Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115 results about "Ni cr alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

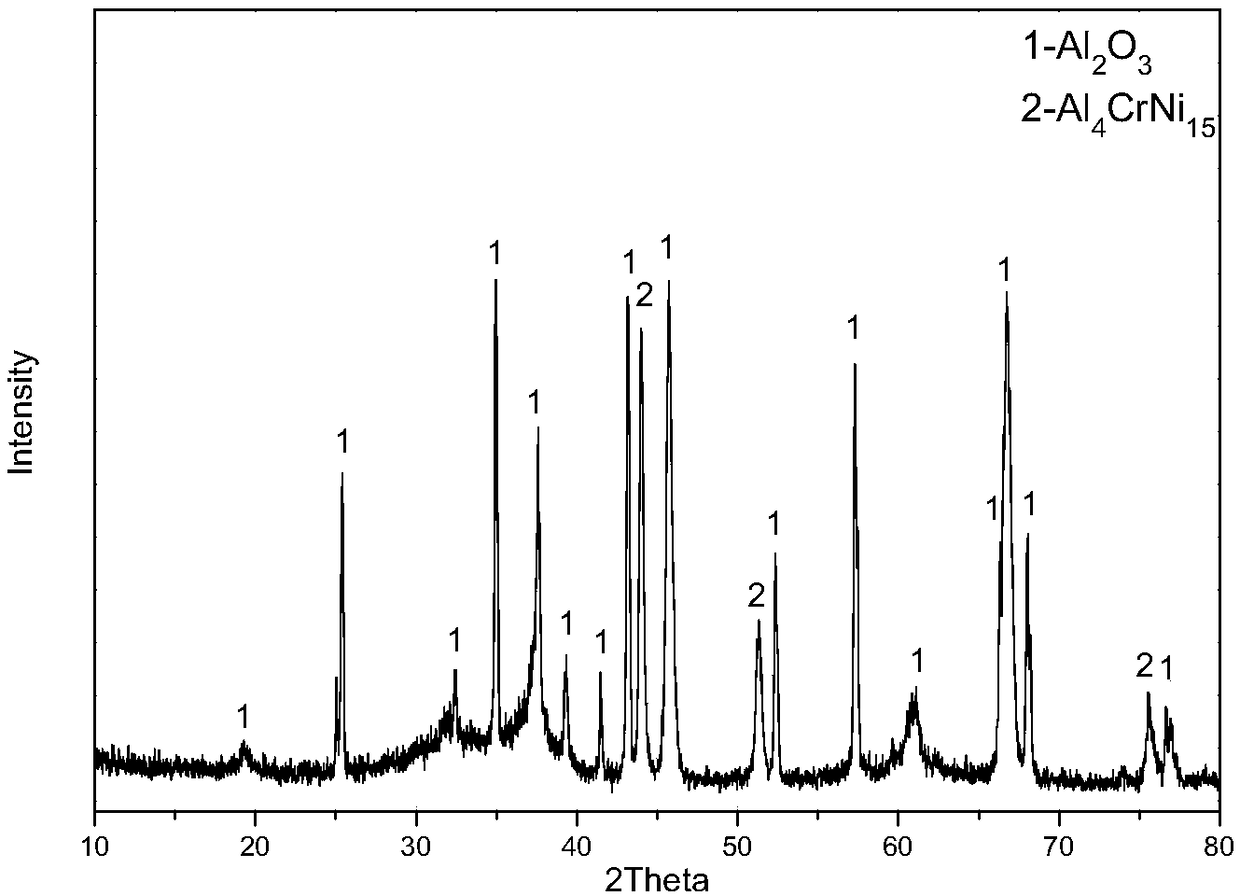

Preparation method of surface-modified ZTA ceramic particle reinforced steel based composite material

ActiveCN109706438AEnhanced interface bindingHigh yield strengthLiquid/solution decomposition chemical coatingAl powderNi cr alloy

The invention discloses a preparation method of a surface-modified ZTA ceramic particle reinforced steel based composite material. The preparation method comprises the steps that sensitization and activation treatment is conducted on ZTA particles, surface plating is conducted, the ZTA particles are plated with nickel and chromium to achieve surface metallization by controlling the components andthe proportion of a plating solution, the ZTA particles plated with Cr-Ni layers, Ni-Cr alloy powder and Al powder are put into a graphite mold to be made into a preform which is of a honeycomb structure through vacuum sintering, molten metal is poured by adopting a casting infiltration method, and after cooling is conducted, the reinforced steel based composite material is obtained. According tothe preparation method of the surface-modified ZTA ceramic particle reinforced steel based composite material, the ZTA particles are plated with nickel and chromium to achieve surface metallization bycontrolling the components and the proportion of the plating solution, the wet problem with a metal matrix is solved, and then the mechanical property of the composite material is improved; and meanwhile, the technology is easy to operate, the cost is reduced to a large extent, no toxicity or pollution is generated, the great potential on increasing the economic benefit and the social benefit isachieved, and the good prospect of being applied to the harsh abrasive wear condition is achieved.

Owner:XI AN JIAOTONG UNIV +1

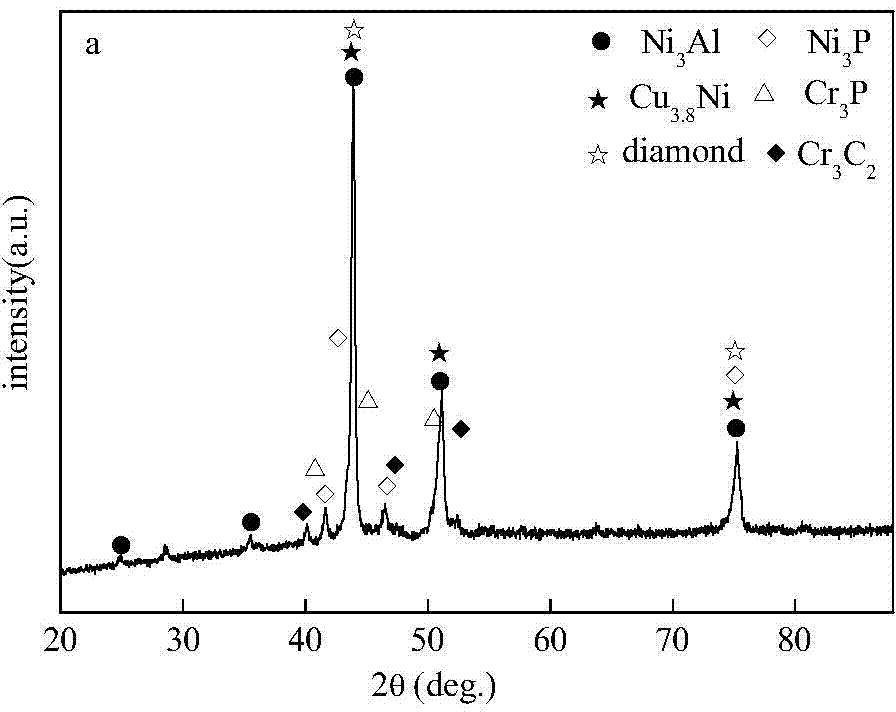

Method for manufacturing diamond tool with self-lubrication function

InactiveCN102059423AEasy to useImprove the lubrication effectSoldering apparatusChemical reactionNi cr alloy

The invention provides a method for manufacturing a diamond tool with self-lubrication function. The method comprises the following steps: adding graphite particles with lubrication function into Ni-Cr alloy, wherein the graphite particles account for 2 to 20 percent of the total mass of the whole brazing filler metal; uniformly stirring mixture of the Ni-Cr alloy and the graphite particles to together form the brazing filler metal of a braze welding diamond tool; manufacturing a molded blank of the diamond tool according to a sequence of diamond tool metal substrate, the brazing filler metal and the diamond abrasive particles; putting the molded blank of the diamond tool into a heating furnace, adopting the brazing process, wherein the heating temperature is between 900 and 1,100 DEG C, the temperature is preserved for 1 to 20 minutes to ensure that the Ni-Cr alloy performs chemical reactions with the graphite particles and the diamond abrasive particles respectively to manufacture the diamond tool with the self lubrication function. The method can effectively improve the use performance, the lubrication effect and the scrap storage capability of the diamond tool to ensure that the diamond tool has higher grinding efficiency.

Owner:禹州市和汇超硬材料有限公司

Guide and guard roller for guiding steel billet in high speed wire rolling machine and its making process

InactiveCN1847439AHigh hardnessGood high temperature wear resistanceFurnace typesHeat treatment process controlWaxSmelting

The present invention discloses one kind of guide and guard roller for guiding steel billet in high speed wire rolling machine and its making process. Chemically, the guide and guard roller has material comprising C 0.7-1.4 wt%, Wt% 7.0-10.0 wt%, V 0.8-1.5 wt%, Cr,5.0-10.0 wt%, B 1.2-2.5 wt%, Mo<1.5 wt%, Si<1.5 wt%, Mn<1.5 wt%, RE 0.08-0.18 wt%, Mg 0.05-0.15 wt%, Ti 0.08-0.20 wt%, S<0.05 wt%, and P<0.05 wt%, except Fe and inevitable impurity. The guide and guard roller is made through electric furnace smelting and precise wax mold casting or evanescent mold casting. It has high strength, high toughness, high wear resistance, high fatigue and oxidation resistance, high quick cooling and heating resistance, and use performance obviously higher than that of high Ni-Cr cast steel guide and guard roller.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

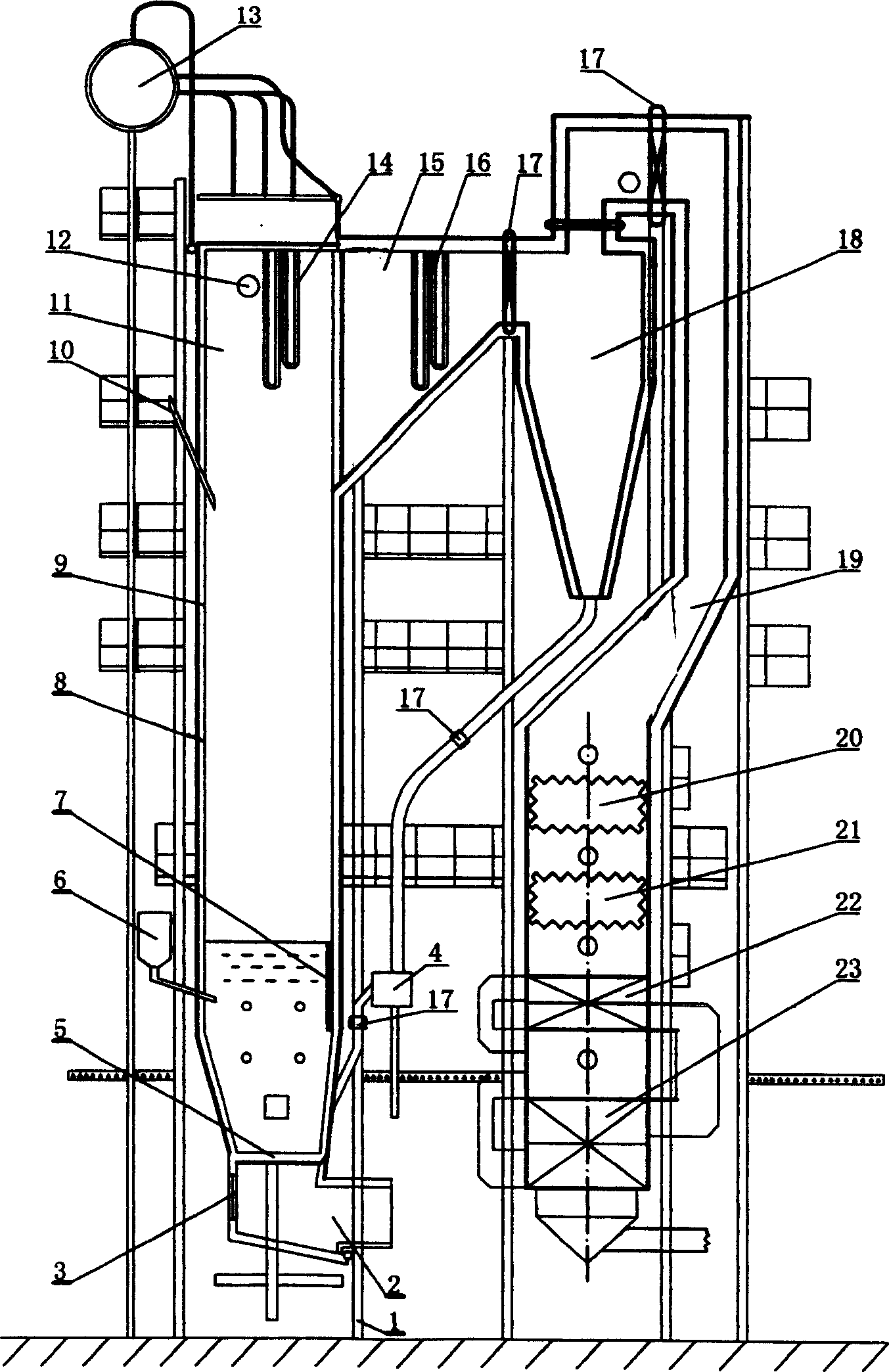

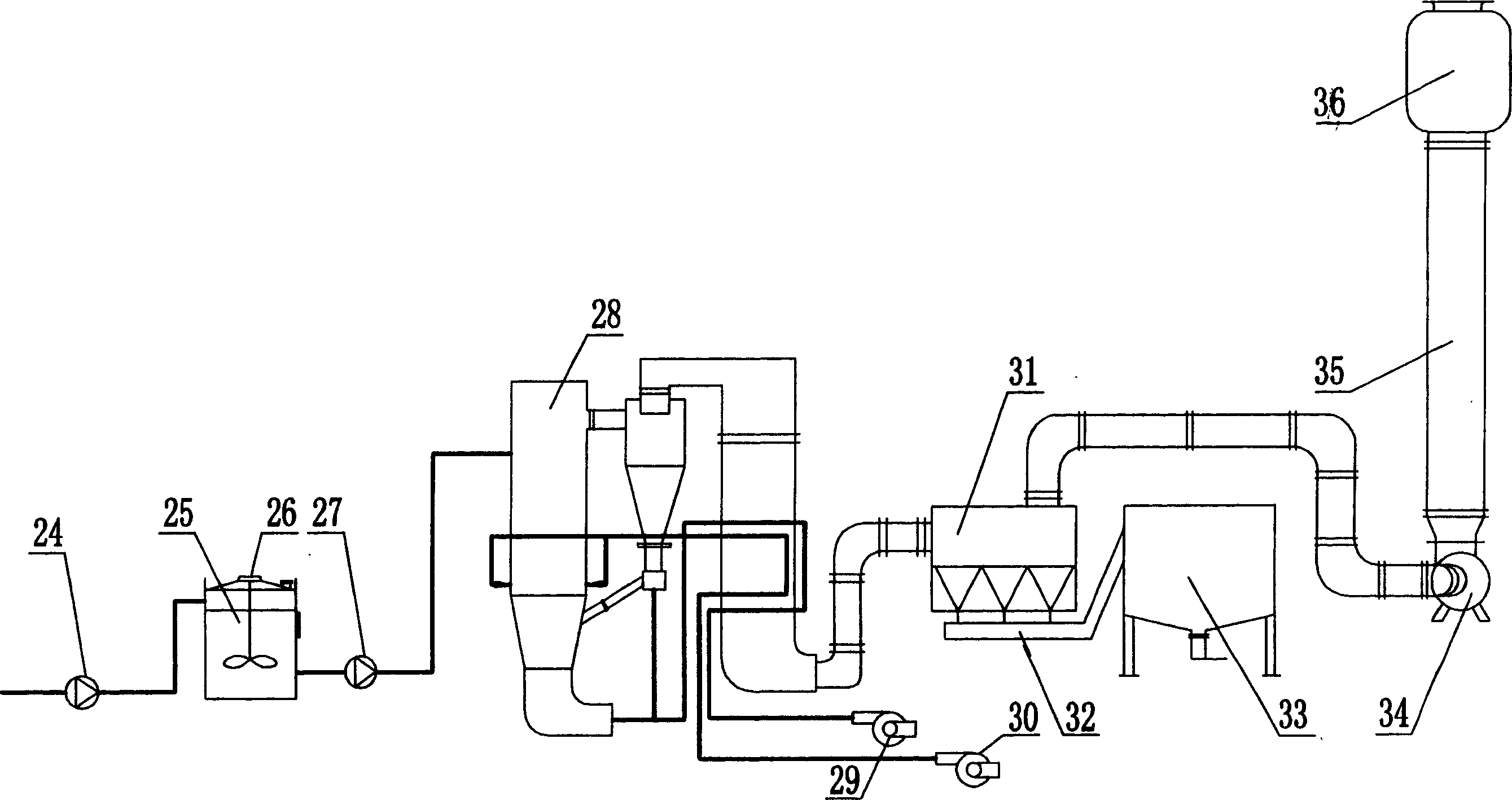

Oil field steam filling boiler of circulation fluidized bed using water coal slurry as fuel

