Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

219results about How to "Good viscosity and temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

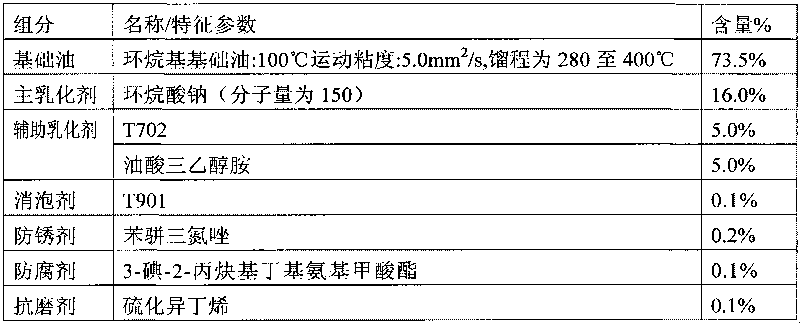

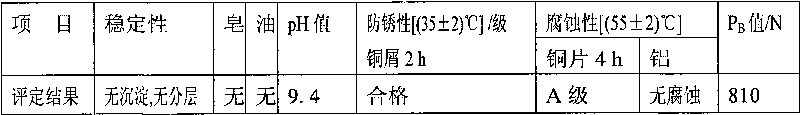

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

Method for preparing polyol ester lubricating oil by using composite solid acid catalyst

InactiveCN102887825AHigh esterification rateHigh purityOrganic compound preparationCarboxylic acid esters preparationDistillationAcid value

The invention relates to a method for preparing polyol ester lubricating oil by using a composite solid acid catalyst. The method comprises the following steps of: adding a water carrying agent into polyol ester and monobasic fatty acid, performing esterification reaction under the action of the composite solid acid catalyst, and dehydrating and esterfying to obtain raw ester; performing filter pressing on the raw ester to separate the raw ester from the solid acid catalyst, wherein the catalyst can be recycled; and performing reduced pressure distillation on the raw ester to remove the residual fatty acid, and then deacidifying and decolorizing to refine with heating by using a refining adsorption bed layer respectively to obtain low-acid value polyol ester lubricating oil. The method has the advantages that the catalyst can be recycled, the esterification rate is high, an aftertreatment process is simple, and a product is low in acid value, high in purity, environment-friendly and suitable to be produced industrially. The reaction esterification rate can reach over 99 percent, and the acid value of the ester product obtained through refining can be controlled to be less than 0.01mg KOH / g. The product is excellent in visco-temperature performance, high in lubricity and thermal stability, strong in hydrolytic stability, low in volatility and excellent in electrical insulation property.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

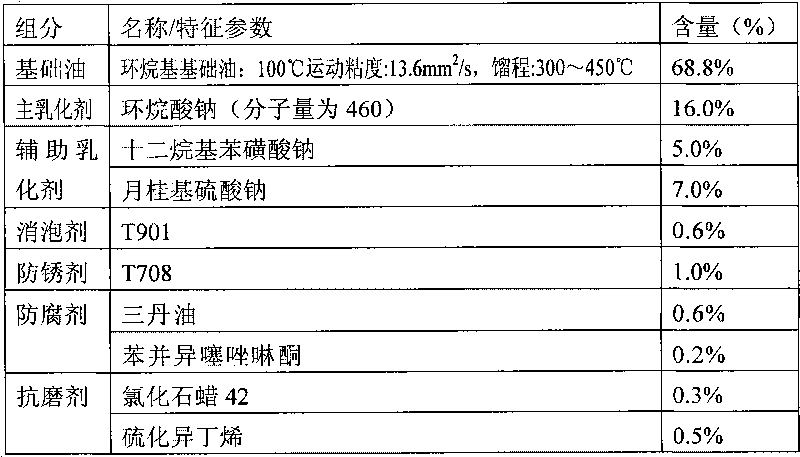

Lubricating oil compound and preparation method thereof

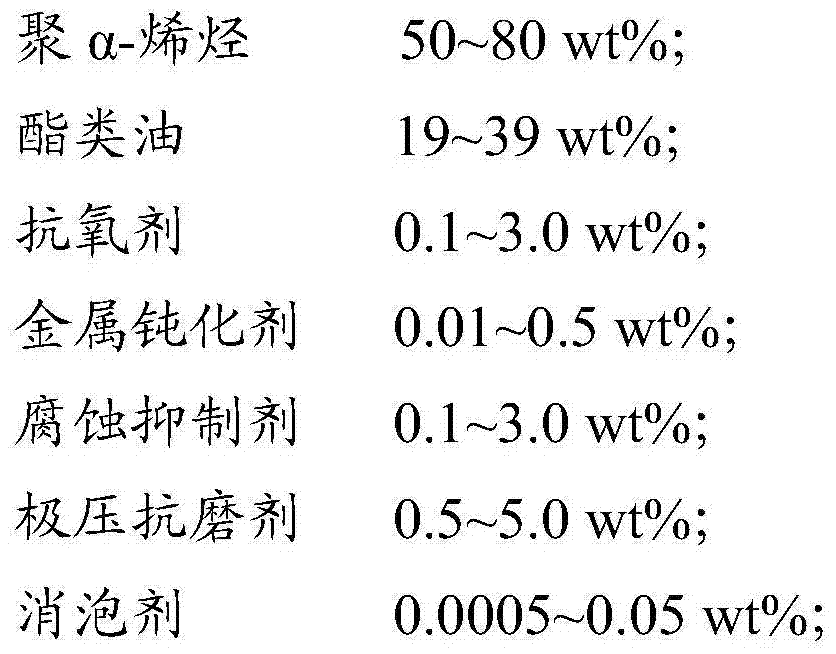

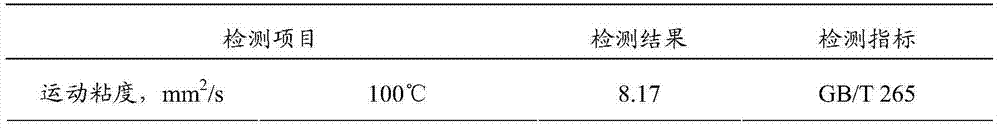

InactiveCN103497818AImproved high temperature oxidation stabilityGood viscosity and temperatureLubricant compositionOxidation stabilityAlpha-olefin

The invention provides lubricating oil compound and a preparation method thereof. The lubricating oil compound comprises 50-80wt% of poly alpha olefin, 19-39 wt% of ester oil, 0.1-3.0wt% of antioxidant, 0.01-0.5wt% of metal passivator, 0.1-3.0wt% of corrosion inhibitor, 0.5-5.0wt% of extreme pressure antiwear agent and 0.0005-0.05wt% defoaming agent. Compared with existing lubricating oil, the lubricating oil compound has the advantages that the poly alpha olefin in the lubricating oil is good in viscosity-temperature performance, low-temperature flowability and good in thermal oxidation stability; by the ester oil with good oxidation stability and high-temperature performance, high temperature oxidation performance of the lubricating oil compound can be increased; additives with good oxidation stability and extreme pressure antiwear performance are added to form a composite system, and the lubricating oil compound is good in extreme pressure lubricity and high-temperature oxidation stability under interaction of the additives.

Owner:CHINA PETROLEUM & CHEM CORP

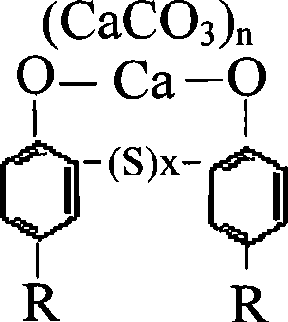

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

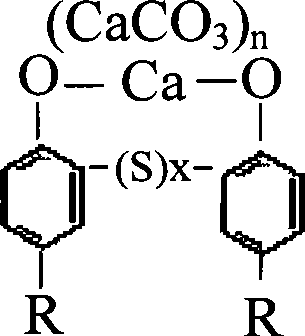

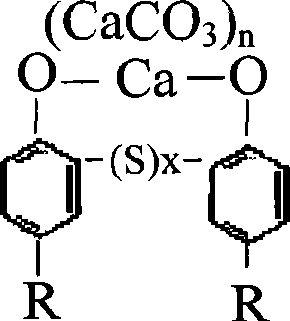

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

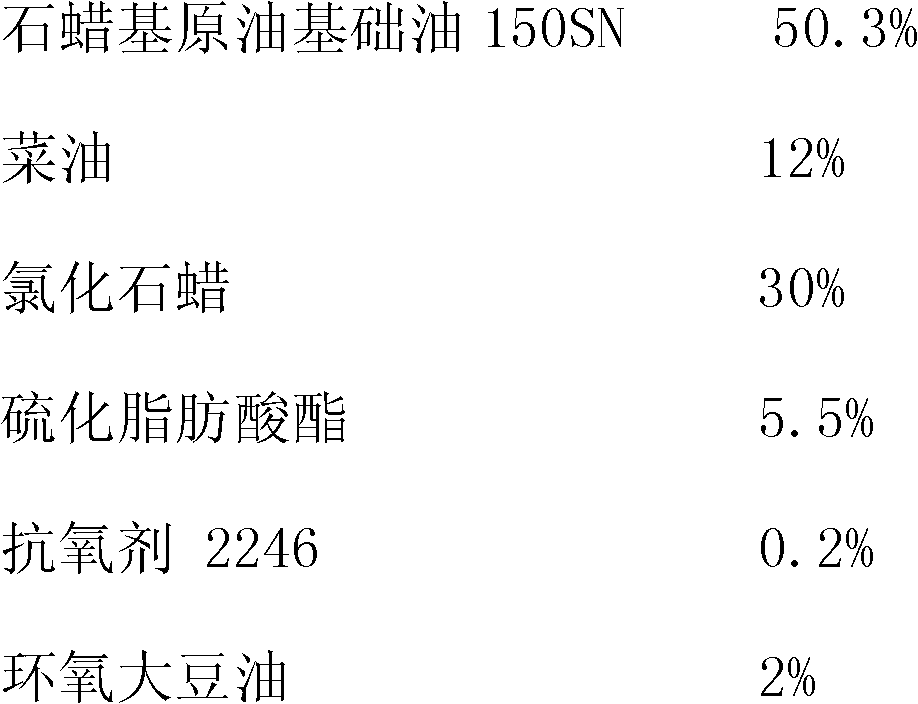

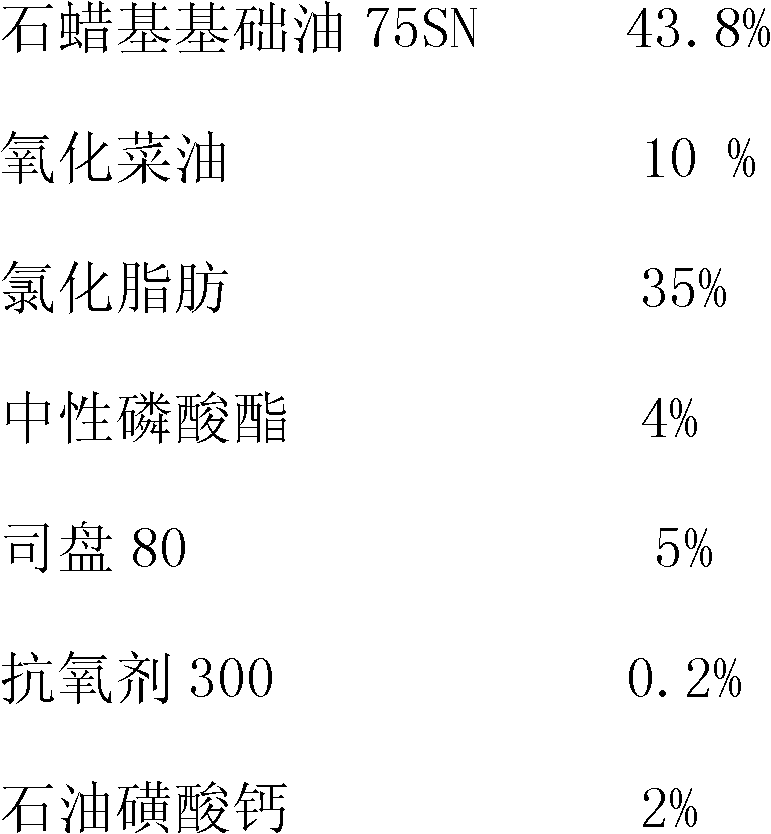

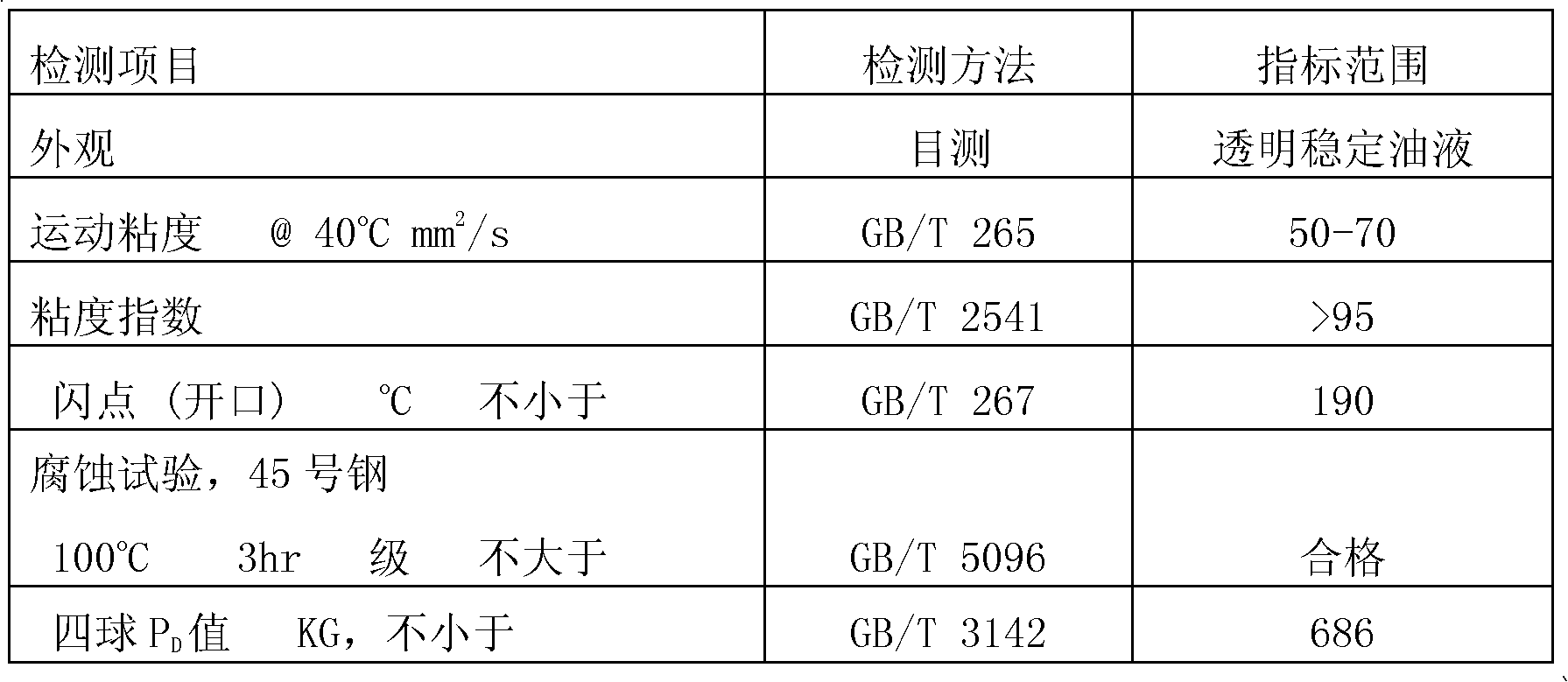

Metal drawing oil

The invention discloses metal drawing oil which is characterized by containing the following components in percentage by weight: 10-30% of oiliness agent, 20-40% of extreme pressure additive, 0-0.5% of antioxidant, 0-5% of corrosion inhibitor and the balance of base oil. The product disclosed by the invention contains a great deal of oiliness agent and extreme pressure additive, and can be used for providing favorable lubricating property and strong adhesive force, reducing the heat in a forming process, effectively lubricating a workpiece and a die, favorably protecting the die and prolonging the service life of the die. Due to the excellent extreme pressure property, the workpiece quality is effectively improved and the processing power is effectively increased under high, deep and difficult processing conditions; and the metal drawing oil is high in viscosity index, good in viscosity-temperature characteristics and high in temperature and weather adaptability.

