Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Uniform roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

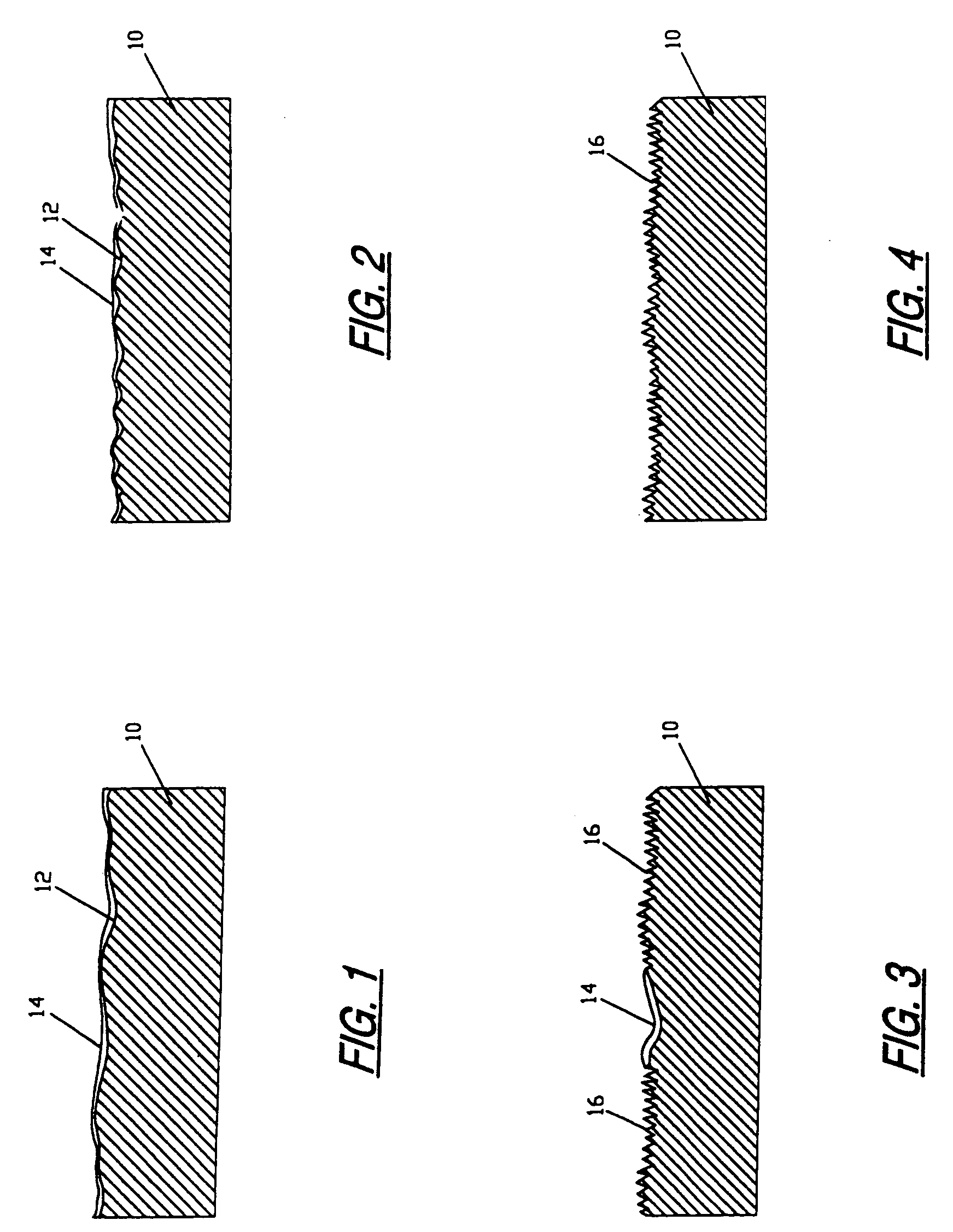

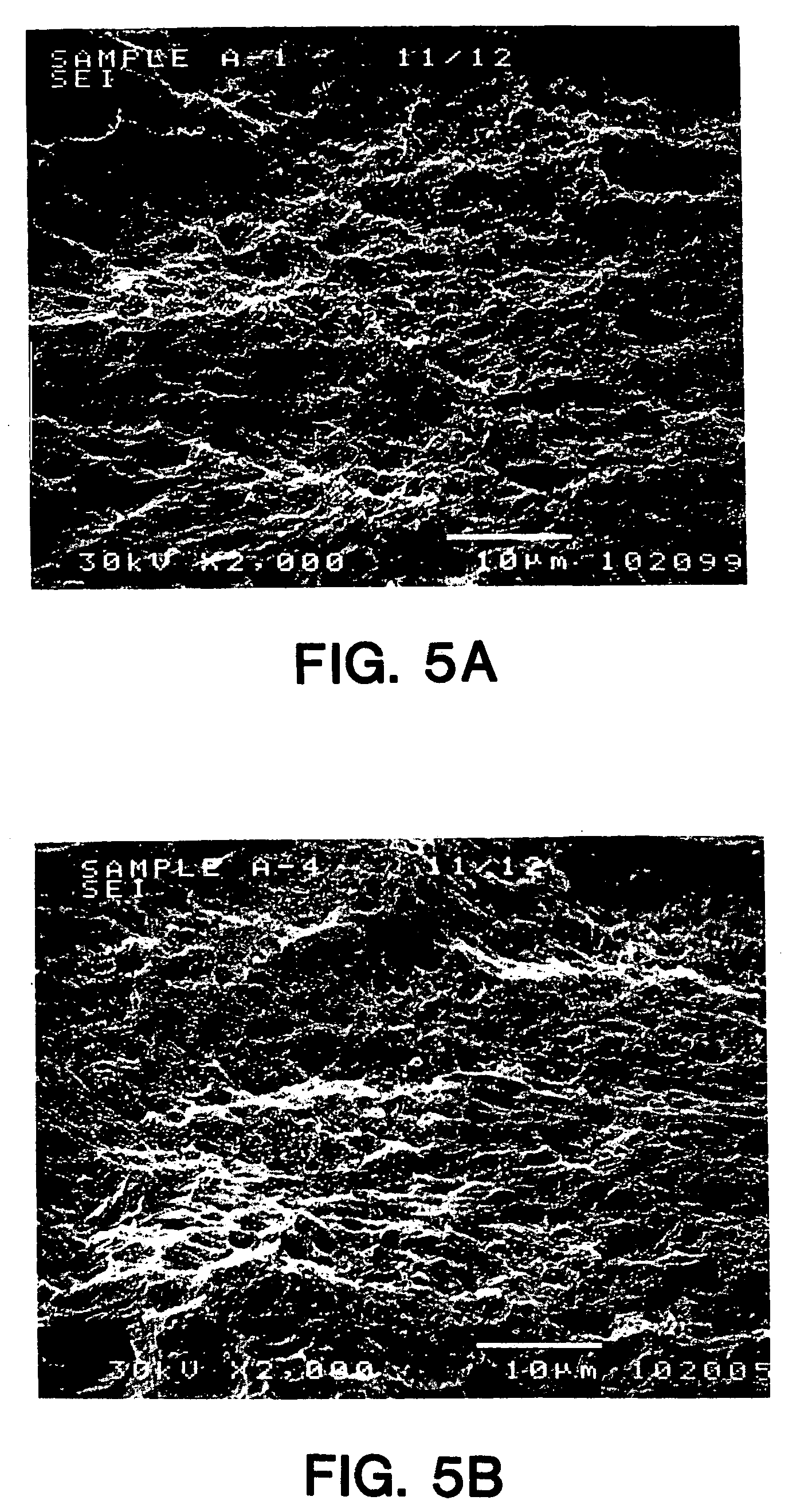

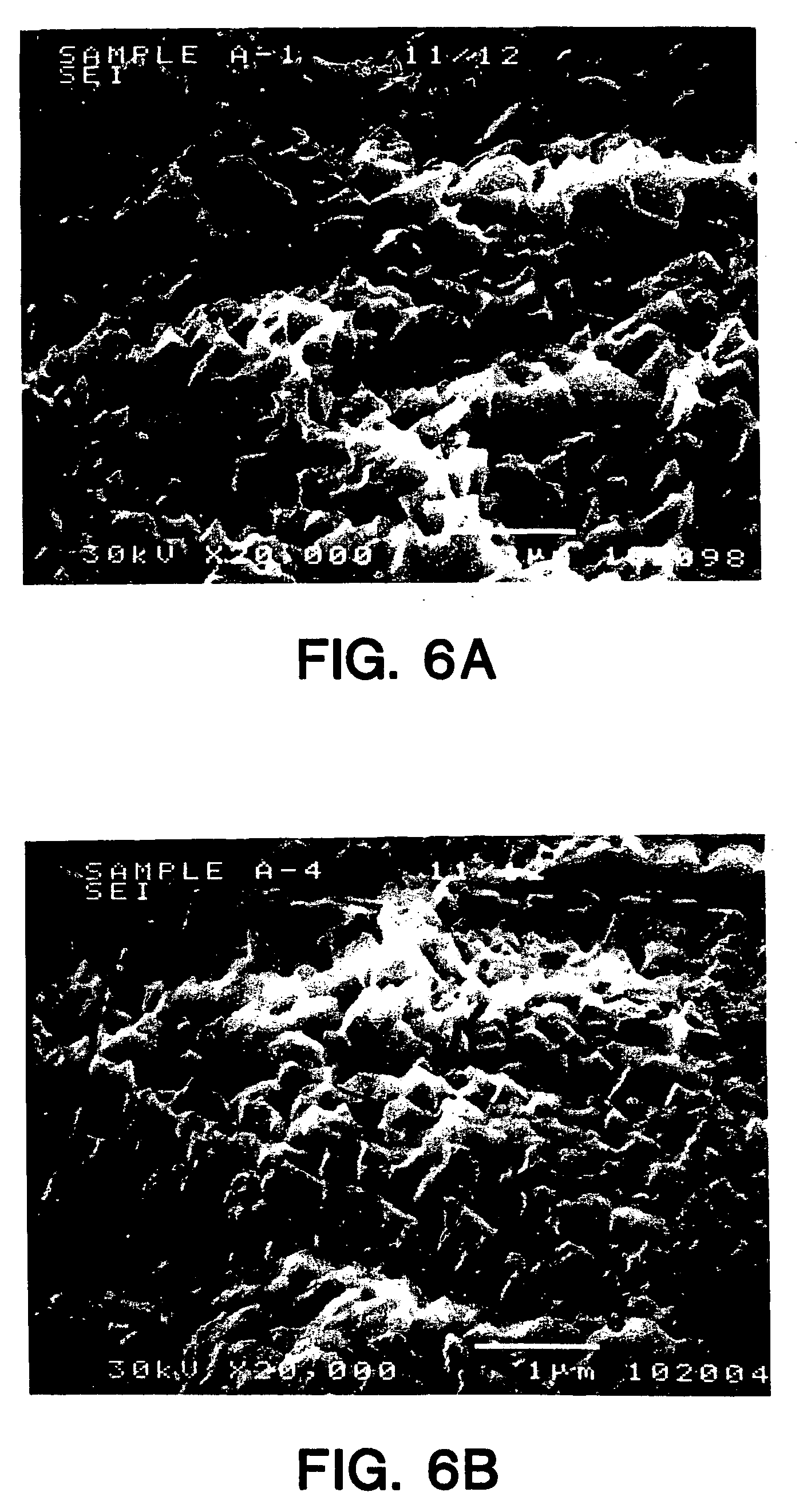

Implant surface preparation

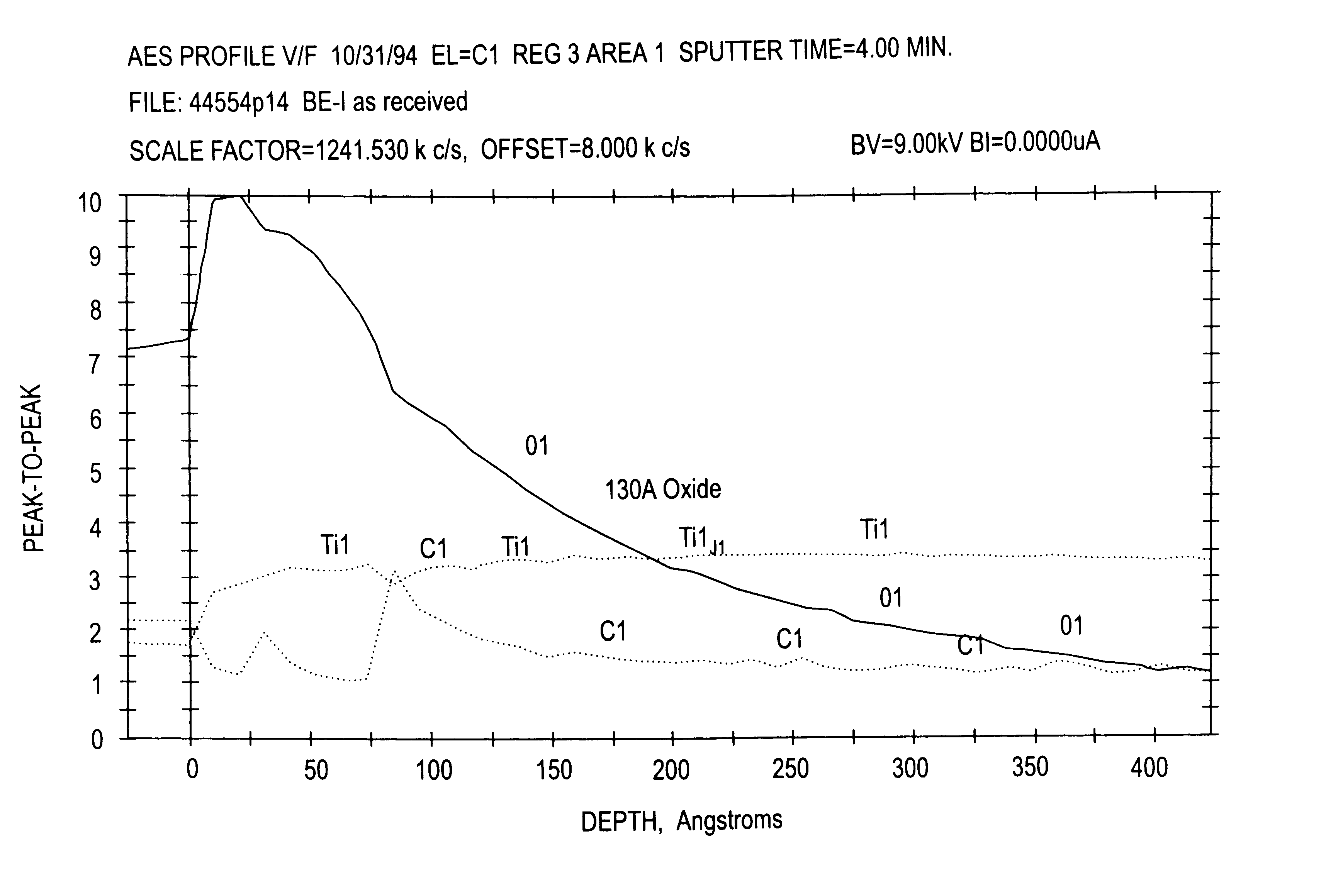

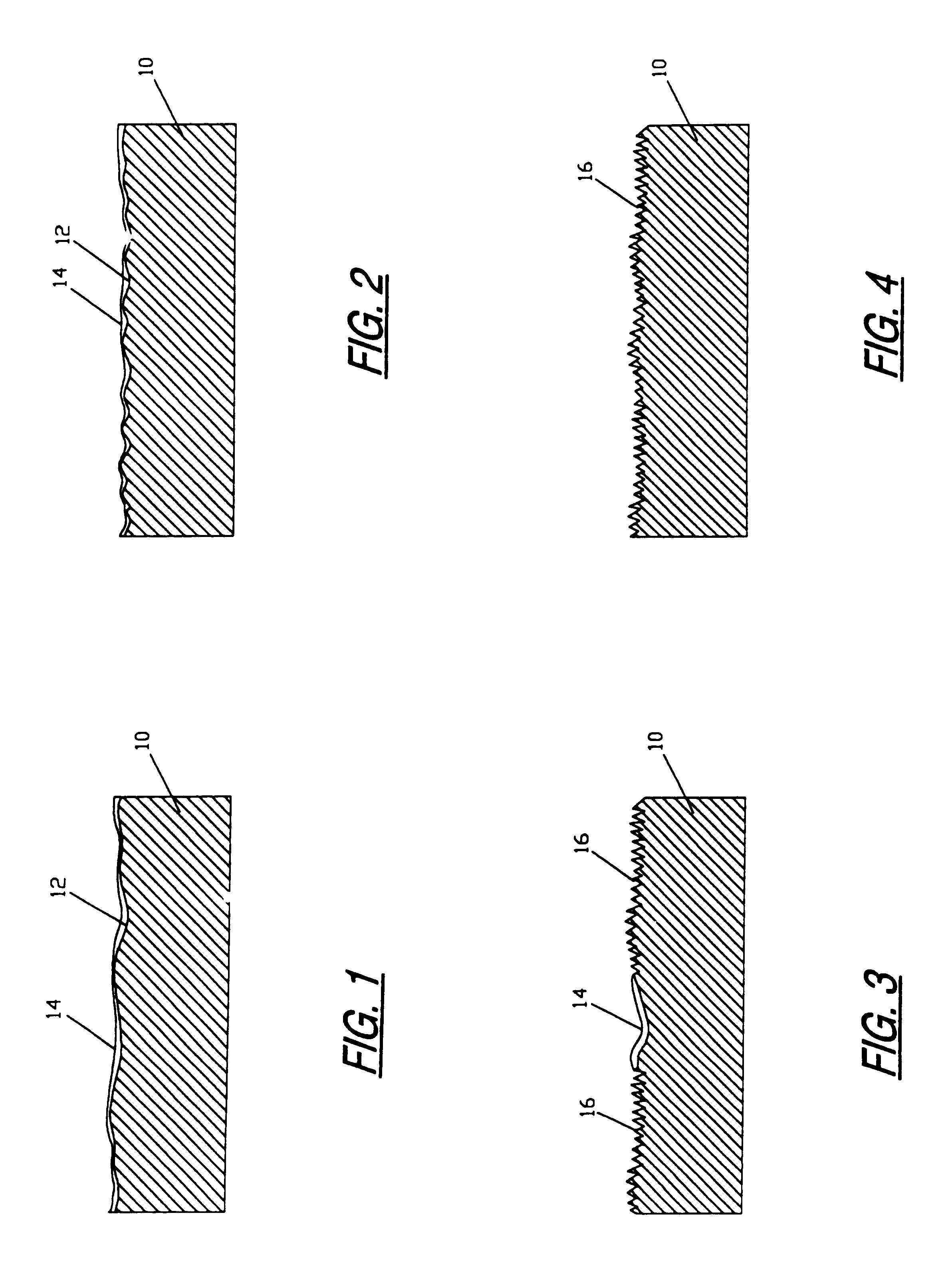

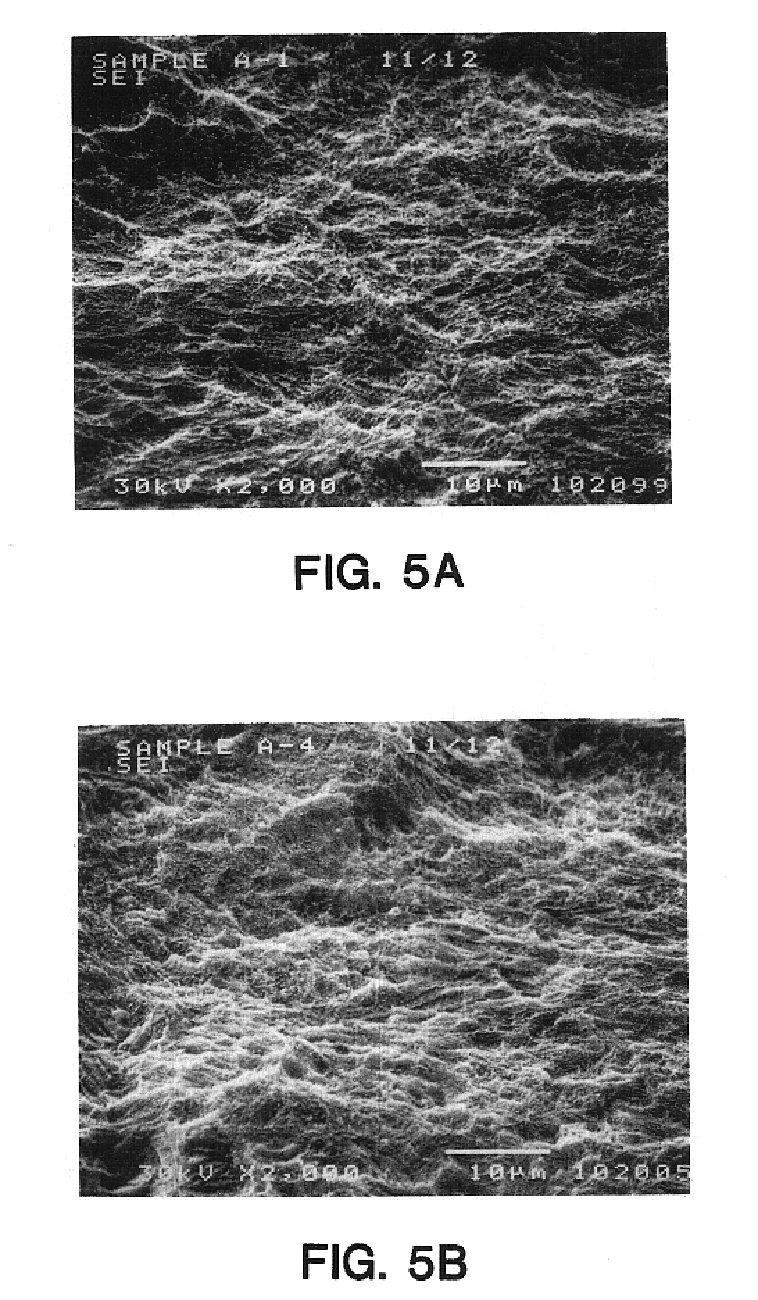

InactiveUS6969474B2Uniform roughnessUniform surface topographyDental implantsImpression capsTitaniumOxygen

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

Manufacture method of cold-rolled electrolytic tin substrate

ActiveCN102794301AStable productionReduce manufacturing costWork treatment devicesFurnace typesHydrogenPush pull

The invention discloses a manufacture method of a cold-rolled electrolytic tin substrate. The manufacture method comprises the steps of: (1) processing the produced molten iron by converter smelting, vacuum treatment, continuous casting and hot rolling after desulfuration to obtain a cold-rolled material; (2) pickling by a shallow-trench turbulent push-pull hydrochloric acid pickling set; (3) carrying out cold rolling for the first time by using a six-roller HC reversing mill, and rolling to a semi-product with a thickness of 0.5 to 0.6 mm after passing through 4 to 7 rolling passes; (4) cleaning by an electrolytic degreasing set; (5) carrying out annealing for the first time in a full-hydrogen shine-cover annealing furnace; (6) carrying out cold rolling for the second time by using the six-roller HC reversing mill; (7) carrying out annealing for the second time in the full-hydrogen shine-cover annealing furnace; (8) leveling by using a four-roller leveling machine, wherein the rolling force is controlled between 3000 to 4500kN; and (9) trimming by a re-reeling set, oiling, packaging and storing in a warehouse. The manufacture method disclosed by the invention has the advantages of stable production and low production cost, and can meet the requirement for high-quality electrolytic thin substrate in the food package industry.