InactiveCN1563793ACurb emissionsRealize direct desulfurizationFluidized bed combustionApparatus for fluidised bed combustionWear resistantEngineering

The oil well gas injecting boiler has screw pump in pressure of 0.2-0.4 MPa to supply fuel from the upper part of the boiler, single steam drum in naturally circulating mode to obtain high pressure steam of 17.5-21 MPa; quartzite and limestone powder as fuidizing medium for low multiplying factor circulation; and power amount of limestone powder for clean burning at temperature of 850-950 deg.c. The boiler of the present invention has water cooling furnace wall, coated heat resistant and corrosion resistant refractory material and sprayed heat resistant and wear resistant Ni-Cr alloy, pipe type backwards bent boiler top, coal economizer of ribbed spiral pipes, cyclonic separator with wear resistant material, water cooling wall with inner thread pipe, high temp alloy steel material in high temperature and high pressure sections, welded support frame structure, flexible 3D expanding section in important joint part, and hydrostats.

Owner:SHENYANG DAVID ENVIRONMENT PROTECTION & ENERGY SAVING EQUIP LTD

Sea water corrosion resistant low-alloy cast iron

InactiveCN101225496AImproves corrosion resistance of cast ironReduce corrosion resistanceManganeseRare earth

The invention discloses a seawater corrosion-resistant low alloy cast iron, which is mainly used for manufacturing components in seawater hydraulic projects. Adopting the weight percentage as unit, the seawater corrosion-resistant low alloy cast iron comprises 0.6 to 1.6 Ni, 1.5 to 3.0 Cr, 1.8 to 2.8 Si, 2.8 to 3.6 C, 0.6 to 1.0 Mn, 1.5 to 3.0 Cu, 0.1 to 0.3 RE, less than or equal to 0.4 Al, less than or equal to 0.1 Sb, less than or equal to 0.12 P, less than or equal to 0.06 S, and remaining part of Fe. The seawater corrosion-resistant low alloy cast iron has the advantages of improving corrosion resistant performance due to joint action of the cast iron chromium, nickel, copper and other alloy elements, reducing nickel content and cost, and improving corrosion resistant performance of the seawater corrosion-resistant cast iron compared with the Ni-Cr alloy corrosion resistant cast iron.

Owner:山东省耐磨耐蚀材料工程技术研究中心

Acetone gas sensor based on hollow spherical ZnFe2O4 nano material and preparation method thereof

The invention discloses a gas sensor based on a hollow spherical ZnFe2O4 nano material, a preparation method and application of the gas sensor in detection of acetone gas, and belongs to the technical field of gas sensors. The gas sensor consists of an Al2O3 insulating ceramic tube with two discrete annular gold electrodes on the outer surface, an Ni-Cr alloy heating coil penetrating through the Al2O3 insulating ceramic tube and a sensitive material film coated on the outer surface of the Al2O3 insulating ceramic tube and the annular gold electrodes, wherein the sensitive material film is obtained by coating the hollow spherical ZnFe2O4 nano material. The sensor has the advantages of simple structure, low price, small volume, and easiness in integration and large-batch production, and the test results of gas sensitivity show that the sensor has extremely high sensitivity and extremely good long-term stability to acetone, so that the sensor has an important application prospect on the aspect of detection and alarm in acetone leakage in industrial production.

Owner:JILIN UNIV

Superhard grinding tool and manufacturing method thereof

InactiveCN104842286AReduce heat damageHigh bonding strengthAbrasion apparatusGrinding devicesGranularityNi cr alloy

The invention discloses a superhard grinding tool which is composed of a binding agent and a grinding material. The binding agent comprises, by weight, 20-60 parts of Ni, Al, 8-50 parts of Cu and 20-60 parts of Ni-Cr alloy powder, wherein Ni and Al are proportioned according to a molar ratio of 3:1 or 1:1, and the grinding material is diamond which is 40-100% in concentration and 30 / 40-325-400 meshes in granularity. In addition, the invention further discloses a manufacturing method for the superhard grinding tool. The binding agent and the grinding material namely the diamond are taken as raw materials, the superhard grinding tool is manufactured through a method of compositing self-propagating and soldering, thereby being high in binding strength, good in performance, low in cost and small in thermal damage to diamond, high-speed and long-time grinding can be realized, needs on machining are met, and the superhard grinding tool has the advantages of high binding resistance, high hardness, grinding resistance, high sharpness and long service life. The manufacturing method has the advantages of simple process, pollution freeness, low energy consumption, quickness and low cost.

Owner:GUANGDONG UNIV OF TECH

Cubic boron nitride superhard cutter

The invention discloses a superhard cutter with high hardness and good abrasive resistance and heat resistance. The cutter comprises the following components in percentage by weight: 75-85 percent of cubic boron nitride micro powder with the granularity of 1-10 mum, 0.5-3 percent of microlite powdered boron with the purity above 99.5 percent, 5-10 percent of microlite powdered aluminum with the purity above 99.5 percent, and 6-15 percent of carbon with a diamond structure. Because the invention is prepared by adopting the cubic boron nitride as a main raw material and adding the high-purity microlite powdered aluminum and the high-purity microlite powdered boron as well as the carbon with the diamond structure under super-high pressure and high temperature, the high hardness, the abrasive resistance and the heat resistance are obviously improved; and the superhard cutter is used for high-hardness alloy materials with turning HRC within 48-53, and has better effect particularly on chromel alloy materials.

