Imitation wood grain color master batch, preparation method, and applications thereof

A technology of imitating wood grain and color masterbatch, which is applied in the field of imitating wood grain color masterbatch and its preparation method and in imitating wood grain wood-plastic composite materials, which can solve the problems of uneven dispersion and poor high temperature resistance , to achieve excellent dispersion performance, good effect of imitating wood grain and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

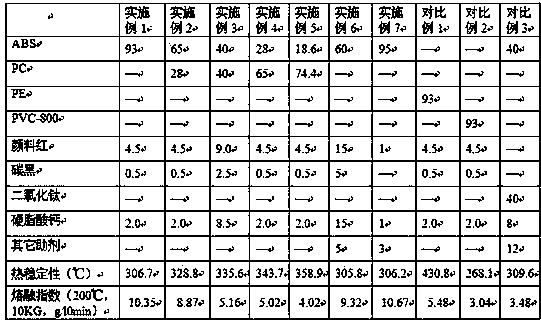

Embodiment 1~7 and comparative example 1~3

[0038] Examples 1~7 and Comparative Examples 1~3: Preparation of imitation wood grain masterbatch

[0039] Under normal temperature and pressure, the carrier resin, pigment, dispersant and / or other additives in Examples 1-7 and Comparative Examples 1-3 were mixed at high speed for 600s in a high-speed mixer, and a twin-screw extruder was used after mixing the materials Carry out melt blending, the temperature control range of the temperature zone of the extruder is 120~250°C, the screw speed is 400r / min, the pigment is uniformly dispersed in the carrier resin through the shearing and mixing of the screw, and the water cooling (water cooling temperature 30°C), pelletizing (the appearance of the masterbatch is cylindrical), and air-drying to obtain the imitation wood grain masterbatch of the present invention.

[0040] The pigment red in the examples and comparative examples is selected as one or more mixtures of iron oxide red 101, iron oxide red 110, iron oxide red 130, iron ...

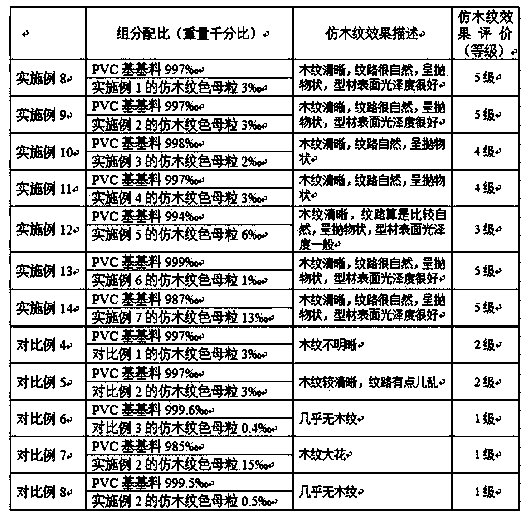

Embodiment 8~14 and comparative example 4~8

[0045] Examples 8-14 and Comparative Examples 4-8: Preparation of imitation wood-grain wood-plastic composite material:

[0046] Mix the imitation wood-grain masterbatch obtained in Examples 1~7 and Comparative Examples 1~3 at 120~190°C with PVC-based base material according to the weight ratio in Table 2, and then extrude in a single-screw extruder (Screw speed is 15.6r / min), vacuum water cooling and shaping, traction, cutting to obtain imitation wood-grain wood-plastic composite materials, samples are prepared to test its performance, and the measured results are shown in Table 2:

[0047] The PVC-based base material described in the embodiments of the present invention can be prepared according to conventional methods, such as in patent 102336989A: add 30 parts of wood powder weighed into a high-speed mixer, and bake at 110-120 ° C for 8-10 Minutes, then add 1.0 parts of coupling agent to activate the wood powder for 5 minutes, put it into the cold mix and cool to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com