Owner:山东泰山轧钢有限公司

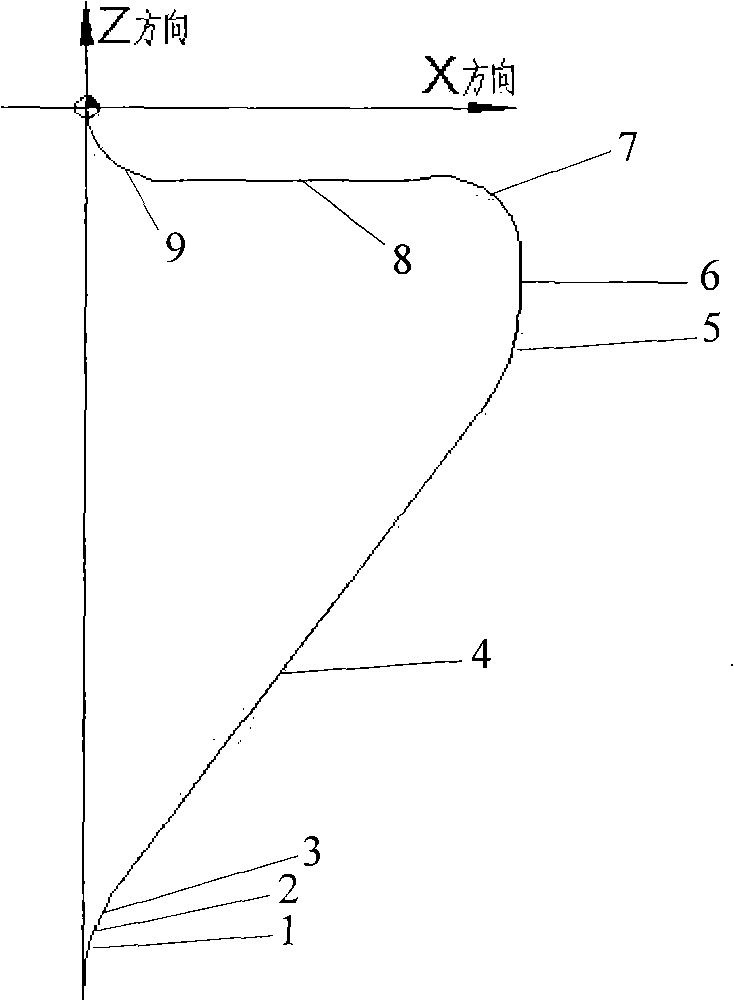

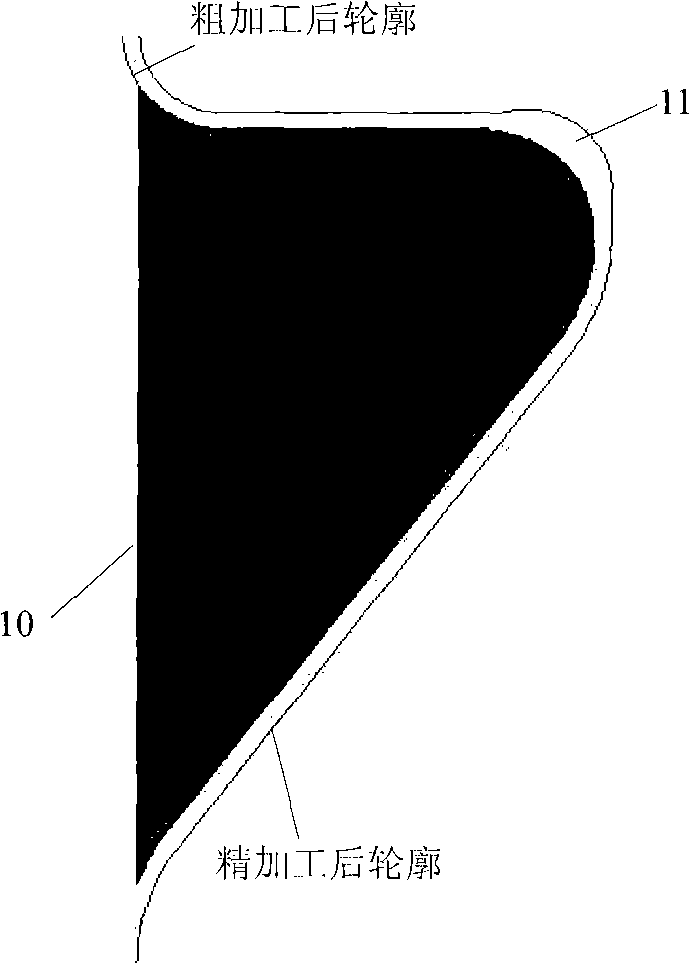

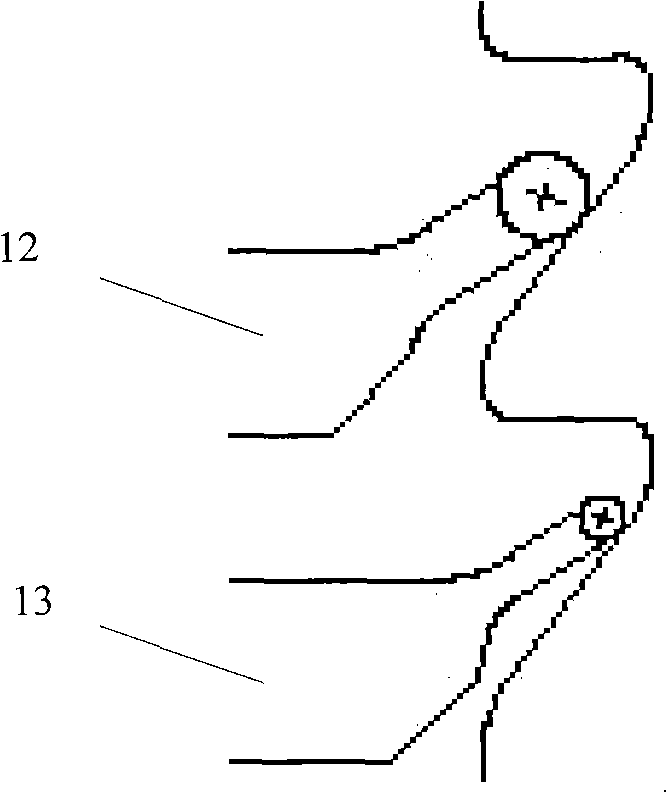

Giant non-standard trapezoidal thread processing method

ActiveCN101266476AImprove processing productivityImprove processing quality and precisionNumerical controlProcessing accuracyHigh pressure

The invention relates to a processing method of high-pressure exterior cylinder component of million grade super critical steam turbine, especially to a processing method of S2099*P50 giant nonstandard trapezoidal thread. A processing method of giant nonstandard trapezoidal thread uses a numerically controlled machine to execute processing, which is carried out according to the following sequences: executing mathematics modeling to the screw thread type wire; using coarse and fine processing methods, determining suitable radius lathe cutters respectively adopted by the coarse and fine processing methods according to required processing wire and required surface accuracy and roughness concentration, and determining suitable deepness allowance of the line face after the coarse processing; determining the coarse processing lathe cutter center track area and the fine processing lathe cutter center track area, and modeling for the cutter center track boundary; determining spacing of every layer during processing and spacing of every cutter in a same layer according to the material to be cut, the selected cutter, machine performance and cutting position; programming the coarse and fine processing lathe cutter walking procedure; and executing the process according to the programmed procedure. The inventive processing method has high process efficiency and high machine precision.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Implant surface preparation

InactiveUS20050263491A1Uniform roughnessUniform surface topographyDental implantsDecorative surface effectsTitaniumOxygen

The surface of a device that is surgically implantable in living bone is prepared. The device is made of titanium with a native oxide layer on the surface. The method of preparation comprises the steps of removing the native oxide layer from the surface of the device and performing further treatment of the surface substantially in the absence of unreacted oxygen.

Owner:BIOMET 3I LLC

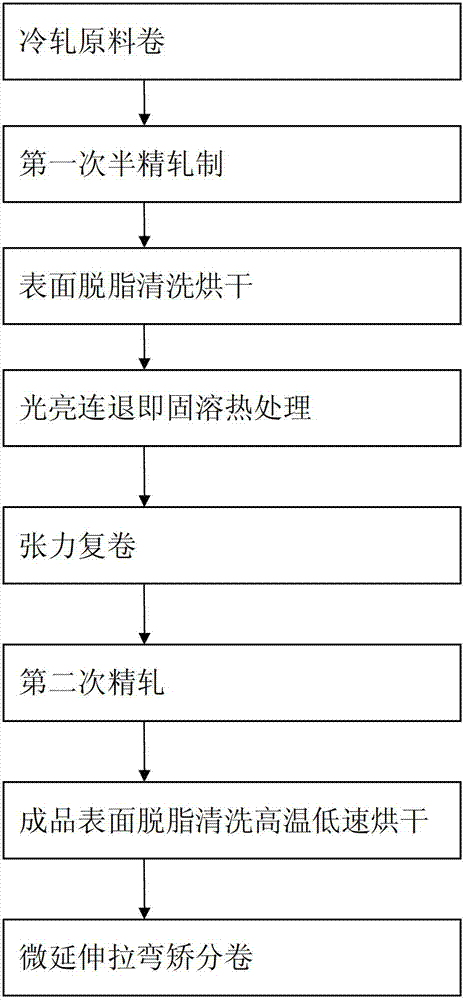

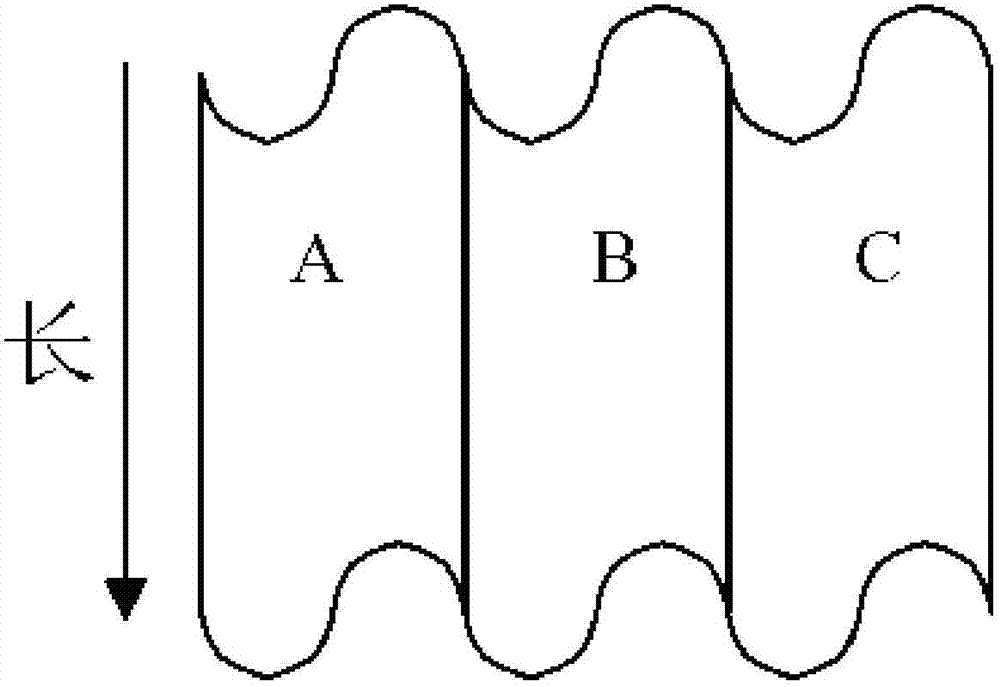

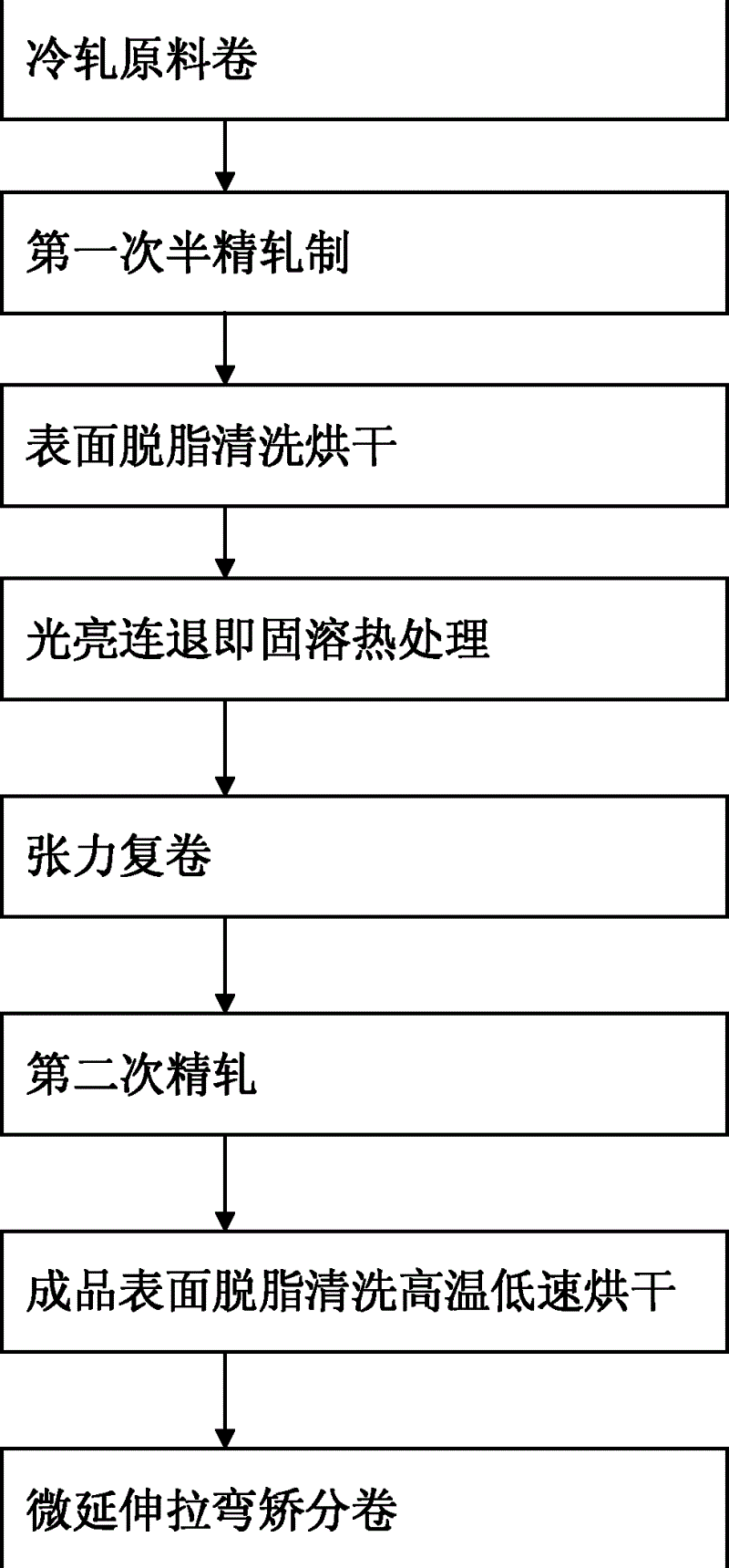

Partially-etched precision stainless steel strip used in communication industry as well as production process and application thereof

ActiveCN102699019AAvoid deformationMeet production requirementsTension/compression control deviceMetal rolling arrangementsCommunication industrySurface roughness

The invention relates to a production method of a partially-etched precision stainless steel strip, which comprises the following steps: semi-finish rolling; degreasing, washing and drying; solution heat treatment; tension rewinding; finish rolling; degreasing, cleaning and drying; micro extending, straightening and bundling. Due to the implementation of the technical scheme of the production process, the product has high thickness tolerance precision, low fluctuation, smooth surface, uniform surface roughness and no surface color difference. The plate is flat, has stable mechanical performance, is not easy to deform after being partially etched and can met the needs of producing the intelligent mobile phones in the communication industry.

Owner:YONGXIN PRECISION MATERIAL WUXI

Matt, biaxially oriented polyester film

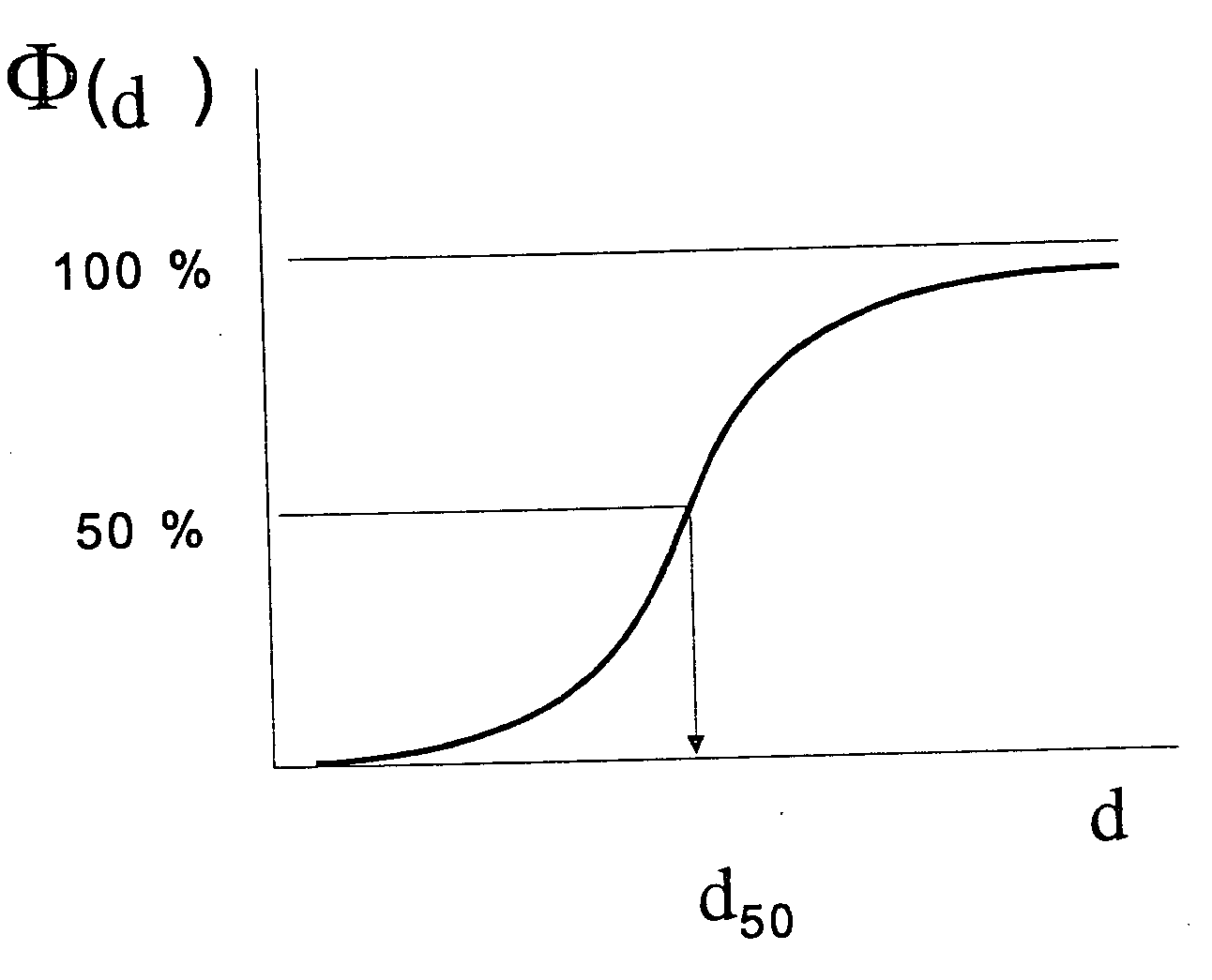

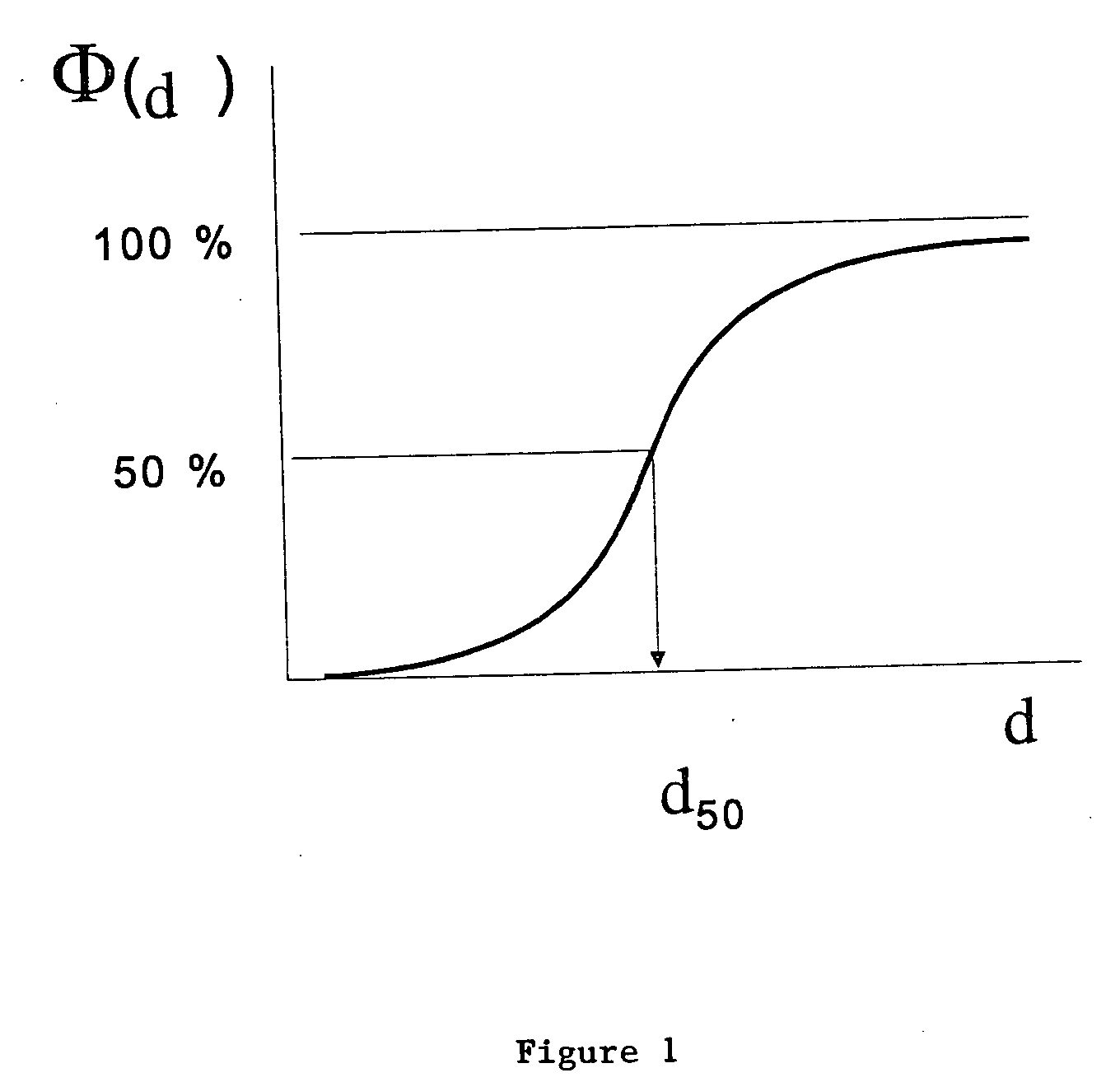

InactiveUS20060134382A1Uniform roughnessDefined optical propertyRecord information storageMagnetic recordingPolyesterSilica particle

The invention relates to a single- or multilayer, biaxially oriented polyester film where at least one layer includes an amount of from 0.2 to <1.0 % by weight, based on the total weight of the film, of silicon dioxide particles whose median particle size, d50 is from 2.5 to 4.5 μm. The inventive films have particular suitability in the industrial sector, e.g. for greenhouses, for more diffuse light-scattering.

Owner:MITSUBISHI POLYESTER FILM

Method for grinding cathode roller for production of very-low-profile copper foil through electrolytic copper foil

ActiveCN104002204ARoughness Ra reducedUniform roughnessPolishing machinesLapping machinesElectrolysisCopper foil

The invention discloses a method for grinding a cathode roller for production of very-low-profile copper foil through electrolytic copper foil and belongs to the technical field of grinding technology for cathode rollers. The method for grinding the cathode roller for production of the very-low-profile copper foil through the electrolytic copper foil is characterized by comprising the following steps that (1) the cathode roller is placed on a cathode roller rotating frame, and the cathode roller rotating frame is started, wherein the rotation speed ranges from 10 r / min to 15 r / min, and the diameter of the cathode roller rotating frame ranges from 2700 mm to 2900 mm; (2) a plurality of parallel green silicon carbide grinding wheels are used in sequence for grinding the cathode roller, wherein the particle size of each green silicon carbide grinding wheel ranges from 400 meshes to 800 meshes, the rotation speed of the parallel green silicon carbide grinding wheels ranges from 2000 r / min to 3600 r / min during grinding, and the work pressure between the parallel green silicon carbide grinding wheels and the cathode roller ranges from 0.1 MPa to 0.18 MPa; (3) after grinding, polishing and grinding are conducted through a scouring pad, wherein the scouring pad is fixedly installed, the particle size of sand contained by the scouring pad ranges from 1000 meshes to 1200 meshes, the work pressure between the scouring pad and the cathode roller ranges from 1.2 MPa to 1.5 MPa during polishing and grinding, and the rotation speed of the cathode roller ranges from 10 r / min to 15 r / min. According to the method for grinding the cathode roller for production of the very-low-profile copper foil through the electrolytic copper foil, the grinding technology is reasonable, and the method is used for grinding the cathode roller.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