Owner:刘书锋

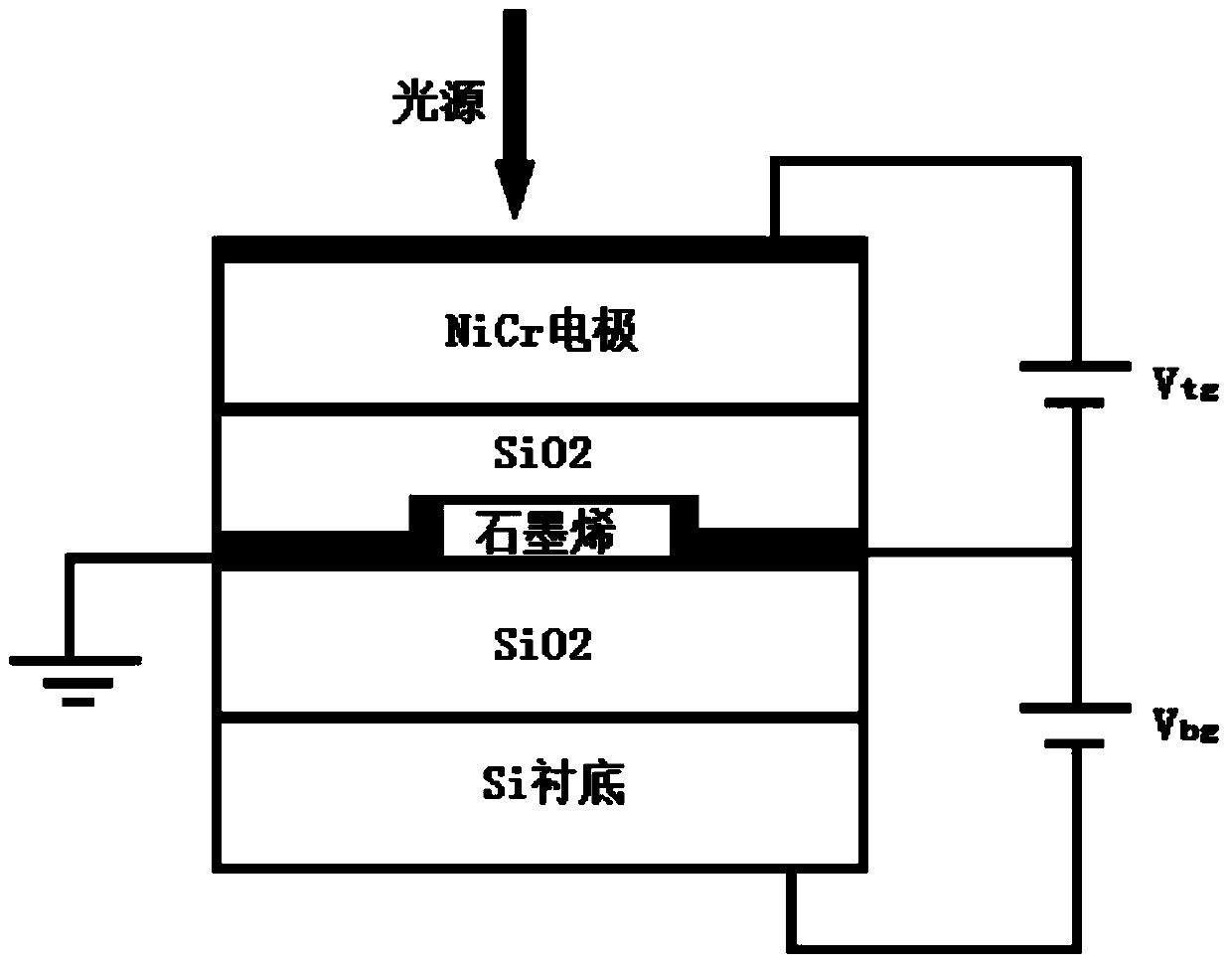

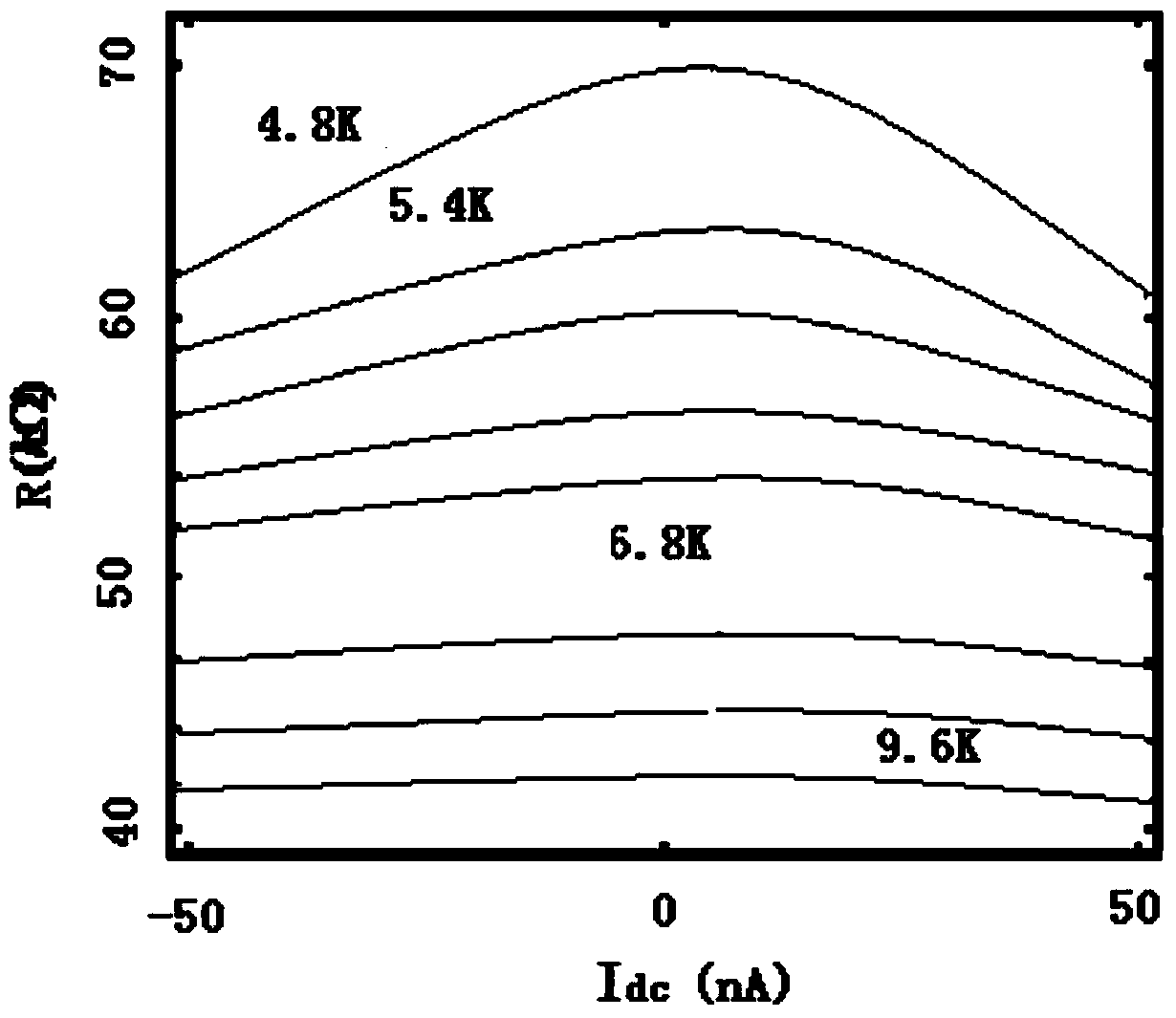

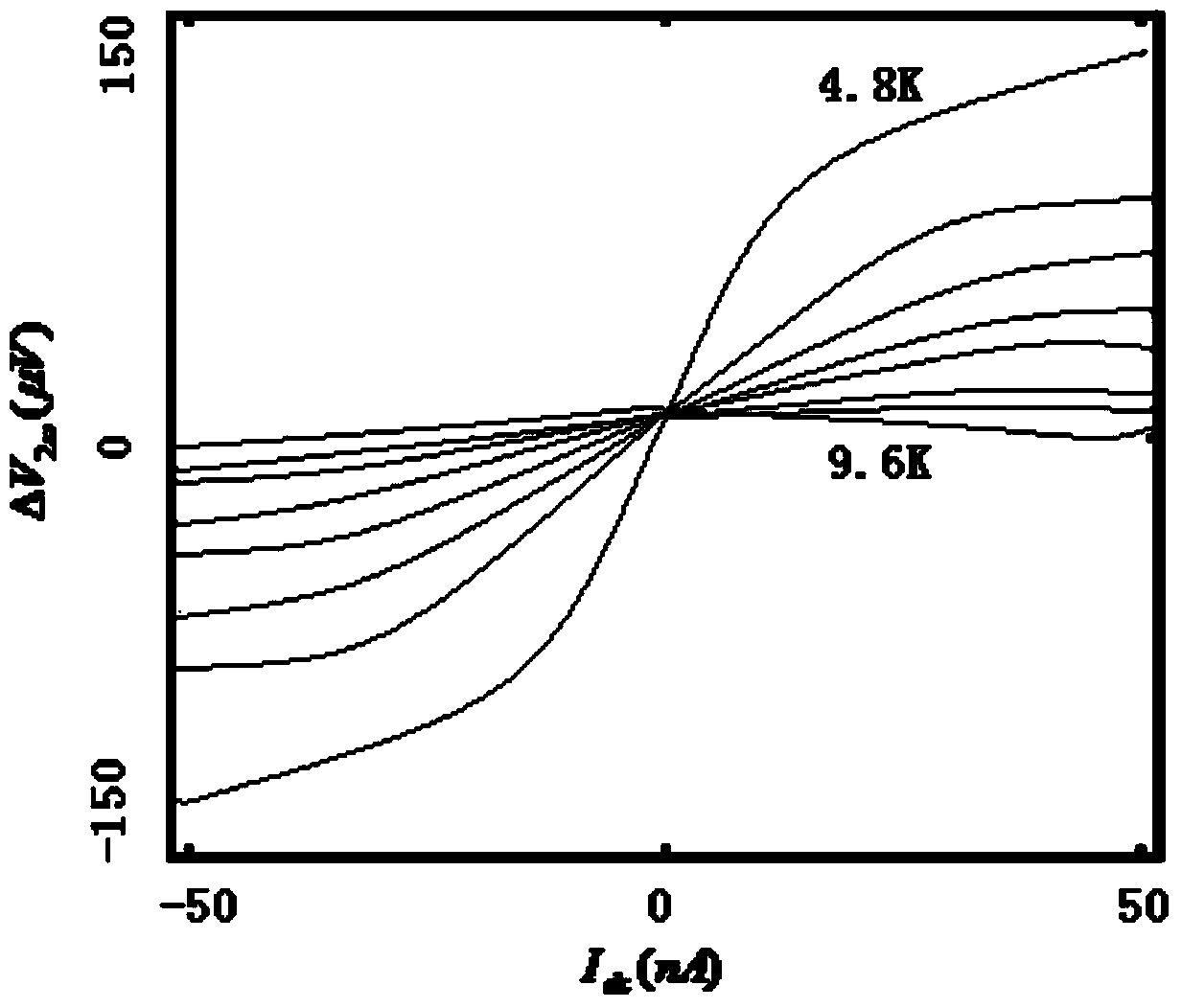

Graphene temperature sensor and preparing process thereof

InactiveCN103630254AThermometers using electric/magnetic elementsUsing electrical meansNi cr alloyCvd graphene

The invention discloses a graphene temperature sensor and a preparing process thereof. The structure of the graphene temperature sensor comprises a top gate electrode, a Ni-Cr alloy film, an upper SiO2 layer, hydrogen silsesquioxane, a dual-layer graphene and source and drain electrode, a lower SiO2 layer, a Si substrate and a back gate electrode from top to bottom. The method comprises the steps of depositing the dual-layer graphene obtained by mechanical stripping at the Si substrate with a SiO2 layer of 300nm thick, manufacturing electrodes at a source end and a drain end by an electronic beam photoetching technology, and thermally evaporating 5nmCr / 100nmAu. Compared with the existing sensor, the graphene temperature sensor has the advantages of very high sensitivity, lower intrinsic noise and very high detection speed and has well application prospect in the aviation field.

Owner:XIDIAN UNIV

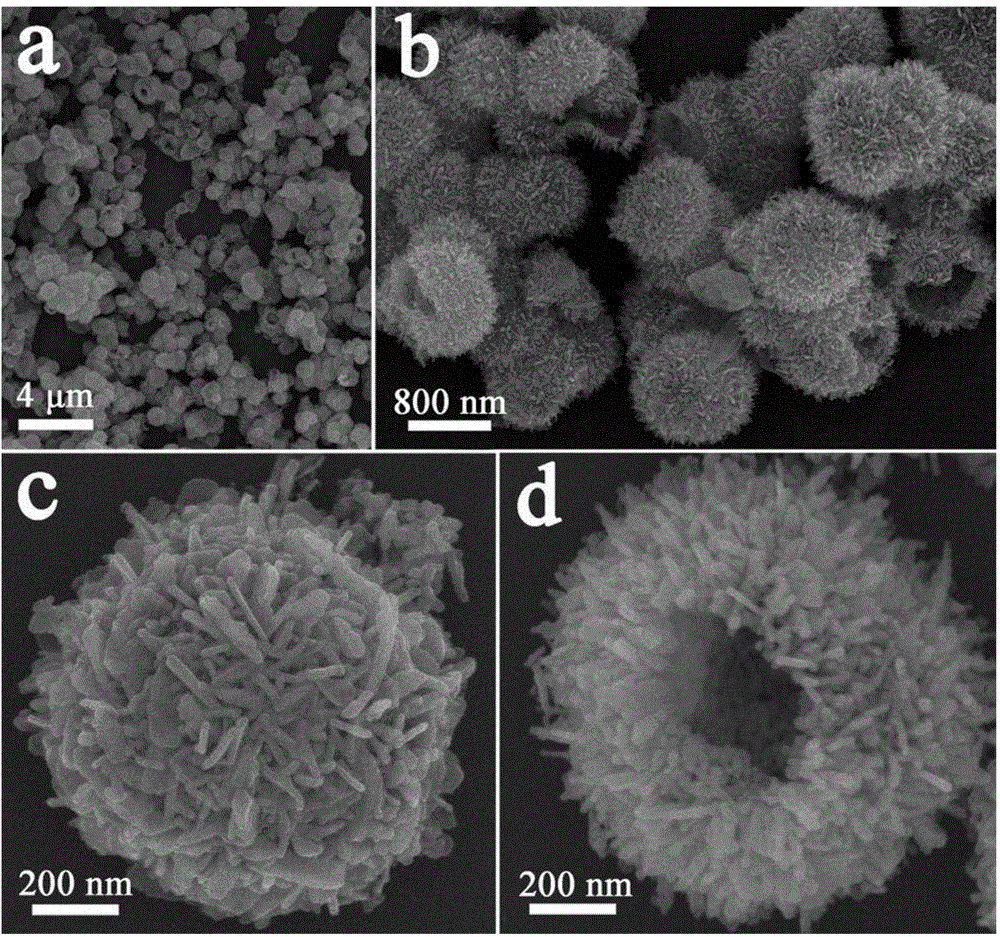

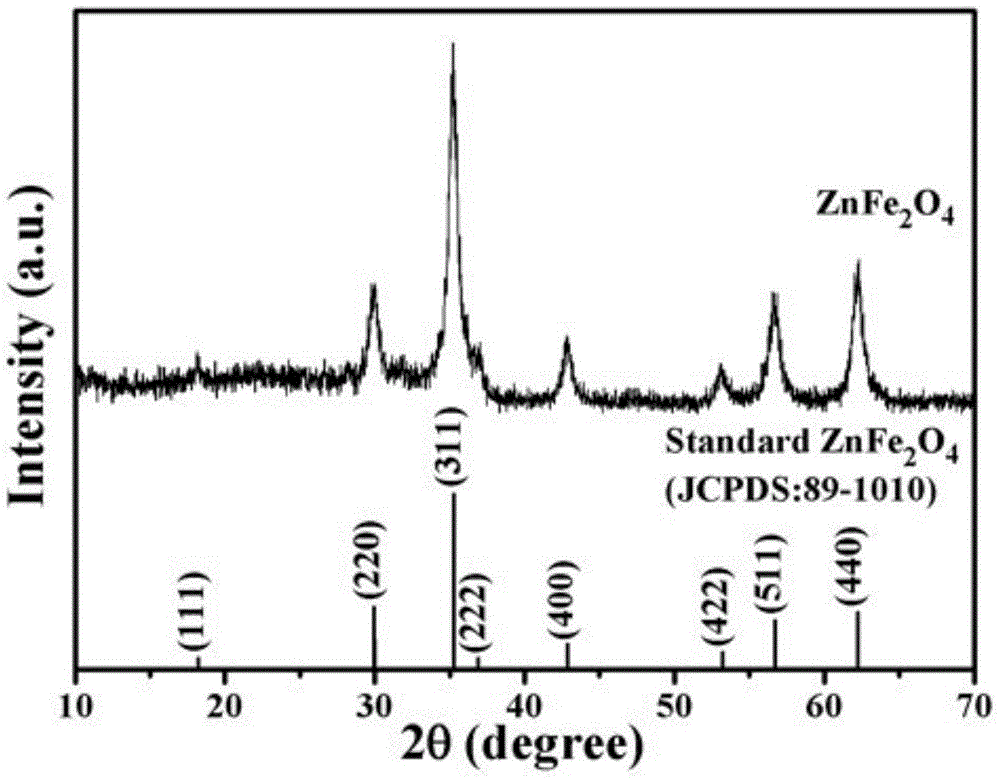

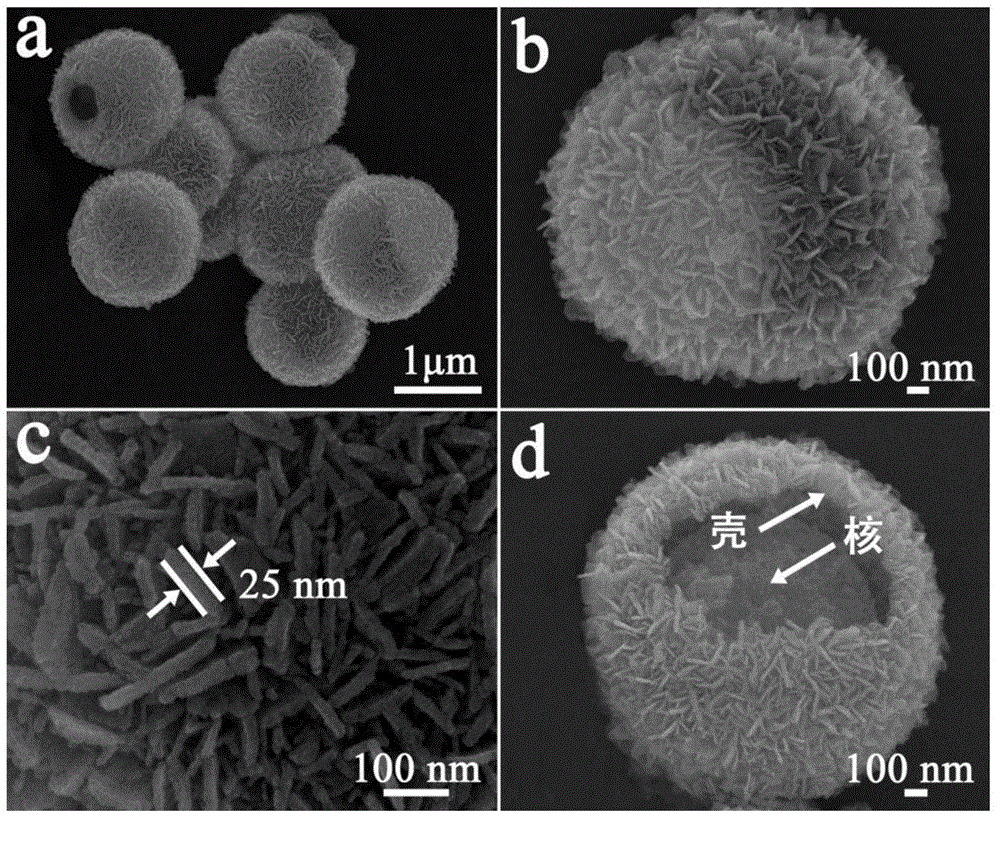

Gas sensor based on core-shell flower-ball-shaped ZnFe2O4 nanometer materials, preparing method and application thereof

InactiveCN104950017AFacilitated DiffusionIncreased sensitivityMaterial nanotechnologyIron compoundsHigh volume manufacturingNi cr alloy

The invention discloses a gas sensor based on core-shell flower-ball-shaped ZnFe2O4 nanometer materials, a preparing method and application thereof on detecting acetone gas and belongs to the technical field of gas sensors. The sensor comprises an Al2O3 insulating ceramic pipe, a Ni-Cr alloy heating coil and sensitive material films. The outer surface of the Al2O3 insulating ceramic pipe is provided with two discrete annular gold electrodes. The Ni-Cr alloy heating coil penetrates through the inner portion of the Al2O3 insulating ceramic pipe. The sensitive material films coats the outer surface of the Al2O3 insulating ceramic pipe and the annular gold electrodes. The sensitive material films are obtained after core-shell flower-ball-shaped ZnFe2O4 nanometer material coating. The sensor has the advantages of being simple in structure, low in price, low in size and large in production batch, the testing results of air-sensitive features show that the sensor has high sensitivity on acetone and good long-term stability, and important potential application is achieved on detecting and warning of acetone leakage in industrial production.

Owner:JILIN UNIV

High temperature Ni-Cr alloy and its production process

InactiveCN1974816AImprove high temperature resistanceImprove oxidation resistanceHeat resistanceChromium nickel

The present invention provides one kind of Ni-Cr alloy with high smelting point, capacity of bearing temperature of 1300 deg.c, high tensile strength and high yield strength and its production process. The Ni-Cr alloy contains C 0-0.1 wt%, Si 0-0.5 wt%, Mn 0-1.0 wt%, S 0-0.015 wt%, Cr 21-25 wt%, Ni 58-63 wt%, Al 1.0-1.7 wt%, Cu 0-1.0 wt%, and Fe for the rest. The production process includes the following steps: smelting, secondary refining, heating at 900-1200 deg.c for 10-40 min before forging, cold working and water cooling. The Ni-Cr alloy has raised heat resistance, high tensile strength, high yield strength and other advantages.

