Honeycomb structure alloy material and application thereof

A technology of honeycomb structure and alloy material, applied in the field of catalytic converter, can solve the problems of limiting the contact area between honeycomb alloy material and automobile exhaust gas, limiting the degree of freedom of alloy composition design, etc., so as to achieve the effect of maximizing the contact area and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the present invention, the current layer is obtained after the particles are flattened, and the particles are selected from Fe-Cr-Al alloy, Ni-Cr alloy or Fe-Mo-W alloy. In the present invention, the particles are preferably spherical or quasi-spherical; the particle size of the particles is preferably 1-50 microns, more preferably 2-30 microns. The present invention preferably adopts the method of melt atomization granulation to prepare granules. The preparation method of the Fe-Cr-Al alloy preferably includes: mixing and melting iron, chromium and aluminum, atomizing and granulating to obtain the Fe-Cr-Al alloy. The method for preparing the Ni-Cr alloy preferably includes: mixing and melting nickel and chromium, atomizing and granulating to obtain the Ni-Cr alloy. The preparation method of the Fe-Mo-W alloy preferably includes: mixing and melting iron, molybdenum and tungsten, atomizing and granulating to obtain the Fe-Mo-W alloy.

[0030] In the present inventio...

Embodiment 1

[0041] Mix and melt iron, chromium and aluminum with a mass ratio of 60:20:20, atomize and granulate to obtain spherical or nearly spherical Fe-20Cr-20Al alloy particles with an average particle size of 40 microns;

[0042] a), paving the Fe-20Cr-20Al alloy to form the current layer;

