Steel rail and producing method thereof

A production method and rail technology, applied in the field of metallurgy, can solve the problems of poor resistance to contact fatigue damage, contact fatigue crack damage, hidden dangers of driving safety, etc., achieve good resistance to contact fatigue damage, reduce residual stress, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

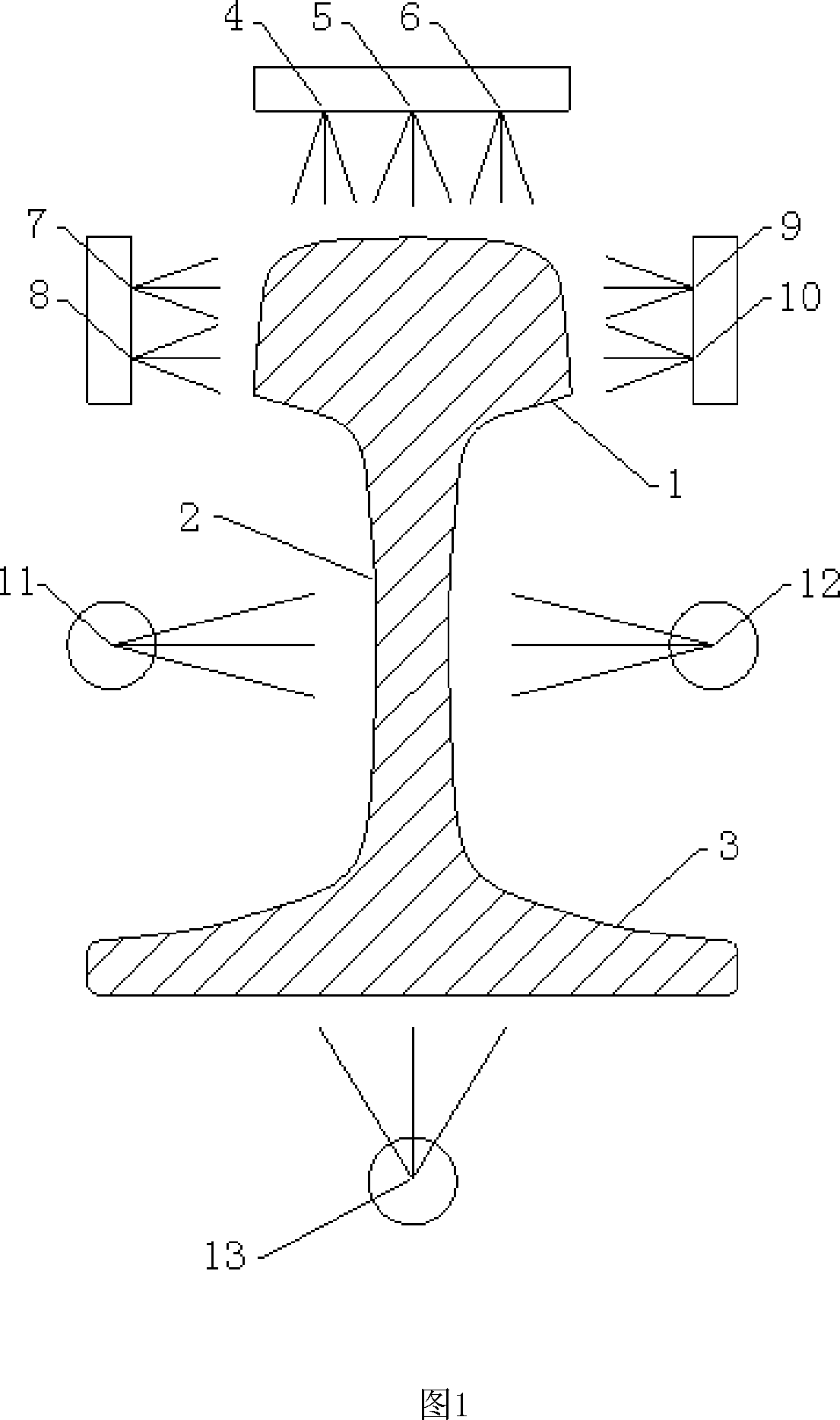

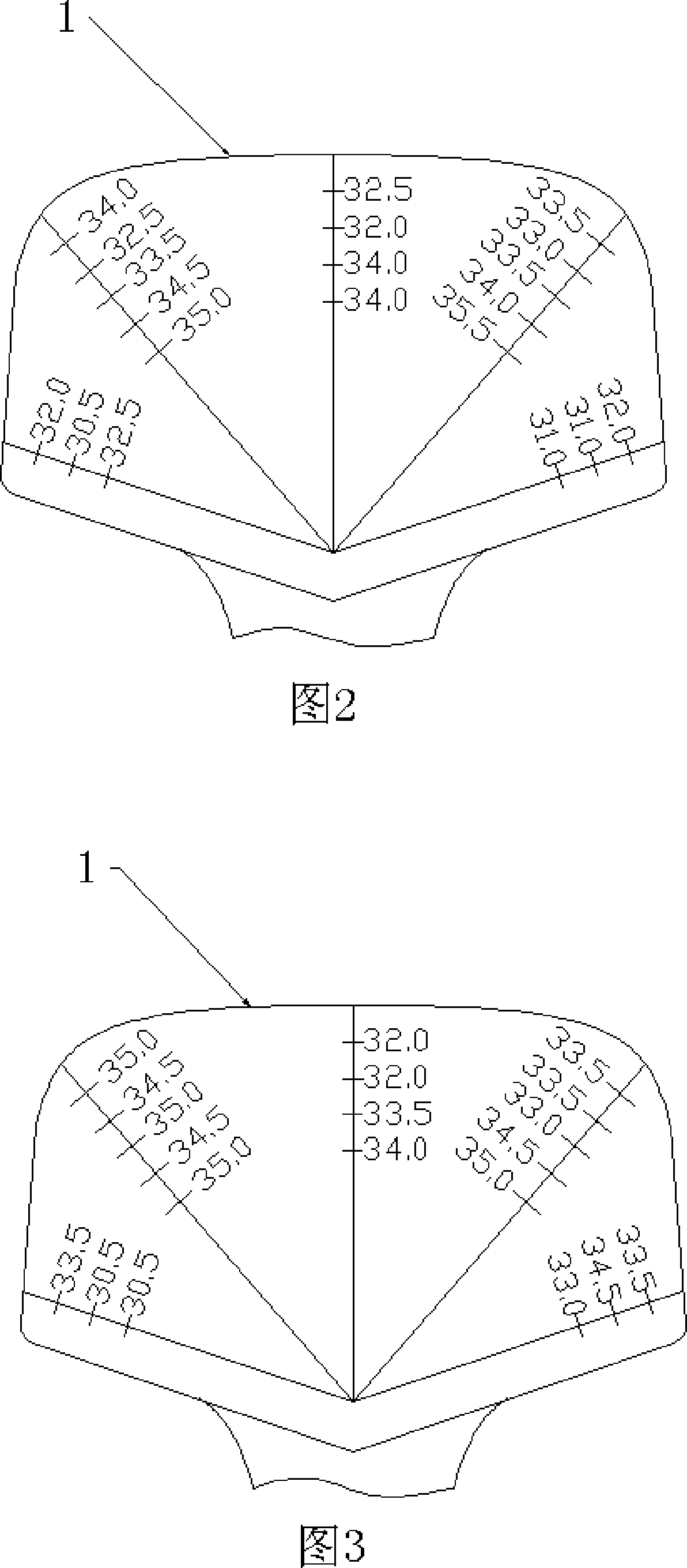

[0028] The steel rail has a chemical composition of C=0.63%, Si=0.22%, Mn=1.05%, Fe=97.95% and other trace elements 0.15%. After the rail is hot-rolled and formed by a universal rolling mill, the residual heat after hot-rolling is used for on-line heat treatment to quench and cool the rail. The temperature before the quenching and cooling of the rail is 750°C, and the quenching and cooling time is 110 seconds. During the quenching and cooling, the rail head 1, the rail waist 2 and the rail bottom 3 of the rail are simultaneously quenched and cooled. By quenching and cooling the rail head 1, rail waist 2, and rail bottom 3 at the same time, the strength of the rail waist 2 and rail bottom 3 can be improved under the condition that the rail head 1 obtains the required structure and performance, so that Improve the overall strength of the rail; at the same time, quenching and cooling the rail head 1, rail waist 2, and rail bottom 3 can reduce the temperature difference between th...

Embodiment 2

[0032] The chemical composition of the steel rail is: C=0.72%, Si=0.31%, Mn=1.25%, Fe=97.54% and 0.18% of other trace elements. After the rail is hot-rolled and formed by a universal rolling mill, the residual heat after hot-rolling is used for on-line heat treatment to quench and cool the rail. The temperature before quenching and cooling of the rail is 790°C, and the quenching and cooling time is 118 seconds. During quenching and cooling, the rail head 1, rail waist 2, and rail bottom 3 of the rail are simultaneously quenched and cooled.

[0033] Wherein, the quenching and cooling intensity of the rail head 1 is greater than that of the rail waist 2 and the rail bottom 3 . As shown in Figure 1, three rows of nozzles 4, 5, 6 are set on the tread of rail head 1, two rows of nozzles 7, 8 and 9, 10 are set on both sides of rail head 1, and two rows of nozzles 7, 8 and 9, 10 are set on both sides of rail waist 2 respectively. A row of nozzles 11 and 12, and a row of nozzles 13 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com