Owner:杭正奎

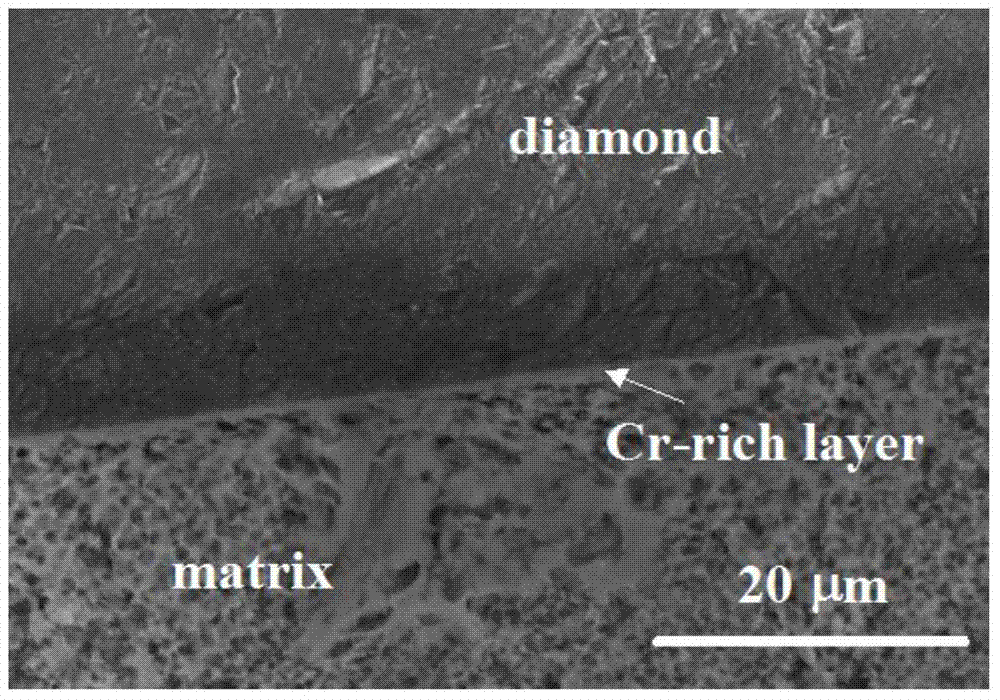

Single-layer high-temperature diamond grinding wheel brazing process

InactiveCN104889518AImprove wettabilityHigh bonding strengthSoldering apparatusGrinding devicesCarbideNi cr alloy

A single-layer high-temperature diamond grinding wheel brazing process is characterized in that Ni-Cr alloy layer with 1mm-1.5mm thickness is sprayed on a metal base body through gas welding firstly, then induction brazing is conducted on a workpiece sprayed with the Ni-Cr alloy layer in the argon at 1080 DEG C temperature till Cr in Ni-Cr alloy is separated and corresponding carbide of with 0.8mm-1mm thickness is gathered and generated on the surface of the workpiece. The alloy layer and the metal base body have good wettability, accordingly higher bonding strength can be obtained, operation is simple and convenient, a product is stable and reliable in quality, and the service life is long.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Method for preparing Fe-Ni, Fi-Ni-Cr alloy foil

InactiveCN1641072AShort production processThickness is easy to controlElectroforming processesElectrolysisNi cr alloy

The present invention relates to the field of electrolysis process for depositing metal, and features that Fe-Ni or Fe-Ni-Cr alloy foil is produced through electrolytic deposition in a water solution system of sulfate and chloride or sulfate, chloride and trivalent chromium. The electrolytic production process of alloy foil has short flow path, stable electrolyte, easy maintenance, simple waste water treatment, easy control of foil components and thickness, low cost and other advantages. The alloy foil has its physical and chemical performance, especially magnetic performance, higher than that produced through rolling process, and the produced Fe-Ni and Fe-Ni-Cr alloy foil may be used in electronic, telecom and electric industry as excellent soft magnetic material, cell skeleton material and packing material.

Owner:CENT SOUTH UNIV

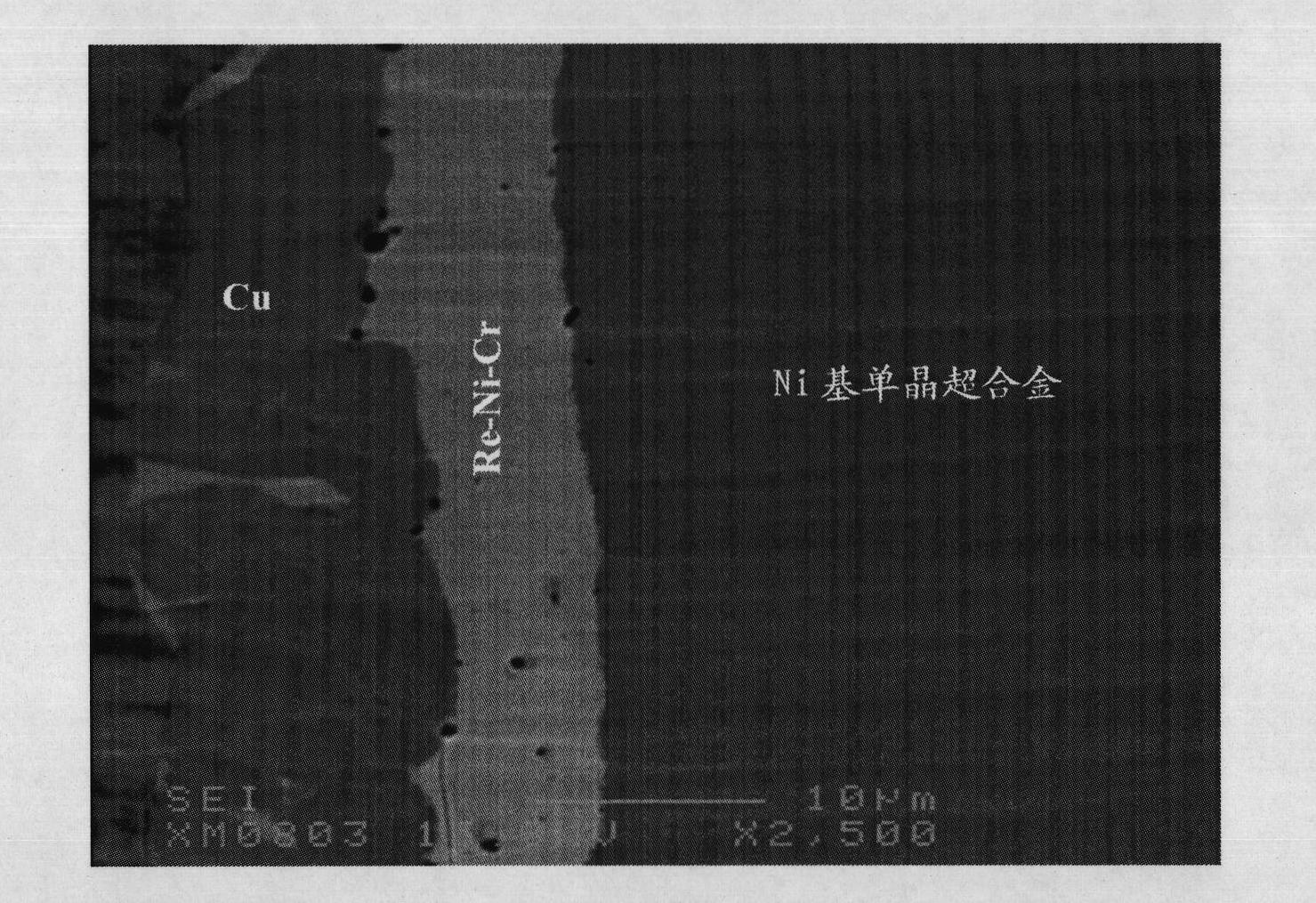

Bonding layer material having Re-Ni-Cr alloy diffusion barrier layer and preparation method thereof

InactiveCN101914774AImprove stabilityReduce interdiffusionSolid state diffusion coatingNi cr alloyDiffusion barrier

The invention discloses a bonding layer material having a Re-Ni-Cr alloy diffusion barrier layer and a preparation method thereof. The Re-Ni-Cr alloy diffusion barrier layer is coated on a matrix material, wherein the matrix material is a Ni, Al, Ti, Fe or Nb-based alloy material, and the Re-Cr-Ni alloy diffusion barrier layer comprises the following elements in percentage by mass: 20-65% of Re, 30-50% of Cr and 5-30% of Ni. The preparation method comprises the step of forming the Re-Cr-Ni alloy diffusion barrier layer material on a matrix high-temperature super alloy by electroplating. The bonding layer material having a Re-Ni-Cr alloy diffusion barrier layer has smooth and uniformly distributed surface coating, can remain stable under high-temperature conditions, can prevent alloy elements in the matrix from outward diffusion and prevents oxygen in the air from inward diffusion to the alloy matrix.

Owner:SHANGHAI INST OF TECH

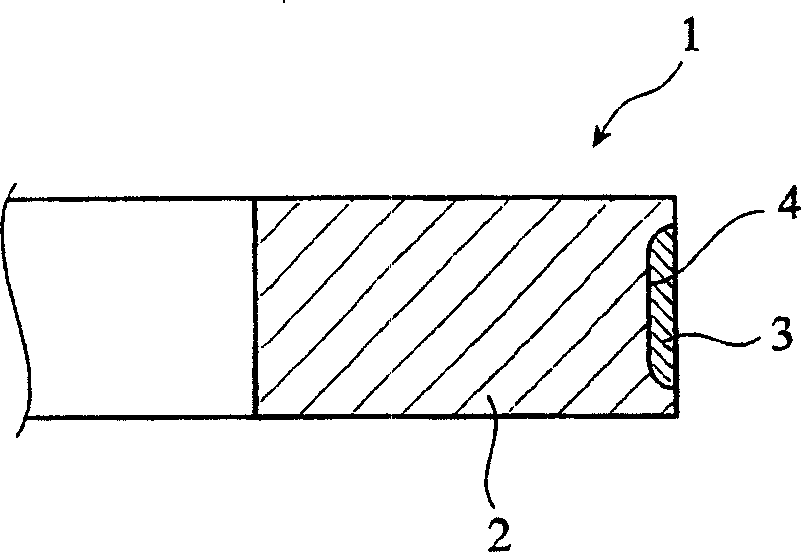

Piston ring and thermal sprayed coating for use therein, and method for manufacture thereof

InactiveCN1705765AImprove wear resistanceEnhanced resistance to peelingMolten spray coatingChromium carbidePiston ring

The piston ring of the present invention comprises a thermal spray coating comprising chromium carbide particles having an average particle size of 5 mum or less, and a matrix metal composed of a Ni-Cr alloy or a Ni-Cr alloy and Ni at least on an outer peripheral surface, said thermal spray coating having an average pore diameter of 10 mum or less and a porosity of 8% or less by volume. A piston ring having excellent wear resistance, scuffing resistance and peeling resistance with little attackability on a mating member is obtained by forming a homogeneous thermal spray coating having a fine microstructure.

Owner:RIKEN CO LTD

Anti-coking anti-carburizing cracking furnace tube and manufacturing method thereof

ActiveCN102399572AEasy to industrializeReduce depositionThermal non-catalytic crackingCarbon numberNi cr alloy

The invention relates to an anti-coking anti-carburizing cracking furnace tube and a manufacturing method thereof. The inner surface of the cracking furnace tube of the invention has a layer which comprises an oxide membrane which comprises at least one of Cr, Ni, Fe, Mn, La, Ce and Y. The manufacturing method comprises the following steps: Ni-Cr alloy containing elements of Cr, Ni, Fe, Mn and C is directly added to at least one element selected from La, Ce or Y in a routine cracking furnace tube manufacturing process to prepare a tube; and the tube is subjected to heat treatment in low oxygen partial pressure atmosphere to generate a layer of the metal oxide membrane on the inner surface. The coke deposition on the inner surface of the radiant section furnace tube can be reduced by more than 60% when the cracking furnace tube of the invention is used in a petroleum hydrocarbon cracking furnace to produce low carbon number olefins.

Owner:CHINA PETROLEUM & CHEM CORP +2

Ni-Cr alloy thin film igniter with low ignition voltage and preparation method thereof

InactiveCN102384486AIncrease reaction rateAchieve mass productionCombustion ignitionNi cr alloyOptoelectronics

The invention discloses a Ni-Cr alloy thin film igniter with a low ignition voltage and a preparation method thereof and belongs to the technical field of a priming system. The Ni-Cr alloy thin film igniter with the low ignition voltage comprises a base; an isolating film is arranged on the base; an igniting element is arranged on the isolating film; the igniting element is provided with a bonding pad area of an igniter lead wire; and the igniting element is made of Ni-Cr alloy. According to the preparation method provided by the invention, the igniter is prepared by using a micro-machining technology. In the Ni-Cr alloy thin film igniter, the ignition is reliably realized at a lower ignition voltage; the ignition voltage is as low as 4.8 V / 10 muF and the ignition energy is as low as 100 mJ; and the shake-proof performance is good.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

