Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2752 results about "3d printed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS20060045787A1Additive manufacturing apparatusTransportation and packagingCopperRapid prototyping

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

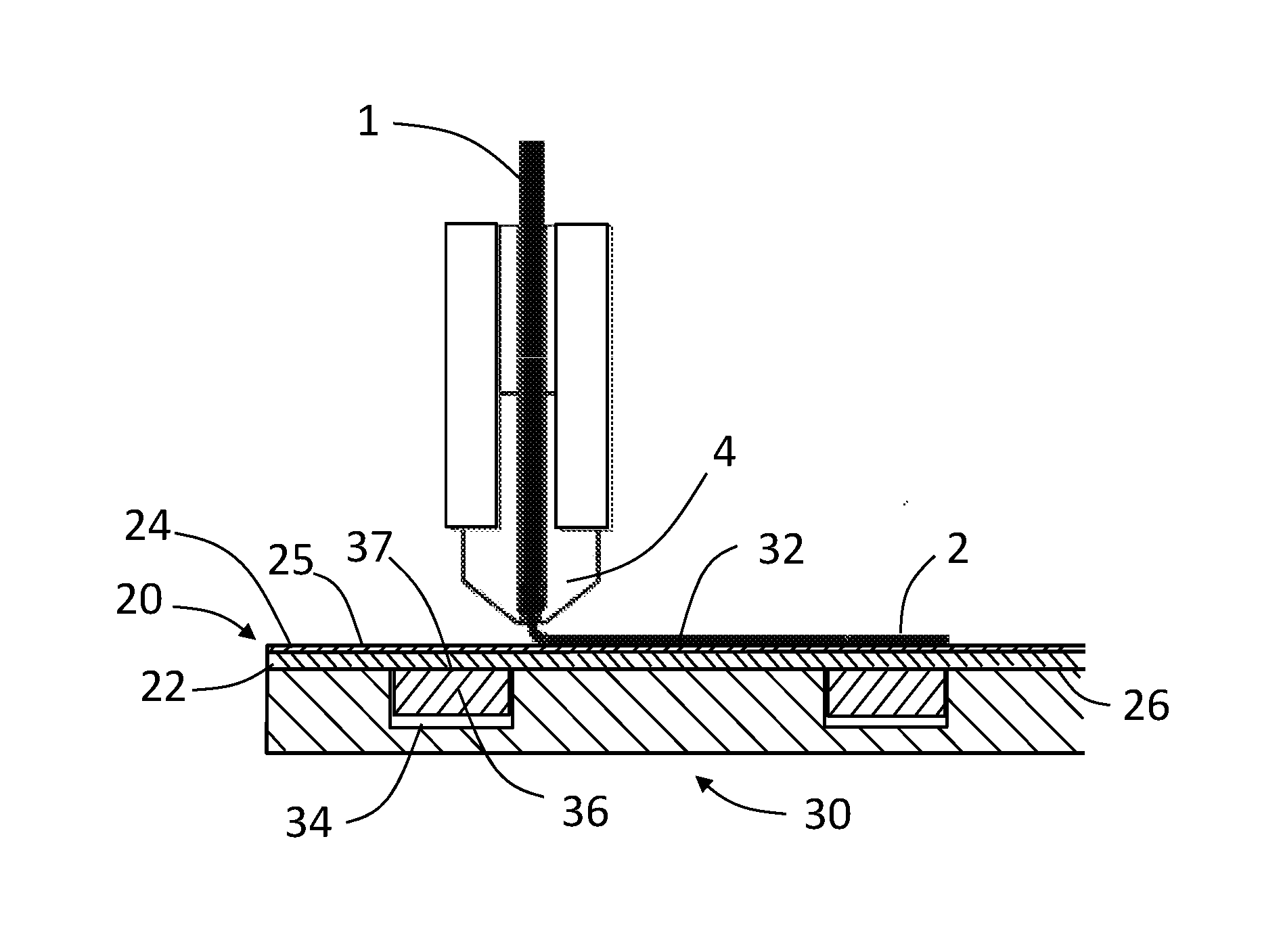

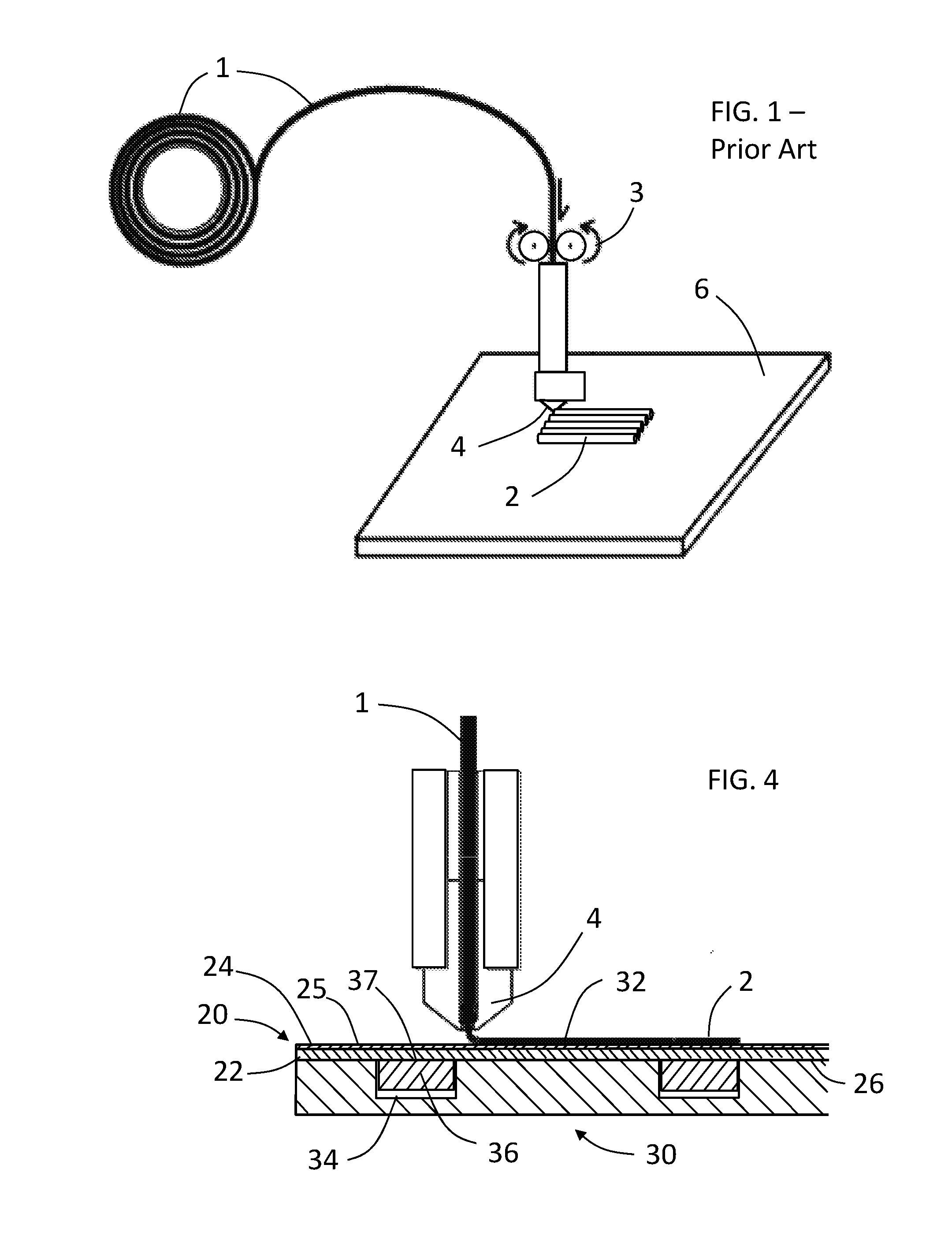

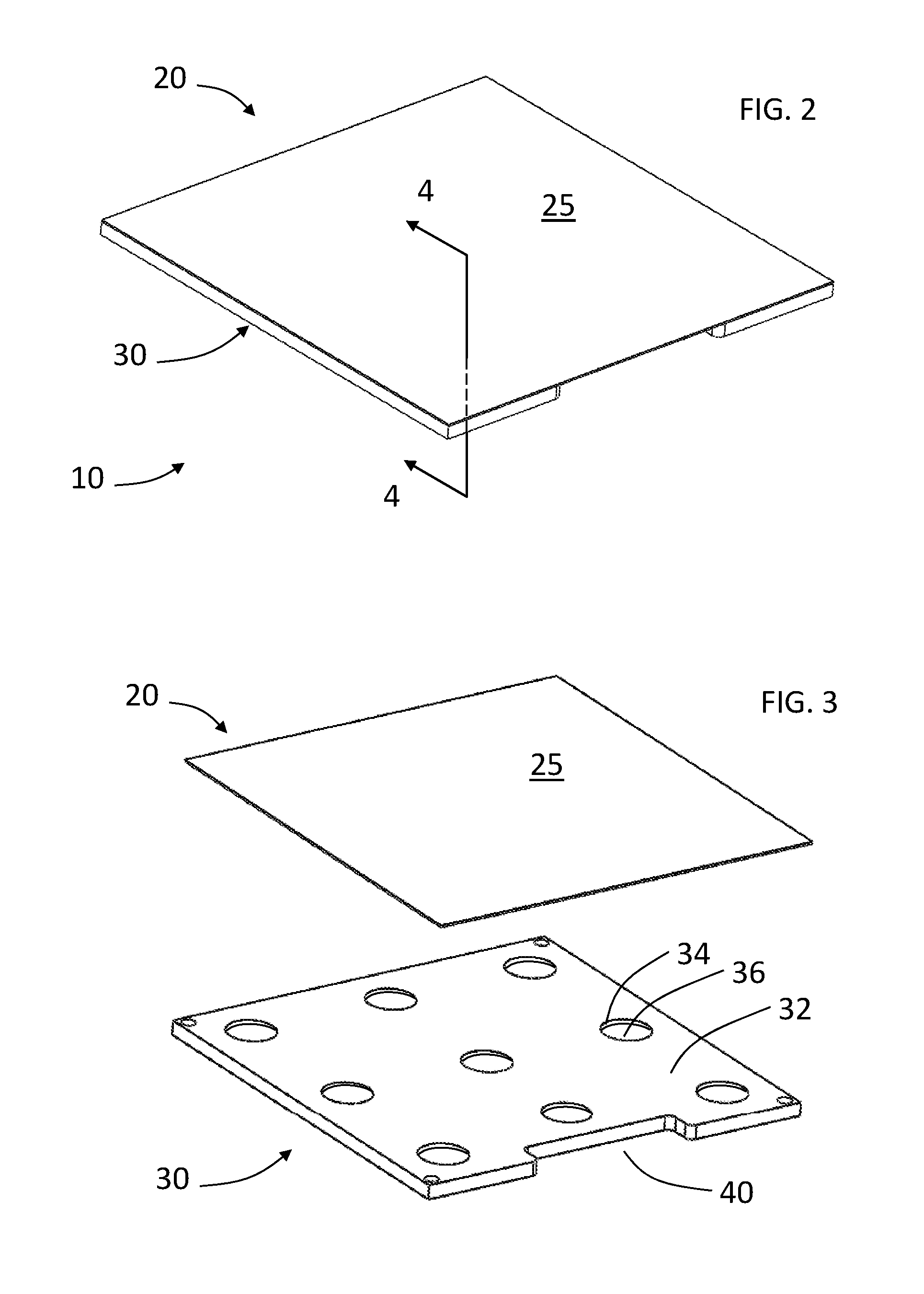

3D Print Bed Having Permanent Coating

PendingUS20170036403A1Improve adhesionSufficient level of adhesionManufacturing platforms/substratesPretreated surfacesEpoxyWater based

A coated print bed for a 3D printer having a permanent print-surface coating permanently secured to a print bed substrate plate, having a smooth, planar surface that provides an adhesive interface layer between a first layer of an applied plastic print material and the coated print bed. The coating contains a matrix-forming compound, such as a solvent- or water-based epoxy resin, an adhesive material, and optionally a filler. The user can print a series of print object directly onto the permanent print surface coating of the coated print bed, without having to refresh or refurbish the print surface, such as by applying to the print bed surface a temporary coating such as painter's tape, or a liquid adhesive.

Owner:EZ PRINT

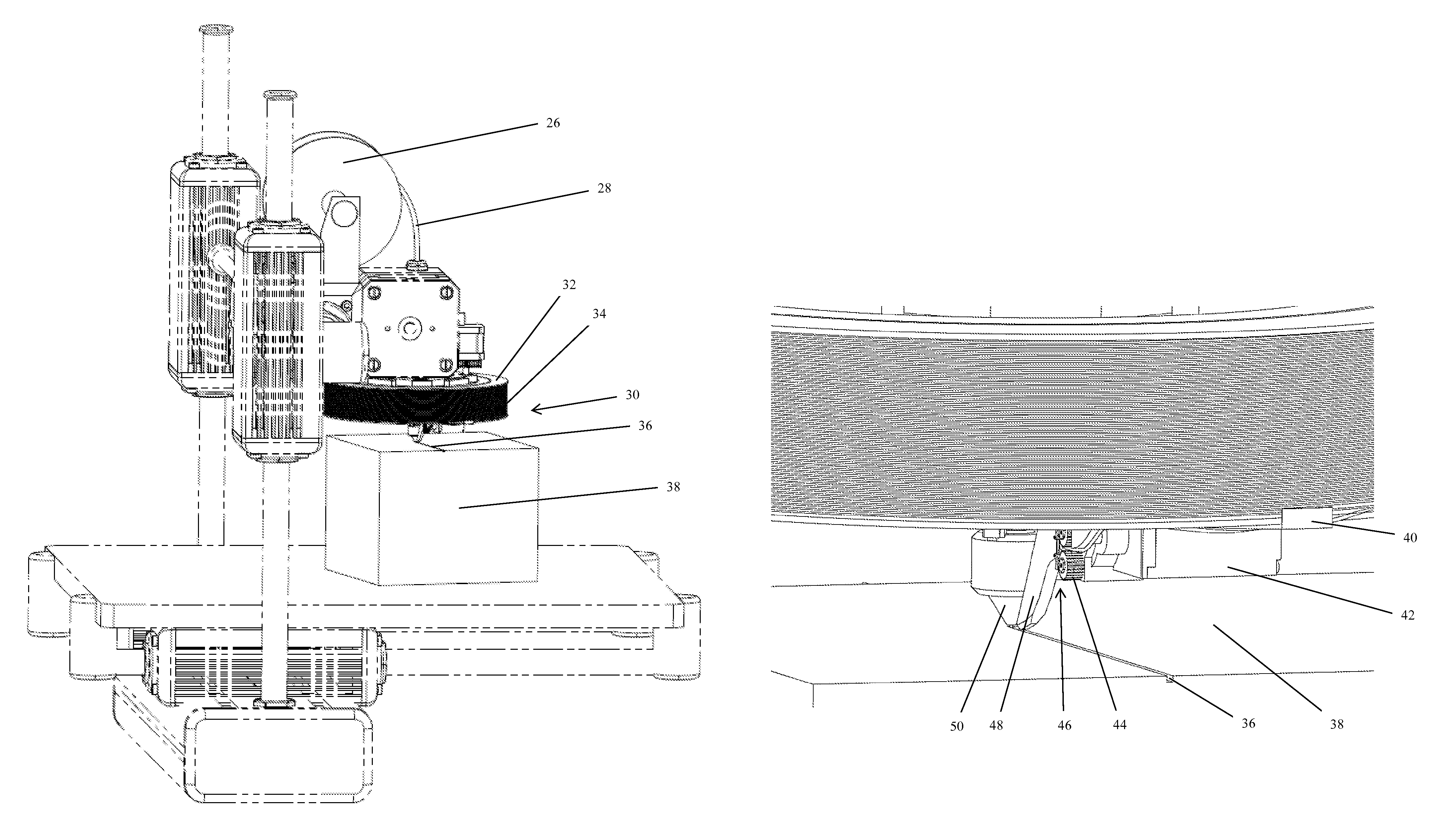

Apparatus and method of embedding cable in 3D printed objects

InactiveUS20160271876A1Additive manufacturing apparatusAdditive manufacturing with liquidsEngineering3d printed

Additive manufacturing method and apparatus for embedding cable in articles of additive manufacture in cooperation with a filament extrusion nozzle to increase their strength and functionality. This capability can be provided autonomously by integrating cable guides and cable cutters with new or existing print heads, enabling them to transition between filament-only, cable-only, and combined cable and filament printing modes to form mechanically stronger objects, integrated circuits within objects, and cable alternatives to filament scaffolding.

Owner:LOWER ROBERT BRUCE

Aluminum/magnesium 3D-Printing rapid prototyping

InactiveUS7141207B2Additive manufacturing apparatusTransportation and packagingRapid prototypingZinc

A 3D Printing Rapid Prototyping process using Al / Mg particles coated with a metal (i.e. copper, nickel, zinc, or tin) that (1) prevents oxidation of the Al / Mg particles, and (2) either alone, or when alloyed with the aluminum or magnesium core metal, melts below the liquidus temperature of the core.

Owner:GM GLOBAL TECH OPERATIONS LLC

Game object advances for the 3D printing entertainment industry

Embodiments describe constructing game-related objects through additive manufacturing systems. At least one construction configuration for building a game-related object is advanced at least partly due to at least one game task result being attained by a user and / or due to when an object is constructed and / or arranged to be built. Several embodiments demonstrate select game task results leading to determined construction configurations instead of alternative construction configurations, causing, for instance, a differing design, complexity, function, and / or number of constructed object portions. Game task results in certain embodiments lead to multiple distinct portions of one or more objects being constructed concurrently and / or successively, at one or more locations. Selected methods and systems disclose objects constructed as awards, puzzles, other assembly challenges, educational challenges, wagering elements, electronic game elements, in multiple inseparable portions, and / or for other entertainment purposes.

Owner:NEVINS JOEL

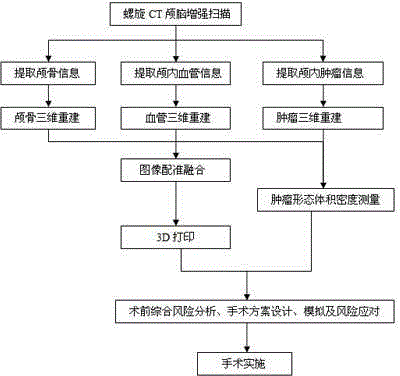

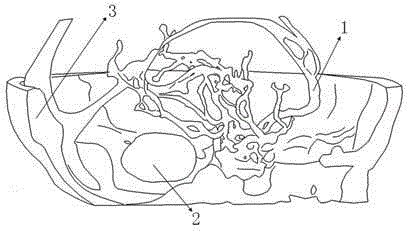

Intracranial tumor operation planning and simulating method based on 3D print technology

InactiveCN104091347AStereoscopic and intuitive anatomical basisHigh precisionImage analysisComputerised tomographsPersonalizationData information

The invention relates to an intracranial tumor comprehensive operation planning and simulating method based on the 3D print technology. DICOM data obtained through patient spiral CT craniocerebral enhancement scanning are utilized first, different partition methods are adopted for data information extraction and reconstruction according to characteristics of skulls, blood vessels and tumors, and registration and fusion of the skulls, the blood vessels and the tumors are achieved in the same coordinate system; craniocerebral entity models of patients are obtained through a rapid prototyping technology and a virtual three-dimensional geometrical model after optimizing processing is conducted; information of diameters, sizes and the number of tumors and adjacent relations between the diameters, the sizes and the number of tumors and important blood vessels and tissue around is extracted, and preoperative comprehensive risk analysis, operation plan design, operation plan simulation and operation risk response analysis are carried out on the basis of the craniocerebral entity models of the patients, personalized operation plans are provided for the patients in order to improve the accuracy and success rate of intracranial tumor excision operations, and a feasible intracranial tumor operation planning and simulating method based on the 3D print technology is explored.

