Rough metallic locking washer

A washer and metal technology, applied in the direction of washers, locking fasteners, threaded fasteners, etc., to achieve good anchoring and enhanced bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

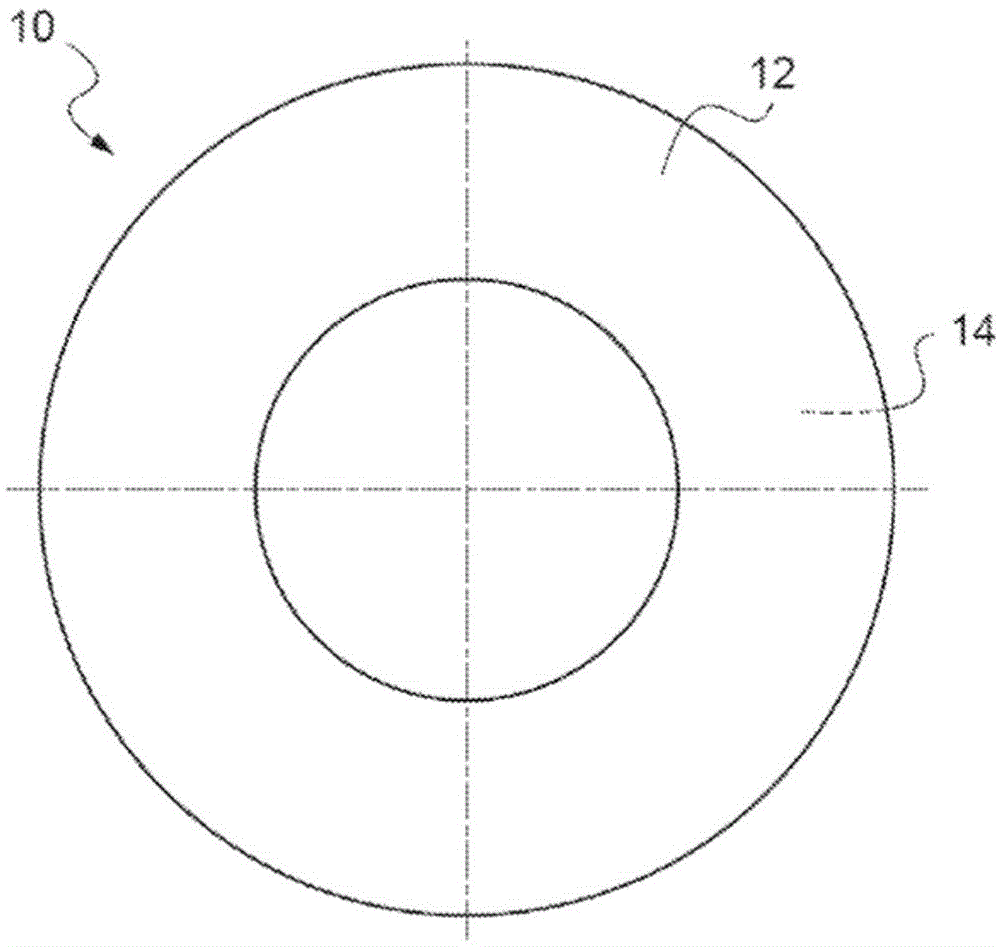

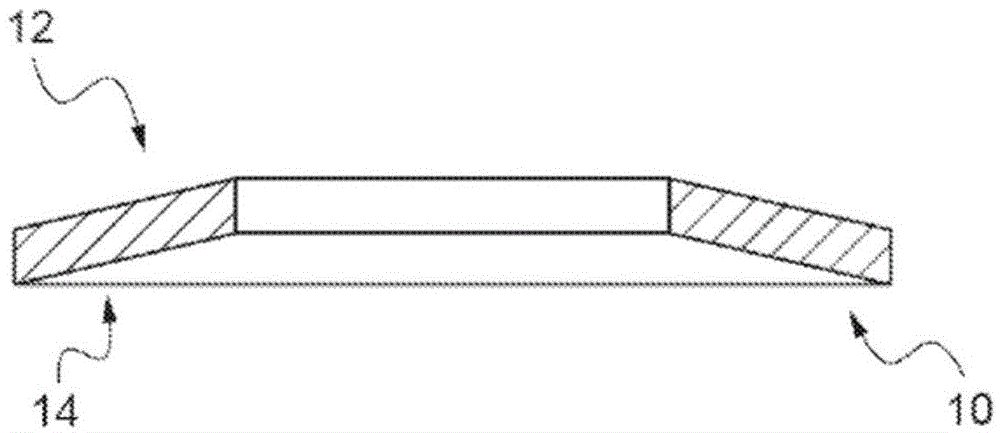

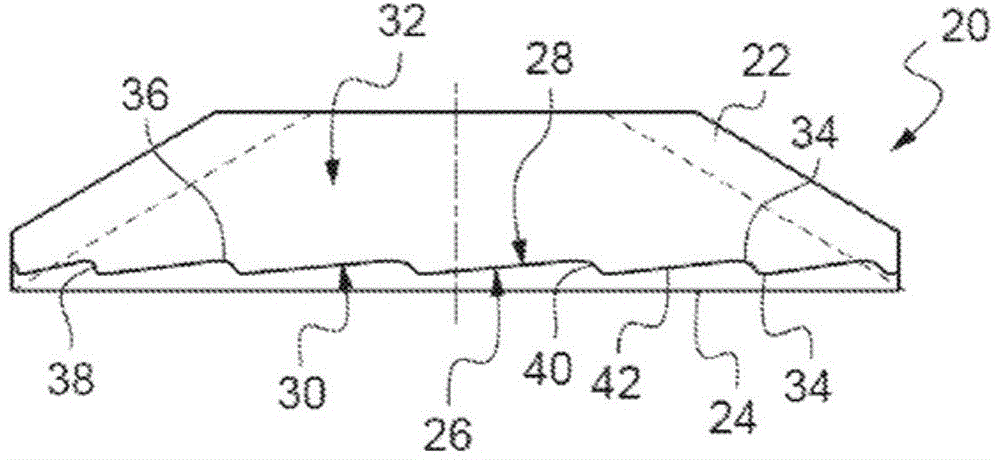

[0021] The subject invention is a metal lock washer having at least one surface roughened to thereby increase in parallel the friction of the surfaces in contact in a screw / nut system.

[0022] For this purpose, the contact surfaces are coated with a rough coating, which is achieved by heat projection of the added material. This is how the rough surface is formed.

[0023] Thus, the surface of the gasket is coated with a rough coating of the added material by means of a carrier gas which accelerates and transports particles of the added material at high temperature to the surface of the gasket.

[0024] Advantageously, usual thermal projection techniques can be used. Examples of such techniques include plasma, projection by spray deformation, wire-arc, cold projection, or by explosive spray gun.

[0025] Plasma technology uses a plasma torch which melts and accelerates the added material towards the surface to be treated to form a coating. Projection by jet deformation cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com