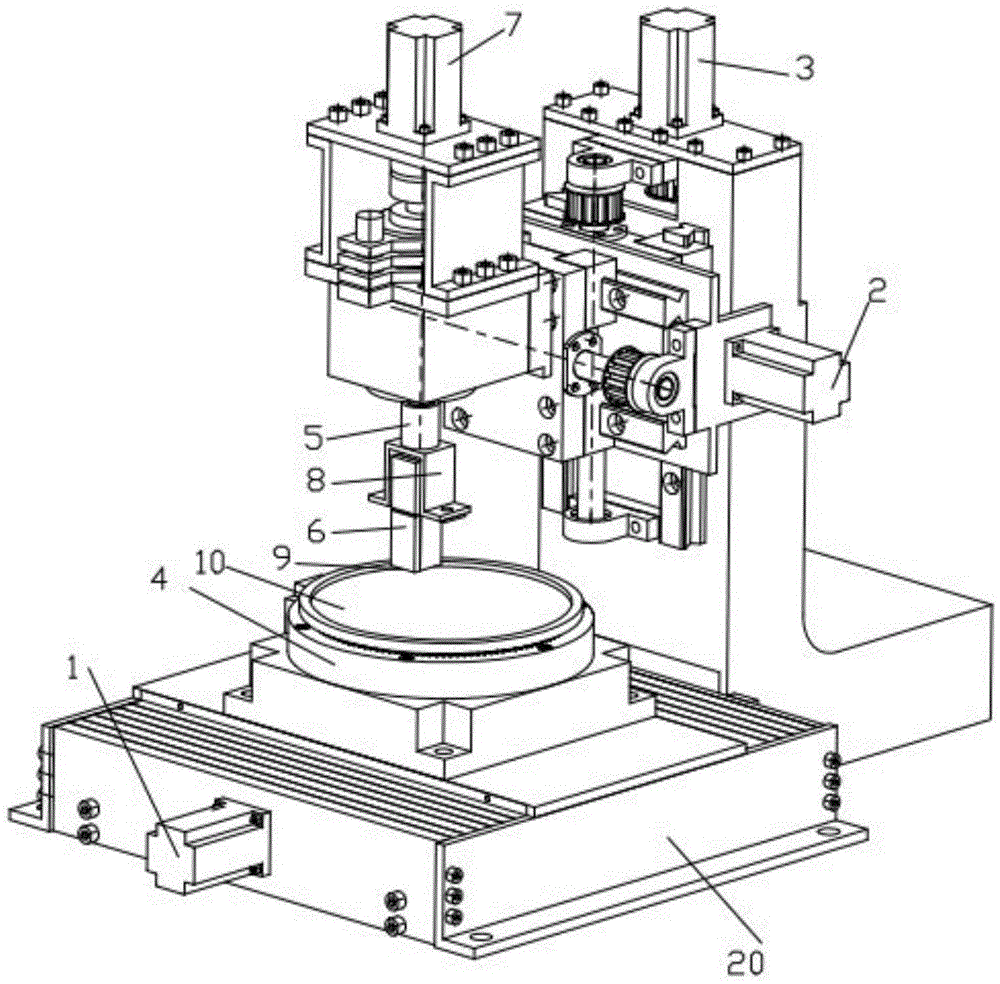

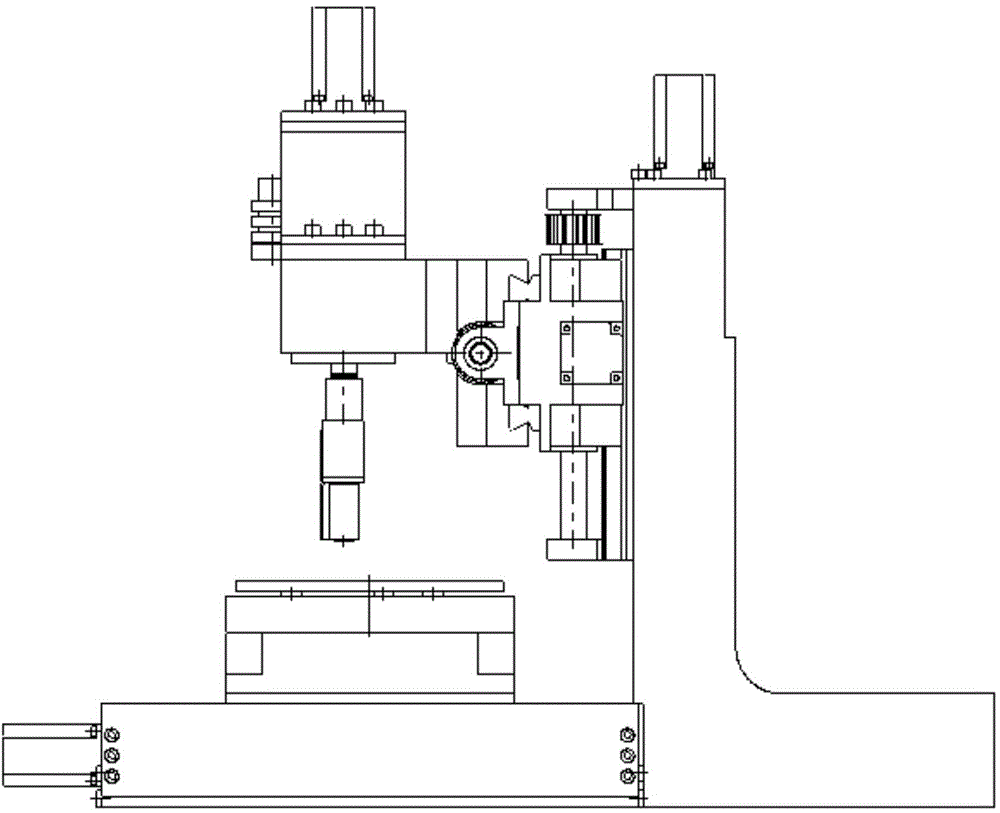

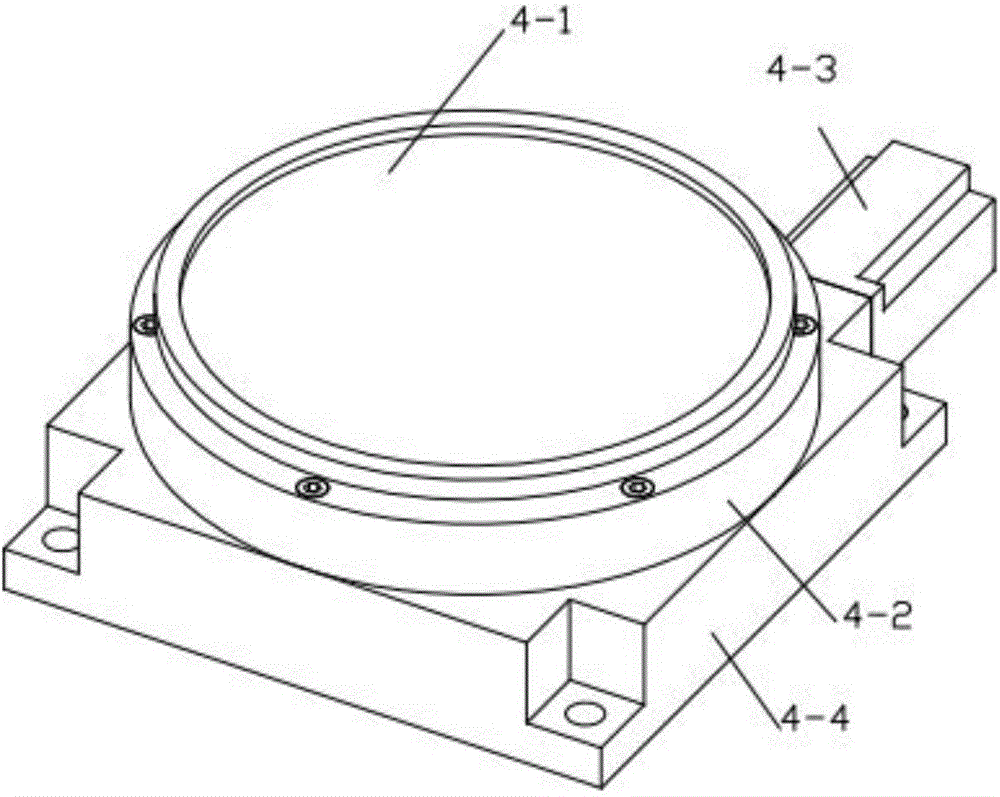

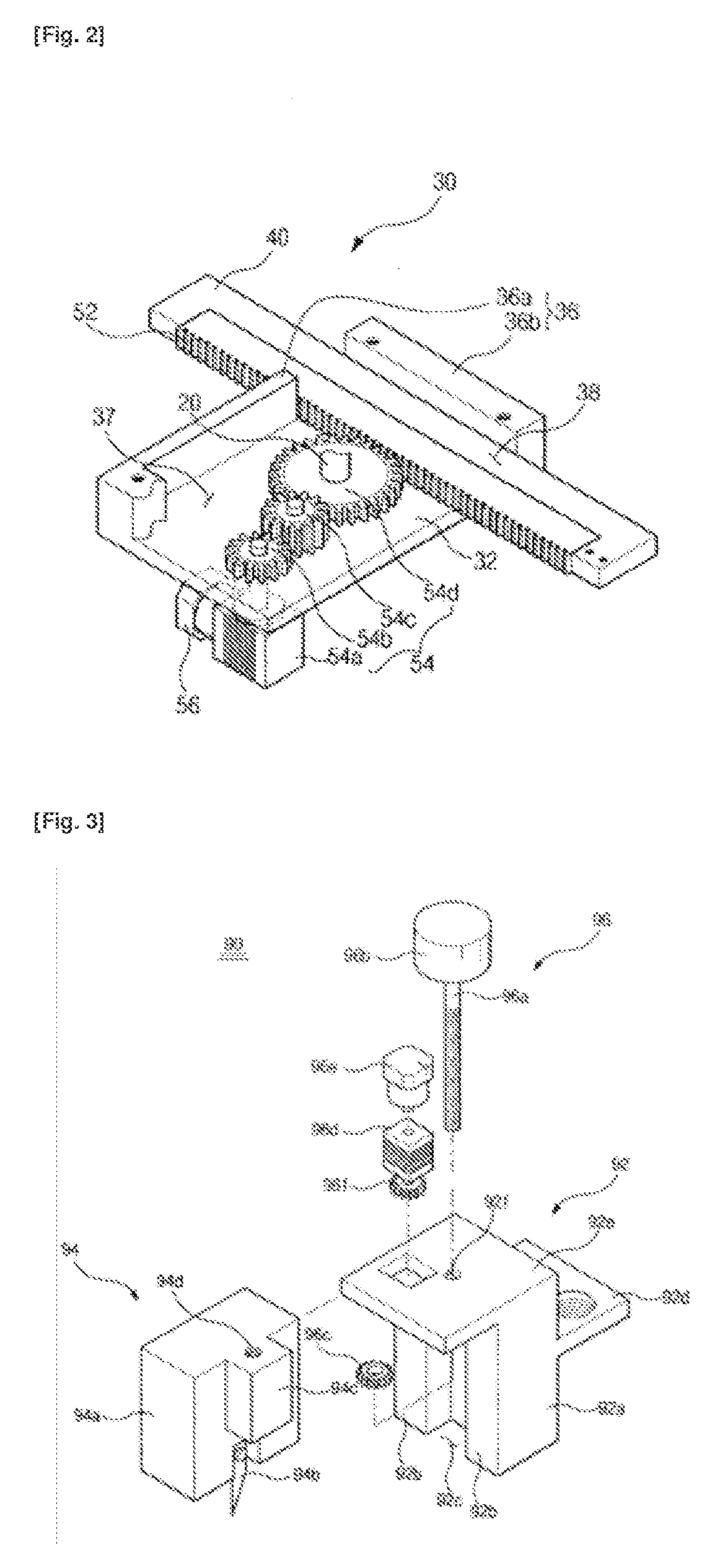

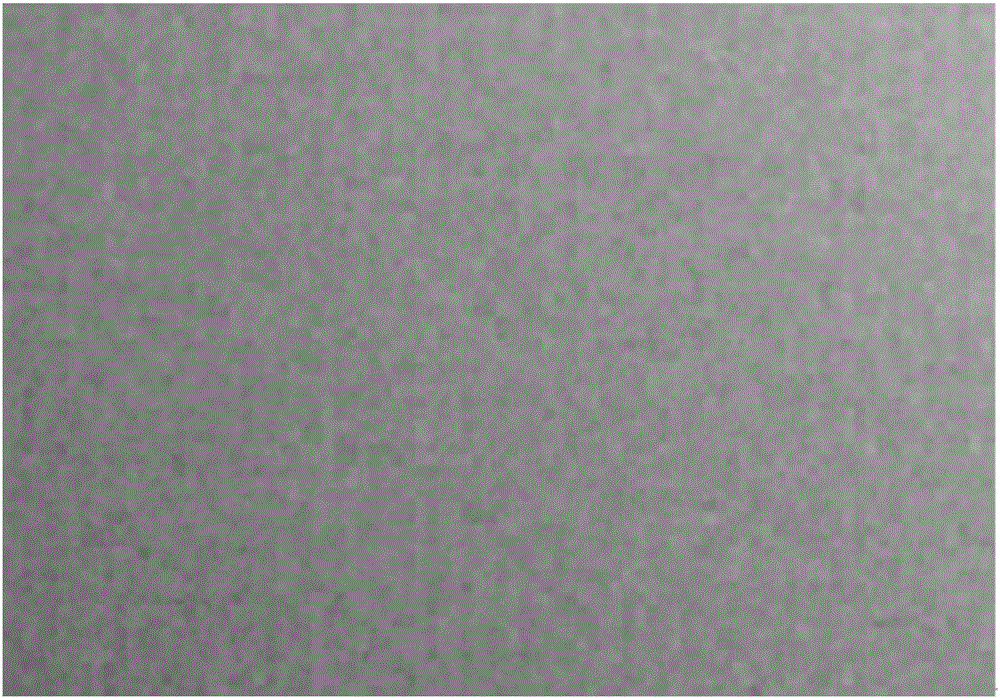

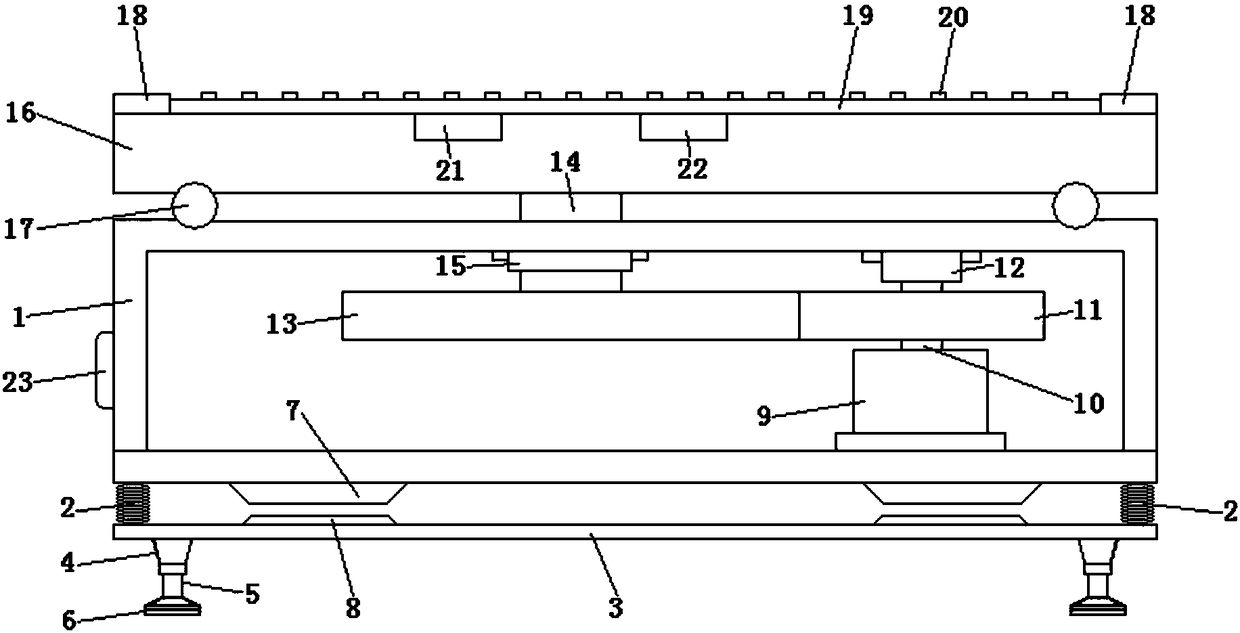

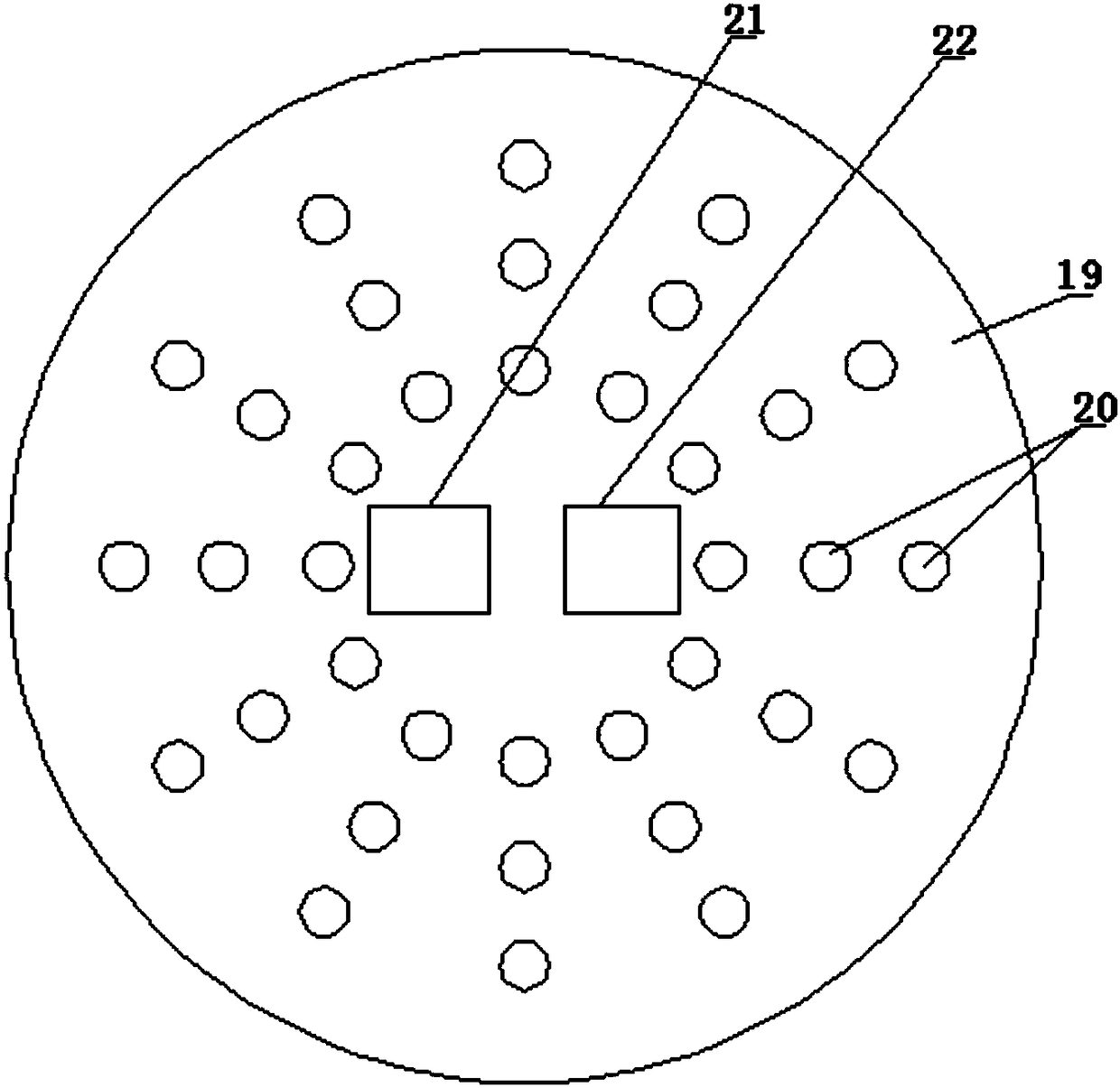

Variable track-ultrasonic elliptic vibration type auxiliary consolidation abrasive polishing machine

InactiveCN104669074AAvoid breakingImprove processing efficiencyPolishing machinesGrinding drivesMachiningUltrasonic generator

The invention relates to a variable track-ultrasonic elliptic vibration type auxiliary consolidation abrasive polishing machine. The polishing machine comprises a power part, a polishing part, a transmitting part and an ultrasonic generator. The power part drives the transmitting part and the polishing part to move. The polishing part comprises a polishing workbench and a rotary polishing tool. The power part comprises power sources in X-axis, Y-axis and Z-axis directions. According to the polishing machine, machining efficiency and precision are high, complicated track movement is realized through a polishing disc, and the polishing speed is roughly the same, thus roughness of points of a polishing surface is basically the same; and meanwhile, the machining surfaces are not easy to damage, so that the polishing machine is suitably used for polishing hard and brittle materials.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