Owner:刘宇清 +4

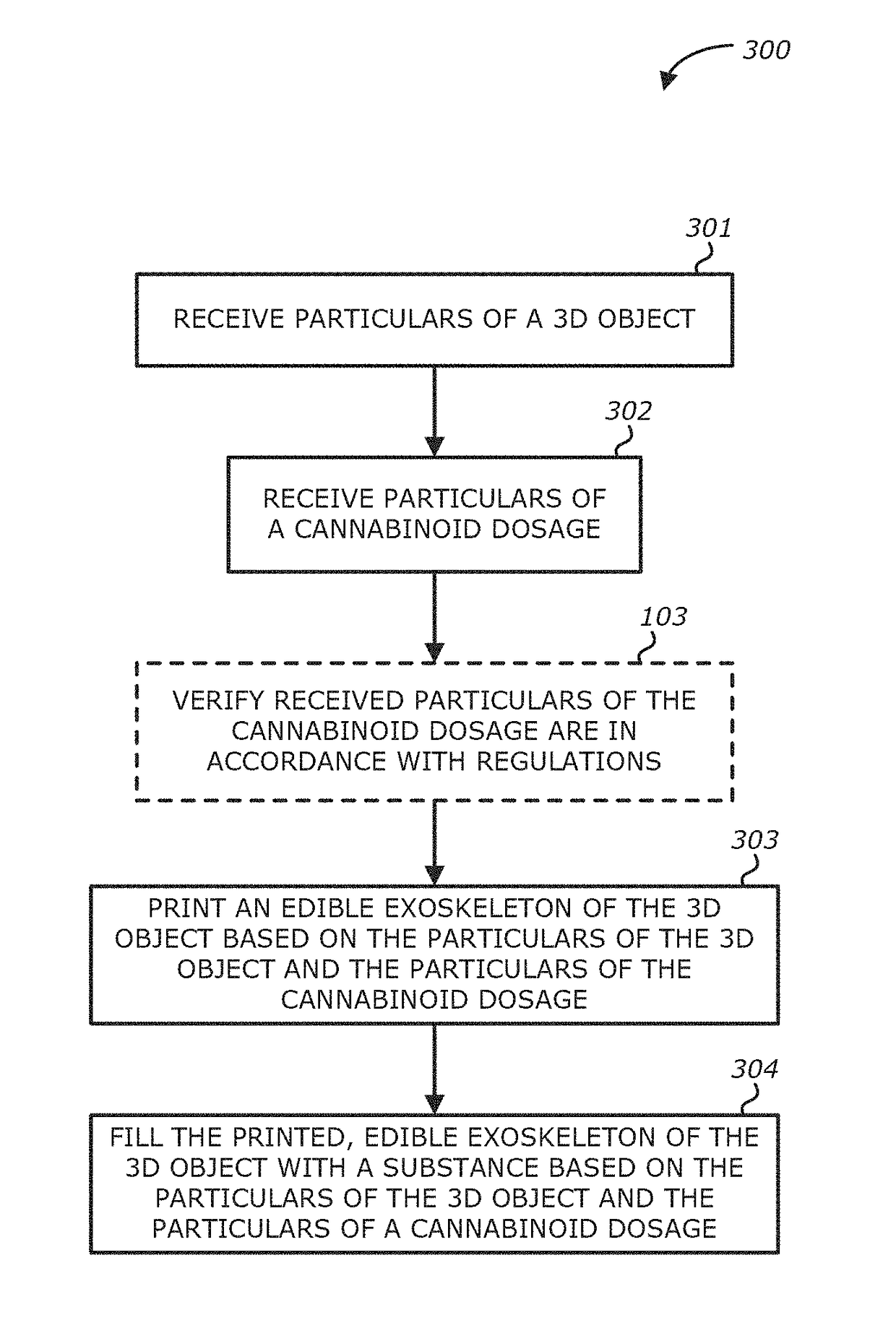

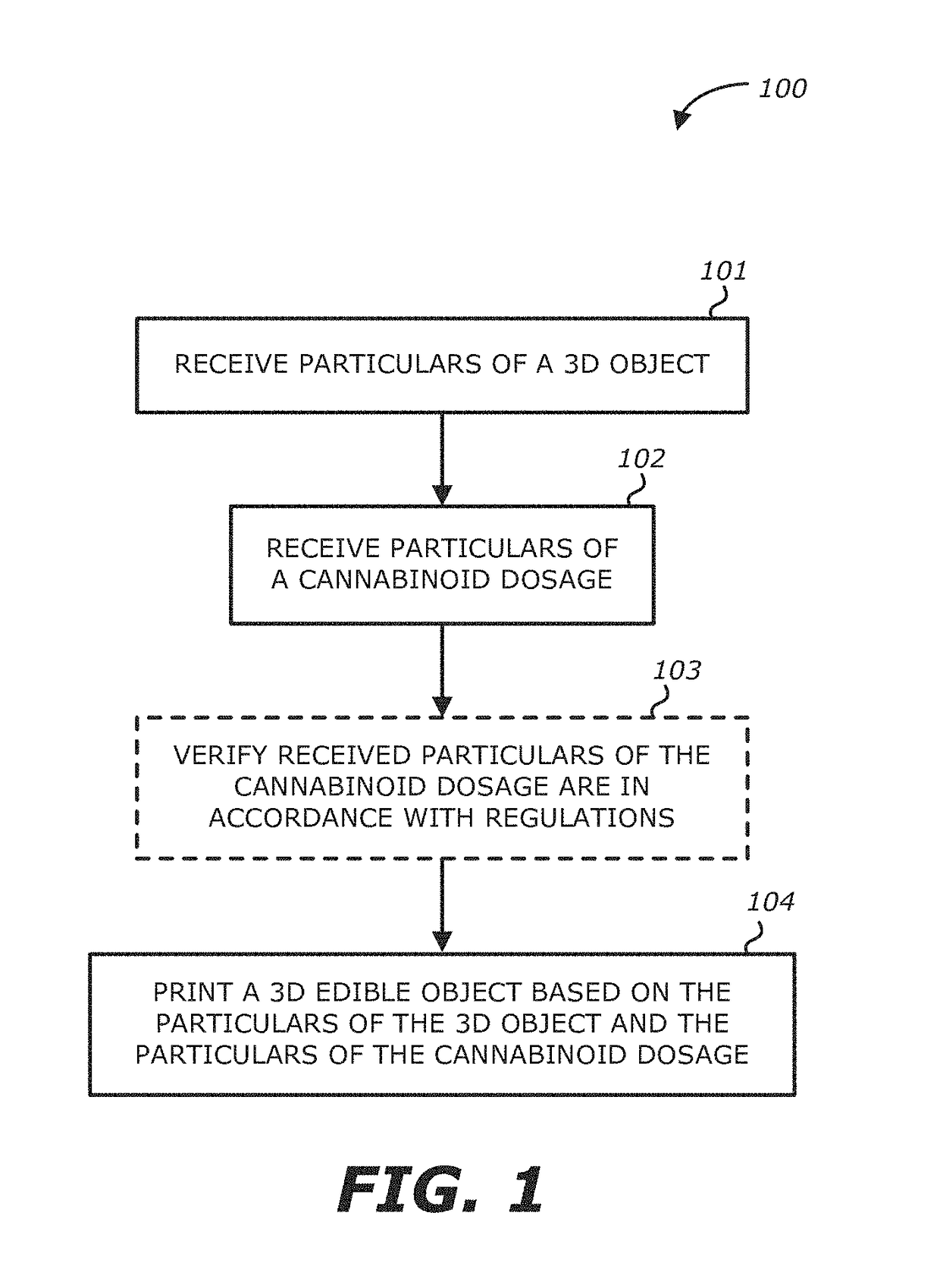

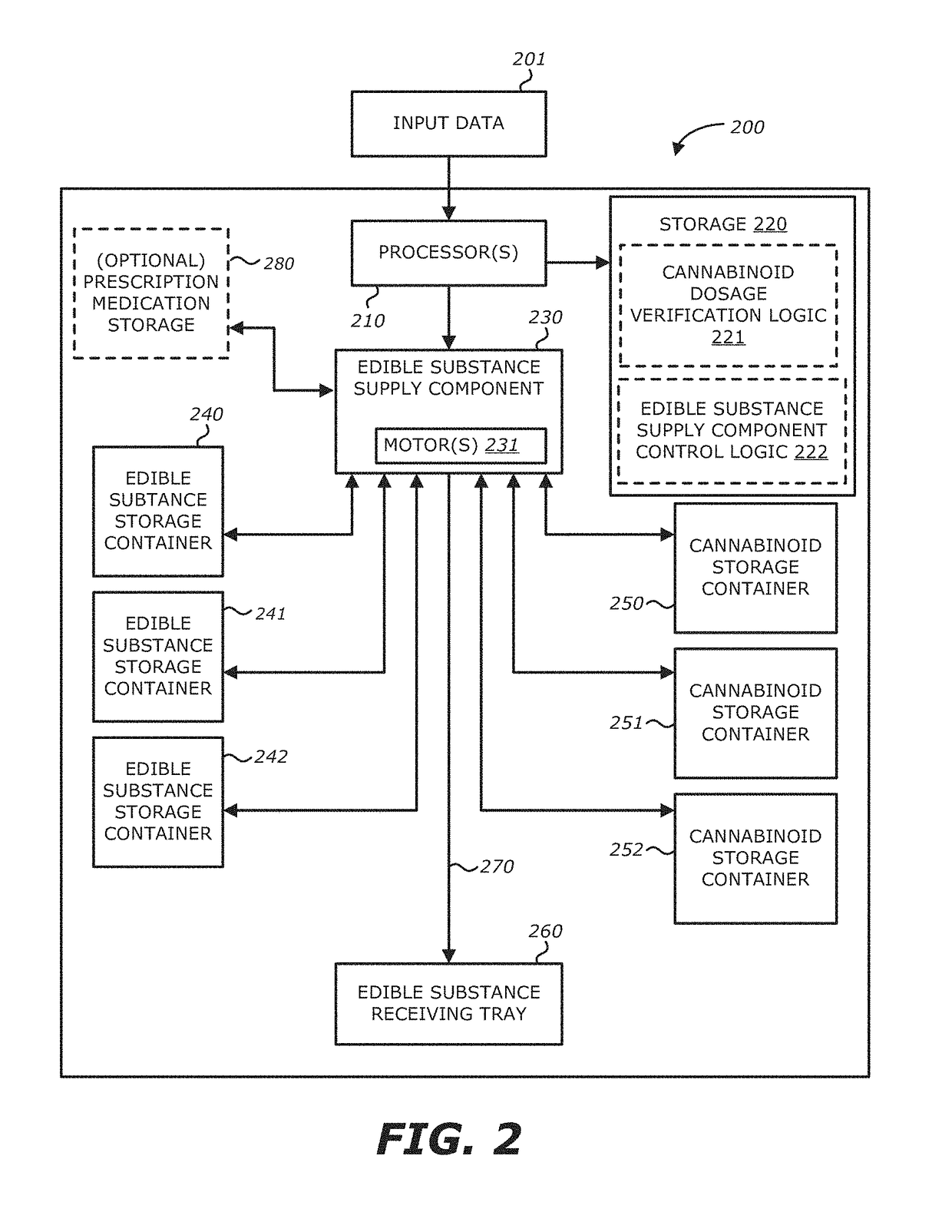

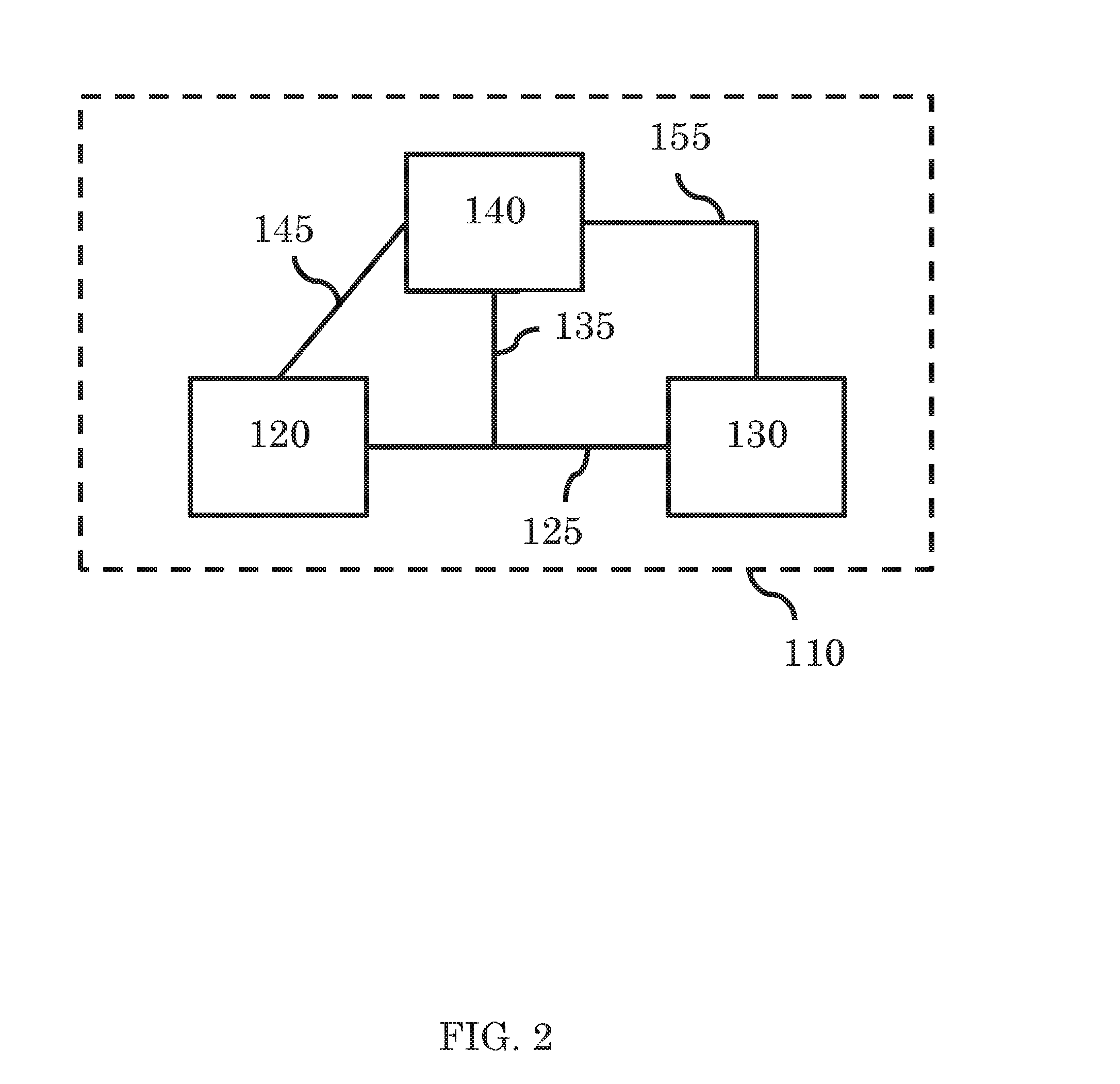

Method, system and apparatus for creating 3D-printed edible objects

InactiveUS9854828B2Additive manufacturing apparatusHydroxy compound active ingredientsObject basedCannabinoid

According to one embodiment, a system of using a three-dimensional (3D) printer to include a cannabinoid comprising: one or more extruders; one or more processors; and a storage module communicatively coupled to the one or more processors, the storage module comprises logic, upon execution by the one or more processors, that receives particulars of a 3D object; receives particulars of a cannabinoid dosage; and instructs the one or more extruders to print the 3D object based on the particulars of the 3D object and the particulars of the cannabinoid dosage, wherein at least a portion of the printed 3D object contains the type of cannabinoid described in the instructions of the particulars of the cannabinoid dosage, and the printed 3D object is edible is provided.

Owner:LANGELAND WILLIAM

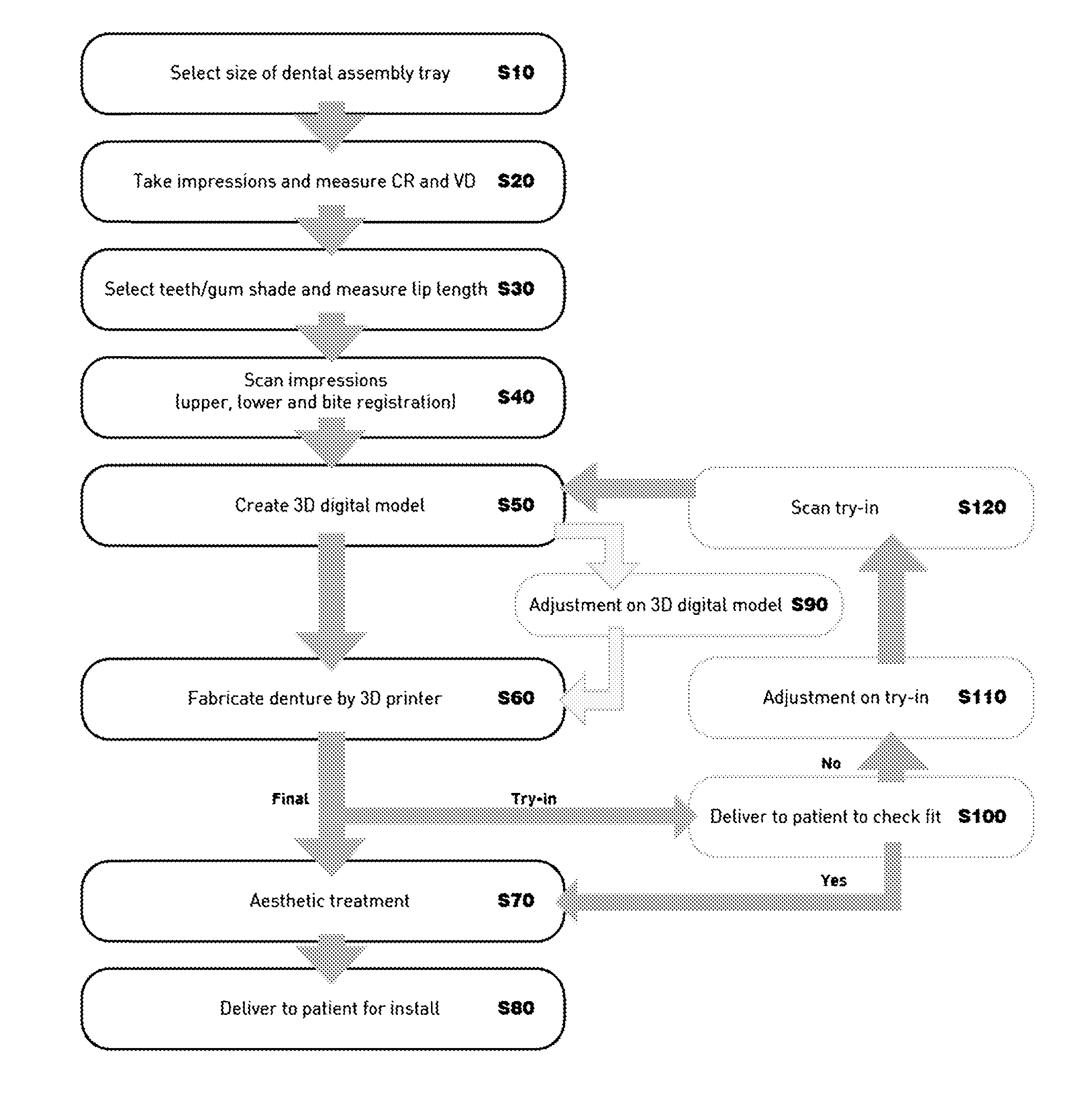

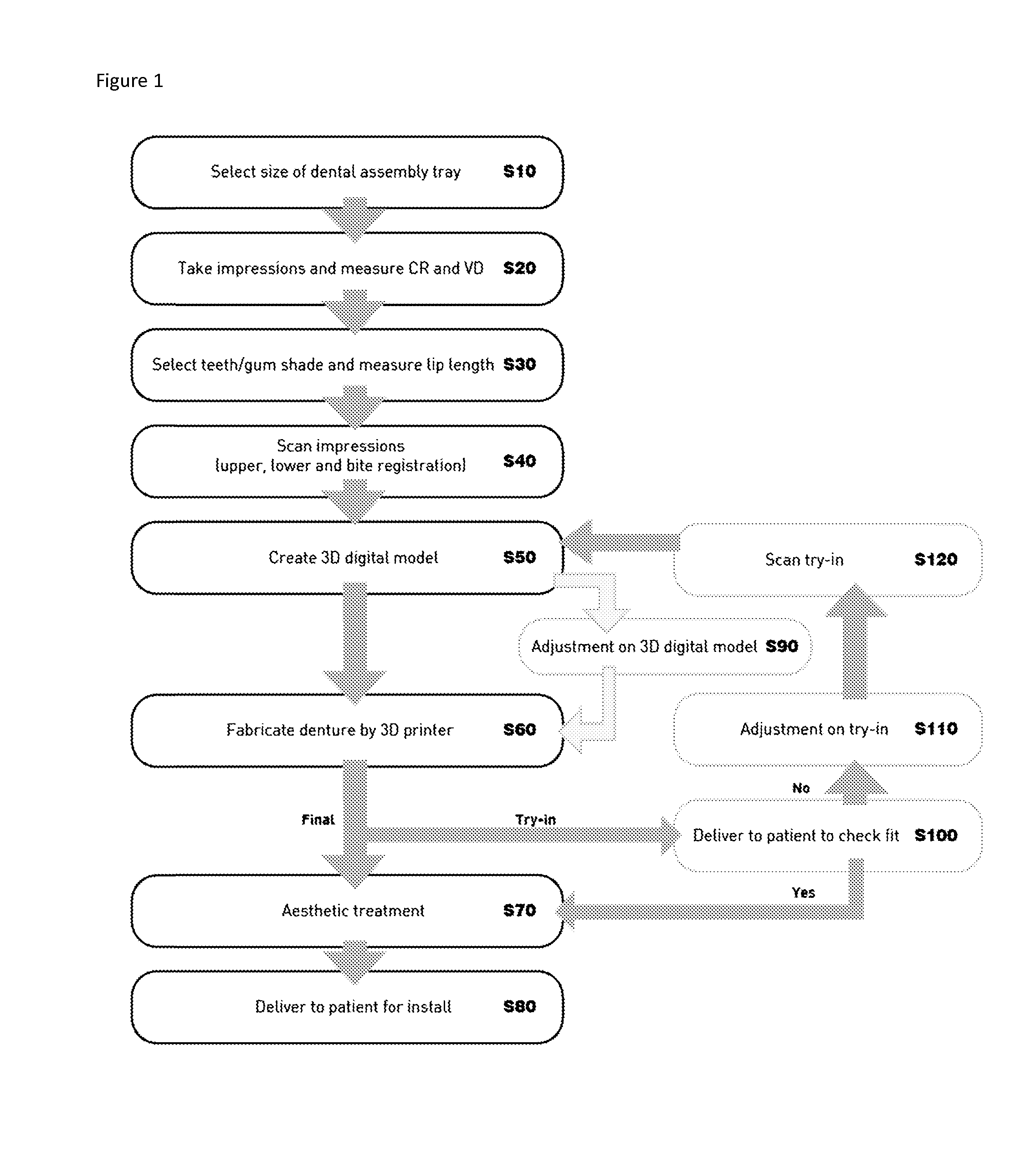

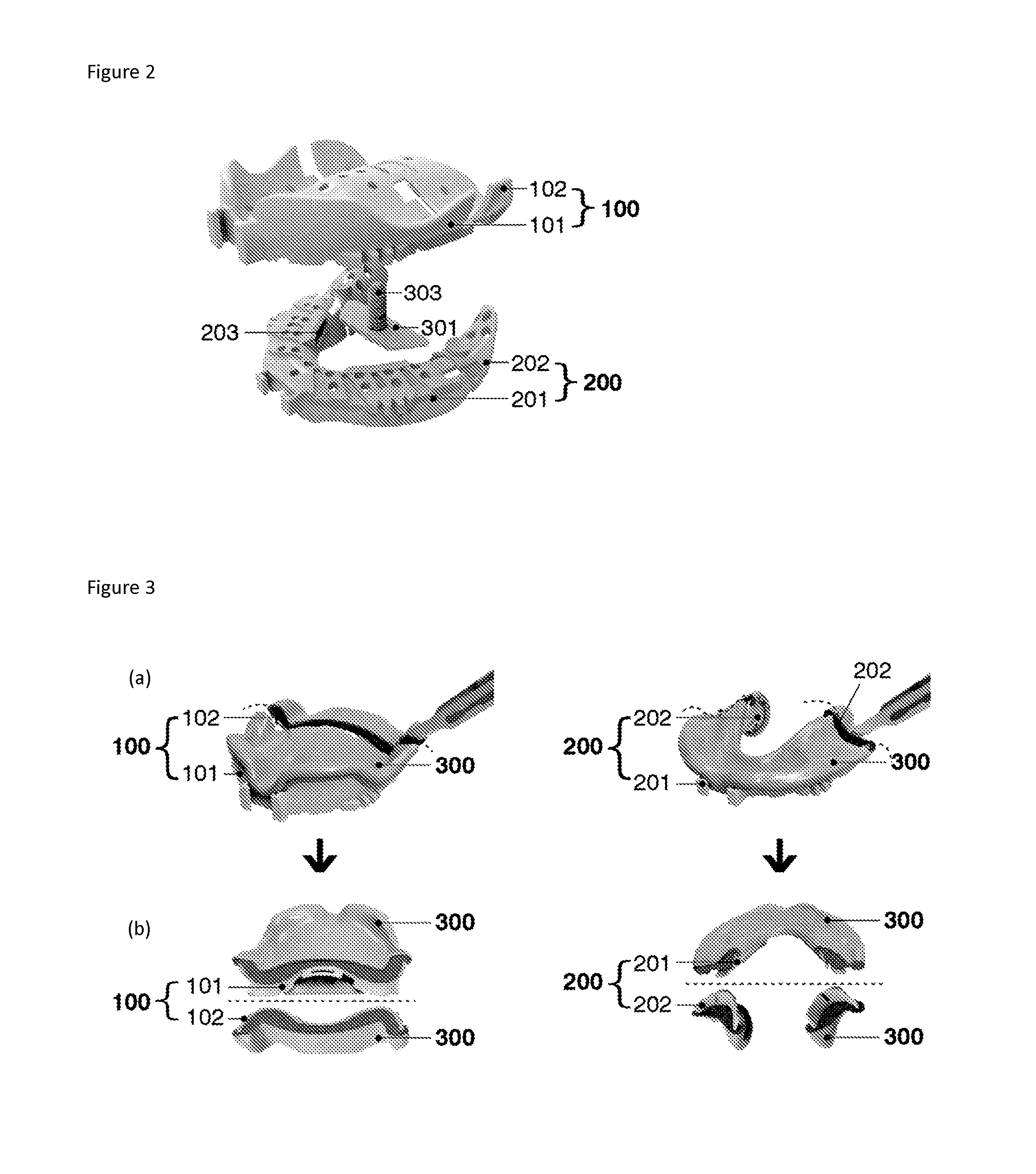

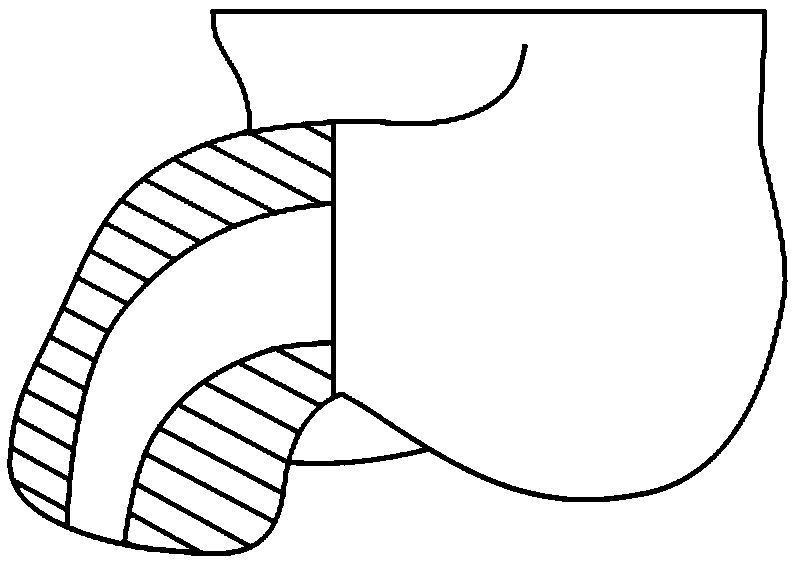

Method and apparatus for preparing removable dental prosthesis

ActiveUS20140308624A1Easy to operateAccurate manufacturing of a complete denture without intensive manual laborImpression caps3D printingSingle visit3d design

A method for manufacturing a removable dental prosthesis using a three-dimensional (3D) printer includes receiving dental impressions of a patient obtained using a dental impression tray assembly, the dental impressions including a bite registration and at least a mandibular impression or a maxillary impression; receiving information related to the patient's jaw relations obtained using the dental impression tray assembly, the jaw relations including a vertical dimension and a centric relation obtained during the patient's single visit to a dentist; scanning the received dental impressions with a 3D scanner to provide data representative of an edentulous shape of the patient; generating a 3D model of the dental prosthesis based on the data and the received information related to the patient's jaw relations using 3D design software; displaying the generated 3D model on a display, allowing customization of the 3D model; and 3D printing the dental prosthesis according to the 3D model.

Owner:DENTCA INC

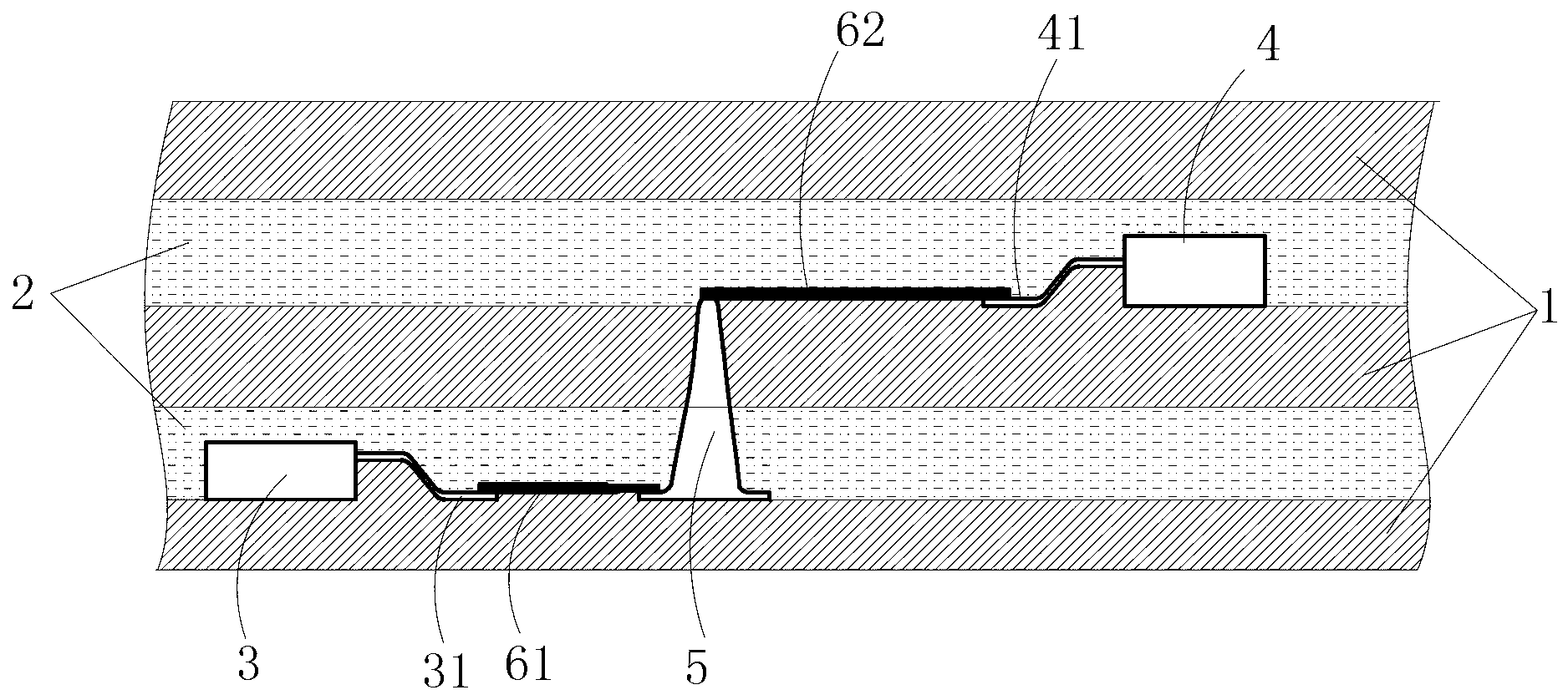

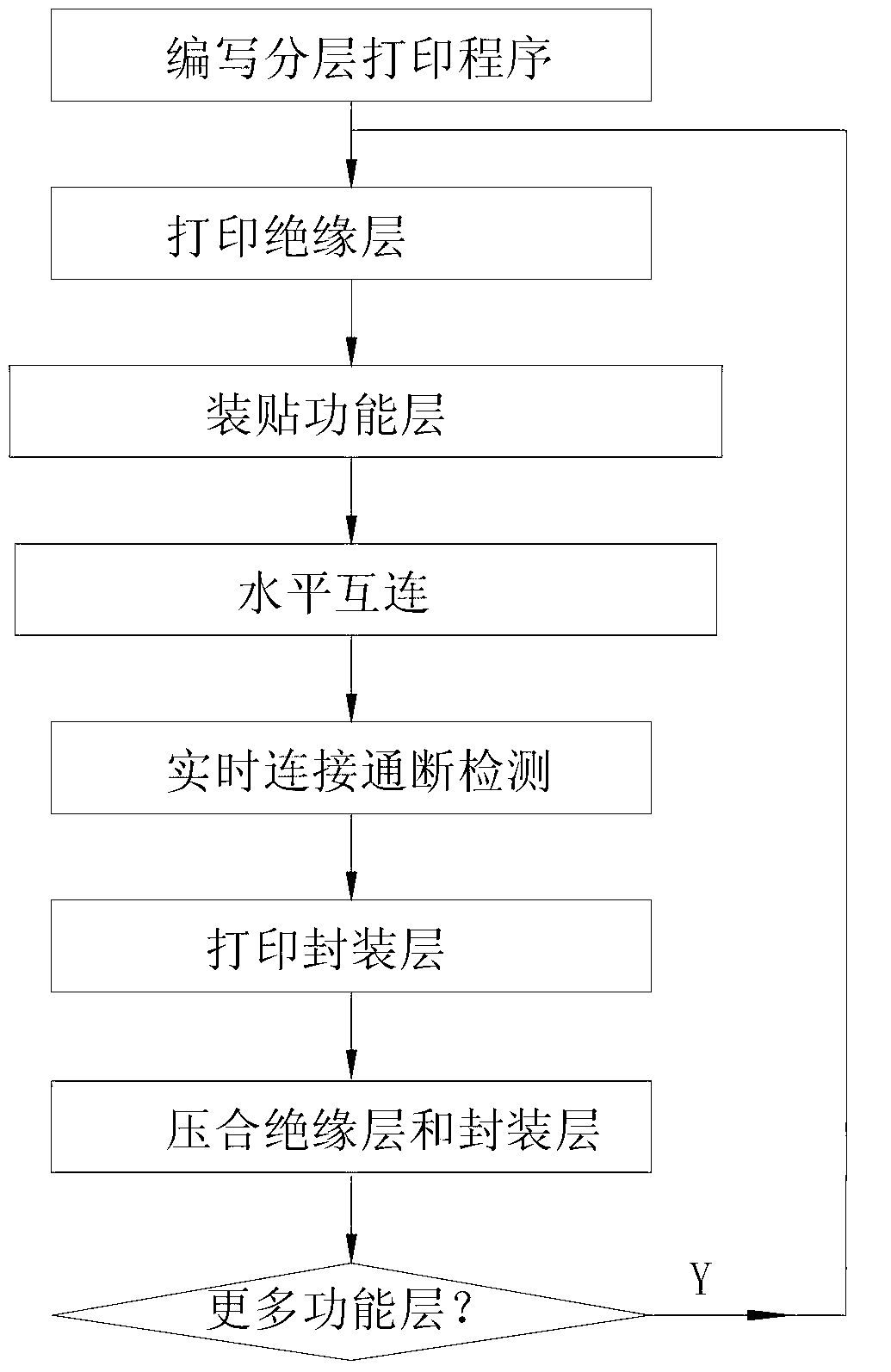

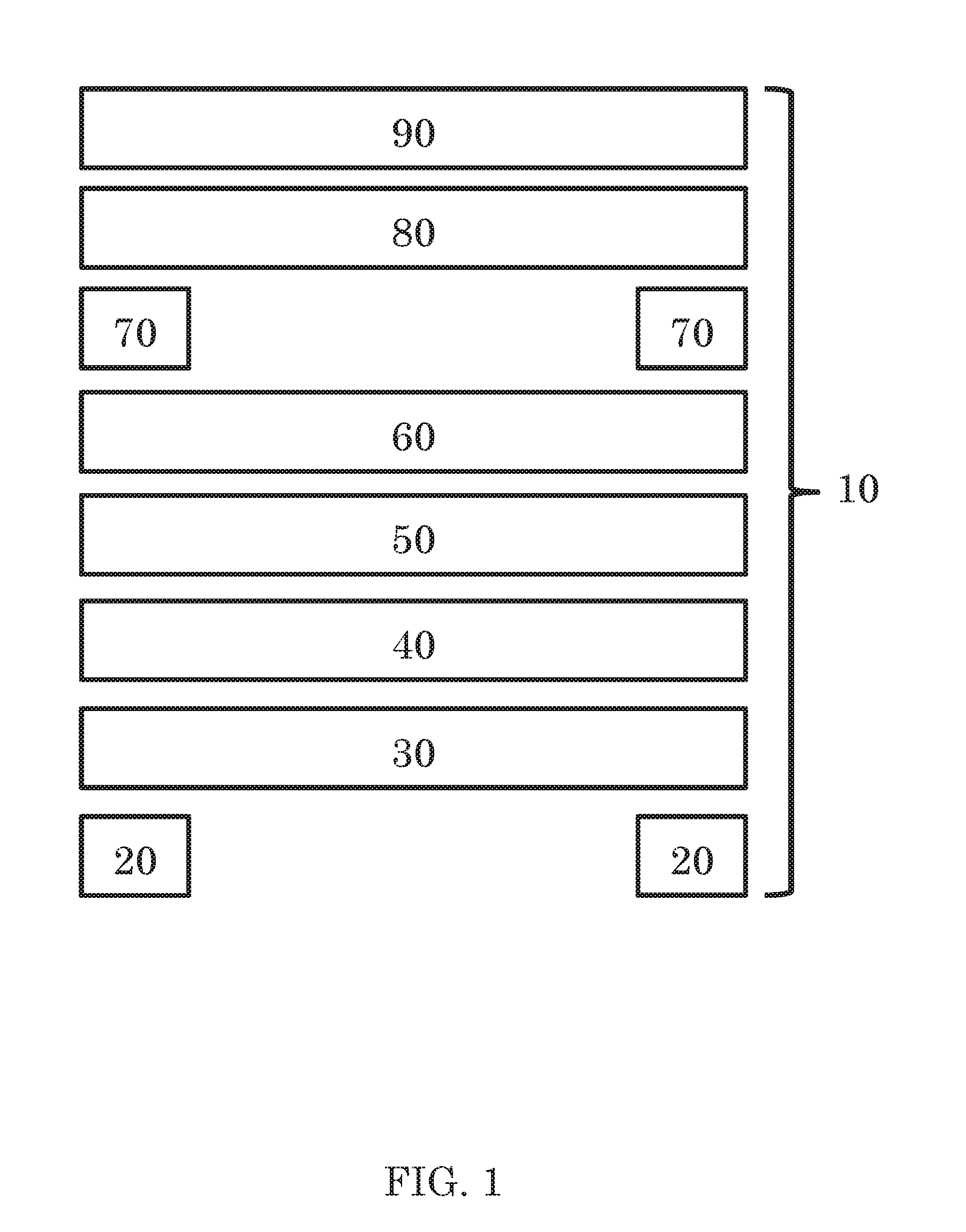

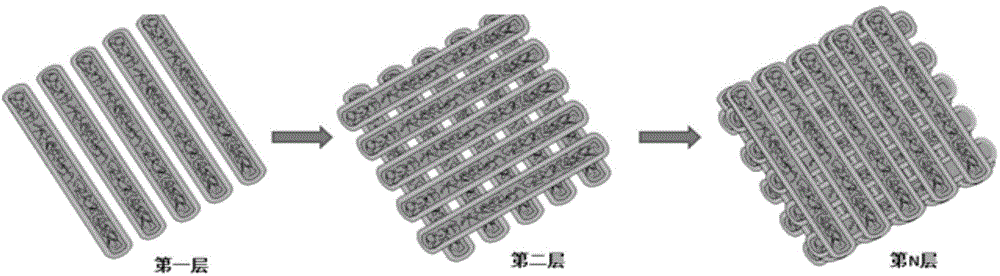

3D (Three Dimensional)-printing-based package substrate and manufacturing method thereof

