Laitance removing device suitable for semi-flexible pavement

A semi-flexible pavement and cleaning device technology, applied in roads, roads, road repairs, etc., can solve the problems of large differences in road surface roughness, low processing efficiency, environmental pollution, etc., and achieve uniform roughness, good surface appearance, and High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

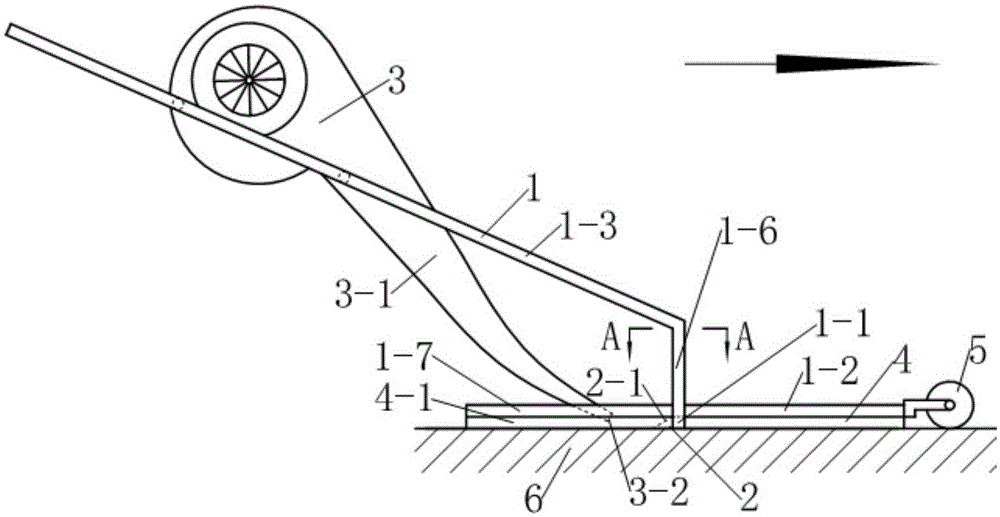

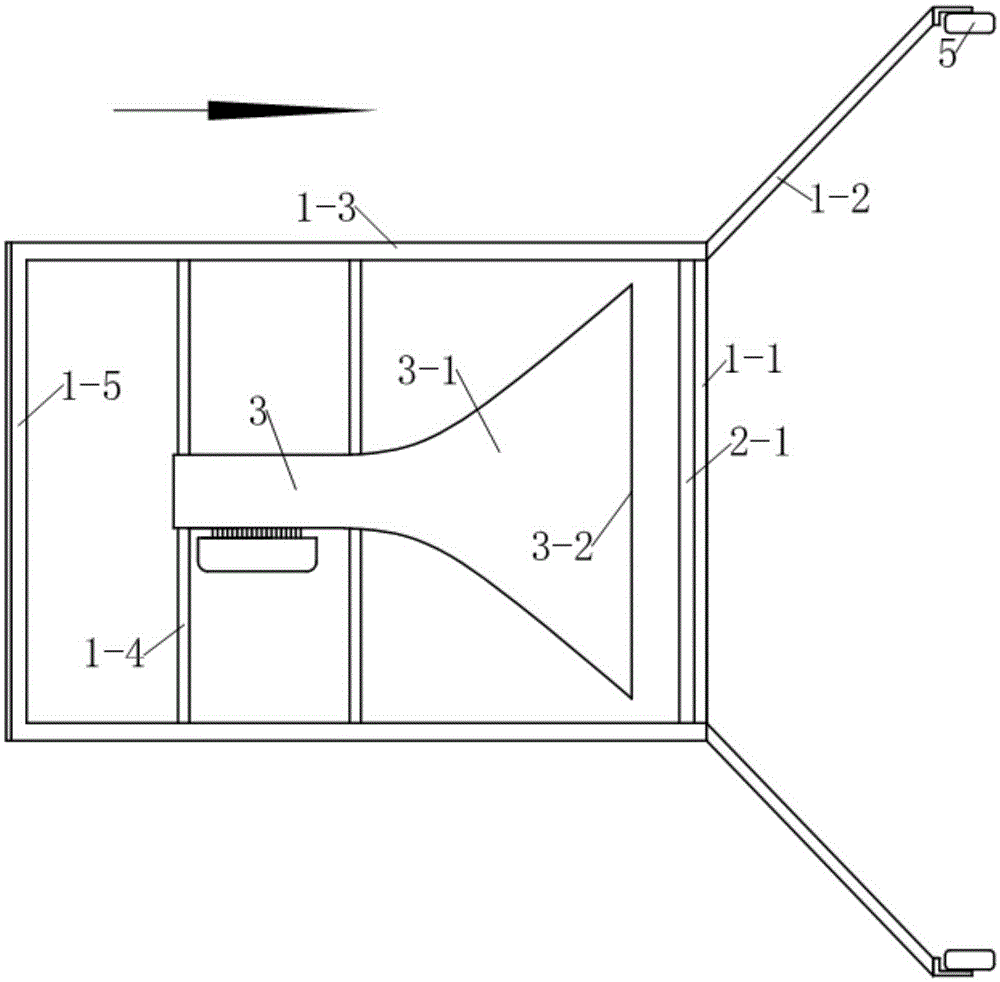

[0018] see Figure 1~4 , the laitance cleaning device in this example includes a frame 1, and the laitance scraper 2 and blower 3 are arranged on the frame 1 from front to back;

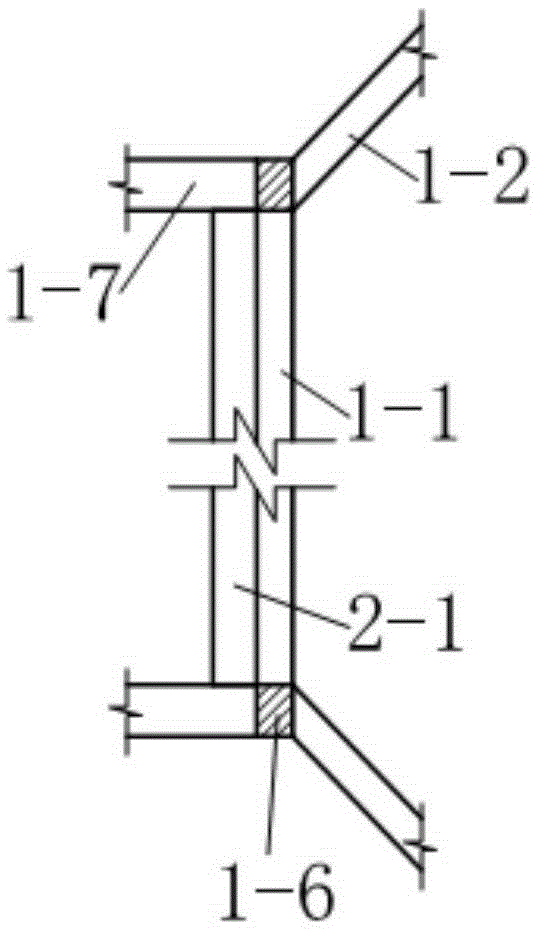

[0019] see Figure 1~4 , the frame 1 includes a rectangular frame 1-3 inclined to the rear and upward, the front ends of the two sides of the rectangular frame 1-3 vertically extend downwards a support rod 1-6, between the two support rods 1-6 A scraper beam 1-1 close to the ground 6 is provided. The scraper beam 1-1 is 2.5 cm high, 100 cm long, and has a rectangular cross section. The beam at the rear end of the rectangular frame 1-3 doubles as the handle 1-5 of the device. The lower heads of the two support rods 1-6 are respectively provided with a baffle beam 1-2 and an auxiliary baffle beam 1-7, and the two baffle beams 1-2 extend to the front of the rectangular frame 1-3 sides respectively, and are connected with the machine. The forward direction of the frame 1 is at an included angle of 45°, ...

example 2

[0024] Example 2 (this example is the experimental example of the effect of the floating slurry cleaning device in the verification example 1)

[0025] 1. Purpose of the experiment

[0026] Verify the use effect of the floating slurry cleaning device described in Example 1.

[0027] 2. Experimental method

[0028] Get two sections of road surface with a length of 50m respectively in the experimental road section with a width of 10m (two lanes including shoulders), one section is used as the experimental section, and the other section is used as the comparison section. The existing hydraulic flushing method cleans up the laitance. Record the construction time and labor quantity respectively.

[0029] After the maintenance of the two sections of pavement, several points were randomly selected on the pavement to investigate the structural depth.

[0030] 3 Experimental results

[0031] Table 1 Comparison results of apparent treatment effects

[0032]

[0033] Table 2 Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com