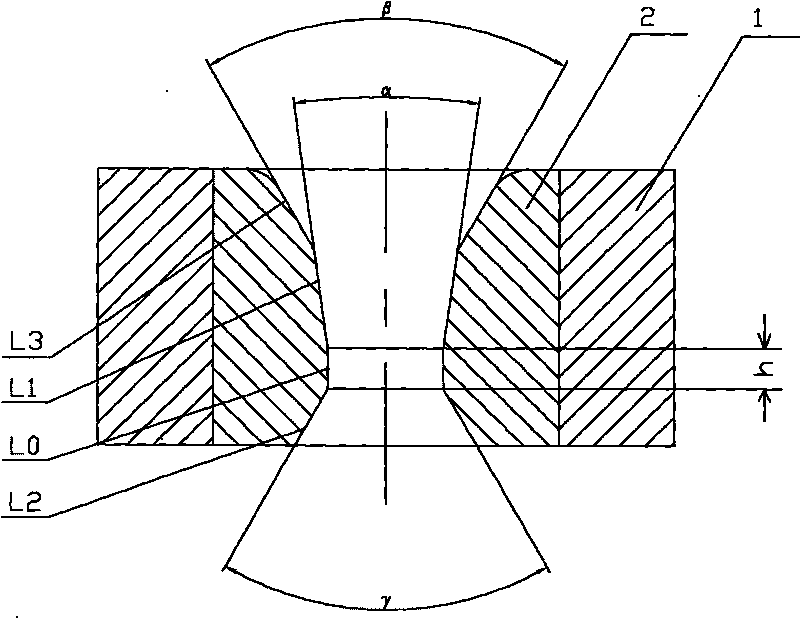

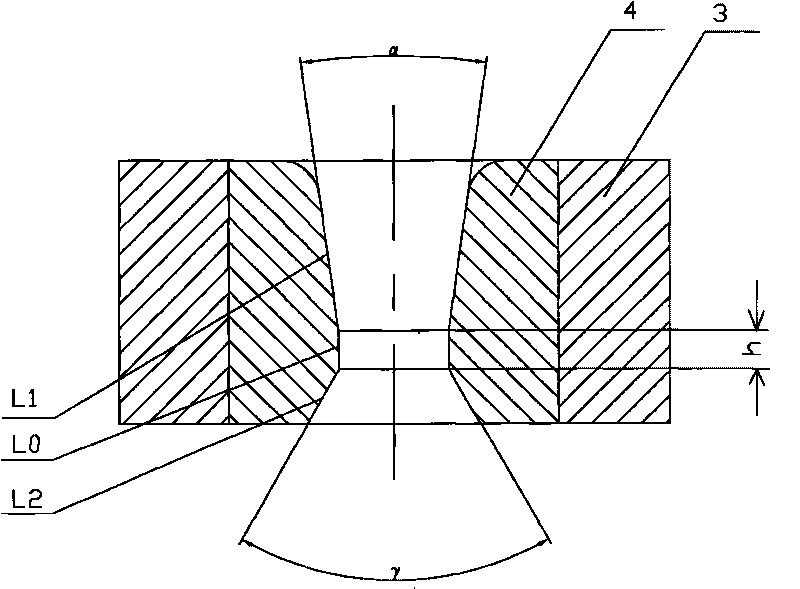

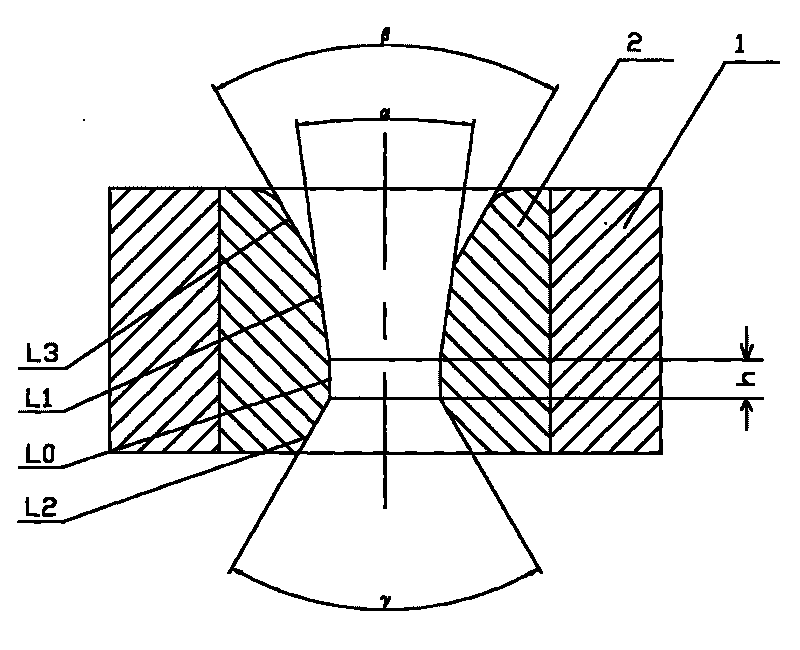

Production method and die of cold-drawing transmission shaft

The invention discloses a method for producing a transmission shaft by adopting a cold-drawing process, comprising the following steps of: A. detection, classification and grading of blanks, classifying the blanks into the following 5 section categories based on hardness: the Brinell Hardness (HB) less than or equal to 170, the HB between 170 and 200, the HB between 200 and 230, the HB between 230 and 250 and the HB larger than 250; B. pre-treatment before the drawing, the pre-treatmetnt comprises acid cleaning treatment, neutralizing treatment, phosphating treatment and soaping treatment of molybdenum disulfide; C. drawing treatment: pointing, drawing, strengthening and detecting the blanks, then packing and putting in the storage. The invention also provides a die for producing the transmission shaft by adopting the cold-drawing and the die comprises an A type wiredrawing hard alloy die and a C type drawing hard alloy die. The invention improves a lead-in conicity and a lead-out conicity of the die as well as the size of a die cavity diameter fixing strip and increases the lead-in cone and extends the diameter fixing strip of the die, thereby reducing the contact area between the blanks and the die when being lead in and increasing the stability of the blanks in the die cavity when being drawn.