InactiveCN103327741AChange the way of productionChanging manufacturing techniquesPrinted circuit assemblingAdditive manufacturing apparatusInsulation layerManufacturing technology

The application discloses a 3D (Three Dimensional)-printing-based package substrate and a manufacturing method thereof, which are based on re-examination on an existing package substrate (with multilayer circuit boards) and manufacturing methods of wiring layers of the package substrate. According to the application, an insulation layer and a package layer with complicated stereo structures are considered as a main body of the package substrate (with the multilayer circuit boards); passive / active electronic devices and electronic connection devices are embedded in the package layer; a lead, a guide pillar, a bonding pad and composite members with different structures are taken as the electronic connection devices, equally treated with the passive / active electronic devices and standardized. According to the technical scheme, almost all processes of the manufacturing of the wiring layer in the prior art are cancelled, and the production manner and the manufacturing technology of the package substrate (with the multiple circuit boards) are changed.

Owner:数驱技术有限公司

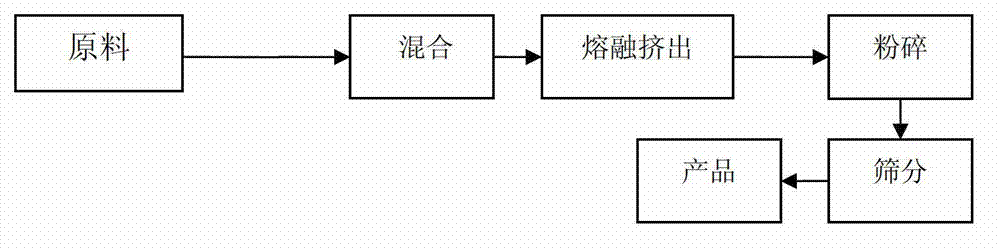

Three-dimensional printing forming material with toughness and high adhesive property and preparation method thereof

The invention discloses a three-dimensional printing forming material with toughness and high adhesive property. The three-dimensional printing forming material comprises a powder material and an adhesive material and is characterized in that the powder material comprises the following components in parts by weight: 40-85 parts of polyamide resin, 5-40 parts of pigments, 5-30 parts of filler, 1-6 parts of pigment and filler dispersing and wetting aid, 0.1-1.5 parts of flatting agent and 0.1-0.5 part of degassing agent; the adhesive material comprises the following components in parts by weight: 60-95 parts of epoxy resin, 5-40 parts of filler, 1-10 parts of toughening agent, 0.1-1.5 parts of flatting agent, 1-4 parts of pigment and filler dispersing and wetting aid, 0.1-0.5 part of degassing agent and 0.1-0.5 parts of powder flowing aid; and when the three-dimensional printing forming material is used, 1 part by weight of powder material and 0.01-0.5 part by weight of adhesive material are cooperatively used. A solid component printed by using the material disclosed by the invention has the advantages of higher adhesion strength and firmness, good flexibility and scratching resistance.

Owner:ZHONGSHAN POLYTECHNIC

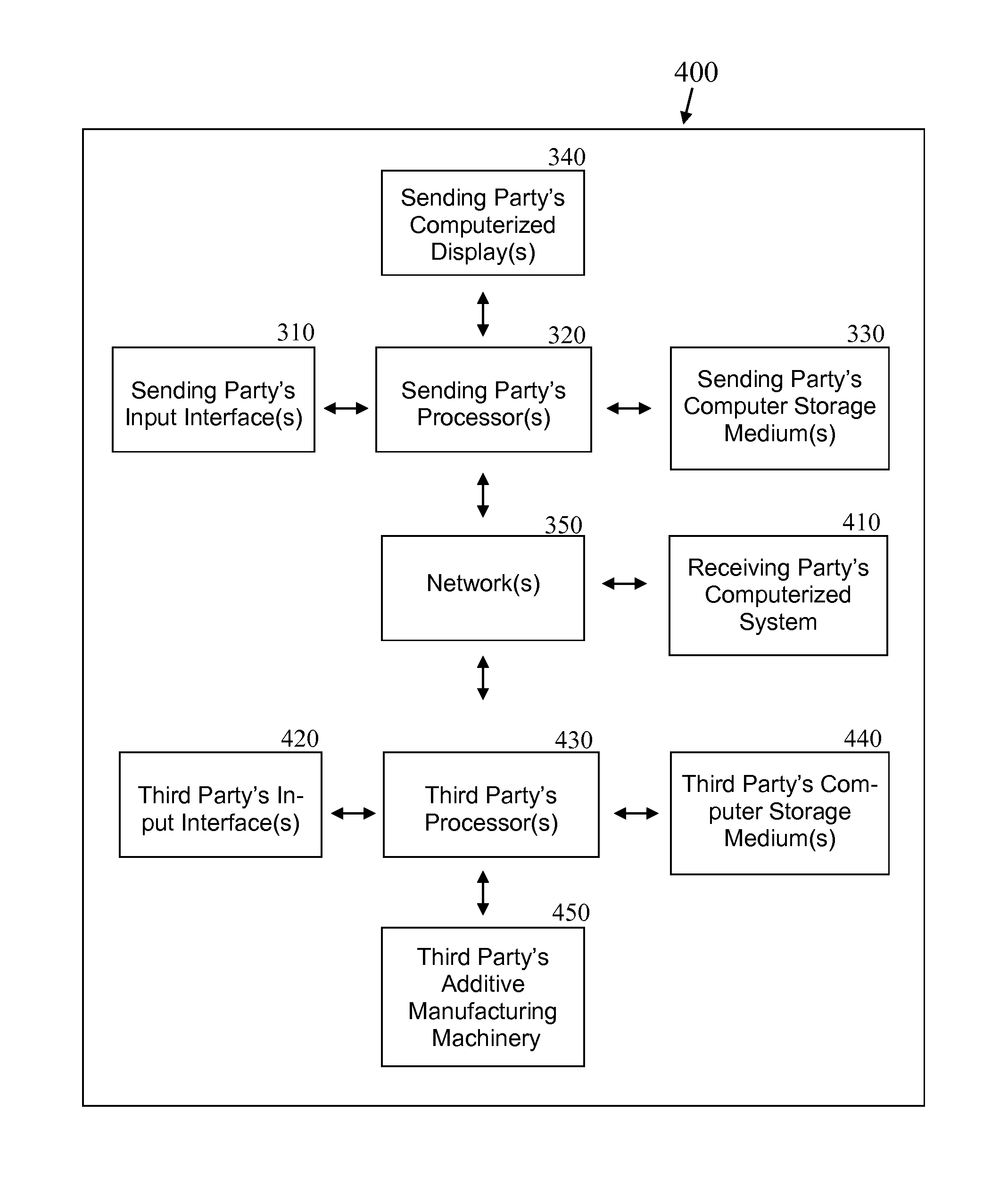

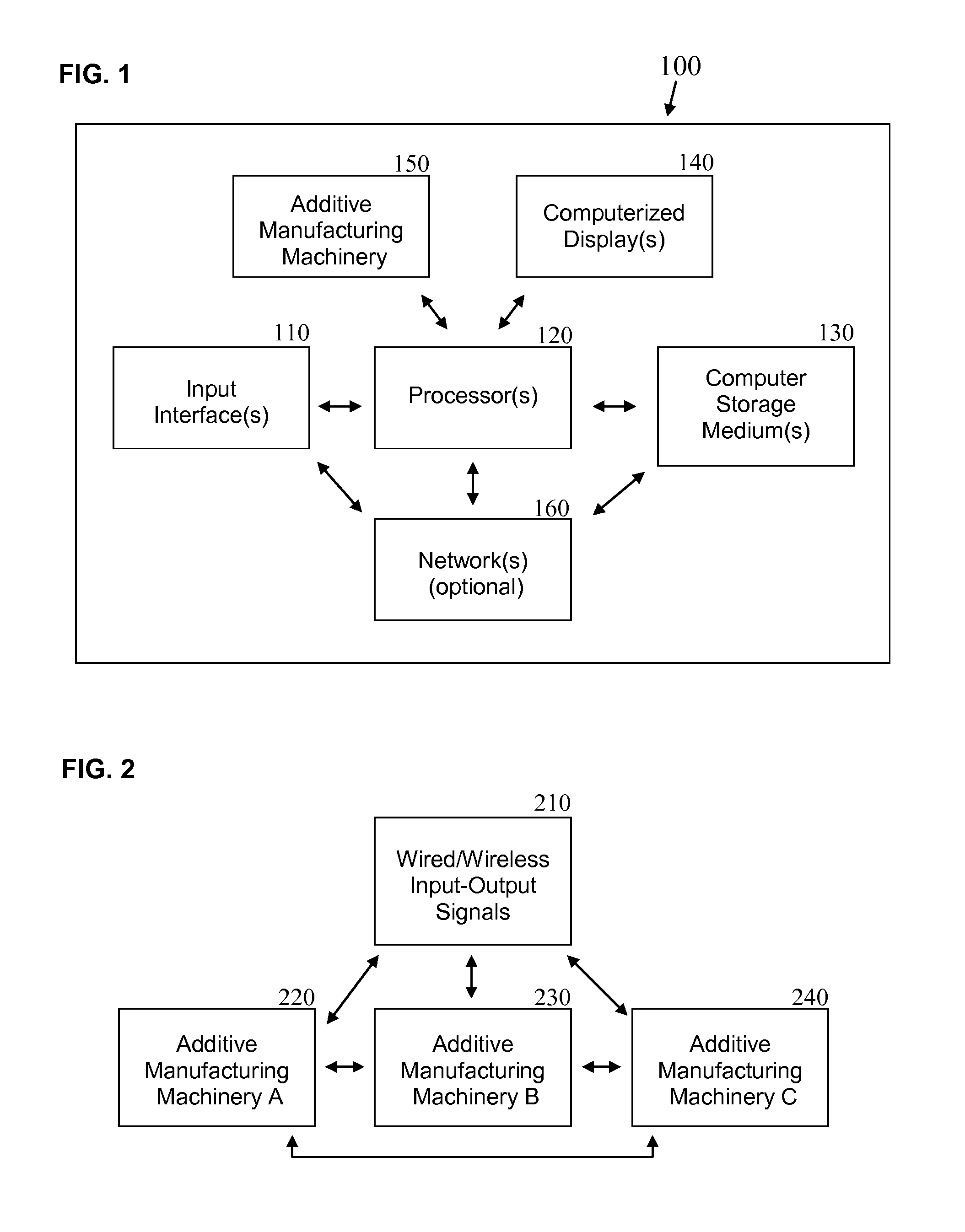

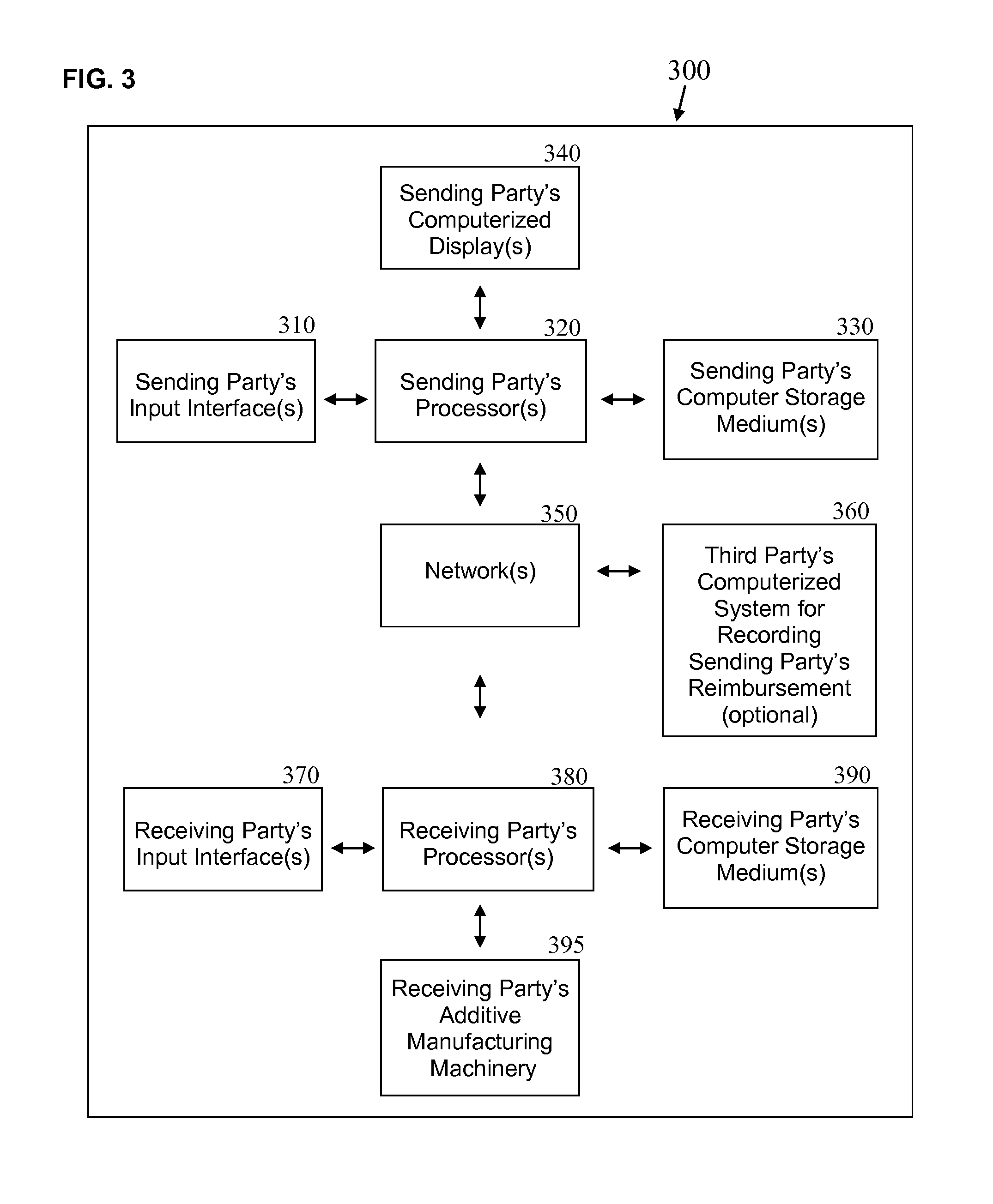

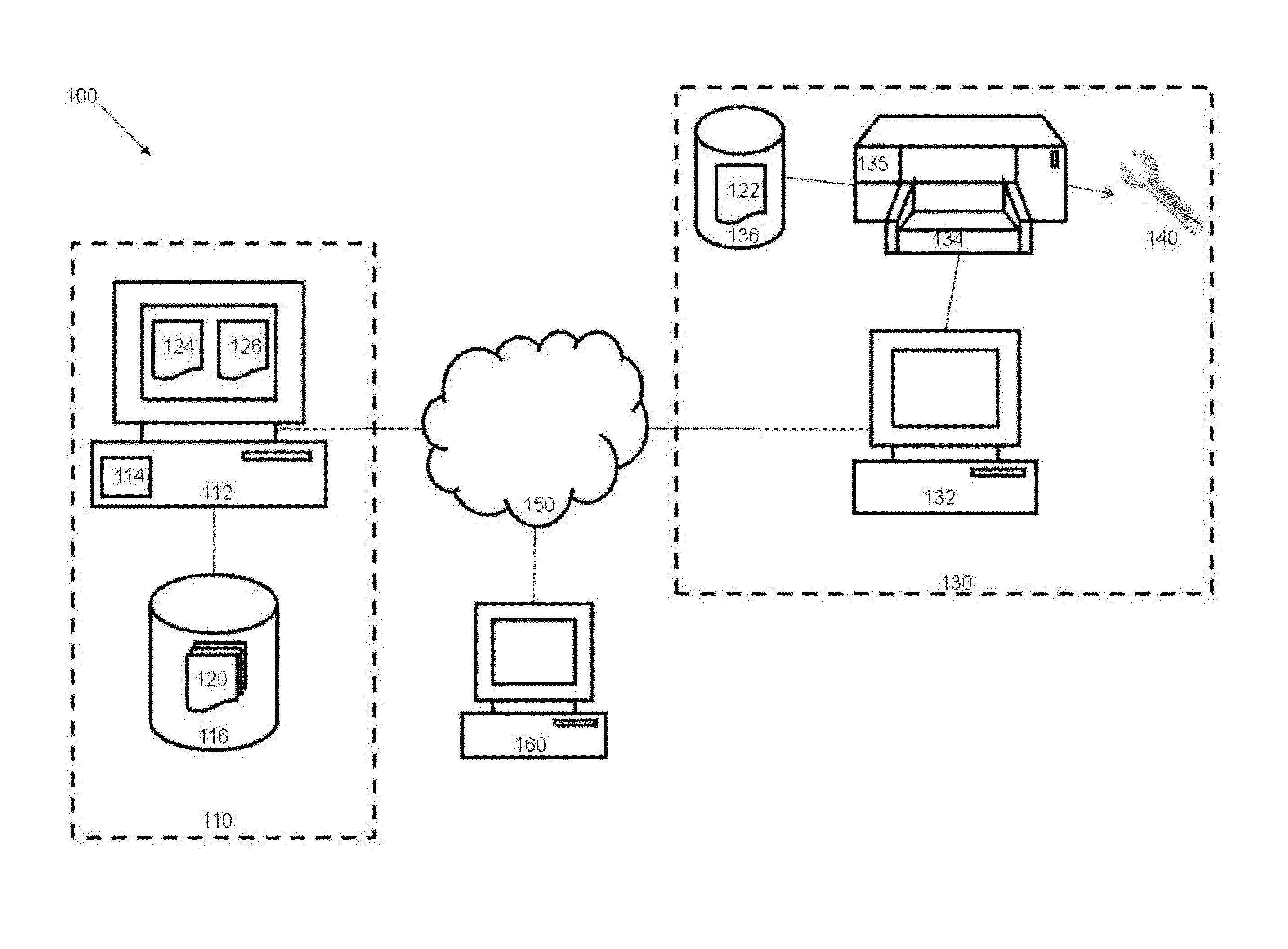

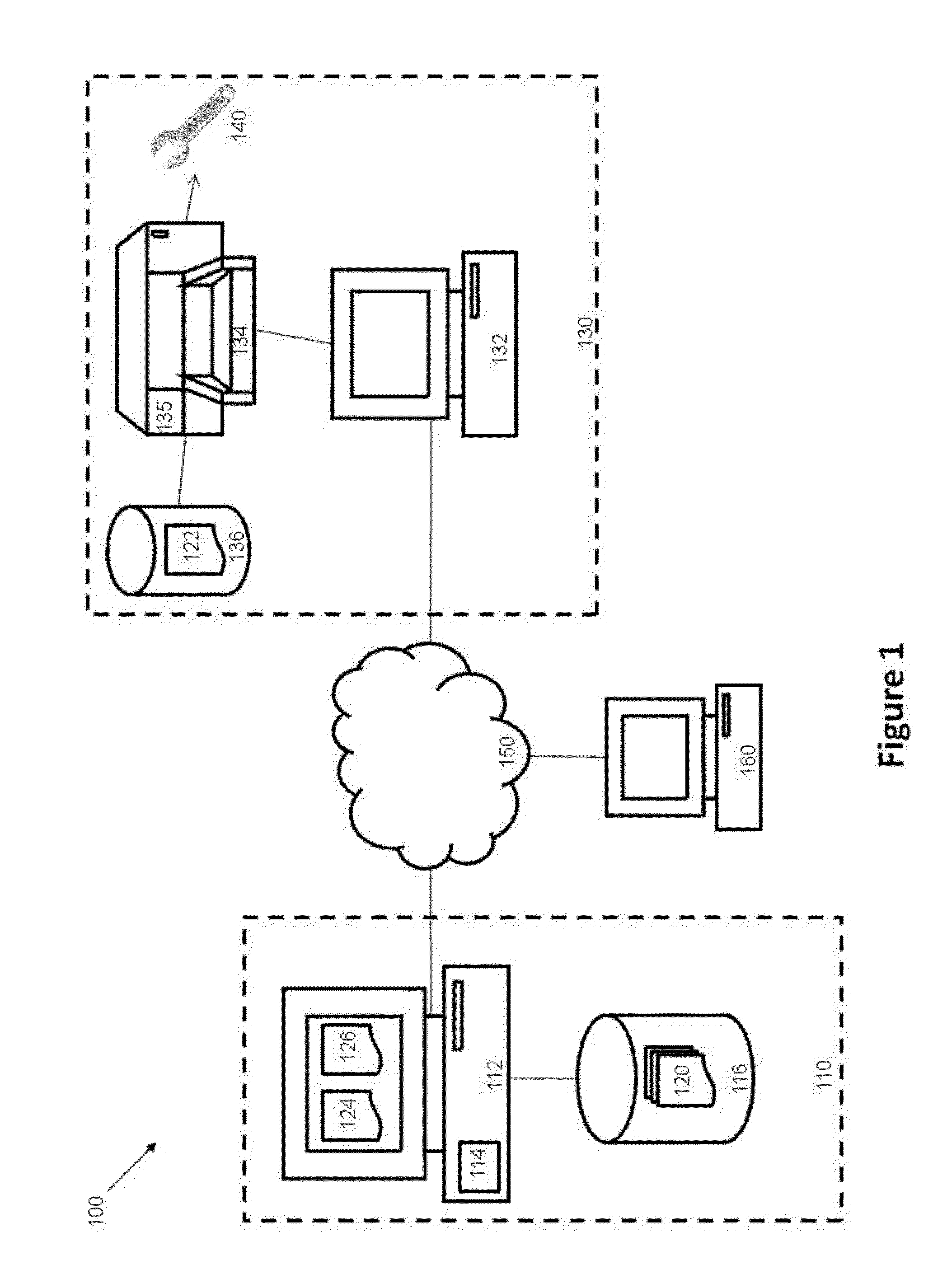

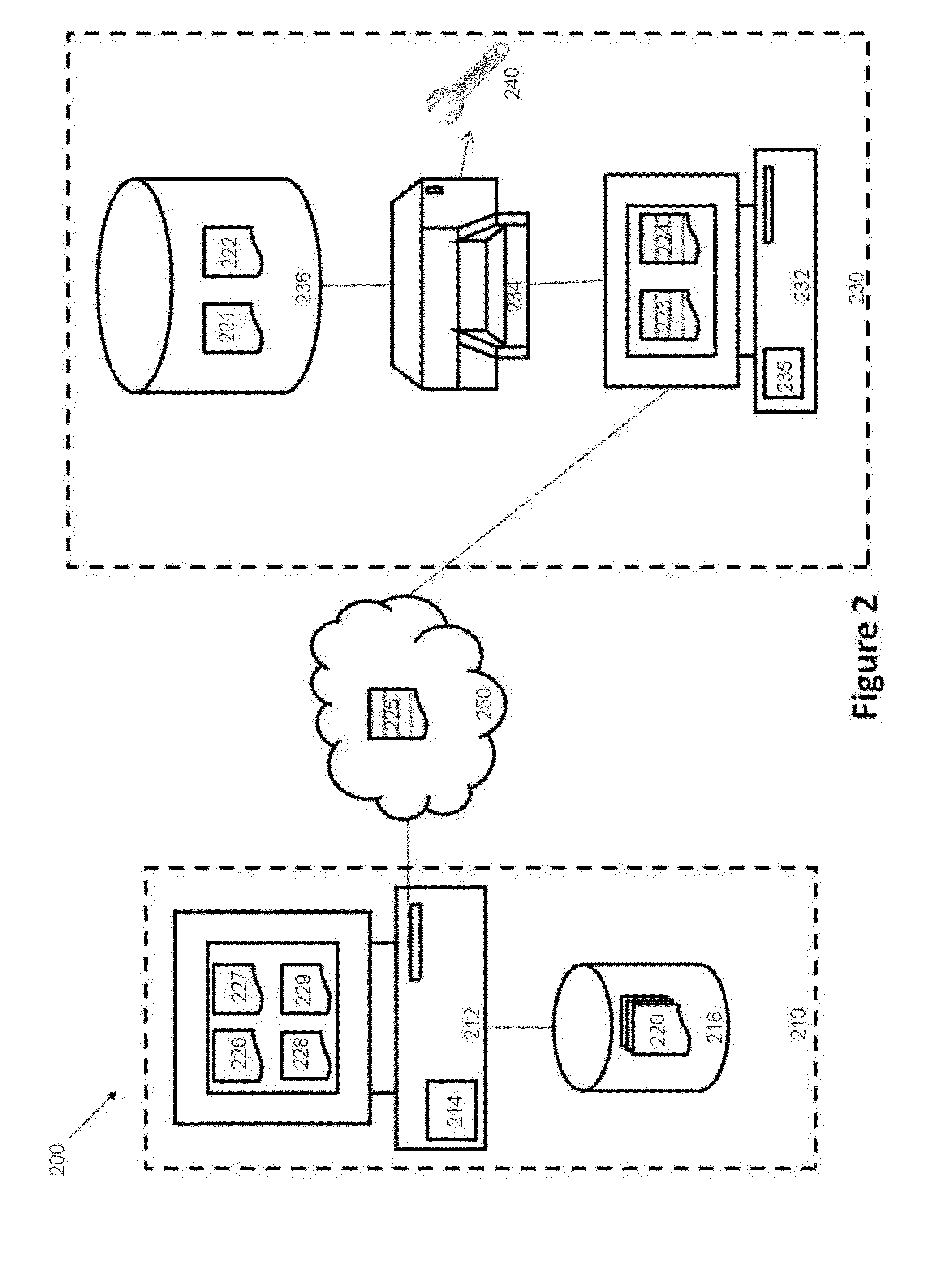

Secure Management of 3D Print Media

InactiveUS20130235412A1Additive manufacturing apparatusComputer security arrangements3d printedDatabase

A system for printing 3D objects protects a 3D object file from being copied by separating the file into a series of instructions for printing the 3D object and sends those instructions piecemeal to a printing facility. The system enforces a methodology that forces the print facility to delete a previous set of instructions before the print facility can receive the next set of instructions to print a 3D object. By using such a system, the print facility never has the entire 3D print file in memory, preserving the rights of the creator of the 3D print file.

