Method for preparing ceramic bond stacking abrasive material through centrifugal drying granulation technology

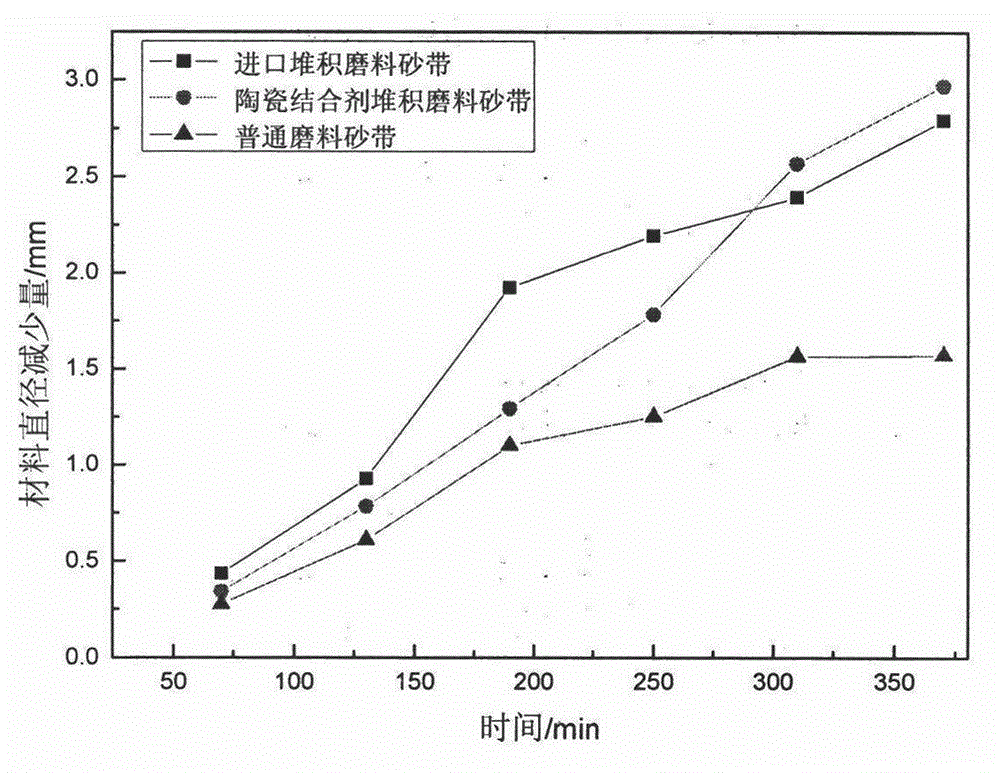

A technology of ceramic bond and accumulation of abrasives, applied in abrasives, chemical instruments and methods, manufacturing tools, etc., can solve the problem of affecting the accuracy and surface roughness of workpieces, unable to meet the requirements of abrasive belt softness, and difficult to ensure the uniformity of sand planting and other problems, to achieve the effect of high grinding efficiency, conducive to automatic production and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