Owner:HENGYANG KANGYI METAL PRODS +1

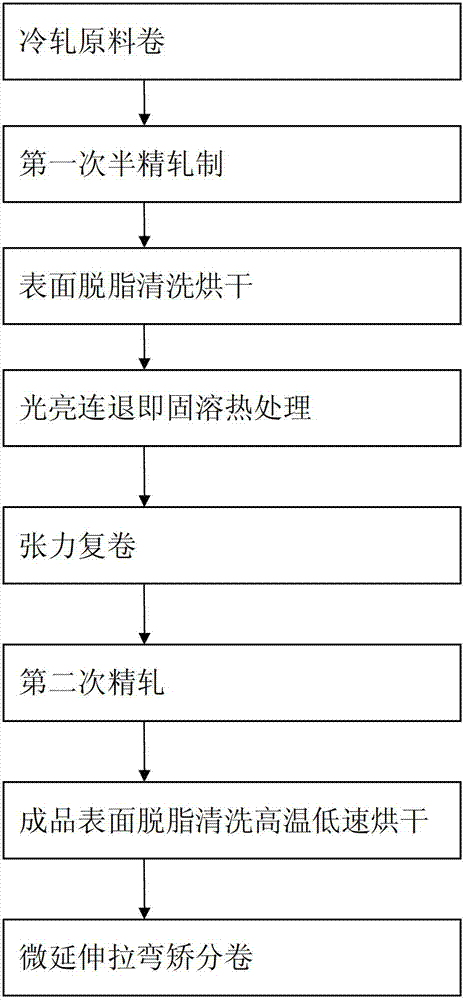

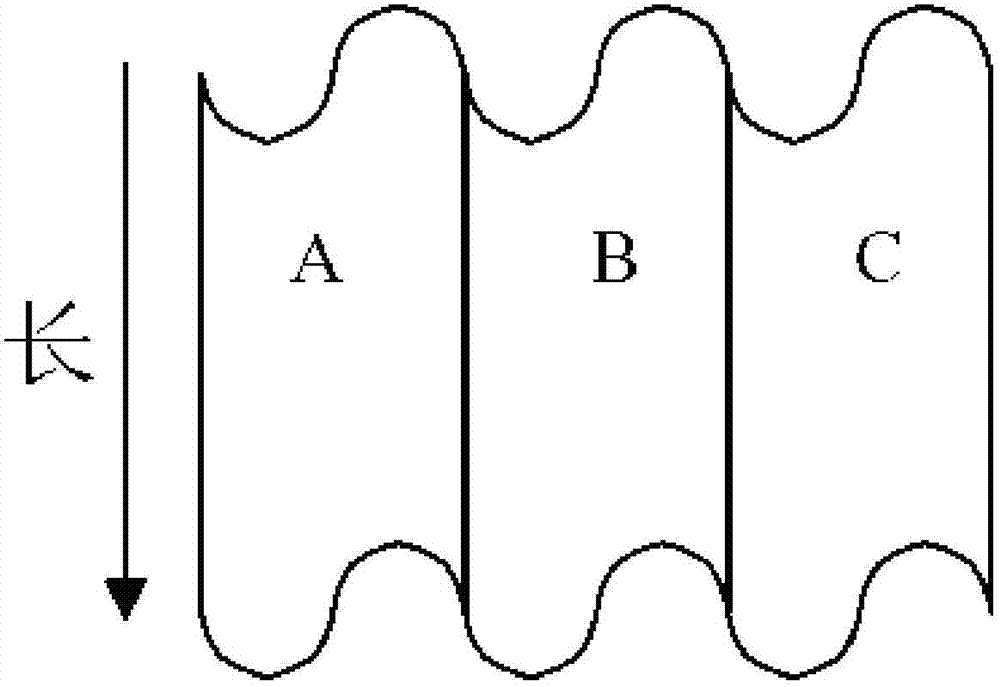

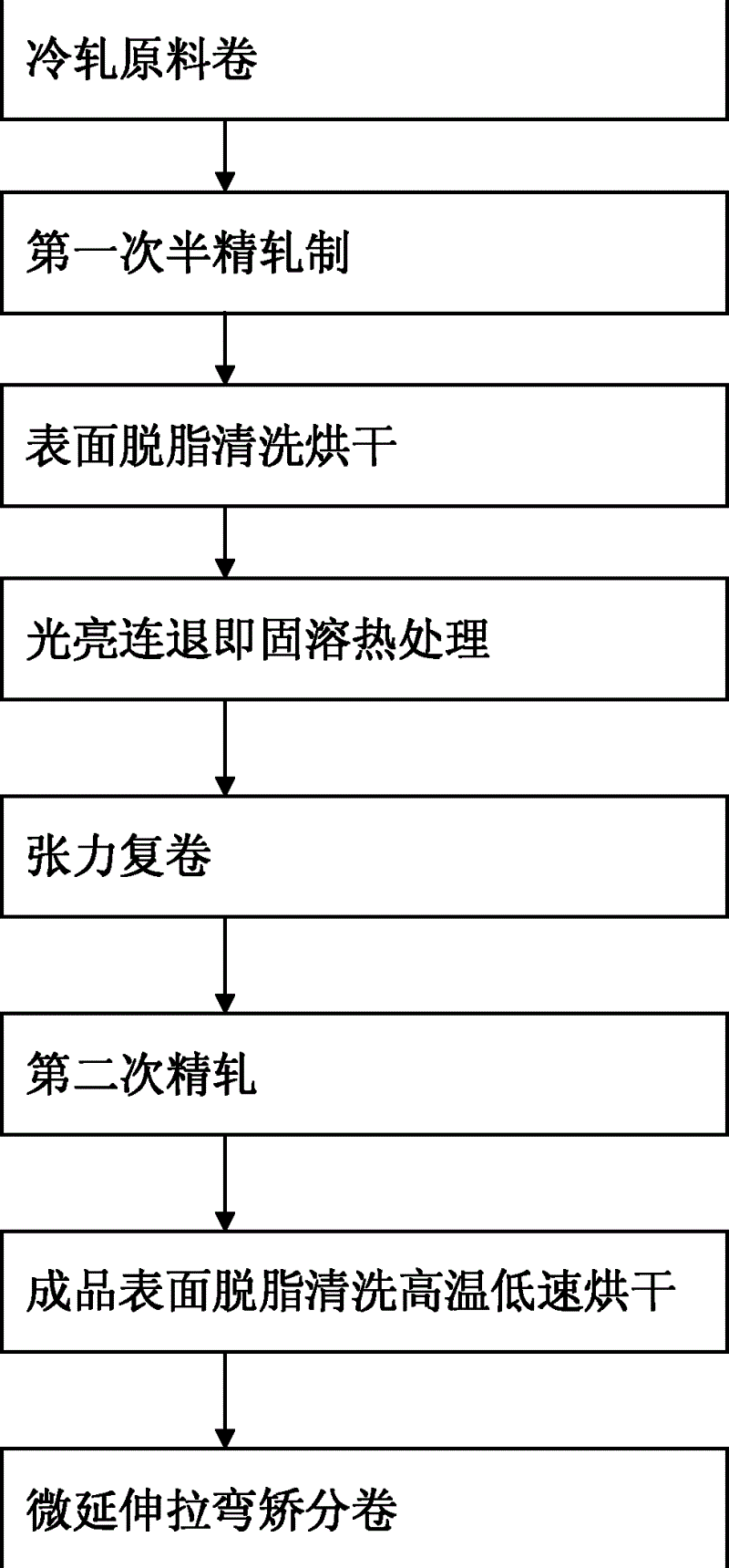

Partially-etched precision stainless steel strip used in communication industry as well as production process and application thereof