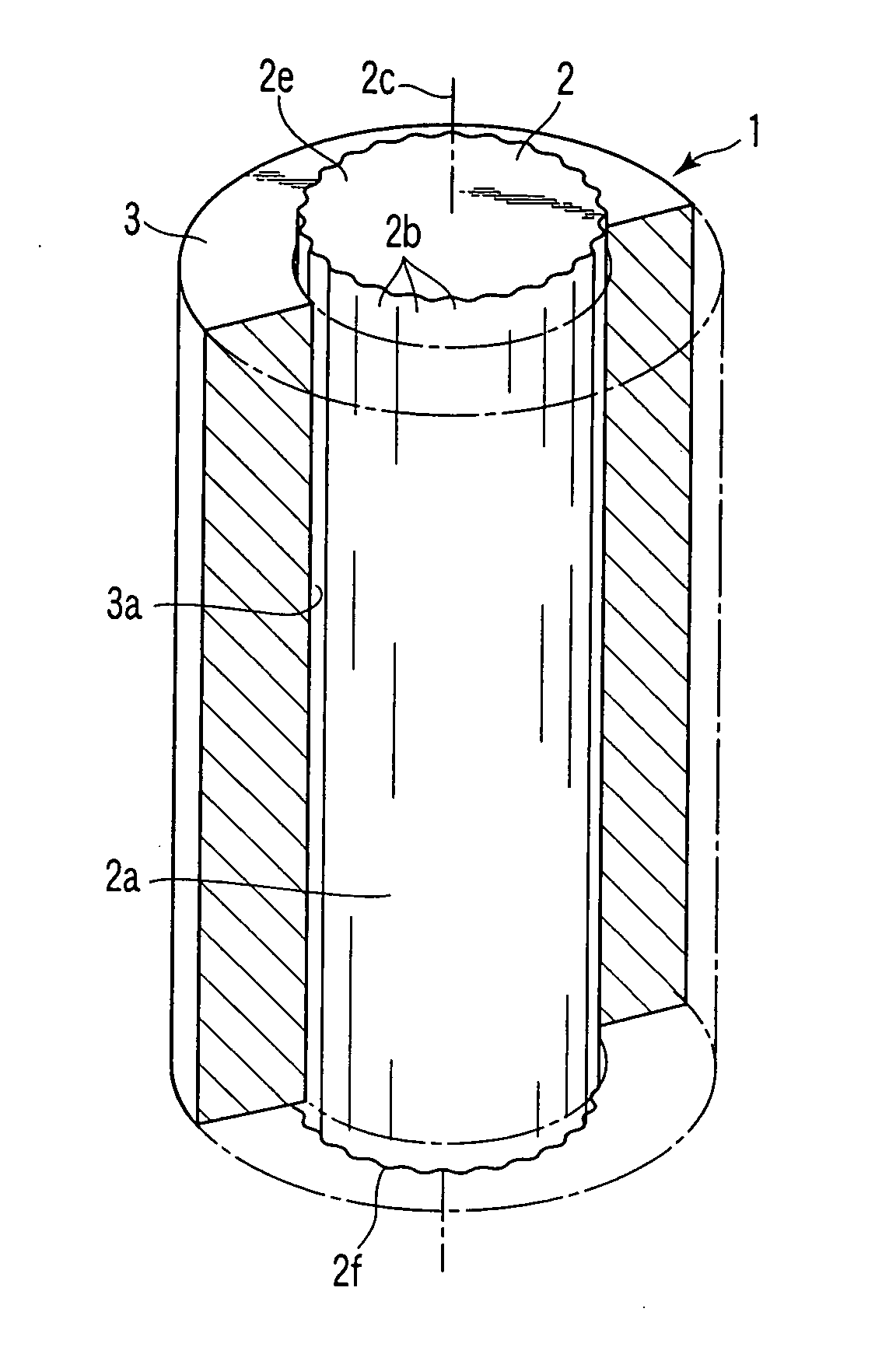

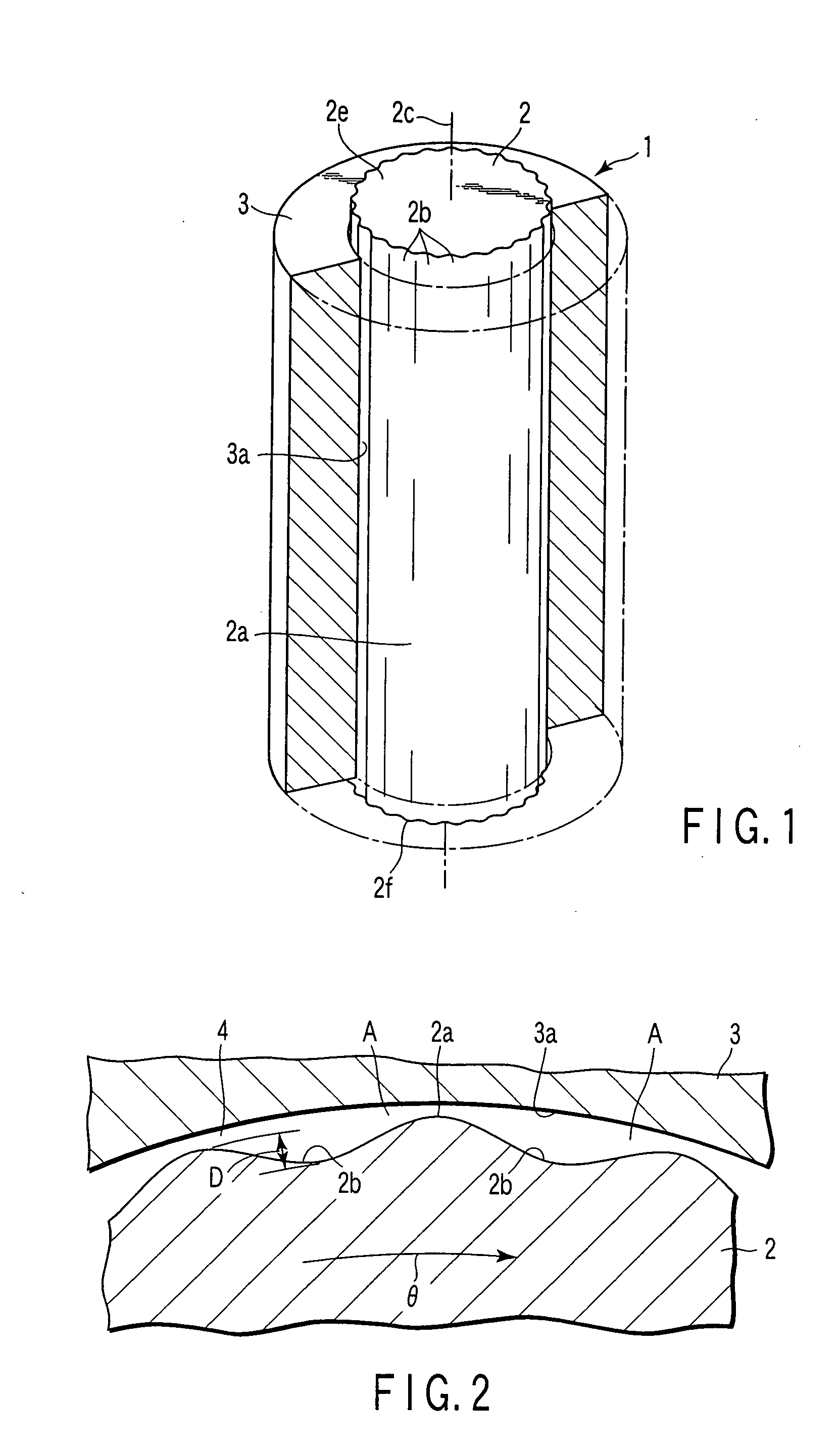

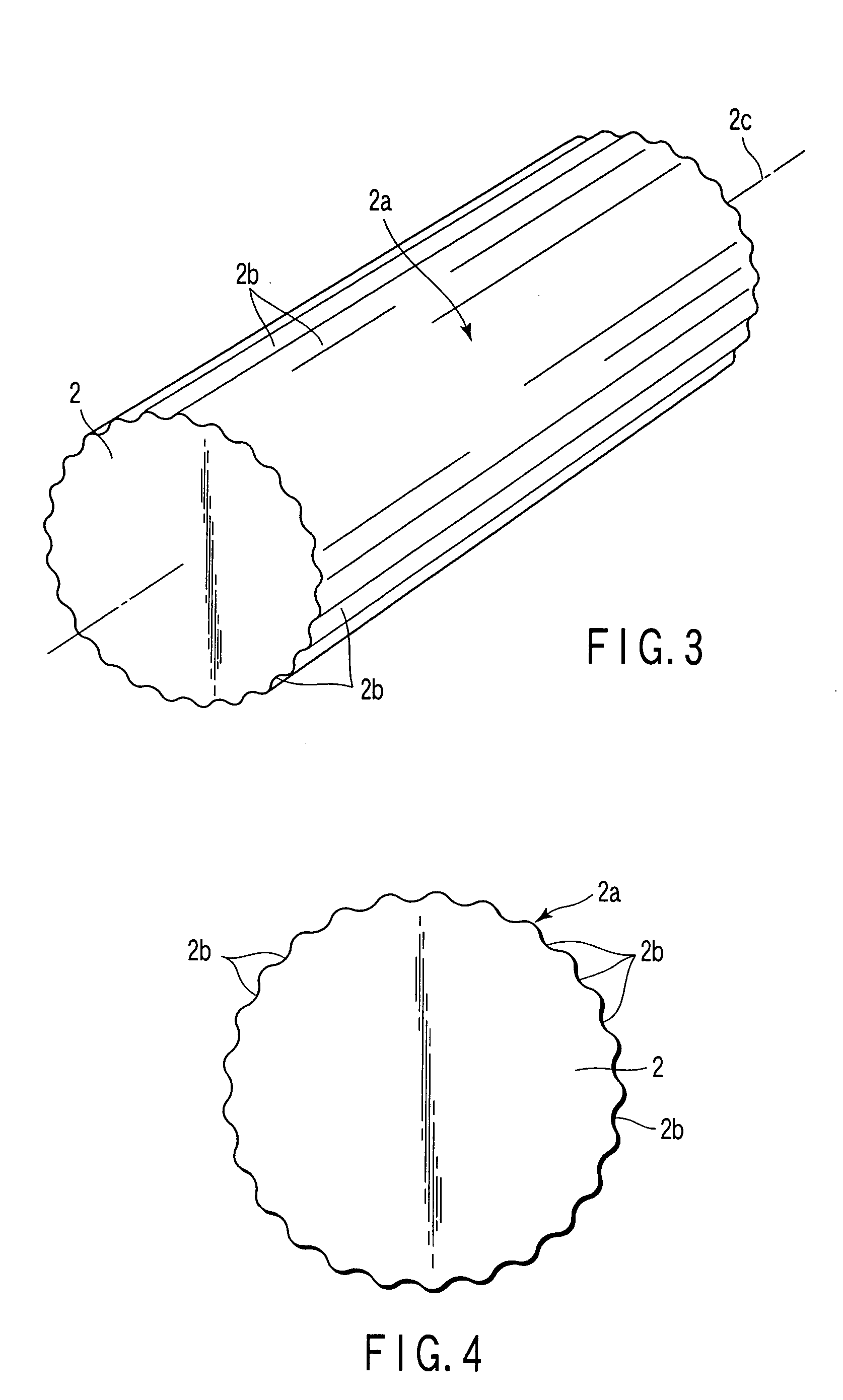

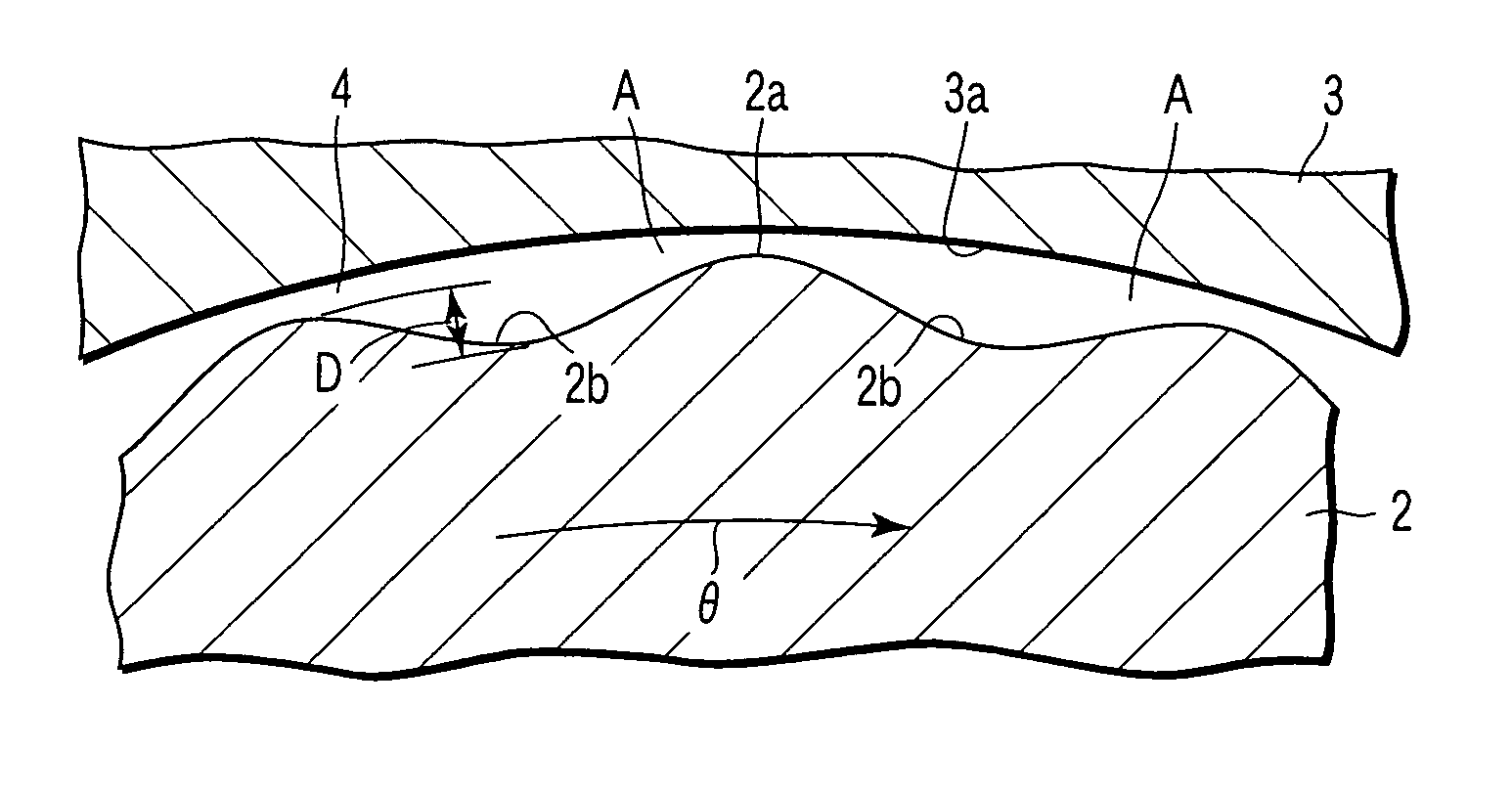

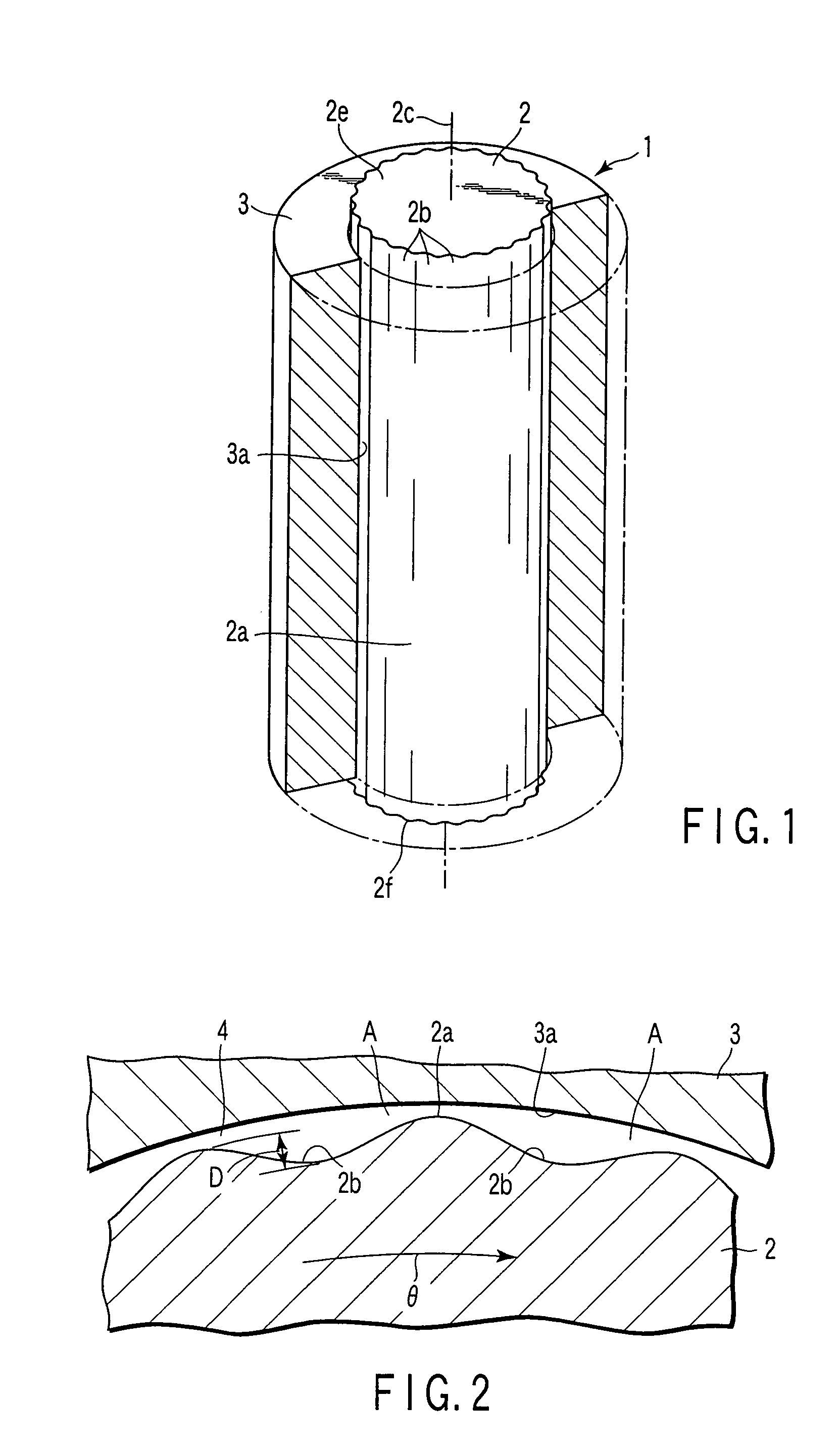

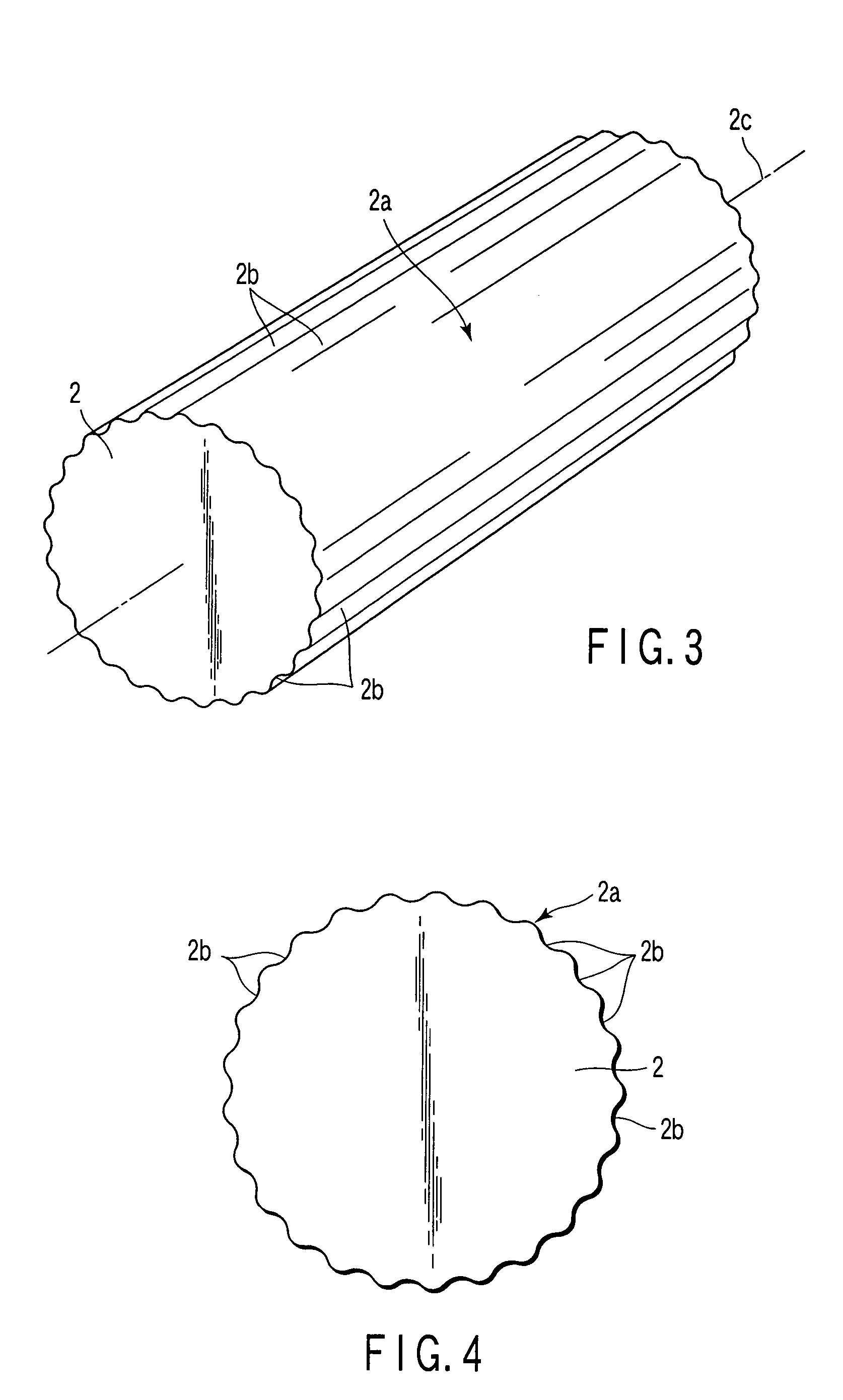

Shaft for fluid dynamic bearing, fluid dynamic bearing device, and method of manufacturing the shaft

InactiveUS20050078893A1High accuracyLow costRevolution surface grinding machinesShaftsEngineeringMachine tool

In a method of manufacturing a shaft for the fluid dynamic bearing device, the shaft is formed with a plurality of grooves arranged in and around the external circumference, the surface of the grooves and external circumference with uniform roughness, and machined marks on the surface aligned in the circumferential direction, by controlling the relative vibration of a rod-shaped blank to be machined as the shaft for a fluid dynamic bearing and a grinding wheel (a machining tool) to grind the external circumference of the blank.

Owner:NHK SPRING CO LTD

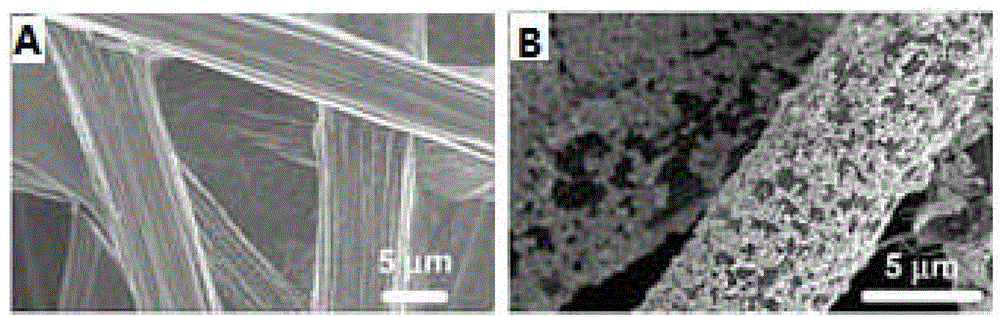

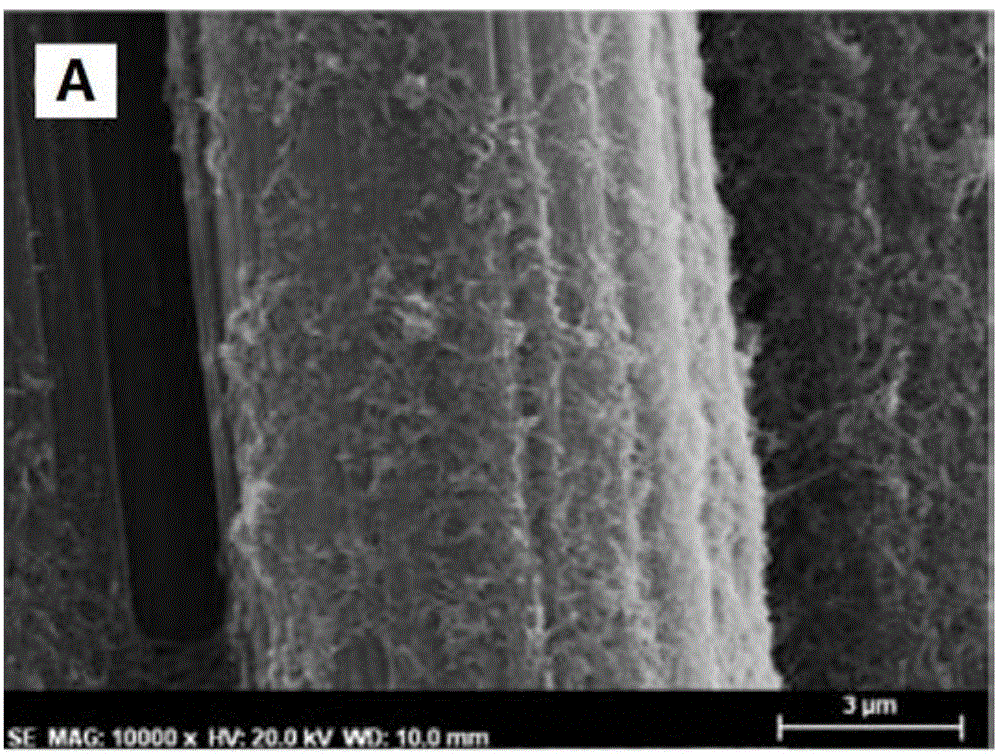

Method for growing carbon nano tube in situ on surface of fiber

InactiveCN104310371AControllable Strong OxidationUniform roughnessMaterial nanotechnologyFiberHigh volume manufacturing

The invention provides a method for growing carbon nano tubes in situ on the surface of fiber. The method comprises the following steps: (1) pretreating the fiber, namely, treating the surface of the fiber by using a mixed liquid of concentrated sulfuric acid and hydrogen peroxide; (2) growing a catalyst in situ on the surface of the fiber; and (3) growing the carbon nano tubes on the surface of the fiber. As the fiber is pretreated by using the mixed liquid of concentrated sulfuric acid and hydrogen peroxide, the fiber surface which is relatively rough is provided, and the adhesion of the catalyst for preparing the carbon nano tubes is facilitated. Moreover, as the catalyst is uniformly adhered to the surface of the fiber by using a dipping method or a sol-gel method, the growth of the carbon nano tubes is facilitated. The dipping method or the sol-gel method is simple and feasible, easy to control, low in cost and beneficial for on-scale and in-batch production.