Owner:BUILD NETWORKS LLC

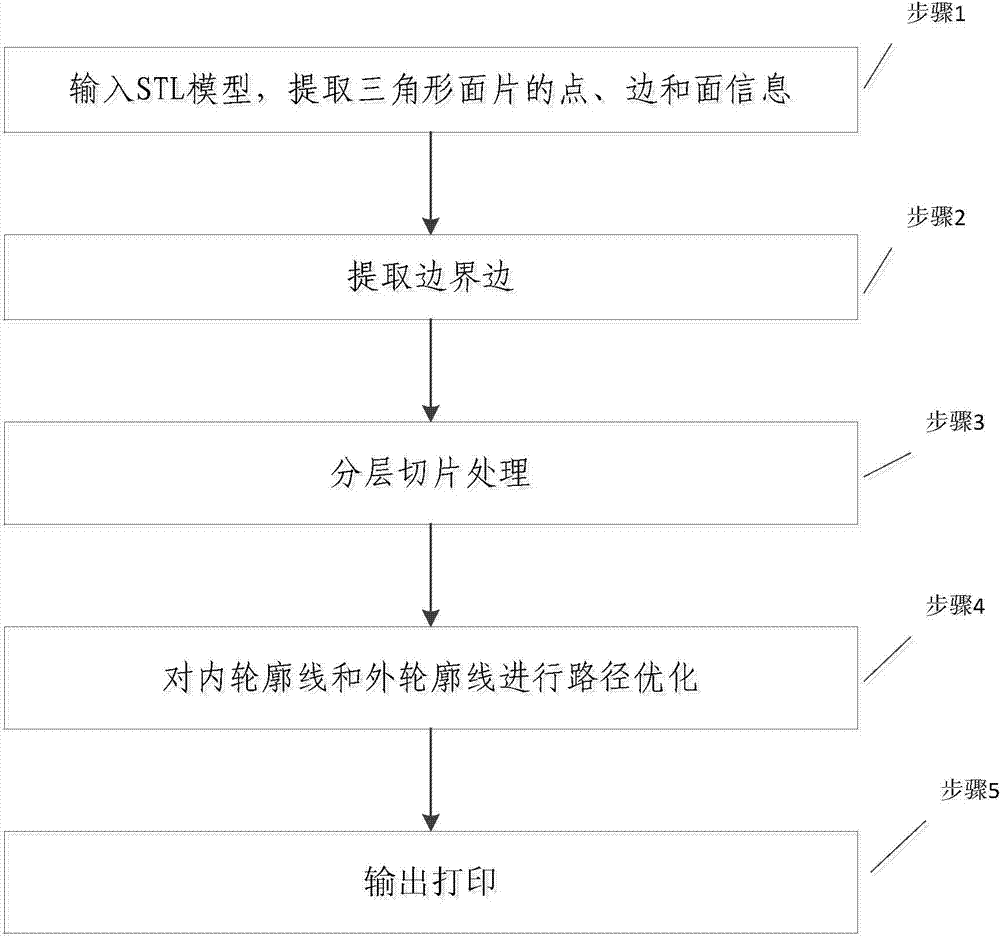

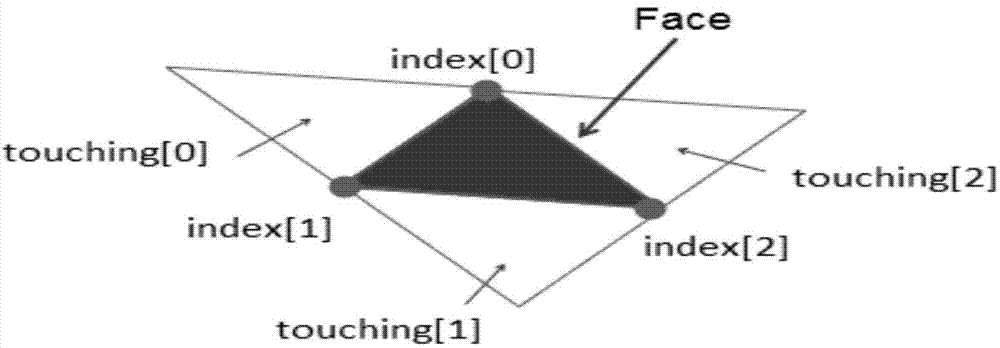

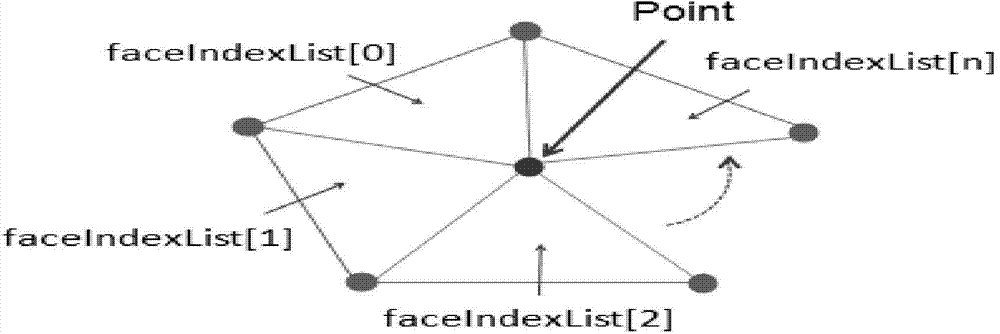

Slicing processing method aiming at non-closed STL model with boundaries

InactiveCN104331555ATroubleshoot slice handling issuesImprove molding efficiencySpecial data processing applicationsComputer graphics (images)3d printer

The invention discloses a slicing processing method aiming at a non-closed STL model with boundaries for a 3D (three-dimensional) printer. The method comprises the following steps that point, edge and surface information of triangles in an STL model are extracted, and in addition, the topology relationship among the point, edge and surface information is built; all boundary edges are extracted according to the boundary edge judging rule; lamination slicing processing is carried out on non-closed lattices to obtain non-closed 2D polygons; printable inner and outer contour lines obtained after the deflection processing on the polygons are subjected to path optimization for reducing idle strokes; a slicing file is used for outputting universal Gcode files which are read and printed by the 3D printer. The invention provides the slicing method aiming at non-closed STL model input from the boundary extraction aspect for the first time, and breaks through the limitation that the traditional 3D printer can only carry out the slicing processing on the closed STL model, and the slicing processing on the non-closed STL model with the boundaries is realized, so that the non-closed STL model can be directly printed and formed.

Owner:上海极臻三维设计有限公司

Manufacturing process for 3D printed objects

ActiveUS20140336808A1Additive manufacturing apparatusComputer aided designComputer graphics (images)3d printed

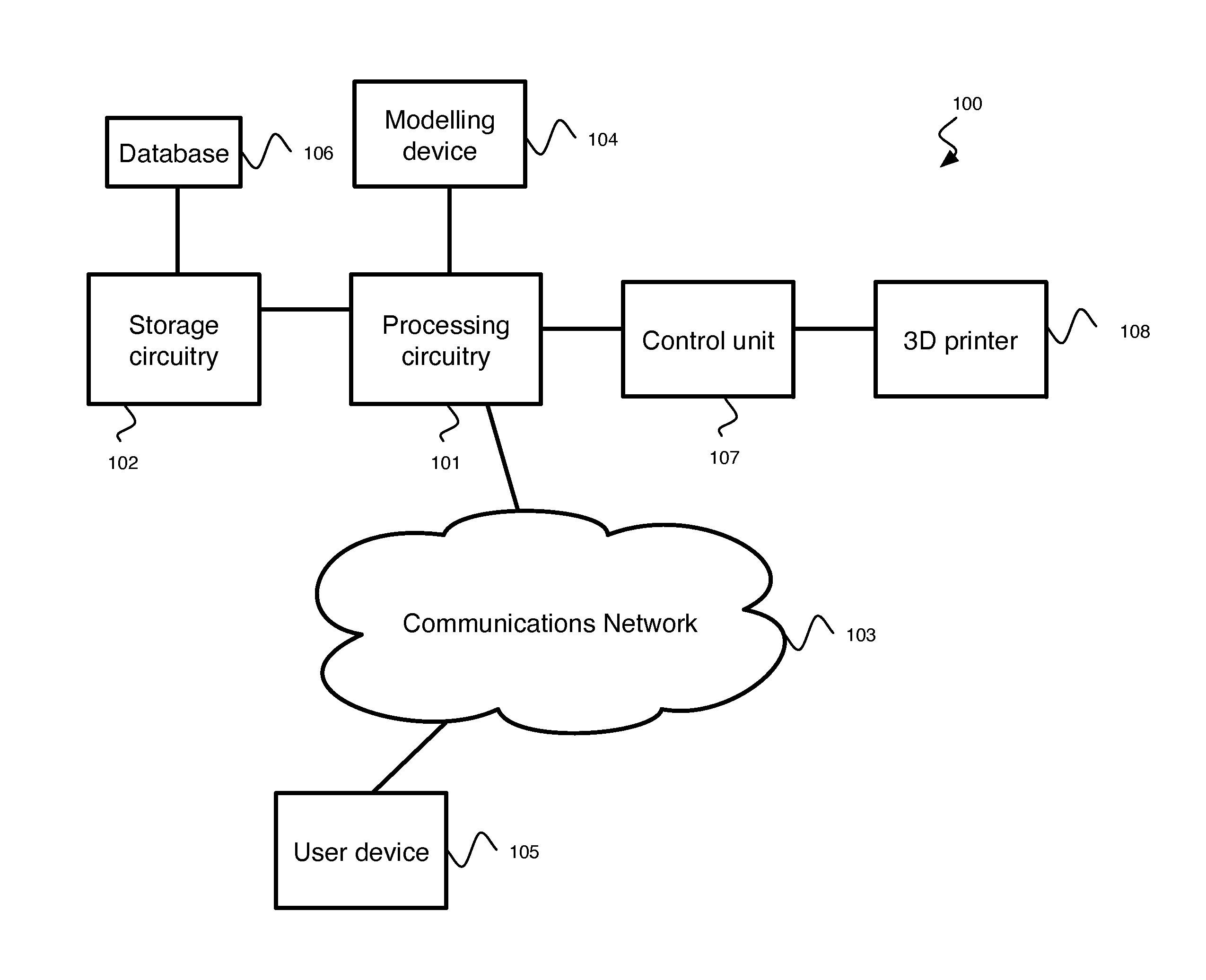

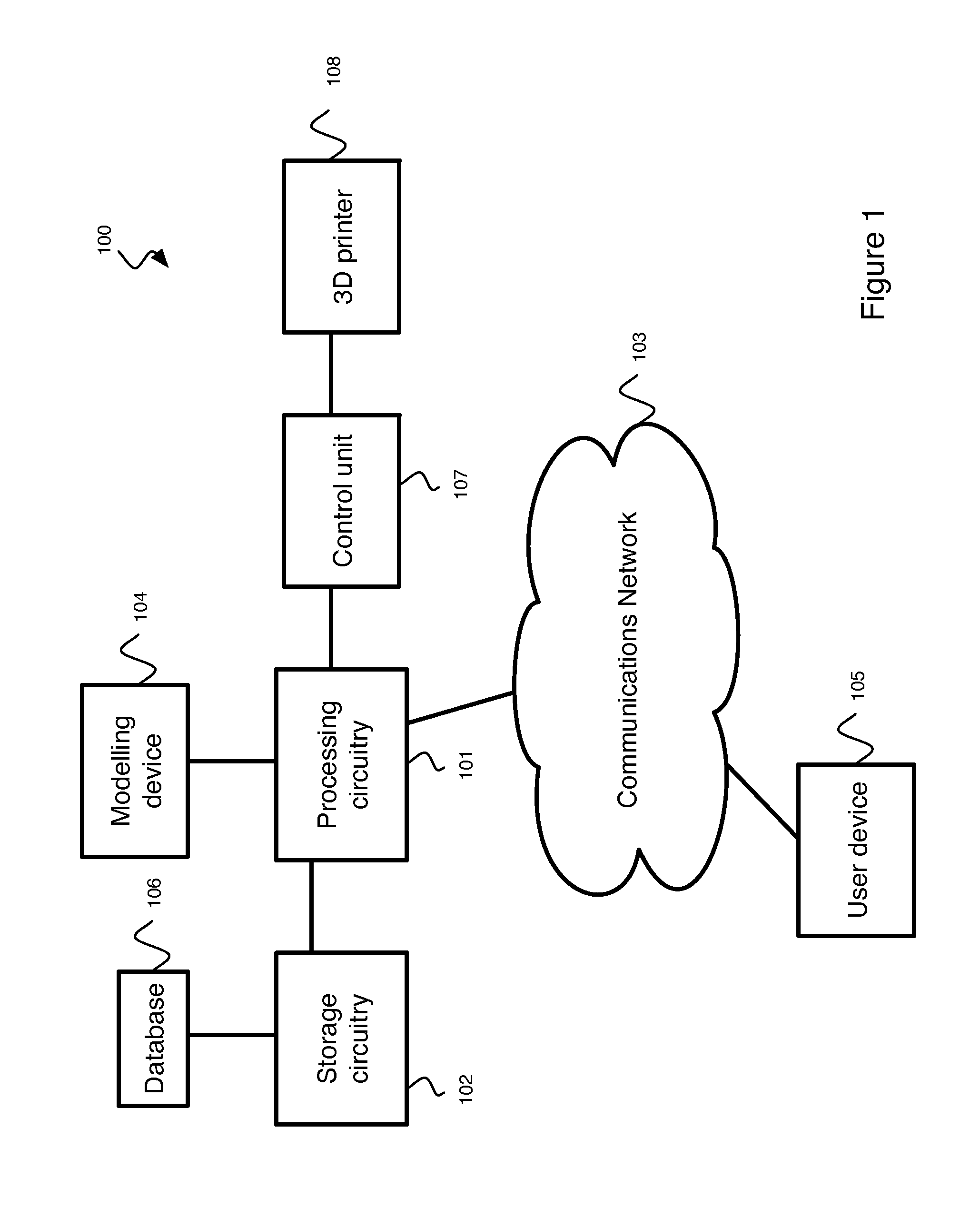

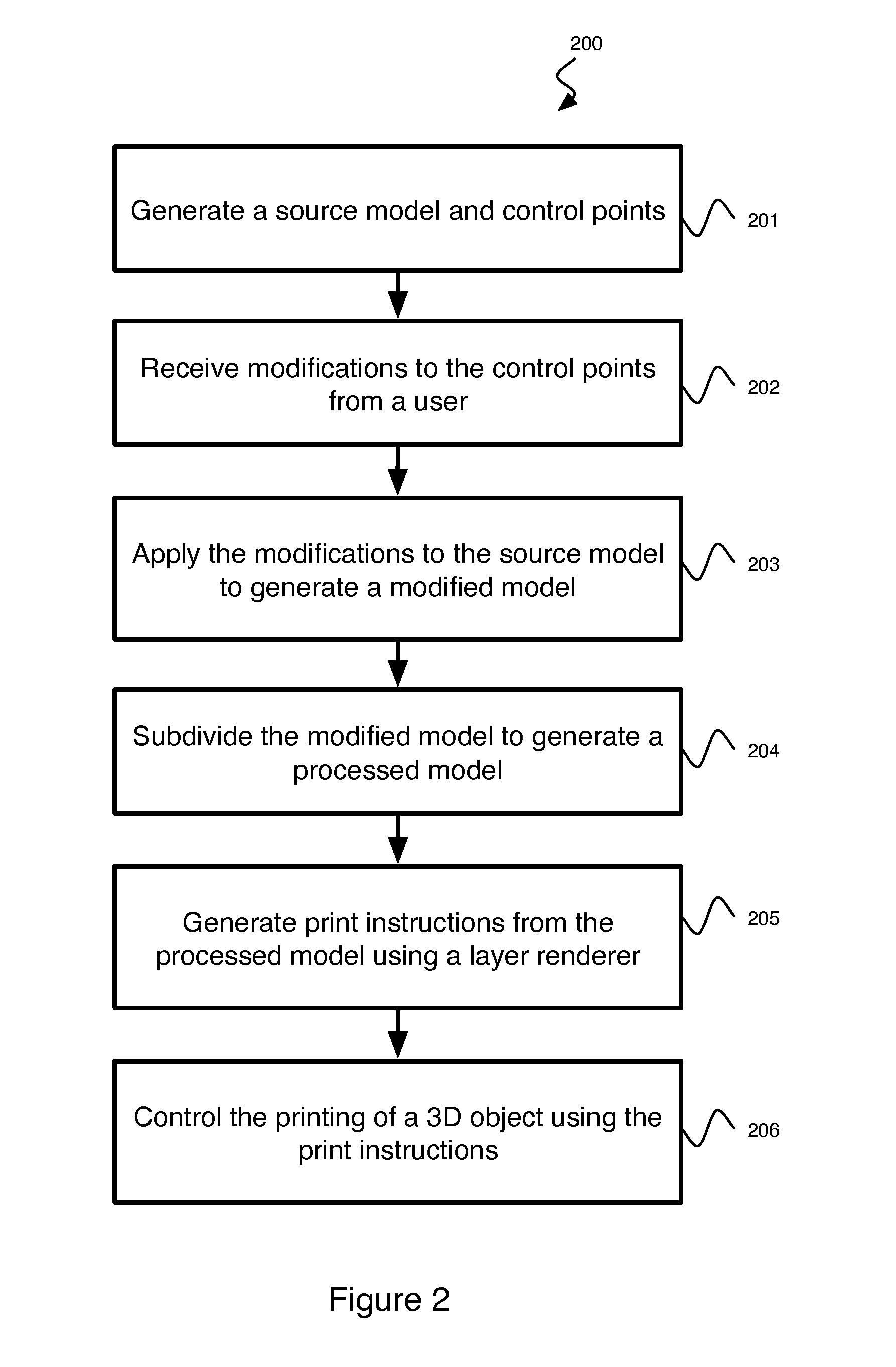

The present invention relates to a computer-implemented method of manufacturing customised 3D objects. The method includes retrieving a source model for a 3D object and a plurality of defined control points for the 3D object from a database; receiving modifications to at least some of the control points from a first user; automatically applying the modifications to the source model to create a modified model; and automatically generating print instructions for manufacture of a customised version of the 3D object. A system and 3D models generated by the method are also disclosed.

Owner:DISNEY ENTERPRISES INC

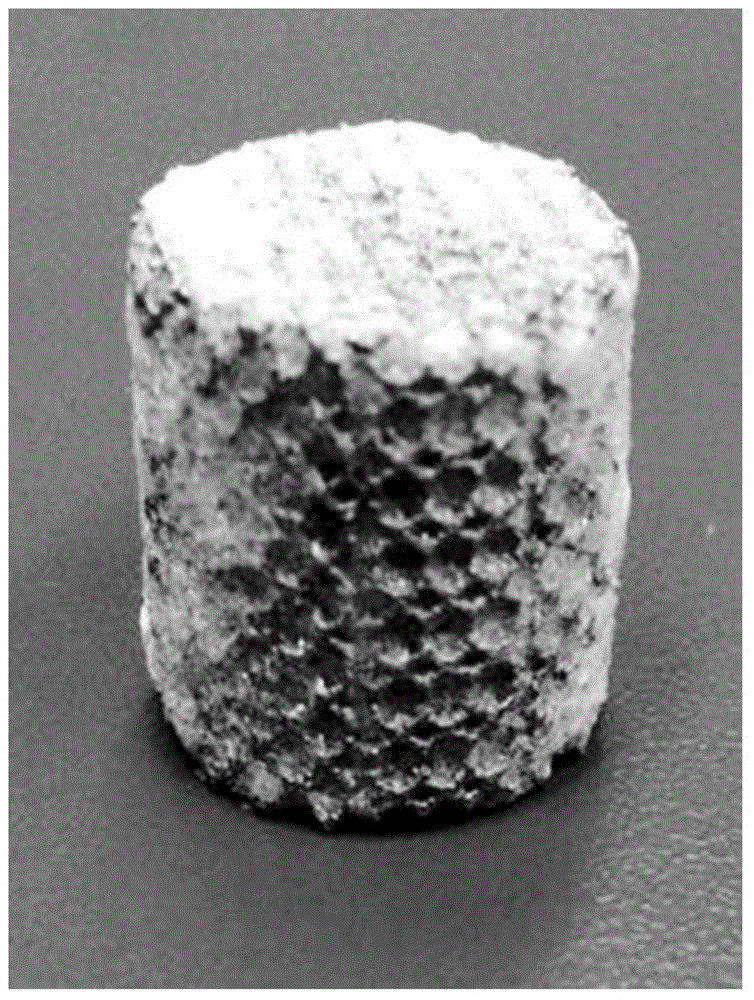

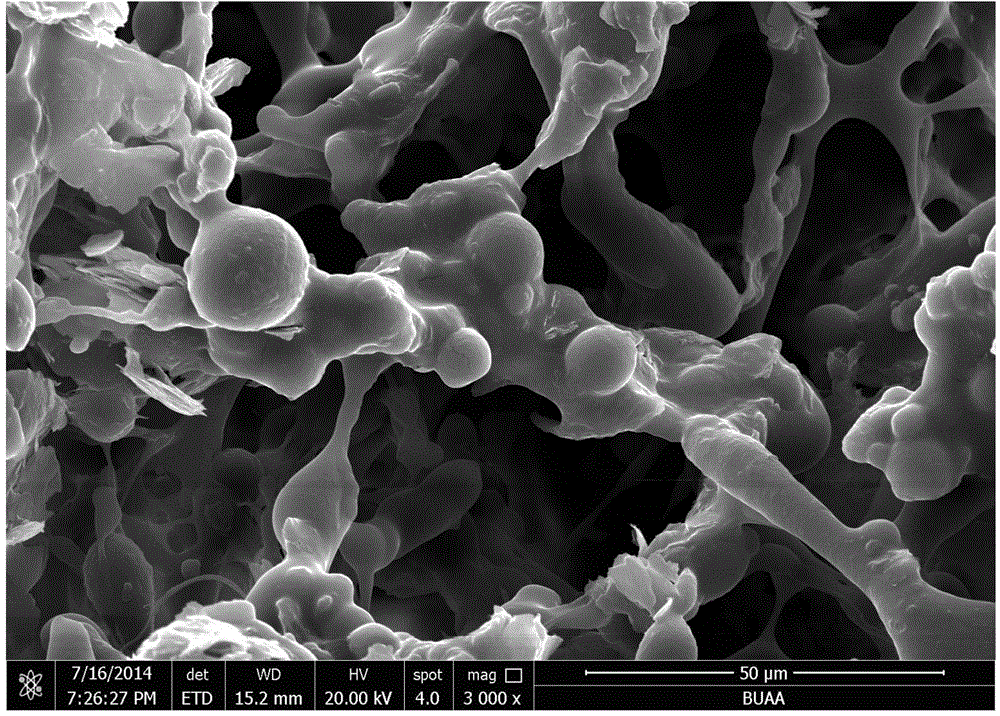

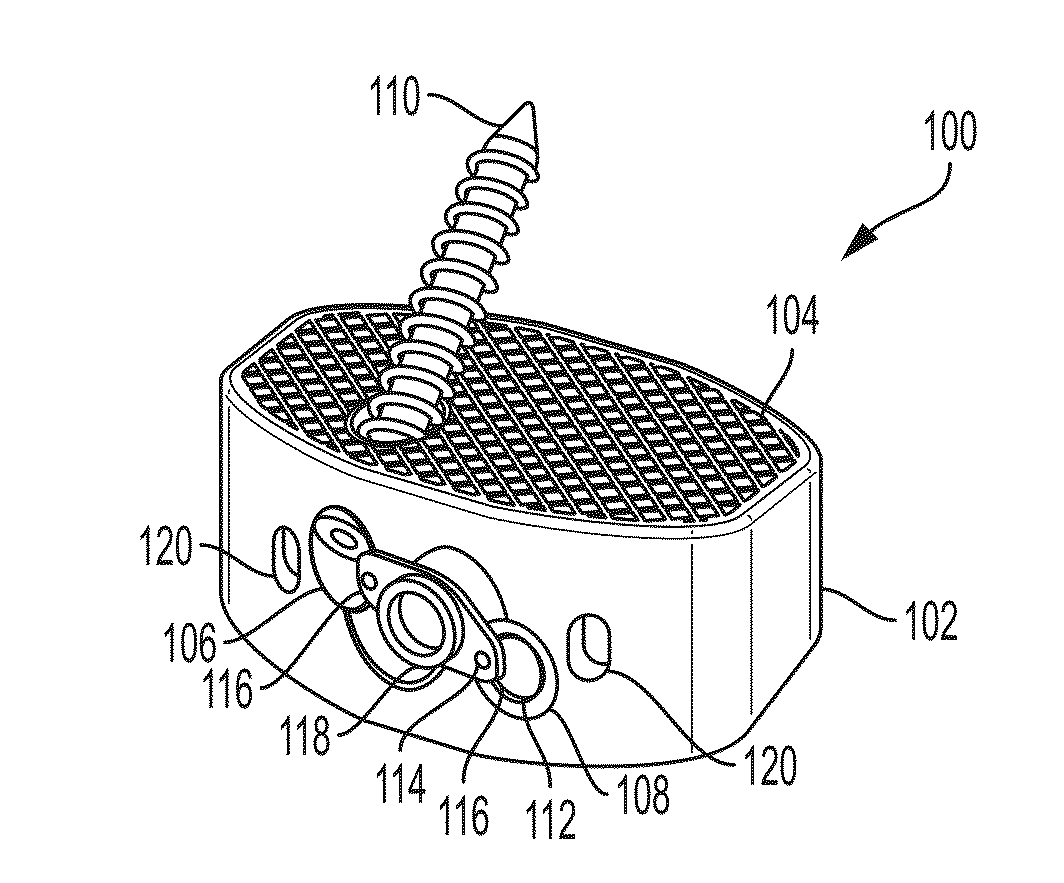

BMP microsphere loaded 3D printing porous metal stent and preparation method thereof

InactiveCN104353121AEarly recovery of weight bearing functionPrevent relapseProsthesisBone tissueInsertion stent

The invention relates to the technical field of biomedical materials, and particularly relates to a BMP microsphere loaded 3D printing porous metal stent and a preparation method thereof. According to the invention, a loaded microsphere-containing three-dimensional micro-stent is built in each hole of a 3D printing titanium stent. The problem that in the prior art, because the diameter of a hole is overlarge, cells only can be subjected to climbed growth on the two-dimensional space of the wall of the hole, and difficult to be subjected to three-dimensional hierarchical growth in the whole hole is solved, and by filling the three-dimensional micro-stent with a rhBMP-2 or rhBMP-7 loaded chitosan microsphere, a better growth and differentiation environment is provided for cells, thereby further promoting the combination of bone tissues and the stent. The three-dimensional micro-stent provided by the invention makes the complete healing of numerous patients with bone tissue defect caused by illnesses and accidents and the like possible; the three-dimensional micro-stent can also be used as a novel interbody fusion instrument, and applicable to an interbody fusion surgery, therefore, the three-dimensional micro-stent has an important clinical application value.