ActiveCN102699019AAvoid deformationMeet production requirementsTension/compression control deviceMetal rolling arrangementsCommunication industrySurface roughness

The invention relates to a production method of a partially-etched precision stainless steel strip, which comprises the following steps: semi-finish rolling; degreasing, washing and drying; solution heat treatment; tension rewinding; finish rolling; degreasing, cleaning and drying; micro extending, straightening and bundling. Due to the implementation of the technical scheme of the production process, the product has high thickness tolerance precision, low fluctuation, smooth surface, uniform surface roughness and no surface color difference. The plate is flat, has stable mechanical performance, is not easy to deform after being partially etched and can met the needs of producing the intelligent mobile phones in the communication industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

Wrought magnesium alloys in high intensity, high plasticity, and preparation method

This invention discloses a method for preparing Mg alloy with high strength and high plastic deformation. The compositions of the Mg alloy are: Zn 4.5-5.5 wt.%, Ce 0.5-2.5 wt.%, Ti 0.01-0.20 wt.%, Si less than or equal to 0.08 wt.%, Fe less than or equal to 0.01 wt.%, Cu less than or equal to 0.01 wt.%, Ni less than or equal to 0.002 wt.%, impurities less than or equal to 0.05 wt.%, and Mg as balance. The method adds rare earth element Ce to Mg-Zn-Zr alloy, and replaces Zr with Ti, thus can refine the alloy grains. Besides, Mg forms a dispersed reinforcing phase, which can effectively improve the comprehensive properties of the Mg alloy. The surface quality of the extruded product of the Mg alloy is obviously improved when compared with ZK series deformed Mg alloys. The average tensile strength, yield strength and elongation at breakage of the Mg alloy at room temperature are 360 MPa, 245 MPa and 7%, respectively. The average tensile strength and elongation at breakage of the Mg alloy at 150 deg.C are 250 MPa and 11%, respectively.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