Owner:张映波

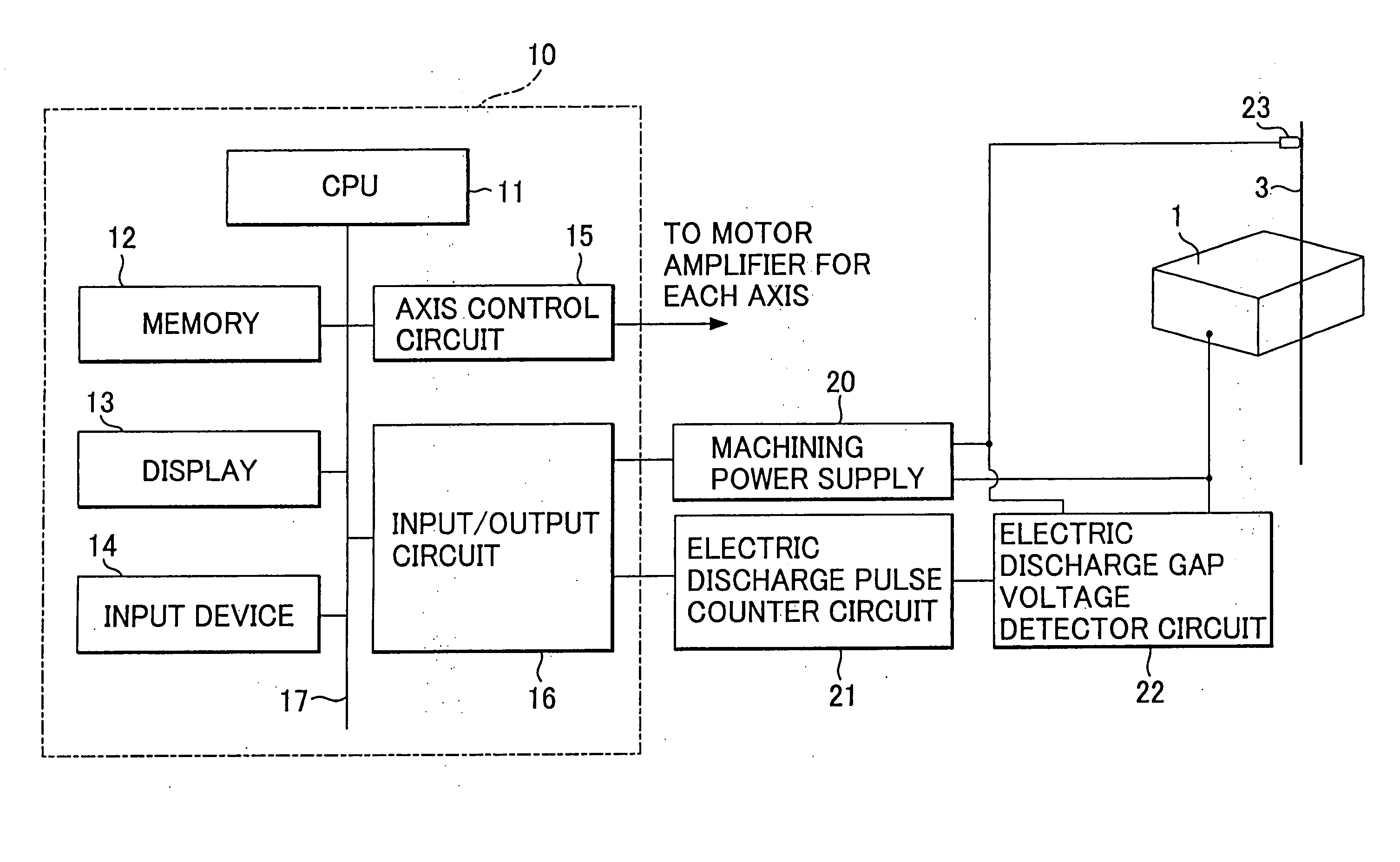

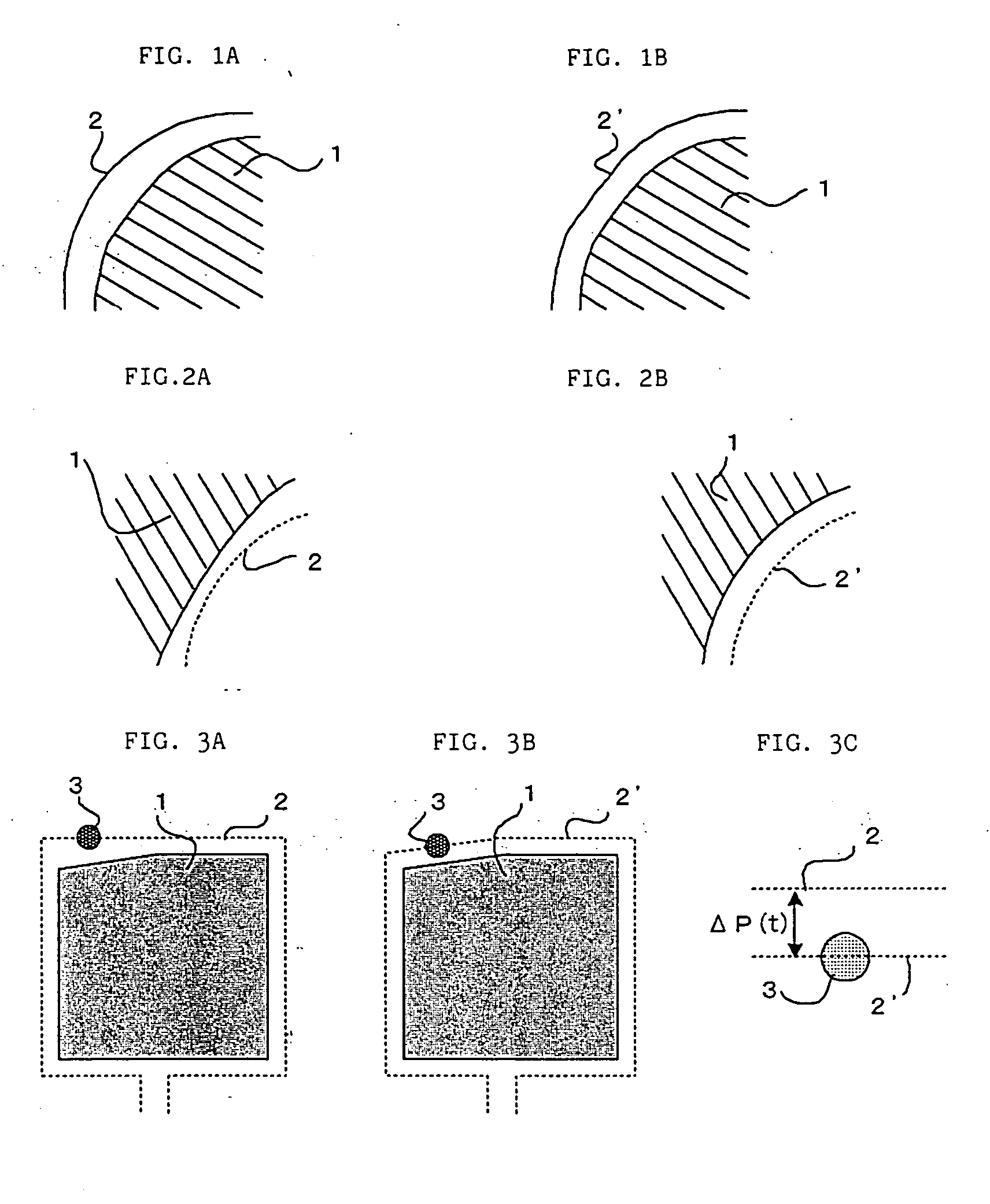

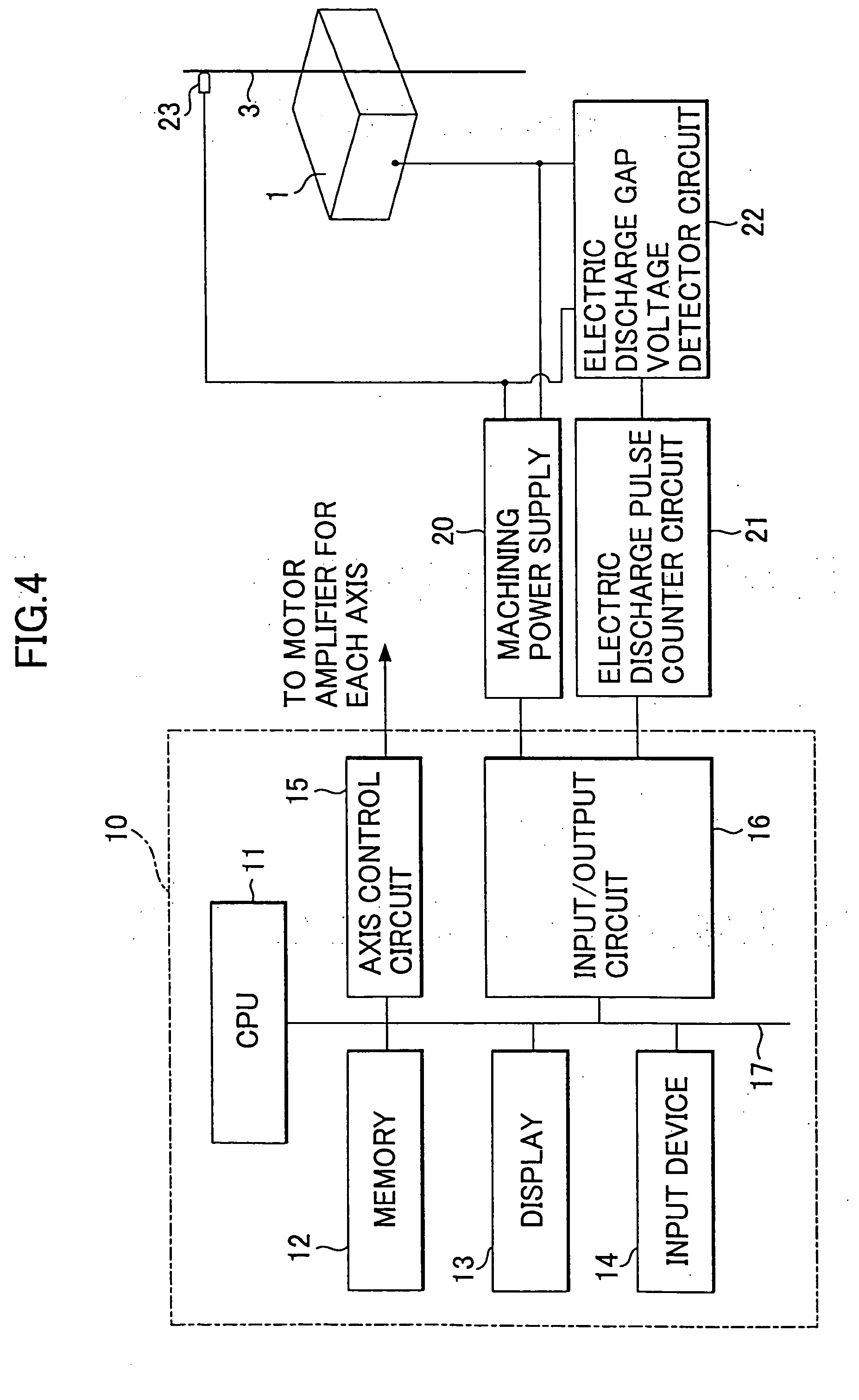

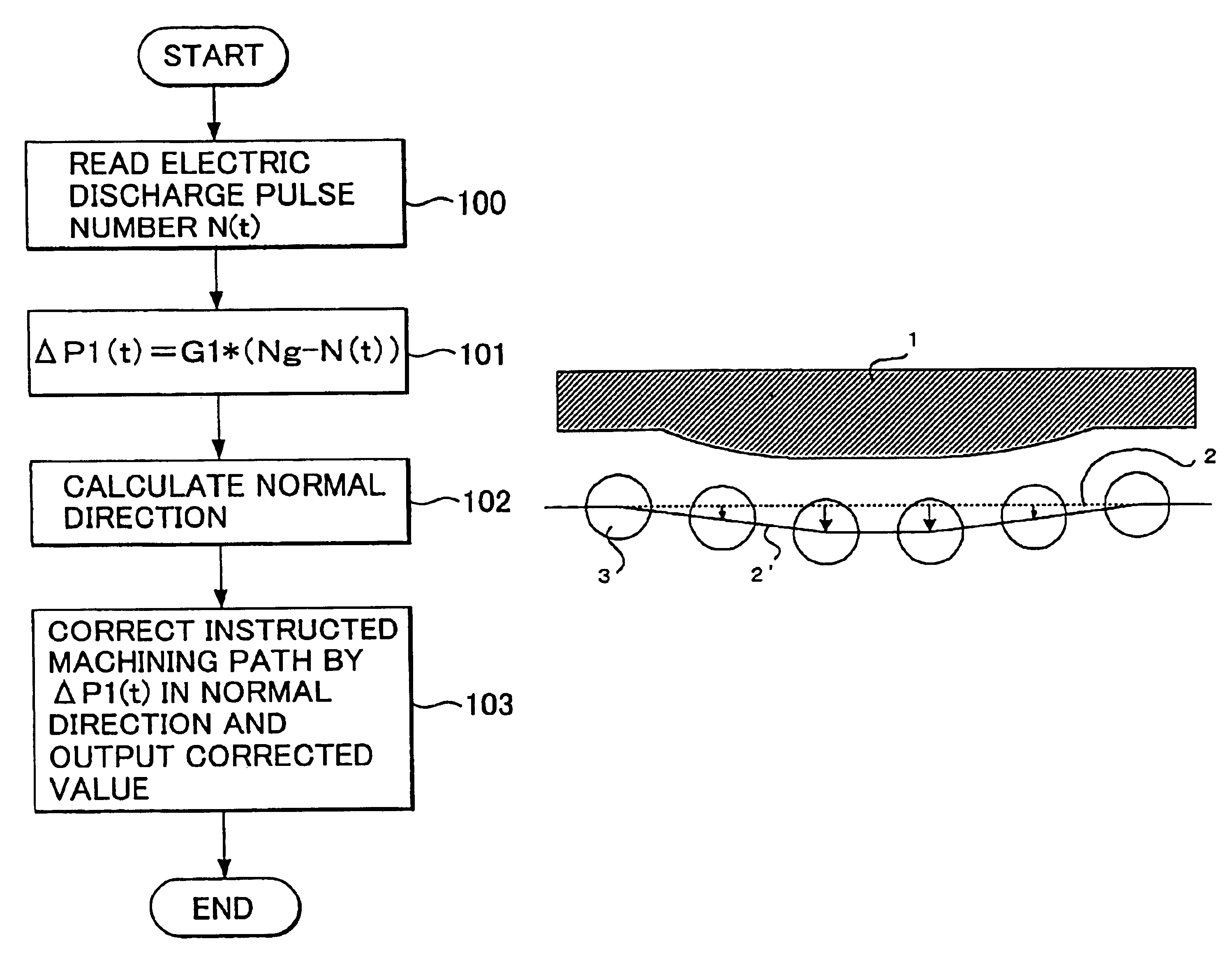

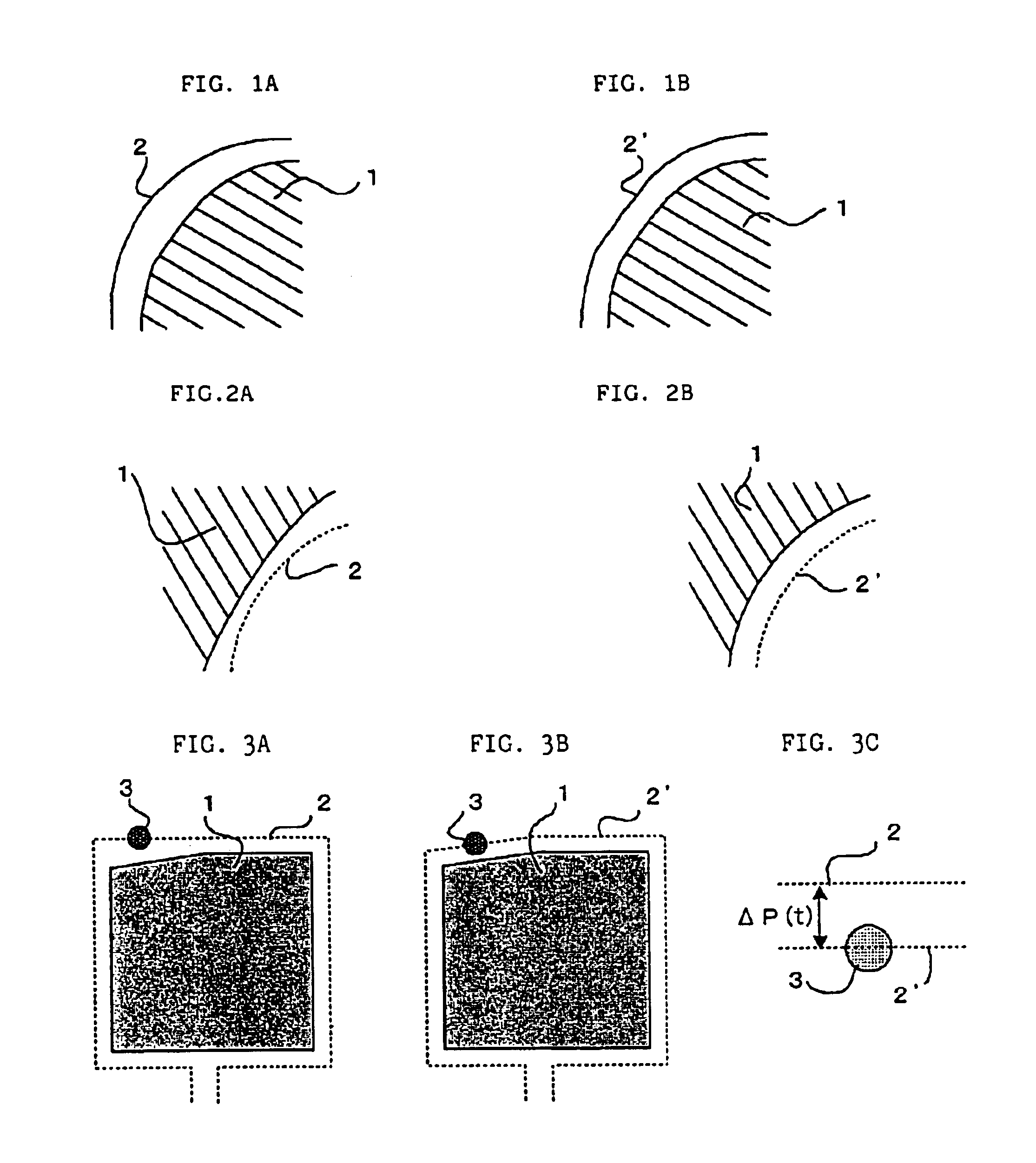

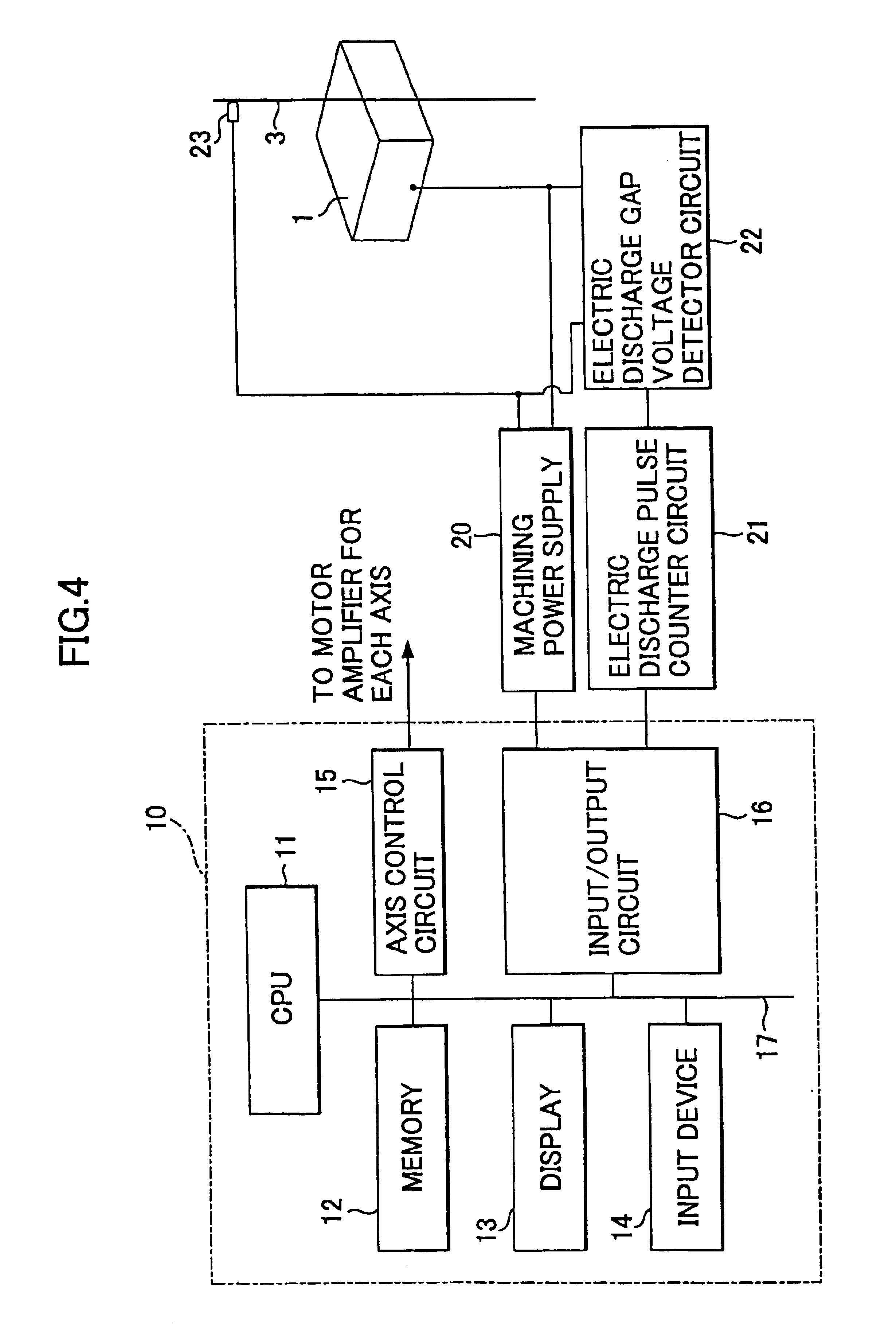

Machining control method for wire-cut electric discharge machine

InactiveUS20050040142A1Uniform surface roughnessUniform roughnessElectric circuitsMachine controlElectrical and Electronics engineering

Owner:FANUC LTD

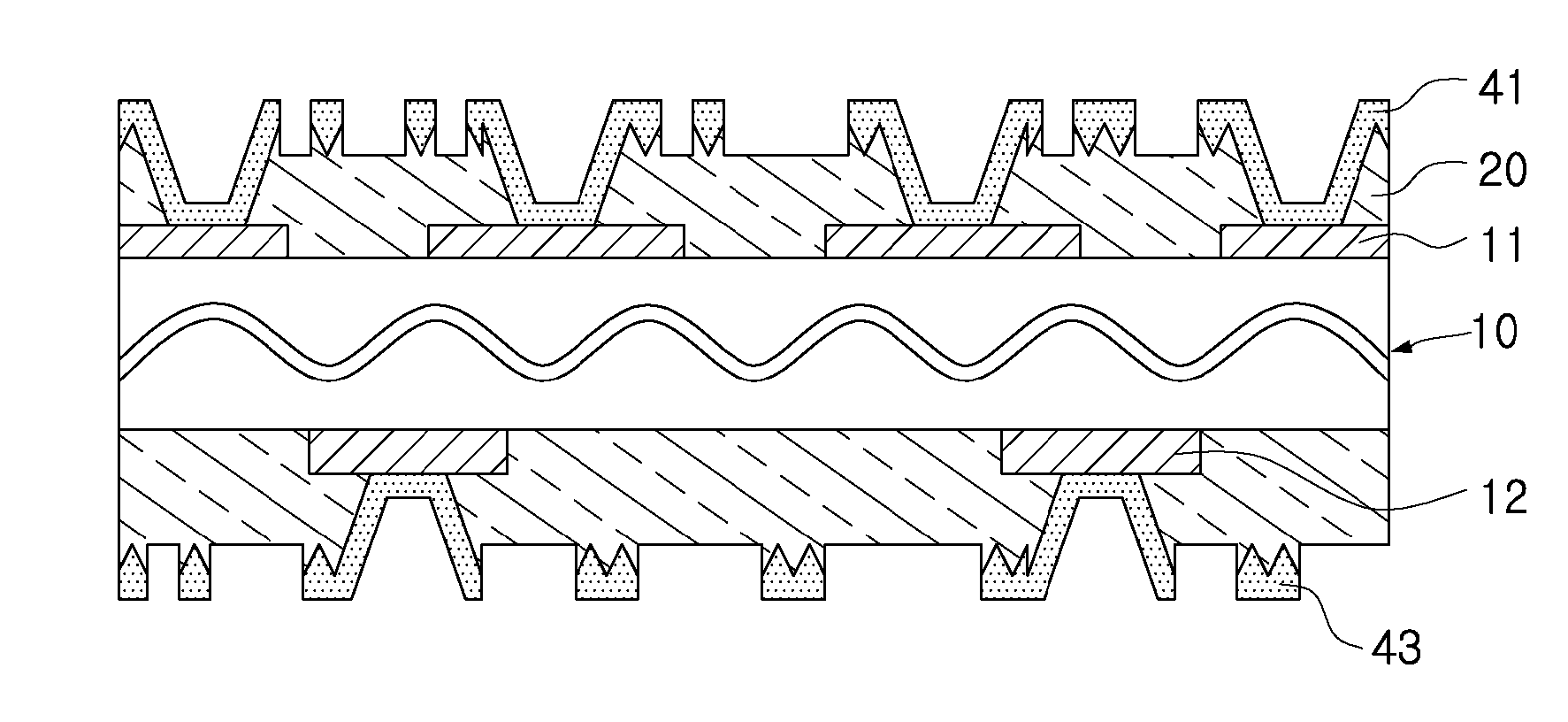

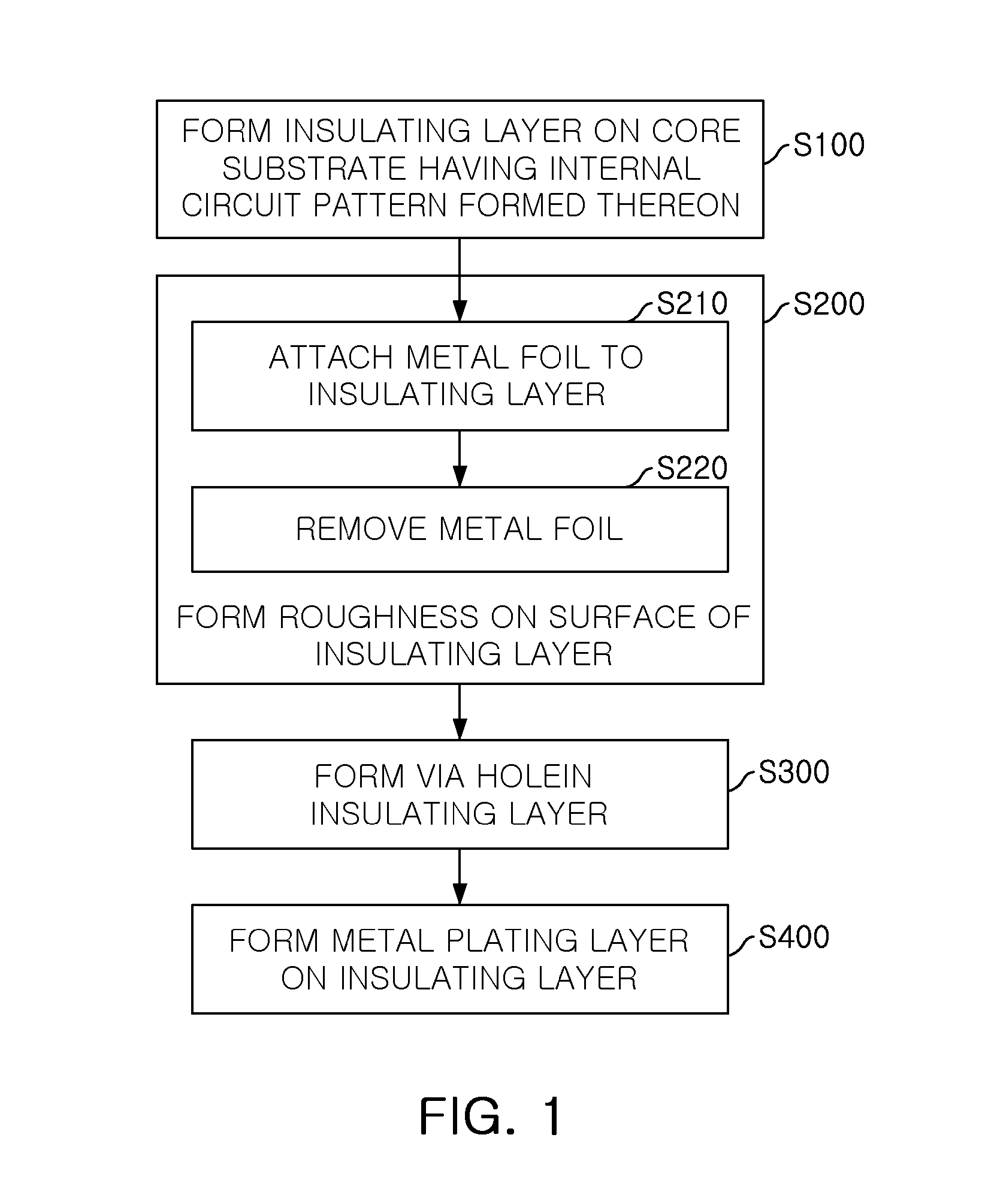

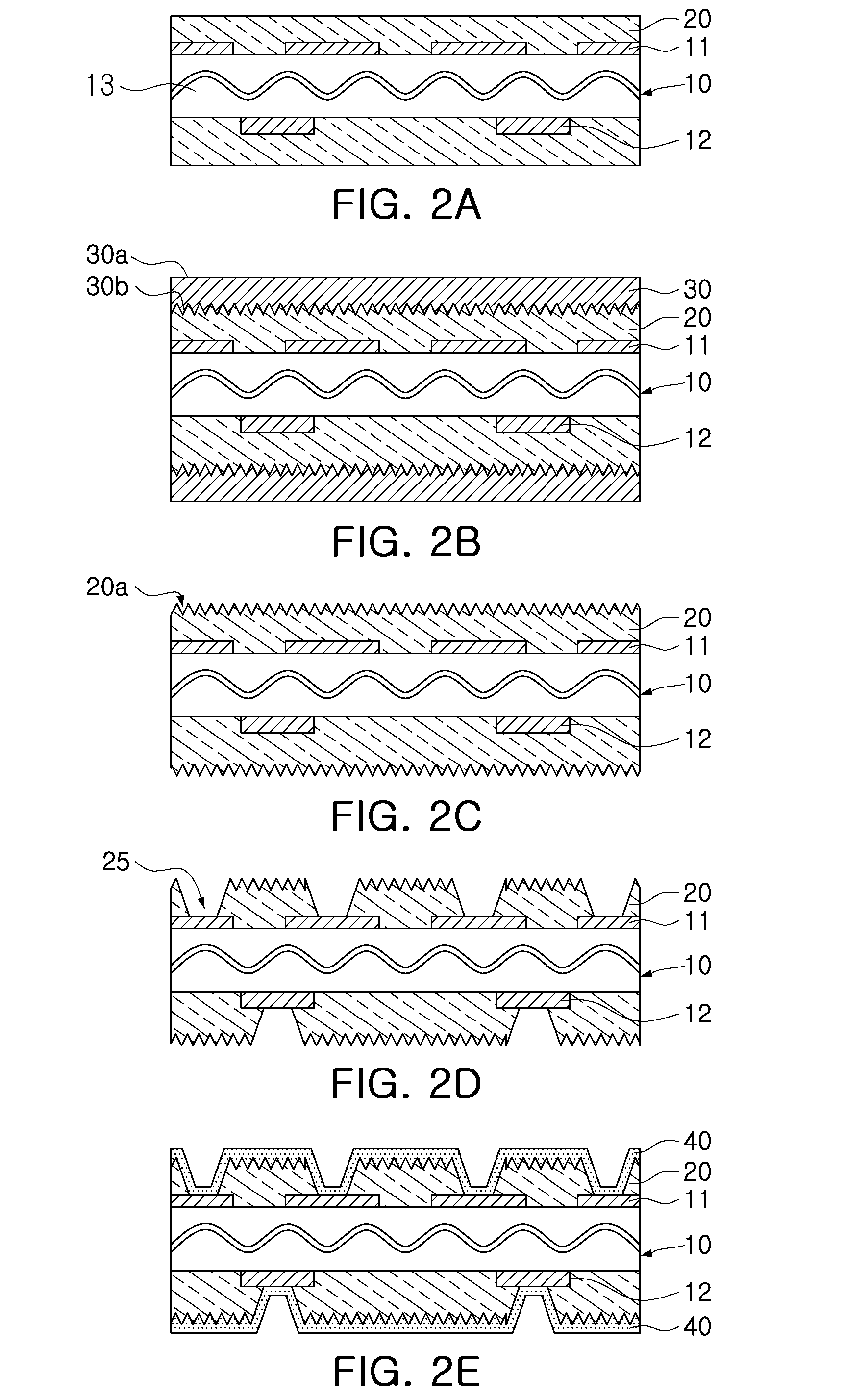

Printed circuit board and method of manufacturing the same

InactiveUS20120125667A1Uniform roughnessImprove adhesionPrinted circuit aspectsConductive pattern formationSurface roughnessEngineering

