Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

466 results about "Tert butyl phenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The tert-butylation of phenols with tert-butyl alcohol is an industrially important reaction. tert-Butyl phenols are widely used as raw materials for resins, antioxidants, agrochemicals, ultraviolet absorbers and heat stabilizers for polymeric materials [1].

Air compressor oil composition

ActiveCN101724489AImprove anti-coking performanceImprove wear resistanceAdditivesBase-materialsTert butyl phenolFoaming agent

The invention relates to an air compressor oil composition, which comprises the following components in percentage by weight: 1.5 to 5 percent of antioxidant, 0.03 to 0.5 percent of ashless antirust agent, 0.01 to 0.5 percent of metal deactivator, 0.01 to 1 percent of ashless antiwear agent, 0.001 to 0.01 percent of anti-foaming agent and the balance of base oil, wherein the base oil is prepared by mixing poly alpha-olefin with ester oil in a weight ratio of 7-9:3-1 or mixing hydrogenated oil with the ester oil in the weight ratio of 7-9:3-1; and the antioxidant is the mixture of dialkylaniline, high-molecular thioether phenol and 4,4-methylenedi(2,6-di-tert-butyl phenol) in the weight ratio of 1:0.1-10:0.1-10. The air compressor oil composition has the advantages of excellent high-temperature anti-oxidation stability, anti-carbon deposition property, abrasive resistance, obvious energy-saving effect, good cost performance and low cost.

Owner:PETROCHINA CO LTD

Capacitor film with biaxially oriented polypropylene as base body and preparation method thereof

InactiveCN103102588AImprove barrier propertiesImprove air tightnessFixed capacitor dielectricLow-density polyethyleneEpoxy

The invention discloses a capacitor film with biaxially oriented polypropylene as a base body and a preparation method thereof. The capacitor film comprises the raw materials in parts by weight: 68-72 parts of biaxially oriented polypropylene, 23-28 parts of LDPE (low-density polyethylene), 10-15 parts of homo-polypropylene, 3-5 parts of epoxy linseed oil, 2-3 parts of polyving akohol, 1-2 parts of aluminium hydroxide, 1-2 parts of polyisobutene, 8-12 parts of diatomite, 1-2 parts of ferrocene, 0.7-0.9 part of poly-4-methyl-1-amylene, 10-12 parts of K-feldspar powder, 1-3 parts of nanosilicon dioxide, 0.9-1.1 parts of 2,6-di tert butyl phenol-alpha-dimethylamino phenol, 1-3 parts of calcium stearate, 1.4-1.6 parts of phenyltriethoxysilane, and 1.7-2.3 parts of modified tree ash. The biaxially oriented polypropylene serving as a primary material, low-density polyethylene serving as an auxiliary material and a plurality of auxiliary materials are mixed, extruded and subjected to film blowing, shaping and cutting to prepare the capacitor film. The capacitor film is simple in preparation method; and the diatomite, the K-feldspar powder, the nanosilicon dioxide and the modified tree ash are added to the materials at the same time. Therefore, the barrier property and the gas tightness of the film are increased; and the capacitor film has good resistance to pressure and shock resistance, and has the characteristics of high heat sealing strength and good heat sealing property at the same time.

Owner:TONGLING YIHENGDA ELECTRONICS

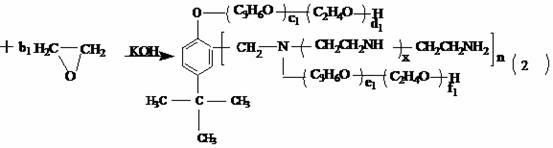

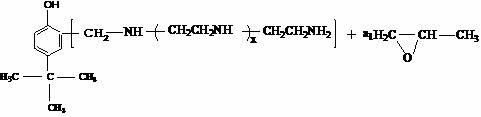

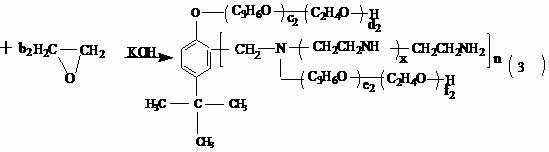

Preparation of polymer flooding produced fluid demulsifier

ActiveCN102676209ASolve the problems of increased difficulty in separation and high oil content in the extracted waterGood effectHydrocarbon oil dewatering/demulsificationCross-linkPolymer science

The invention provides a preparation method of a polymer flooding produced fluid demulsifier, which mainly comprises the following steps: condensing p-tert-butyl phenol, polyethylene polyamine and formaldehyde to obtain a thermoplastic phenol amine resin of which the molecular weights are within a certain range; sequentially and proportionally carrying out ring-opening polymerization on the resin, epoxyethane and propylene oxide; mixing the synthesized products with different molecular weights in a certain mass ratio, and regulating the pH value with acetic acid; and finally, cross-linking with dicarboxylic acid to obtain the final product. The invention aims to solve the problems of severe oil / water emulsification, greater difficulty in oil-water separation, high oil content in dehydrated water and the like in the polymer flooding produced fluid, and the problem that the dehydration effect of the conventional demulsifier on the produced fluid is not ideal.

Owner:DESHI ENERGY TECH GRP CO LTD

Modified polyether amine epoxy curing agent and preparation method thereof

The invention discloses a modified polyether amine epoxy curing agent. The modified polyether amine epoxy curing agent comprises the following raw materials in parts by weight: 45-60 parts of amine-terminated polyether (D-230), 2-5 parts of N-aminoethylpiperazine (N-AEP), 4-10 parts of benzyl alcohol, 3-8 parts of an accelerant (DMP (Dimethyl Phthalate)-30), 20-30 parts of nonyl phenol or tert-butyl phenol and 6-10 parts of epoxy resin (E-51). The modified polyether amine epoxy curing agent is scientific and reasonable in raw material component ratio; the modified polyether amine epoxy curing agent is low in viscosity, high in hardness and good in glossiness; the adhesive force, the solvent property, the low-temperature resistance and high wet resistance can be remarkably improved; the temperature and time of reaction in the preparation process can be effectively controlled; the cost is lowered; therefore, the modified polyether amine epoxy curing agent has a broad market application prospect.