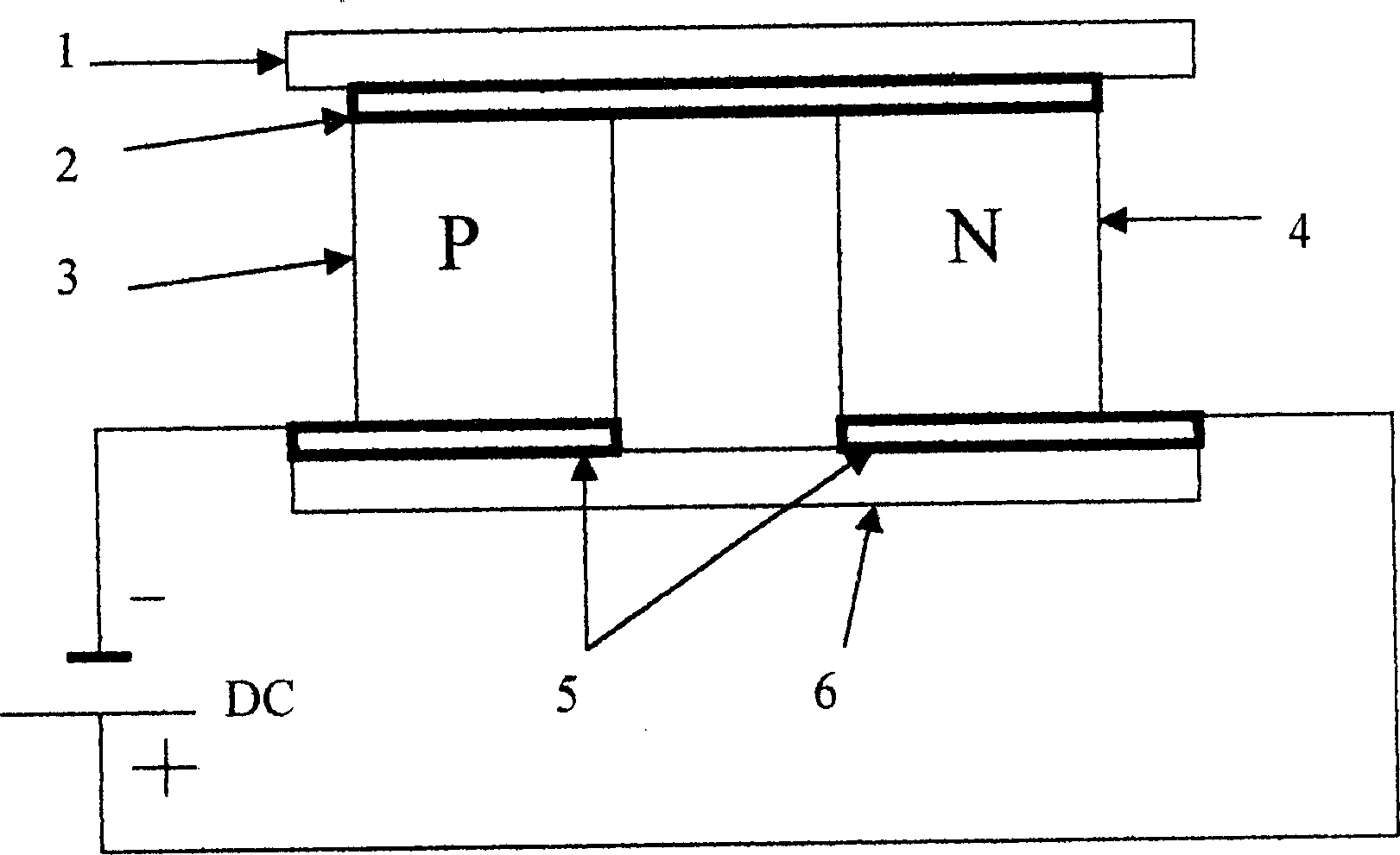

Method and device for producing thermoelectric semiconductor device and its products obtained thereof

InactiveCN1750287ANo mechanical cutting damageCompact structureThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSemiconductor materialsThermoelectric element

This invention discloses a method for manufacturing a thermal electric semiconductor device, the equipment and its products charactering in applying an accurate casting technology to directly cast the melt type P and type N thermal electric semiconductor materials to preset special models separately by quantitatively controlling the exit unit, which casts the materials onto the models separately by a conduit charactering that the P and N thermal electric elements are set at either side of a baffle, the bending part of the metal connection sheets is inserted into the elements and the plane part are fixed on the upper and the lower base plates.

Owner:杜效中

Silver-platinum alloy and methods of manufacturing same

A silver-platinum alloy formulated to provide improved tarnish resistance and hardness as compared to sterling silver. The alloy can be incorporated in various jewelry, flatware, and like articles. The alloy generally includes silver and platinum, with silver being the predominant component. In certain applications, the alloy includes about 90–95.5% silver and about 0.5–6% platinum. A small amount of gallium can also be added to the composition to provide ease of manufacture of the alloy. The resulting alloy has the favorable properties afforded by sterling silver, but also has brighter surface finish, greater tarnish resistance and increased hardness as compared to traditional sterling silver.

Owner:AMERICAN BULLION INVESTMENT

Aluminium wiredrawing lubricant and preparation method thereof

The invention provides an aluminium wiredrawing lubricant and a preparation method thereof. The lubricant is characterized by comprising the following raw materials by weight parts: 0.3-0.4 parts of monoethanolamine, 0.6-0.8 parts of triethanolamine, 0.2-0.3 parts of mercapto benzimidazole, 1-2 parts of caprylic-capric acid blend, 1-2 parts of sodium dodecyl sulfate, 1-2 parts of dibutyltin dilaurate, 1-2 parts of zinc acetate, 1-2 parts of tung oil, 2-3 parts of methyl trimethoxy silane, 3-4 parts of a film forming auxiliary agent and 150-160 parts of water. According to the invention, the tung oil is added to promote lubricity, water base is used to play a relatively good heat dissipating effect, the triethanolamine is added to improve an anti-corrosion effect, and the methyl trimethoxy silane is combined with the mercapto benzimidazole, the caprylic-capric acid blend and the film forming agent to improve a film forming performance and prolong an anti-corrosion time of the aluminium conductor after the wiredrawing.

Owner:安徽富华电子集团有限公司

Brightening rust removing agent

The present invention relates to a substance which removes rustiness on the surface of steel and iron, in particular to brightening rust remover, which solves the problem that the steel and the iron have gloomy surfaces after the rust removing in the prior art. The brightening rust remover is composed of materials in the following weight ratio: chlorhydric acid is 30-50 percent, hexamethylene tetramine is 1-5 percent, sodium lauryl sulphate is 2-8 percent, peregal OS-15 is 5-10 percent, and the residual is water. The present invention has the characteristics that rustiness can be removed quickly, the steel and the iron are brighter than the original state after the rustiness is removed, no over corrosion and hydrogen brittleness phenomenon exist, no pollution exists, and the cost is low, etc. Since the difference of the degrees of corrosion, the rustiness removing time is generally within 1-5 minutes.