There are provided a printed circuit board and a method of manufacturing the same. The printed circuit board includes a first circuit pattern formed on a core substrate; an insulating layer stacked on the core substrate to cover the first circuit pattern and having a uniform surface roughness on a nano scale; a second circuit pattern formed on the insulating layer; and a via pattern electrically connecting the first circuit pattern to the second circuit pattern and penetrating through the insulating layer.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

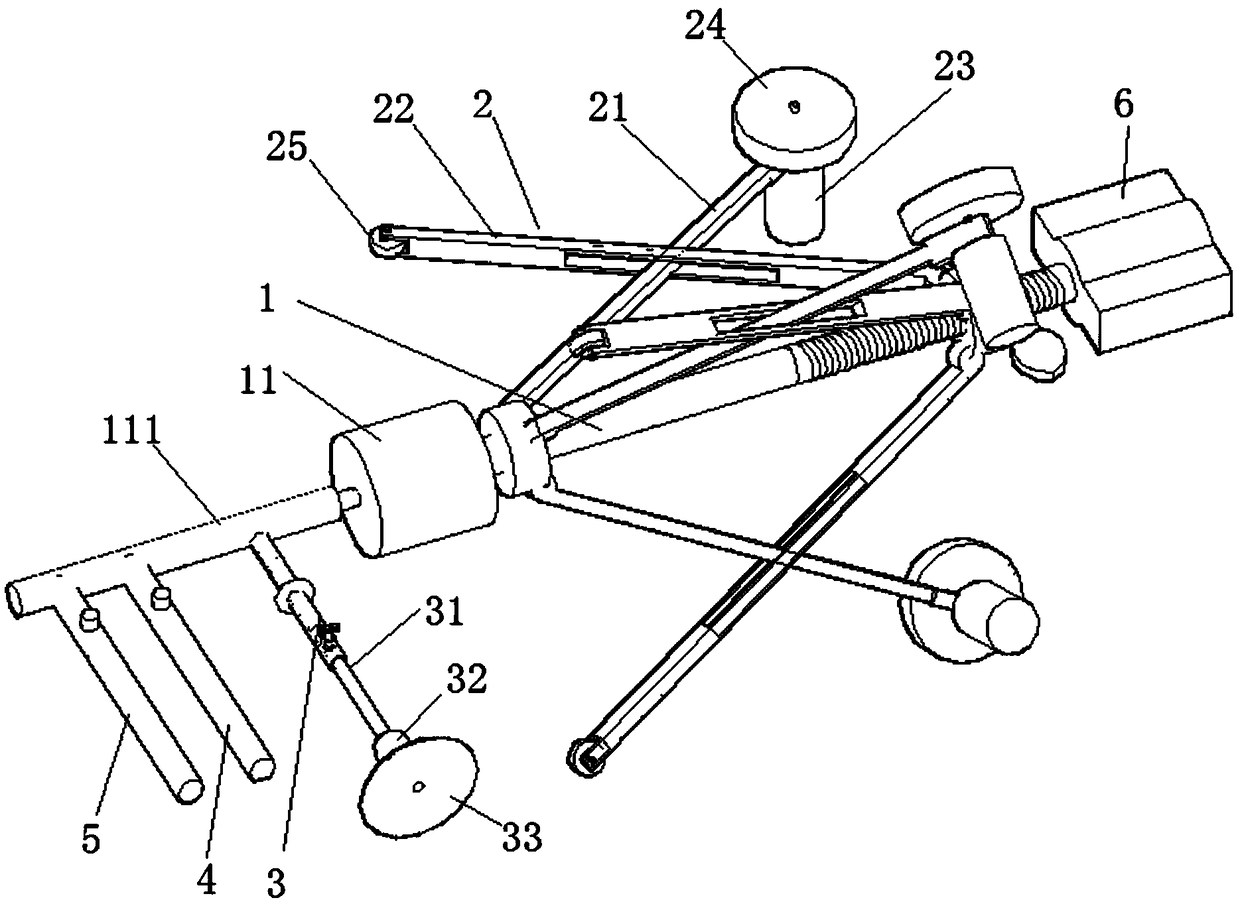

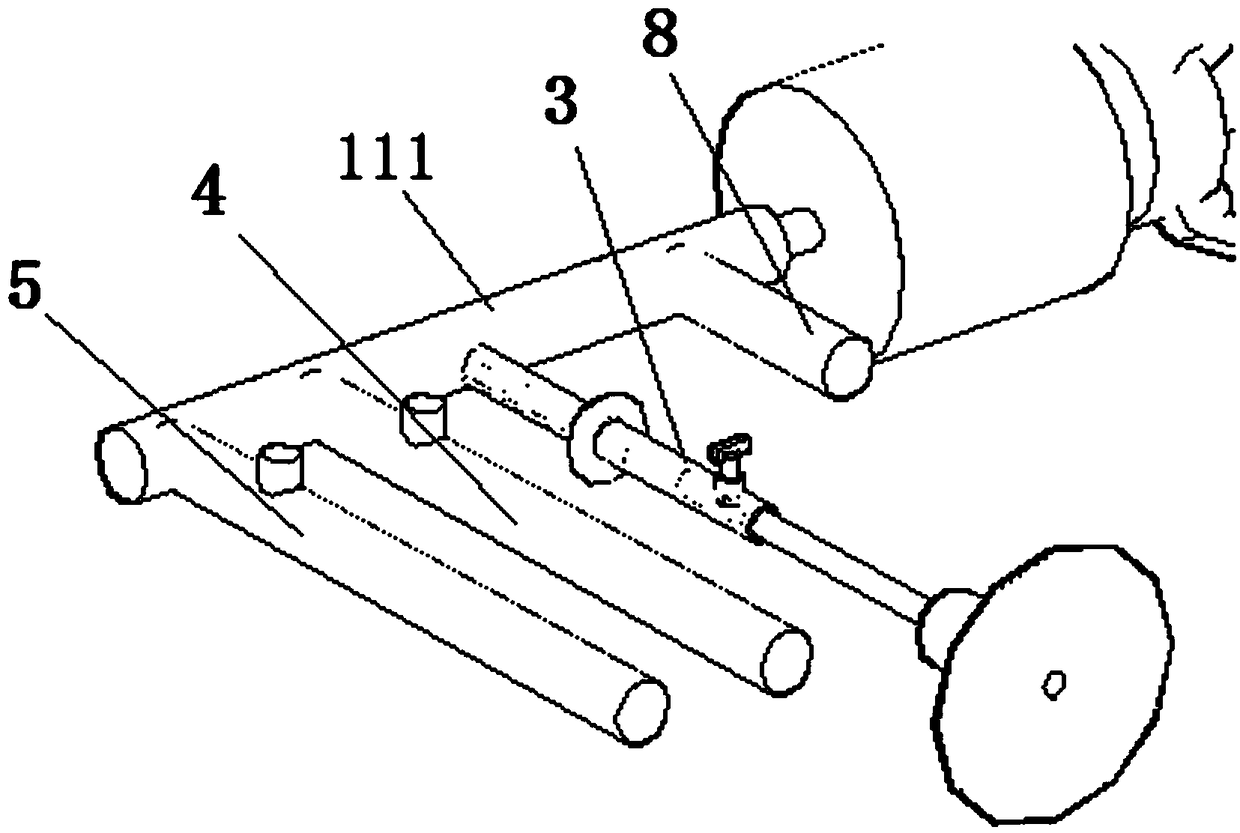

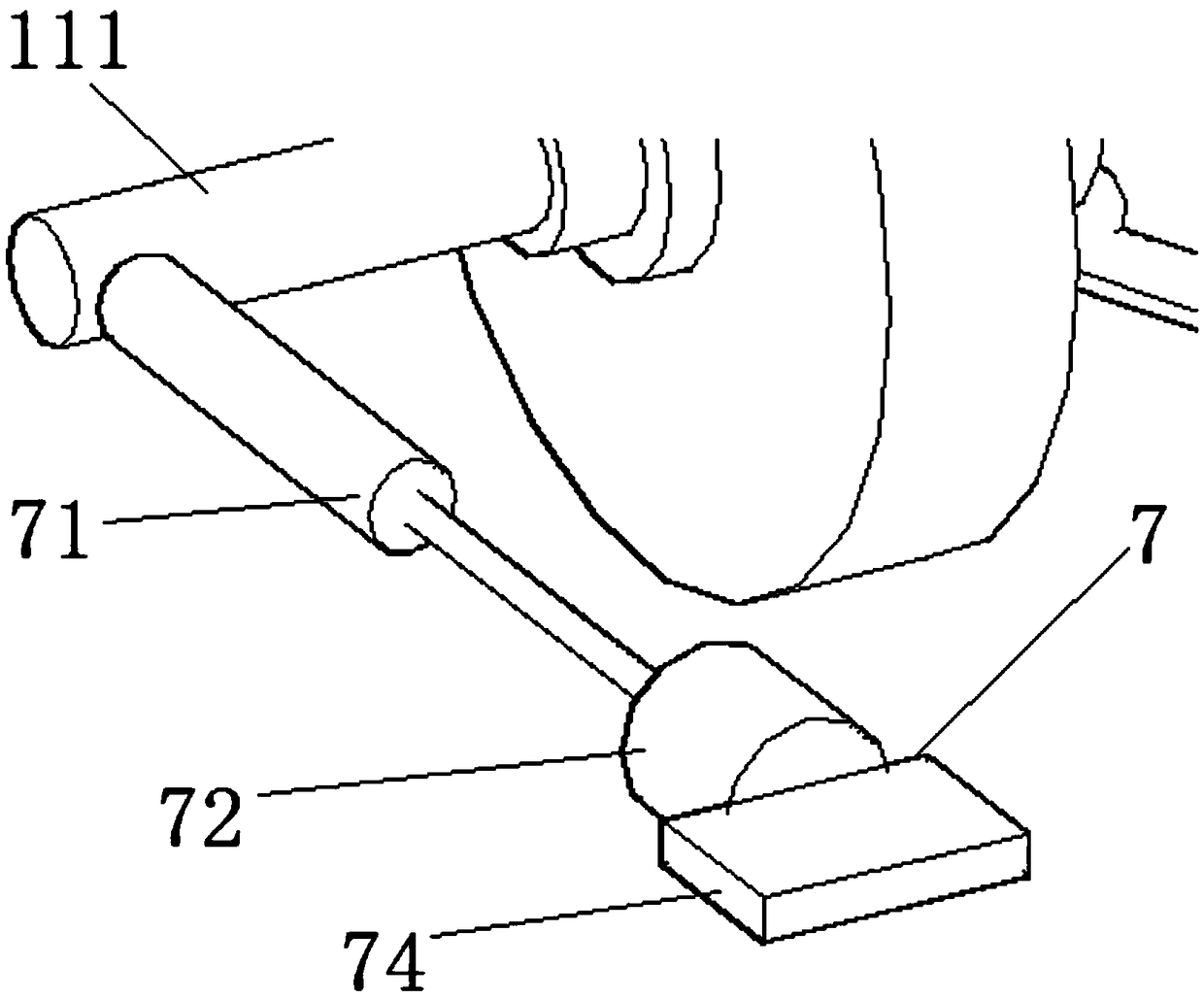

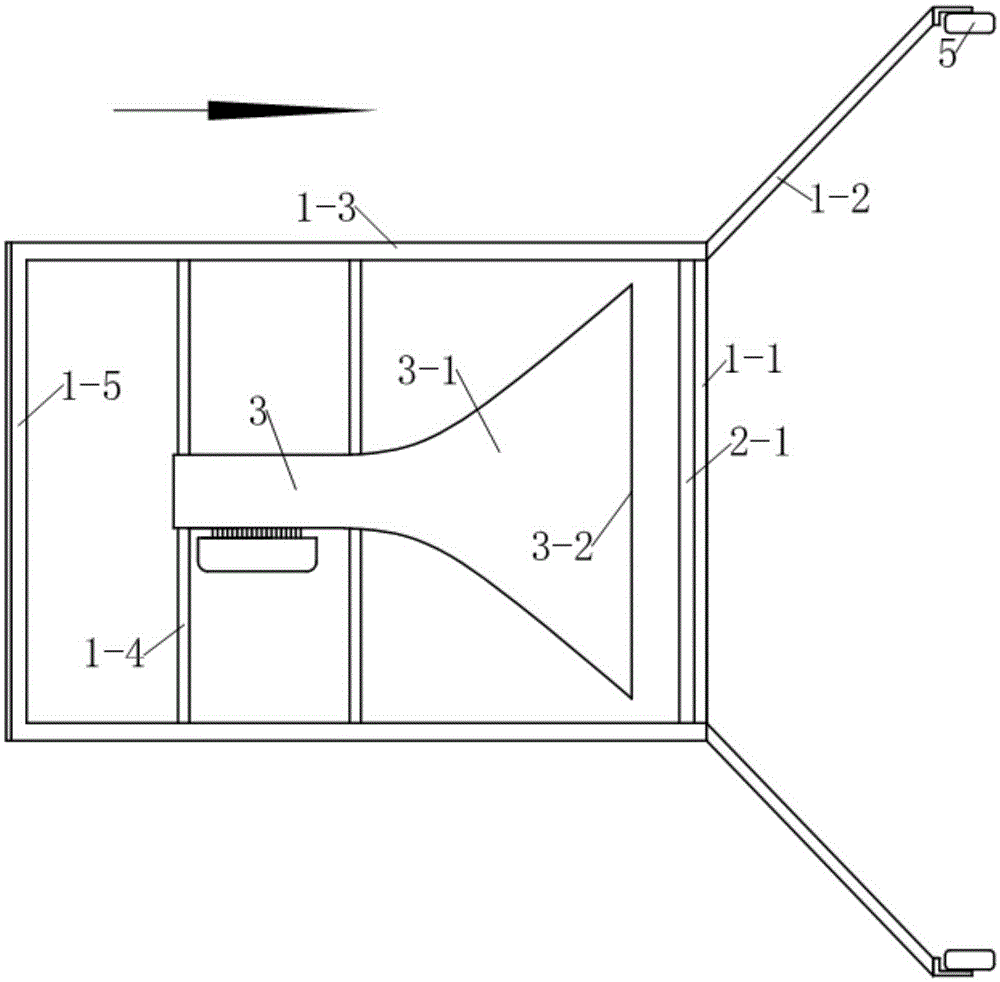

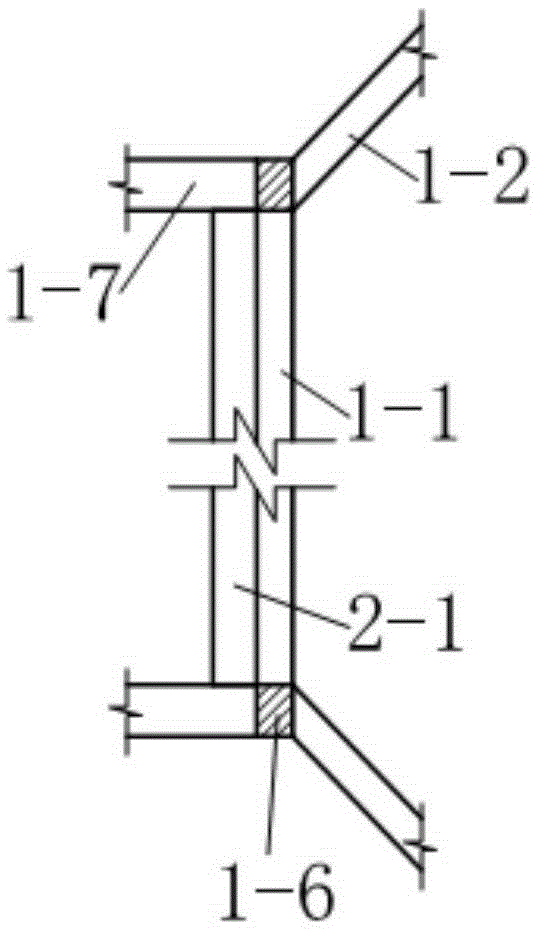

Galling and dust blowing and sucking device for coating of inner wall of pipeline

ActiveCN109365431AStable roughnessUniform roughnessRevolution surface grinding machinesGrinding drivesMotor driveGalling

The invention provides a galling and dust blowing and sucking device for a coating of the inner wall of a pipeline. The device comprises a main pipe body, a walking mechanism, a galling device, a dustblowing pipe, a dust sucking pipe, a cleaning device and a main controller. The walking mechanism drives the galling device, the dust blowing pipe and the dust sucking pipe to move on the inner wallof the pipeline along the axis, a main rotary motor drives the galling device, the dust blowing pipe and the dust sucking pipe to move on the inner wall of the pipeline along the circumference, the inner wall of the pipeline is stably galled through the galling device, intense blowing airflow is generated by the dust blowing pipe, abrasive dust left after galling is completed is blown up, the abrasive dust is sucked through the dust sucking pipe, cleaning liquid is sprayed on cotton cloth a wiping cloth single unit through a liquid sprayer, the cotton cloth makes contact with the inner wall ofthe pipeline for wiping, the abrasive dust left after galling is completed is effectively removed, the cleanliness of a grinding surface is greatly improved, the surface with the uniform and stable roughness is obtained on the inner wall of the pipeline, adhesive force between two coatings is improved, the spraying effect is improved, and the corrosion resistance of the inner wall of the pipelineis improved.

Owner:NANTONG INST OF TECH

Machining control method for wire-cut electric discharge machine

InactiveUS6924453B2Uniform surface roughnessUniform roughnessElectric circuitsMachine controlElectric discharge

The number of electric discharge pulses is detected every given period. A deviation between the detected number and a target number of electric discharge pulses is obtained. Based on the obtained deviation, a correction value for the correction of a machining path in a direction normal to the machining path is calculated, whereby a corrected path is obtained. A wire electrode is moved relatively to a workpiece along the corrected path.

Owner:FANUC LTD

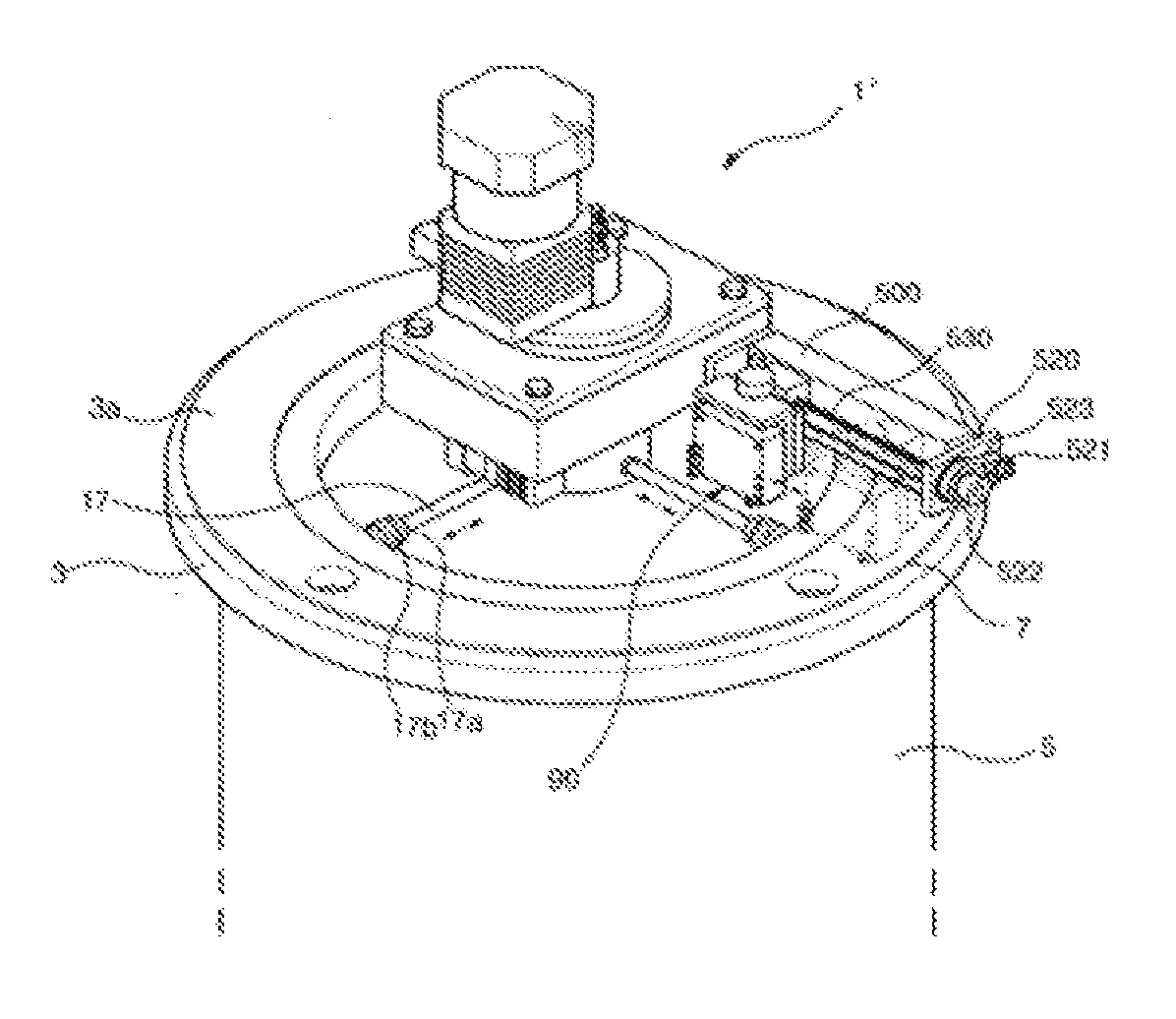

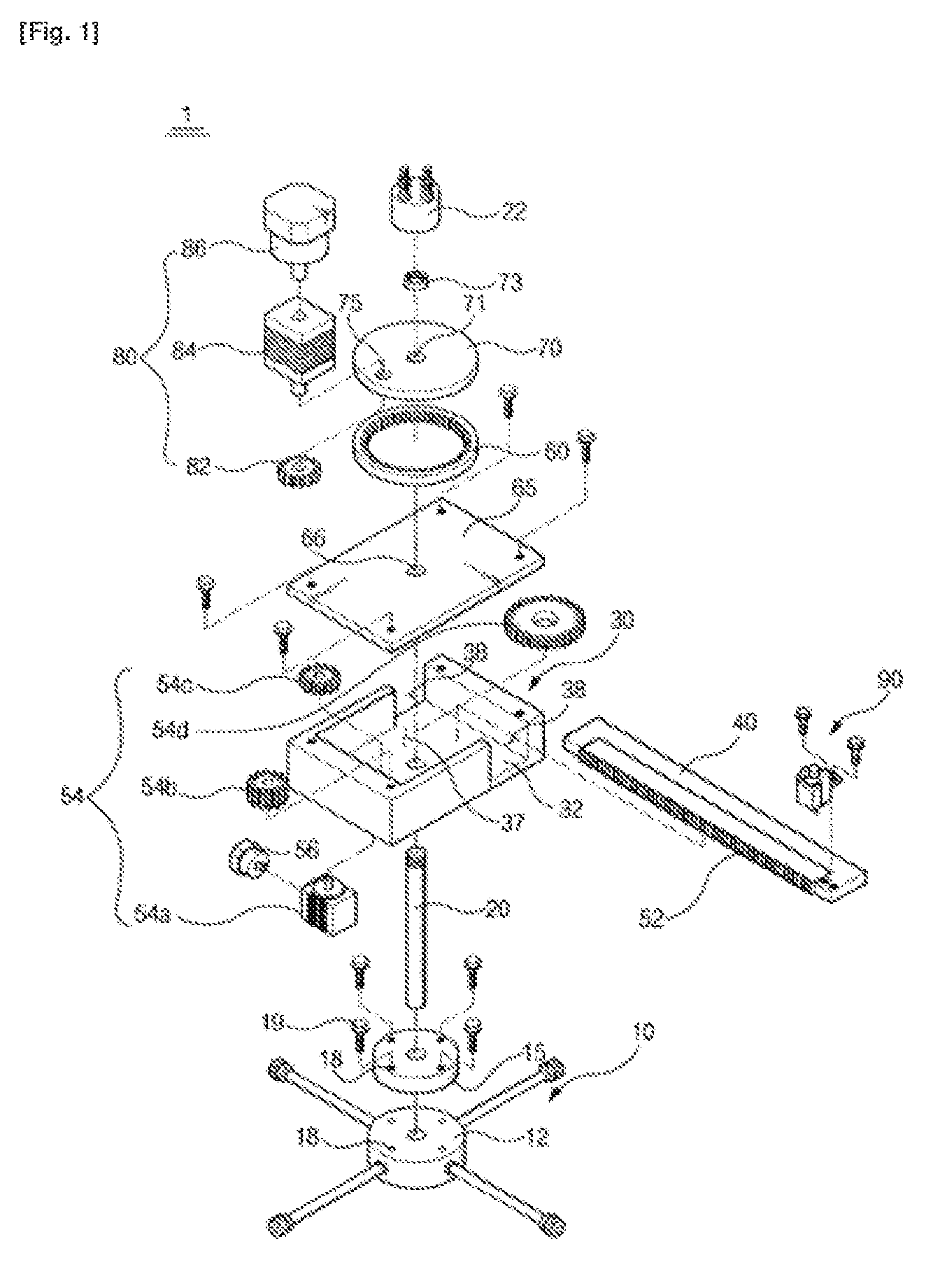

Automatic flange surface machining apparatus

InactiveUS20110179933A1Uniform roughnessAccurate position and rotational speedGang saw millsChain sawsGear wheelElectric machinery

Disclosed is an automatic flange surface machining apparatus for machining a flange surface. The automatic flange surface machining apparatus of the present invention comprises a flange fixing unit fixed at the inner surface of a pipe formed on a flange, a shaft secured onto the flange fixing unit, a main body which has a linear toolbar guiding path formed at one side thereof, and which has a guide protrusion for providing a space that communicates with the toolbar guiding path to enable the penetration of the shaft, and which is rotatably coupled to the shaft that has penetrated the space, a toolbar installed in the toolbar guiding path such that the toolbar moves along the toolbar guiding path, a toolbar moving means arranged in the main body to move the toolbar, an inner gear coupled onto the main body, a rotating motor base installed on the inner gear, and fixed at the shaft, an inner gear driving means coupled to the rotating motor base to rotate the inner gear, and a flange surface machining unit installed on one side of the toolbar to machine the flange surface.