Owner:宋良俊

Reproduced energy-saving material produced by using waste raw material and usage thereof

The invention discloses a regenerative energy saving material by using waste raw material, setting the mass percent at 42-52% regenerating particle mixed with waste polyvinyl chloride, waste polyethylene and waste propane polymer, 42-52% waste tailings ore, 0.5-0.8% silane cross linker, 0.2-0.5% antioxidant phosphorous acid bisphenol A or 2, 4, 6-tri- tertiary butyl phenol, 2-3% epoxide modified phenol resin or oil resin, 0.5-1% cadmium zinc heating stabilizer and 1-2% waste machine oil, the surplus is industrial alcohol. This material can be used to produce inspection cub, well cover, sewer well grate, curb, dustbin, railway sleeper or environmental material.

Owner:XIAN TIANJIU ENVIRONMENT PROTECTION REGENERATIVEMATERIAL

Synthetic method of perfume o-tert-butylcyclohexyl acetate

InactiveCN103193638AExpand sourceLow costOrganic compound preparationCarboxylic acid esters preparationTert butyl phenolAcetic anhydride

The invention relates to a chemical synthetic method, and concretely relates to a synthetic method of a perfume o-tert-butylcyclohexyl acetate. The synthetic method comprises the following steps: reacting a raw material phenol with isobutene under the catalysis of anhydrous aluminum trichloride to obtain o-tert-butyl phenol, carrying out catalytic hydrogenation of o-tert-butyl phenol under the catalysis of Raney nickel to obtain o-tert-butyl cyclohexanol, and carrying out an esterification reaction of o-tert-butyl cyclohexanol and acetic anhydride under the catalysis of anhydrous sodium acetate to obtain o-tert-butylcyclohexyl acetate. The method has the advantages of mild reaction conditions, safe and convenient operation, high reaction yield, fine and strong fragrance of the obtained product, raw material source enlargement and raw material cost saving because of the adoption of industrially cheap phenol and isobutene as initial raw materials, total synthetic reaction yield improvement, suitableness for the industrial adoption, and good economic benefit.

Owner:南昌洋浦天然香料香精有限公司

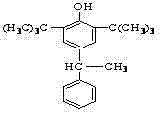

Preparation and application method of polyvinyl chloride (PVC) resin terminator

InactiveCN102492064ADifficult to constitute migrationNot easy to cause volatile lossPhosphoric Acid EstersPolymer science

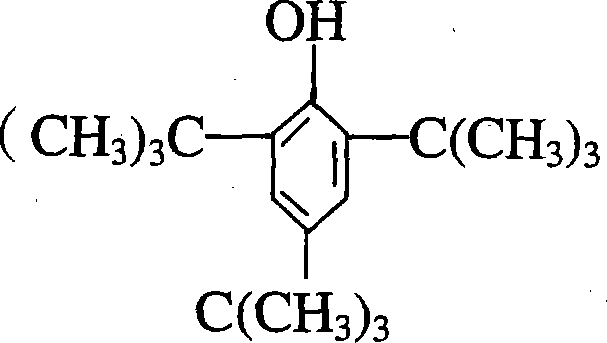

The invention relates to a preparation and application method of a polyvinyl chloride (PVC) resin terminator, belonging to the technical field of chemical products. The invention particularly relates to a liquid antioxidant product, which mainly comprises 2,6-di-bert-butyl-4-(1-phenylethyl)phenol and is obtained by carrying out catalytic alkylation reaction on 2,6-di-bert-butyl phenol and styrene as raw materials. An organic solvent is added into the liquid antioxidant product which mainly comprises the 2,6-di-bert-butyl-4-(1-phenylethyl)phenol, and is sufficiently stirred to obtain the liquid antioxidant product HKY-10. The HKY-10 is compounded with a benzofuran ketone antioxidant and a phosphite ester antioxidant to obtain an oil-soluble compound liquid terminator product as a terminator for a general-purpose PVC resin product preparation process by a suspension method; and the liquid terminator is added in a polymerization reaction process to obtain a PVC resin product with stable properties, thereby enhancing the aging whiteness of the PVC resin product. The PVC resin terminator has the characteristics of no toxicity and environmental protection, and does not generate water pollutants.

Owner:CHANGZHOU UNIV

Preparation method of styrenated hindered phenol or styrenated phenol antioxidant product

ActiveCN102267876AImprove antioxidant capacityAvoid pollutionOrganic chemistryOrganic compound preparationTert butyl phenolButadiene-styrene rubber

The invention discloses a preparation method of a styrenated hindered phenol or styrenated phenol antioxidant product, belonging to the field of preparation process methods of polymer antioxidant products. The preparation method is characterized in that: o-tert-butyl phenol or phenol, p-cresol, o-cresol and m-cresol are used as raw materials, styrene is used as an alkylation reagent, an organic acid compound is used as a catalyst, a small amount of polymerization inhibitor is added, and the styrenated hindered phenol product or styrenated phenol product is prepared through catalytic alkylation reaction; a neutralizing and decolorizing agent is added to the styrenated product to deactivate the acidic catalyst and remove the coloring source material, thus obtaining a white-like or light yellow viscous liquid namely the styrenated phenol antioxidant product which has clear and transparent appearance, pH value of 6.5-7.5, storage stability and high use efficiency; and the styrenated phenol antioxidant product is free of water-soluble pollutants such as free phenol or methyl phenol, thereby solving the problem of environmental pollution caused by the use of the product in styrene butadiene rubber latex.

Owner:CHANGZHOU UNIV

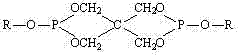

Preparation method of phosphite antioxidant 168

InactiveCN109593101AReduce consumptionReduce generationGroup 5/15 element organic compoundsFiltrationAcid value

The invention discloses a preparation method of a phosphite antioxidant 168 and belongs to the technical field of antioxidant preparation. The preparation method is as follows: adding excessive 2,4-di-tert-butylphenol and a catalyst into a reaction kettle, adding phosphorus trichloride, and carrying out a synthetic reaction to generate tri(2,4-di-tert-butyl)phosphite; then, adding an anti-hydrolytic agent, then, carrying out filtration, and evaporating the excessive 2,4-di-tert-butylphenol in filtrate to obtain a crude product of tri(2,4-di-tert-butyl)phosphite; and then, crystallizing the crude product, and carrying out centrifuging, washing and drying to obtain a final finished product. By using the preparation method of the phosphite antioxidant 168, the consumption of raw materials isreduced, a reaction solvent is reduced, the reaction time is shortened, and the generation amount of byproducts is low; and a phosphite antioxidant 168 product prepared by using the preparation methodhas the characteristics of high purity (larger than or equal to 99%, low acid value (smaller than or equal to 0.3 mgKOH / g) and good hydrolysis resistance (PH is larger than or equal to 7).

