Conveying type digging machine without blocking chain

A chain and frame technology, which is applied in the field of non-chain conveyor excavators, can solve the problems of poor harvest quality, low harvest efficiency, and few types of harvest, so as to expand the operation area, avoid the phenomenon of chain jams, and improve operation efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0015] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

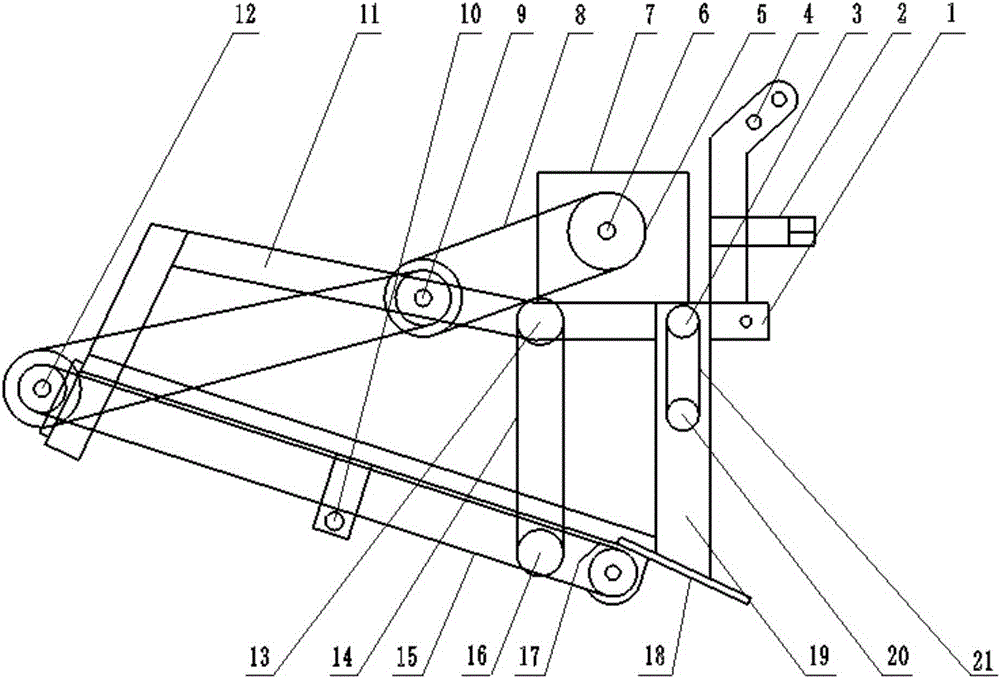

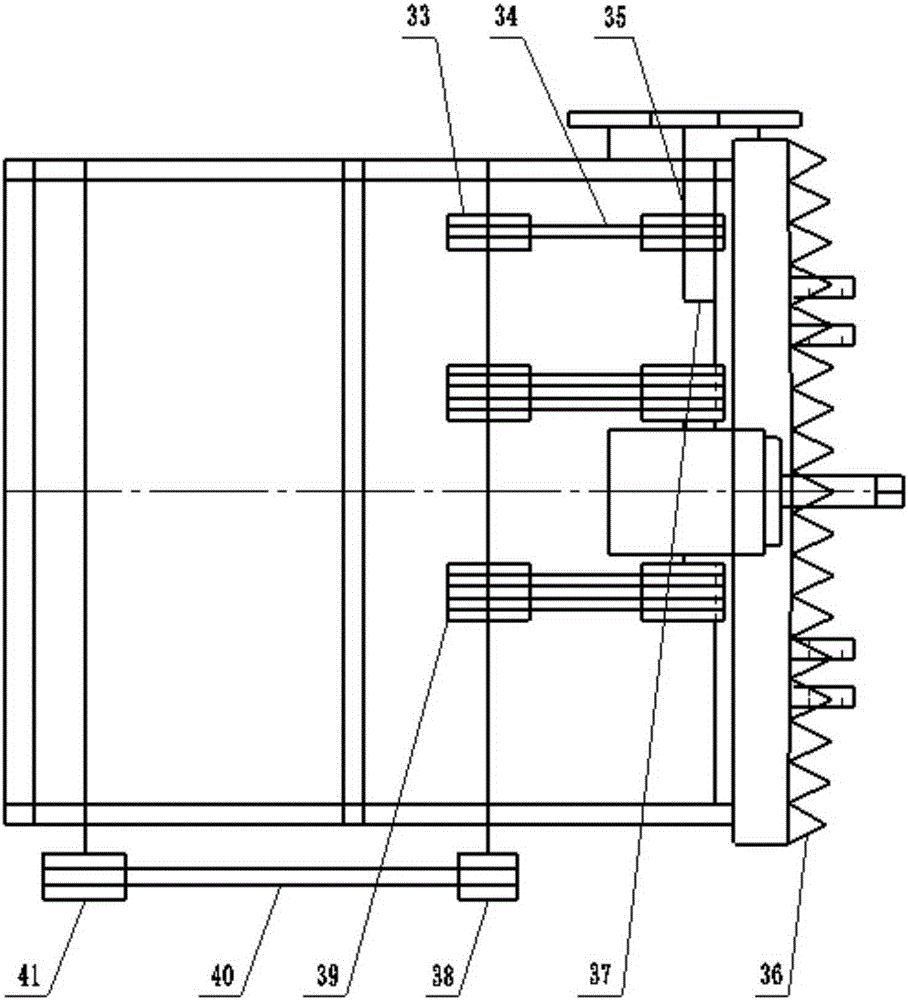

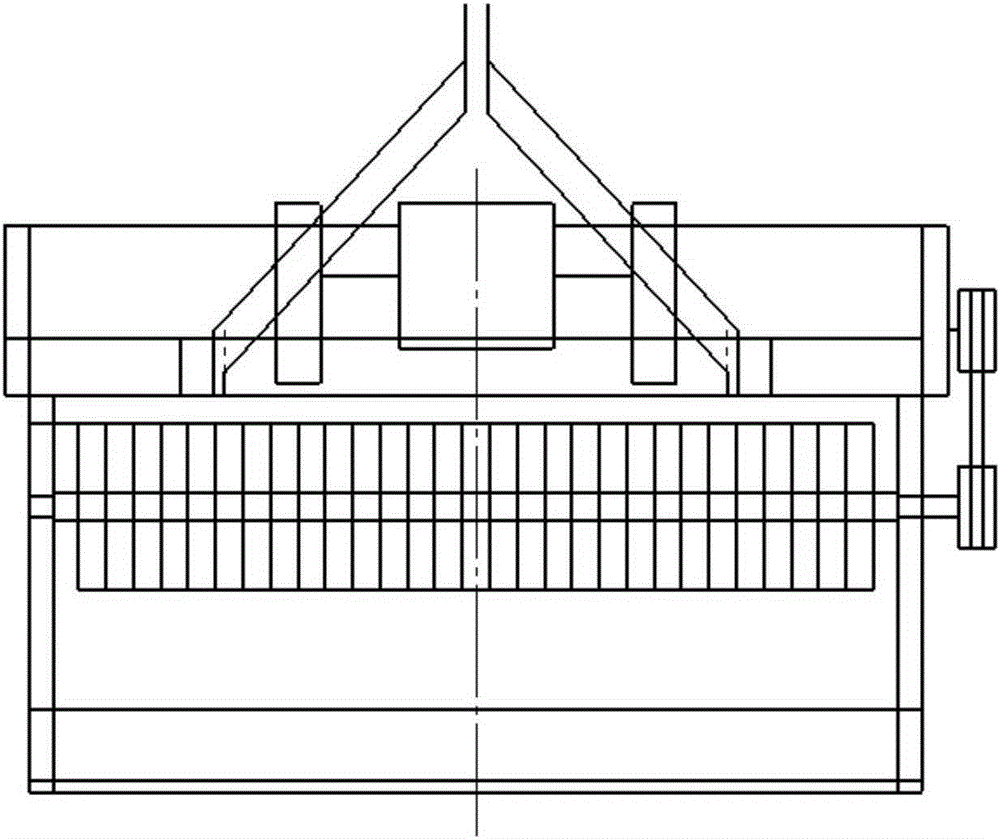

[0016] According to the present invention, a chainless conveyor type excavator, as shown in the drawings, consists of a lower suspension frame 1, a transmission shaft 2, a transmission main pulley 3, an upper suspension frame 4, a main transmission main pulley 5, Gearbox shaft 6, gearbox 7, total drive belt 8, main shaft 9, tie rod 10, frame 11, conveyor chain main shaft 12, stone discharge main pulley 13, stone discharge transmission belt 14, conveyor chain 15, stone discharge pulley 16, Stone guide plate 17, cutter body 18, side blade column 19, transmission slave pulley 20, transmission blade conveyor belt 21, transmission blade gear 22, transmission blade gear shaft 23, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com