Owner:AHN SANG GULK +1

Manufacturing process of superfine grinding roller

The invention relates to a manufacturing process of a grinding roller, in particular to a manufacturing process of a superfine grinding roller, which includes the following steps: firstly a blank roller is processed according to roller graphical dimensions, then fine processing is performed on the blank roller, polishing processing is performed on the surface of a roller body after the fine processing is performed on the roller body, partial repair is performed on the surface of the roller body with air holes or pinholes, chromium plating, fine grinding and polishing are performed on the surface of the roller body, the roller surface is rolled repeatedly in reciprocating mode by using a rubber wheel containing sand to be molded, a certain number of superfine grinding rollers are molded through grinding, finally detection about roughness and gloss is performed on the roller surfaces of the manufactured superfine grinding rollers according to requirements to form quality inspection results. The manufacturing process of the superfine grinding roller changes a traditional manufacturing process of a grinding roller completely, the superfine grinding roller manufactured by the process is good in accuracy, long in service life and consistent in roughness, gloss and uniformity, and the superfine grinding roller cannot be manufactured by an original manufacturing process.

Owner:CHANGZHOU WUJIN GUANGYU EMBOSSING ROLLER MACHINERY

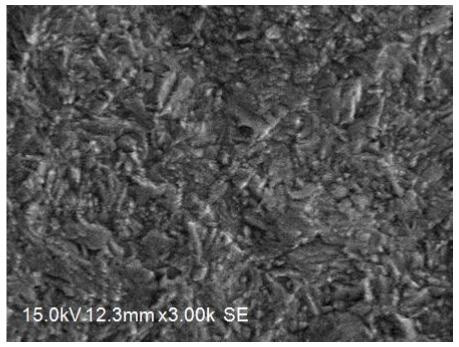

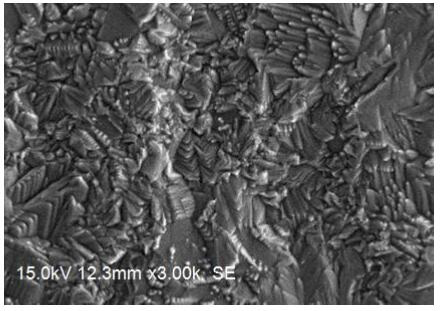

Double-sided surface treatment method for rolled copper foil

The invention provides a double-sided surface treatment method for a rolled copper foil, and two long wide surfaces of the rolled copper foil are sequentially subjected to the following treatments: electrolytic degreasing, alkaline chemical degreasing, washing 1, acid pickling, washing 2, roughening 1, washing 3, curing 1, washing 4, roughening 2, washing 5, curing 2, washing 6, blackening, washing 7, zinc electroplating, washing 8, chromium electroplating, washing 9, washing 10, silicone coupling agent coating and drying. In a corresponding electroplating solution, two long wide surface sidesof the rolled copper foil are equipped with anode plates, and the two long wide surfaces of the rolled copper foil are subjected to roughening 1, curing 1, roughening 2, curing 2, blackening, zinc electroplating and chromium electroplating. Double sides of the rolled copper foil have relatively high peel strength and relatively high roughness, and have good oxidization resistance, so that the double sides of the rolled copper foil can be pressed with PI films, and therefore, the problem that the original light surface and a coating layer cannot be bonded firmly is solved, and a micro-etchingprocess can be saved for downstream production enterprises.

Metal surface micro-etching liquid

The invention discloses metal surface micro-etching liquid and belongs to the technical field of chemical engineering micro-etching liquid. The metal surface micro-etching liquid is prepared from, by mass, 15-25% of dilute sulphuric acid with the mass fraction being 50%, 10-15% of hydrogen peroxide, 2-5% of a stabilizing agent, 0.5-1% of surfactant, 0.2% of an anti-mildew agent and the balance water. The metal surface micro-etching liquid has a quite remarkable effect on solder resist preprocessing and surface chemical treatment of a printed circuit board, the copper face of the circuit board has uniform roughness and cleanness, the binding force between the copper face and an image layer and a pasted film is increased, toxicity is low, pollution is small, use is convenient, metal surface oxide can be fast processed, and metal surface cleanness is improved. The micro-etching liquid product is wide in application range and mainly used for metal surface oxide removing preprocessing and metal coloring preprocessing. The metal surface micro-etching liquid can also be used for super roughening, oxide removing processing, machining, metal deep machining, spraying and other the metallurgical industries of electronic circuit board copper faces.

Owner:广州恩源化工科技有限公司

Surface coarsening method and surface coarsening liquid for copper foil

InactiveCN1715457AShorten the total process timeReduce processInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentChemical structureVolumetric Mass Density

A roughening treatment method for copper foil comprises: a stage A where an acidic solution containing sulfuric acid comprising at least one roughening additional substance as a heterocyclic compound having a chemical structure represented by the formula in each molecule and also having two or more cyclic structures is prepared as a treatment liquid for roughening treatment; and a stage B where one side or both the sides of copper foil are subjected to cathode treatment at the critical current density or higher using the acidic solution containing sulfuric acid, and projection-shaped copper electrodeposited material is formed on the surface of the copper foil. The invention provides a roughening treatment method where uniform roughened particles having no danger of falling can be obtained in a short time, the obtained roughened particles have low roughness and high adhesion with resin or the like, and productive efficiency is high even to thin copper foil, and to provide a treatment liquid used in the roughening treatment method for the copper foil.

Owner:FUKUKA METAL FOIL & POWDER CO LTD

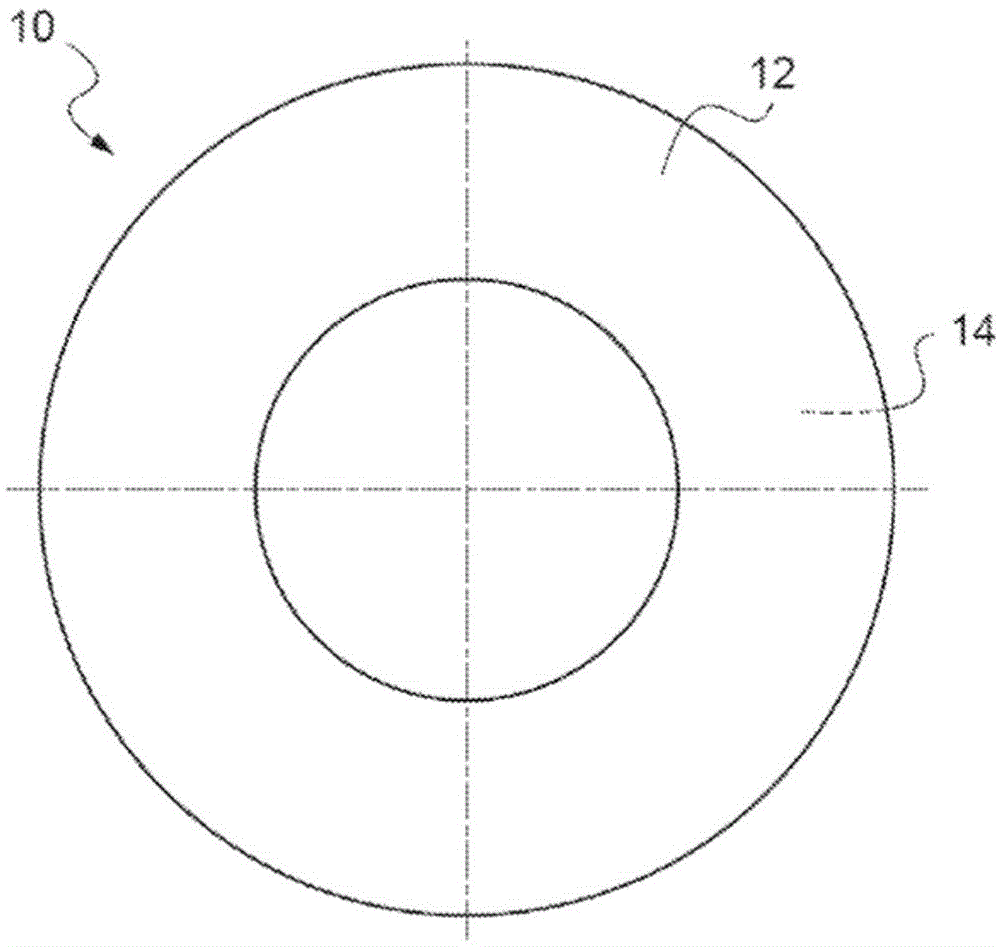

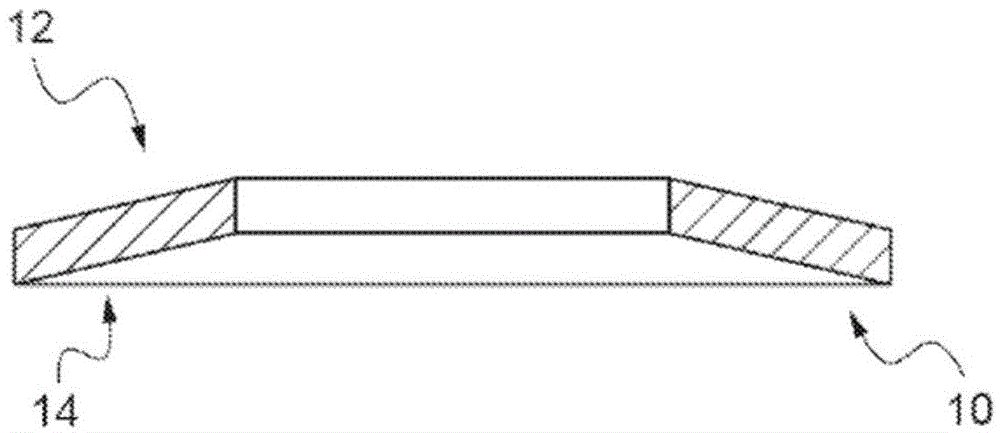

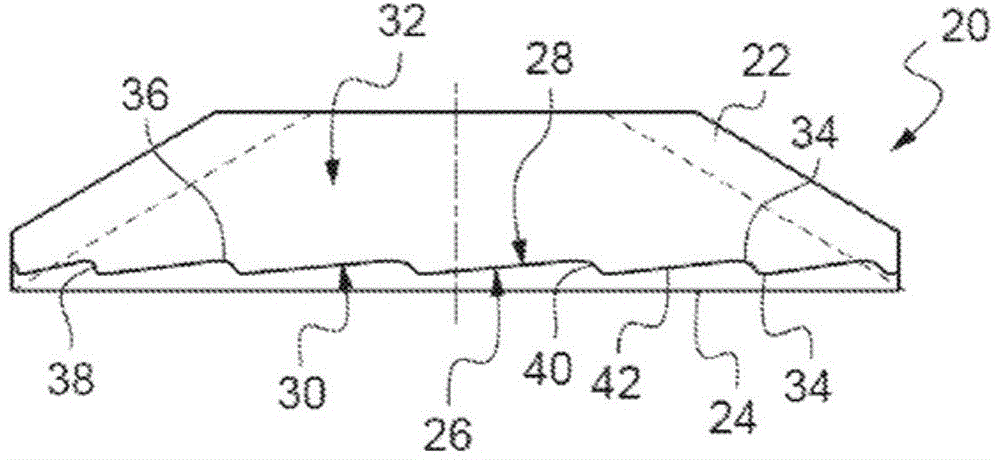

Rough metallic locking washer

Rough metallic locking washer The present invention relates to a metallic locking washer(10, 20, 20') intended for being mounted in a screw / nut system to engage between a nut and a bearing element, said metallic locking washer having a contact face (12, 14; 20, 30; 30', 32') suitable for coming into contact with one or the other of the nut and the bearing element, said contact face (12, 14; 30, 32; 30', 32') having a surface which is suitable for being brought along in friction against one or the other of the nut and the bearing element when the nut loosens. According to the invention said contact face is coated, by thermal projection of an additive material, with a rough coating forming a rough surface in order to enable an increase in the friction forces between the contact face (12, 14; 30, 32; 30', 32') of the metallic washer(10, 20, 20') and one or the other of the nut and the bearing element.

Owner:NORD LOCK INT

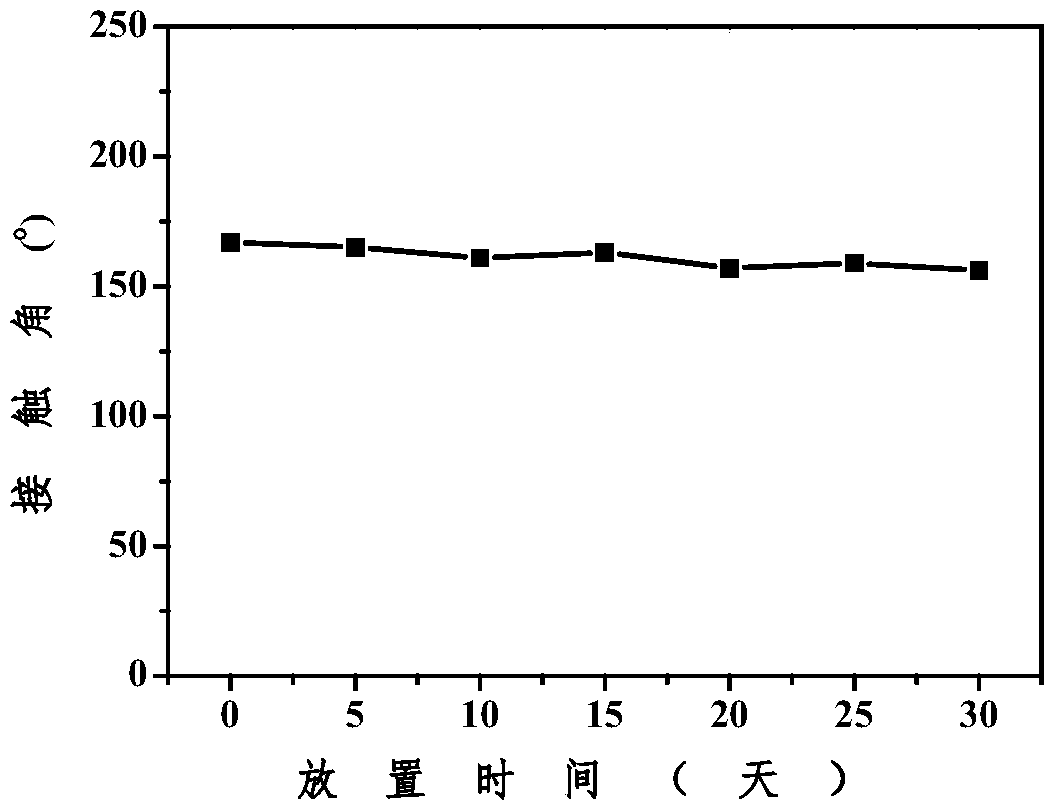

Method for building super-hydrophobic coating on metal surface

ActiveCN109127328AShape constraintsMild conditionsPretreated surfacesCoatingsRoom temperatureAqueous solution

The invention relates to a method for building a super-hydrophobic coating on a metal surface. The method comprises the steps that metal base materials are cleaned in a lye solution at 50-70 DEG C andan acid solution at 50-70 DEG C to remove grease on the surface; chemical etching treatment is carried out on the metal surface by using an aqueous hydrochloric acid solution at room temperature for5-15 minutes; and hydrophobic substance with low-surface-energy is assembled onto the metal surface after the chemical etching treatment, and then solidification treatment is carried out. According tothe method for building the super-hydrophobic coating on the metal surface, the super-hydrophobic coating is built on the metal surface, the used preparation method has no special restrictions on theshape of metal, and coating can be carried out on the surface of a test piece with complicated shape. The method does not require special equipment, has simple process, easy operation and mild condition, is especially suitable for metal parts with irregular shape such as heat exchanger fins, and is easy for industrialized mass production. After the gained coating is placed for a long period, preferable super-hydrophobic performance is still maintained.

Owner:XI AN JIAOTONG UNIV

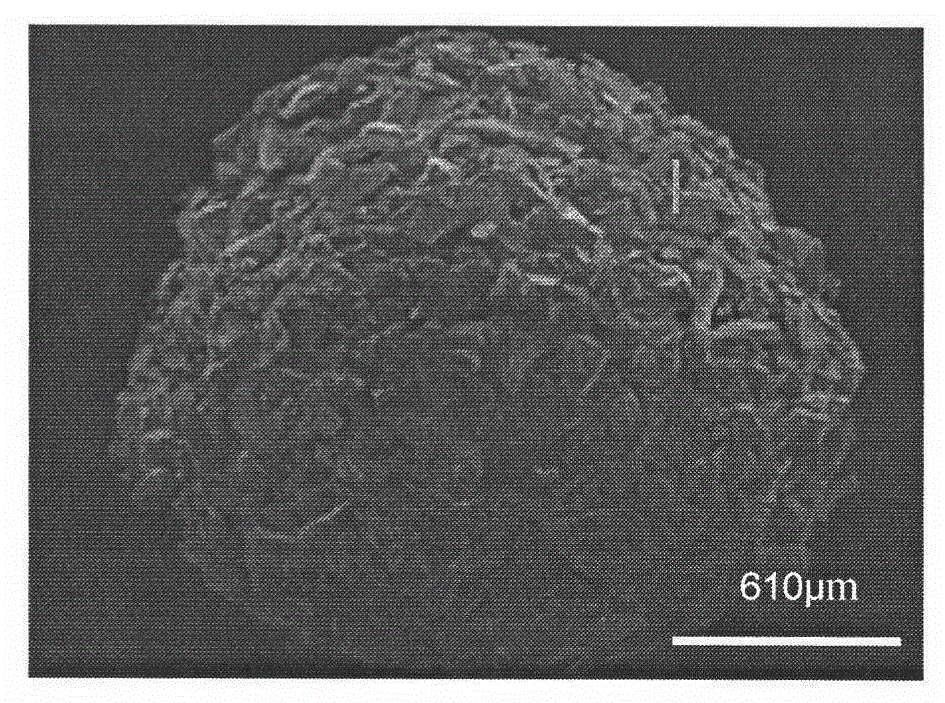

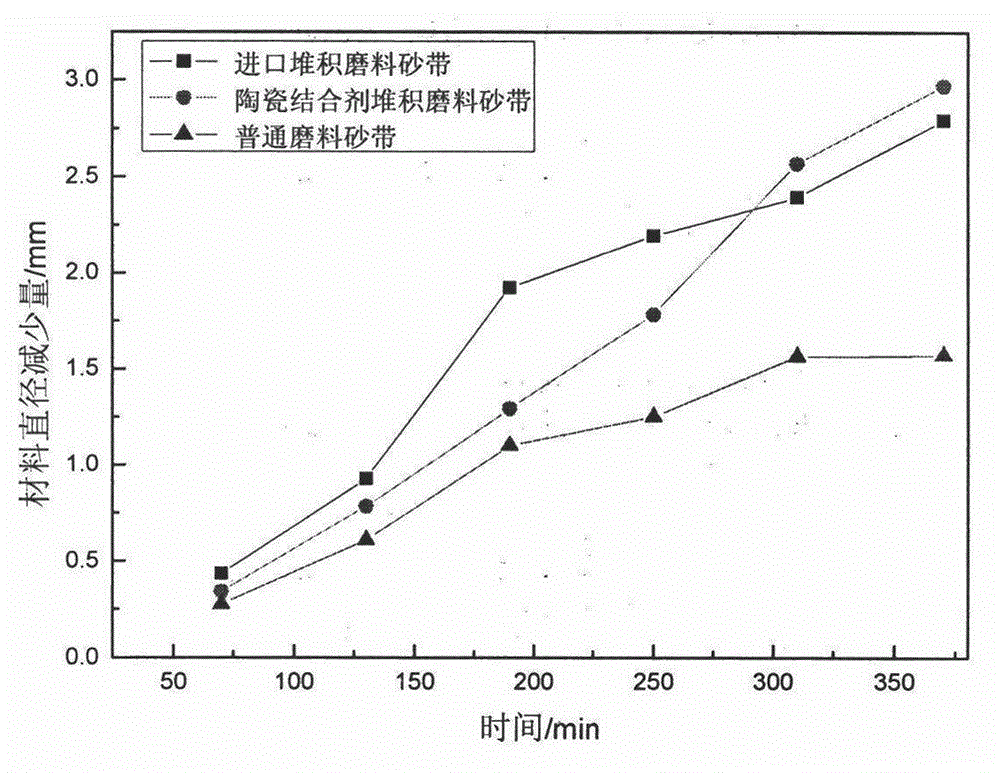

Method for preparing ceramic bond stacking abrasive material through centrifugal drying granulation technology

ActiveCN105563363AImprove gripAchieve uniformityOther chemical processesAbrasion apparatusIonSilicon oxide

The invention provides a method for preparing a ceramic bond stacking abrasive material through a centrifugal drying granulation technology. The method is characterized in that an abrasive material and ceramic bond powder composed of silicon oxide powder, aluminum oxide powder, lithium carbonate powder, sodium carbonate powder, boric acid powder and zirconium oxide powder are adopted as the raw materials, mixed slurry is obtained by adding deionized water and dextrin liquid into the raw materials, stacking abrasive material fresh pellets are obtained through centrifugal drying, and the ceramic bond stacking abrasive material can be obtained through calcination. The abrasive material can be evenly wrapped and high bonding force can be generated through the liquid phase formed after the powder bond in the stacking abrasive material is fused. The spherical stacking abrasive material prepared through the method has the characteristics of the uniform particle granularity and the uniform organization structure, and can be used for preparing abrasive cloth, abrasive belts and resin bond grinding wheels. The abrasive belts prepared from the ceramic bond stacking abrasive material have the characteristics of being high in grinding efficiency, good in self-sharpening performance and grinding heat dissipation and long in service life; automatic production can be easily achieved through the technology.