Owner:LIAONING DINGJIDE PETROCHEM

Polyurethane composite material regenerated from waste polyurethane soles and preparation process thereof

InactiveCN104448775ASolving Recycling ProblemsRaw materials are easy to getAmmonium polyphosphateChemistry

The invention discloses a polyurethane composite material regenerated from waste polyurethane soles and a preparation process thereof. The polyurethane composite material is prepared from the following raw materials in parts by weight: 170-180 parts of waste polyurethane soles, 10-14 parts of a compatibilizer, 5-7 parts of toluene diisocynate, 2-4 parts of tri(2,4-di-tert-butylphenol) phosphite ester, 4-6 parts of medical stone powder, 6-8 parts of organic silicon, 2-3 parts of ammonium polyphosphate, 12-18 parts of polyisocyanate, 3-5 parts of hybrid polyester polyol, 5-7 parts of dibutyltin dilaurate, 6-8 parts of alkanolamide, 4-5 parts of nano-alumina powder, 2-3 parts of antioxidant TNP, 7-9 parts of aluminum stearate, 8-10 parts of isocyanate, 4-6 parts of zirconium oxide, 9-11 parts of nano montmorillonite and 10-12 parts of additives. According to the invention, on one hand, the recovery problem of the waste polyurethane soles is solved, on the other hand, the raw materials are easy to obtain, the cost is low, the operation is simple, and emission of three wastes is avoided in the production, so as to protect the environment and reduce the production cost, and ensure that the economic benefit and the social benefit are considerable.

Owner:JINJIANG MINGAO TEXTILE SCI & TECH

Method for synthesizing antioxidant 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene

InactiveCN101717326AEasy to makeEasy to prepareOrganic chemistryOrganic compound preparationAlkyl transferSuperacid

The invention discloses a method for preparing antioxidant 1,3,5-trimethyl-2,4,6-tri(3,5-di-tert-butyl-4-hydroxybenzyl)benzene by using solid superacid as catalyst, wherein 1,3,5-trihalo methyl-2,4,6-trimethyl benzene and 2,6-do-tert-butylphenol, as raw materials, are subject to alkylation in inert solvent under the action of solid superacid-type catalyst SO42- / MXOY, so as to prepare target products. The method simplifies operating process, achieves mild reaction conditions, has the characteristics of easy separation of products, good reusability of the catalyst, small environmental pollutionand the like, and is suitable for industrial production.

Owner:BOHAI UNIV

New method of preparing tert-butyl phenol by alkylation of phenol and isobutene

InactiveCN1948247AIncrease profitReduce manufacturing costOrganic chemistryOrganic compound preparationAlkyl transferGas liquid reaction

The present invention relates to a new method for preparing tert-butyl phenol by utilizing phenols and isobutylene and making them produce alkylation reaction. Said method is characterized by that on the basis of gas-liquid reaction equipment a Venturi ejector or gas-liquid mixing pump and a feed liquor circulating pump are added, so that the unreacted isobutylene can be further absorbed and fed into reaction still, under the action of ejector and feed liquor circulating pump the isobutylene gas and liquid material can be continuously circulated in the system so as to make the gas-liquid reaction be more uniform.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