Owner:山西银河镀锌有限公司

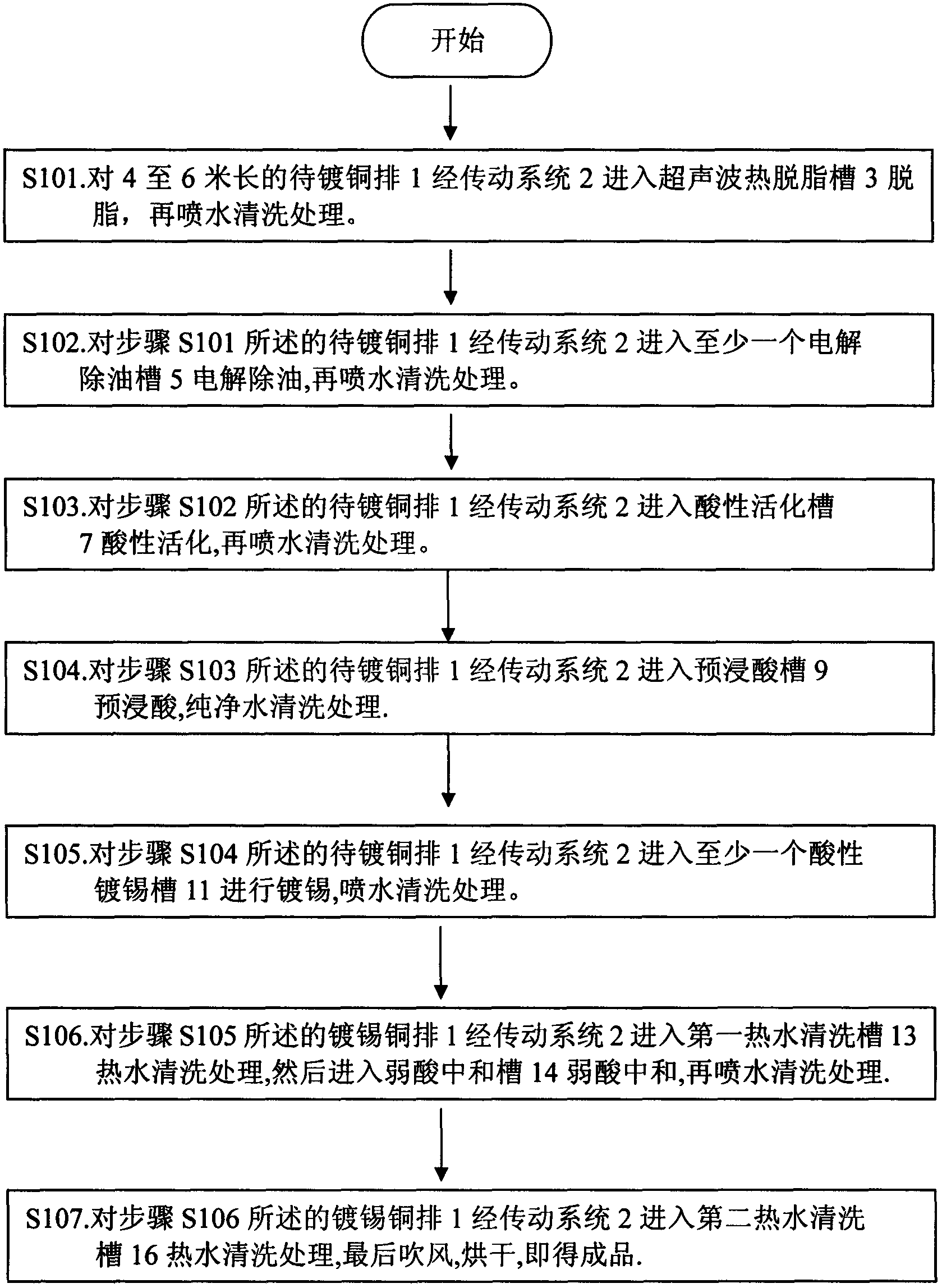

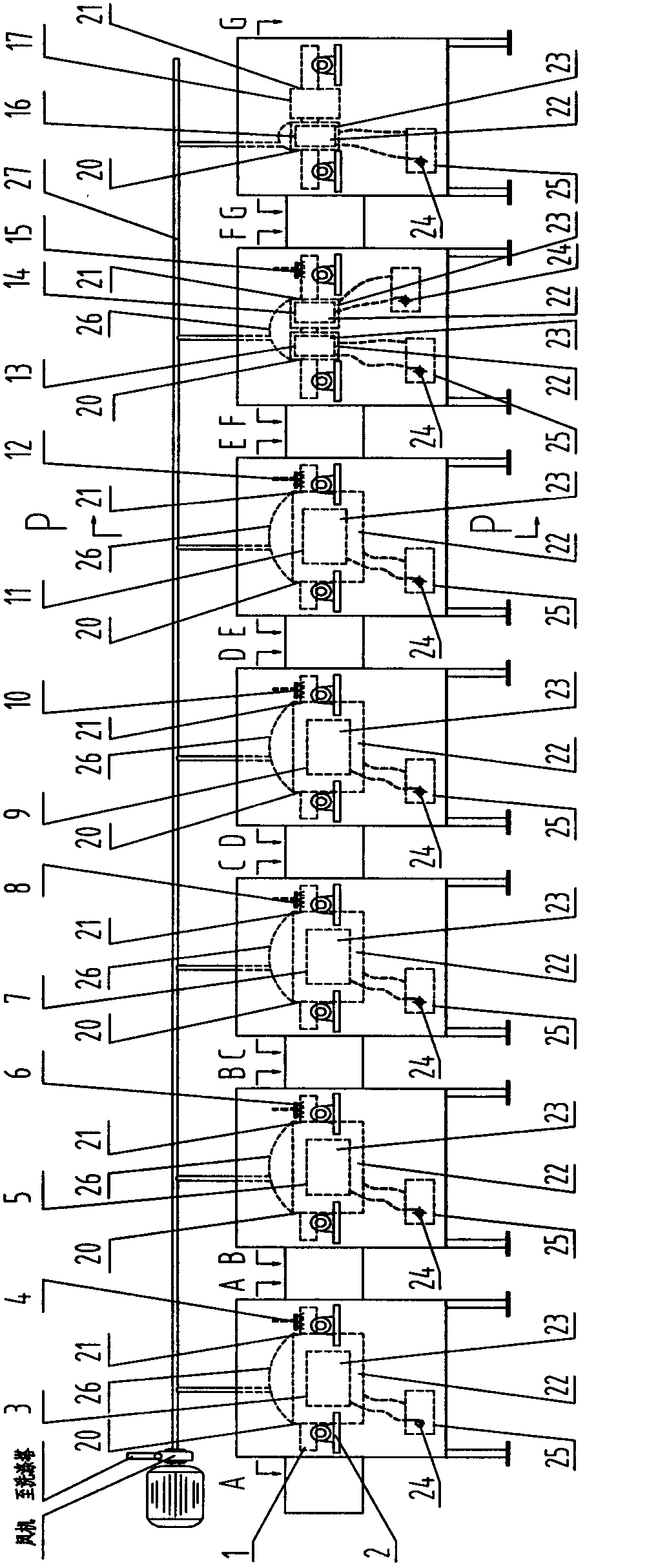

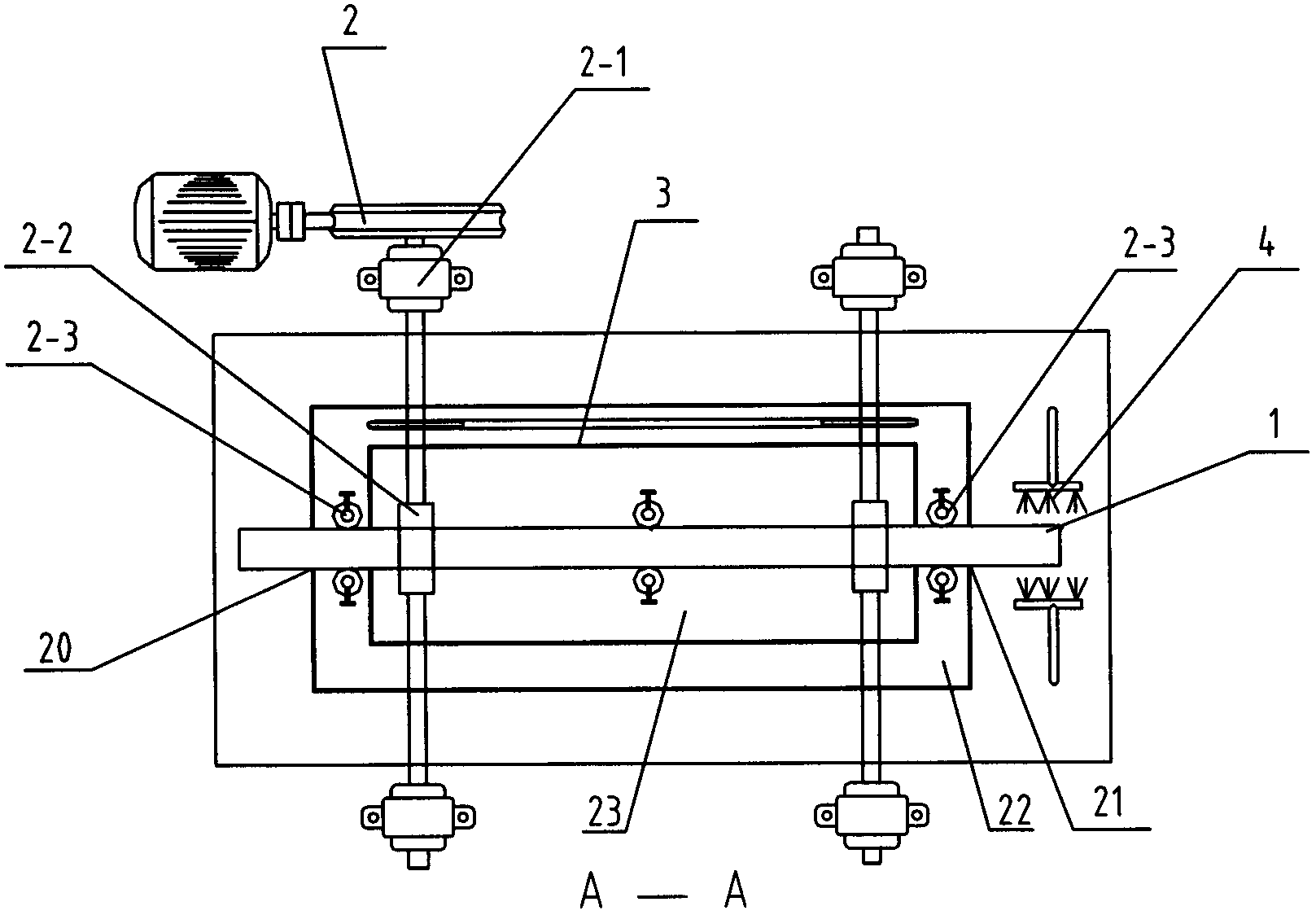

Copper bar continuous travelling tinning method and equipment

ActiveCN102703959ABright surfaceUniform crystallizationElectrolysis componentsTinningHigh current density

The invention discloses a copper bar continuous travelling tinning method and equipment, which includes the follows steps: step S101 is that a to-be-tinned copper bar of 4 to 6 meters in length undergoes ultrasonic thermal bebinding and water-spray washing through a transmission system; step S102 is that the to-be-tinned copper bar undergoes electrolytic degreasing and water-spray washing; step S103 is that to-be-tinned copper bar undergoes acid activating and water-spray washing; step S104 is that the to-be-tinned copper bar undergoes pre-pickling and purified water washing; step S105 is that the to-be-tinned copper bar undergoes tinning and connected with a