Owner:LOCKS LUBE SHANGHAI

Preparation method of alcohol ester type environment lubricating oil

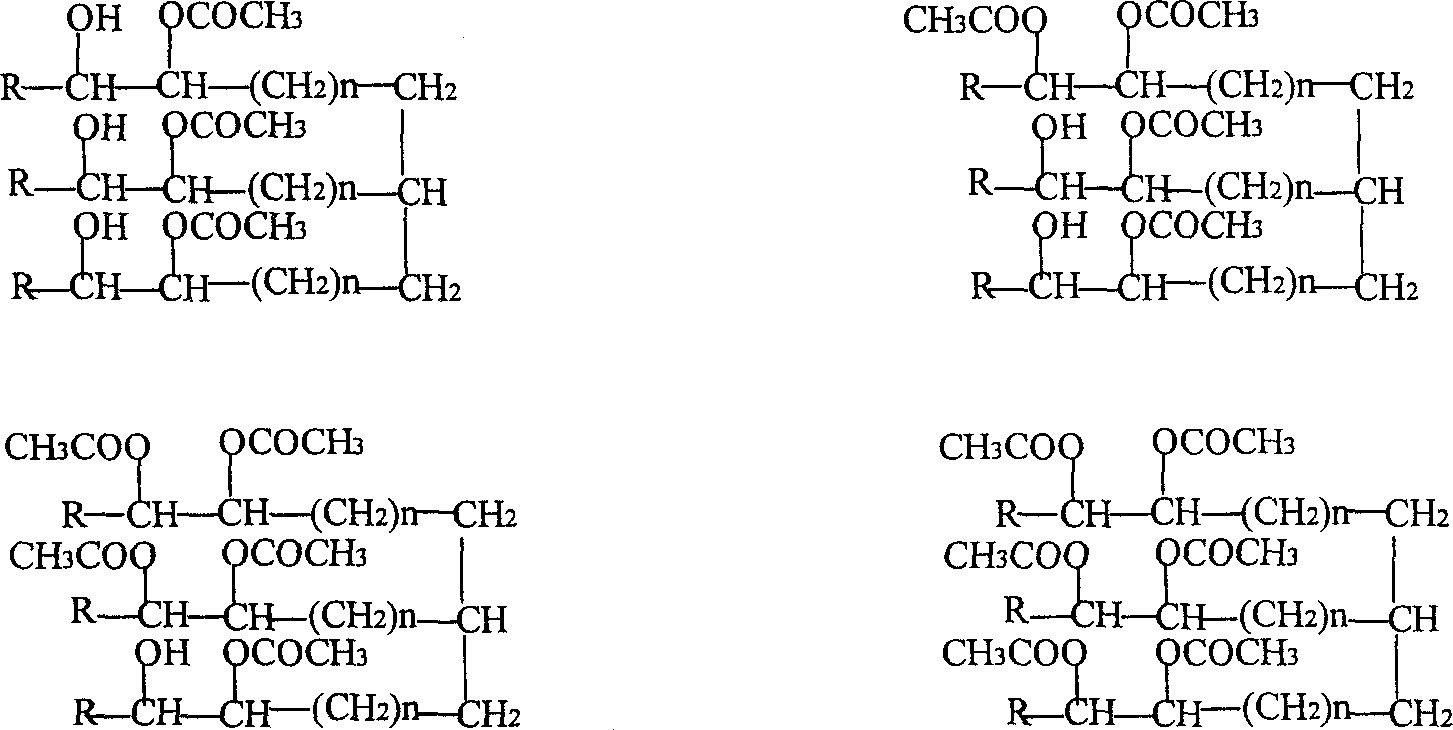

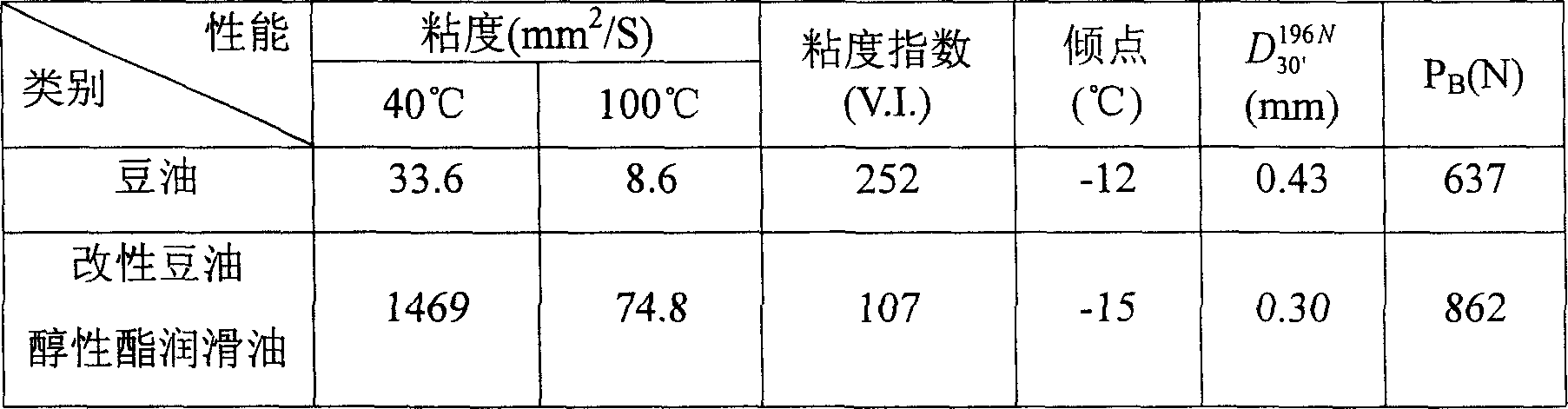

InactiveCN1869176AImprove antioxidant capacityExtended service lifeFatty acid chemical modificationBase-materialsAlcoholVegetable oil

The invention relates to an alcohol ester type green lubricating oil manufacturing method. It improves vegetable oil oxidation stability by chemical modification. It belongs to lubrication oil modification technique field. It adopts vegetable oil to do chemical medication, such as bean oil, castor oil, cotton oil, and so on. It uses H202 to change double bond into saturated epoxy bond, and open oxidation bond to form isomery ester by esterifying method. It processed lubricating oil has better anti-oxygen performance, viscosity, abrasion resistant, and viscosity-temperature characteristics.

Owner:SHANGHAI UNIV

Flame-retardant hydraulic oil and preparation and application thereof

ActiveCN101831346AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceLubricant compositionAntioxidantHigh pressure