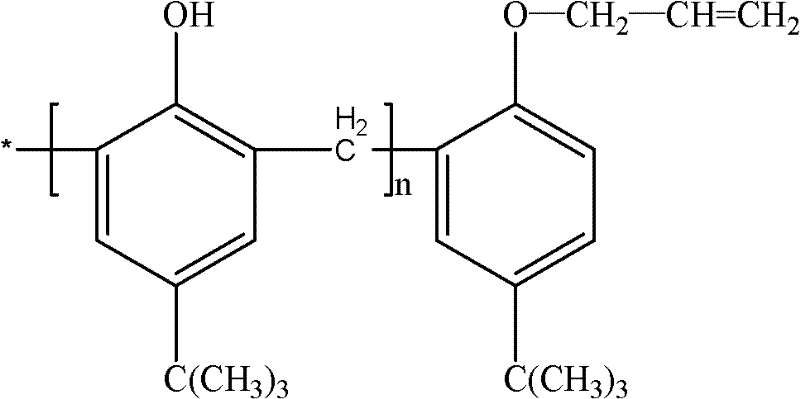

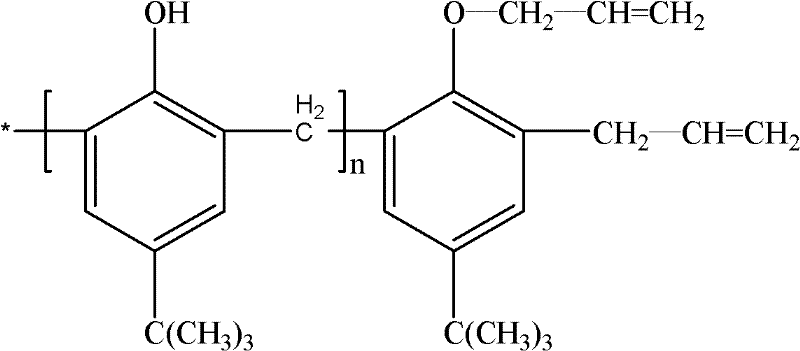

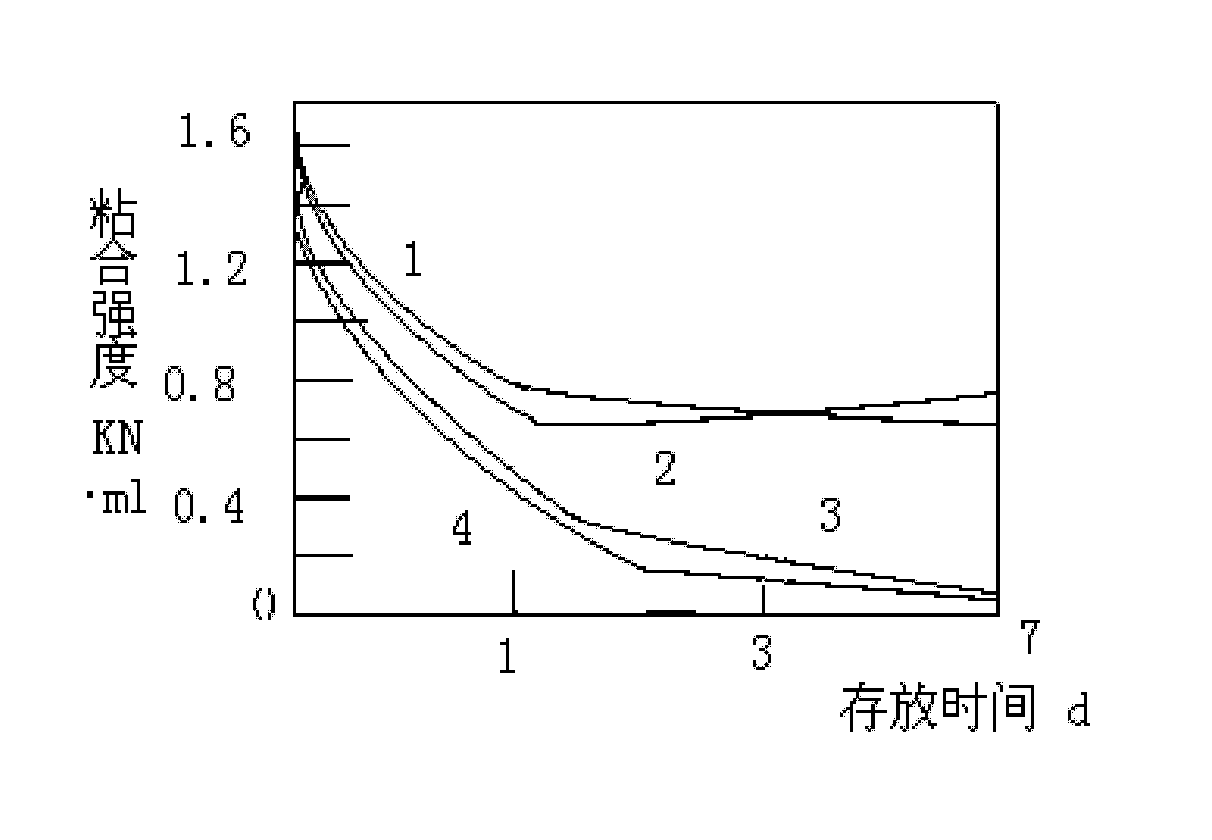

Allyl para-tert-butyl phenyl ether formaldehyde tackifying resin and preparation method thereof

The invention discloses allyl para-tert-butyl phenyl ether formaldehyde tackifying resin and a preparation method thereof. The preparation method comprises the following steps: mixing para-tert-butyl phenol with formaldehyde at the molar ratio of 1:1, increasing the temperature to 80-120 DEG C, adding hydrochloric acid till the boiling of reaction lasts for 3-5 hours, using toluene to dissolve, washing with hot water till neutrality, mixing the obtained resin with allyl chloride at the molar ratio of (3-1):(0.5-2), using ethanol to dissolve, further adding potassium hydroxide to regulate the pH to 8-10, heating for 30-90 minutes, then using the toluene to extract, washing with distilled water till the neutrality, and performing reduced pressure distillation so as to get an allyl para-tert-butyl phenyl ether formaldehyde resin purified product. The product has higher self-adhesion strength and excellent long-acting tackifying capability.

Owner:SOUTH CHINA UNIV OF TECH

Environment-friendly high-elasticity rubber material

The invention discloses an environment-friendly high-elasticity rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of powder nitrile-butadiene rubber, 10-18 parts of polyvinyl chloride thermoplastic elastomer, 10-20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3-5 parts of p-tert-butyl phenol-formaldehyde resin, 1.5-2 parts of sulfur, 1.2-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of zinc oxide, 5-8 parts of epoxy soybean oil, 0.5-1 part of paraffin, 1-3 parts of zinc-barium stabilizer, 2-3 parts of organophosphate, 20-30 parts of modified kaolin, 15-20 parts of silica white, 1.5-3 parts of carbon master batch and 0.5-1.5 parts of novel rubber reinforcing agent XRE. The rubber material has the advantages of excellent elasticity, wear resistance, favorable tear resistance and low cost, and reduces the hazard to the environment.

Owner:宁国日格美橡塑股份有限公司

Lubricant composition for refrigerating machine

InactiveUS20110000253A1Stably usableExcellently suppressHeat-exchange elementsAdditivesEngineeringBase oil

Owner:IDEMITSU KOSAN CO LTD

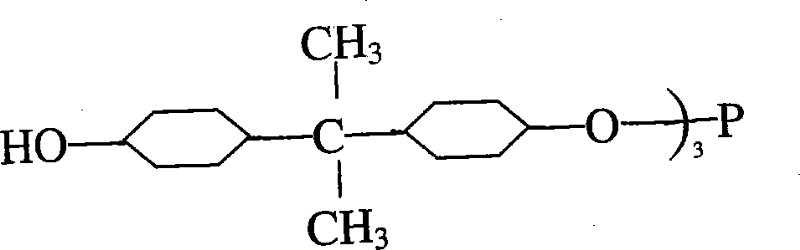

Bisphenol monomer containing bi-tert-butyl and fluorenyl structure, and preparation method and application thereof

ActiveCN103274908AThe synthetic route is simpleHigh yieldOrganic chemistryOrganic compound preparationPolymer scienceTert butyl phenol