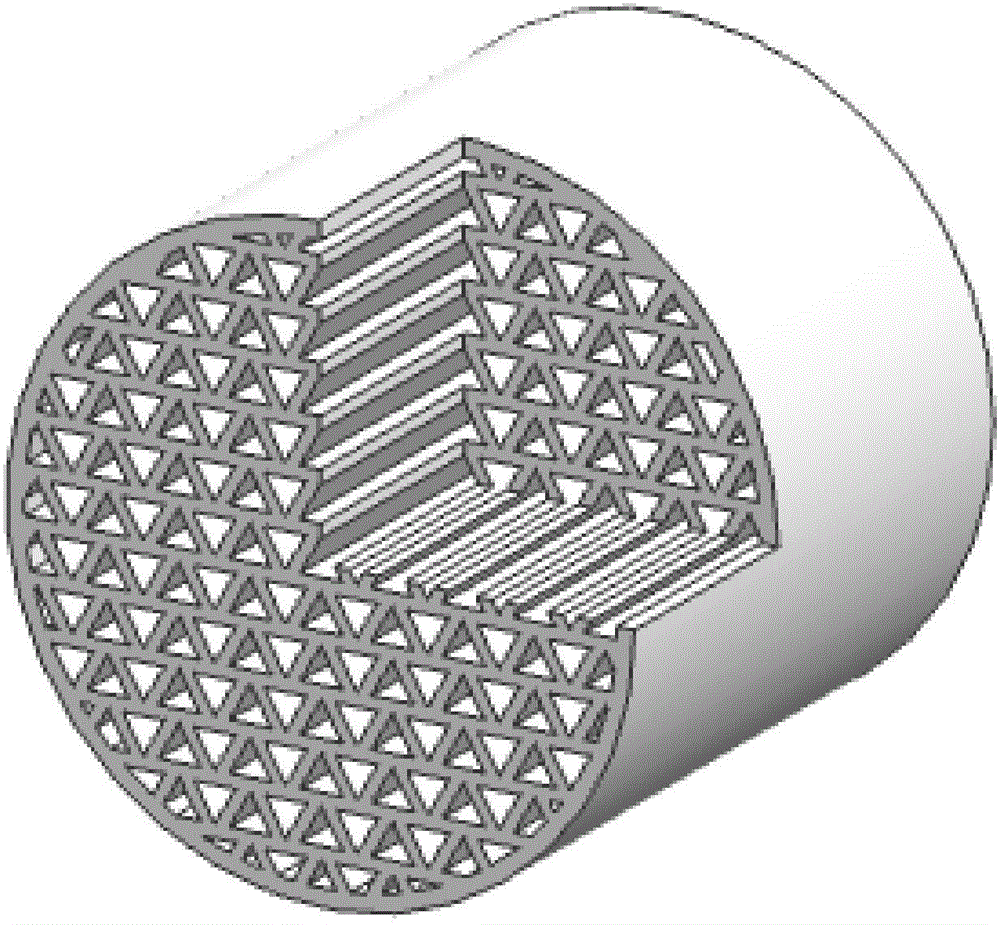

[0043]b) Using a laser beam with a power of 375-425W to scan according to the preset current layer cross-sectional profile, the scanning distance is 0.06 mm, and the scanning speed is 1000 mm. The shape of the honeycomb structure in the cross-sectional profile of the honeycomb structure is triangular, Sinter spherical or nearly spherical particles at 1250°C to 1950°C to form a cross-sectional layer. The cross-sectional view of the cross-sectional layer is as follows figure 1 as shown, figure 1 The schematic diagram of the cross-sectional structure of the cross-section layer prepared in Example 1 of the present invention; by figure 1 It can be seen that the honeycomb structure of the cross-sect...

Embodiment 2

[0050] Mix nickel and chromium with a mass ratio of 65:35, atomize and granulate to obtain spherical or nearly spherical Ni-35Cr alloy particles with an average particle size of 30 microns;

[0051] a), the Ni-35Cr alloy is tiled to form the current layer;

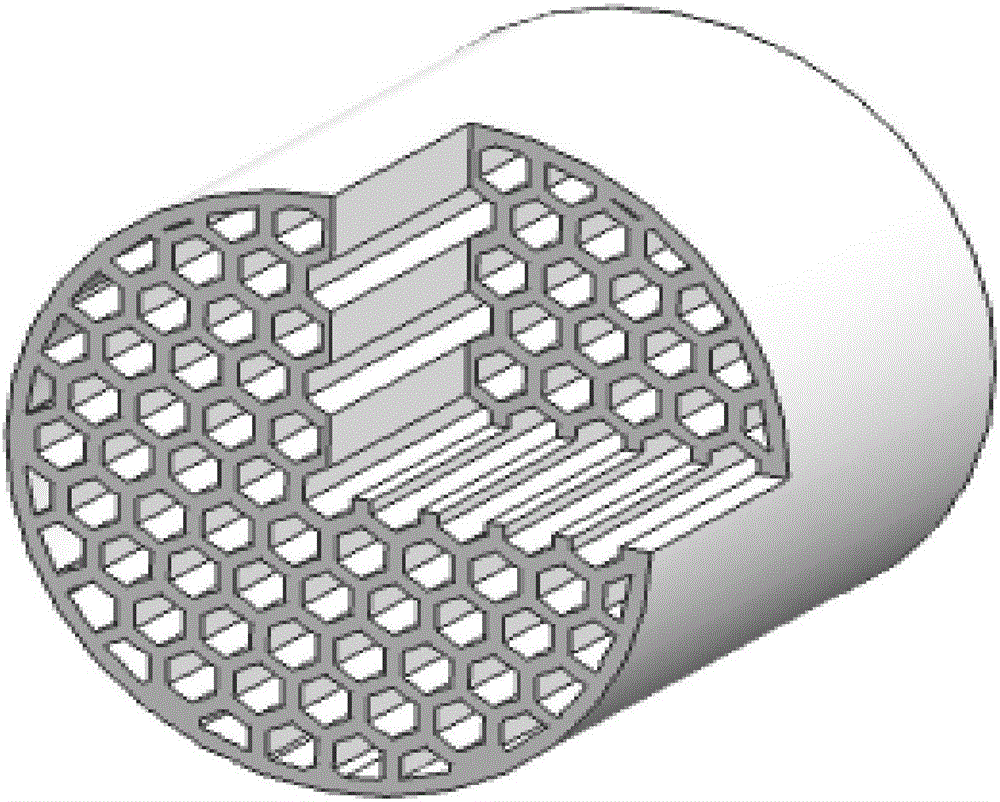

[0052] b) Use a laser beam with a power of 375-425W to scan according to the preset cross-sectional profile of the current layer. The scanning distance is 0.05 mm, and the scanning speed is 1200 mm. The shape of the honeycomb structure in the cross-sectional profile of the honeycomb structure is circular , to sinter spherical or nearly spherical particles at 1250°C to 1950°C to form a cross-sectional layer; the cross-sectional view of the cross-sectional layer, such as figure 2 as shown, figure 2 The schematic diagram of the cross-sectional structure of the cross-section layer prepared in Example 2 of the present invention; by figure 2 It can be seen that the honeycomb structure of the cross-sectional layer is circula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com