Owner:吴志宏

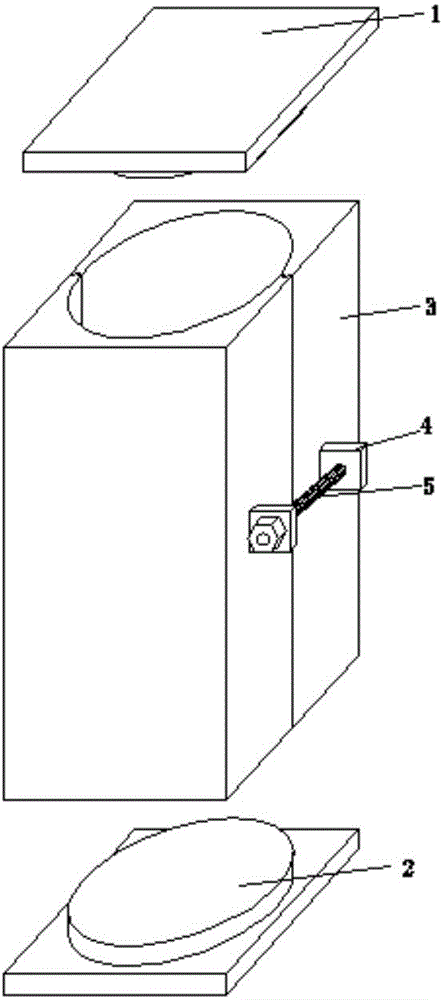

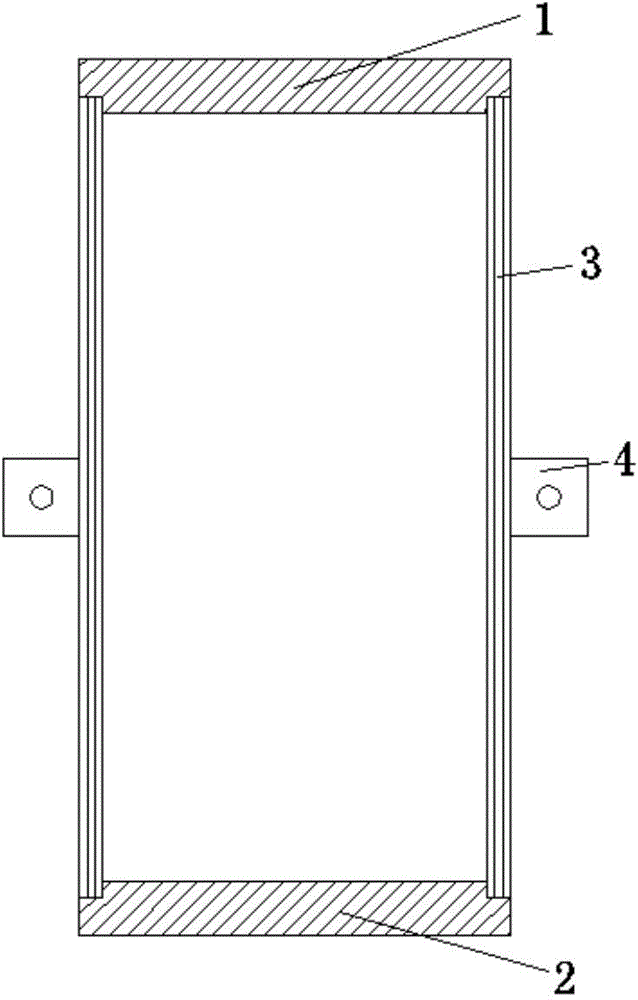

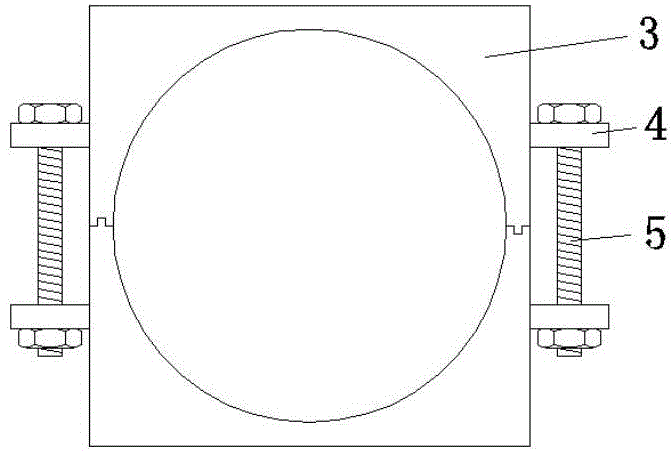

Joint test specimen method using 3D (three-dimensional) printing for making structure surface containing specific geometrical characteristics

ActiveCN104807685AThe sample preparation process is simple and fastOperational securityPreparing sample for investigationEngineeringModel test

The invention provides a joint test specimen method using 3D (three-dimensional) printing for making a structure surface containing specific geometrical characteristics, and belongs to a specimen making method of model test specimens similar to joint rock bodies. According to the method, the structure surface is independently designed according to study requirements, or the actual rock body structure surface appearance is obtained through a surface outline scanning technology; the designed structure surface penetrates through a complete cylinder model in 3D graphics software, two parts of complementary test block models obtained through separation are obtained through Boolean operation, and a 3D printer is used for respectively printing and forming the two parts of test block models; printing molds are respectively put into two specimen making boxes and are assembled, similar materials are cast into the specimen making boxes, and the mold dismounting maintenance is carried out after the materials are solidified and formed; the two parts of test blocks are correctly combined to obtain the standard test specimens containing the designed structure surface. The method has the advantages that (1) the operation of the method is safe, simple and convenient; (2) the complicated and variable structure surface is embedded in the standard test specimens, the actual rock body structural surface can be reproduced through being matched with the surface outline scanning technology, and the reasonable test result is obtained.

Owner:CHINA UNIV OF MINING & TECH

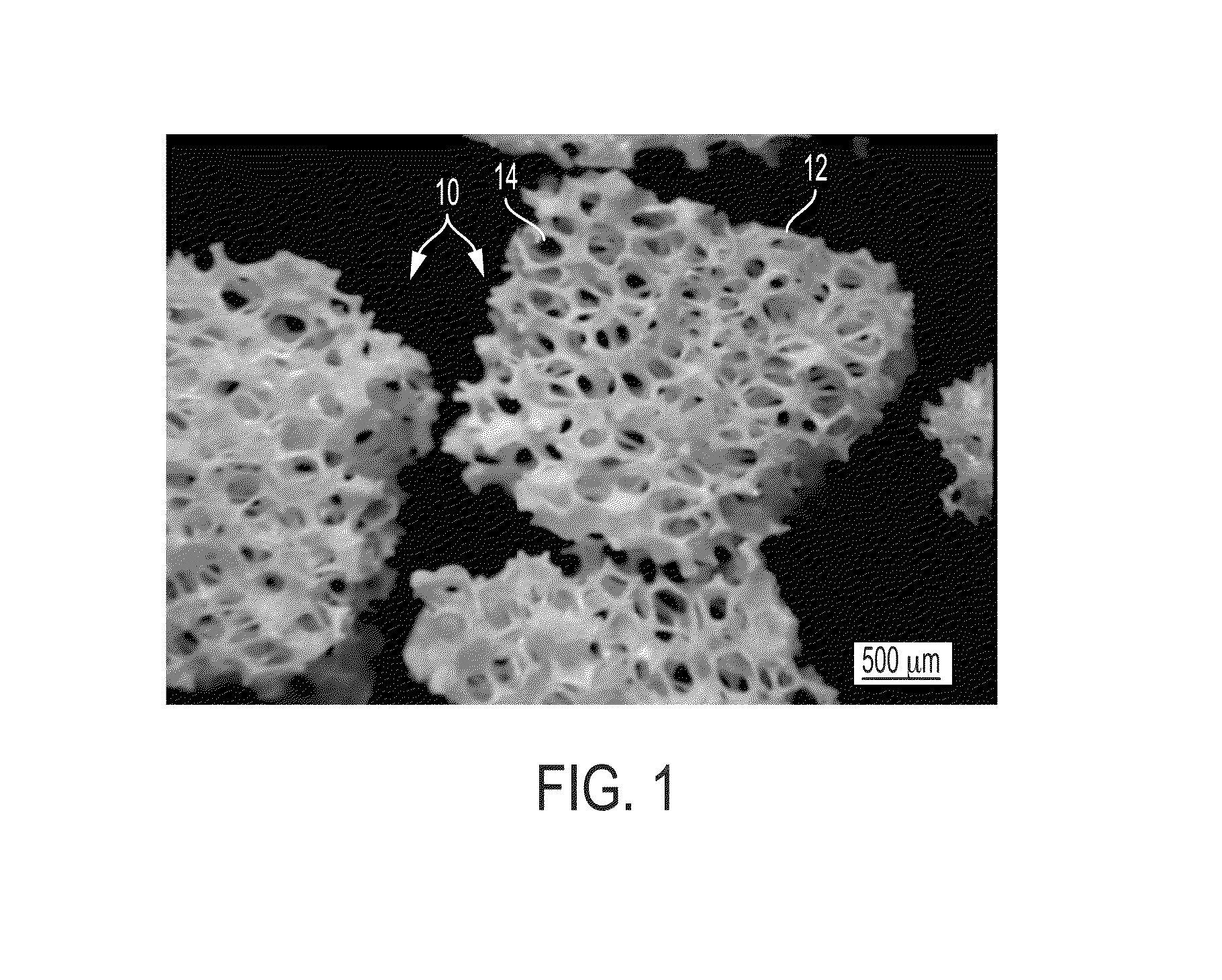

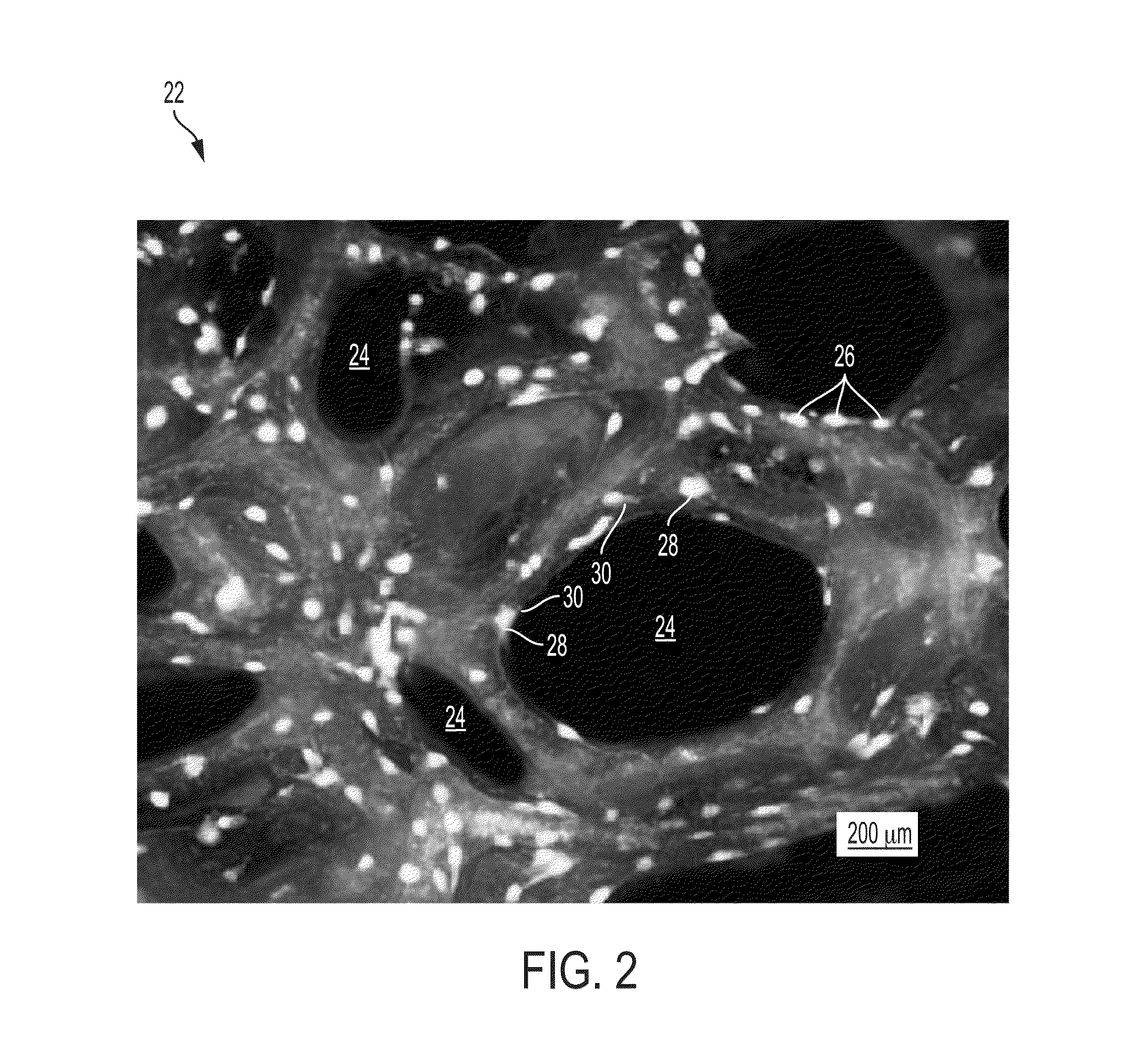

Treatment of skeletal voids with implantable substrate hydrated with bone marrow concentrate

ActiveUS20160270920A1Good adhesionContinued viability of cellJoint implantsSpinal implantsCellular componentCell-Extracellular Matrix

The invention is directed to a bone void filler comprising a scaffold or matrix. The scaffold or matrix may include a porous inorganic matrix component and / or a 3D-printed implantable device. The bone void filler may include a cellular component containing cells, some of which are capable of making extracellular matrix resembling native bone tissue. The bone void filler may include an organic matrix, such as, an organic biopolymer that aids in cell retention and renders the scaffold or matrix moldable. The bone void filler may include growth factors and / or cytokines. The bone void filler may include a clotting agent.

Owner:SPINESMITH PARTNERS

Method for producing 3D print fastening piece of three-layer structure from inside to outside

InactiveCN103611934AImprove performancePrecise positioningAdditive manufacturingElectrographic process apparatusGraphicsLatent image

A method for producing a 3D print fastening piece of a three-layer structure from inside to outside comprises the specific steps that computer modeling and layer-by-layer cutting are carried out; graphs are converted to light beams carrying graph information, a photosensitive drum is charged to obtain electric potential, and an electrostatic latent image is formed through light beam scanning; the electrostatic latent image passes through a magnetic brush and attracts powder to from an internal component, the surface of the internal component is processed, the steps are executed repeatedly to print the intermediate layer and the outer layer, and the surfaces of the intermediate layer and the outer layer are processed. The 3D print fastening piece made through the method has the advantages of being high in manufacturing precision, long in service life, and good in performance.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

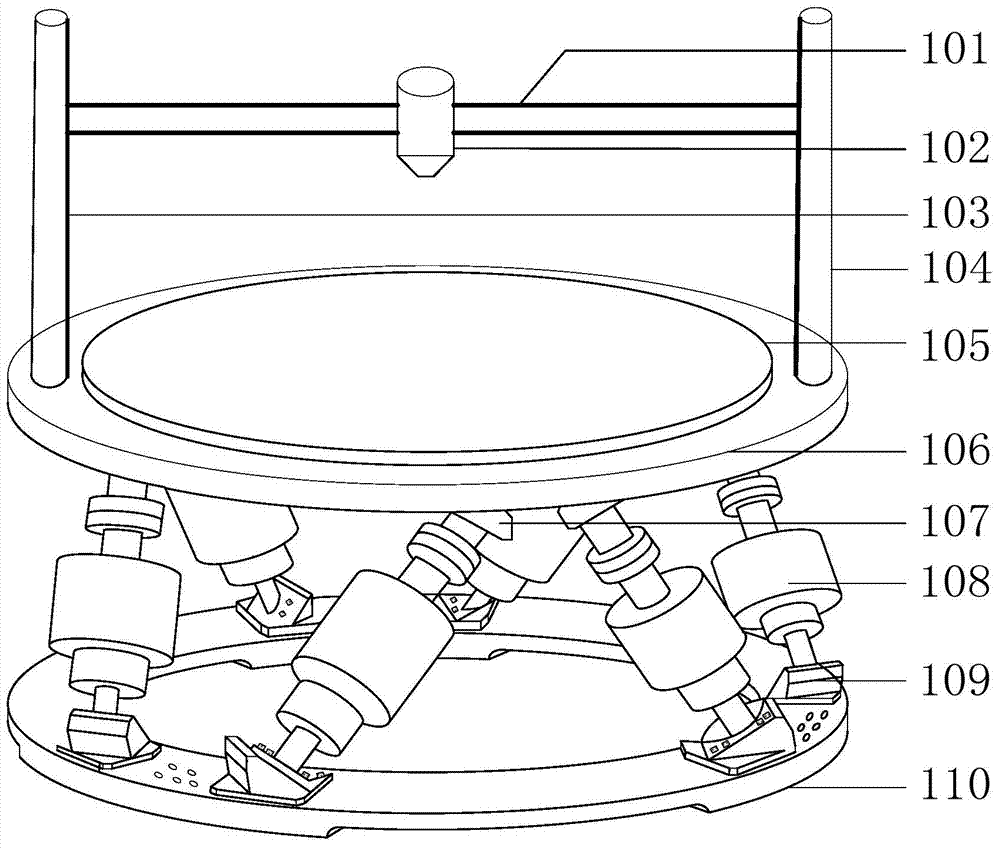

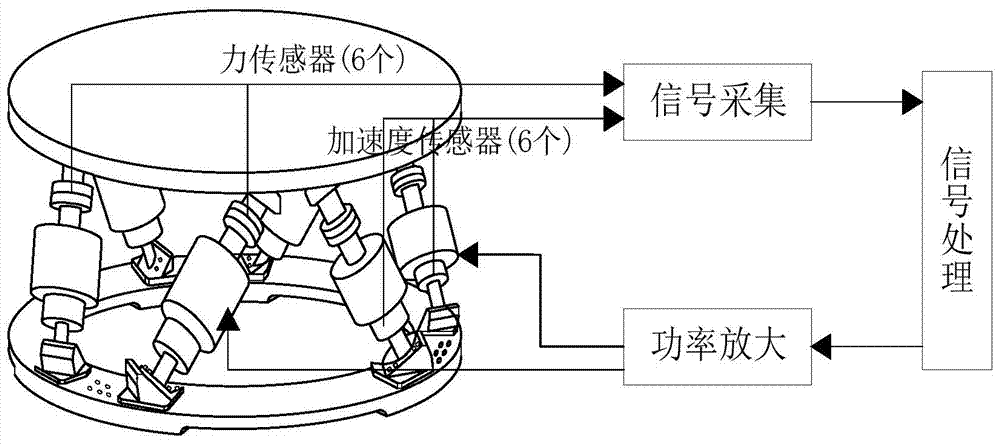

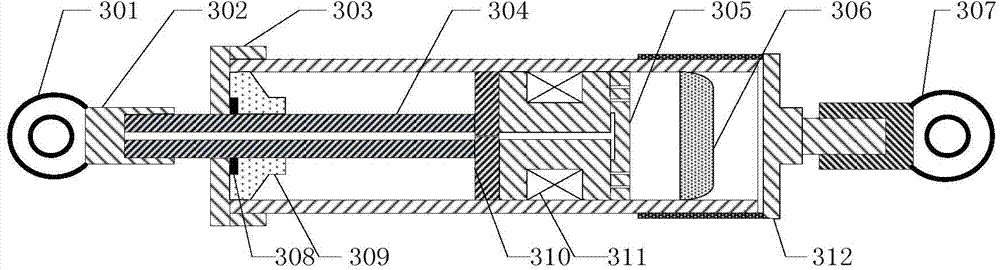

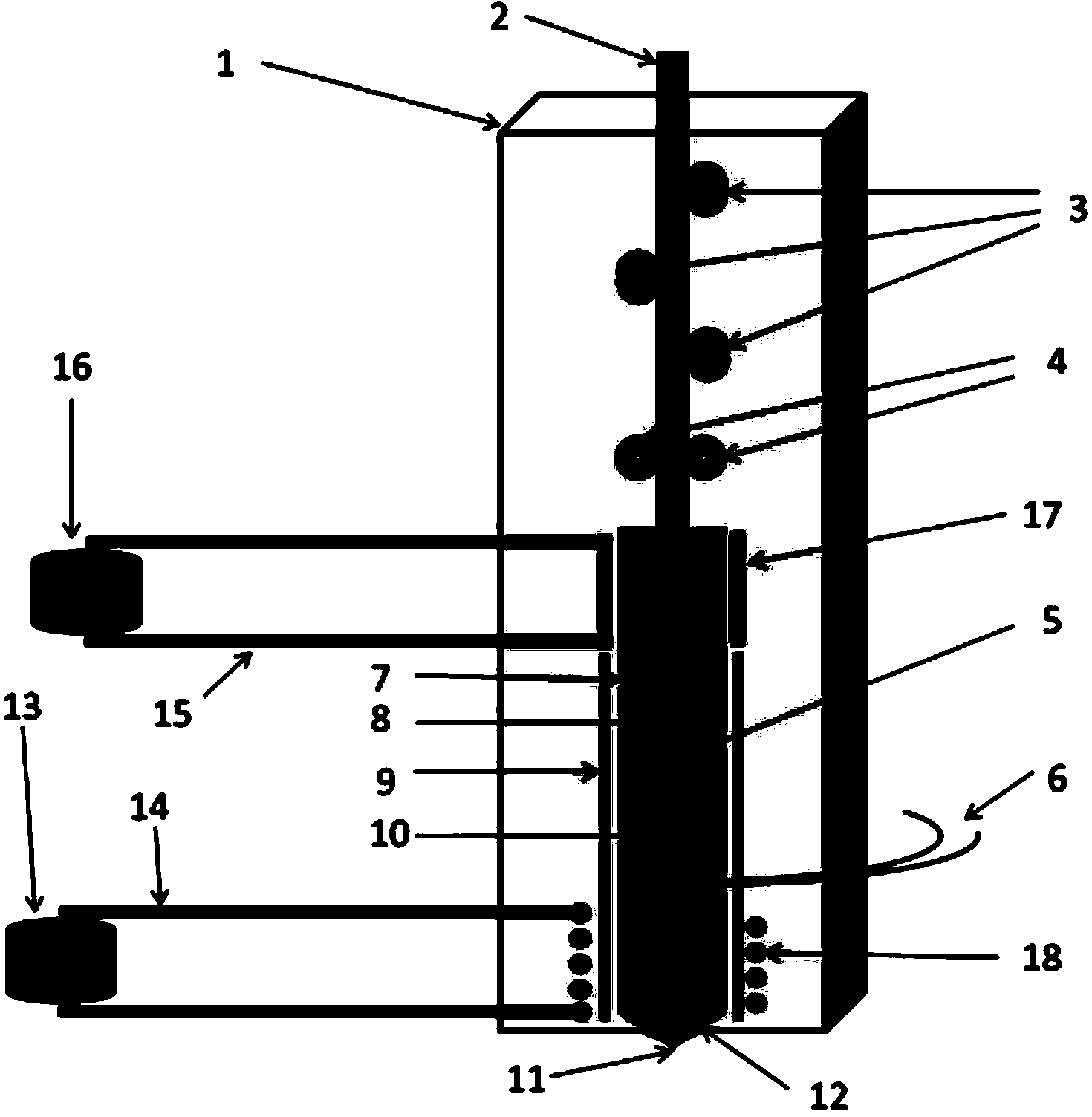

Intelligent anti-vibration three-dimensional printer for ship

The invention relates to the technical field of three-dimensional printers, in particular to an intelligent anti-vibration three-dimensional printer for a ship. The three-dimensional printer comprises a printing mechanism and an anti-vibration platform; the printing mechanism comprises a printing sprayer, a shift rod, a lifting rod and a rotary table; the anti-vibration platform comprises an upper platform, a lower platform and actuator bars, and the actuator bars are used for connecting the upper platform with the lower platform. According to the intelligent anti-vibration three-dimensional printer for the ship, the rotation of the rotary table is precisely controlled, the shift rod moves up and down on the lifting rod, the printing sprayer horizontally moves on the shift rod and spatial three-dimensional point searching can be performed, so that three-dimensional printing can be realized; the actuator bars with the same structure of the anti-vibration platform respectively connect the upper platform with the lower platform through the two ends of flexible spherical hinges; multivariant interference vibration of an object, such as a ship body, is changed into independent unidirectional vibration by the actuator bars and is isolated by the actuator bars. The intelligent anti-vibration three-dimensional printer for the ship solves the problem of anti-vibration of a three-dimensional printer, and can be applied to three-dimensional printing in a vibration environment.