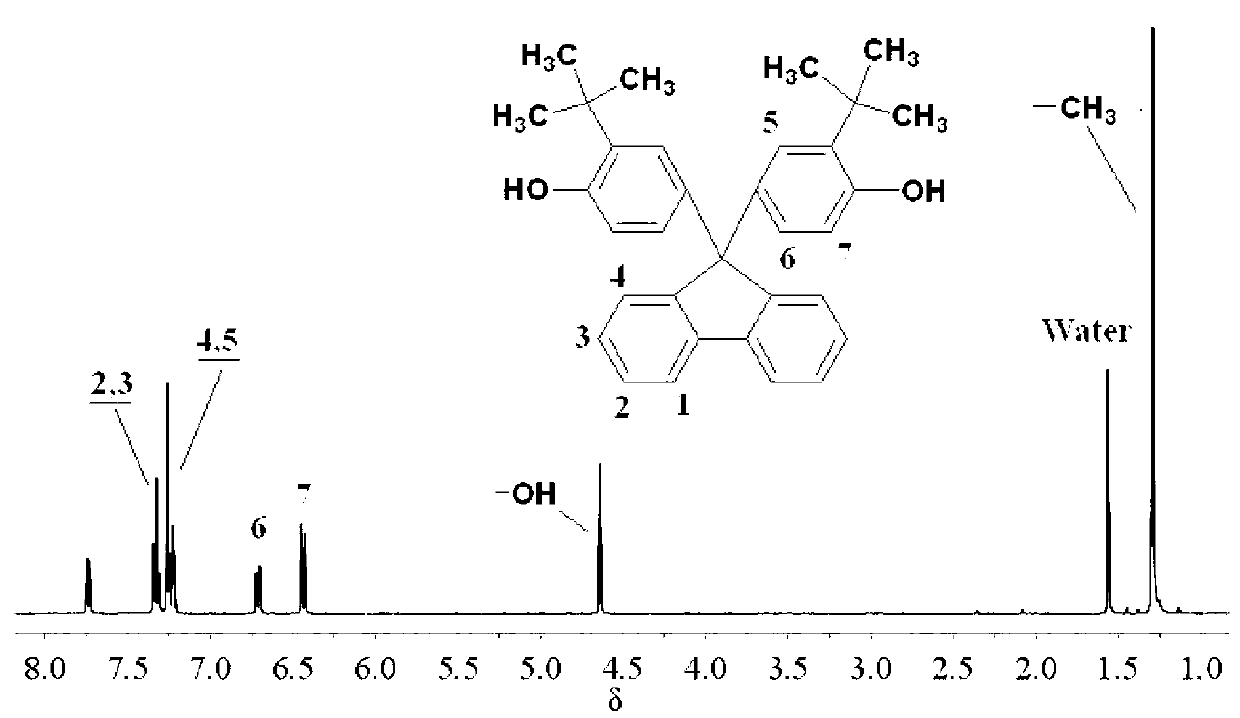

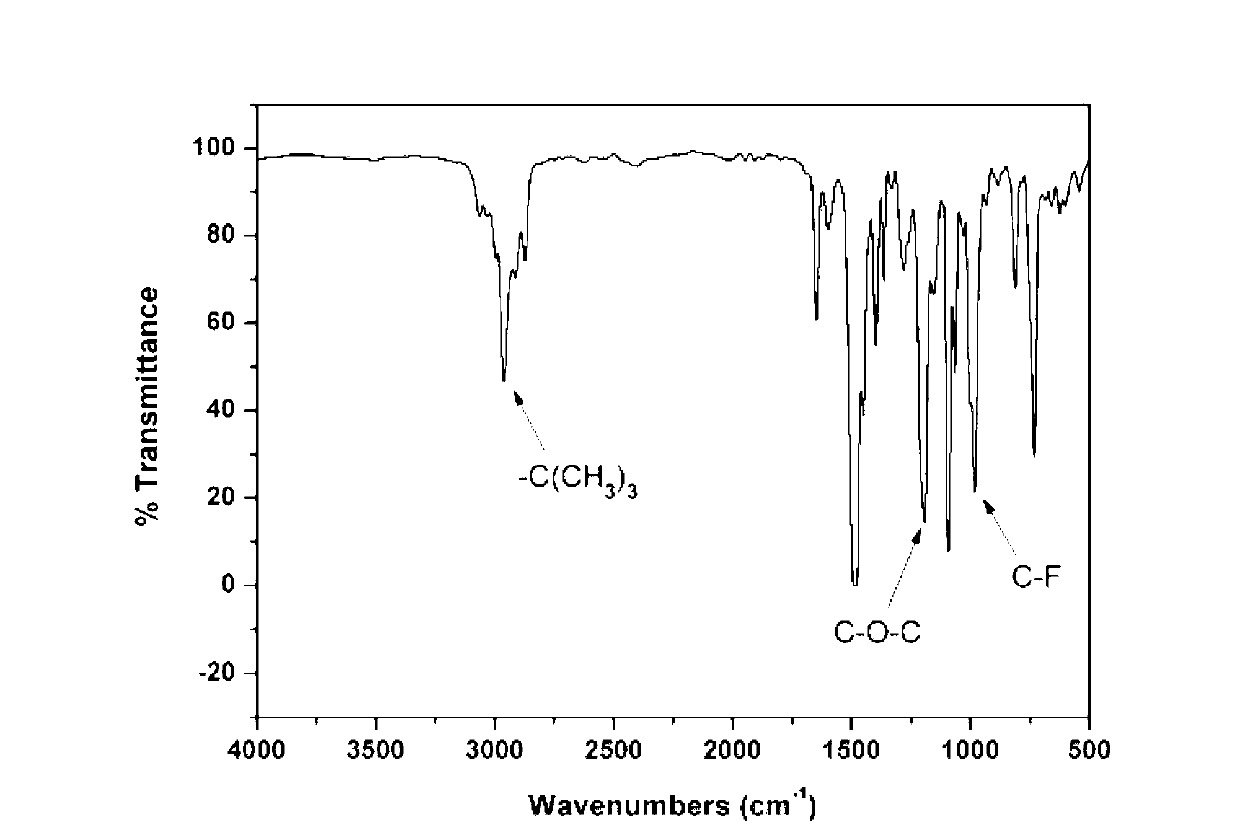

The invention relates to a bisphenol monomer containing a bi-tert-butyl and fluorenyl structure. The bisphenol monomer is 9, 9-bi(4-hydroxyl-3-tert-butyl phenyl) fluorine. The monomer is simple in a synthetic route, high in yield, easy to purify, stable at the room temperature and can be used for preparing fluorine-contained polyarylether. The bisphenol monomer containing the bi-tert-butyl and fluorenyl structure is prepared by the following steps of: reacting reactants 2-tert butyl phenol and 9-fluorenone in the presence of an acid catalyst, transferring a product into a mixed solvent of ethanol and water, carrying out suction filtering, and further recrystallizing to obtain the target product. The bisphenol monomer containing the bi-tert-butyl and fluorenyl structure is used for preparing the fluorine-contained polyarylether. The prepared polyarylether has good dissolving film forming property, excellent thermal property and low dielectric constant.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

