Method for growing carbon nano tube in situ on surface of fiber

A fiber surface, in-situ growth technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of increasing process difficulty and investment cost, and achieve simple preparation and storage, and simple method Easy-to-do, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Pretreatment

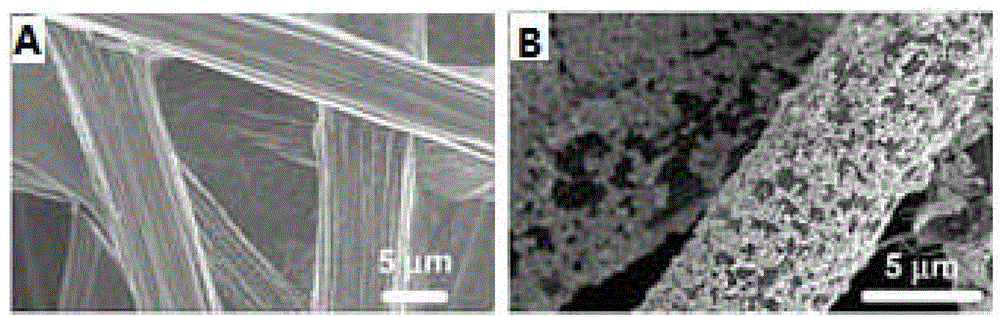

[0026] Put the carbon cloth into a mixture of 98% concentrated sulfuric acid and 30% (mass / volume) hydrogen peroxide (concentrated sulfuric acid:hydrogen peroxide=3:1), treat for 30min, take it out and wash it in distilled water at least three times , and dried at 80°C for two hours. From figure 1 It can be seen that the surface of the unpretreated carbon fiber is very flat, while the surface of the pretreated carbon fiber has many grooves.

[0027] 2) Preparation of catalyst

[0028] Fe(NO 3 ) 3 9H 2 O was dissolved in ethanol to prepare 100 mM Fe(NO 3 ) 3 solution; then put the carbon cloth pretreated in step 1) into the solution and soak for 2h. Arrange the treated carbon in a quartz tube, and heat it under an inert gas atmosphere; when the temperature rises to 700°C, it is kept for half an hour, and 200 sccm hydrogen gas is introduced.

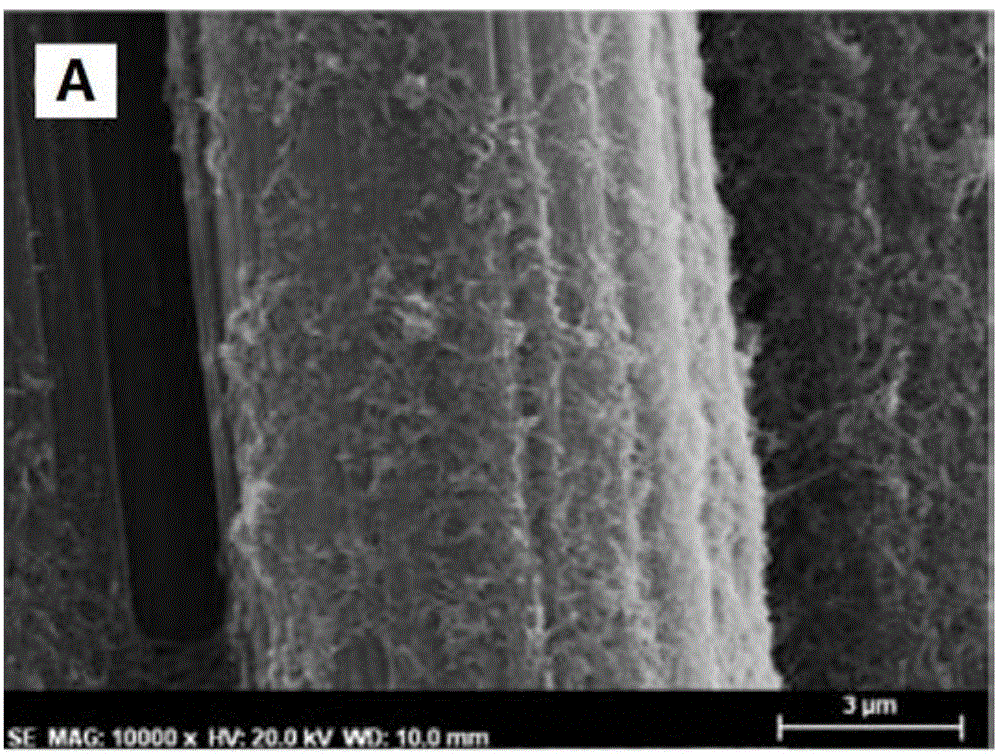

[0029] 3) Growth of carbon nanotubes on the surface of carbon fibers

[0030] Keep the temperature at ...

Embodiment 2

[0033] 1) Pretreatment

[0034] Put the carbon cloth into a mixture of 98% concentrated sulfuric acid and 30% (mass / volume) hydrogen peroxide (concentrated sulfuric acid:hydrogen peroxide=3:1), treat for 30min, take it out and wash it in distilled water at least three times , and dried at 80°C for two hours.

[0035] 2) Preparation of catalyst

[0036] With 2M Ni(NO 3 ) 2 The solution and ethylene glycol methyl ether were used to prepare a sol, and an appropriate amount of ammonia water was added, stirred at a high speed for 6 hours, and then sealed and left to stand for 10 hours to obtain a transparent sol. The sol was uniformly coated on the surface of the pretreated fiber by dipping and pulling method, and the pulling speed was 8 cm / min. After the wet film was heat-treated at 100°C, it was dipped and pulled repeatedly, and the number of times of pulling was 3 times. The fiber coated with the Ni-containing sol was placed in the chamber of the chemical vapor deposition s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com