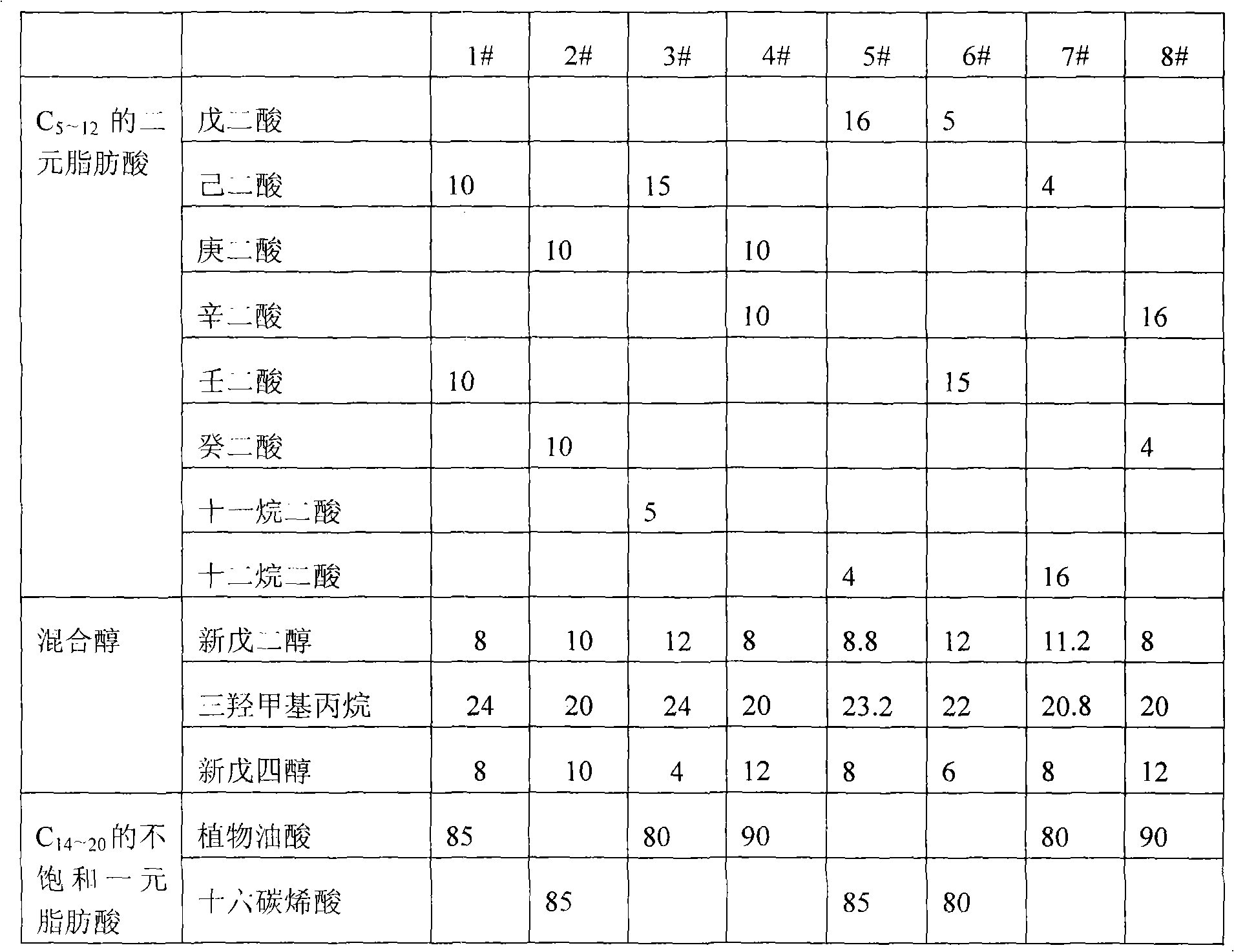

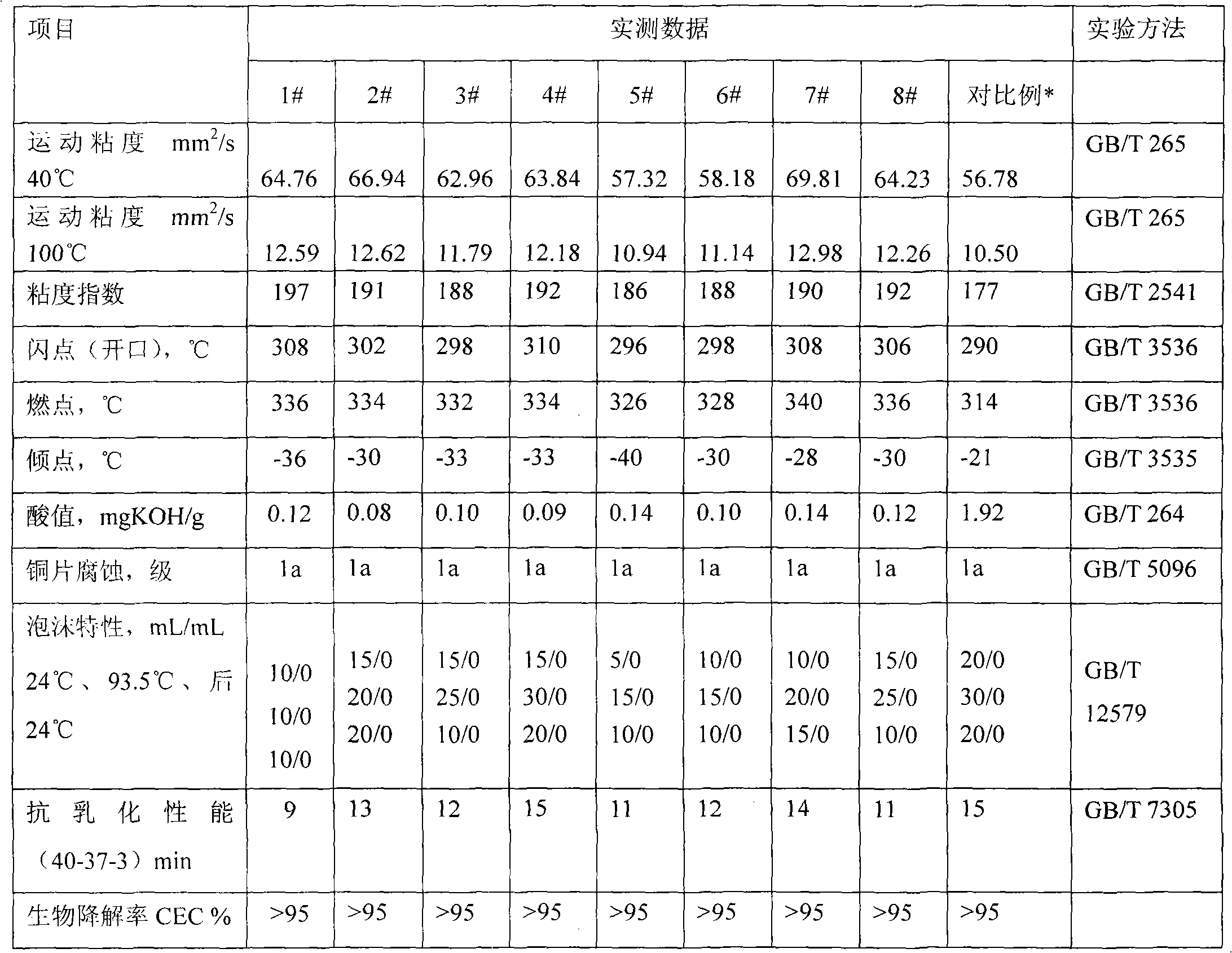

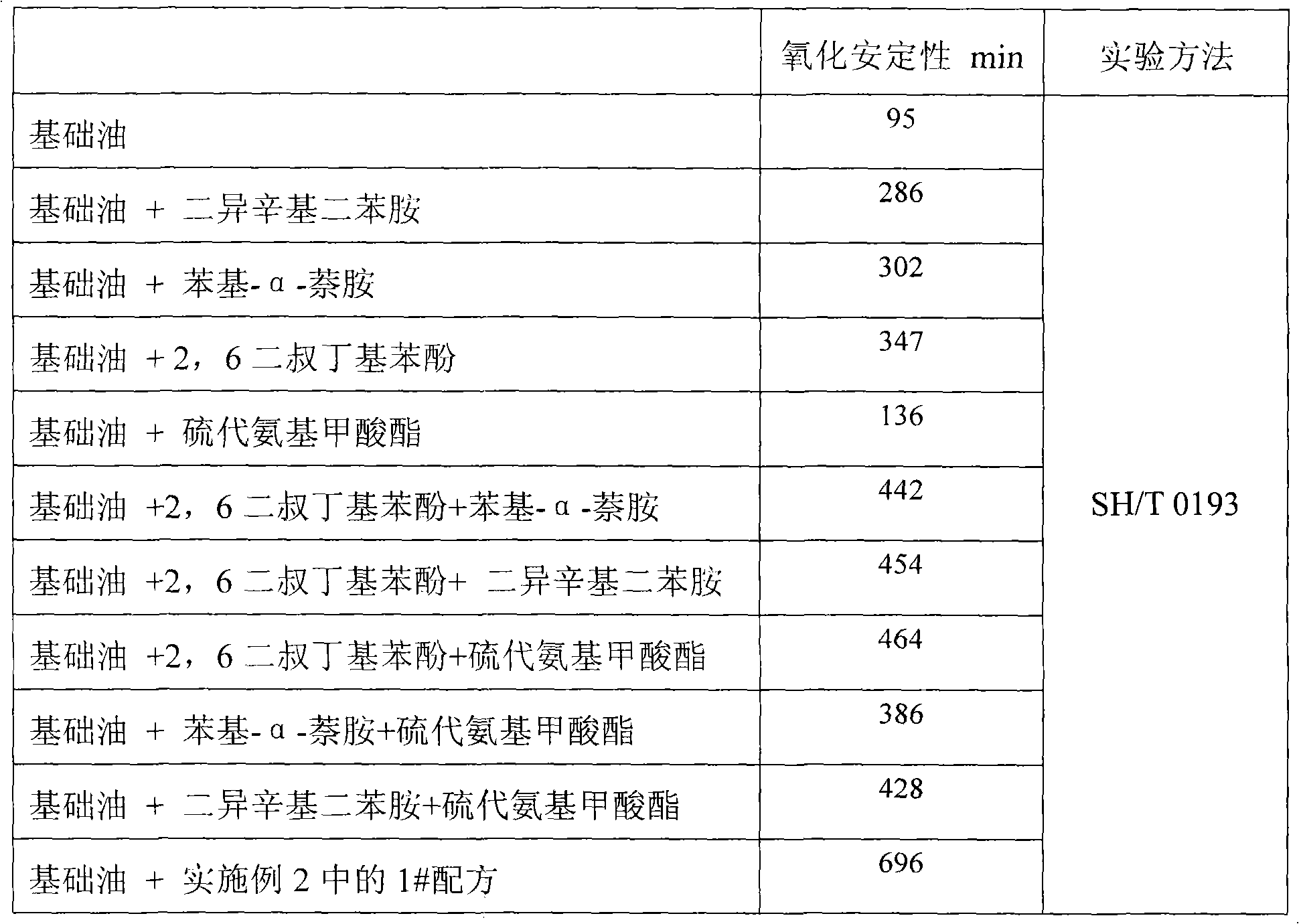

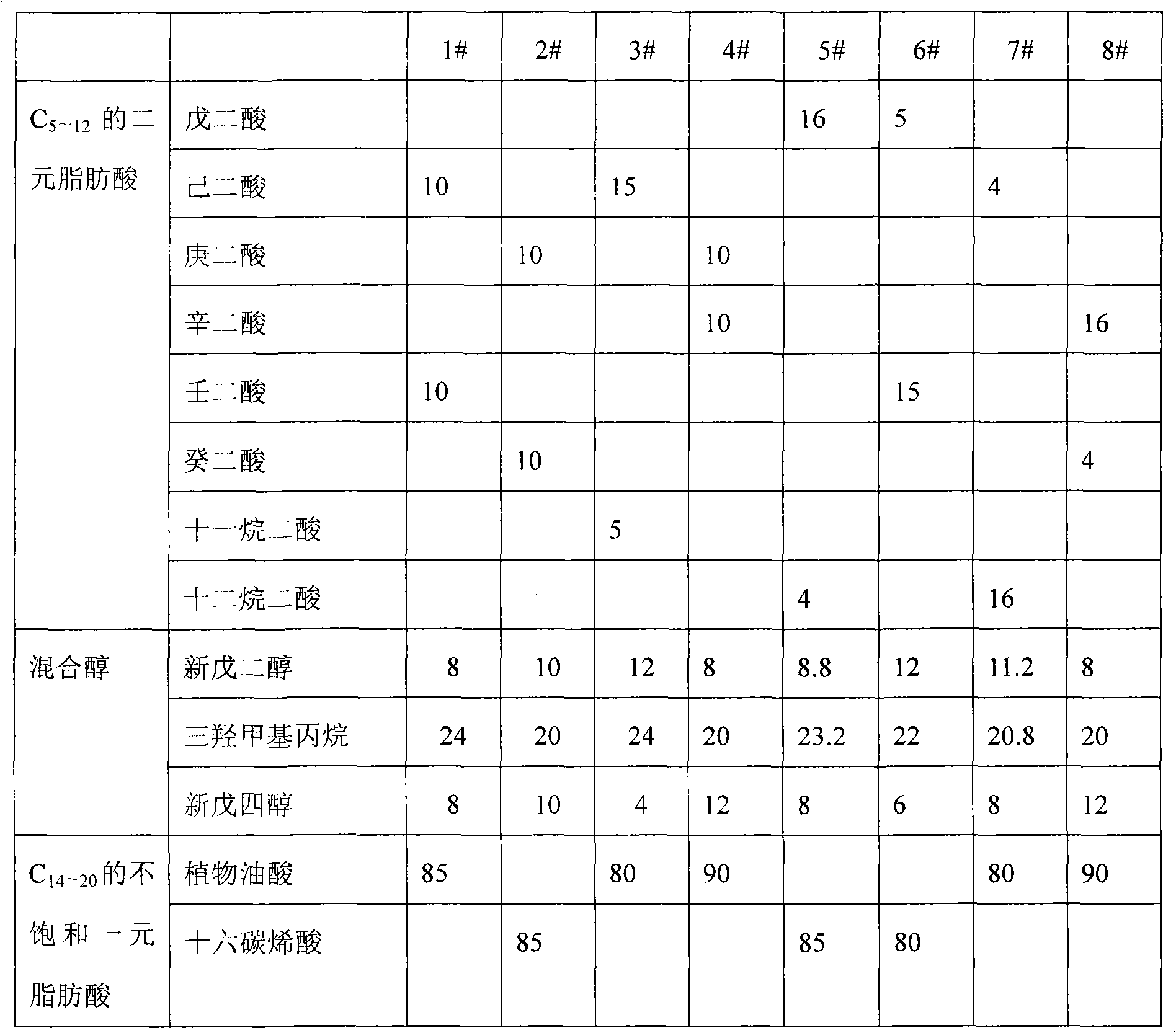

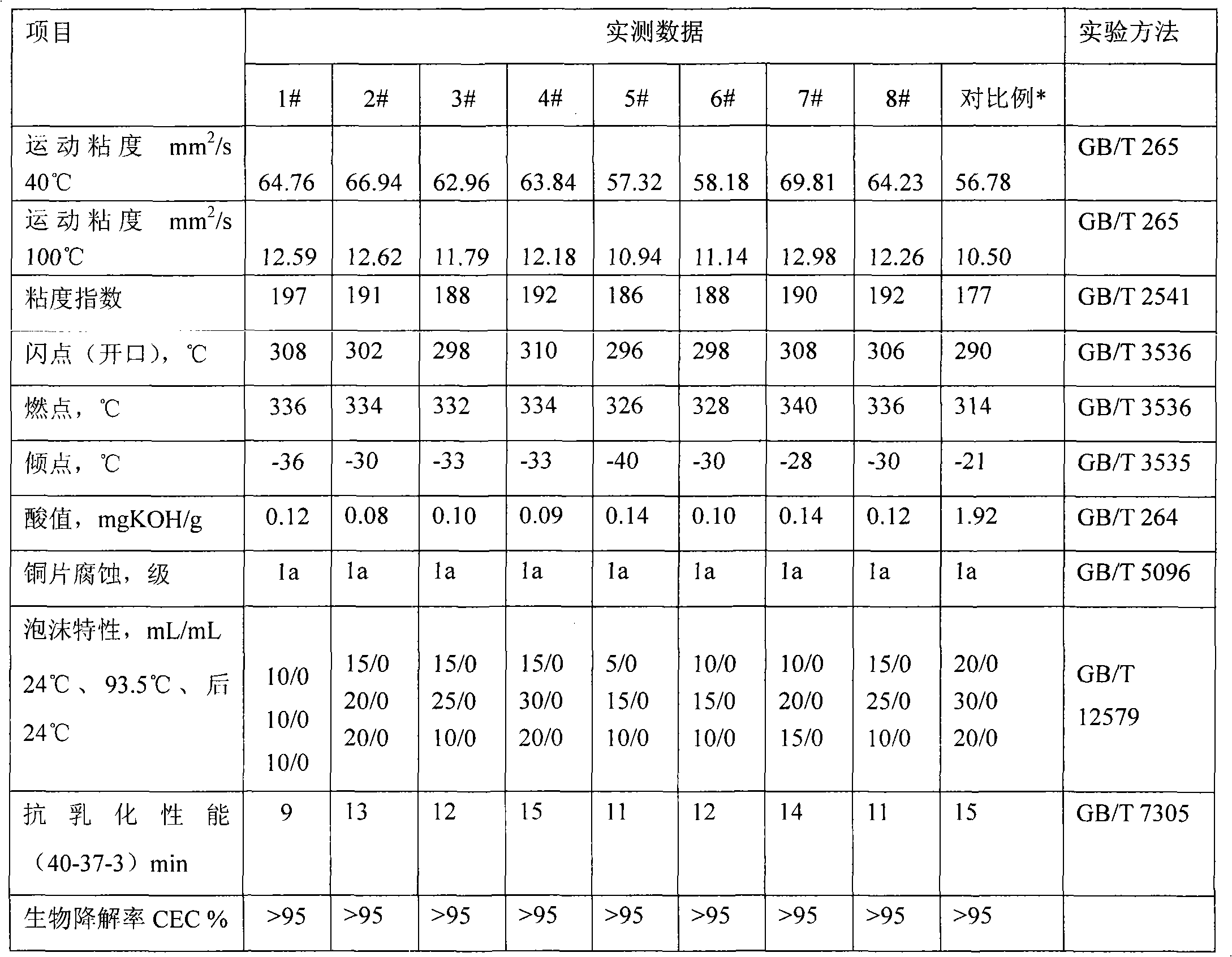

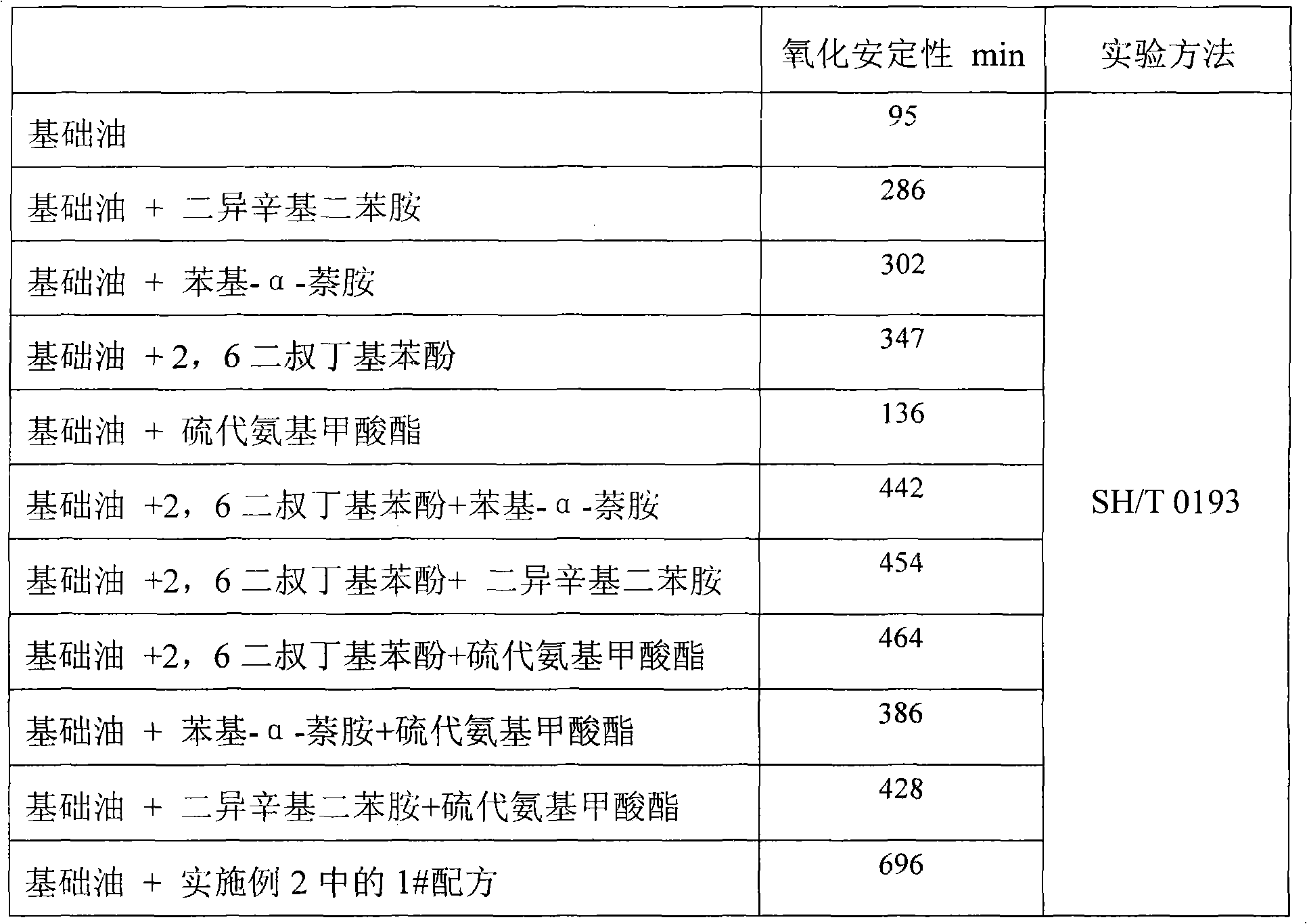

The invention provides flame-retardant hydraulic oil, which comprises the following components in percentage by weight: 1.9 to 4.5 percent of antioxidant, 1.5 to 3.5 percent of extreme-pressure abrasion resistant agent, 5 to 50ppm of antifoaming agent, 0.1 to 0.4 percent of anti-rusting agent and 92 to 97 percent of base oil, wherein the base oil is neopentyl polyol diacid composite ester which is prepared by fully esterifying carboxyl of aliphatic dibasic acid of C5-12 with mixed alcohol consisting of neopentyl glycol, trimethylolpropane and pentaerythritol and terminating the esterified product with unsaturated unitary fatty acid of C14-20. The flame-retardant hydraulic oil provided by the invention can be applied to various high-temperature and high-pressure hydraulic systems easy to contact naked flame. Compared with mineral-based (compressor) hydraulic oil, the flame-retardant hydraulic oil has the advantages of energy conservation, reduced oil consumption, reduced environmental pollution and prolonged service life, and can fully meet the working requirements of the high-temperature and high-pressure hydraulic systems easy to contact naked flame.