BADGE- and BPA-Free Can Coating

ActiveUS20080299343A1Suitable flexibilitySuitable resistanceSynthetic resin layered productsPretreated surfacesAcrylic resinPolyvinyl chloride

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components:(a) 30 to 90 wt. % of a polyvinylchloride-(PVC)-polymer,(b) 7 to 25 wt. % of an acrylic resin,(c) 3 to 40 wt. % of a crosslinking agent, which is produced from phenol, para-tert.-butylphenol, xylenol or a mixture thereof, and formaldehyde,(d) 0 to 8 wt. % additive,(e) 0 to 50 wt. % pigment and(f) a solvent-component,where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl-ether (“BADGE”) and also substantially free of bisphenol-A-resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

Prepn process of 2,2'-methylene bis (4-methyl-6-tert-butyl phenol)

InactiveCN1506345AImprove stabilityEasy to separateOrganic chemistryOrganic compound preparationTert butyl phenolCresol

The present invention relates to the preparation process of 2,2'-mehtylene bis(4-methyl-6-tert-butyl phenol). The present invention adopts macroporous strong acid cationic exchange resin, zeolite with SiO2 / Al2O3 molar ratio of 15-100, or heteropolyacid or other solid acid as catalyst; and formal and 2-tert-butyl-4-cresol as material, with the catalyst amount being 10-80 wt% of 2-tert-butyl-4-cresol. The reaction is performed at the temperature of 40-100 deg.c for 1-5 hr, and the reaction resultant is filtered, distilled and refined to obtain the product. The process of the present invention has the features of simple post-reaction treatment, high product yield, high product quality, no corrosion to the apparatus and high catalyst stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rubber anti-aging agent, preparation method thereof, and rubber

The invention provides a rubber anti-aging agent, a preparation method thereof, and rubber. The rubber anti-aging agent comprises tris(2,4-di-tert-butylphenyl)phosphite, dilauryl dithiodipropionate, and 4,4'-thiobis-(3-methyl-6-tert-butyl phenol) and / or 2,2'-methylenebis-(4-methyl-6-tert-butyl-phenol). The rubber anti-aging agent preparation method comprises the step that the tris(2,4-di-tert-butylphenyl)phosphite, dilauryl dithiodipropionate, and 4,4'-thiobis-(3-methyl-6-tert-butyl phenol) and / or 2,2'-methylenebis-(4-methyl-6-tert-butyl-phenol) are well mixed. With the rubber anti-aging agent provided by the invention, prepared rubber has excellent aging resistance and high strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Pressure-sensitive adhesive for metals and preparation method thereof

ActiveCN103450826ANatural rubber adhesivesNon-macromolecular adhesive additivesTert butyl phenolRoom temperature

The invention discloses a pressure-sensitive adhesive for metals and a preparation method thereof. The pressure-sensitive adhesive for metals comprises the following components in parts by weight: 60-70 parts of polyisobutylene rubber, 10-20 parts of soft butadiene styrene rubber, 40-50 parts of rubber smoked sheet, 0.5-2 parts of stearic acid, 0.5-2 parts of anti-aging agent, 0.5-2 parts of accelerator, 10-20 parts of tert-butyl phenol-formaldehyde resin and 3-8 parts of chlorosulfonated polyethylene. The preparation method comprises the following steps: mixing and heating the components to 70-80 DEG C, keeping the temperature for 30-60 minutes while stirring, and cooling to room temperature. The performance test indicates that the holding power of the pressure-sensitive adhesive for metals is more than 8 hours, the stripping force is greater than 12N, and thus, the pressure-sensitive adhesive for metals is much superior to the commercially available common organic silicon pressure-sensitive adhesive.

Owner:苏州凯盛净化科技有限公司

Preparation method of high-cis vertenex

InactiveCN101830798AIncrease contentMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationChemical synthesisAcetic acid

The invention discloses a chemical synthesis method, in particular to a preparation method of high-cis vertenex. The vertenex is prepared from two steps of reactions: firstly, using p-tert-butyl phenol and hydrogen as raw materials to synthesize tert-butyl cyclohexanol under the condition of a catalyst; secondly, using tert-butyl cyclohexanol and acetic acid as raw materials to carry out a synthesis reaction under the condition of a catalyst III to obtain high-cis vertenex. The invention has the advantages of mild reaction conditions, safe and convenient operation, high cis body content in the product and thinner and stronger and fine product fragrance. The method can be widely applied to the preparation process of perfume.

Owner:杭州友邦香料香精有限公司

High-temperature anti-oxidant for lubricating oil and preparation method of high-temperature anti-oxidant

ActiveCN105038904AExtension of timeImprove solubilityOrganic compound preparationAdditivesTert butyl phenolPtru catalyst

The invention discloses a preparation method of a high-temperature anti-oxidant for lubricating oil. 2,6-di-tert-butyl phenol and substituted diphenylamine are taken as raw materials, and n-decane is taken as a high-boiling-point solvent. The materials above are reacted at 120-170 DEG C for 2-4 h under the action of a catalyst and in the presence of a noble gas to obtain a product, and the product is treated to obtain the target product. Anti-oxidants, of 2,6-di-tert-butyl phenol and substituted diphenylamine, with excellent antioxidant performance are used in the invention. The use temperature of the anti-oxidant is increased, and the working time of lubricating oil is greatly prolonged. The high-temperature anti-oxidant for lubricating oil has advantages of high temperature resistance, good anti-oxidant performance, and good solubility in lubricating oil. It is proved through a high-temperature antioxidant experiment that the high-temperature anti-oxidant has excellent properties and a bright application prospect.