Owner:CLOUD COMPUTING CENT CHINESE ACADEMY OF SCI

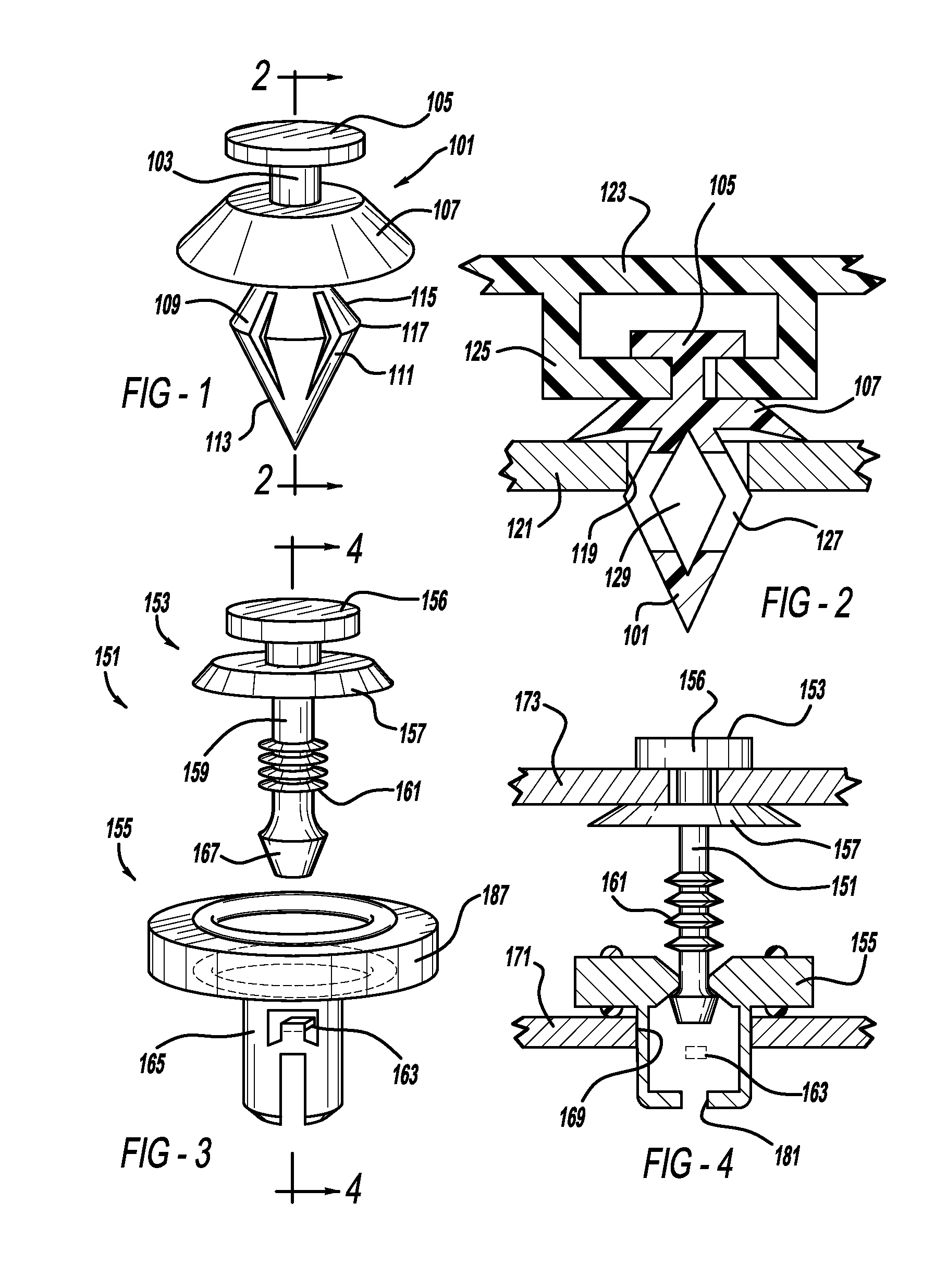

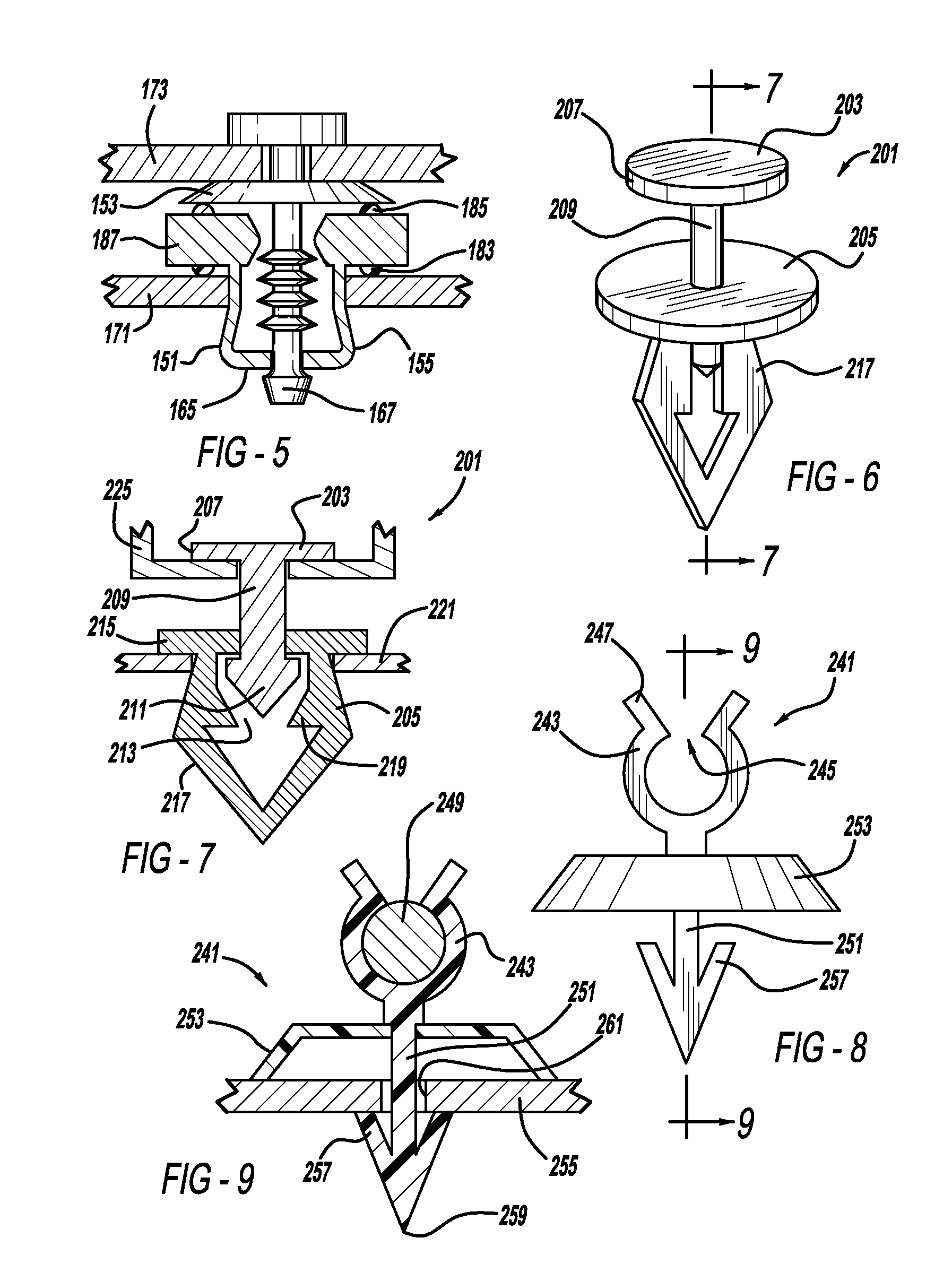

Method of making fasteners by three-dimensional printing

Owner:A RAYMOND & CO

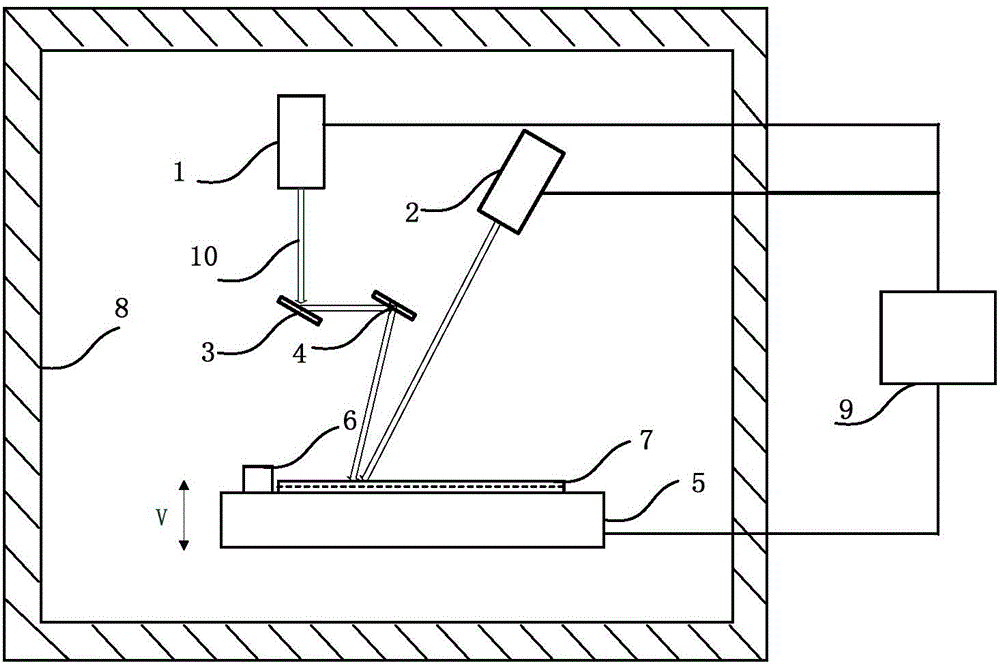

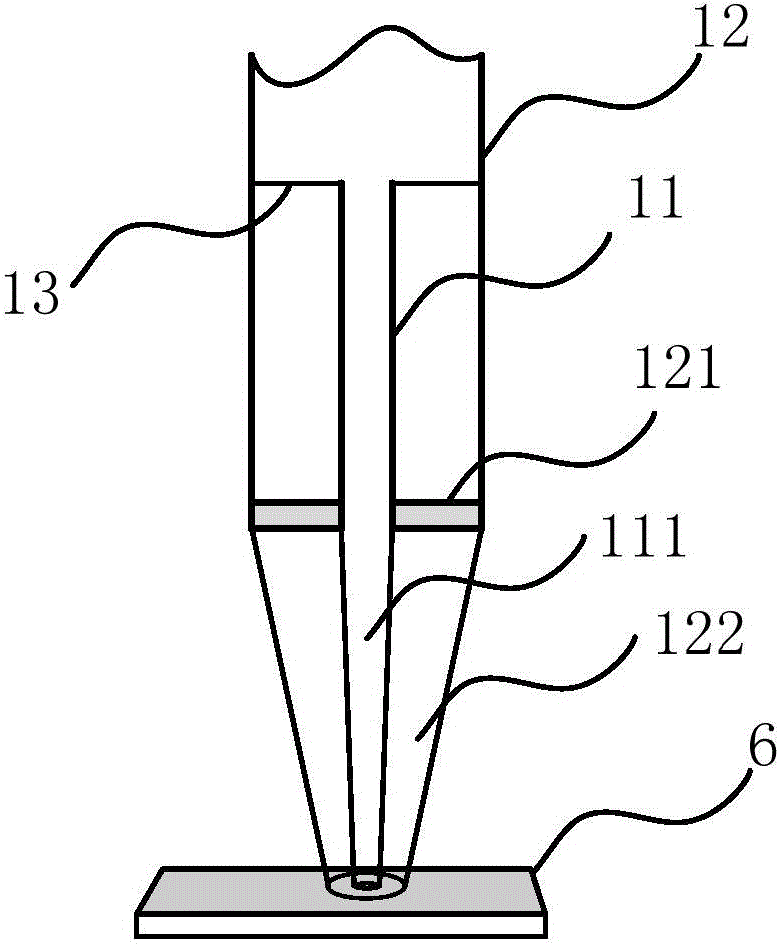

High polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control

ActiveCN103978307ALess frizzReduce temperature gradientAdditive manufacturing apparatus3D object support structuresUltravioletThermostat

The invention discloses a high polymer material ultraviolet laser 3D (three-dimensional) printing method and device for precise temperature control. The device comprises a thermostat, a laser head, a non-contact type temperature monitoring device, a scanning galvanometer, a machining platform, a powder paving device, a machining material and a computer control system. The laser head adopts a dual-tube core structure, an inner tube and an outer tube are coaxially fixed, one or more than one gradual-change neutral filter piece is arranged between the two tubes, and the laser transmittance of the filter piece(s) is radially reduced from the inner tube to the outer tube. The method comprises the following steps: presetting the machining temperature by the control system, in the process of machining, monitoring the temperature rise condition of an object to be machined in real time under the irradiation of laser by the non-contact type temperature monitoring device, feeding back to the control system, recording the increased value of the temperature within a certain time, and obtaining the absorption capability of the material to be machined to the laser and the temperature rise degree by the system, so that according to the preset machining temperature value, the laser output power can be calculated, the laser power can be timely adjusted, and the machining temperature can be precisely controlled.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Method for producing high-strength fasteners in batch by using 3D (three dimensional) printing technology

InactiveCN103612393AImprove efficiencyIncrease productivityElectrographic process apparatusGraphicsPunching

The invention discloses a method for producing high-strength fasteners in batch by using a 3D (three dimensional) printing technology. The method specifically comprises the following steps: carrying out computer modeling, segmenting layer by layer, converting a graph into a light beam loaded with graph information; charging a photosensitive drum to obtain a potential, scanning by the light beam to form an electro-static latent image; enabling the electro-static latent image to pass through a magnetic brush, absorbing powder to form an internal member; forming the internal member; and carrying out punching cutting and surface treatment. According to the method for producing the fasteners in batch, the production efficiency is high, the accuracy is high, and the obtained fasteners in batch are excellent in performance.