Owner:上海海都化学科技有限公司 +1

Lubricating oil and grease base oil, and preparation method and applications thereof

ActiveCN101812349AImprove long-term high-temperature anti-oxidation stabilitySatisfy flame resistanceBase-materialsOil and greaseEvaporation

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Owner:上海海都化学科技有限公司 +1

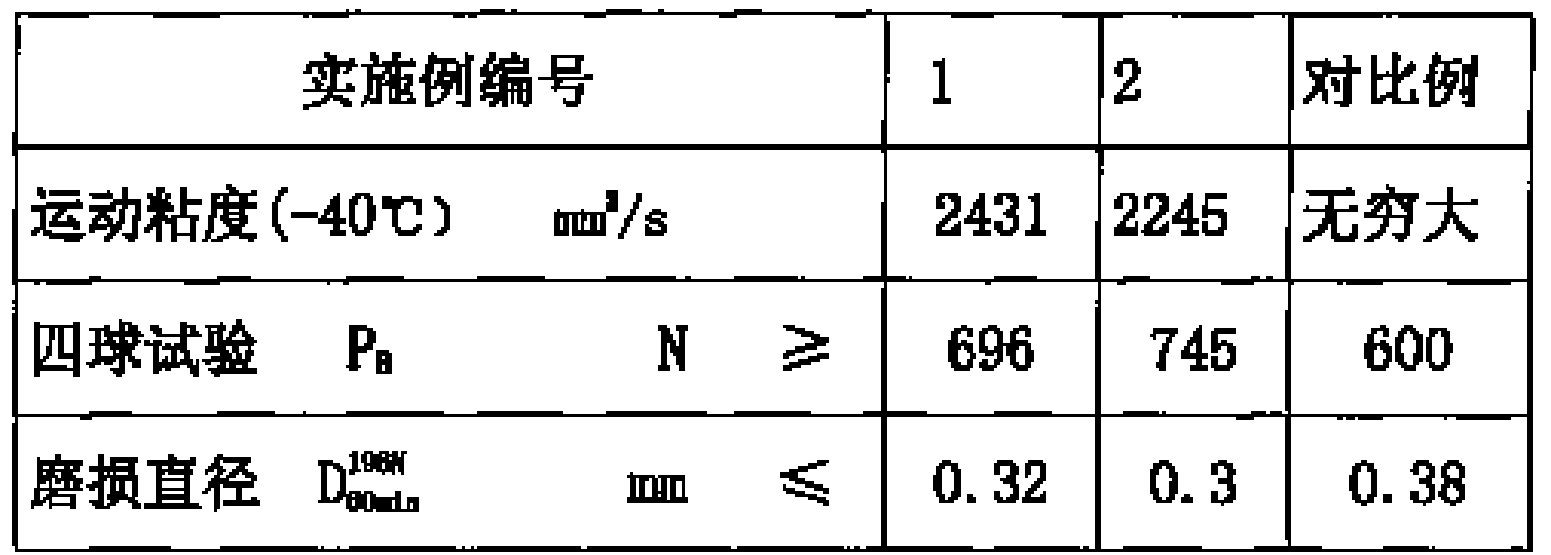

Total synthesis shock absorber oil with high viscosity index

InactiveCN101993766ASolve the viscosity temperature performanceAddress low temperature performanceLubricant compositionMethacrylatePolymer science

The invention relates to total synthesis shock absorber oil with a high viscosity index, which comprises the following components in percentage by weight: 85-95% of poly-alpha-olefin synthetic oil, 1-10% of ester synthetic oil, 1-10% of polymethacrylate viscosity index improver, 0.1-5% of anti-wear additive, 0.5-5% of antioxidant, 0.001-0.1% of anti-foaming agent, 0-1% of pour point depressant and 0.01-2.0% of antirust additive. Compared with the common shock absorber oil, the invention has the advantages of remarkable viscosity-temperature performance and antifoaming performance, excellent low temperature performance and lubricating property, favorable antirust and anticorrosion performance, and very remarkable oxidation resistance and appropriate cost, has favorable adaptability with rubber at the same time and can satisfy the use requirements, such as all weather, long life, universality, and the like.

Owner:WUXI HUIYUAN PACKAGING TECH +1

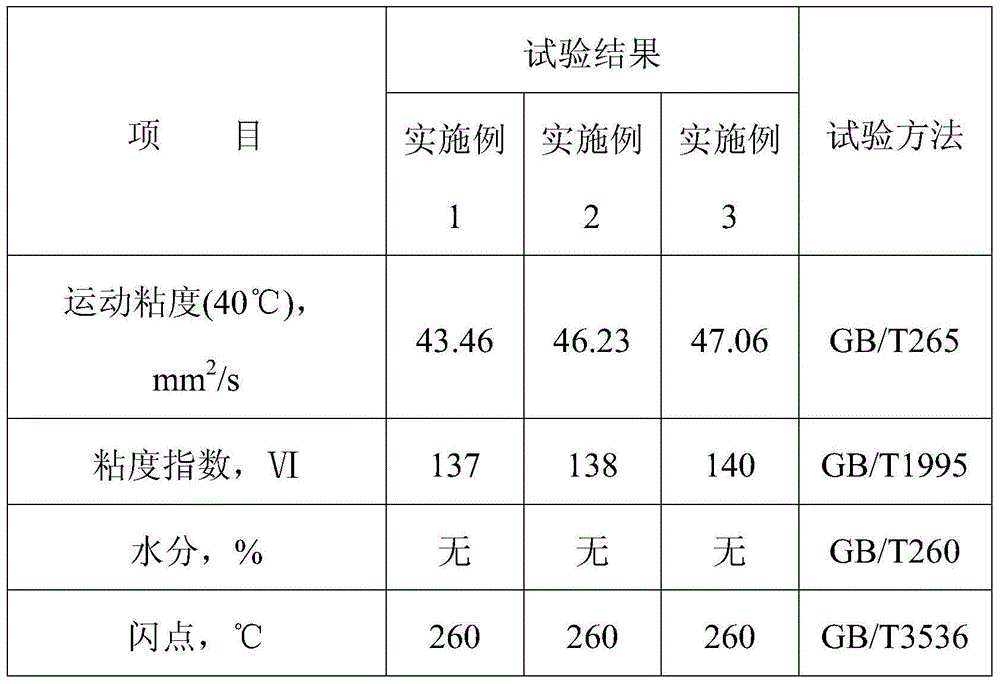

Synthetic compressor lubricant for compressing multi-component hydrocarbon mixture gas

ActiveCN101955841ASolving Dilution ProblemsReduce downtime lossesLubricant compositionHydrocarbon mixturesAntioxidant

The invention provides synthetic compressor lubricant for compressing a multi-component hydrocarbon mixture gas. The synthetic compressor lubricant consists of polyalkalene glycol synthetic oil serving as base oil and an additive. The synthetic compressor lubricant comprises the following components in percentage by weight: 90 to 97 percent of polyalkalene glycol synthetic oil, 0.05 to 2 percent of antioxidant, 0.01 to 2 percent of anti-rusting agent, 0.5 to 3 percent of oiliness agent, 0.01 to 0.5 percent of metal passivator, 0.5 to 5 percent of extreme-pressure antiwear agent and 0.001 to 0.01 percent of antifoaming agent. The synthetic compressor lubricant can resist dilution of a hydrocarbon gas to a lubricant, can adapt to the compression to the hydrocarbon gas, has good compatibility with a water vapor-containing gas mixture, and meets special requirement on the oil for a multi-component hydrocarbon mixture (such as flare gas) compressor system. The problem of dilution of the multi-component hydrocarbon mixture gas (such as the flare gas or gas) to the lubricant is successfully solved; accidents, such as stop, shaft locking and the like, of a compressor, caused by reducing of viscosity, are radically avoided; and the work stoppage loss and the worker labor intensity of enterprises are reduced.

Owner:CHINA PETROLEUM & CHEM CORP

Process for synthesizing pentaerythritol oleate

InactiveCN1381437ASimple processLess side effectsOrganic compound preparationCarboxylic acid esters preparationOrganic acidPentaerythritol

A process for synthesizing pentaerythritol oleate from pentaerythritol and oleic acid as raw materials includes dewatering condensation reaction under the action of organic acid as catalyst and removing residual acid under 20-100 Pa to obtain the pentaerythritol oleate. Its advantages are simple process, little by-reaction, low cost and high output rate. The said product has good high-temp. resistance, good lubricating performance, excellent viscosity-temp. characteristic and low-temp. flowability.

Owner:王伟松

Biodegradable lubricating oil and preparation method thereof

ActiveCN102911770AExcellent thermal and oxidation stabilityExcellent Hydrolytic StabilityLubricant compositionLubricationChemistry

The invention is suitable for the field of new materials, and provides a type of biodegradable lubricating oil and a preparation method thereof. The biodegradable lubricating oil comprises hindered polyol ester, inorganic nanoparticles and diluents, wherein the hindered polyol ester is prepared by mainly using a bio-enzyme catalysis method. The lubricating oil, prepared according to the preparation method provided by the invention, has the characteristics of excellent heat stability and oxidization stability, good hydrolytic stability, low temperature fluidity, viscosity-temperature property, lubrication property and biodegradability, and can be applied to the fields of aviation, metal processing, textile and tanning.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