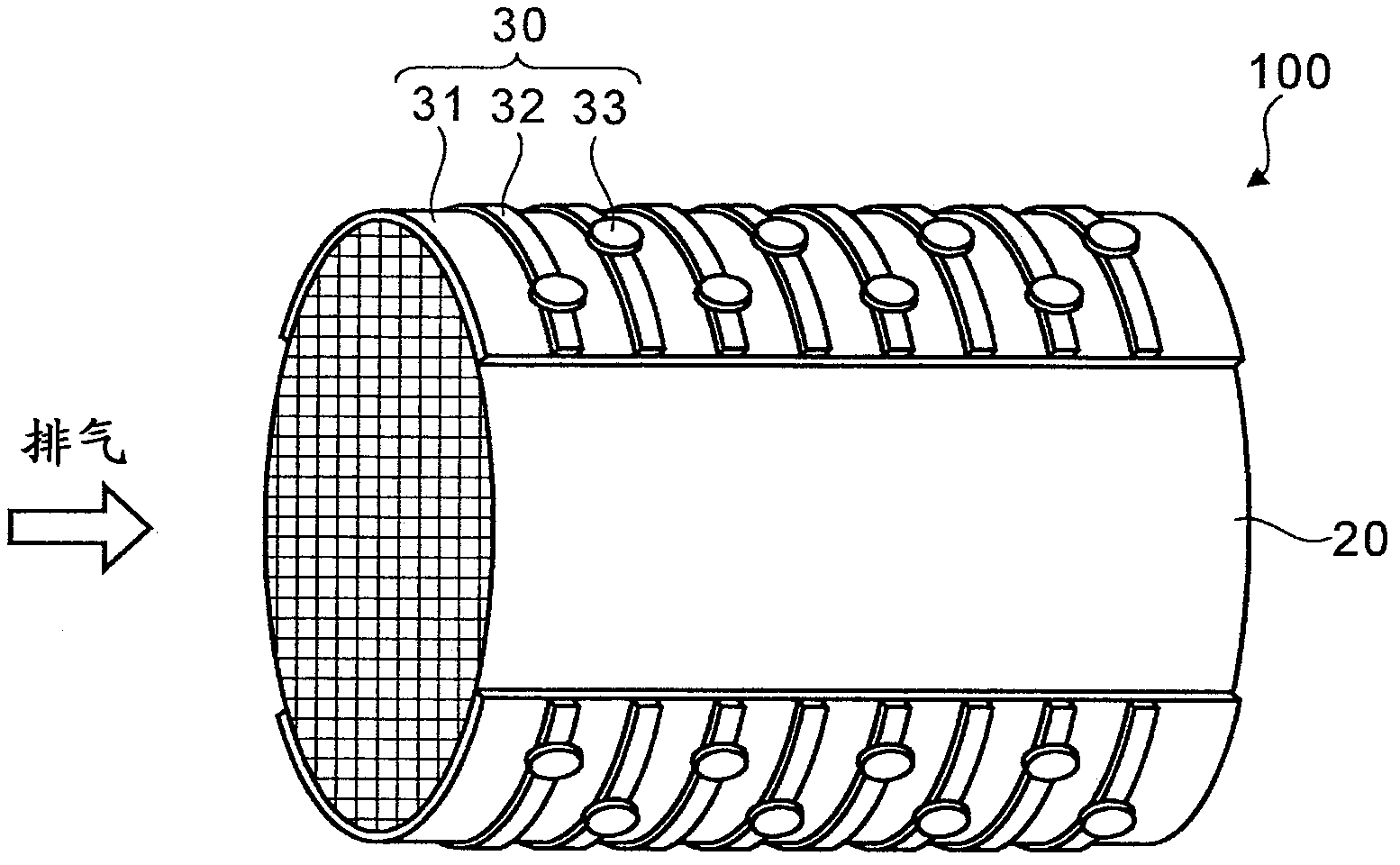

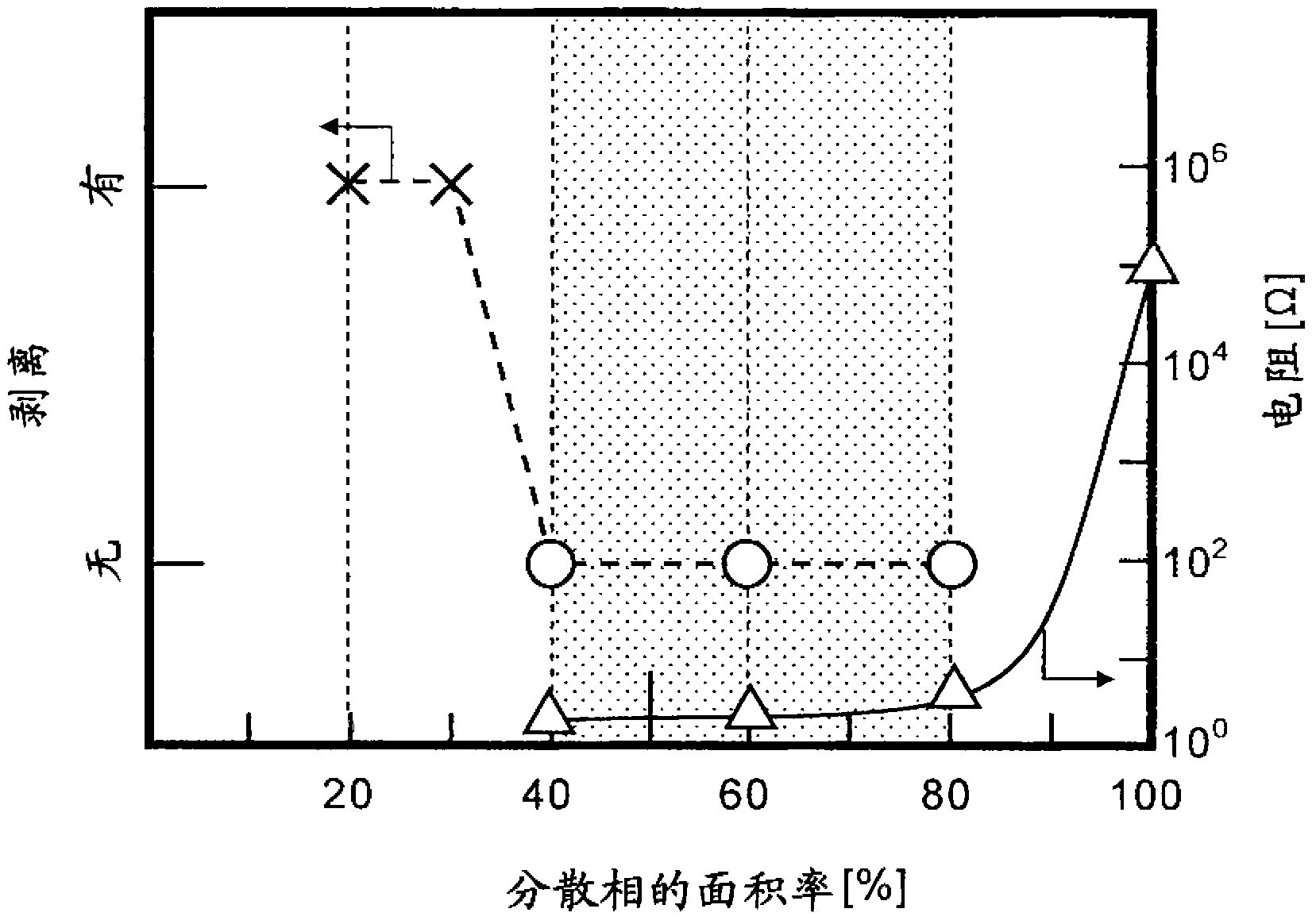

Electrode, electrically heating type catalyst device using same, and manufacturing method of electrically heating type catalyst device

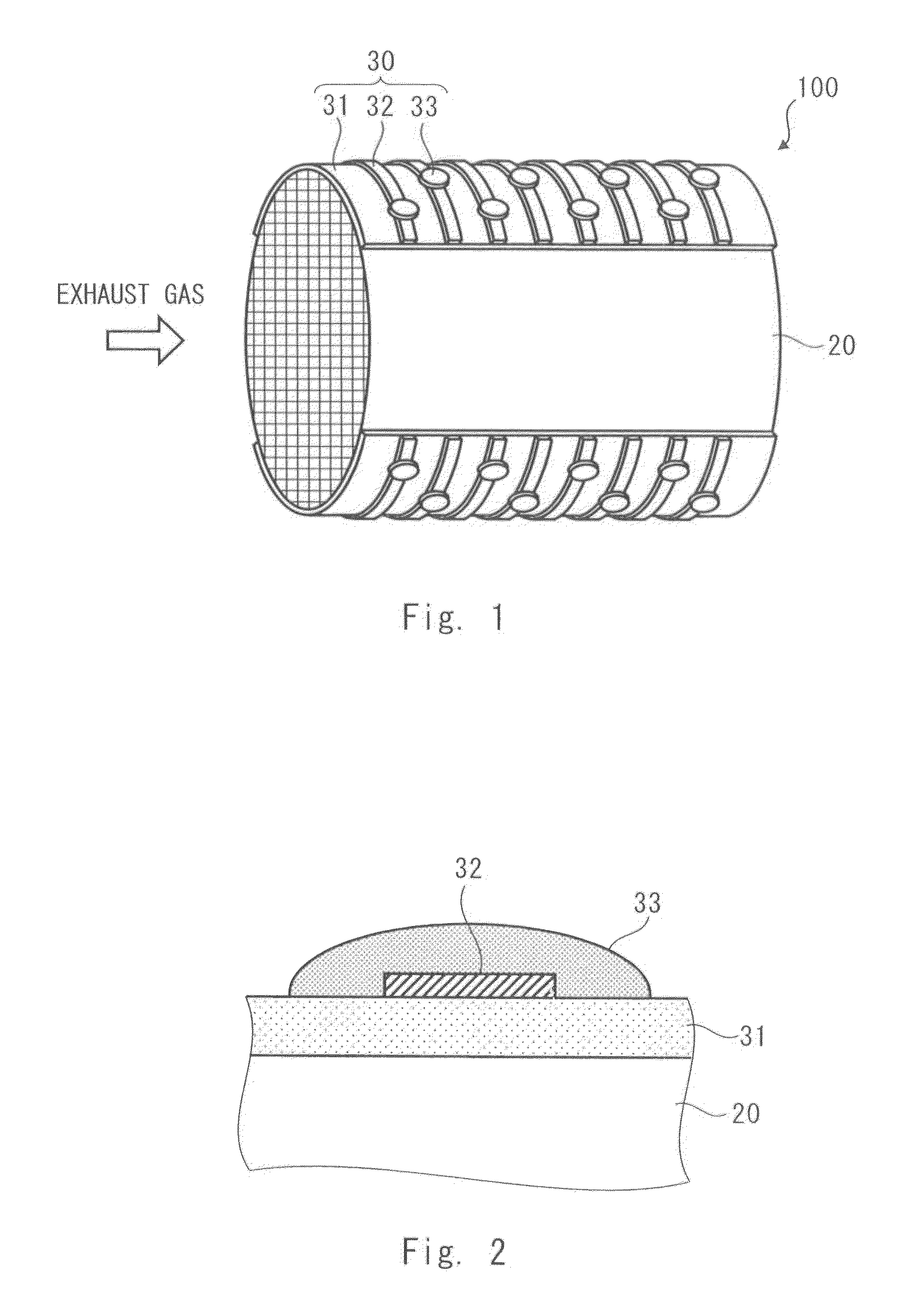

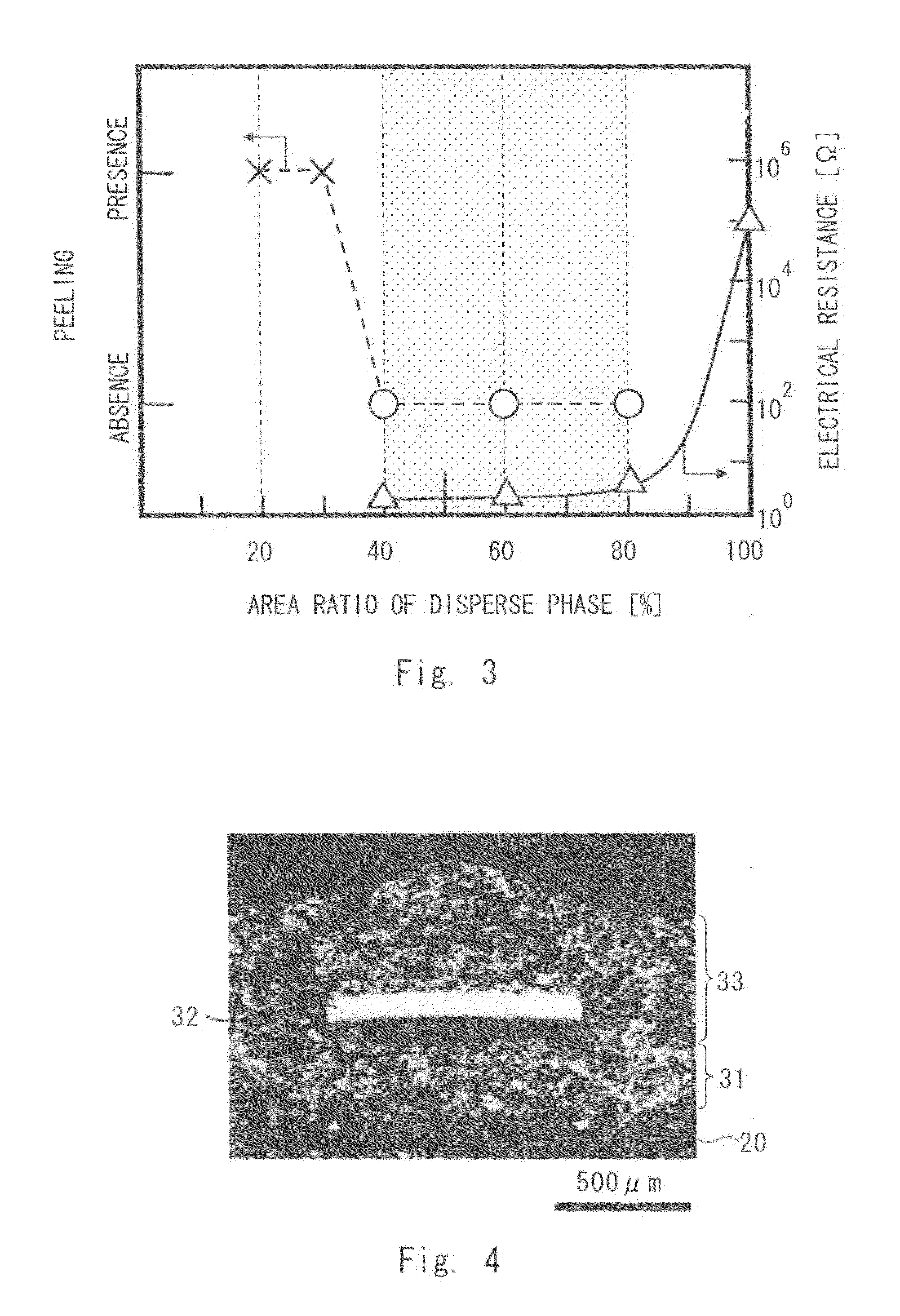

ActiveUS20130062328A1Minimizing increase in electrical resistanceLiquid surface applicatorsMolten spray coatingElectrical resistance and conductanceOxide minerals

An electrode according to one aspect of the present invention is formed on a base material composed of a ceramics. The electrodes includes a matrix composed of an Ni-Cr alloy (with a Cr content of 20 to 60 wt. %) or an MCrAlY alloy (M is at least one material selected from Fe, Co and Ni), and a disperse phase that is dispersed in the matrix and composed of an oxide mineral having a laminated structure. The ratio of area occupied by the disperse phase in a cross section of the electrode is 40 to 80%. With the structure like this, it is possible to suppress the increase in the electrical resistance even after a thermal cycle is performed.