Owner:江苏华东砂轮有限公司

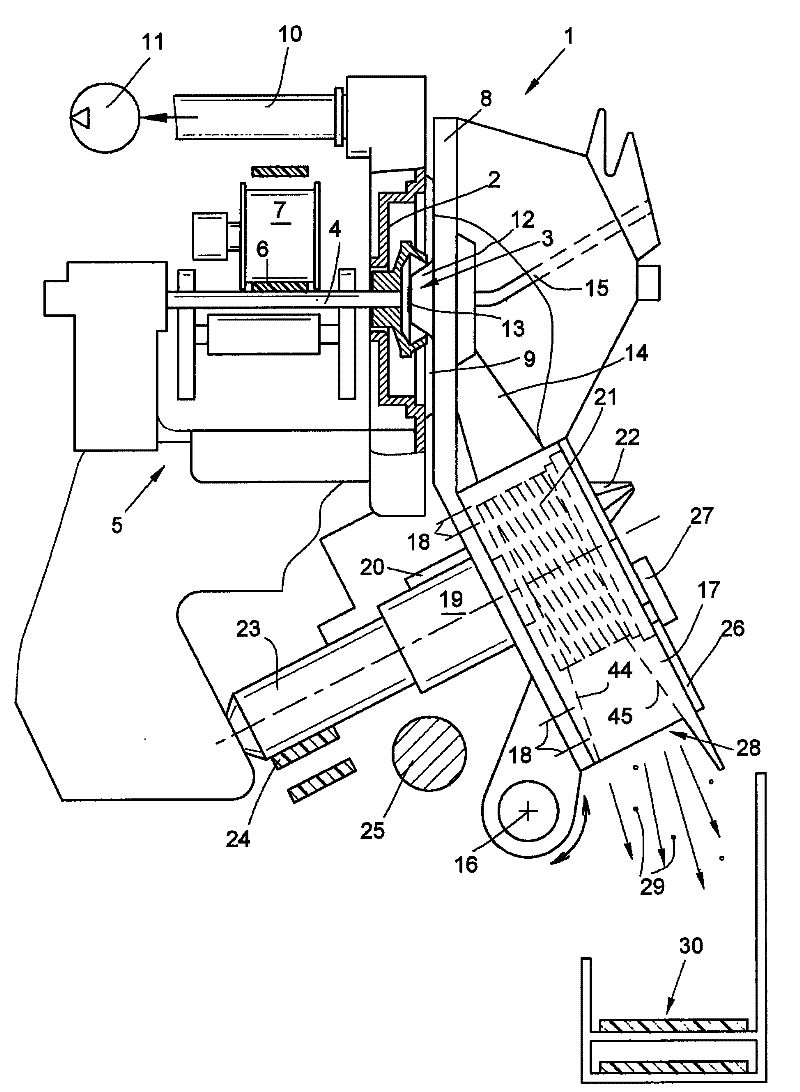

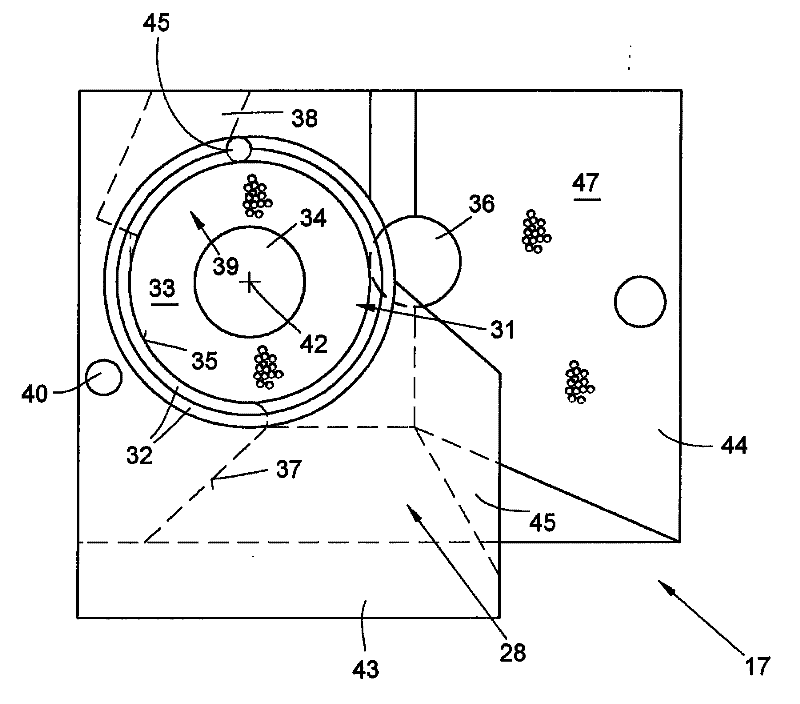

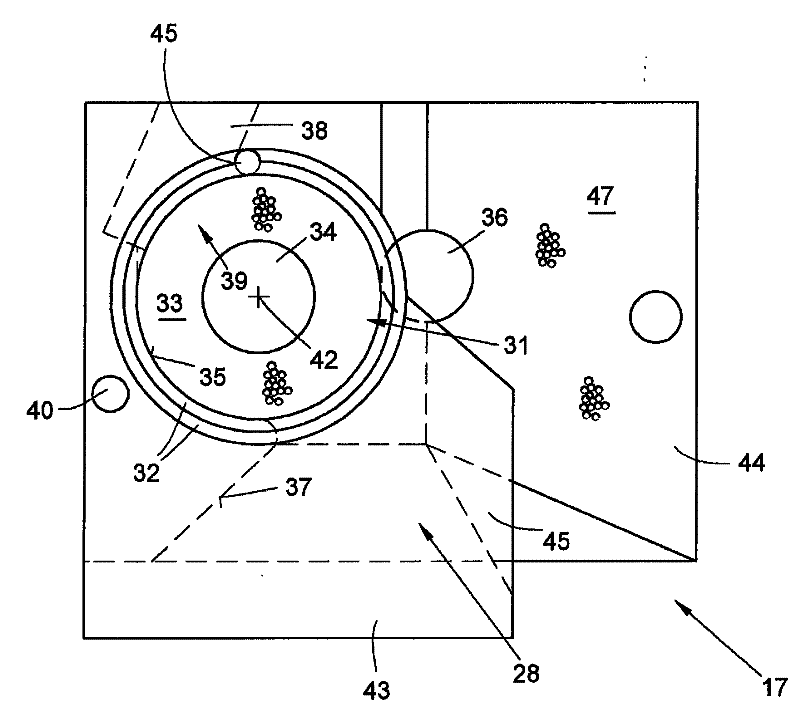

Method for producing a disintegrating roller housing of an open end spinning machine and disintegrating roller housing

ActiveCN102191591AEnsure orderly deliveryIncrease roughnessContinuous wound-up machinesOpen-end spinning machinesAdhesion forceSingle fiber

The method involves using a light metallic material for manufacturing the opening roller housing (17), where the opening roller housing has a circular opening roller receiver (31). Openings are arranged in the circumferential wall of the opening roller receiver. The opening roller housing is so impinged with a sand blast medium in a finishing process that the surfaces (33,35) of the opening roller receiver (31) is micro compressed and supports a roughness which ensures that no adhesion forces occur in area of the surfaces (33,35) during the operation of the opening roller housing (17), thereby ensuring ordered conveying of the opened single fiber in the opening roller receiver (31).

Owner:SAURER GERMANY GMBH & CO KG

Shaft for fluid dynamic bearing, fluid dynamic bearing device, and method of manufacturing the shaft

InactiveUS7226211B2Improve accuracyLow costRevolution surface grinding machinesShaftsEngineeringGrinding wheel

In a method of manufacturing a shaft for the fluid dynamic bearing device, the shaft is formed with a plurality of grooves arranged in and around the external circumference, the surface of the grooves and external circumference with uniform roughness, and machined marks on the surface aligned in the circumferential direction, by controlling the relative vibration of a rod-shaped blank to be machined as the shaft for a fluid dynamic bearing and a grinding wheel (a machining tool) to grind the external circumference of the blank.

Owner:NHK SPRING CO LTD

Etching solution for preparing filter glass and preparation method of filter glass

ActiveCN111393031AMeet the special requirements of output and inputHigh precisionOptical filtersEtchingO-Phosphoric Acid

The invention belongs to the technical field of glass chemical etching, and particularly relates to an etching solution for preparing filter glass and a preparation method of the filter glass. The etching solution for preparing the filter glass is prepared from the following raw materials in percentage by mass: 5 to 10% of ammonium bifluoride, 4 to 6% of ammonium fluoride, 12 to 18% of sulfuric acid, 15 to 28% of hydrofluoric acid, 3 to 8% of phosphoric acid, 4 to 8% of copper sulfate, 0.5 to 0.8% of borax, 10 to 25% of cane sugar and 5 to 20% of water. The etching solution is used for treating glass, so that the filter glass meeting the use requirements of medical instruments can be prepared.

Owner:ZHENGZHOU HIHO OPTICAL TECH CO LTD

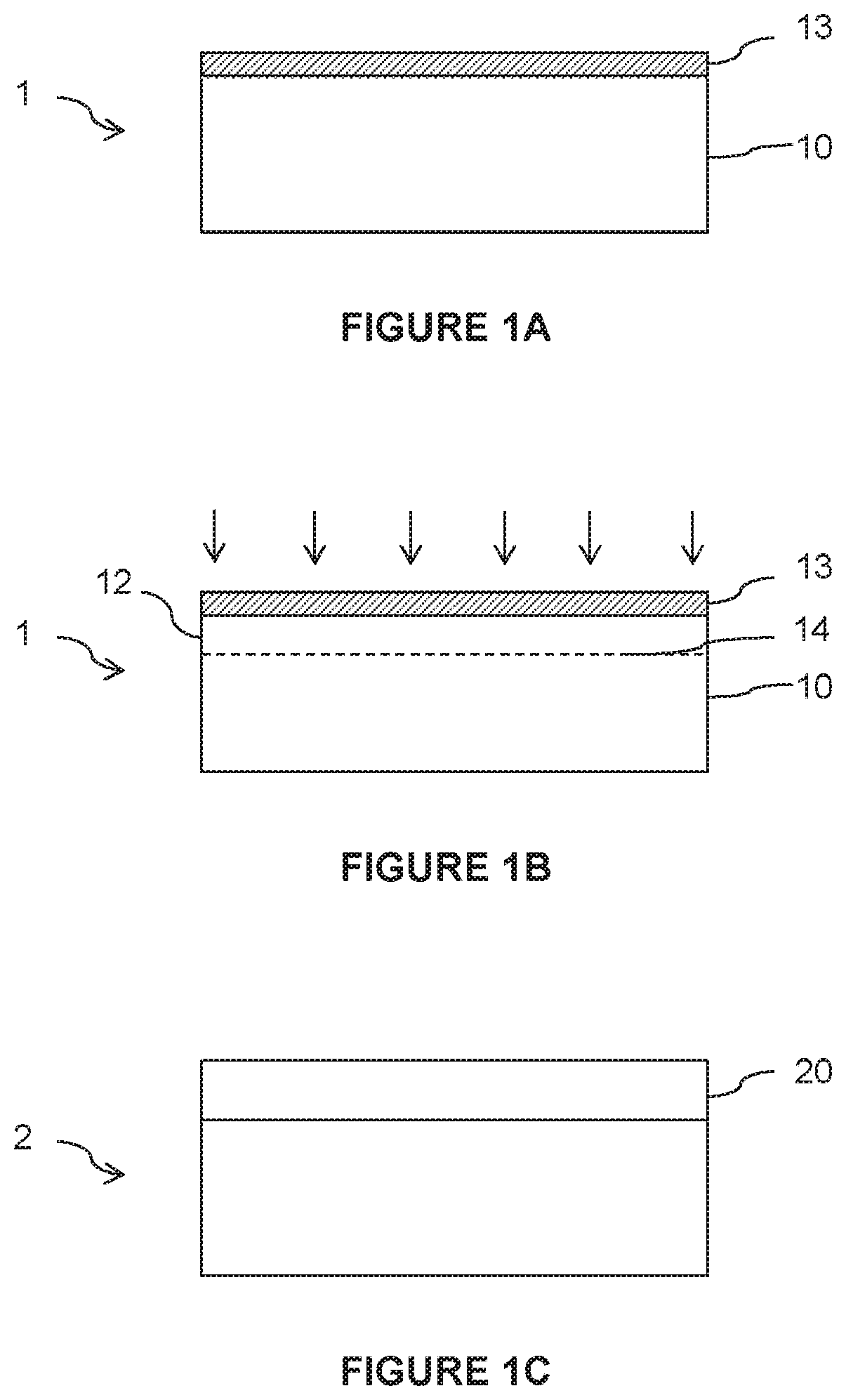

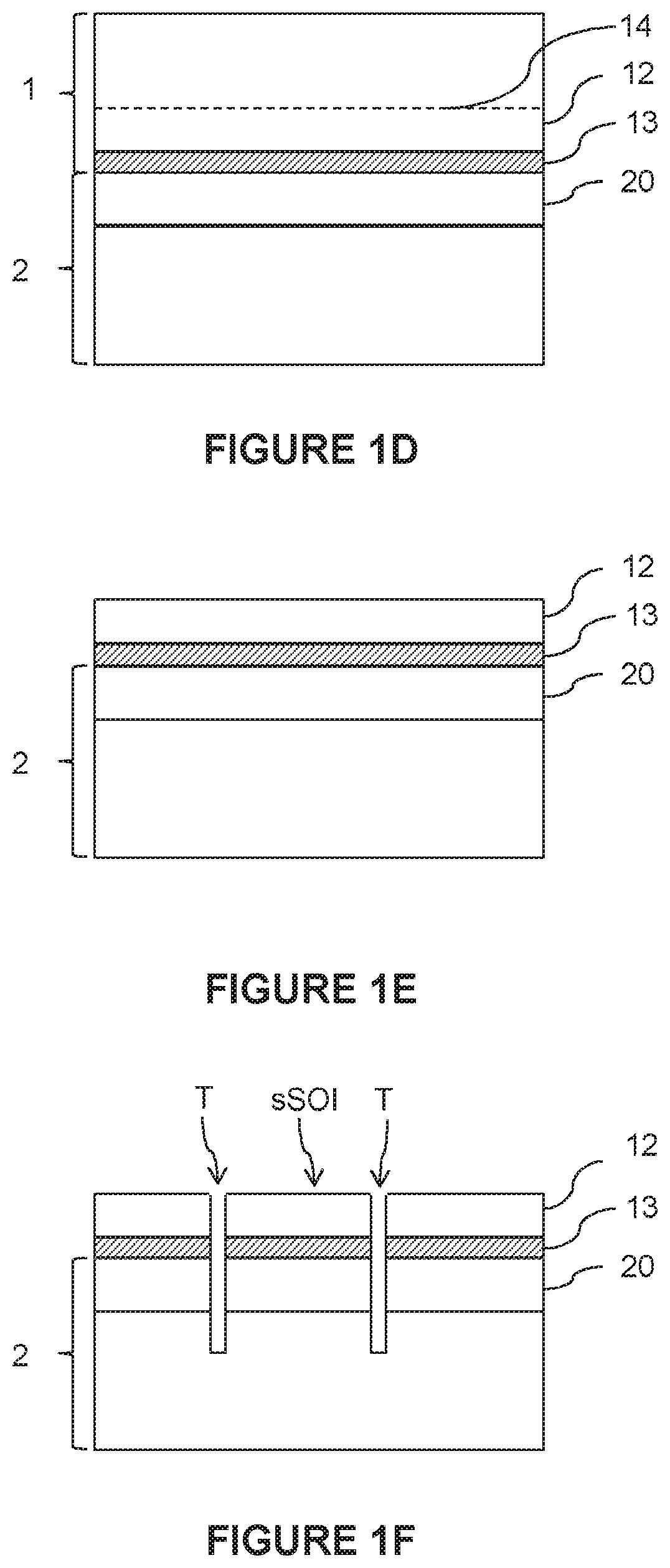

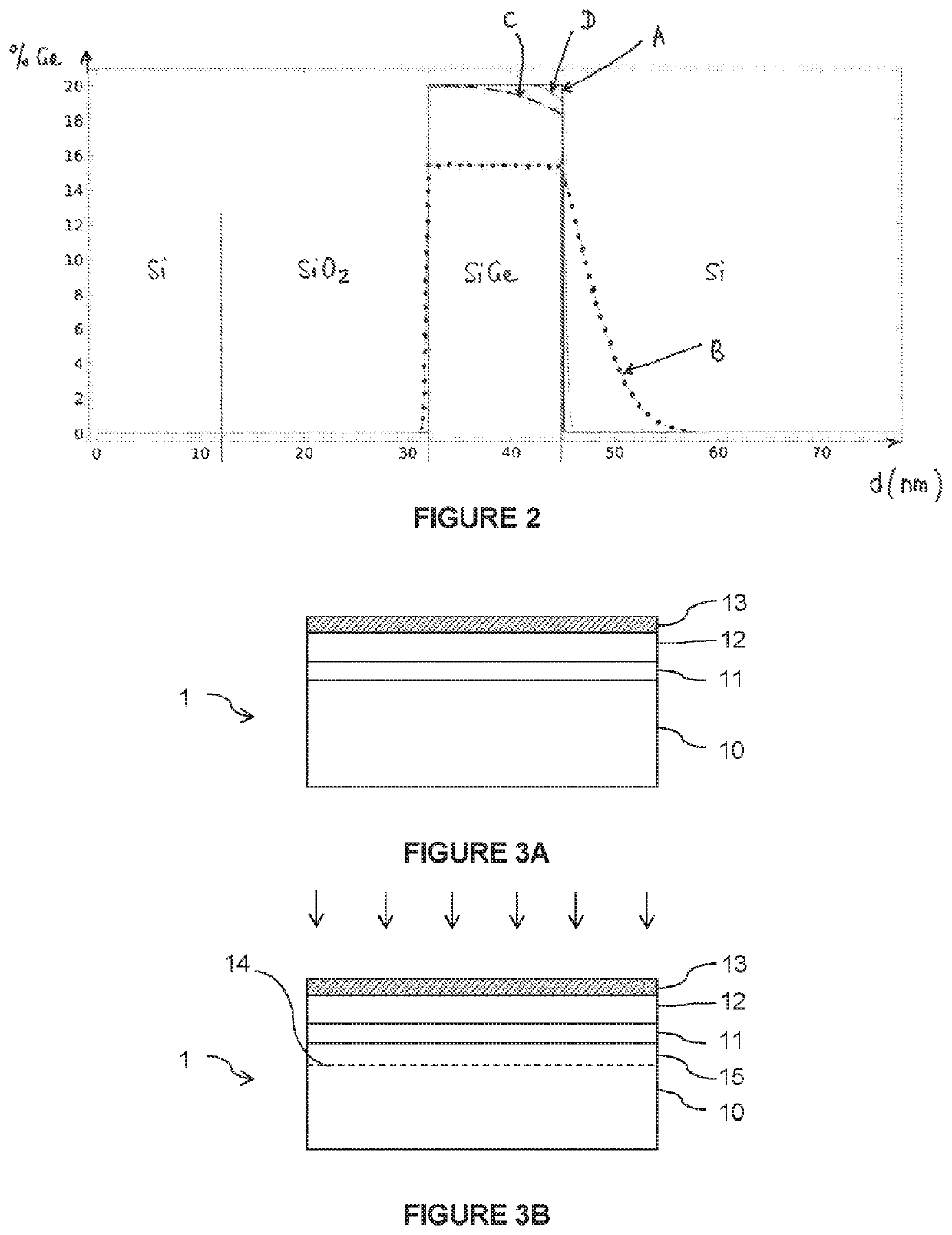

Method for fabricating a strained semiconductor-on-insulator substrate

ActiveUS10957577B2Uniform roughnessSemiconductor/solid-state device manufacturingSemiconductor materialsSingle crystal

A method for fabricating a strained semiconductor-on-insulator substrate comprises bonding a donor substrate to a receiving substrate with a dielectric layer at the interface. The donor substrate comprises a monocrystalline carrier substrate, an intermediate etch-stop layer, and a monocrystalline semiconductor layer. The monocrystalline semiconductor layer is transferred from the donor substrate to the receiving substrate. Trench isolations are formed to cut a portion from a layer stack including the transferred monocrystalline semiconductor layer, the dielectric layer, and the strained semiconductor material layer. The cutting operation results in relaxation of strain in the strained semiconductor material, and in application of strain to the transferred monocrystalline semiconductor layer. After transferring the monocrystalline semiconductor layer and before the cutting operation, a portion of the carrier substrate is selectively etched with respect to the intermediate layer, and the intermediate layer is selectively etched with respect to the monocrystalline semiconductor layer.

Owner:SOITEC SA

Method for making ceramic selenium drum development magnetic roller aluminum sleeve

InactiveCN102400117APrevent reoxidationUniform zinc layerSolid state diffusion coatingLiquid/solution decomposition chemical coatingTotal thicknessSelenium

The invention provides a method for making a ceramic selenium drum development magnetic roller aluminum sleeve. The method is used for preventing oxidation of an adsorption layer on the surface of the aluminum sleeve, improving the abrasion resistance of the aluminum sleeve and improving the conductivity of the aluminum sleeve at the same time. The method comprises the following processes of: directly blasting sand to the surface of the aluminum sleeve to perform roughening treatment; and coating a chemically plated nickel-phosphorus alloy protective layer with the total thickness of less than 5 microns and a chemically plated ceramic and nickel-phosphorus alloy protective layer on the aluminum sleeve with a frosting layer. On the basis of keeping high particle fineness and uniformity of the adsorption layer on the surface of the aluminum sleeve, the service life of the aluminum sleeve can be greatly prolonged by the coated nickel-phosphorus alloy protective layer and the ceramic and nickel-phosphorus alloy protective layer; and meanwhile, because the chemically plated nickel-phosphorus alloy protective layer, the chemically plated ceramic and nickel-phosphorus alloy protective layer, the sand blasting method and the secondary zinc galvanizing technology are combined, the conductivity and the abrasion resistance of the adsorption layer on the surface of the aluminum sleeve are improved, the oxidation property of the adsorption layer is reduced, and various properties of common development magnetic rollers are obviously improved.

Owner:郑杰 +1

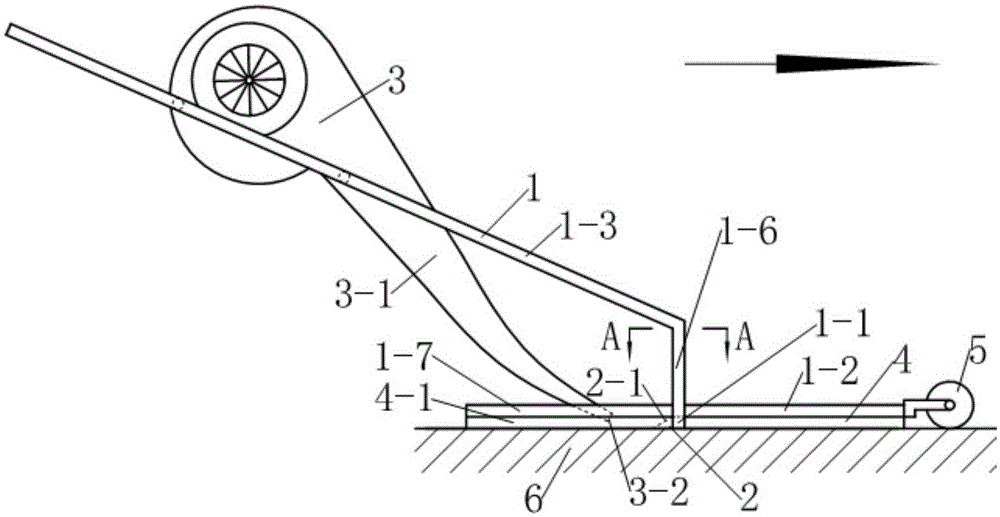

Laitance removing device suitable for semi-flexible pavement

ActiveCN105274926AExpand the operating areaImprove cleaning efficiencyRoads maintainenceRoad surfaceEngineering

The invention discloses a laitance removing device suitable for a semi-flexible pavement. The laitance removing device comprises a rack and an air blower. The rack comprises a rectangular frame. Two supporting rods extend downwards vertically from the front ends of the two sides of the rectangular frame respectively. A scraper beam close to the ground is arranged between the two supporting rods. The lower portions of the two supporting rods are each provided with a baffle beam. The two baffle beams extend to the front portions of the two sides of the rectangular frame respectively and the tail ends of the baffle beams are each provided with a guide wheel borne on the pavement. A rubber baffle is arranged below each baffle beam. A laitance scraper is arranged on the rear side face of the scraper beam. The bottom of the laitance scraper is tightly attached to the pavement and the laitance scraper is provided with a slope extending from the rear edge of the upper surface of the scraper beam to the position, behind the scraper beam, of the pavement. The air blower is arranged on the rectangular frame, an exhaust duct of the air blower extends obliquely to the position, behind the slope on the laitance scraper, of the pavement and to the position close to the lower edge of the slope, and the tail end of the exhaust duct is parallel to the laitance scraper.

Owner:GUANGZHOU UNIVERSITY

Micro-etching liquid and micro-etching method for 5G high-frequency line production process and application of micro-etching liquid and micro-etching method

ActiveCN114807943ALong potion lifeStable roughnessConductive material chemical/electrolytical removalMicroetchingEtching rate

Owner:SHENZHEN BANMING SCI & TECH CO LTD

Multifunctional aerobics pedal

InactiveCN108057228AUniform roughnessSimple structureDevices for pressing relfex pointsSport apparatusEngineeringTreadle

The invention discloses a multifunctional aerobics pedal. The pedal comprises a box body, a spring is connected to the bottom surface of the box body through a screw, a bottom plate is connected to the lower end of the spring through a screw, the box body is internally provided with a motor, an output shaft of the motor is connected with a first rotating shaft through a coupling, and the upper endof the first rotating shaft is fixed to the top surface inside the box body through a first bearing pedestal; a driving gear is arranged on the first rotating shaft and meshed with a driven gear, a second rotating shaft concentrically matched with the driven gear is installed on the driven gear, the second rotating shaft is fixed to the top surface inside the box body through a second bearing pedestal, the upper end of the second rotating shaft vertically penetrates through the box body, and the pedal is connected to the upper end of the second rotating shaft. According to the device, the height of the whole body can be adjusted conveniently through a telescopic support rod, the driving gear is driven by the motor to rotate, the driving gear drives the driven gear to rotate, the driven gear drives the pedal to rotate through the driving gear, and then a user can stamp different parts on the pedal, and it is guaranteed that the roughness of the surface of the pedal is uniform.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com