Owner:NINGBO JINPENG HIGH STRENGTH FASTENER

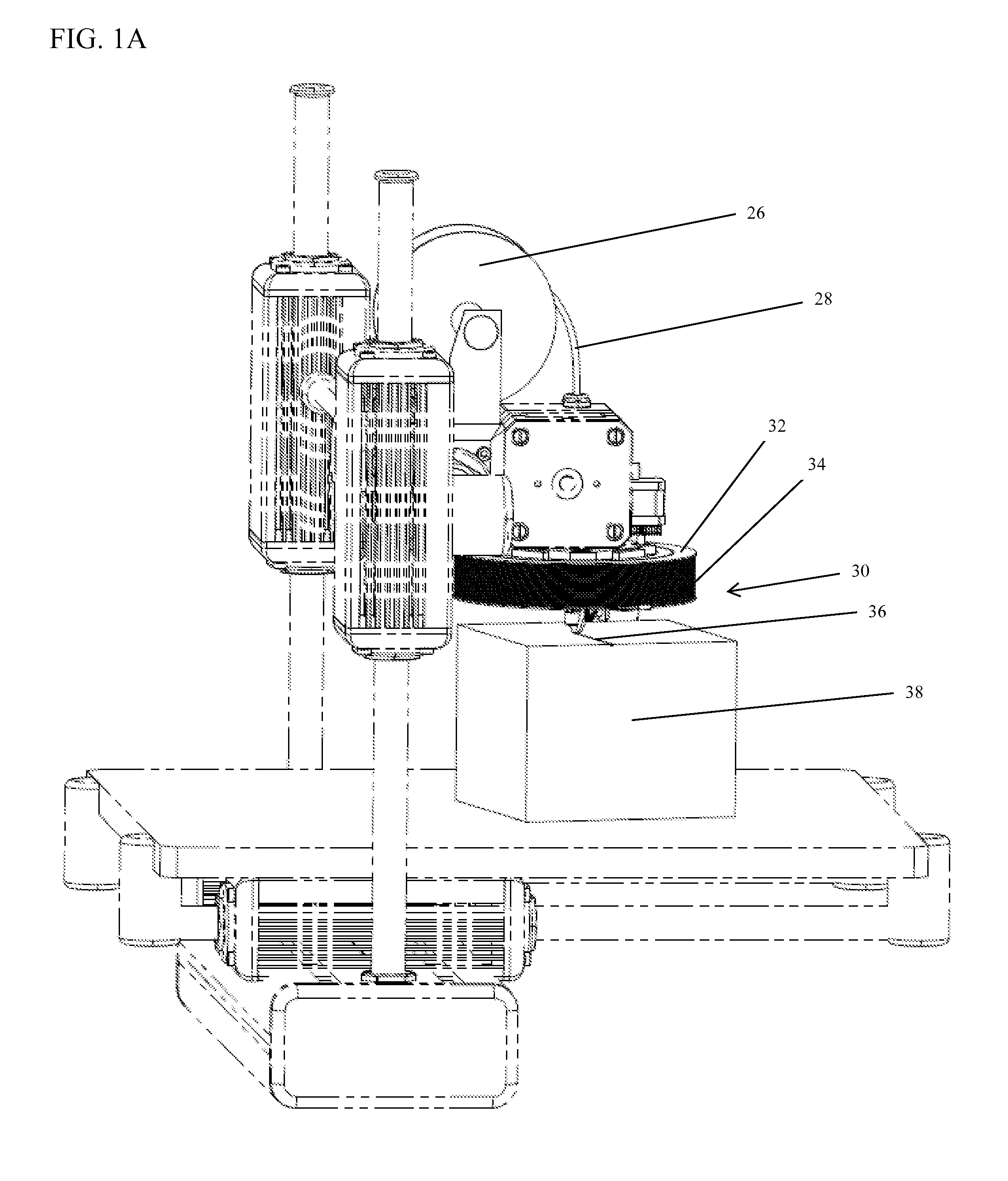

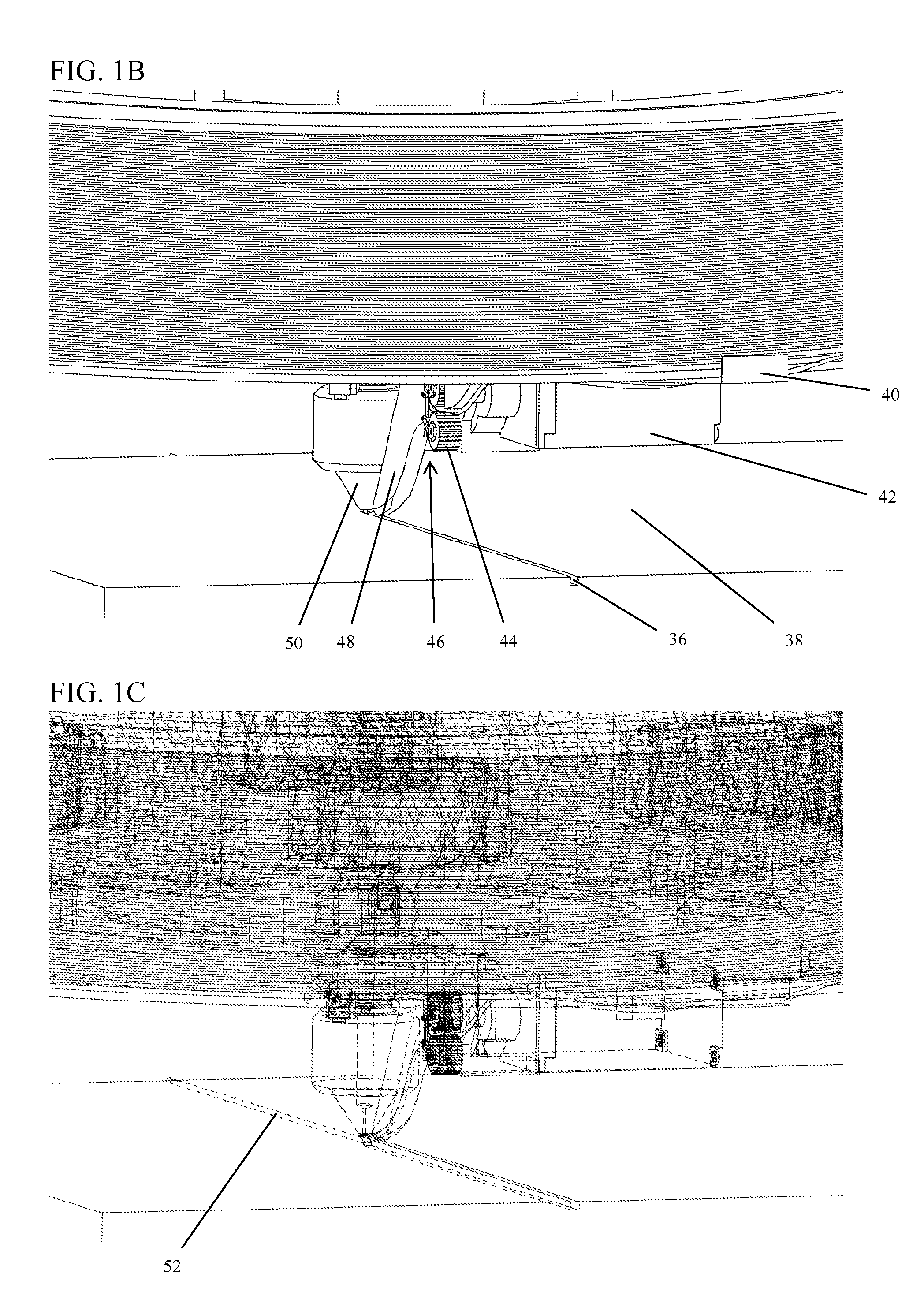

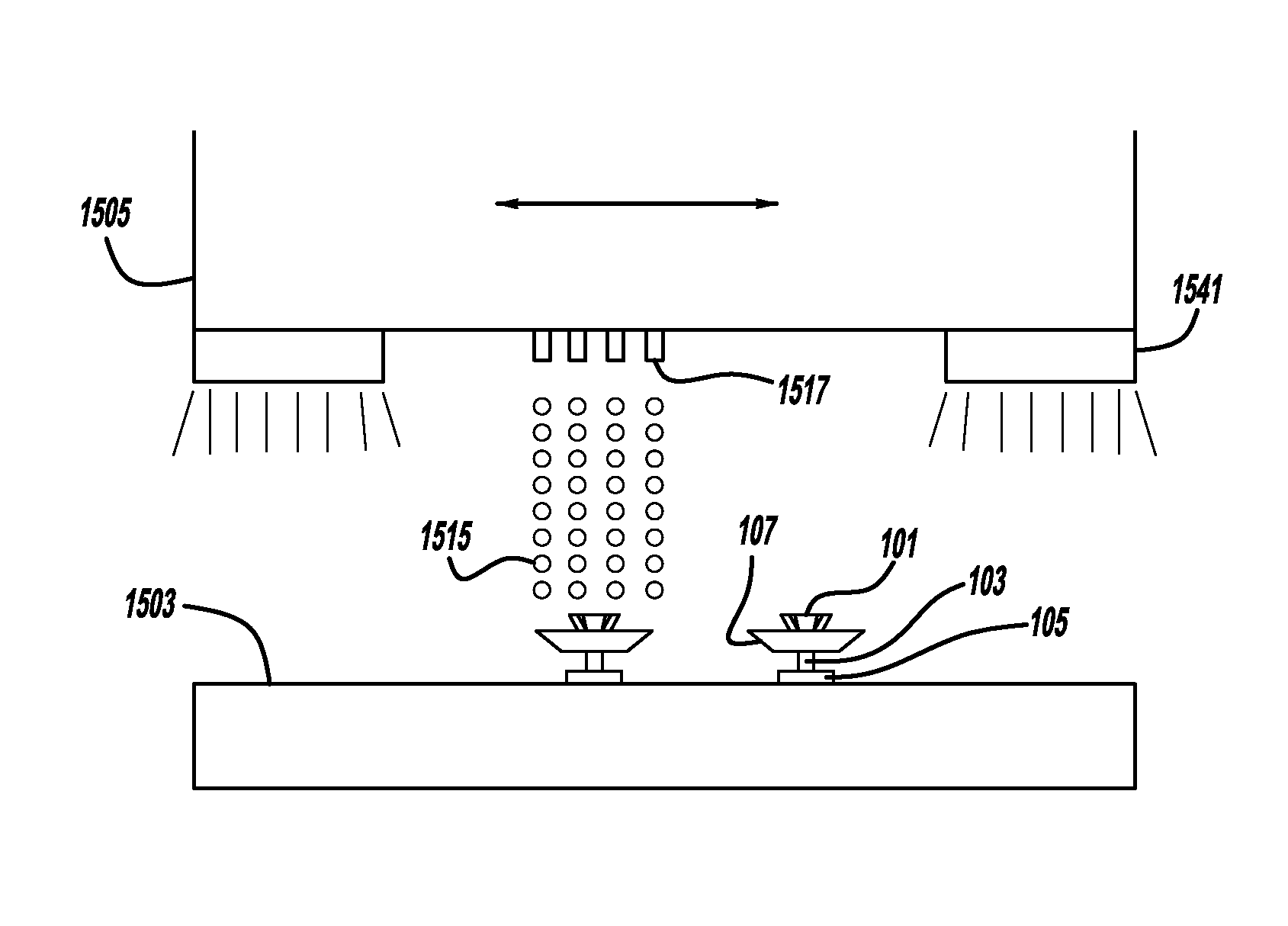

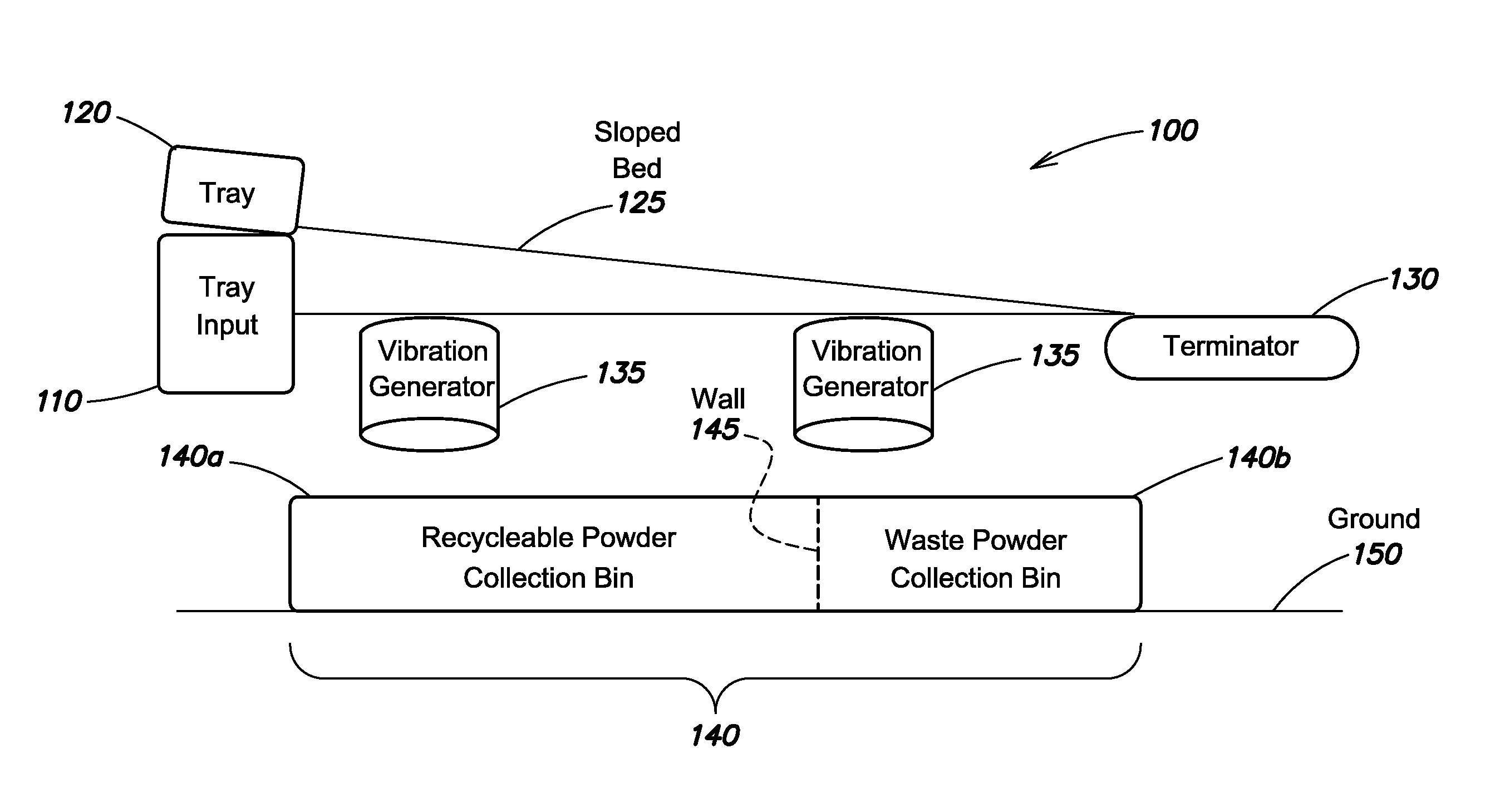

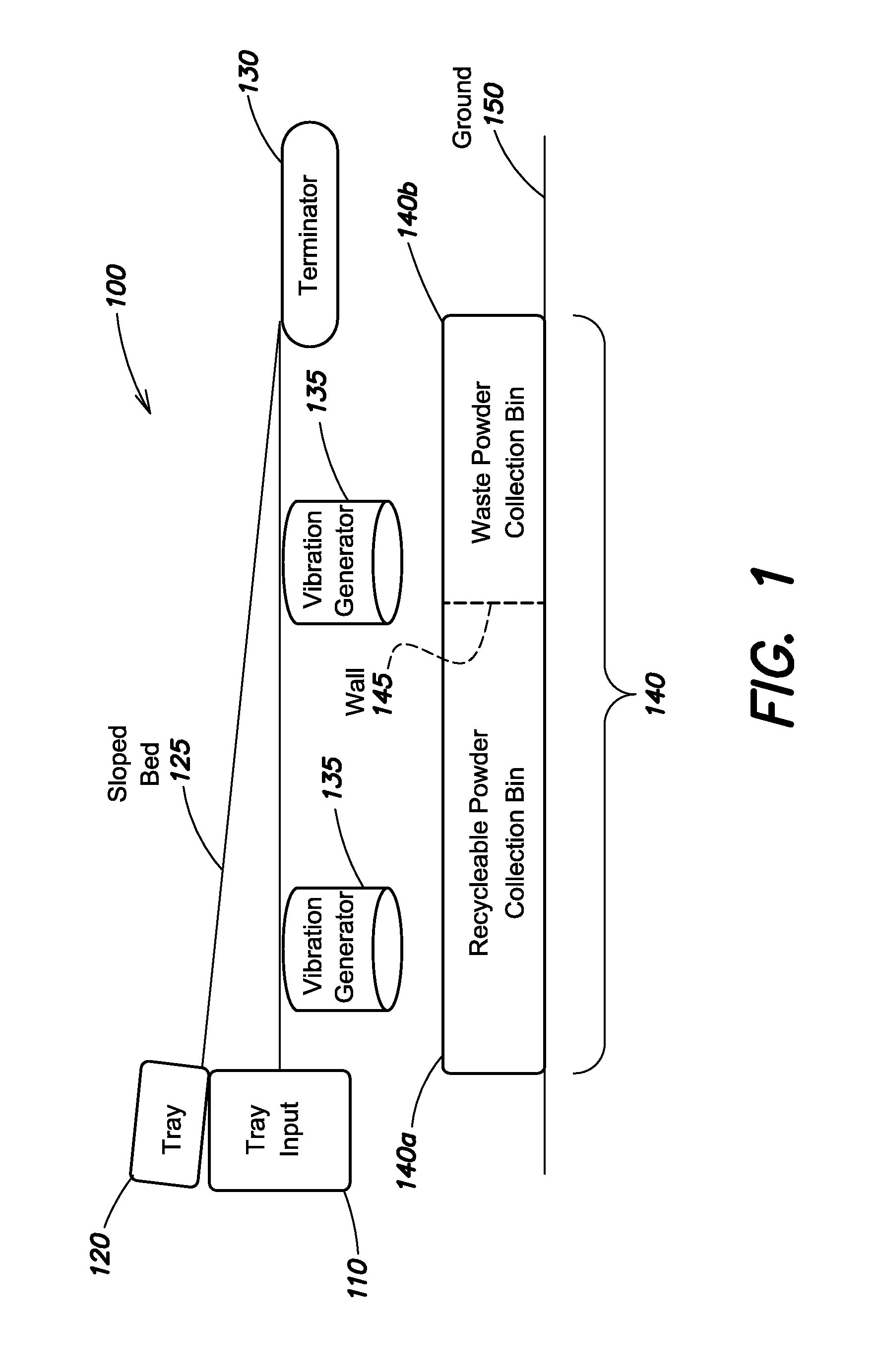

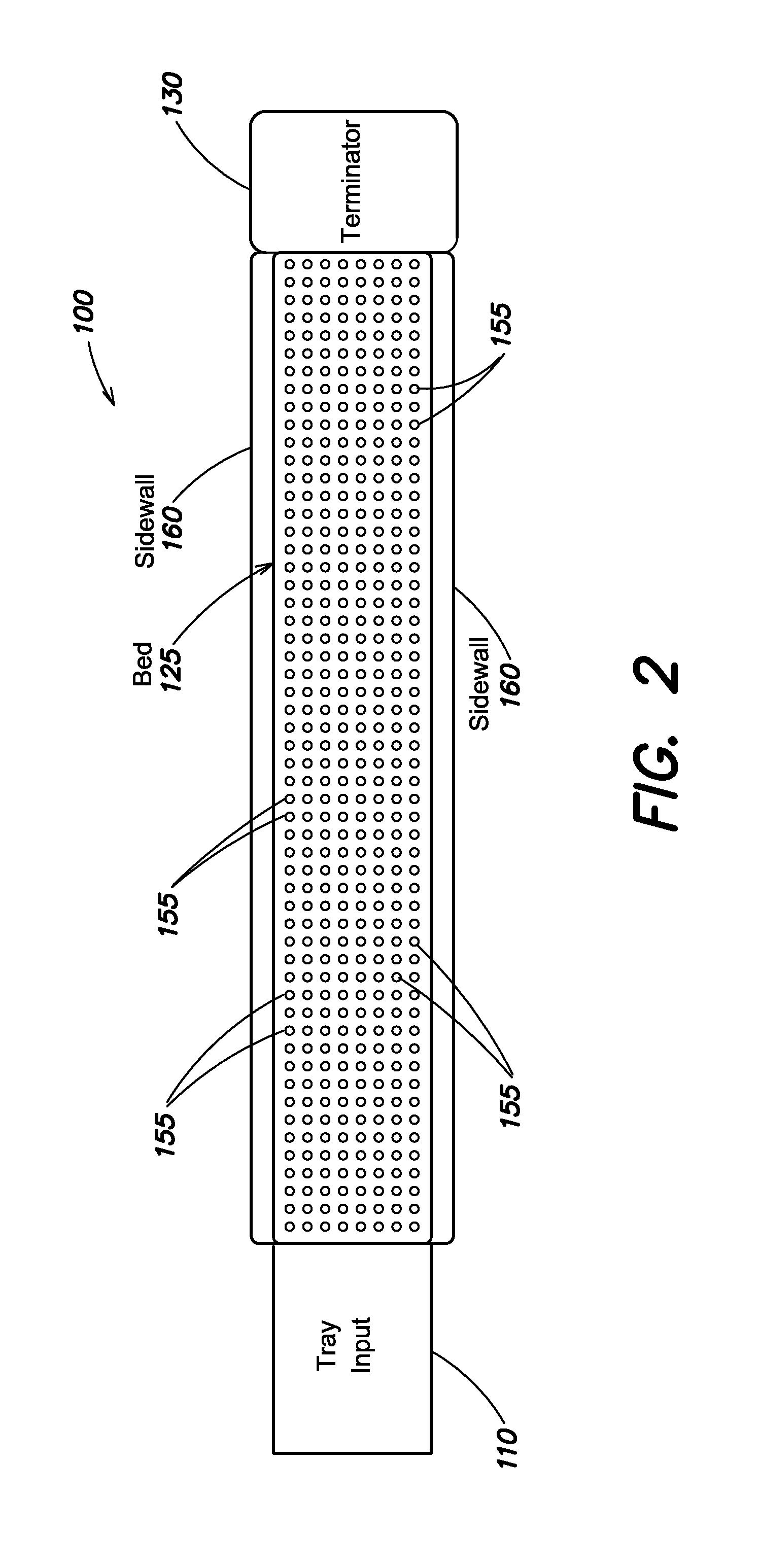

Processing of three dimensional printed parts

A system for post-print processing of 3D printed parts includes an automated breakout system for separating 3D printed parts from printing media in a tray and a vibratory media cleaning system for removing printing media from the 3D printed parts. The automated breakout system includes a tray input mechanism, a bed including a first end disposed adjacent the tray input mechanism, the bed including one or more passageways configured to pass printing media through the bed, a vibration generator coupled to the bed and configured to vibrate the bed, and a part terminator disposed adjacent a second end of the bed. The vibratory media cleaning system include a vibratory bin, a vibration generator coupled to the vibratory bin and configured to vibrate the vibratory bin, an automated parts loader configured to introduce 3D printed parts to be cleaned into the bin, and an automated parts removal mechanism.

Owner:SHAPEWAYS

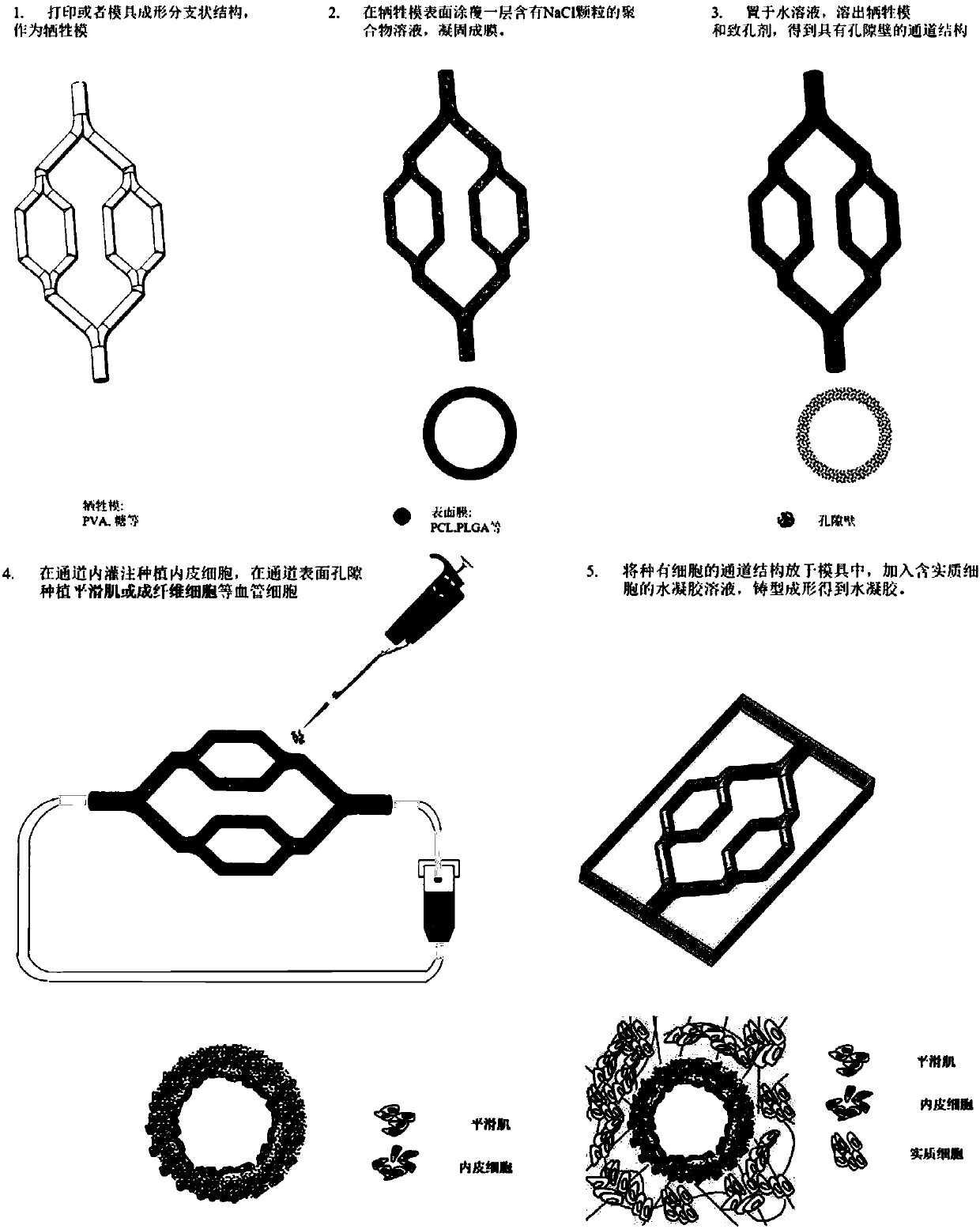

Bionic vascularized soft tissue with multilayer vascular structure and preparation method thereof

ActiveCN107693846AAdditive manufacturing apparatusEducational modelsPolymer thin filmsPolymer solution

The invention discloses a bionic vascularized soft tissue with a multilayer vascular structure and a preparation method thereof. The preparation method comprises the steps of: employing a moulding process or 3D printing way to obtain a sacrificial membrane with a branched structure; coating or spraying a polymer solution containing a pore-foaming agent on the surface of the sacrificial membrane toobtain a polymer film; removing the treated sacrificial membrane of the structure and the pore-foaming agent to obtain a vascular channel-like structure with surface pores; conducting perfusion planting of endothelial cells in the channel of the vascular channel-like structure; planting smooth muscle cells or fibroblasts in the surface pores of the vascular channel-like structure; and placing thetreated vascular channel-like structure in a mold, adding an aquogel solution containing parenchymal cells, and conducting moulding so as to obtain the bionic vascularized soft tissue. The method provided by the invention can construct bionic blood vessels with a multilayer structure in artificial tissues.

Owner:TSINGHUA UNIV

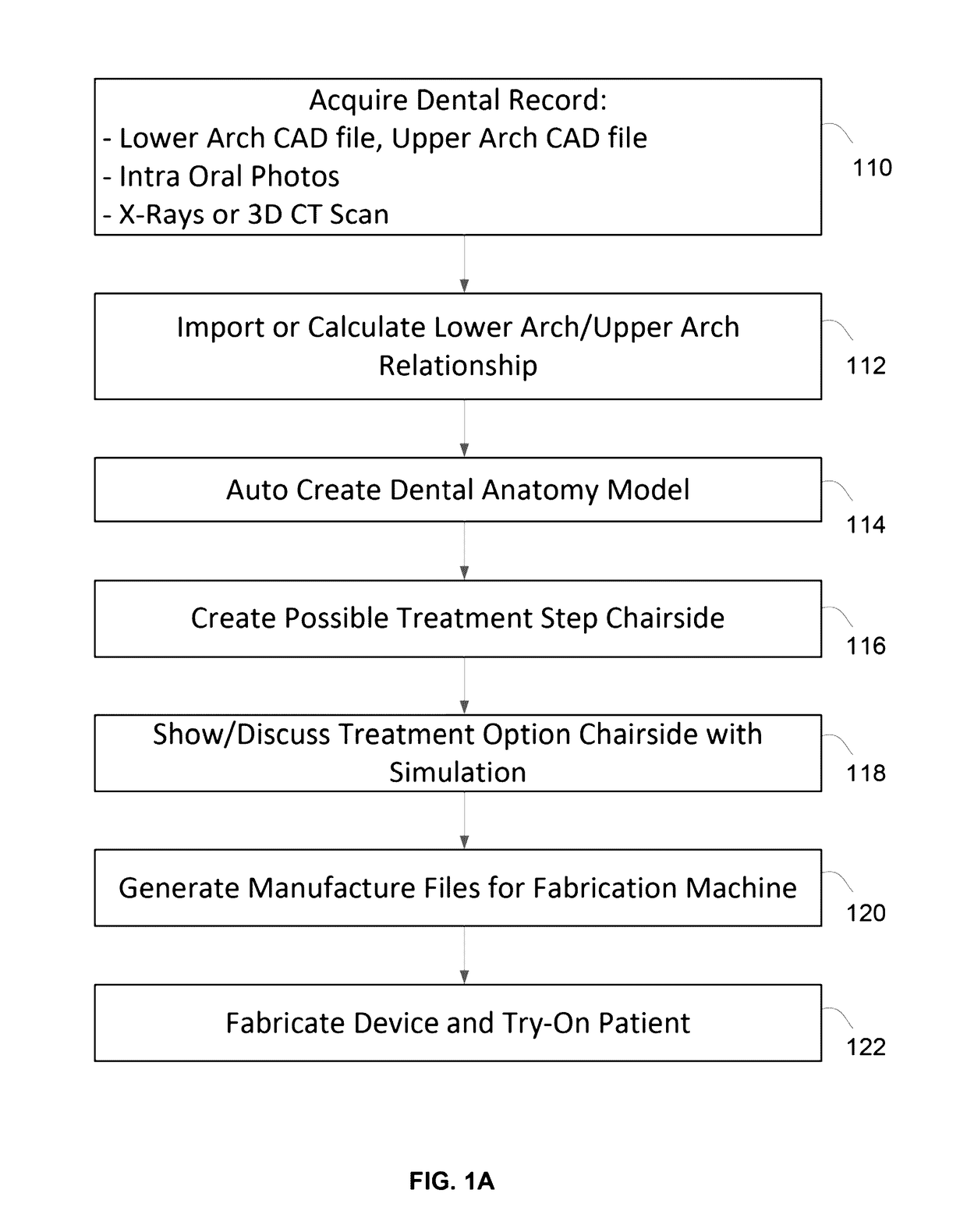

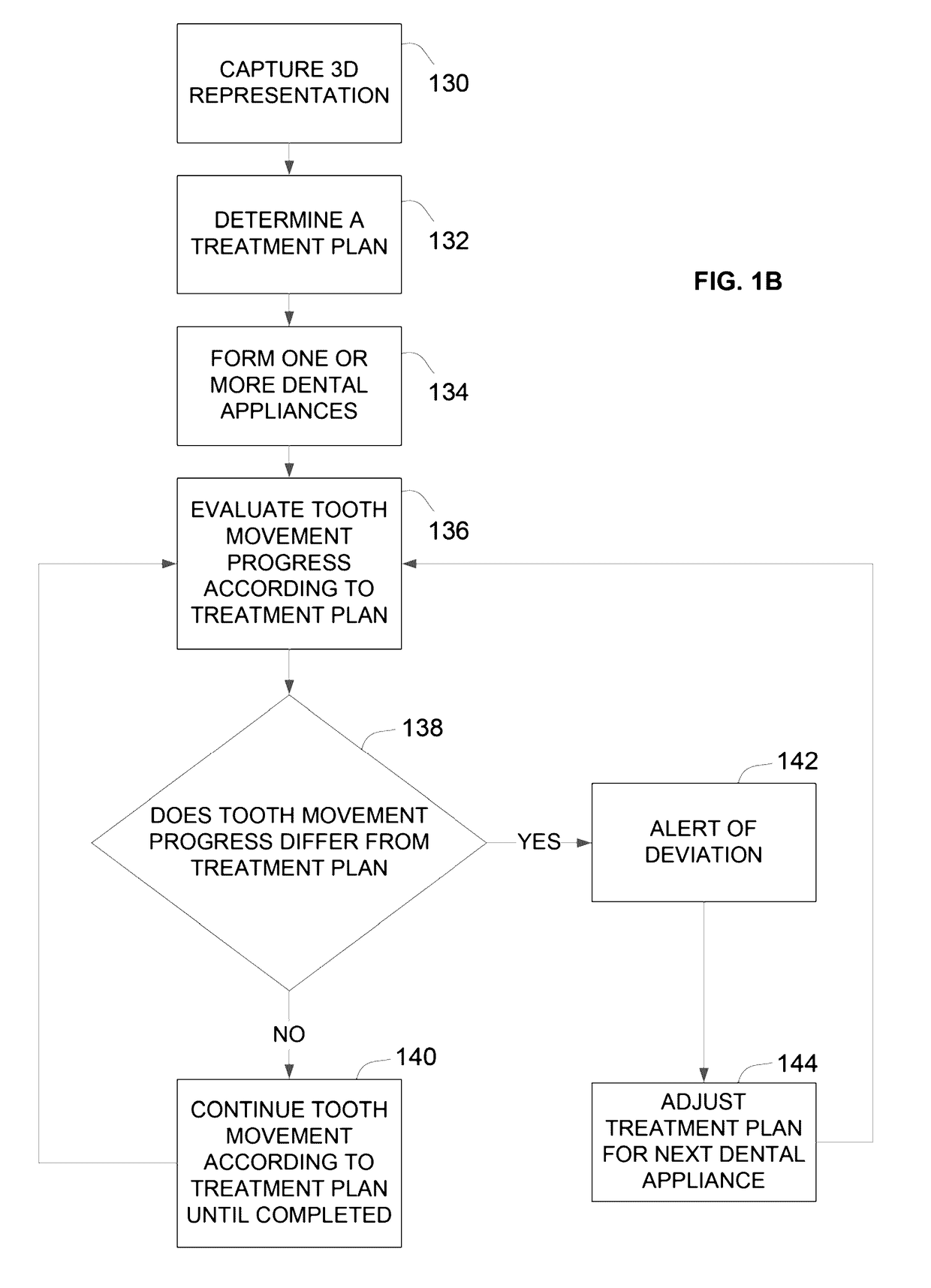

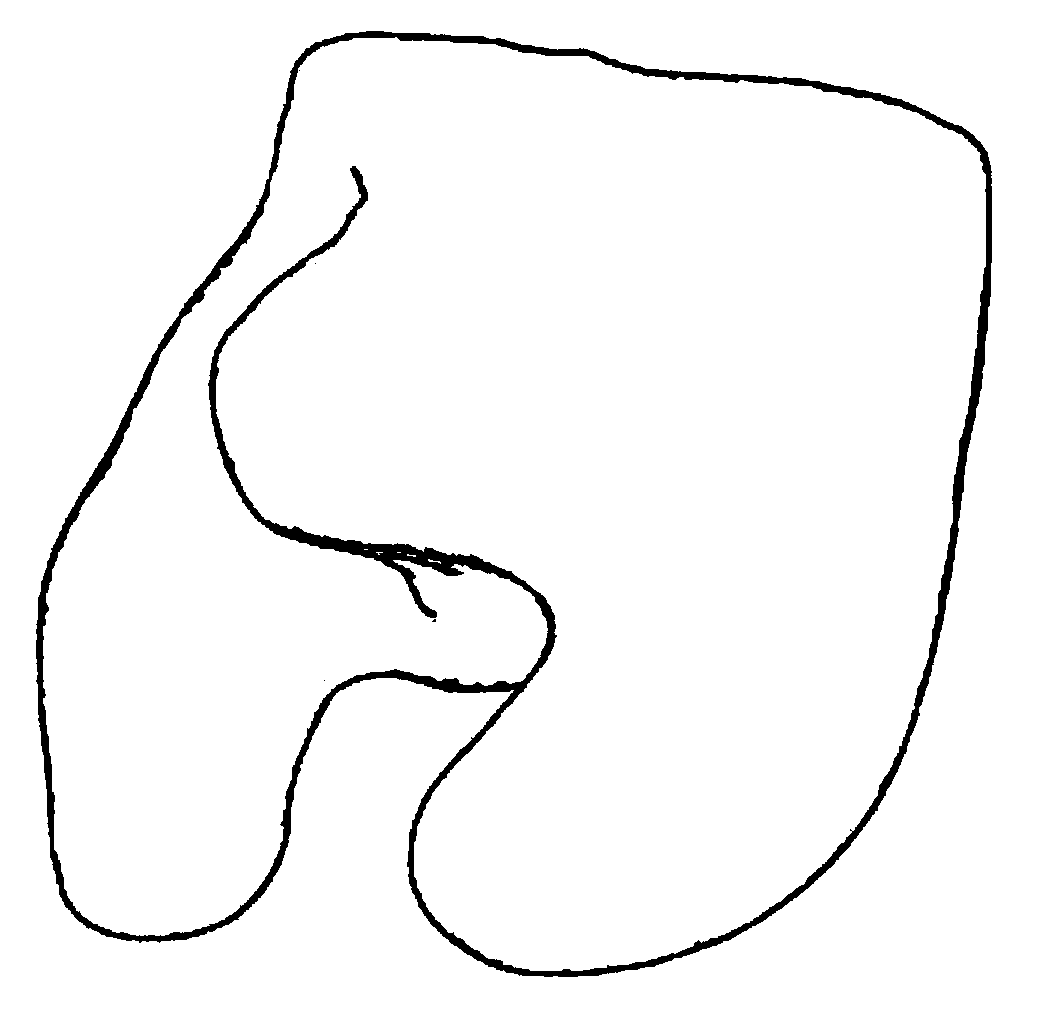

Tooth modeling system

ActiveUS20170100207A1Avoid collisionReact SafeImage enhancementImpression caps3d printedDental Models

Systems and methods are disclosed for treating teeth to correct for malocclusions. This may be accomplished by applying a series of labels to a digital dental model and applying a rolling ball process to identify tooth boundaries separating one tooth from a neighboring tooth and to also determine the crown / gum margin. The user may further assign regions to the dental model to indicate hard regions and soft regions. With the dental model labeled and defined, the user may then generate a treatment plan for moving the labeled and defined tooth or teeth relative to one another to correct for any malocclusions. Upon approval of the treatment plan, a series of 3D printed dental appliances or aligners to be worn in series by the patient may be fabricated to ultimately move the tooth or teeth to a desired position.

Owner:ULAB SYST INC

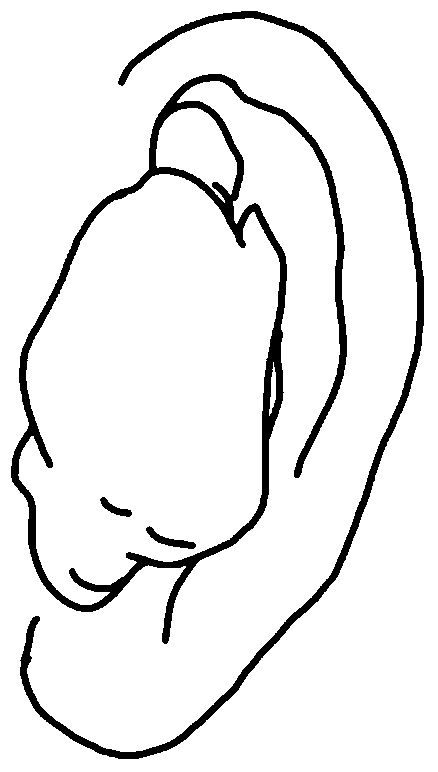

Customized earphone based on 3D (three-dimensional) printing technology and manufacturing method thereof

InactiveCN103974183APrecise thickness controlPrecise control of the internal structureEarpiece/earphone attachmentsSpecial data processing applicationsWire rodDividing circuits

The invention discloses a customized earphone based on a 3D (three-dimensional) printing technology and a manufacturing method of the customized earphone. The earphone comprises an earphone shell, a hard sound induction tube, a unit clamping groove, a sounding unit, a sound outlet connection device, a frequency dividing circuit, a seal cover and a wire socket; the earphone shell, the unit clamping groove, the hard sound induction tube and the seal cover are formed by a 3D printer in a printing manner; the frequency dividing circuit is connected with the sounding unit and the wire socket; the sounding unit is arranged in the unit clamping groove; the sounding unit is communicated with the hard sound induction tube through the sound outlet connection device; the seal cover is used for sealing the earphone shell to form the customized earphone. The thickness, internal structure, mechanical characteristics and acoustics characteristics of the customized earphone shell can be precisely controlled, the sound induction tube material can be optimized, the limitation on a soft material can be broken through, the labor and time cost can be greatly reduced, and the yield of the customized earphone can be greatly increased.

Owner:XIAN MU SHENG ELECTRONICS TECH CO LTD

3D printed active electronic materials and devices

Disclosed is a process whereby diverse classes of materials can be 3D printed and fully integrated into device components with active properties. An exemplary embodiment shows the seamless interweaving of five different materials, including (1) emissive semiconducting inorganic nanoparticles, (2) an elastomeric matrix, (3) organic polymers as charge transport layers, (4) solid and liquid metal leads, and (5) a UV-adhesive transparent substrate layer, demonstrating the integrated functionality of these materials. Further disclosed is a device for printing these fully integrated 3D devices.

Owner:THE TRUSTEES FOR PRINCETON UNIV

3D (3-dimensional) print head for metal melt extrusion molding

ActiveCN104338933AAffecting workMeet the requirements of melt extrusionThermal insulationMetallic materials

The invention discloses a 3D (3-dimensional) print head for metal melt extrusion molding. The 3D print head comprises a casing, a raw material channel, a heating system, a cooling system and a temperature control system, wherein the raw material channel comprises a raw material inlet, conveying rollers, a strip-shaped hollow crucible, a raw material outlet and a thermal insulation ring located at the raw material outlet, and the outside, close to the raw material outlet end, of the crucible is wrapped with a thermal shielding layer; the heating system comprises an electromagnetic induction coil and an electromagnetic induction power supply which are arranged between the thermal shielding layer and the crucible in a sleeving manner; the cooling system comprises a water cooling jacket arranged on the crucible and close to the outside of the raw material inlet end as well as a cooling water supply device; and the temperature control system comprises a temperature sensor, a data analysis module and a PLC (programmable logic controller) control unit used for adjusting the power of the electromagnetic induction coil and / or the flow of cooling water. The 3D print head can finish heating melting of a metal raw material quickly and solves the problem that a common metal material cannot be subjected to melt extrusion molding.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

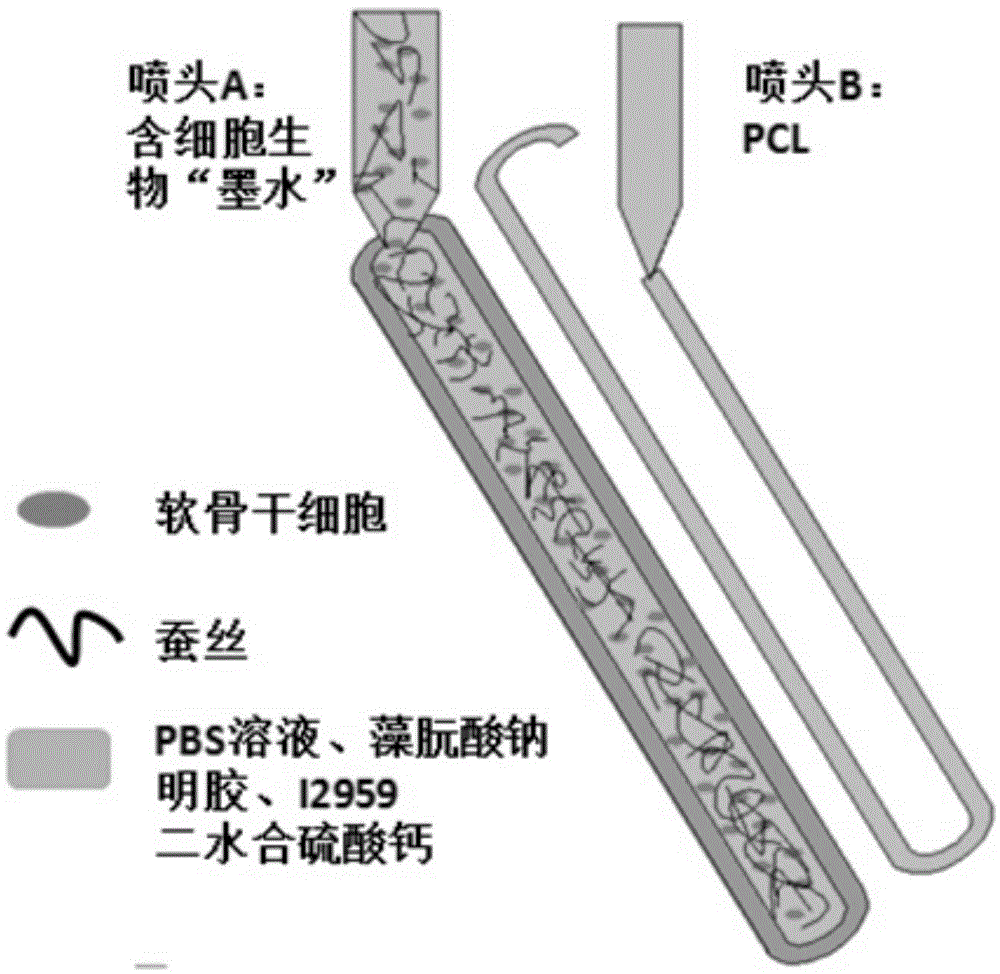

Method for preparing cartilage with high mechanical property based on 3D bioprinting

ActiveCN104399119AImprove mechanical propertiesGood mechanical propertiesProsthesisBiocompatibility TestingBiological materials

The invention provides a method for preparing cartilage with a high mechanical property based on 3D bioprinting. The method comprises the following steps: preparing silk fibers, preparing a gelatin solution, preparing ciological ink containing cells, carrying out 3D cartilage printing, performing cell culture and differentiation on a printed tissue to form the cartilage. The method solves the problems of polarization of 2-dimension culture for cells and high body and surface ratio of cells through the 3D bioprinting technology; sodium alginate and calcium ions form ionic bonds, and gelatin and methacrylic anhydride form covalent bonds, so that the 3D bioprinted cartilage is good in mechanical property and is not easily broken; the gelatin has biocompatibility and degradability of normal biological material hydrogel, has bioactivity, and is good for cell growth and differentiation and realization of cell functions.