Owner:TOYOTA JIDOSHA KK

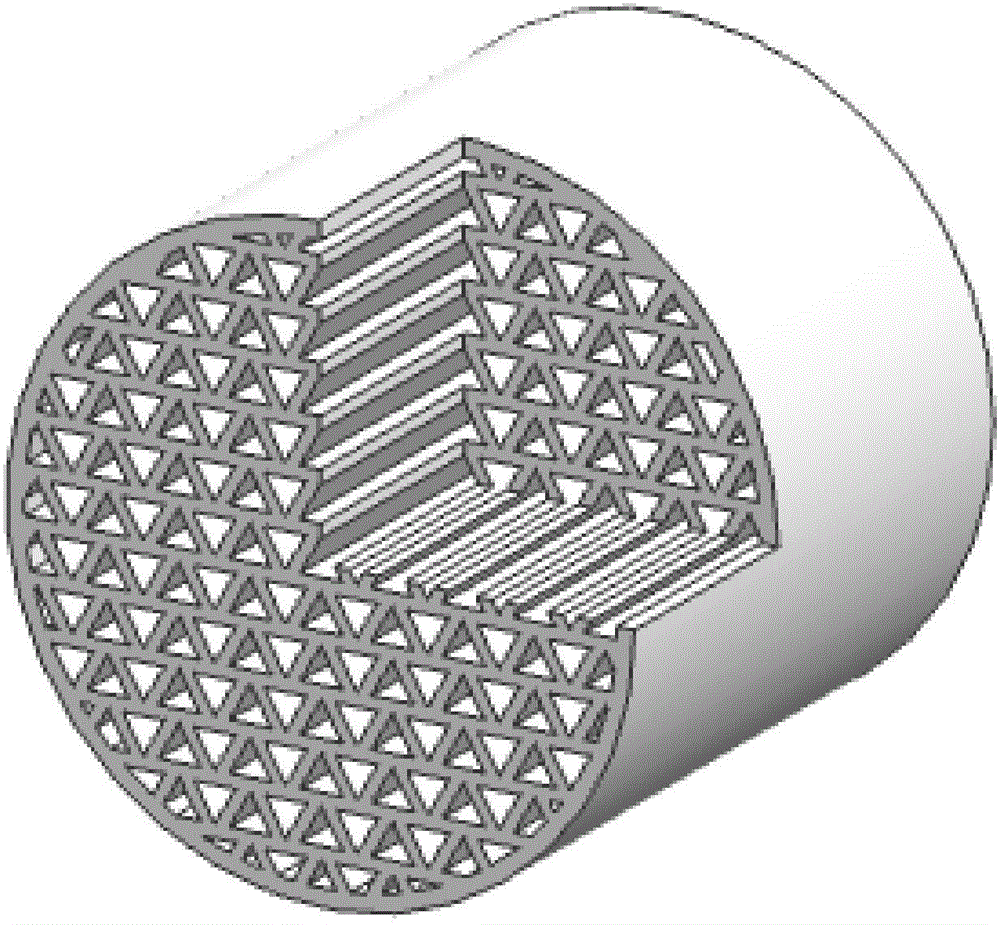

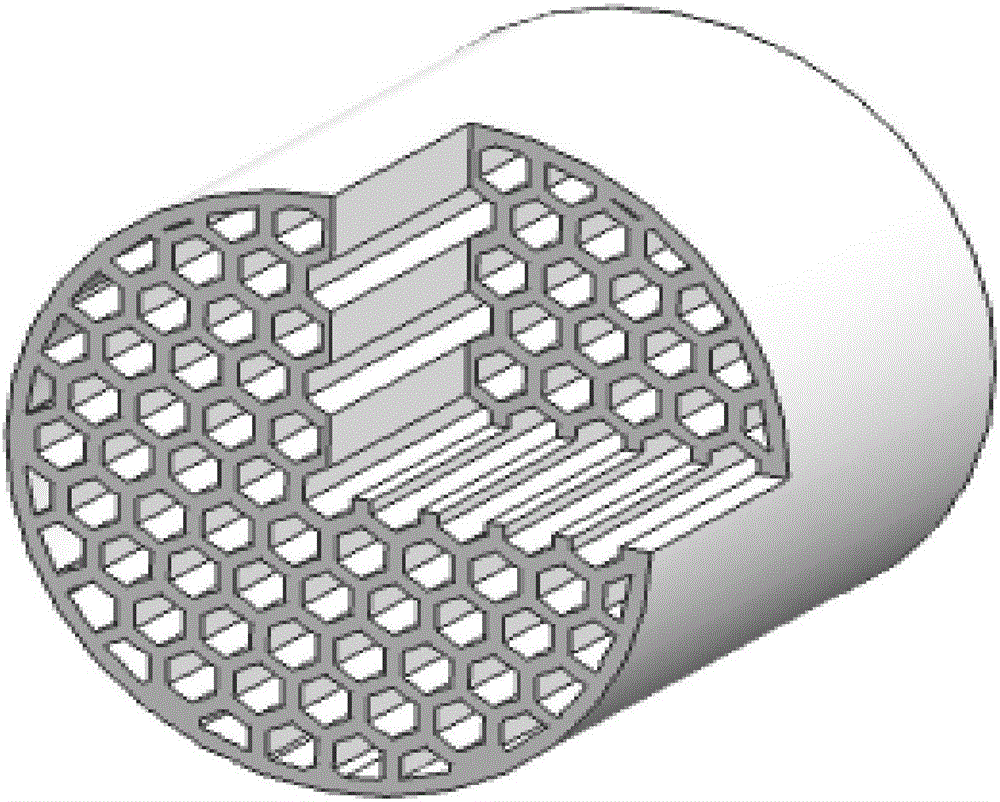

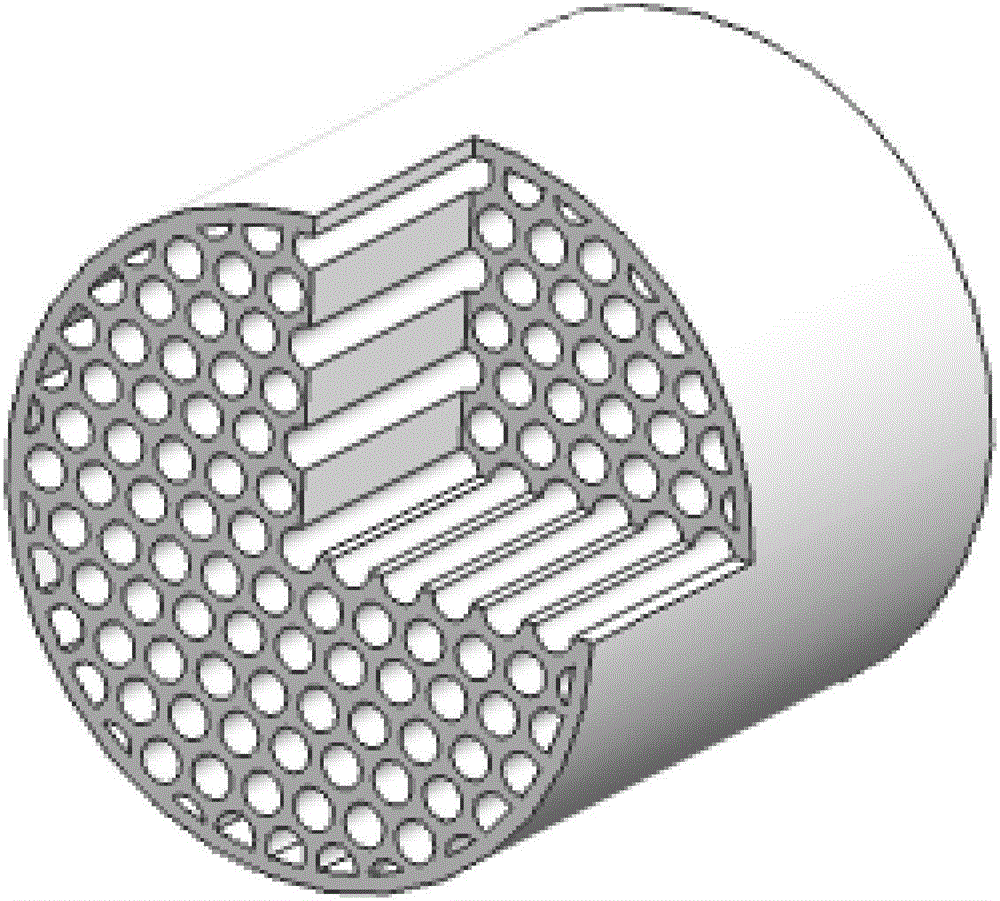

Honeycomb structure alloy material and application thereof

InactiveCN106825575ALarge specific surface areaMaximize contact areaAdditive manufacturing apparatusExhaust apparatusNi cr alloyLaser beams

The invention provides a honeycomb structure alloy material and application thereof. The alloy material is prepared through the following additive manufacturing method, and the method comprises the first step of flatly laying particles to obtain a current layer, wherein the particles are selected from Fe-Cr-Al alloy, Ni-Cr alloy or Fe-Mo-W alloy; the second step of using laser beams to scan the current layer according to a preset honeycomb structure section profile of the current layer so that the particles can be sintered and a cross section layer can be obtained; the third step of repeating the first step and the second step on the cross section layer for multiple times till the honeycomb structure alloy material with a preset shape is obtained. The alloy with specific materials is printed into the honeycomb structure alloy material with exact one step according to pore shapes, dimensions and distribution of the preset honeycomb structure and through the combination of a laser selective melting 3D print method. In the laser selective melting 3D print method, the honeycomb geometrical shape, dimension and distribution can be freely designed, a larger specific area is achieved, and the maximization of the contact area of the honeycomb structure alloy material and tail gas can be reached as much as possible.

Owner:GUANGDONG UNIV OF TECH

Preparation method of NiCr/Al2O3 composite coating

The invention discloses a preparation method of a NiCr / Al2O3 composite coating. The preparation method comprises the steps of firstly, mechanically mixing Ni-Cr alloy powder with Al2O3 powder, and conducting ultrasonic oscillation, so that NiCr / Al2O3 composite powder is obtained; and then, conducting plasma spraying, so that the NiCr / Al2O3 composite coating with the NiCr content ranging from 10% to 30% is synthesized. By means of the preparation method, bonding strength of an Al2O3 coating is improved, and the defect that corrosion resistance of an aluminum oxide coating is lost in a strong acid environment is overcome.

Owner:HEBEI UNIV OF TECH

Method for preparing high-temperature self-lubricating coating by fast induction and thermal sintering

The invention discloses a method for preparing a high-temperature self-lubricating coating by fast induction and thermal sintering, which is particularly suitable for preparing heat resistance, abrasion resistance and self-lubricating coating materials of the surface of a service metal part in the condition of high temperature. In the method, a composite powder is prepared by carrying out rubber-surfaced rolling and ball milling on powders of Ni, Cr, Cr2O3, BaF2, CaF2 and Ag for 24-96h; the composite powder is paved on an Ni Cr alloy matrix and is treated by cold pressing with the cold pressing pressure of 300-400MPa and the pressure keeping time of 10-15min, thereby obtaining a coating; and finally, the coating after cold pressing is treated by hot pressing and sintering in an intermediate frequency induction hot pressing and sintering furnace, the temperature is controlled at 900-1000 DEG C for 10-30min in the process of sintering and then fast rises to 1100-1200 DEG C for 5-15min in the pressure of 9-20MPa, and the high-temperature self-lubricating coating materials can be formed on the Ni Cr alloy matrix.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electrode, electrically heated catalytic converter using same and process for producing electrically heated catalytic converter

InactiveCN103155695AIncrease the resistance valueOhmic-resistance electrodesExhaust apparatusOxide mineralsNi cr alloy

Owner:TOYOTA JIDOSHA KK

High-strength fastening bolt production technology

The invention belongs to the technical field of bolt processing, and aims at providing a high-strength fastening bolt production technology. The high-strength fastening bolt production technology comprises the following steps of: step 1. selecting a steel product; step 2. carrying out spheroidizing annealing; step 3. shelling and descaling; step 4. drawing; step 5. carrying out cold forging and shaping; step 6. carrying out thread machining; step 7. carrying out heat treatment; step 8. detecting; step 9. tempering; step 10. carrying out secondary detection; and step 11. plating an anti-corrosion layer. Bolts screened out finally through material selection, annealing, descaling, drawing, cold forging, heat treatment, screening and tempering have the characteristic of high strength. The bolts have the characteristic of corrosion resistance by coating the surfaces of the bolts with Fe-Ni-Cr alloy coatings, and can be prevented from be corroded under harsh physicochemical conditions, and thus, the shape and strength of the bolts are maintained.

Owner:森冈精机(南通)有限公司

Composite strengthening and toughening technology of high-tensile Fe-Ni-Cr-based high-temperature corrosion-resisting alloy

The invention discloses a composite strengthening and toughening technology of a high-tensile Fe-Ni-Cr-based high-temperature corrosion-resisting alloy. According to the composite strengthening and toughening technology, beneficial microelements are controlled by the compounding ratio of alloy components and the matching of specific vacuum-induction melting and an electro slag remelting duplex smelting technology, then a composite strengthening and toughening technique is adopted, namely isothermal controlled forging is adopted, forged meta-stable-state tissues are reserved in the alloy through quick cooling, and ageing strengthening is directly adopted. According to the composite strengthening and toughening technology disclosed by the invention, the corrosion resisting property of the Fe-Ni-Cr alloy is guaranteed, besides, the impact toughness (especially low-temperature impact toughness) of the alloy, the room-temperature tensile strength of the alloy, and the yield strength of the alloy can achieve a high level, and the combination property of the alloy disclosed by the invention is superior to that of the Incoloy925 alloy regulated by the American ASTM technical standard.

Owner:HENAN INST OF ENG

Acetone gas sensor of LaFeO3 nano sensitive material based on nuclear shell microsphere structure and its preparation method

InactiveCN107655942AEasy accessIncrease profitMaterial nanotechnologyIron compoundsMicrosphereNi cr alloy

The invention discloses an acetone gas sensor of a LaFeO3 nano sensitive material based on a nuclear shell microsphere structure and its preparation method, and belongs to the technical field of an oxide semiconductor gas sensor. The sensor is a tubular structure and composed of an Al2O3 ceramic tube, a Pt wire, a Ni-Cr alloy heating coil and a LaFeO3 nano sensitive material; the outer surface ofthe Al2O3 ceramic tube is coated with two separated annular Au electrodes in parallel, the Pt wire is welded to the annular Au electrodes; the Ni-Cr alloy heating coil crosses through the Al2O3 ceramic tube core, and the LaFeO3 nano sensitive material of the nuclear shell microsphere structure is coated on the Al2O3 ceramic tube and the annular Au electrode. The sensor is featured by high integrity degree, simple structure, low price, small volume, durability and large batch production; the testing result of the air-sensitive property indicates that the sensor has quick response and recovery speed to acetone gas and extremely good long-term stability; thus the sensor has important application prospect in detection of acetone gas in the indoor environment.