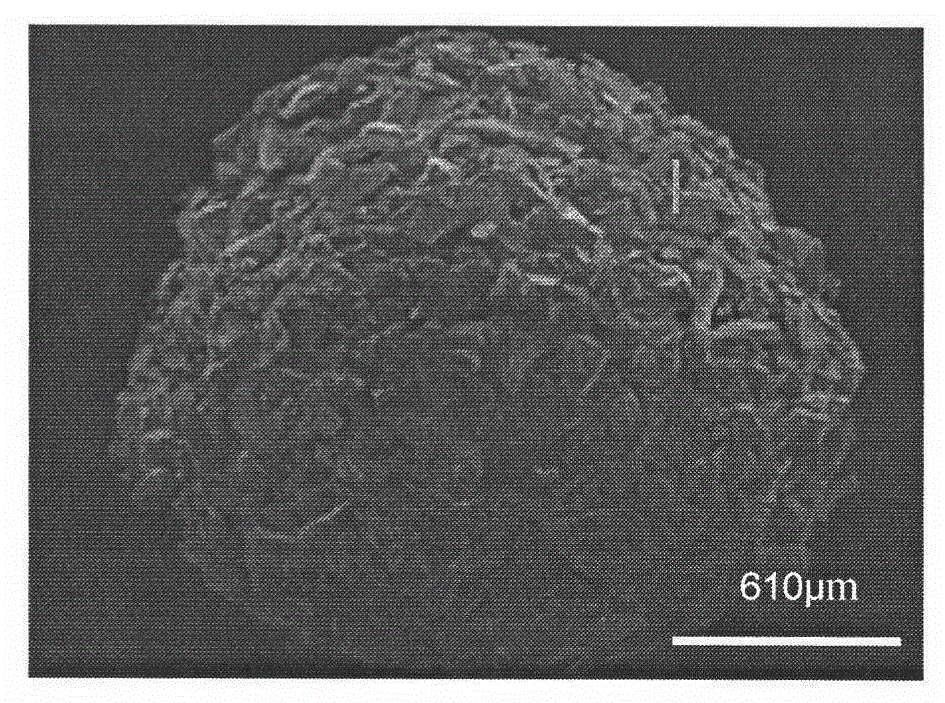

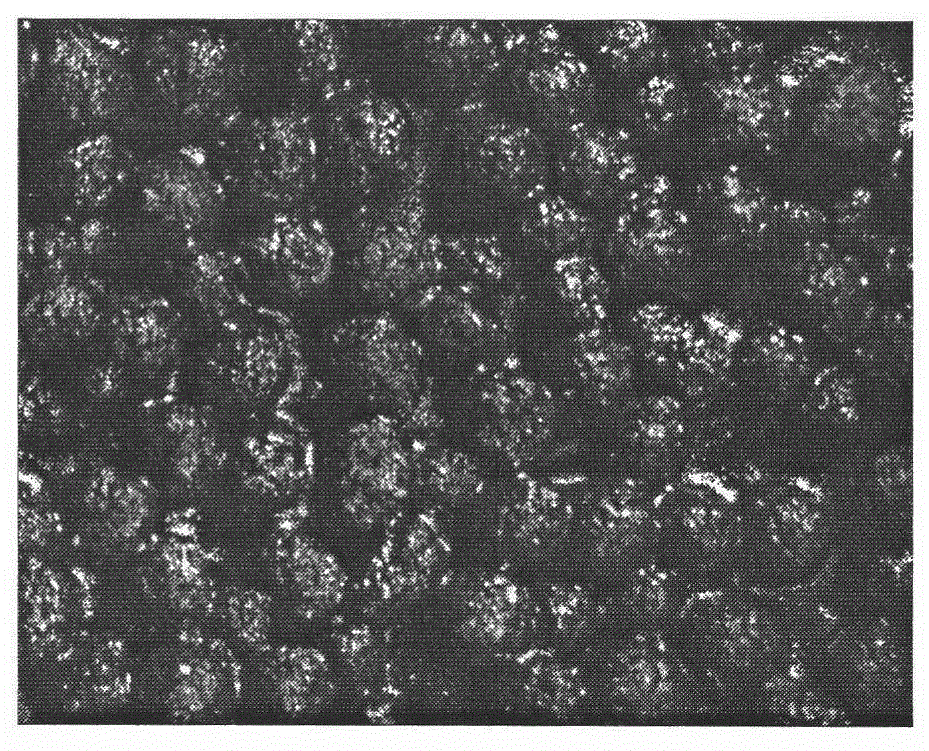

[0031] The raw materials used in the preparation of the ceramic bond accumulation abrasive in the present invention are: corundum (particle size: W32), alumina, silicon oxide, sodium carbonate, zirconia, lithium carbonate, boric acid, and the ceramic bond composition ratio is shown in the following table:

[0032] Component

[0033] Add silicon oxide, aluminum oxide, lithium carbonate, sodium carbonate, boric acid, and zirconium oxide to the ball mill in the above proportions, mix on the ball mill for 3 hours, and then smelt the mixed powder at high temperature, quench it, and crush it by ball milling, and then pass through a 325 mesh sieve. A low melting point ceramic bond powder is obtained. In 4.6 kg of corundum, 0.4 kg of ceramic bond, 6.0 kg of deionized water and 0.5 kg of dextrin liquid were added to the wet ball mill and mixed for 3 hours at 300 rpm. The prepared slurry is subjected to centrifugal drying and granulation to obtain ceramic bond accumulation abrasive, the...

Embodiment 2

[0035] The raw materials used in the preparation of the ceramic bond accumulation abrasive in the present invention are: corundum (particle size: W32), alumina, silicon oxide, sodium carbonate, zirconia, lithium carbonate, boric acid, and the ceramic bond composition ratio is shown in the following table:

[0036] Component

[0037] Add silicon oxide, aluminum oxide, lithium carbonate, sodium carbonate, boric acid, and zirconium oxide to the ball mill in the above proportions, mix on the ball mill for 3 hours, and then smelt the mixed powder at high temperature, quench it, and crush it by ball milling, and then pass through a 325 mesh sieve. A low melting point ceramic bond powder is obtained. 0.4 kg of ceramic bond, 5 kg of deionized water and 0.5 kg of dextrin liquid were added to 4.6 kg of corundum abrasives, respectively, and mixed by wet ball milling at 350 rpm for 4 hours. The prepared slurry is subjected to centrifugal drying and granulation to obtain a ceramic bond acc...

Embodiment 3

[0039] The raw materials used in the preparation of the ceramic bond accumulation abrasive in the present invention are: green silicon carbide (particle size: W32), aluminum oxide, silicon oxide, sodium carbonate, zirconium oxide, lithium carbonate, boric acid, and the ceramic bond composition ratio is shown in the following table:

[0040] Component

[0041] Add silicon oxide, aluminum oxide, lithium carbonate, sodium carbonate, boric acid, and zirconium oxide to the ball mill in the above proportions, mix on the ball mill for 3 hours, and then smelt the mixed powder at high temperature, quench it, and crush it by ball milling, and then pass through a 325 mesh sieve. A low melting point ceramic bond powder is obtained. In 4.6 kg of corundum, 0.4 kg of ceramic bond, 4.0 kg of deionized water and 0.5 kg of dextrin liquid were added to the 4.6 kg of corundum, and the wet ball milling was carried out at 400 rpm for 5 hours. The prepared slurry is subjected to centrifugal drying a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com