Lubricating oil and grease base oil, and preparation method and applications thereof

A technology of base oil and fatty acid, applied in lubricating compositions, base materials, petroleum industry, etc., can solve the problems of viscosity, pour point, flash point that cannot meet the requirements, and improve long-term high-temperature oxidation stability and excellent comprehensive performance. , the effect of low pour point

Active Publication Date: 2010-08-25

上海海都化学科技有限公司 +1

View PDF4 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the deficiencies of the prior art above, and provide a lubricating oil and grease base oil to solve the technical problem that the existing base oil cannot meet the requirements in viscosity, pour point and flash point

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

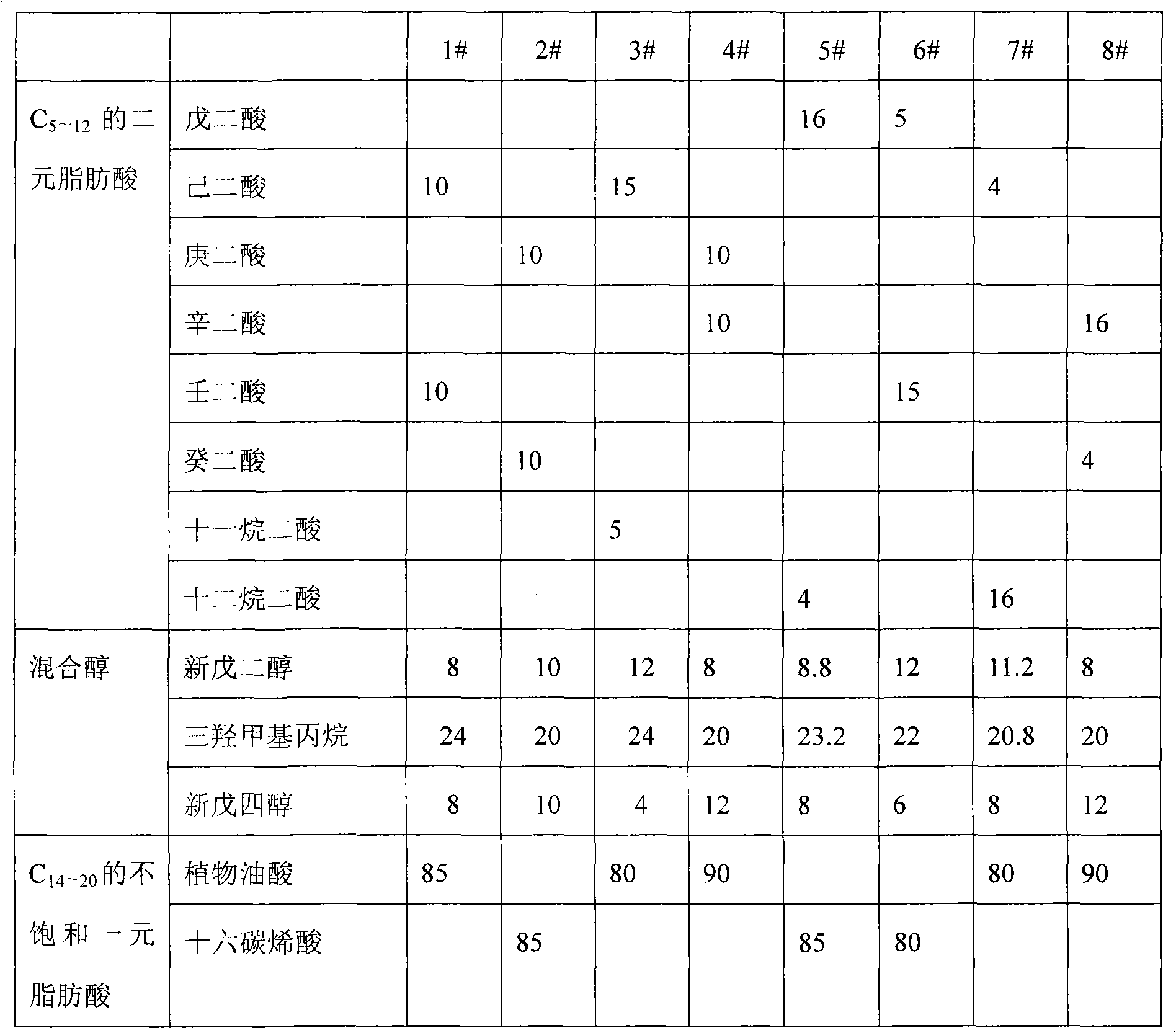

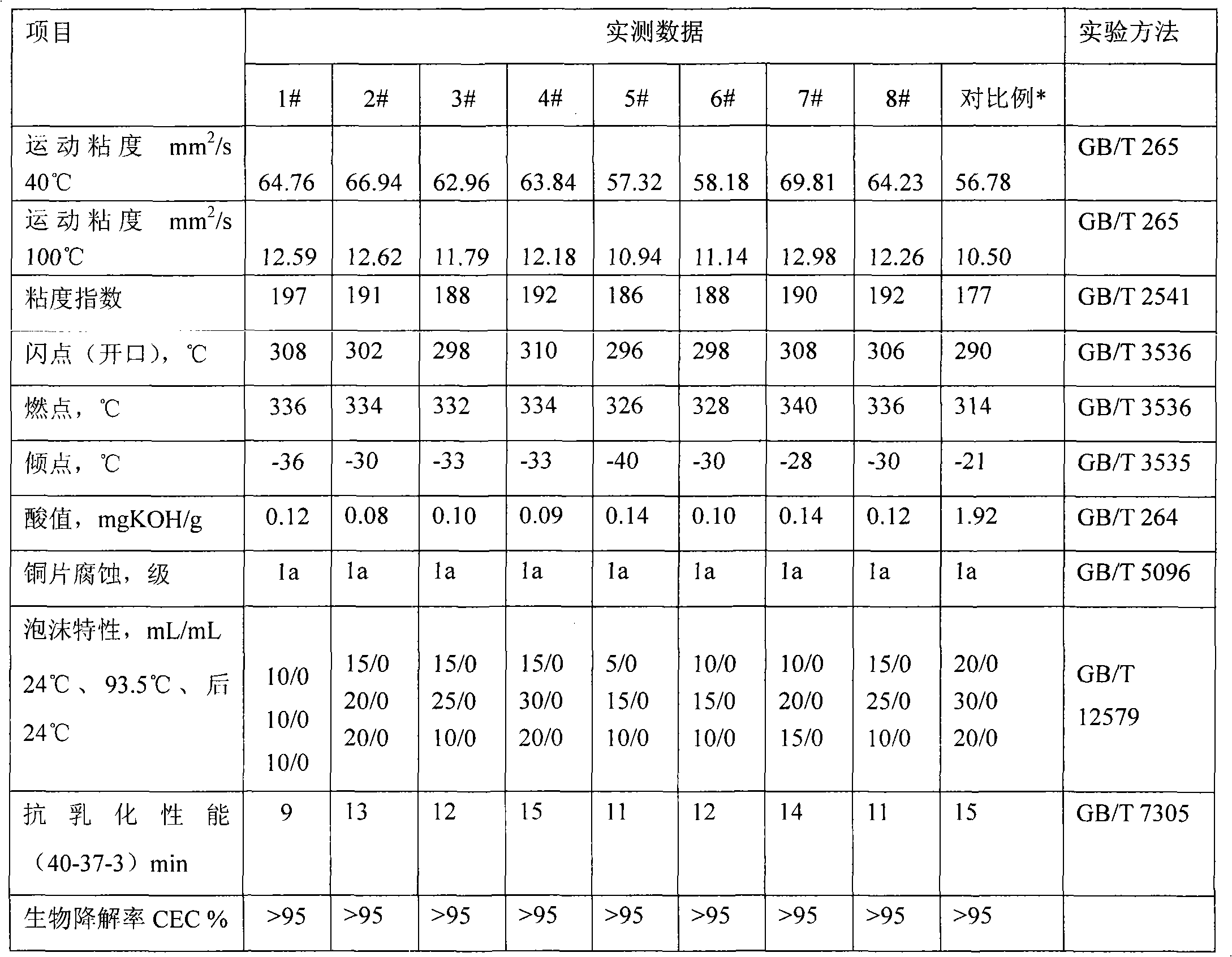

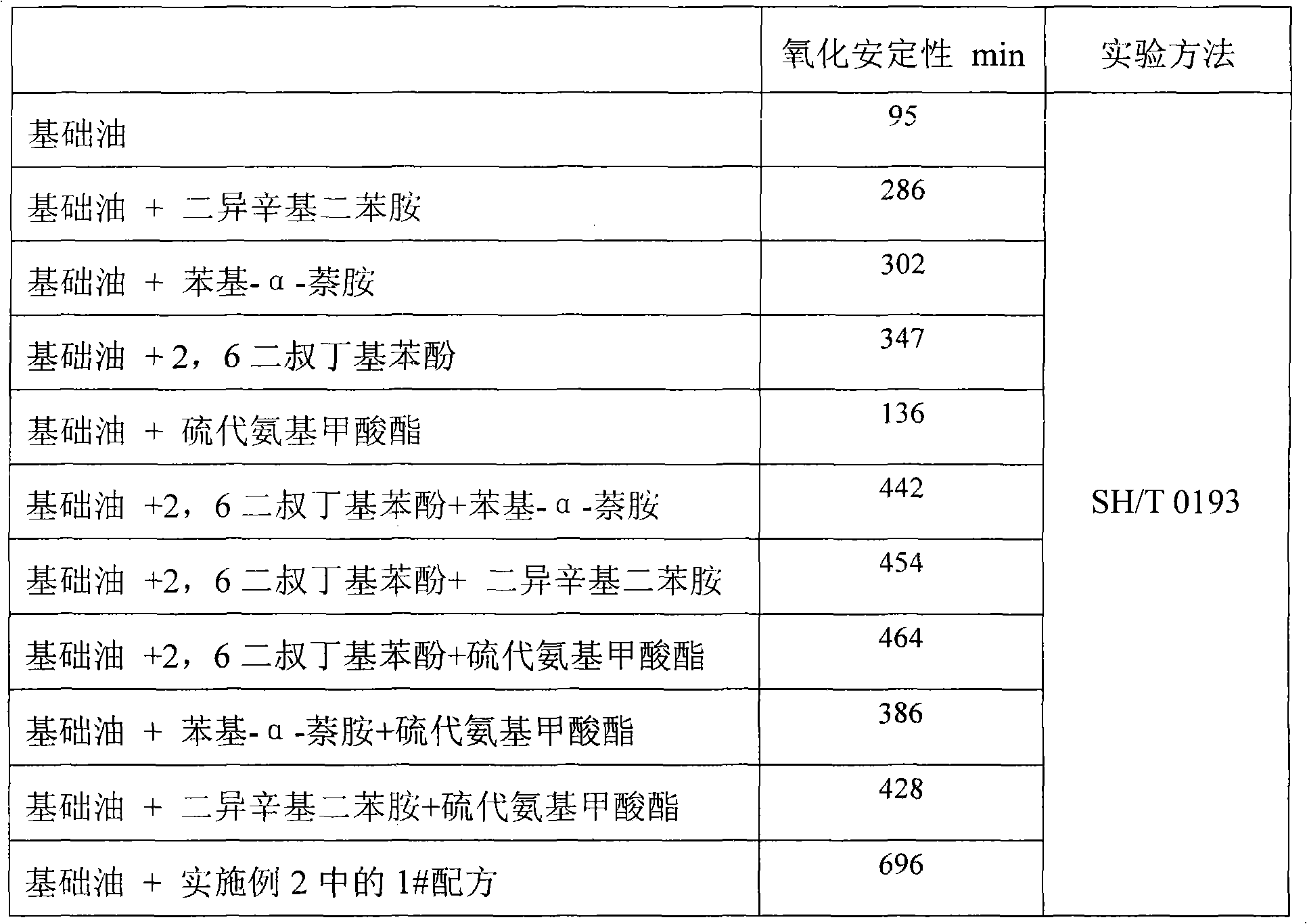