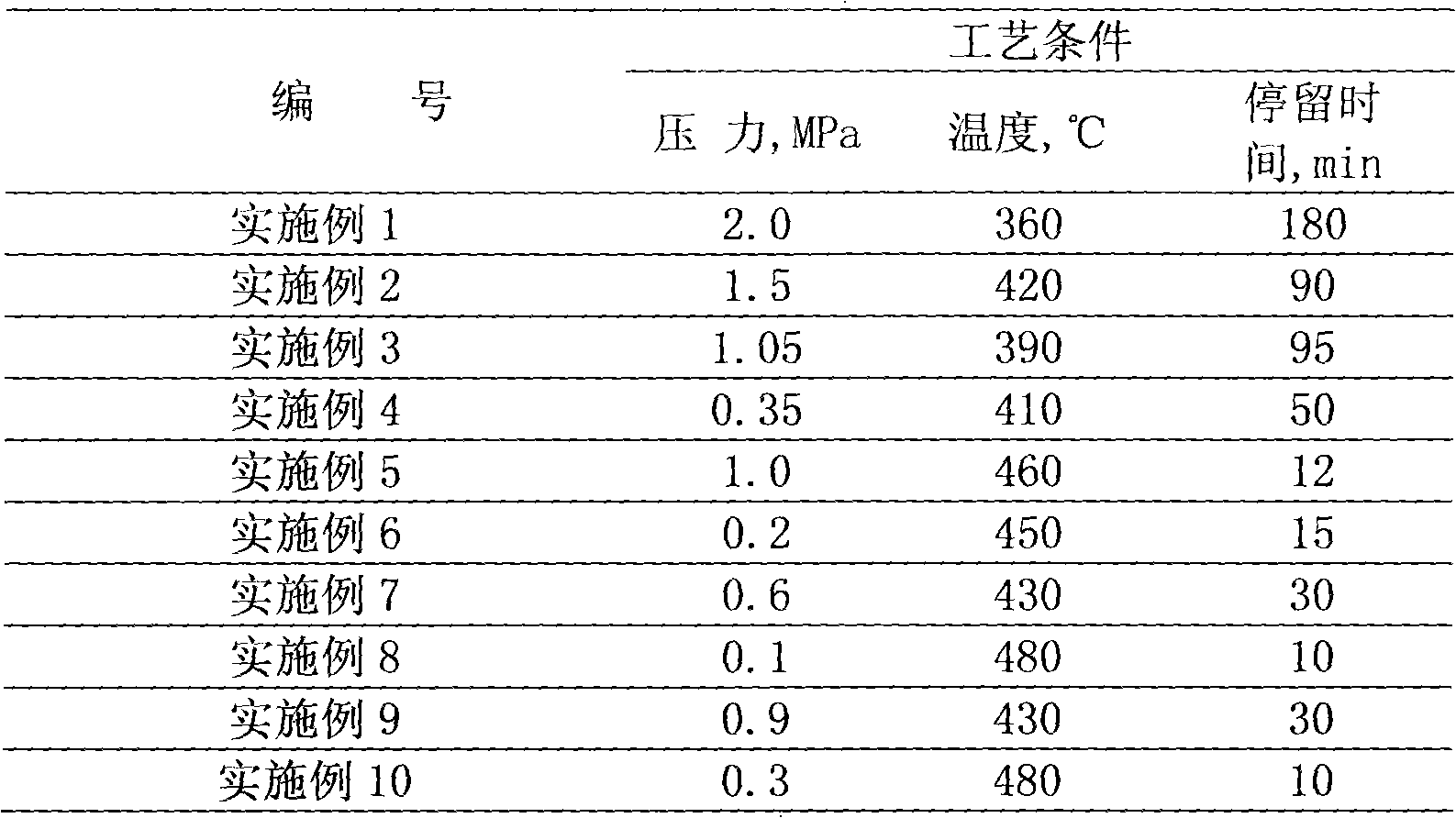

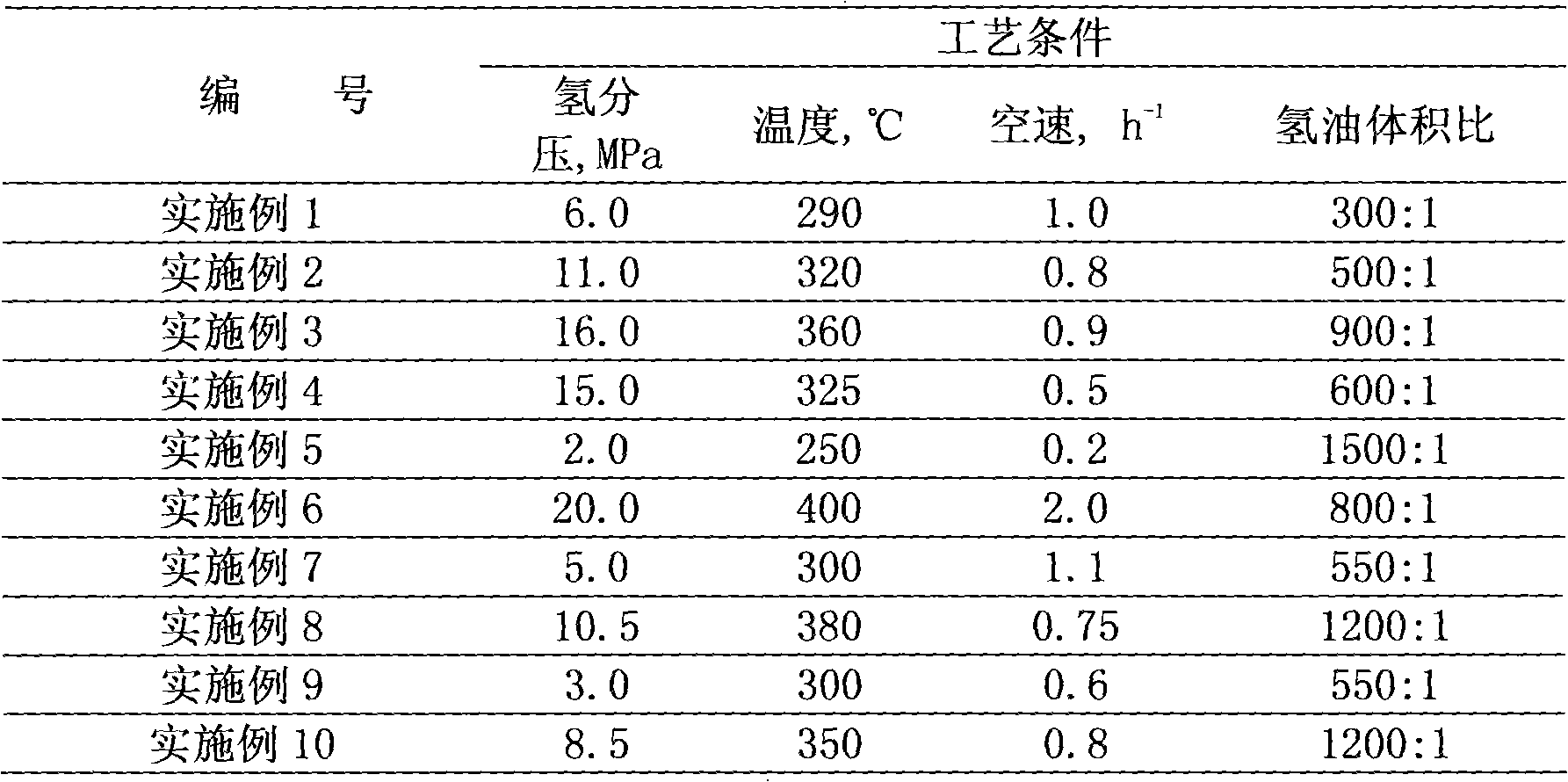

Preparation method of base oil of transformer oil

ActiveCN102485846ABroaden sources of raw materialsExpand sourceLiquid organic insulatorsTreatment with hydrotreatment processesParaffin waxSide chain

The invention relates to a preparation method of base oil of transformer oil. The preparation method utilizes inferior heavy oil and naphthenic atmospheric / reduced pressure residuum and / or paraffin-based atmospheric / reduced pressure residuum as raw materials and comprises the following steps of heating the raw materials, feeding the heated raw materials into a reactor, carrying out cooling and fractionation of the reaction products to obtain a fraction of 260 to 360, carrying out hydrofinishing of the fraction of 260 to 360 to remove S atoms, N atoms and O atoms, carrying out an olefin saturating process and an aromatic hydrocarbon hydrogenation process, carrying out solvent-based refining of the hydrofinished oil obtained by the previous step to remove polycyclic short-side chain aromatic hydrocarbons, compounds containing S, O and N, and colloid asphalt so that refined oil is obtained, carrying out hydrogenation sedimentation of the refined oil to remove a high-pour point component, and carrying out white clay-based refining of the hydrogenation sedimentation product oil obtained by the previous step to obtain white clay refined oil, wherein the white clay refined oil is the base oil of transformer oil. The preparation method provided by the invention widens raw material sources of base oil of transformer oil. Through the preparation method, the base oil of transformer oil has good viscosity-temperature characteristics and accords with standards of the IEC60296 (2003) standard, the ASTM D3487 standard, the GB 2536-90 standard and the SH0040-91 standard.

Owner:PETROCHINA CO LTD +1

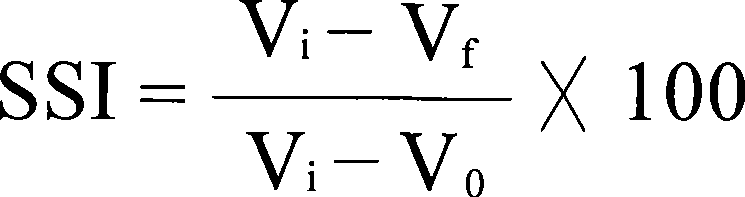

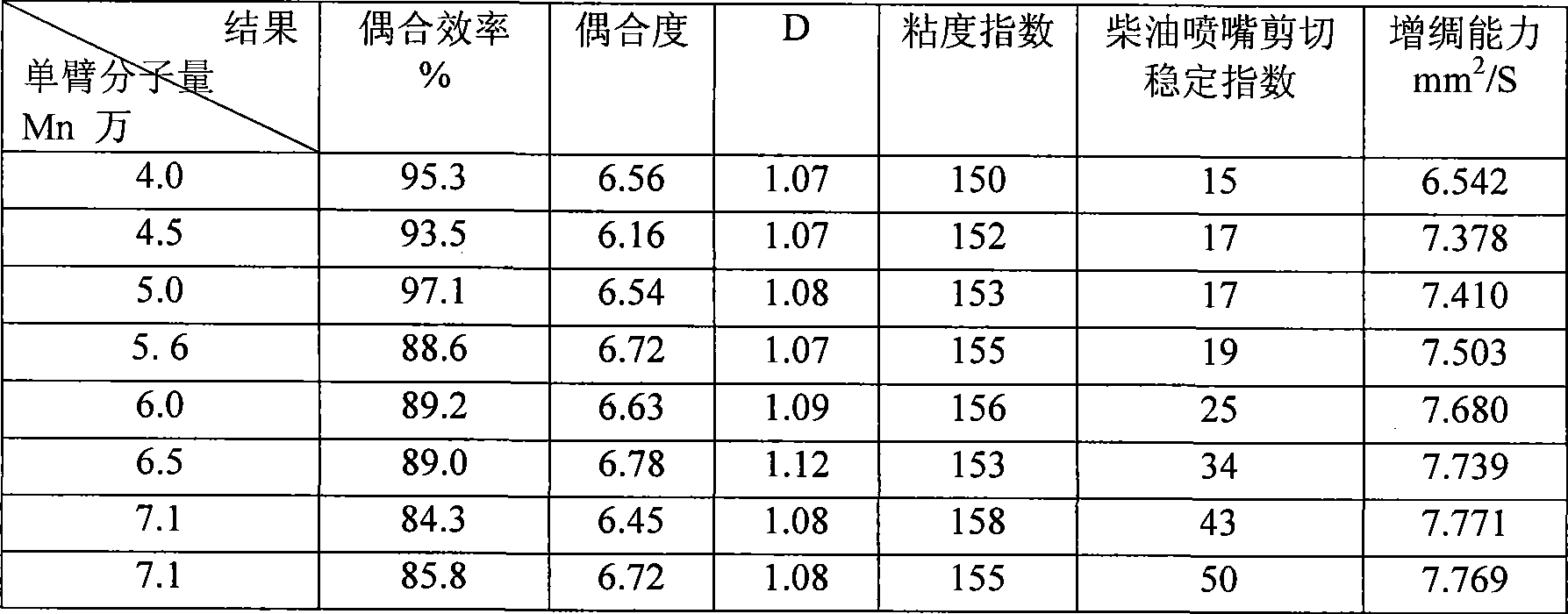

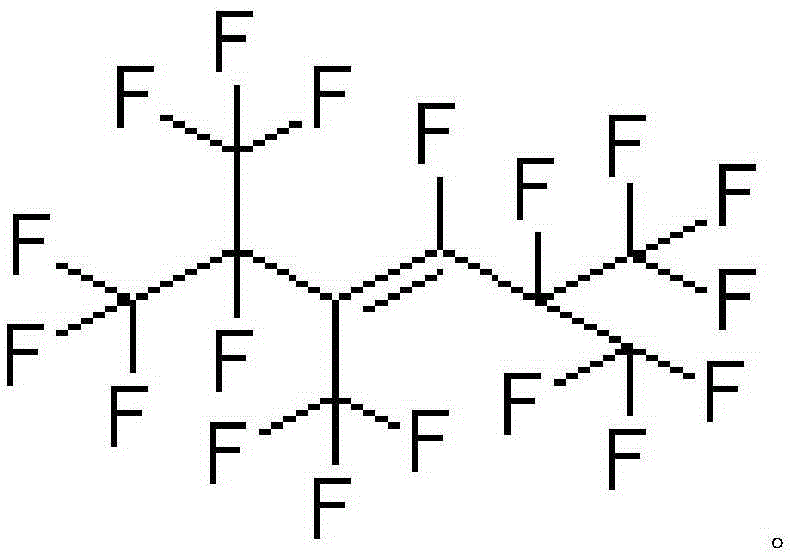

Lubricating oil viscosity index improver and preparation thereof

ActiveCN101434887APrevent crystallizationStable chemical propertiesAdditivesViscosity indexOil viscosity

The invention provides a lubricating oil viscosity index improver and a preparation method thereof; the lubricating oil viscosity index improver has stable chemical performance, oxidation resistance, shear resistance and good compatibility with lubricating oil; in addition to good thickening ability to the lubricating oil, the lubricating oil viscosity index improver further has excellent anti-shear stability and viscosity-temperature performance. The viscosity index of the lubricating oil after modification is greater than 150, and low-temperature kinematic viscosity is less than 1600mpa.s. The lubricating oil viscosity index improver can not only be used for preparing multi-level lubricating oil, but also be used for improving the viscosity index of base oil of the lubricating oil with the low viscosity index, thereby having broad application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy-duty antiemulsifying oil film bearing oil

InactiveCN1346874AGuaranteed normal operationImprove the lubrication effectAdditivesWire rodDemulsifier

A heavy-duty antiemulsifying oil film type bearing oil for high-speed wire rolling mill contains demulsifier, antiwear agent, antifoaming agent, alkylnaphthalene, antioxidant and mineral oil. Its advantages are excellent antiemulsifying, antiwear, anti-extreme-pressure, anticorrosion, antirust, antifoaming and antioxidizing performance, and better viscosity-temp characteristic.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Oil-soluble polyether oil for screw-type air compressor

InactiveCN104130842AExcellent antioxidant stabilityGood demulsibilityLubricant compositionPerformance indexMechanical equipment

The invention discloses oil-soluble polyether oil for a screw-type air compressor. The oil-soluble polyether oil is prepared from 20-40 parts or 10-20 parts by mass of oil-soluble polyether base oil, 60-80 parts or 80-90 parts by mass of poly(alpha-olefin), 0.1-1.4 parts by mass of benzenamine, 0.8-2 parts by mass of a borate anti-oxidant, 1.2-2.2 parts by mass of a high-temperature ashless antiwear agent, 0.5-1.8 parts by mass of polyoxyethylene sorbitan fatty acid ester and 0.001-0.05 parts by mass of an acrylate-ether copolymer. The oil-soluble polyether oil for a screw-type air compressor is environmentally friendly, has the advantages of excellent antioxidation stability, emulsification resistance, corrosion and rusting resistance, very good defoaming performance and excellent viscosity-temperature performance, has performance indexes satisfying standards of air compressor oil 46 and can be used for mechanical equipment of an air compressor system.

Owner:张家港市胜宇石油化工制品有限公司

Refrigerating engine oil composition and application thereof

InactiveCN104087388AGood compatibilityImprove high temperature stabilityLubricant compositionRefrigeration compressorAlkane

The invention relates to a refrigerating engine oil composition and an application of the refrigerating engine oil composition. One aim of the invention is to provide a refrigerating engine oil composition which has good compatibility with hydrocarbon refrigerants, is high in flash point and low in viscosity, can be used for furthest increasing the COP (coefficient of performance) value of a compressor, and has excellent thermal stability and relatively low cost. The other aim of the invention is to provide an application of the refrigerating engine oil composition used as a lubricating agent in a refrigeration compressor which uses isobutane, propane or a mixture of isobutane and propane as a refrigerant. The refrigerating engine oil composition consists of the following components in percentage by weight: 96.5-99.5% of base oil and 0.5-3.5% of a lubricating oil additive, wherein by taking the weight of the base oil as 100%, the base oil comprises the following components in percentage by weight: 20-79% of alkylated aromatic hydrocarbon and 21-80% of an alkane mixture; by taking the total weight of the composition as 100%, the lubricating oil additive comprises the following components in percentage by weight: not more than 3% of an extreme pressure anti-wear additive, 0-3% of an antioxidant, 0-3% of the lubricating agent, 0-0.8% of a metal deactivating agent and 0-0.02% of an anti-foaming agent.