Owner:西安博恩生物科技有限公司

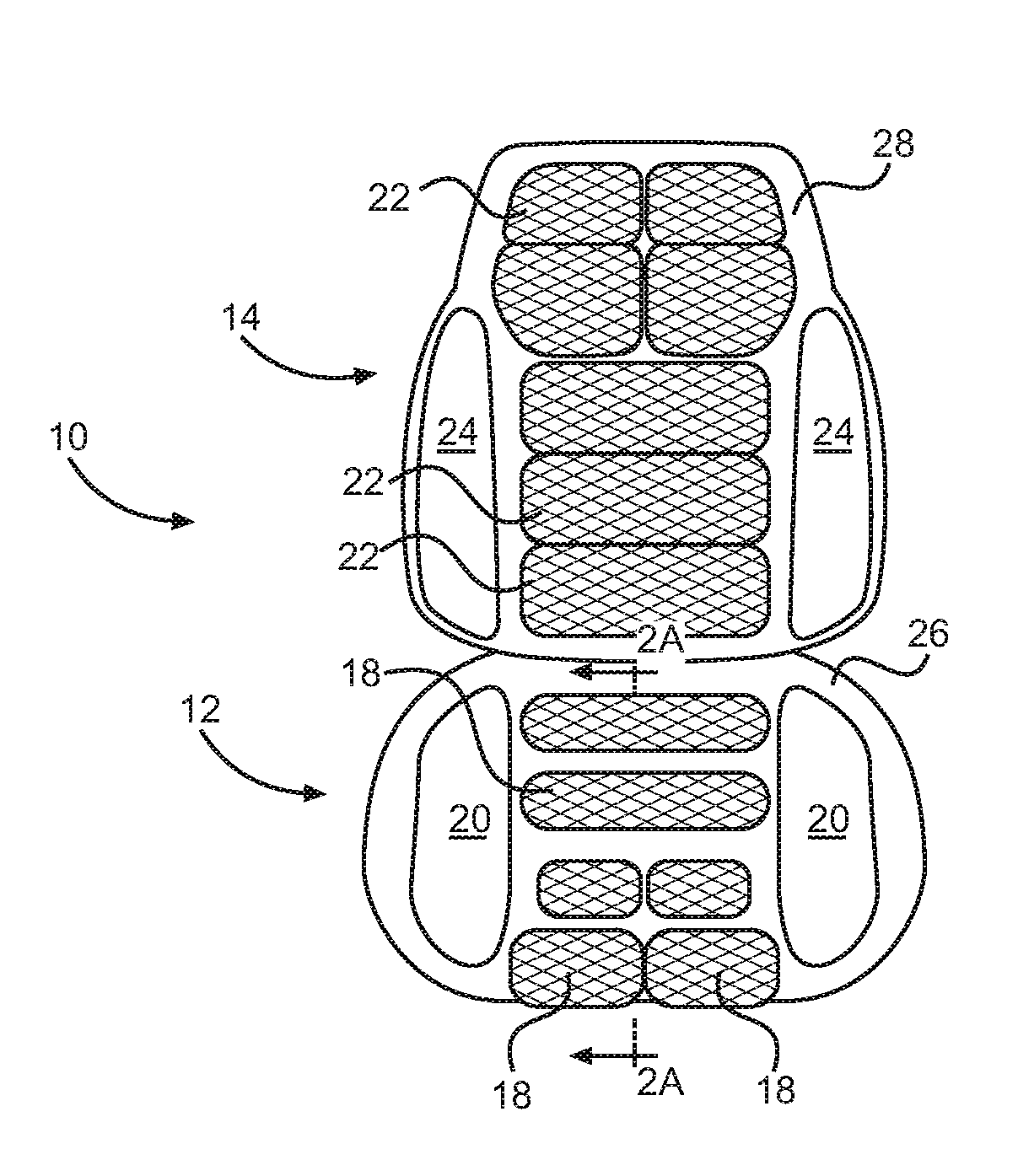

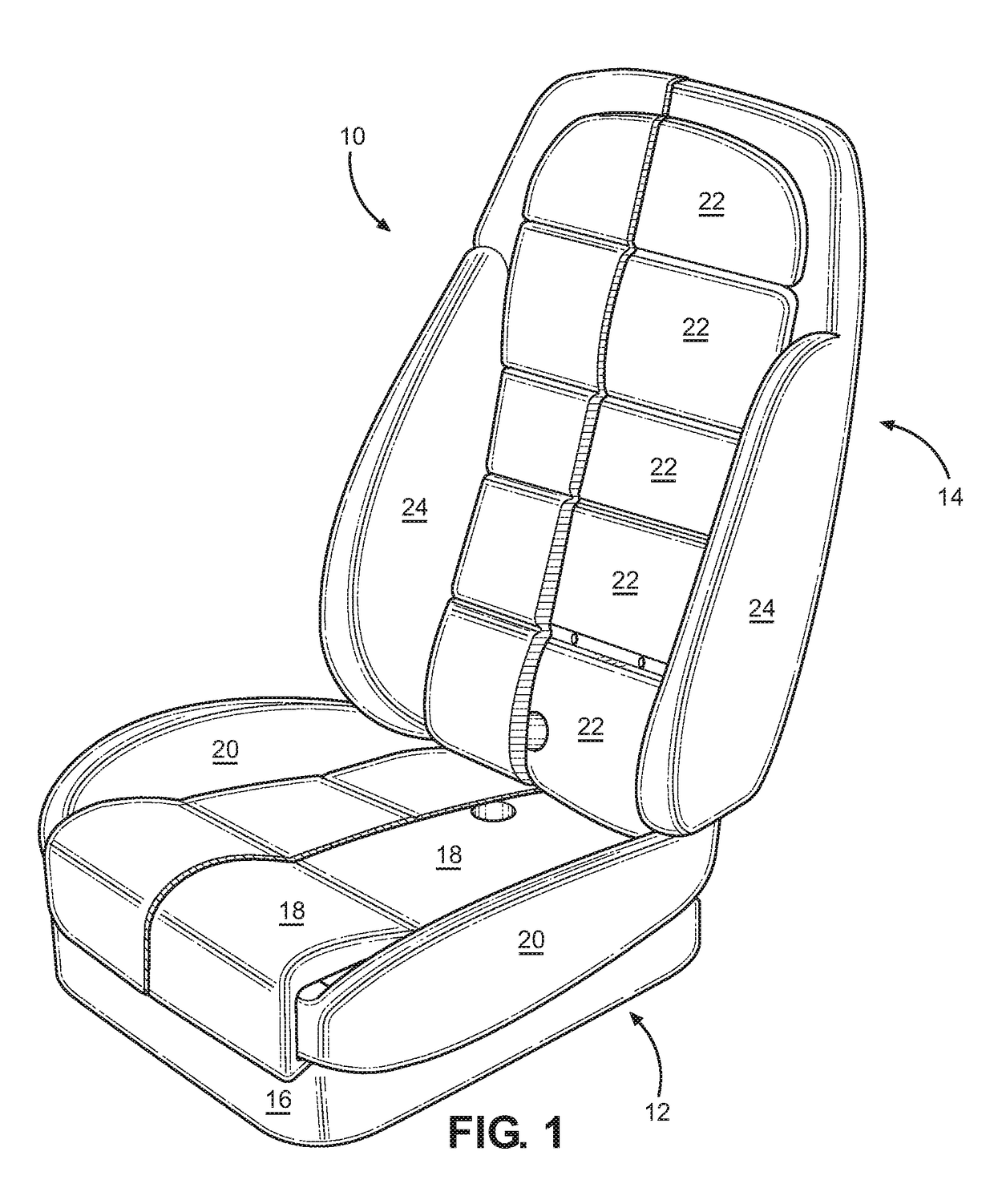

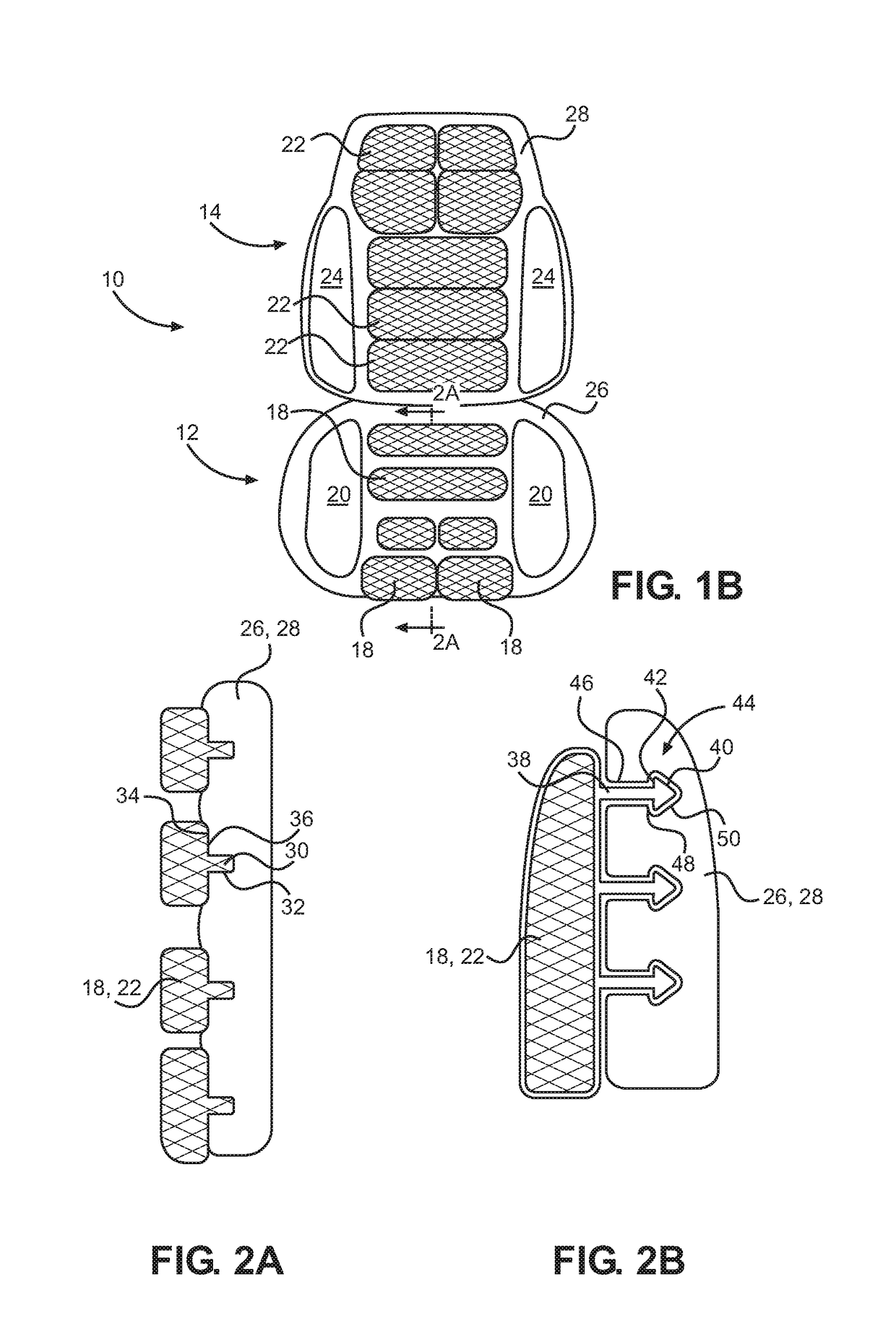

Ventilated Seat Cushion

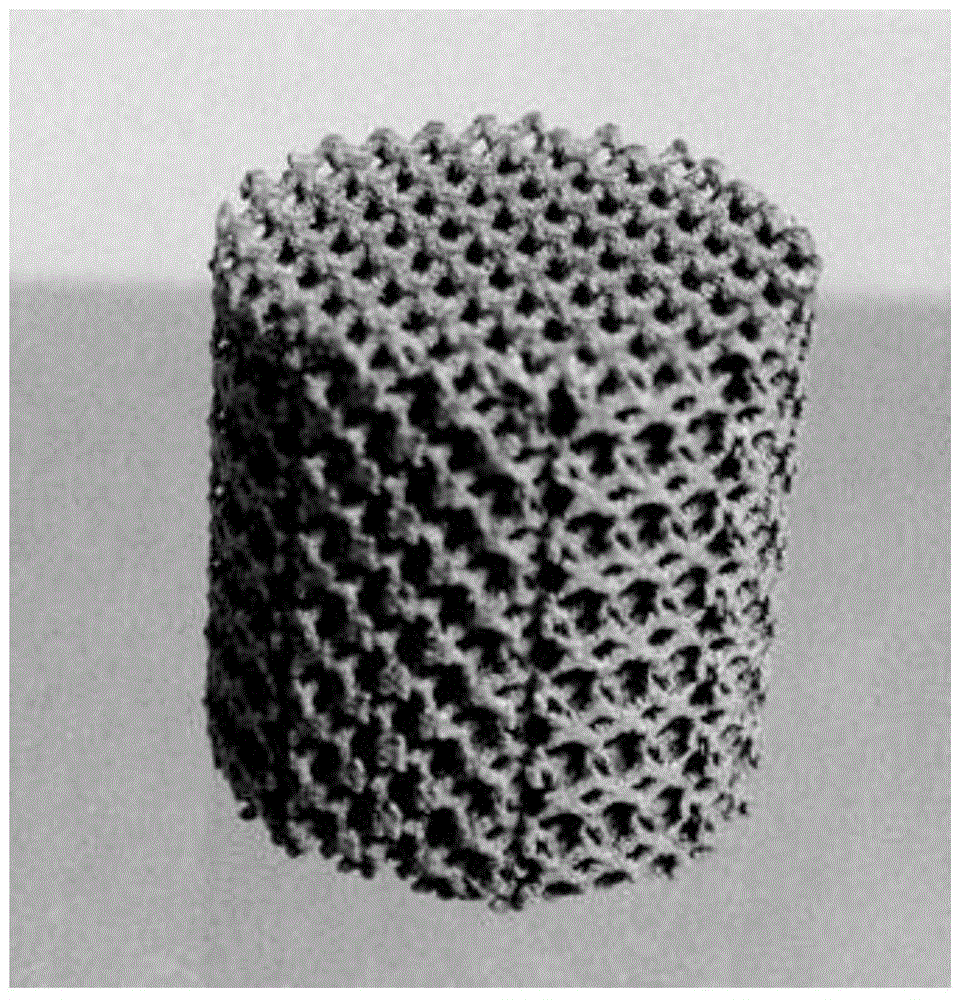

ActiveUS20180043805A1Additive manufacturing apparatusSeat heating/ventillating devicesEngineering3d printed

A seat includes one or more cushions secured to a shell. The cushions include a 3D printed lattice of repeating cells. The cells may include nodes interconnected by branches. The nodes may be arranged in a cubic, parallelepiped, diamond, or other arrangement. The branches may extend directly between nodes or may be bent. The branches may extend from each node to an adjacent node that is closest to its point of attachment to the each node or the branches may be curved or bent to secure to a different adjacent node. The 3D printed lattice may include 3D printed barbs formed thereon that engage receptacles in the seat shell. The 3D printed lattice may be printed with a groove that engages a fastening structure on a cover or a separate fastening element. The cover may be a perforated sheet of material or fabric.

Owner:FORD GLOBAL TECH LLC

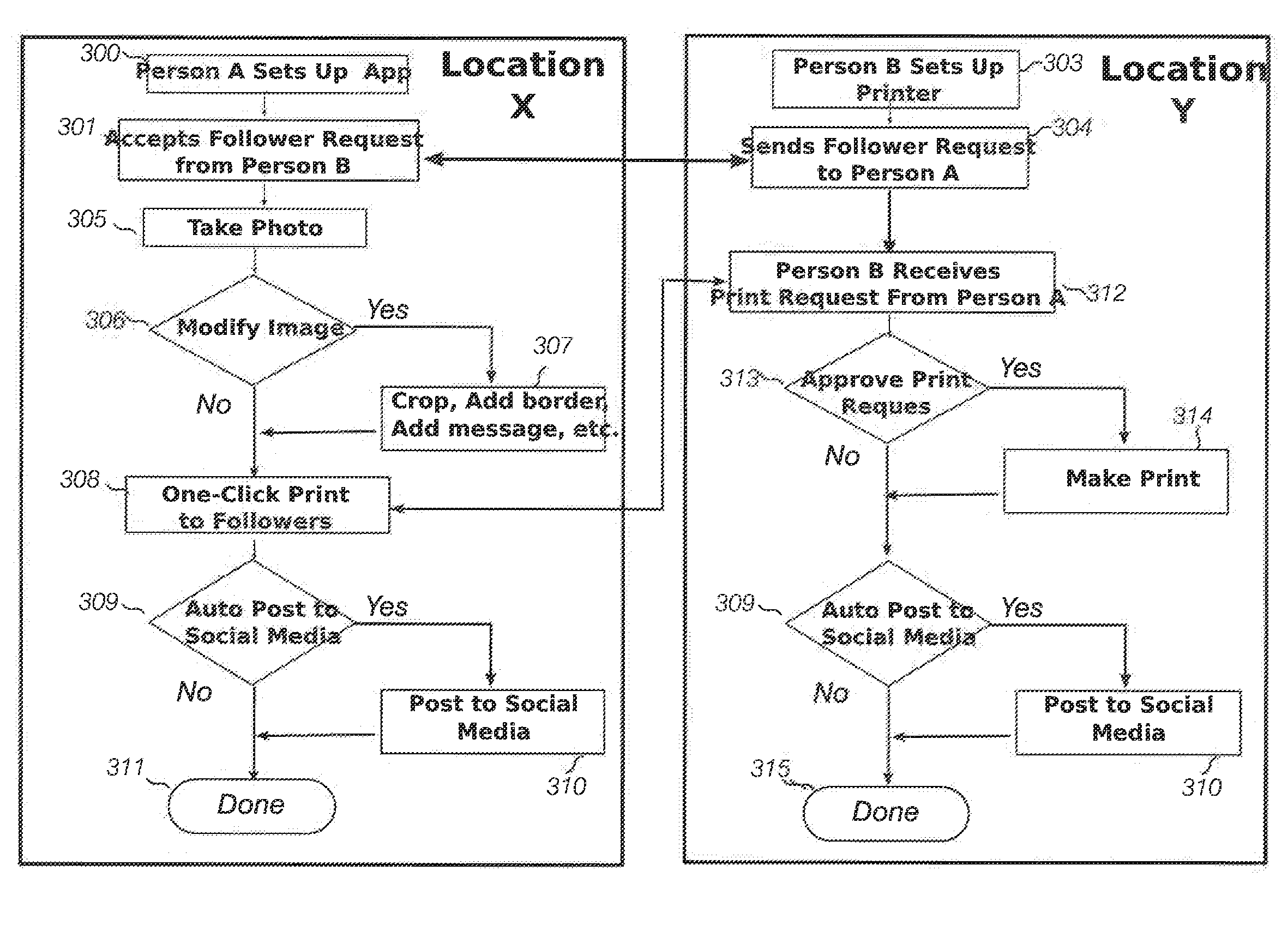

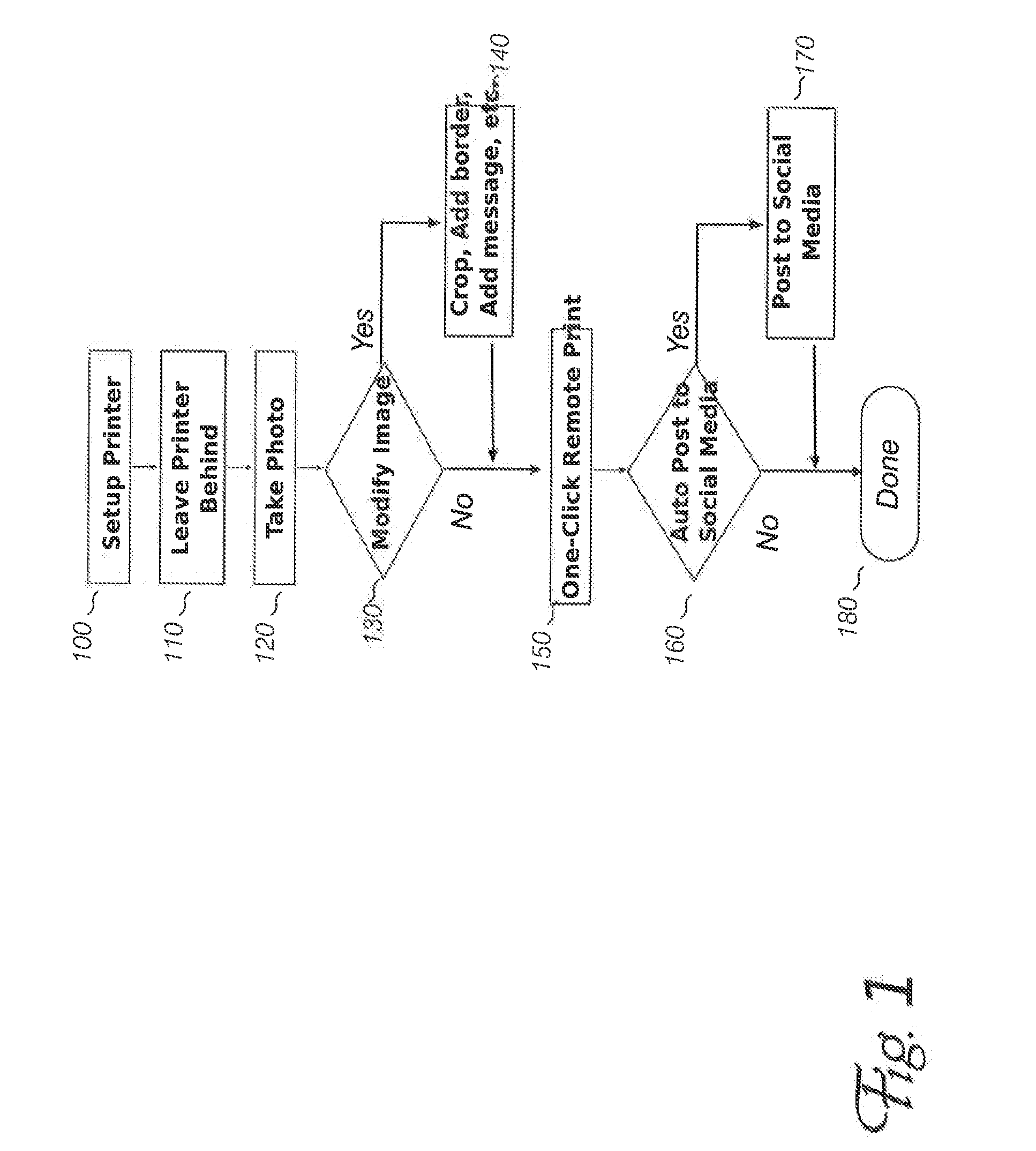

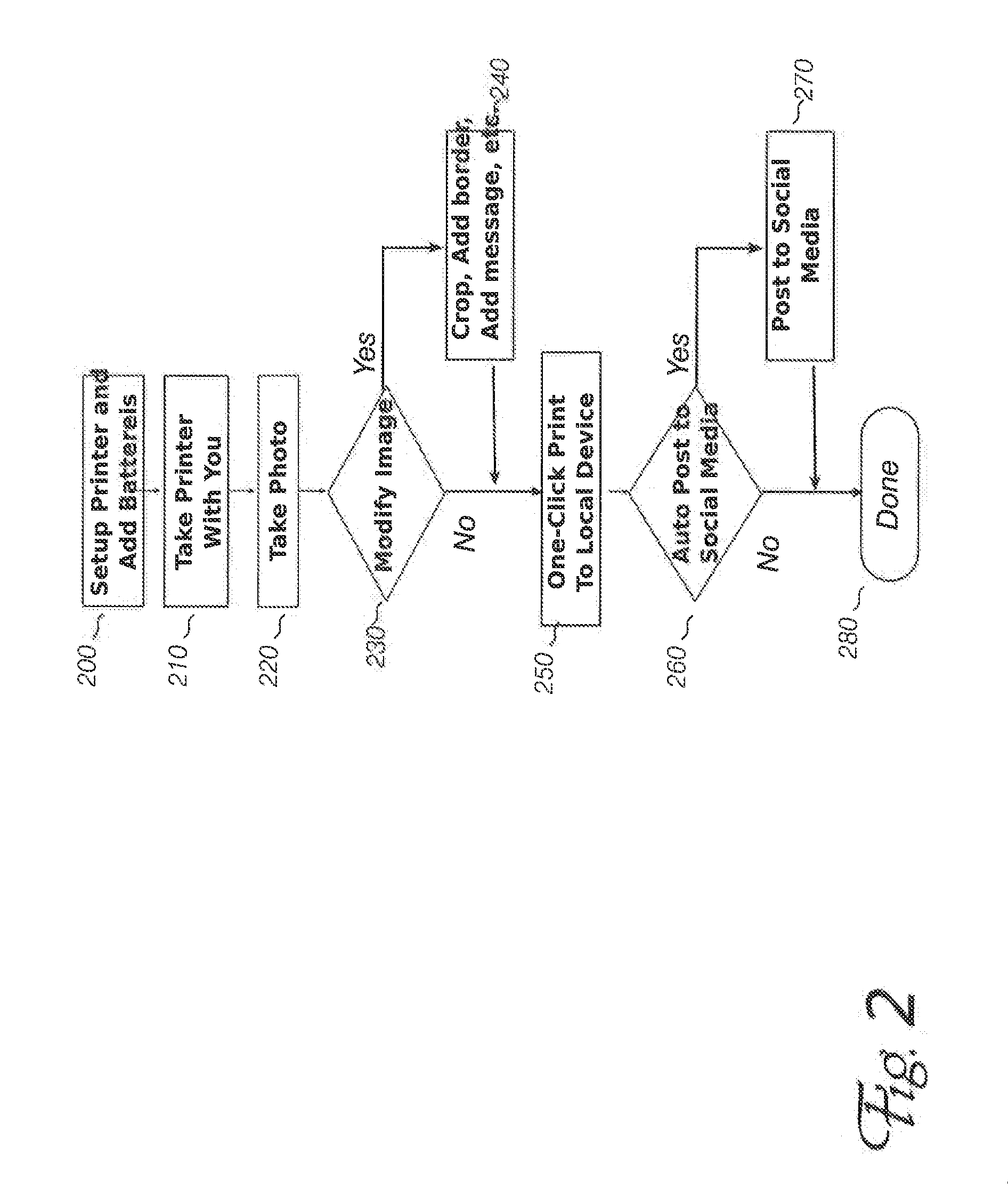

Distributed Printing Social Network

InactiveUS20150244878A1Efficient data transferLessDigitally marking record carriersDiscounts/incentivesData stream3d printed

Owner:LIFEPRINT +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com