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides base oil, in particular to a neopentyl polyalcohol dibasic acid complex ester. The neopentyl polyalcohol dibasic acid complex ester is prepared in a way that: completely esterifying C5-12 binary fatty acid carboxyl with the mixture of neopentyl glycol, trimethylolpropane and pentaerythritol, and blocking with C14-20 unsaturated monobasic fatty acid. The base oil provided bythe invention has the characteristics of high flash point, high flammability point, low pour point, high viscosity index, low evaporation loss, high thermal oxidation stability and high biodegradation rate. The invention can be used as syntholube and grease base oil, especially syntholube base oil used under the conditions of high temperature and high pressure. The invention is especially suitable to be used in fire resistant hydraulic fluid, high-temperature chain oil, high-temperature grease and the like in severe working spaces at which naked flame can is accessible under the conditions ofhigh temperature and high pressure.

Description

technical field The invention relates to a lubricating oil and a lubricating grease base oil and a preparation method and application thereof, in particular to the preparation and application of a hydraulic oil base oil, and belongs to the technical field of industrial lubricating oil. Background technique Hydraulic machinery has been widely used in industries such as iron and steel, electric power, coal and machinery. As a power medium, hydraulic oil is the key material of hydraulic transmission technology, and it is also one of the three important oil products with the largest consumption of industrial lubricating oil. With the continuous development of modern hydraulic technology, some hydraulic systems often work under high pressure and high temperature conditions. More stringent requirements are placed on the flame resistance of the hydraulic oil used. Before the 1970s, countries devoted themselves to the development of water-containing emulsions (W / O and O / W types), ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10M105/42C10M169/04C10N40/08C10N40/32C10N50/10C10N30/08

Inventor 王鹏汪宪臣姜作泰

Owner 上海海都化学科技有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com