Owner:SHRIEVE CHEM SHANGHAI LTD

Multi-graded anti-wearing hydraulic oil composition and preparation method thereof

The invention provides a multi-graded anti-wearing hydraulic oil composition and a preparation method thereof. The multi-graded anti-wearing hydraulic oil composition is prepared from the following components according to the total weight of 100%: (a) 85%-95%, preferably 88%-93%, of type III hydroisomerizing base oil; (b) 3%-5%, preferably 3%-4.5%, of a viscosity index improver; (c) 0.5%-4%, preferably 1.5%-3%, of an antioxidant; (d) 0.5%-5%, preferably 0.5%-2%, of an extremely pressure anti-wearing agent; (e) 0.002%-0.020%, preferably 0.005%-0.015%, of an anti-foaming agent; and (f) 0.5%-4%, preferably 1%-3%, of a cleaning dispersant. The product provided by the invention has relatively high comprehensive performance and low cost and has good viscosity-temperature characteristics, low-temperature flowability and oxidization stability; meanwhile, nano titanium dioxide which has dual advantages of fluid smoothing and solid smoothing is compounded with dialkyldithiophosphate, so that the product has good bearing capability and anti-wearing performance; and furthermore, when the product is used, the number of times of replacing oil can be reduced, so that the working efficiency of hydraulic machinery is improved and the aims of energy saving and environmental friendliness are realized.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

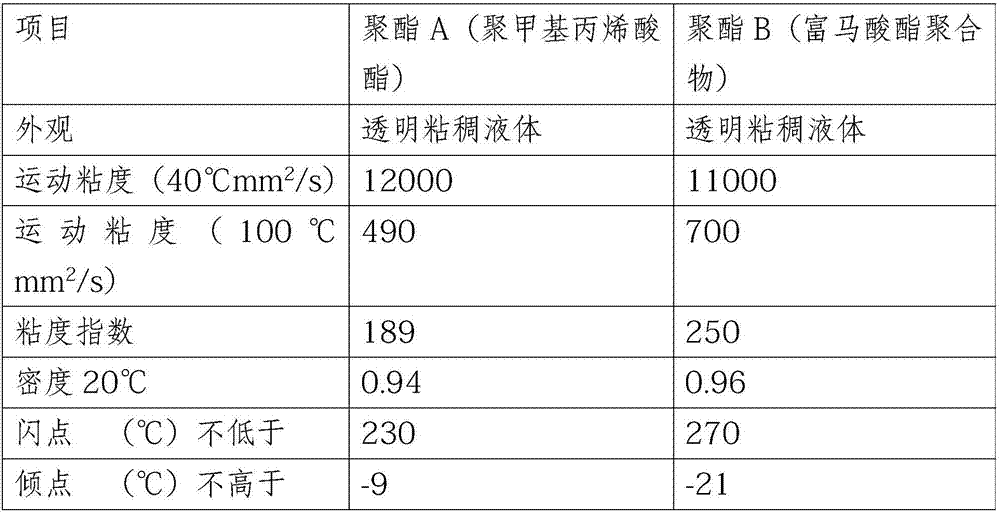

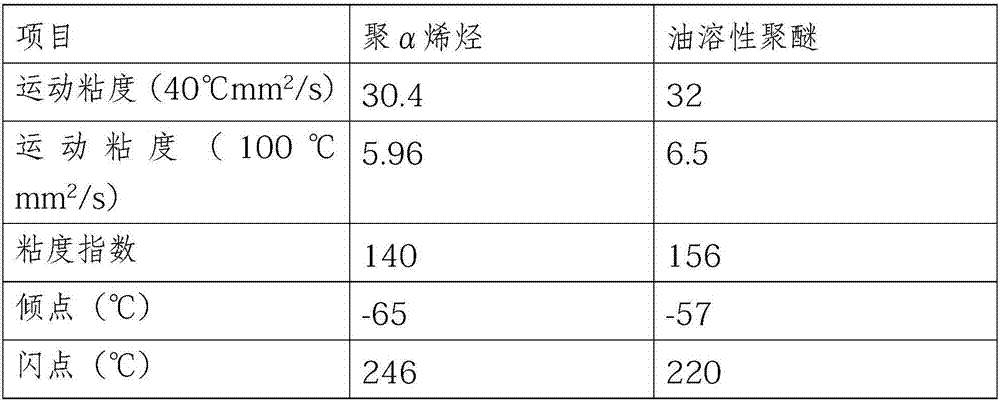

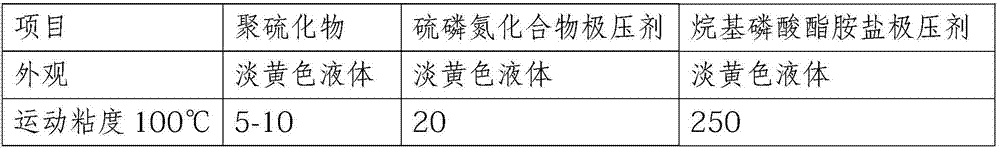

Biodegradable screw air compressor oil

ActiveCN103773575AReduce the content of double bondsImprove oxidation stabilityLubricant compositionPerformance indexAir compressor

The invention discloses a preparation method of biodegradable screw air compressor oil. The preparation method comprises the following steps: 1) synthetizing base oil A; 2) synthetizing base oil B; 3) preparing combined base oil A1; 4) preparing combined base oil B1; 5) preparing combined base oil C1; and 6) adding the combined base oil A1, the combined base oil B1 or the combined base oil C1 into a blending kettle, then adding other regents, mixing and fully dissolving all the components to obtain the biodegradable screw air compressor oil. Through optimization of ratio, an excellent lubricating oil product which has good oxidization stability, viscosity-temperature performance, wearing resistance, anti-rust performance and defoaming performance and no toxicity and can be biodegradable is prepared, which is environment-friendly, has a performance index achieving 46 # compressor oil standard, and is suitable for a screw air compressor and the like.

Owner:张家港市胜宇石油化工制品有限公司

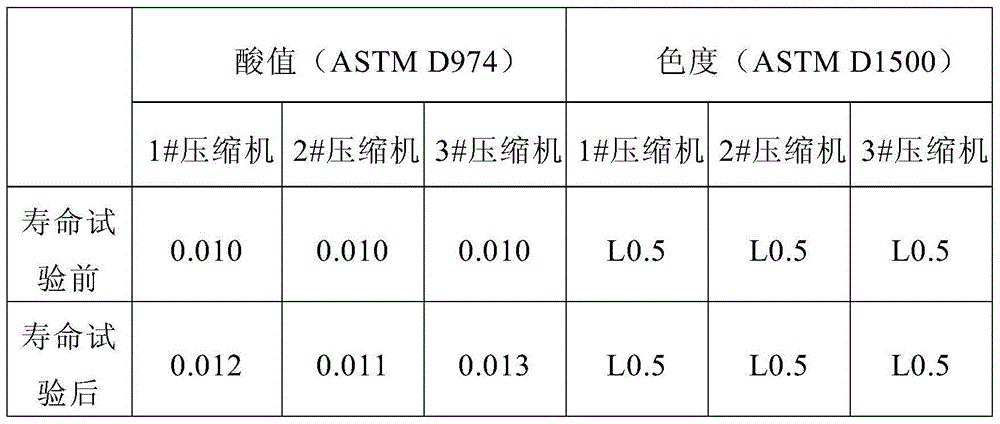

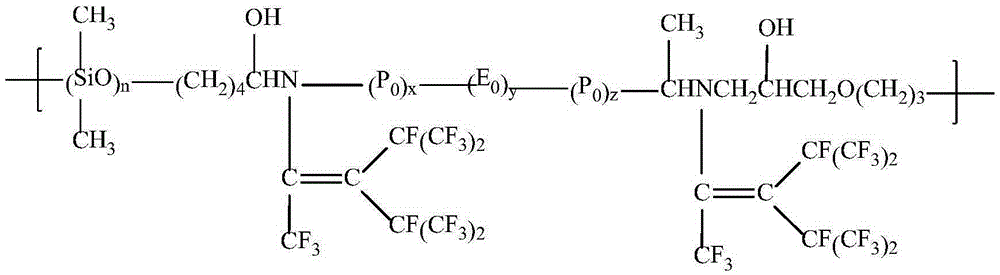

Organic fluorine-silicon surface treatment agent and preparation method thereof

ActiveCN105330867AGood high and low temperature resistanceGood viscosity and temperatureGroup 4/14 element organic compoundsFibre treatmentEpoxyFiber

The invention discloses an organic fluorine-silicon surface treatment agent and a preparation method thereof. According to the organic fluorine-silicon surface treatment agent, amino silane coupling agents, amino-polysiloxane and epoxy polysiloxane serve as basic reactants, hexafluoropropene trimer serves as a modifying agent, glycol dimethyl ether serves as solvent, triethylamine serves as a catalyst, and the organic fluorine-silicon surface treatment agent is a fluorine-silicon oxidane compound synthesized through a reaction or a fluorine-silicon oxidane polymer with a perfluoroalkyl group introduced to a side chain. According to the organic fluorine-silicon surface treatment agent and the preparation method thereof, it is not needed to generate a reaction intermediate through a link chain structure in the first place, the synthesis route is simple, the conversion rate is high, and the prepared organic fluorine-silicon compound has high surface activity and high stability and can be used for water resistance, oil resistance and stain repellent finishing of fiber fabric as well as waterproof and stain repellent treatment of metal and building materials.

Owner:ZHEJIANG HAPPY CHEM

Aqueous cutting fluid and preparation method thereof

ActiveCN103666729AGood viscosity and temperatureImprove the lubrication effectLubricant compositionPolyethylene glycolAlkylphenol

The invention discloses an aqueous cutting fluid, which is prepared from the following raw materials in parts by weight: 10-12 parts of polyethylene glycol, 2-3 parts of triethanolamine, 6-9 parts of dibutyl phosphate, 19-22 parts of castor oil, 1-2 parts of calcium sulfide alkylphenol, 1-2 parts of sorbic monostearate, 6-8 parts of assistant and 200 parts of water. The aqueous cutting fluid disclosed by the invention has excellent viscosity-temperature performance, lubricity, extreme pressure property and biodegradability, fast cooling speed, and good corrosion inhibition property, is long in service cycle in comparison with the traditional cutting fluid, small in abrasion on a tool, and high in yield, and has good protection roles on nonferrous metals and black metal, and the processed work-piece is bright.

Owner:广州南星润滑科技股份有限公司

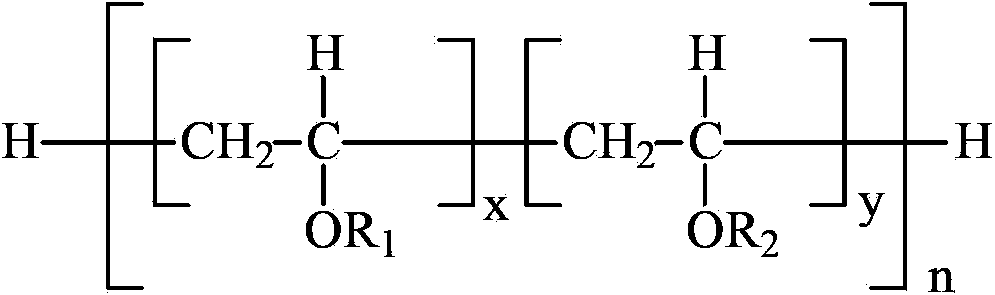

Lubricating oil composition

The present invention provides a lubricating oil composition, which comprises 1-15% by mass of a viscosity index improver, zinc dialkyl dithio phosphate, and a main amount of a lubricating base oil, wherein the viscosity index improver is prepared by carrying out a polymerization reaction and a hydrogenolysis reaction on straight chain alkyl vinyl ether and branched-chain alkyl vinyl ether, and the phosphorus element content in the zinc dialkyl dithio phosphate is 0.01-0.07% of the mass of the composition. According to the present invention, the lubricating oil composition has characteristics of excellent low temperature property, excellent viscosity-temperature property, excellent shear stability and excellent wear resistance; and the sulfur content in the composition does not exceed 0.4% by mass, the sulfate ash content in the composition does not exceed 1% by mass, and the phosphorus content does not exceed 0.08% by mass.