Owner:JILIN UNIV

Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

ActiveCN103895280AGood workmanshipInhibit sheddingElectrolytic coatingsMetallic material coating processesHigh power lasersHigh energy

The invention belongs to the technical field of material science, and particularly relates to a repairing composite layer of an amorphous / nanocrystalline cooling roller and a preparation method of the repairing composite layer. The composite layer consists of two layers, namely a copper-based alloy layer connected with base materials and a nickel-based alloy layer, wherein the copper-based alloy layer comprises the following components by weight percent: 7-9% of Ni, 8-12% of Sn, 5-15% of Co, 0.8-2% of Si and the balance being Cu; the nickel-based alloy layer comprises one of Ni-Co alloy, Ni-P alloy, Ni-Fe alloy and Ni-Cr alloy, and the weight content of Ni in alloy is 60-75%. The preparation method comprises the following steps of pretreating the surface of the cooling roller, electroplating the copper-based alloy layer and performing wide-strip cladding on the nickel-based alloy layer by a high-power laser. The prepared composite coating is uniform and compact, and excellent in wear resistance and heat resistance, and has the characteristics of high cladding efficiency and high energy absorptivity of the cooling roller to the laser beam.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

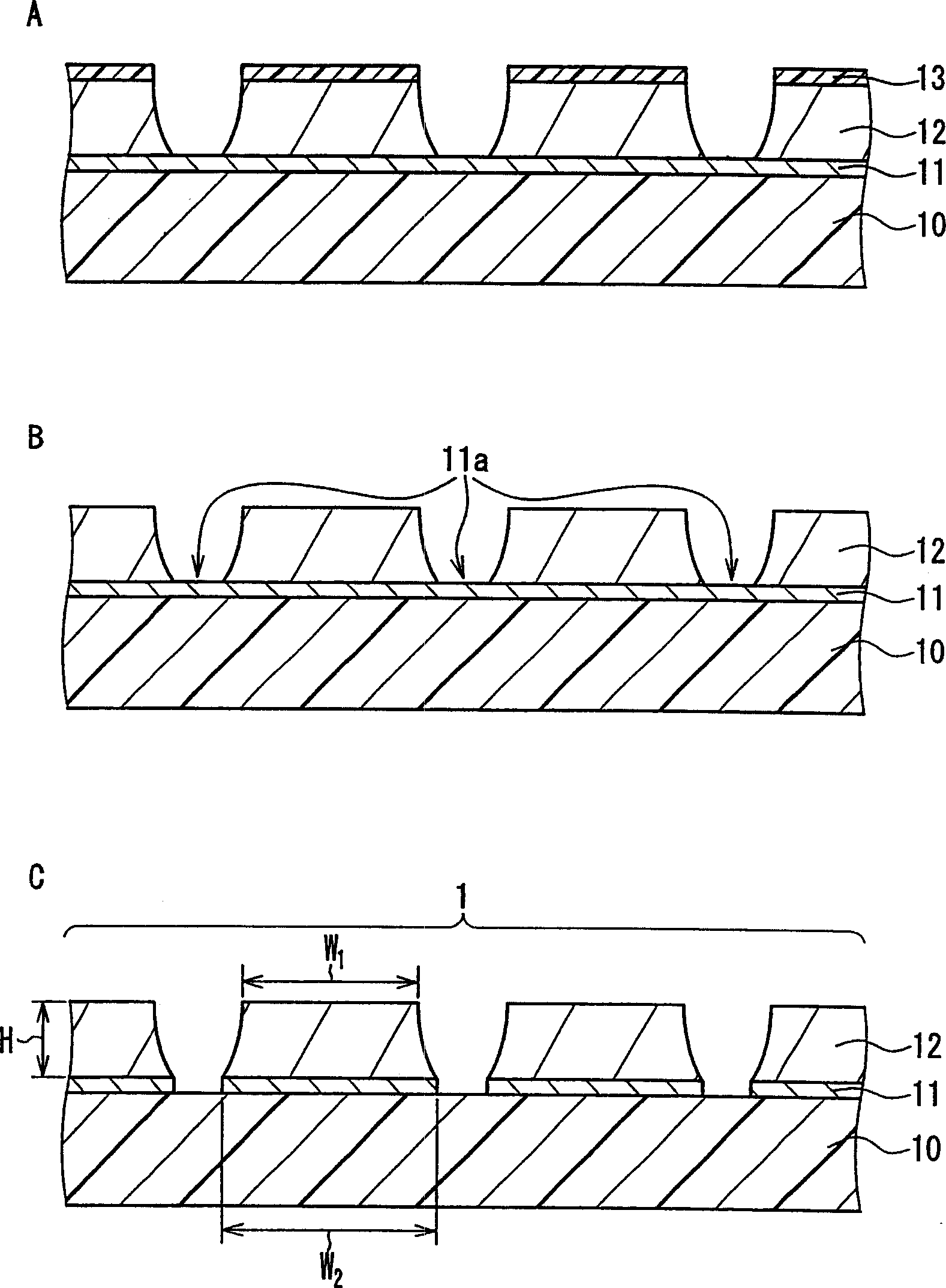

Etching liquid, bulking liquid and forming method of conductive image using same

To provide an etching liquid and refilling liquid which can promptly etch at least one metal chosen from Ni, Cr, Ni-Cr alloy, and Pd, and a forming method of conductor pattern using it. The etching liquid or a solution of water, which contains at least one component chosen from NO, N2O, NO2, N2O3 and these ions, and an acid component, etches at least one metal chosen from Ni, Cr, Ni-Cr ally and Pd. The forming method of a conductor pattern (1) forms the conductor pattern (1) by etching at least one metal chosen from Ni, Cr, Ni-Cr alloy and Pd with the liquid.

Owner:MEC CO LTD

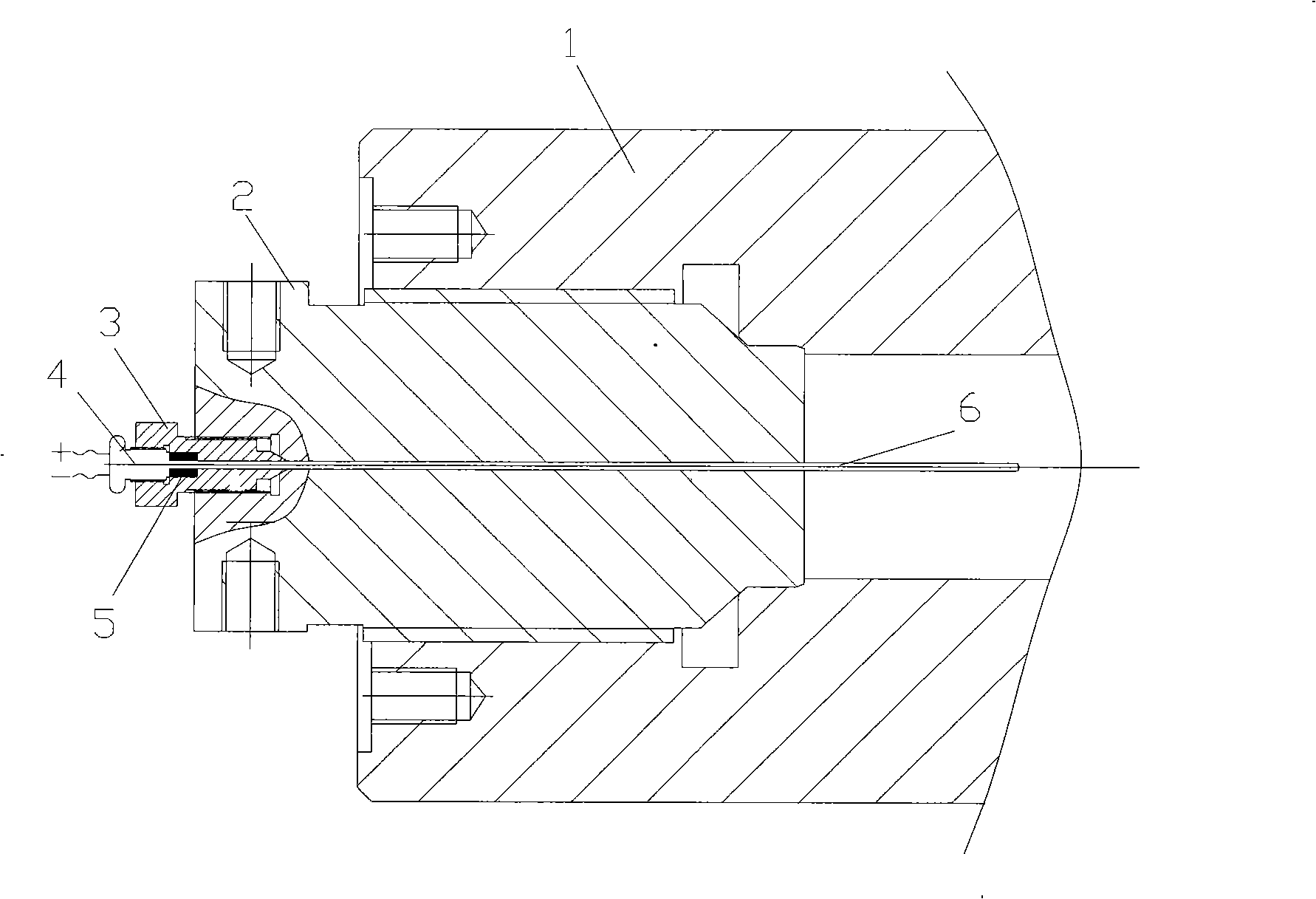

Armored thermocouple thermometer

InactiveCN101403642AAccurate temperature measurementConvenient sealing designThermometer detailsThermometers using electric/magnetic elementsNi cr alloyThermocouple

The invention belongs to the thermocouple thermometer field and particularly relates to a sheathed thermocouple thermometer. The invention mainly comprises a temperature measurement wire plug, a sensor, a sealing element and a temperature measurement rod which is made of stainless steel and coated with a layer of Ni-Cr alloy. The temperature measurement rod is threaded through the wire plug to be connected with the sensor at the other end; the sealing element is formed by bushing an alloy ring, an O-ring and a PTFE gasket onto the temperature measurement rod; a taper face is arranged at the end of the temperature measurement wire plug to match the taper face of a container plug; after the temperature measurement rod and the sensor are fixedly connected with the temperature measurement wire plug through the sealing element, the temperature measurement wire plug is connected with the container plug through threads and finally is threaded through the taper face at the end. The temperature measurement is accurate and the error is plus or minus 0.001 DEG C and the maximum bearing-pressure can reach 600MPa; the design for the sealing is excellent; and the structure is simple, the operation is easy and the cost can be lowered.