conducting wheel in a sliding way, and the flowing cooling water pipe on the upper side of the conducting wheel performs water-spray washing after the tinning; step S106 is that the tinned copper bar undergoes hot water washing, weak acid neutralization and water-spray washing; and step S107 is that the tinned copper bar undergoes hot water washing and drying through blowing, so as to obtain the finished product. The method and equipment enable the to-be-tinned copper bar to continuously travel at a uniform speed in the electroplating baths through the transmission system, can electroplate under high current density, and improve the tinning efficiency; the surface of the tinned surface is uniform, smooth and is highly anti-corrosive, the harmful waste gases as alkali and acid mist produced during the tinning process can be purified by the equipment, and the equipment doesn't pollute the environment.

Owner:周建元

Method for preparing Fe-Ni, Fi-Ni-Cr alloy foil

InactiveCN1641072AShort production processThickness is easy to controlElectroforming processesElectrolysisNi cr alloy

The present invention relates to the field of electrolysis process for depositing metal, and features that Fe-Ni or Fe-Ni-Cr alloy foil is produced through electrolytic deposition in a water solution system of sulfate and chloride or sulfate, chloride and trivalent chromium. The electrolytic production process of alloy foil has short flow path, stable electrolyte, easy maintenance, simple waste water treatment, easy control of foil components and thickness, low cost and other advantages. The alloy foil has its physical and chemical performance, especially magnetic performance, higher than that produced through rolling process, and the produced Fe-Ni and Fe-Ni-Cr alloy foil may be used in electronic, telecom and electric industry as excellent soft magnetic material, cell skeleton material and packing material.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com