Partially-etched precision stainless steel strip used in communication industry as well as production process and application thereof

A stainless steel strip and production process technology, applied in the direction of tension/pressure control, roll speed control, metal rolling, etc., can solve the problems of parts scrapping, not fully meeting the production requirements of precision stainless steel parts, and the precision stainless steel strip is easy to be seriously deformed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

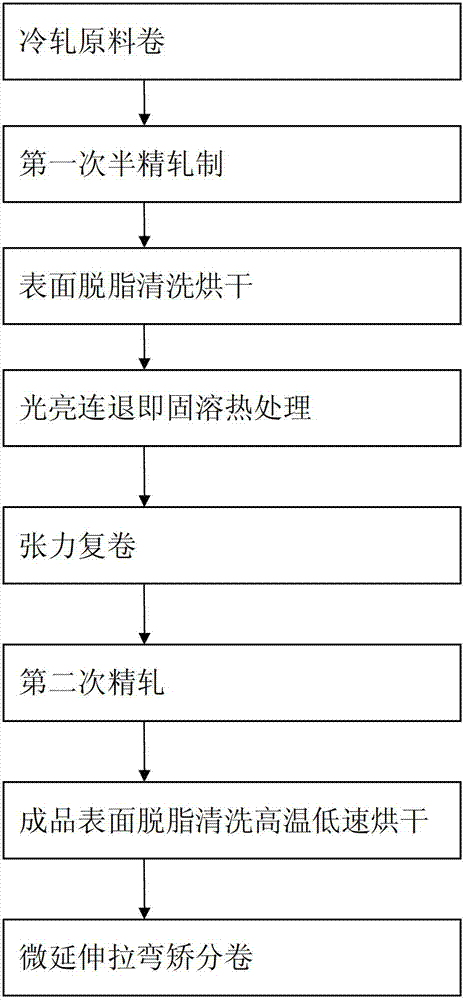

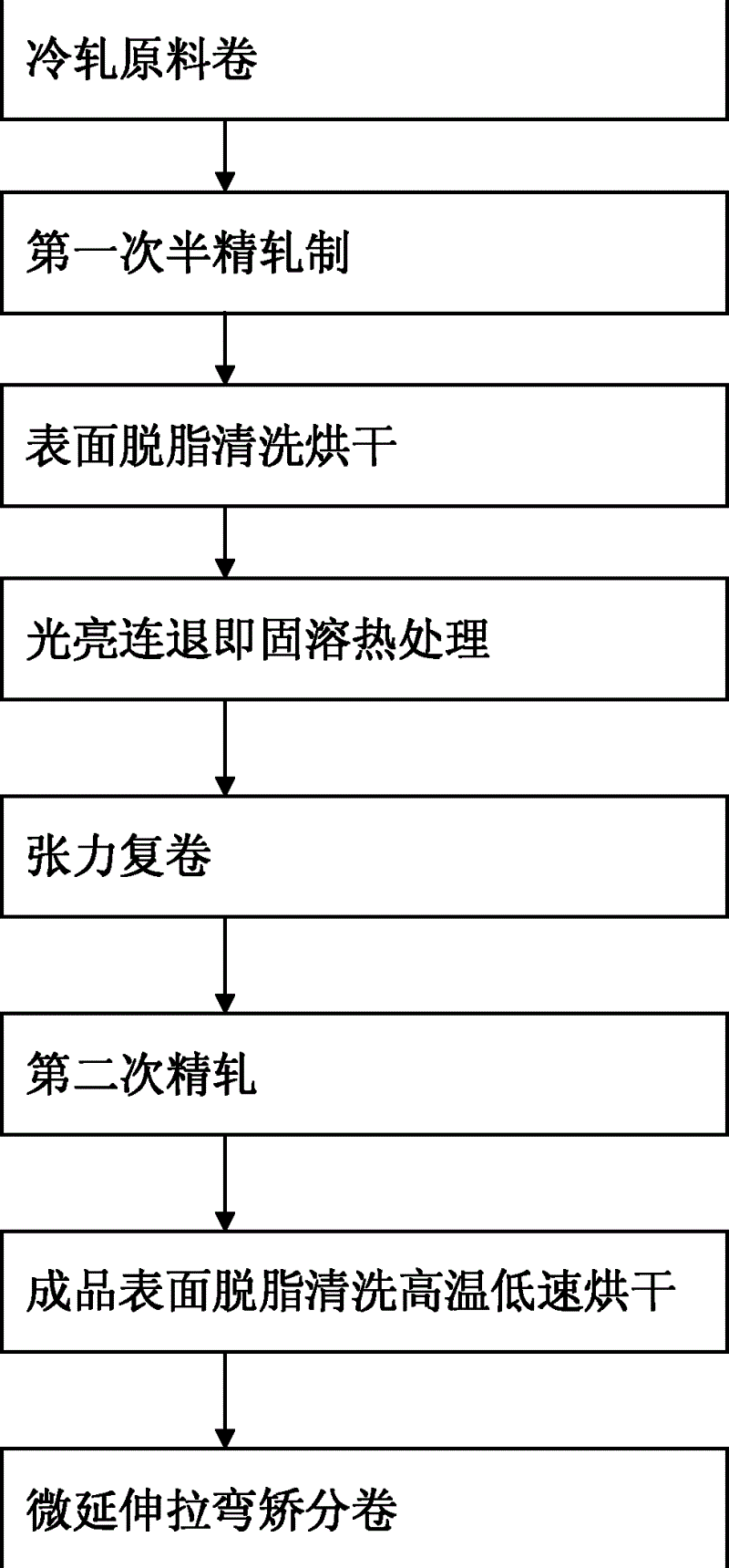

Method used

Image

Examples

Embodiment 1

[0099] In this example, the selected grade is the surface of SUS304 cold-rolled raw material coil 2B, with a thickness of 0.60mm and a width of 400mm. Requirements for finished steel strips: thickness 0.30mm, width 125+125+128 each, tensile strength ≥ 930Mpa, Vickers hardness HV310-370, elongation ≥ 3%, semi-etched without deformation.

[0100] (1) First select SUS304 cold-rolled raw material coil, the surface is in 2B state, chemical composition: carbon (C) 0.05%, silicon (Si) 0.41%, manganese (Mn) 1.3%, phosphorus (P) 0.045%, sulfur (S ) 0.028%, nickel (Ni) 8.03%, chromium (Cr) 18.1%, copper (Cu) 0.13%, nitrogen (N) 0.029%, molybdenum (Mo) 0.01%.

[0101] (2) For the stainless steel cold-rolled raw material coil with a thickness of 0.60mm, use Sendzimir 20-roll mill for semi-finish rolling, and use Guohong Lubricating Oil (China) Co., Ltd. model DN.STAINLESS ROLLP-T mineral rolling during rolling Make oil for lubrication and cooling, control the oil temperature at 25°C duri...

Embodiment 2