Owner:CHINA AGRI UNIV

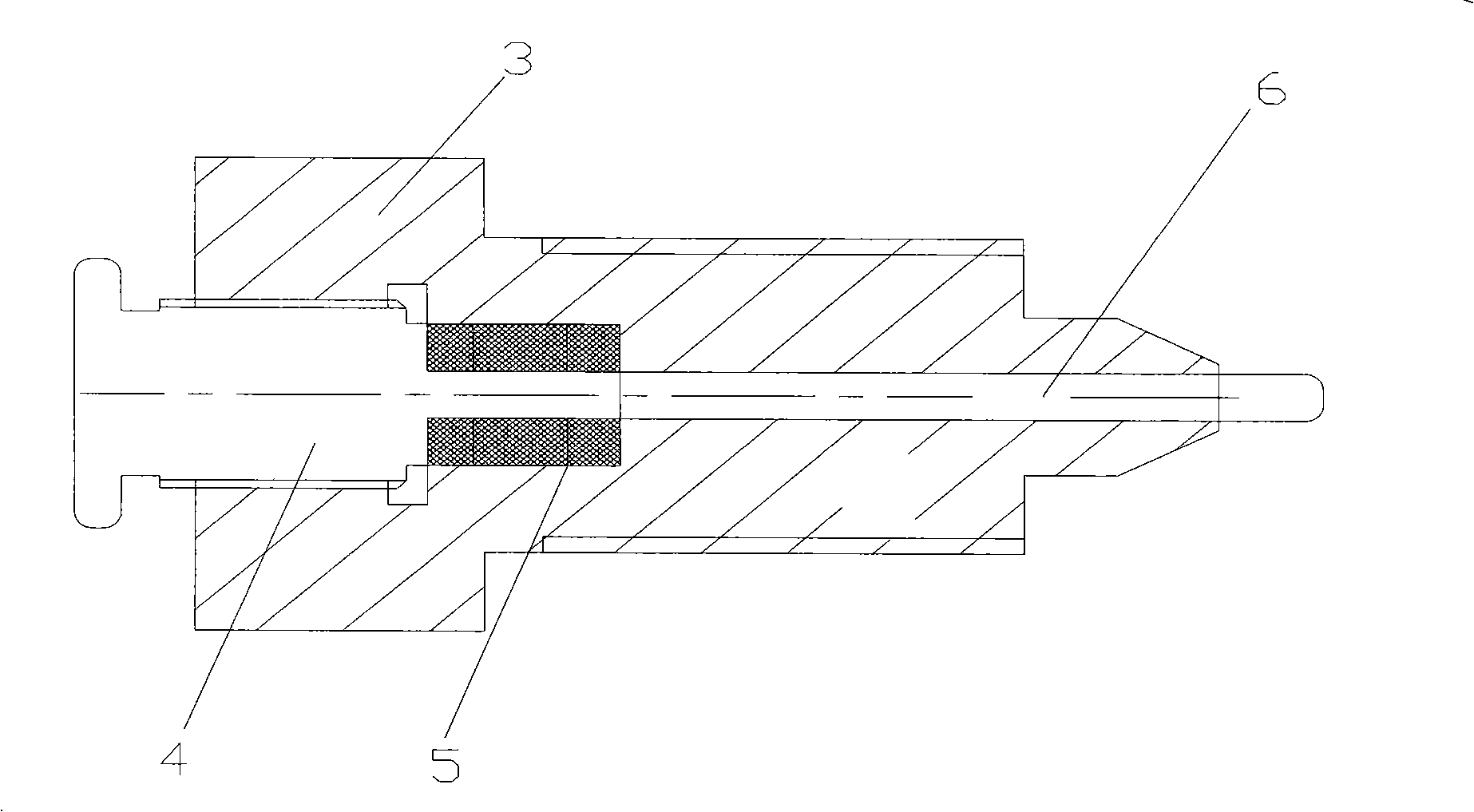

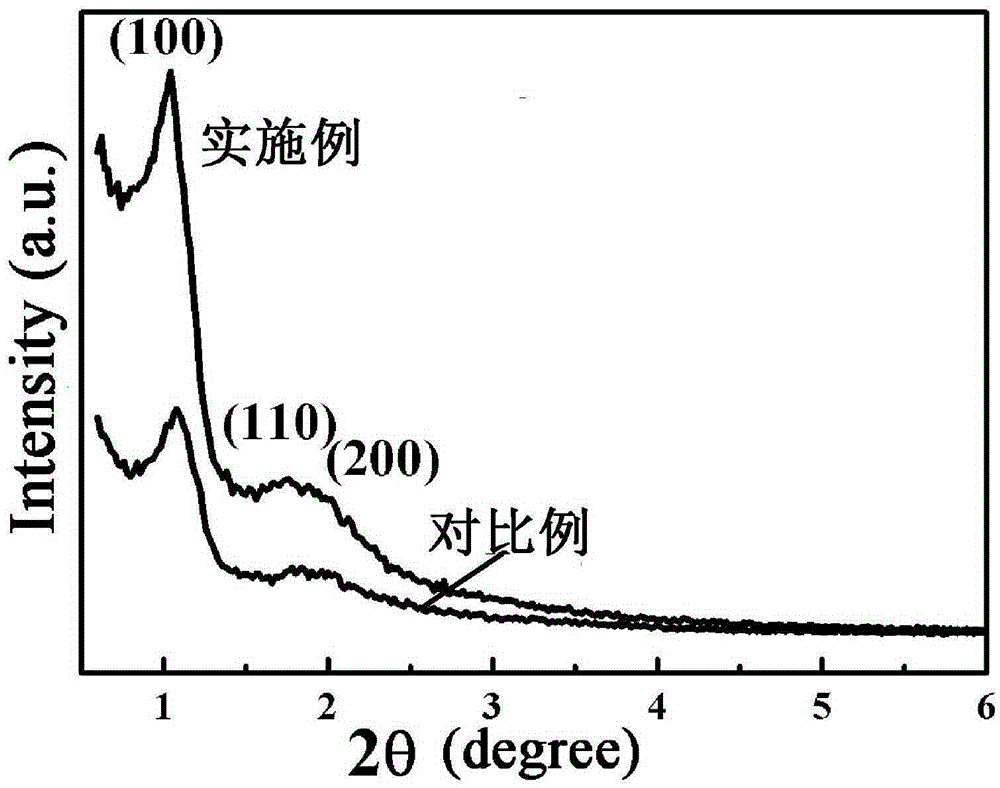

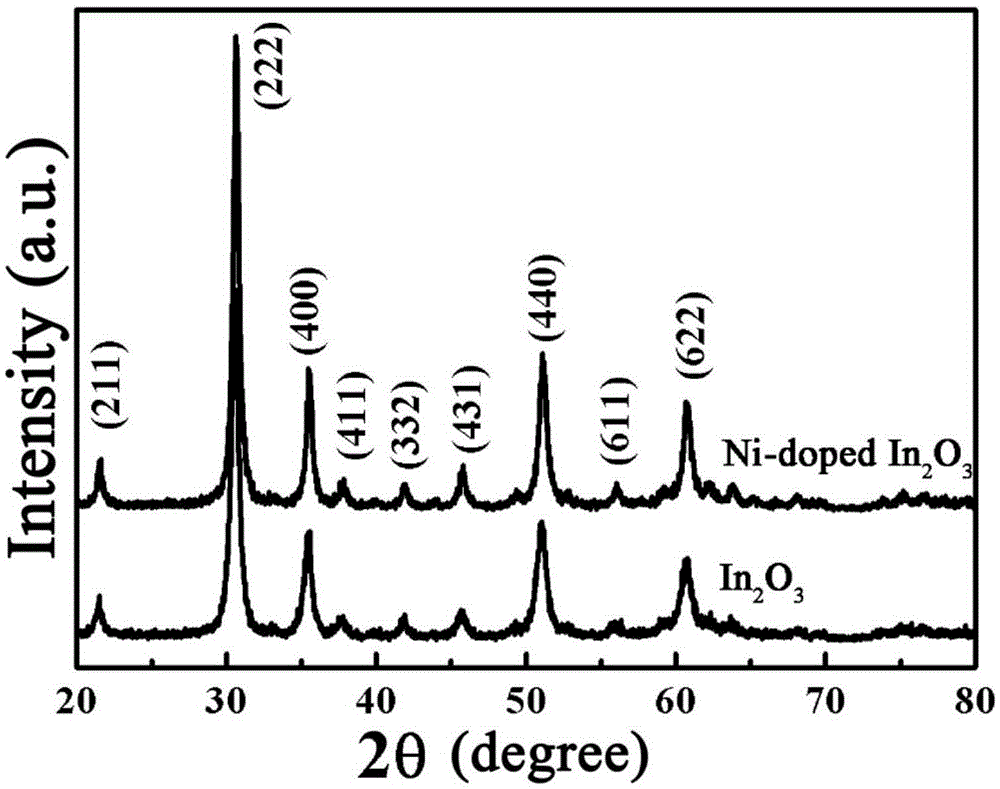

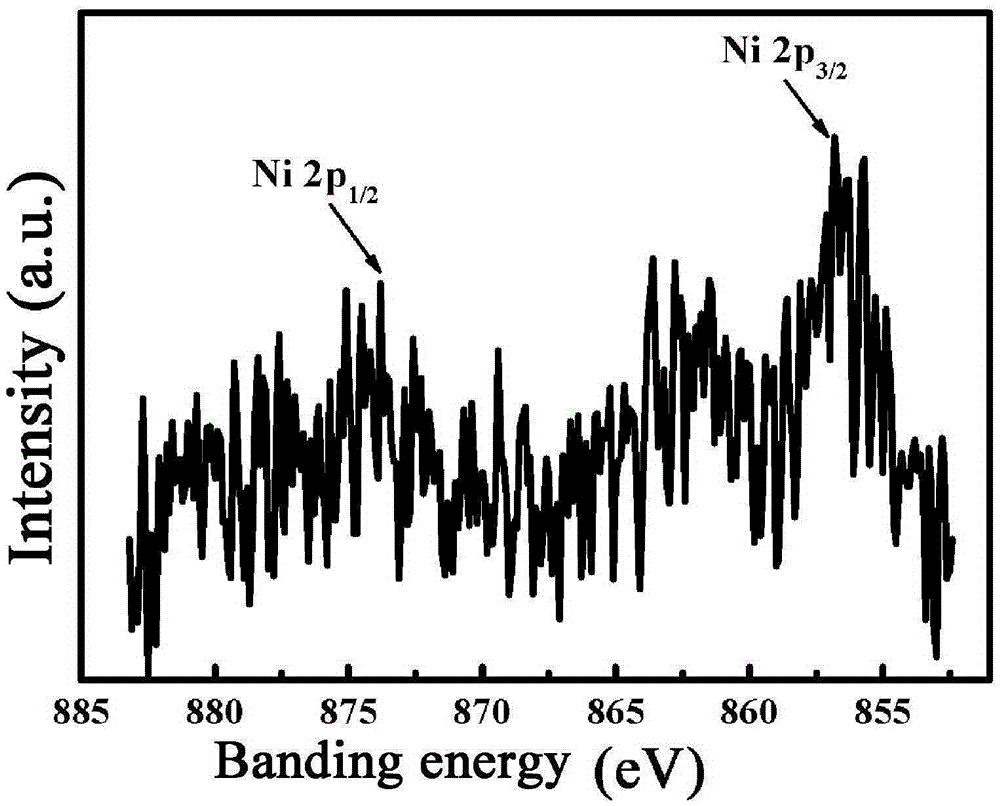

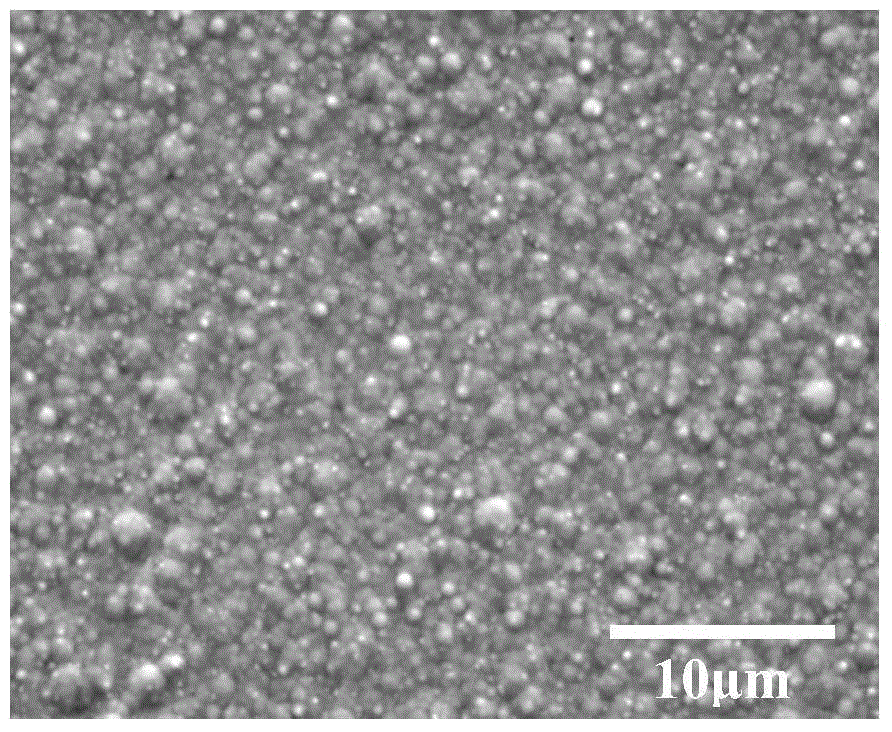

Nitrogen dioxide sensor based on orderly-channel Ni-doped mesoporous indium oxide and preparation method thereof

InactiveCN105424764AThe synthesis method is simpleFavorable for adsorption and desorptionMaterial resistancePlatinumNitrogen dioxide

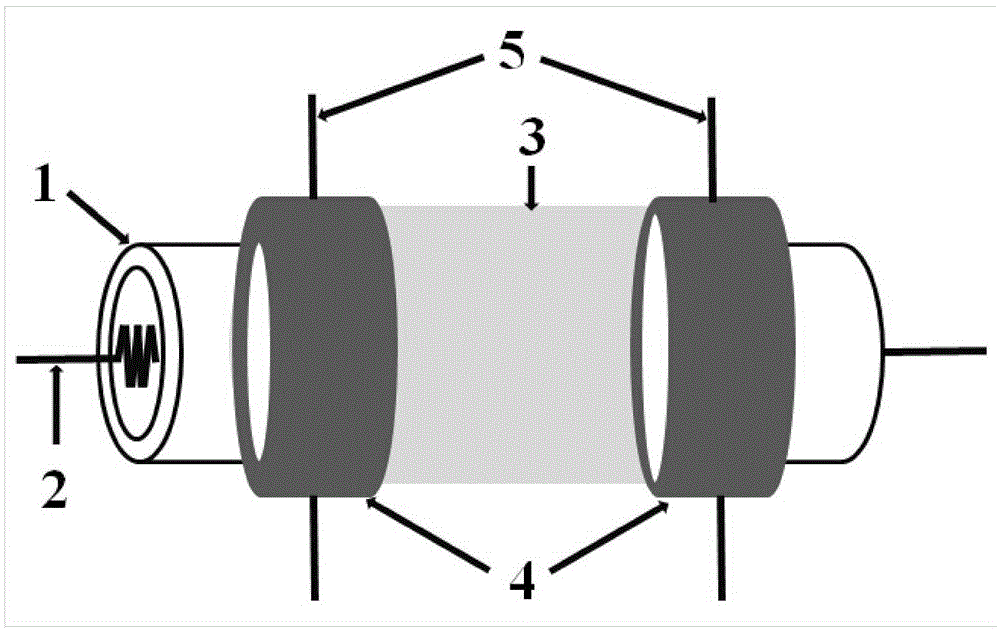

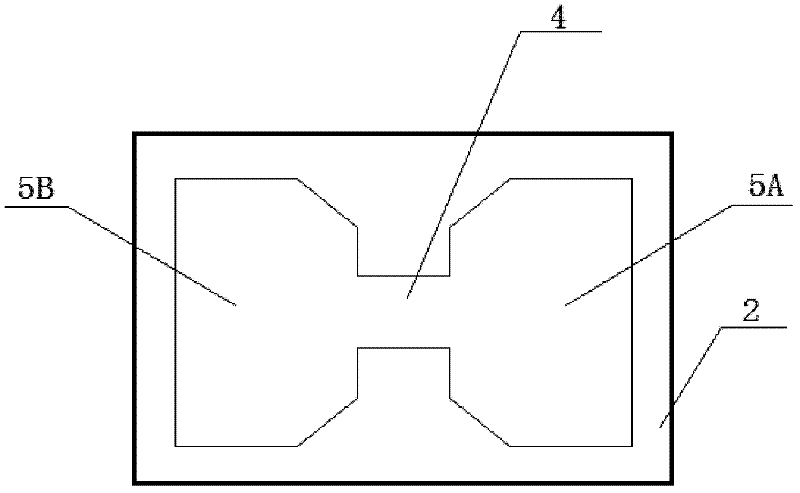

The invention provides a nitrogen dioxide sensor based on orderly-channel Ni-doped mesoporous indium oxide and a preparation method thereof and belongs to the technical field of semiconductor oxide gas sensors. The nitrogen dioxide sensor is composed of a Al2O3 insulating ceramic tube 2, a Ni-Cr alloy heating coil 1 and sensitive material films 4, wherein the outer surface of the Al2O3 insulating ceramic tube 2 is provided with two discrete annular gold electrodes 3, the Ni-Cr alloy heating coil 1 penetrates through the Al2O3 insulating ceramic tube 2, and the outer surface of the Al2O3 insulating ceramic tube 2 and the annular gold electrodes 3 are coated with the sensitive material films 4. Each annular gold electrode 3 is connected with a pair of platinum wires 5. The sensitive material films 4 are obtained by being coated by orderly-channel Ni-doped mesoporous indium oxide. An orderly-channel Ni-doped mesoporous indium oxide material can provide a large specific surface area, and more active sites are provided easily. More oxygen vacancy defects are introduced to Ni-doped indium oxide, sensitivity is improved easily, and the nitrogen dioxide sensor has wide application prospects in the aspect of detection of the nitrogen dioxide content in the microenvironment.

Owner:JILIN UNIV

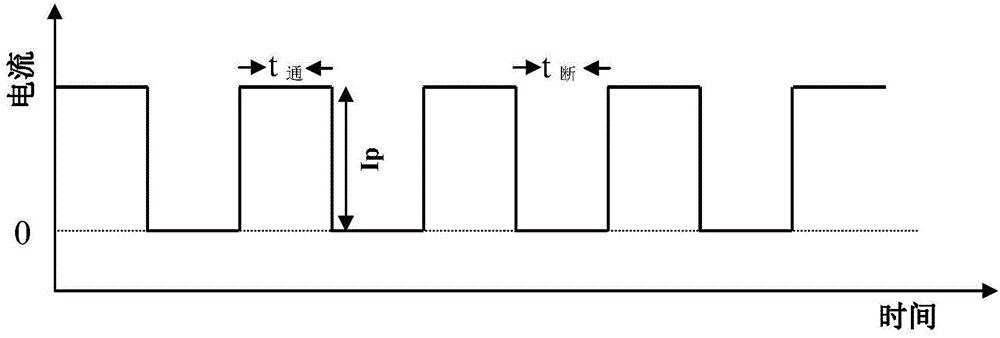

Method for improving corrosion resistance of nickel-aluminum bronze

The invention discloses a method for improving the corrosion resistance of nickel-aluminum bronze. The method comprises the following steps: firstly, grinding and polishing the surface of nickel-aluminum bronze, degreasing, pickling and activating, placing the treated nickle-aluminum bronze in a nickel-chromium plating solution of which the temperature is 30-40 DEG C and the pH value is 2.0-3.5 and electroplating the treated nickel-aluminum bronze serving as a cathode to obtain a crack-free Ni-Cr alloy coating having a smooth surface on the surface of the nickel-aluminum bronze. The chromium ion used in the plating solution is trivalent; the coating stress is released by virtue of a pulse plating process and the surface cracks are eliminated; the surface of the coating is smooth and clean, free of defects such as cracks and pinholes; good adhesion force is kept between the coating and the substrate, the surface hardness can reach 440-630HV, which is 2-3 times that of the substrate material; and the coating has excellent corrosion resistance and is used as a protective coating to isolate nickel-aluminum bronze from a corrosive medium so that the corrosion resistance is greatly improved. The method has the characteristics of low cost, no toxicity and the like and is simple and feasible and is a preparation method which integrates economy, high efficiency and high quality into a whole.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com