Owner:CHINA PETROLEUM & CHEM CORP +1

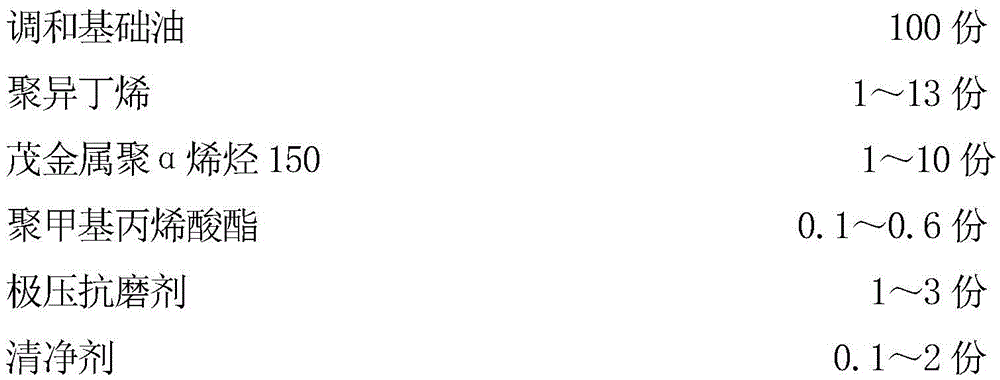

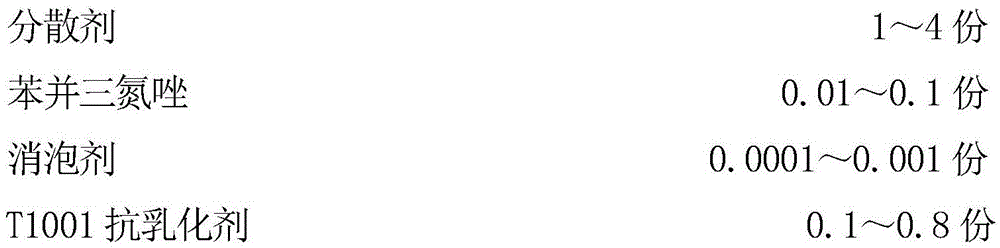

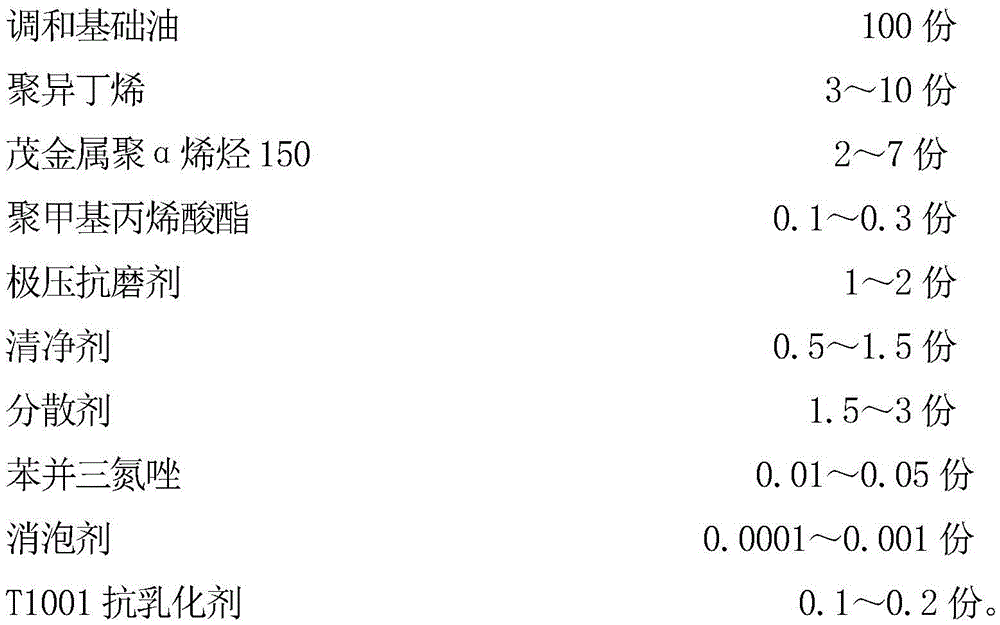

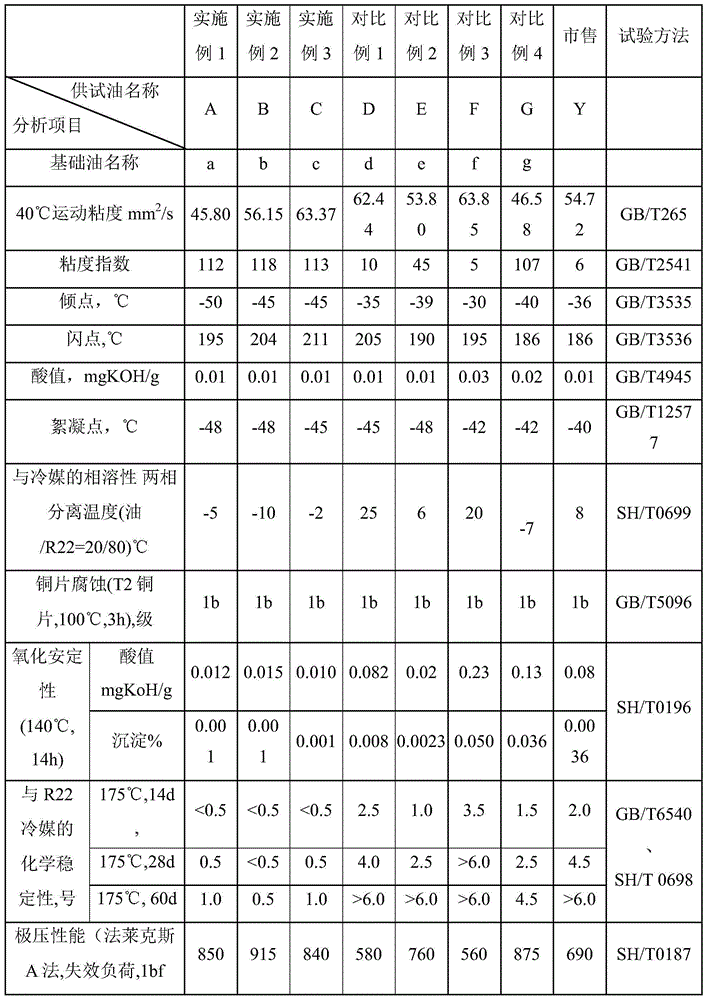

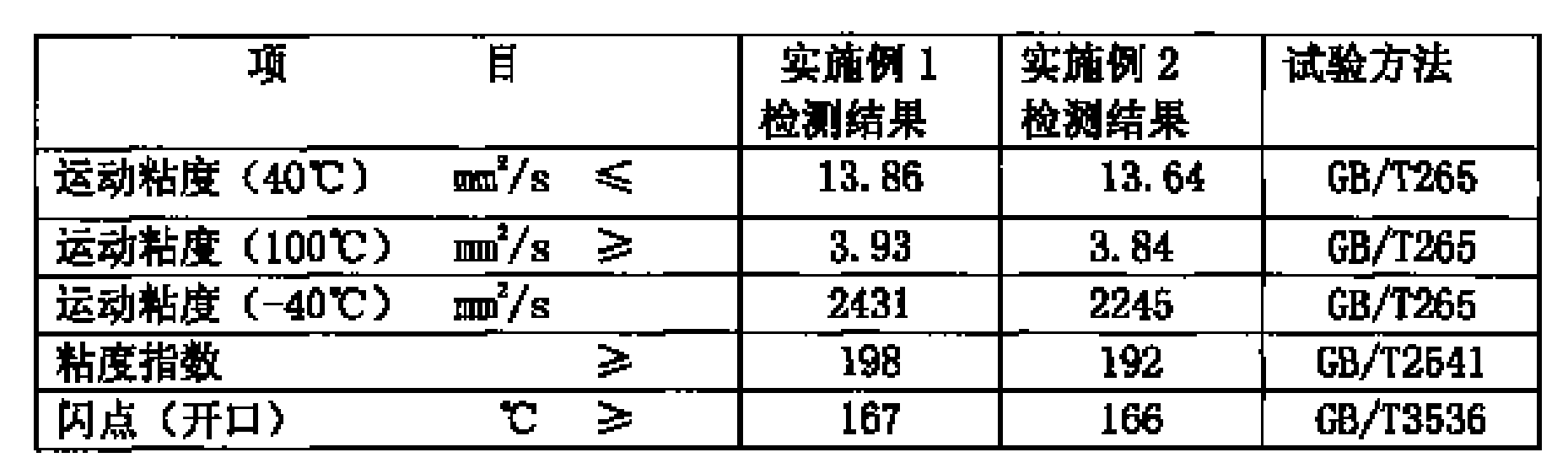

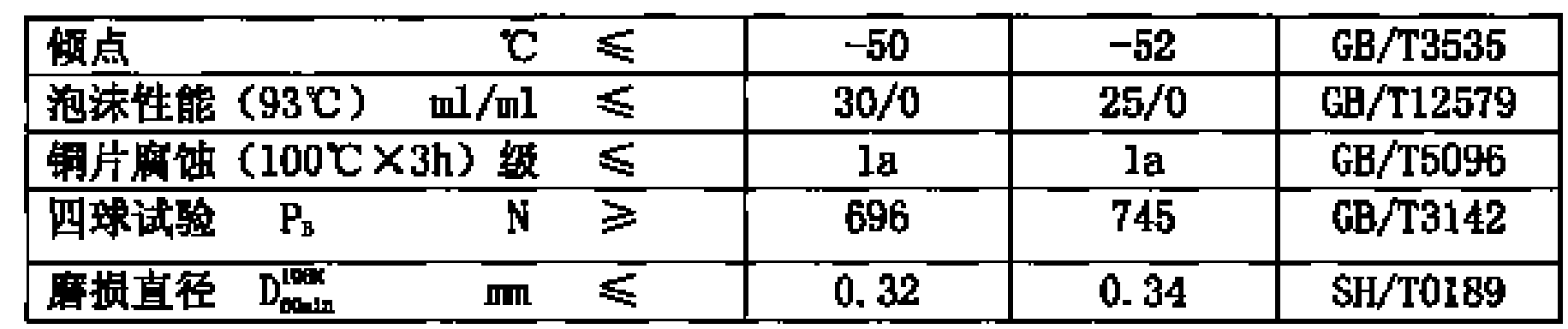

Gear oil special for reduction gearbox of pumping unit

The invention discloses gear oil special for a reduction gearbox of a pumping unit. The gear oil is prepared from, by mass, blend base oil, metallocene polyisobutene, metallocene polymerized alpha olefin 150, polymethacrylate, an extreme pressure anti-wear agent, a cleaning gent, a dispersing agent, benzotriazole, a defoaming agent and a demulsifying agent T1001, wherein the blend base oil is prepared from paraffin-base base oil 600 SN, residual oil 150 BS and hydrofined oil 250 N, and a mixture of thiophosphoric acid amine salt, bisoctyl dithiophosphate zinc and / or oil-soluble molybdenum is adopted as the extreme pressure anti-wear agent. The gear oil for the reduction gearbox is better in physical and chemical index and using performance than industrial closed gear oil, has the good extreme pressure anti-wear performance, thermal oxidation stability, corrosion resistance and anti-emulsification performance and meets the using requirements of oil pumping unit oil of an oil field.

Owner:郑生宏

Refrigerant oil composition and application thereof

ActiveCN106147946AGood viscosity and temperatureIncreased viscosity-temperatureChemical industryHeat-exchange elementsChlorofluorocarbonHigh pressure

The invention provides a refrigerant oil composition and application thereof. The refrigerant oil composition comprises, on the basis of the weight of base oil, (1) 15 to 40 wt% of alkyl benzene synthetic lubricant base oil, (2) 15 to 40 wt% of oil-soluble polyether base oil, i.e., OSP base oil, (3) 20 to 70 wt% of high-pressure hydrogenation cycloalkyl mineral lubricant base oil, and (4) an additive, wherein the high-pressure hydrogenation cycloalkyl mineral lubricant base oil is prepared by using a high-pressure tandem all-hydrogen process consisting of hydrodemetallization, hydrotreatment, hydrodewaxing and hydrofinishing. The refrigerant oil provided by the invention has good intersolubility with hydrochlorofluorocarbons (HCFCs, such as R22), a low flocculation point and thermo-chemical stability; the refrigerant oil is especially applicable as refrigerant oil with HCFCs as refrigerants and also applicable as refrigerant oil with chlorofluorocarbons as refrigerants; and the refrigerant oil can prolong an oil change period and improve energy conservation performance, and has excellent abrasion resistance.

Owner:PETROCHINA CO LTD

Shock absorber oil

ActiveCN101486944AImprove low temperature performanceImprove wear resistanceAdditivesSulfateTricresyl phosphate

The invention discloses oscillating damper oil; the components and contents include: 0.2 to 5.0 percent of antiwear agent, 2 to 25ppm of polymethylphenyl siloxane fluid, 0.1 to 1.0 percent of polymethyl methacrylate, 0.1 to 0.6 percent of N-octadecylamine oleyl sarcosinate, 0.5 to 4.0 percent of polyisobutylene (PB2400), and the balance of base oil; the antiwear agent consists of triphenyl phosphate sulfate and tricresyl phosphate. The oscillating damper oil has excellent properties and prominent low-temperature performance and wear-resistance performance.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Lubricating oil for mechanical equipment and preparation method thereof

InactiveCN108822934AHigh viscosityImprove the lubrication effectLubricant compositionAntioxidantMechanical equipment

The invention discloses lubricating oil for mechanical equipment and a preparation method thereof, and relates to the field of lubricating oil. The lubricating oil for the mechanical equipment comprises the following raw materials in parts by weight: 30-40 parts of polyalphaolefin, 15-20 parts of fluorosilicone oil, 1.5-4 parts of pentaerythritol ester, 2-5 parts of modified nanodiamond, 1-3 partsof castor oil, 3-6 parts of grapheme, 1-3 parts of molybdenum disulfide, 0.4-0.8 part of Tween, 0.5-1.2 parts of sorbitol monooleate, 0.2-0.6 part of an antioxidant, 0.4-0.8 part of a demulsifying agent and 0.7-1.5 parts of a viscosity index improver. Through cooperation of the raw materials, the lubricating oil has good viscosity, lubricity and antioxidation; the lubricating oil forms a curing protection layer on the surface of the mechanical equipment; meanwhile, the lubricating oil has good wear resistance and durability.

Owner:合肥博创机械制造有限公司

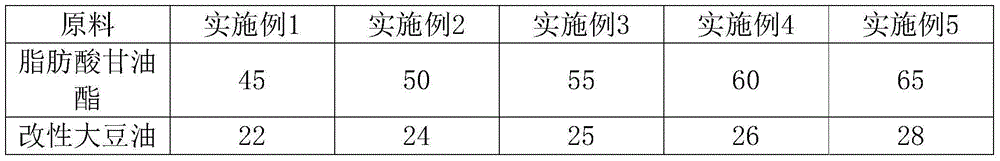

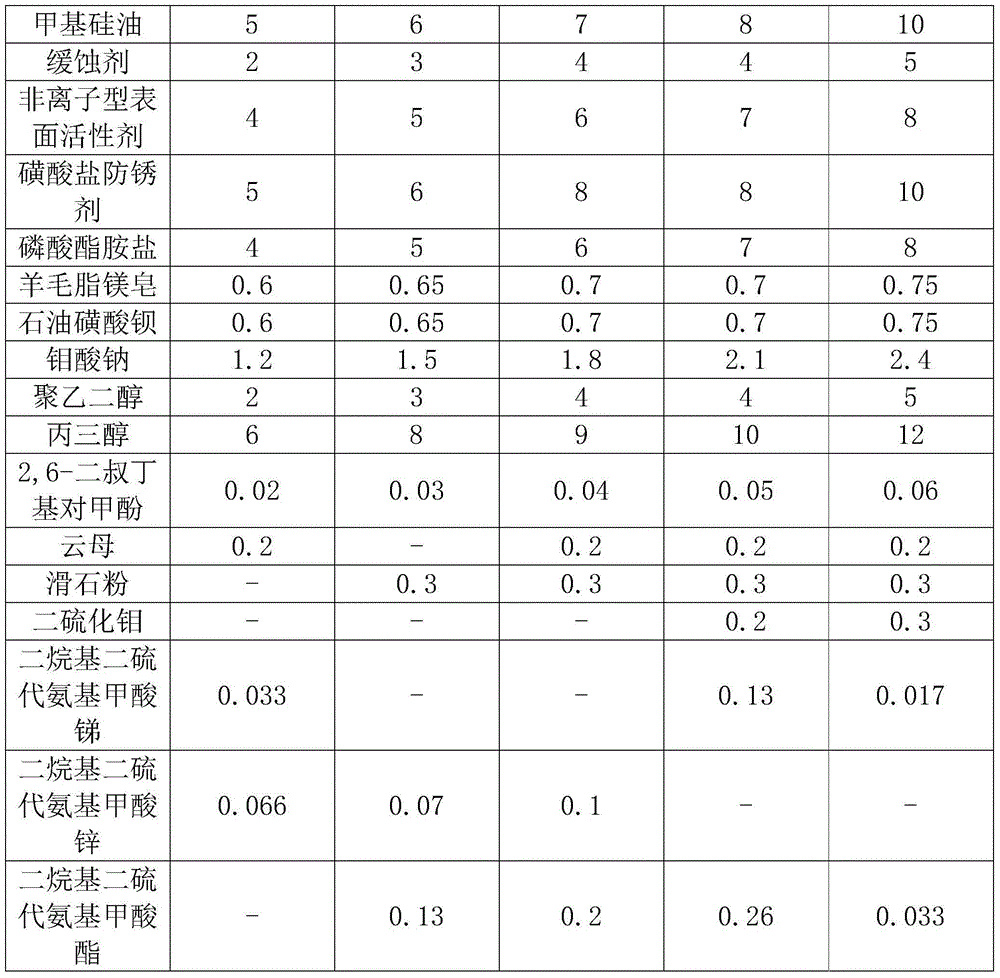

Antirust lubricant and preparation method thereof

InactiveCN104830491AHigh biodegradation rateHigh viscosity indexLubricant compositionVegetable oilPhosphate

The invention relates to the technical field of lubricants, particularly an antirust lubricant and a preparation method thereof. The antirust lubricant is composed of the following components in parts by mass: 45-65 parts of fatty glyceride, 22-28 parts of modified soybean oil, 5-10 parts of methyl silicone oil, 2-5 parts of corrosion inhibitor, 4-8 parts of non-ionic surfactant, 5-10 parts of sulfonate rust inhibitor, 4-8 parts of phosphate amine salt, 1.2-1.5 parts of antirust compound oil, 1.2-2.4 parts of sodium molybdate, 2-5 parts of polyethyleneglycol, 6-12 parts of glycerol, 0.02-0.06 part of 2,6-di-tert-butyl-para-cresol, 0.2-0.8 part of solid additive and 0.1-0.5 part of antioxidation preservative. By using the modified soybean oil as the base oil, the biodegradability is high. The antirust lubricant has the advantages of high viscosity index, favorable viscosity-temperature characteristics, favorable low-temperature fluidity, accessible raw materials and low cost. The antirust lubricant has excellent extreme pressure abrasion resistance since the vegetable oil polar molecules can form a protective film on the metal surface.