Owner:道骐科技有限公司

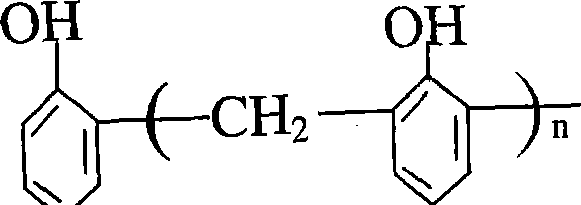

Morpholine modified p-tert-butylphenol-formaldehyde resin and preparation method thereof

ActiveCN102295621AGood viscosity increasing effectSimple processOrganic chemistryTert butyl phenolPolymer science

The invention relates to a morpholine modified para-tert-butyl phenolic resin and is characterized in that the structural formula of the morpholine modified para-tert-butyl phenolic resin is described in the specification, wherein R is morpholine, n can be 1,2,3,4 or 5, and the average molecule weight of the substance is 800-1000. According to the invention, the resin can improve the tackifying property of a product so that the tackifying property of the product meets the processing technology of automobile tyre and rubber; and the performance of the resin is equivalent to that of para-tert-butyl phenol-acetylene resin produced by BASF in German. The invention also discloses the preparation process of the morpholine modified para-tert-butyl phenolic resin.

Owner:WUHAN JINGHE CHEM

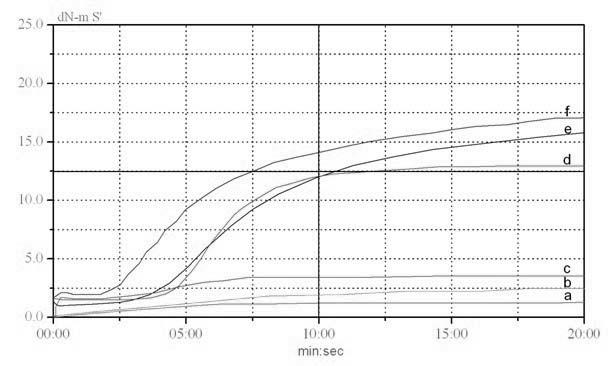

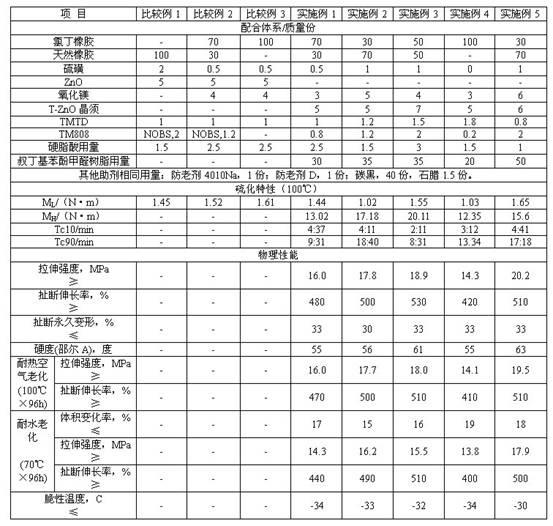

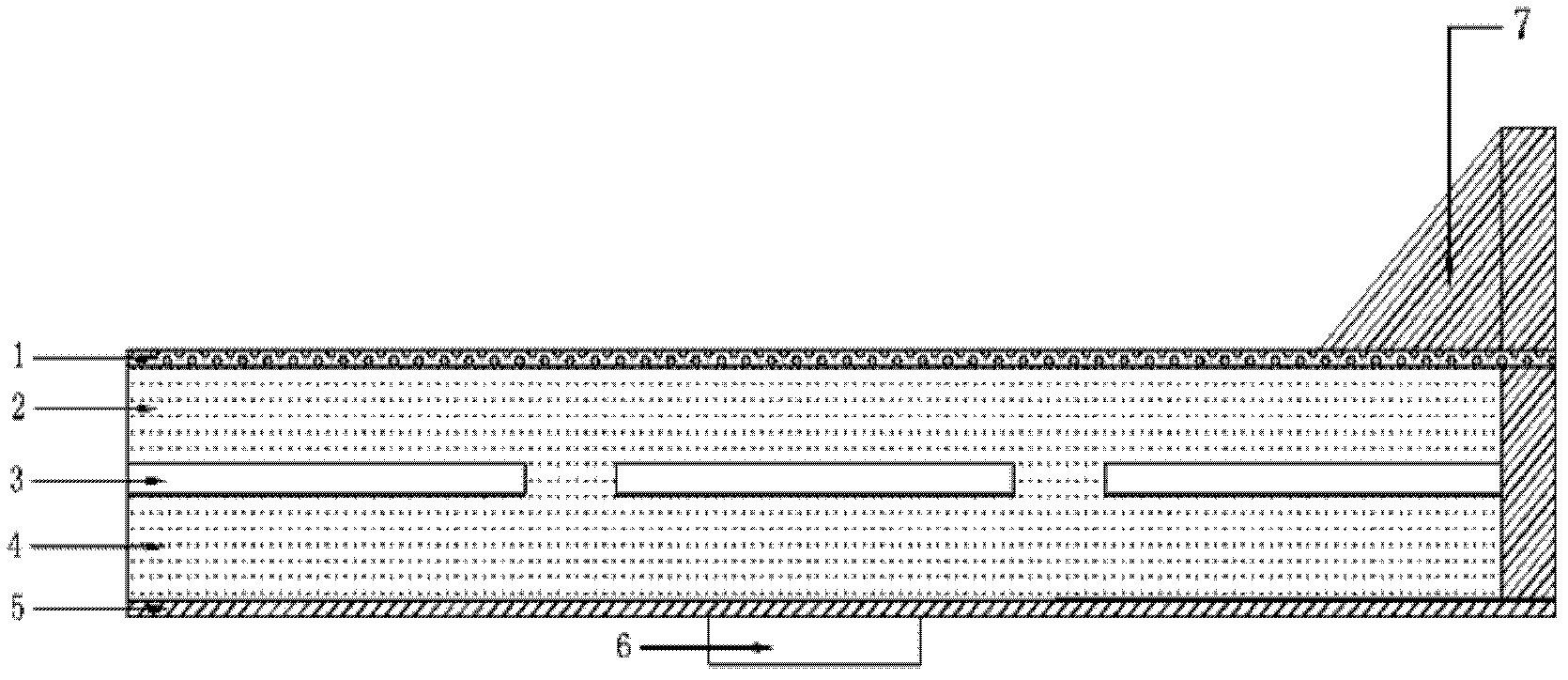

Room temperature/low temperature vulcanized chloroprene rubber sizing material

ActiveCN102115553AStable room temperature/low temperature vulcanization performanceImproved scorch performancePolymer scienceTert butyl phenol

