Micro-etching liquid and micro-etching method for 5G high-frequency line production process and application of micro-etching liquid and micro-etching method

A production process and technology of micro-etching solution, which is applied in the field of micro-etching solution and micro-etching for 5G high-frequency circuit production process, can solve the problems of less signal loss, poor signal transmission capability of circuit boards, strong bonding force of copper surface, etc., to achieve The effect of less signal loss, stable roughness, and strong bonding force on the copper surface

Active Publication Date: 2022-07-29

SHENZHEN BANMING SCI & TECH CO LTD

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The micro-etching solution in the prior art has a certain micro-etching effect and can complete the etching of thin lines, but for the production of 5G high-frequency circuit boards, there are still the following disadvantages: due to the technical requirements of high-frequency circuit boards, circuit boards need To meet the problems of fast transmi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

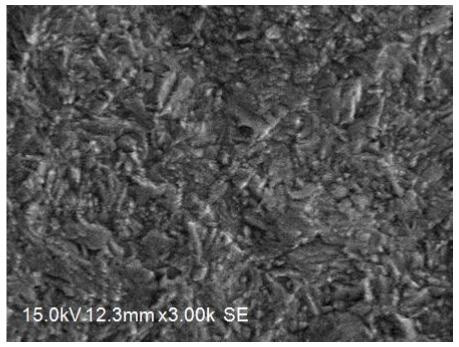

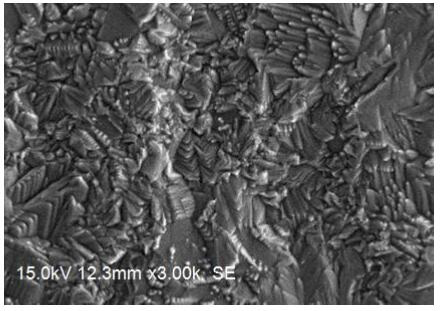

The invention discloses micro-etching liquid for a 5G high-frequency line production process, a micro-etching method and application of the micro-etching liquid and the micro-etching method, and relates to the technical field of printed circuit board production. The micro-etching liquid for the 5G high-frequency line production process is based on a sulfuric acid and hydrogen peroxide system and comprises a corrosion inhibitor, a brightener, a wetting agent, a stabilizer and a cosolvent, the cleaning agent comprises the following components in percentage by mass: 60-100g/L of sulfuric acid; 20-40 g/L of hydrogen peroxide; 0.1 to 1.5 percent of corrosion inhibitor; 0.1 to 1.5 percent of a brightening agent; 0.5%-3.5% of a wetting agent; 0.1 to 2.0 percent of a stabilizer; 0.5%-3.5% of a cosolvent; and the balance water. The micro-etching liquid disclosed by the invention has the advantages of long service life, high etching rate, stable and uniform coarsening degree of the etched copper surface and the like, can solve the problem of poor transmission signal after microetching in 5G high-frequency circuit board production, and meets the requirements of high transmission speed, low signal loss, strong copper surface binding force and the like.

Description

technical field [0001] The invention relates to the technical field of printed circuit board production, in particular to a micro-etching solution and a micro-etching method for a 5G high-frequency circuit production process and applications thereof. Background technique [0002] With the advent of the 5G era, the high frequency of electronic equipment is an inevitable development trend. With the miniaturization and multi-function of electronic products, and the rapid development of electronic components in the direction of high precision and high density The production is getting more and more refined, and the production difficulty is getting higher and higher. The metal wires in the printed circuit board not only need to play the role of current conduction, but also have the function of signal transmission lines. [0003] Especially in the era of the increasing development of wireless networks and satellite communications, the iteration of information products is becoming...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23F1/18H05K3/06

CPCC23F1/18H05K3/067

Inventor 韦金宇李初荣

Owner SHENZHEN BANMING SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com