[0117]In this example, the cold-rolled raw material coil of brand SUS304 is selected, the surface is in 2B state, the thickness is 0.90mm, the width is 400mm, the thickness of the finished steel strip is 0.50mm, the coil degree is 128+128+125mm each, and the tensile strength is ≥930Mpa. Vickers hardness HV310 ~ 370, elongation ≥ 3%, half-etching requires no deformation.

[0118] (1) First select SUS304 cold-rolled stainless steel raw material coil, the surface is in 2B state. Chemical composition: with embodiment 1.

[0119] (2) For the stainless steel cold-rolled raw material coils with a thickness of 0.90mm, a 20-roll Sendzimir rolling mill is used for semi-finish rolling. During rolling, the model DN.STAINLESSROLL OIL P-T mineral rolling oil produced by Guohong Lubricating Oil (China) Co., Ltd. is used for lubrication and cooling. The oil temperature is controlled at 50°C during rolling, and the hardness of the work roll surface is selected to be HRC62. The surface roughn...

Embodiment 3

[0135] In this example, the cold-rolled raw material coil of brand SUS304 is selected, the surface is in 2B state, its thickness is 1.50mm, and its width is 400mm. Vickers hardness HV310 ~ 370, elongation ≥ 3%, half-etching requires no deformation.

[0136] (1) First select SUS304 cold-rolled stainless steel raw material coil, the surface is in 2B state. Chemical composition: with embodiment 1.

[0137] (2) For the stainless steel cold-rolled raw material coils with a thickness of 1.50mm, a 20-roller Sendzimir is used for semi-finish rolling. During rolling, DN.STAINLESSROLL OIL P-T mineral rolling oil produced by Guohong Lubricating Oil (China) Co., Ltd. is used for lubrication and cooling. The oil temperature is controlled at 30°C during rolling, and the hardness of the work roll surface is selected to be HRC61. The surface roughness of the roll is controlled at Ra0.10μm, and the shape control roll selects a cone length of 270mm and a taper of 1 / 850. Then the 1.5mm thick ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com