Owner:ZHANGJIAGANG SHANMU NEW MATERIAL TECH DEV

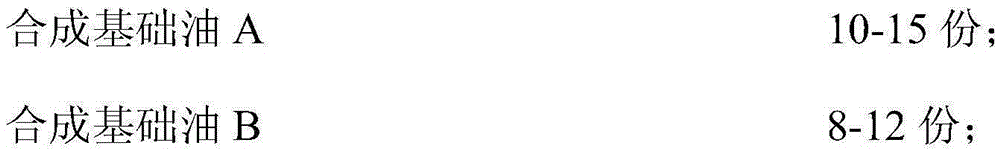

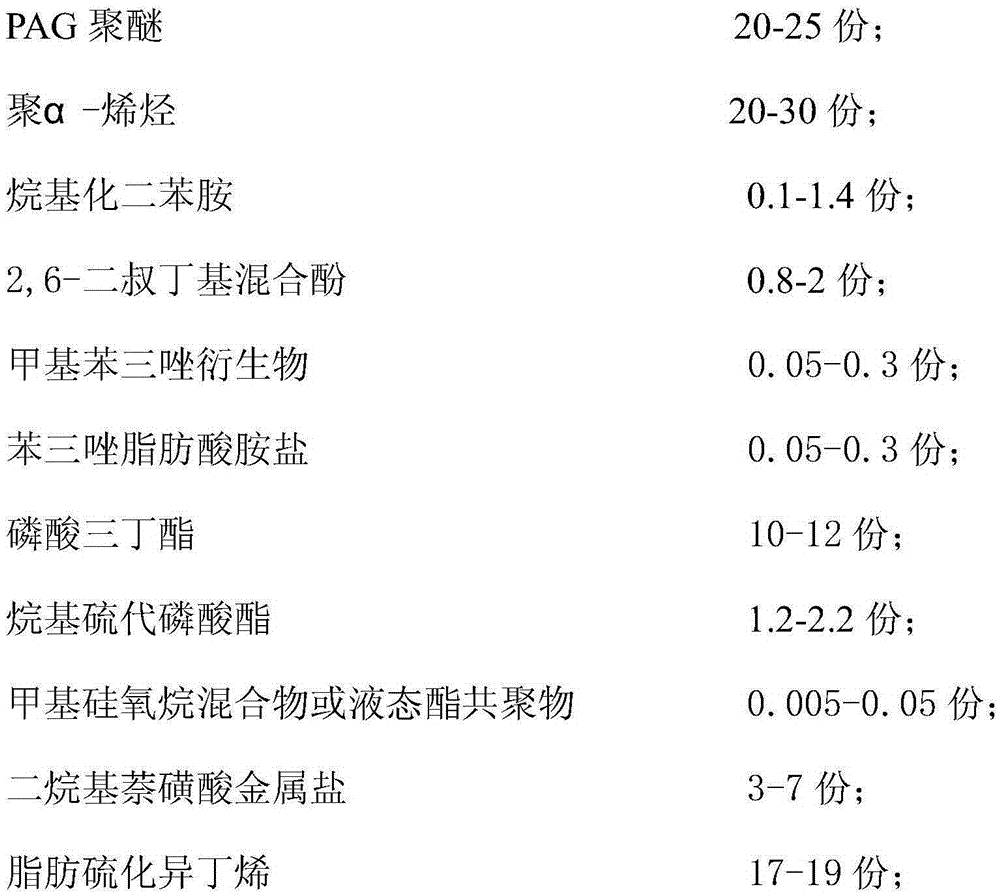

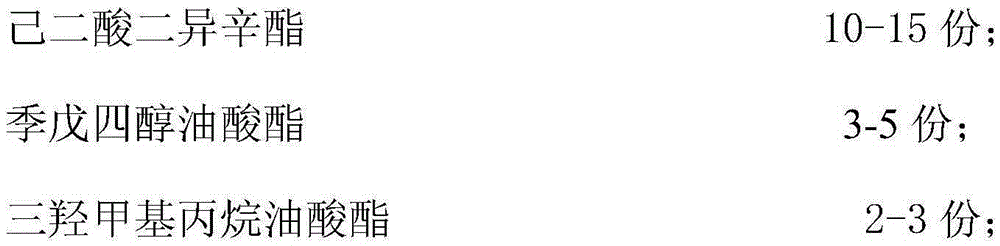

Composite screw type air compressor oil

ActiveCN105296107AEnvironmentally friendlyExcellent antioxidant stabilityLubricant compositionGreek letter alphaPhenols

The invention discloses composite screw type air compressor oil which comprises, by mass, 10-15 parts of raw material synthesis base oil A, 8-12 parts of synthesis base oil B, 20-25 parts of PAG polyether, 20-30 parts of poly-alpha-olefins, 0.1-1.4 parts of alkylated diphenylamine, 0.8-2 parts of 2,6-di-tert-butyl mixed phenols, 0.05-0.3 part of methyl benzene triazole derivative, 0.05-0.3 part of benzene triazole fatty acid amine salt, 10-12 parts of tributyl phosphate, 1.2-2.2 parts of dialkyl dithiophosphate, 0.005-0.05 part of methylsiloxane mixture or liquid ester copolymer, 3-7 parts of dialkyl group naphthalene metal organic sulfonate and 17-19 parts of fat sulphide isobutene. The composite screw type air compressor oil has the advantages of good antioxidation stability, demulsibility and anti-corrosion and anti-rust property, extremely good defoaming performance, excellent viscosity-temperature property and the like. Compared with mineral compressor oil, the energy is saved, oil consumption is lowered, environment pollution is reduced, the service life is prolonged, the performance index reaches the standard of 46# compressor oil, and the compressor oil is used for air compression system mechanical equipment.

Owner:张家港市胜宇石油化工制品有限公司

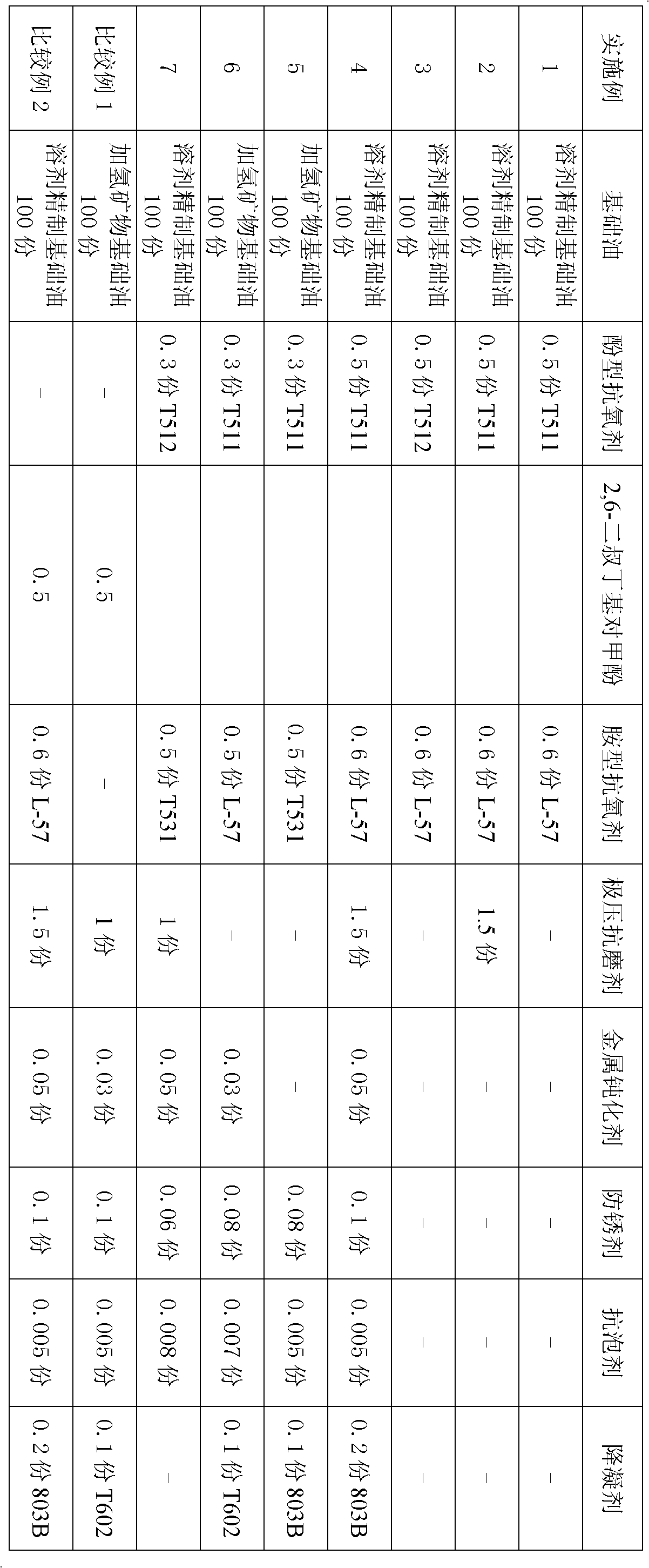

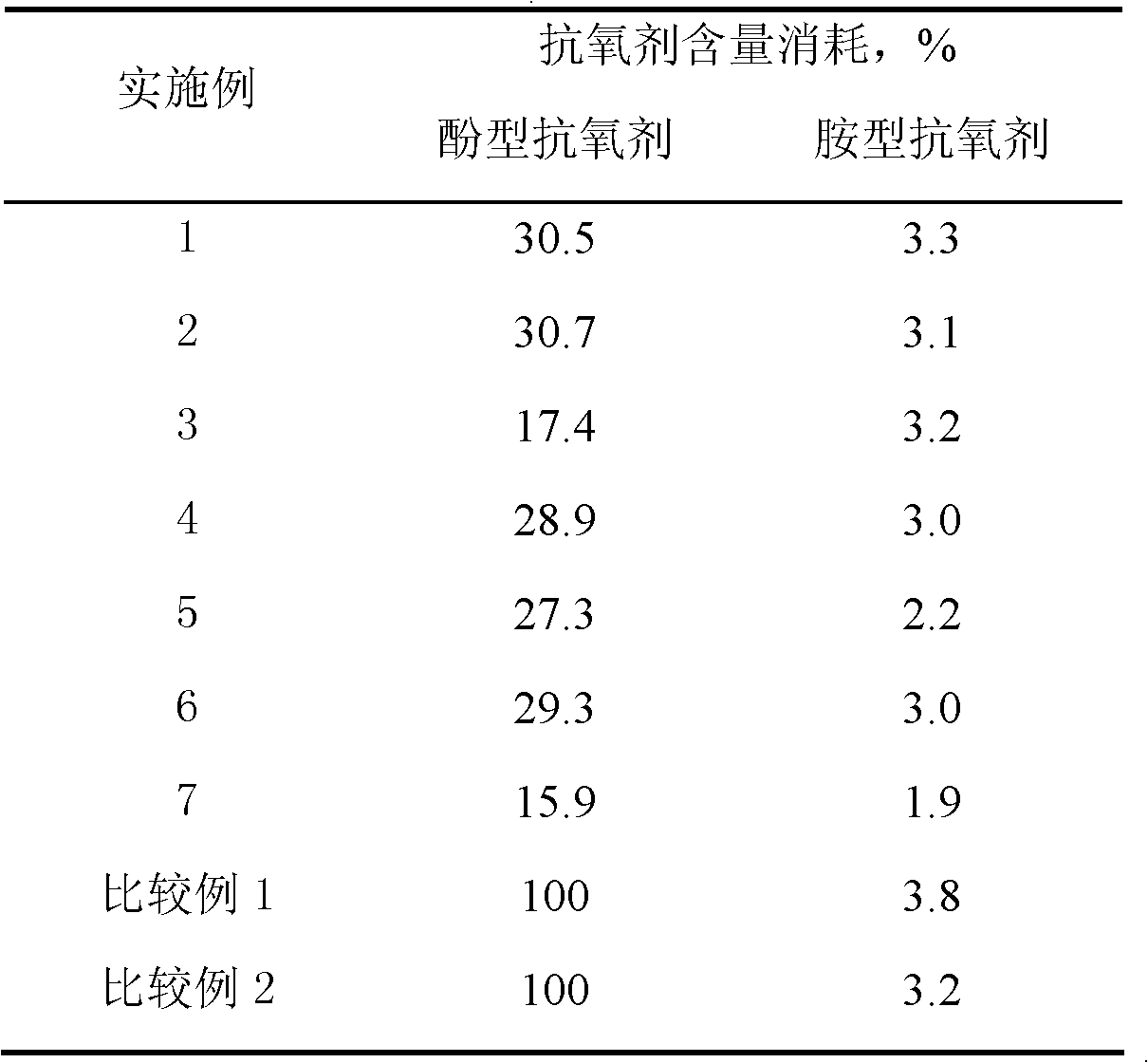

Screw-type ammonia compressor oil composite

InactiveCN103031188AImprove Oxidation StabilityGood viscosity and temperatureAdditivesPropanoic acidTert butyl phenol

The invention relates to a screw-type ammonia compressor oil composite, which mainly solves the technical problems of poor resistance to oxidation and short oil product service life of the screw-type ammonia compressor oil composite under the condition that cuprammonia is mixed with ammonia in the prior art. The screw-type ammonia compressor oil composite comprises the following ingredients in parts by weight: 100 parts of mineral base oil and 0.01-2 parts of antioxygen, wherein the antioxygen consists of phenol-type antioxygen and ammonia-type antioxygen; the phenol-type antioxygen is selected from at least one of 4,4-methylenebis (2,6- di-tert-butyl phenol), 3,5-di-tert-butyl-4-hydroxy phenyl acrylic ester or quadri[beta(3,5-di-tert-butyl-4-hydroxy phenyl) propionic acid] pentaerythritol ester; and the ammonia-type antioxygen is selected from at least one of phenyl-alpha-naphthylamine, alkylating phenyl-alpha-naphthylamine and octyl butyl diphenylamine or alkylating diphenylamine. According to the technical scheme, the problem is favorably solved, and the technical scheme can be used for the industrial production of the screw-type ammonia compressor oil composite.

Owner:CHINA PETROLEUM & CHEM CORP

Full-synthetic wind power generation gear oil

ActiveCN107338099AThe effect of dragging is weakenedReduce the chance of collision contactLubricant compositionEmulsionBenzotriazole

The present invention relates to a full-synthetic wind power generation gear oil, which at least comprises: 91% of a mixed base oil, 2.25-3.45% of an extreme pressure agent, 1-2% of a polytetrafluoroethylene emulsion friction reducer, 3.6-3.8% of a dispersant, 0.5% of a benzotriazole derivative metal deactivator, 0.4% of an antioxidant, and 0.05% of a polyether-based demulsifier. According to the present invention, the full-synthetic wind power generation gear oil uses the new specially-synthesized material polyester having the high viscosity index and the oil-soluble polyether, has advantages of excellent viscosity-temperature performance, good micro-pitting resistance, prominent gear cleanliness, excellent high-temperature lubricating property and excellent low-temperature fluidity, can effectively reduce the downtime number of the wind turbine due to the change of the ambient temperature, can improve the operation efficiency of the wind turbine, can substantially prolong the oil change maintenance period and the service life of the wind power gear speed increasing box, and can objectively achieve the energy saving and the environmental protection.

Owner:北京雅士科莱恩石油化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com