The invention discloses a room temperature / low temperature vulcanized chloroprene rubber sizing material, which relates to rubber. The rubber sizing material is obtained by mixing and processing the following components in parts by mass: 100-30 parts of chloroprene rubber, 0-70 parts of natural rubber, 0-1 part of sulfur S, 4-7 parts of T-ZnO crystal whiskers, 1-6 parts of magnesium oxide, 0-3 parts of TM808, 0.5-1.5 parts of accelerating agent TMTD (Tetramethylthiuram Disulfide), 20-50 parts of tert-butyl phenol formaldehyde resin, 1-6 parts of stearic acid and the balance of compound anti-ageing system consisting of 4010Na and D, carbon black and a paraffin aid, wherein the sulfur S, the T-ZnO crystal whiskers and the magnesium oxide jointly serve as a dual vulcanizing agent, and the TM808 and the accelerating agent TMTD jointly serve as a compound accelerating agent. The chloroprene rubber sizing material obtained by the invention can be vulcanized at room temperature / low temperature, has high scorching property, high adhesion on a framework material and the advantages of ageing resistance, high physical and mechanical performance, high ozone resistance, high oxidation resistance, combustion resistance and the like, and is particularly suitable for the production of large-sized rubber products or the construction of field vulcanization.

Owner:陈尔凡

High-speed rail turnout rust-preventative oil

ActiveCN104046420AApplicable useGood kinematic viscosityLubricant compositionTert butyl phenolBarium salt

The invention discloses high-speed rail turnout rust-preventative oil which is composed of the following raw materials, by weight, 52-60 parts of machine oil, 4-6 parts of p-tert-butylphenol formaldehyde resin, 1-2 parts of vaseline, 4-6 parts of dinonyl-naphthalenesulfonic acid barium salt, 2-4 parts of neutral dinonyl-naphthalenesulfonic acid barium salt, 3-4 parts of petroleum sodium sulfonate, 1-2 parts of lauric diethanolamide, 0.7-1 part of aluminium isopropoxide, 0.2-0.4 part of 2,2'-methylene-bis(4-methyl-6-tert-butyl phenol), and 4-6 parts of an antirust auxiliary agent. The rust-preventative oil has stable film, can completely cover a rust layer and a metal surface, can saturate the rust layer within a short time to form a hard film, has good kinematic viscosity and is especially suitable for outdoor steel rails and turnouts.

Owner:徐州邦贤信息科技有限公司

Method for producing 2, 2'-methylene double (4-methyl -6-tertiary butyl phenol)

InactiveCN1500768AExtended service lifeEasy to separateOrganic chemistryOrganic compound preparationTert butyl phenolAdhesive

The present invention relates to the production process of 2, 2'-methylene-bis(4-methyl-6-tert butyl phenol). The materials including formal and 2-tert-butyl-4-cresol are made to react inside two serially connected fixed bed reactors with solid acid catalyst, which is macroporous strong acid cationic exchange resin or zeolite catalyst, and in the reaction temperature of 30-150 deg.c. The zeolite catalyst contains zeolite in 60-80 wt% and adhesive in 20-40 wt%, and the zeolite is ZSM-5 zeolite and / or flokite with SiO2 / Al2O3 molar ratio of 15-100. The present invention realizes continuous production, has simple post-reaction treatment, high product yield, high product quality and high catalyst stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified geogrid processed by using waste cross-linked polyethylene cable material and preparation method of modified geogrid

The invention relates to a modified geogrid processed by using waste cross-linked polyethylene cable material. The modified geogrid is obtained by processing the following component raw materials in parts by weight: 30-40 parts of a waste cross-linked polyethylene cable material, 30-40 parts of styrene-maleic anhydride copolymer, 5-8 parts of a phosphate coupling agent, 30-40 parts of high-density polyethylene, 0.2-0.3 part of an anti-aging agent 168, 0.2-0.3 part of 2,4,6-tristertbutylphenol, 5-10 parts of a plasticizer DOP (Dioctyl-Phthalate), 1-2 parts of straw ashes, 8-10 parts of carbon black, 1-2 parts of sodium carboxymethyl cellulose, 6-10 parts of palygorskite clay and 15-20 parts of a modified filler. The modified geogrid is processed by using the waste cross-linked polyethylene cable material by virtue of the steps of mixing the materials in the formula, extruding, molding the melt through a three-roller calender to obtain a plate, punching the plate by a punching machine, heating the punched plate and then stretching to obtain the geogrid. The geogrid processed by the preparation method disclosed by the invention is low in cost of raw materials and has the effects that the waste is recycled and resources are saved and meanwhile, the product has the characteristics of high impact strength, large toughness and strong corrosion resistance.

Owner:ANHUI JIEAOMAKE SYNTHETIC MATERIAL TECH

Paint for pot not containing BADGE and BPA

ActiveCN101316892AModerate flexibilitySuitable for abrasion resistancePretreated surfacesLinings/internal coatingsXylylenePolymer science

The present invention relates to a composition, which is useful for producing coatings for metal sheet substrates of metal cans for storing and / or transporting food or beverages or a lid thereof, and which comprises the following components: (a) 30 to 90 wt. % of a polyvinylchloride- (PVC) -polymer, (b) 7 to 25 wt. % of an acrylic resin, (c) 3 to 40 wt .% of a crosslinking agent, which is produced from phenol, para-tert, -butylphenol, xylenol or a mixture thereof, and formaldehyde, (d) 0 to 8 wt. % additive, (e) 0 to 50 wt. % pigment and (f) a solvent-component, where all weight percentages are on the basis of the total dry weight of the coating composition (without solvents) and the composition is substantially free of bisphenol-A-diglycidyl- ether ('BADGE') and also substantially free of bisphenol-A- resins. The composition provides metal can coatings that have suitable flexibility, scratch resistance, adherence and sterilization resistance when processed in contact with food. The coatings are suitable for three-piece cans as well as deep-drawn metal cans. In particular they are, however, useful for lids that are to be torn open due to their extraordinary flexibility and sterilization resistance.

Owner:HENKEL KGAA

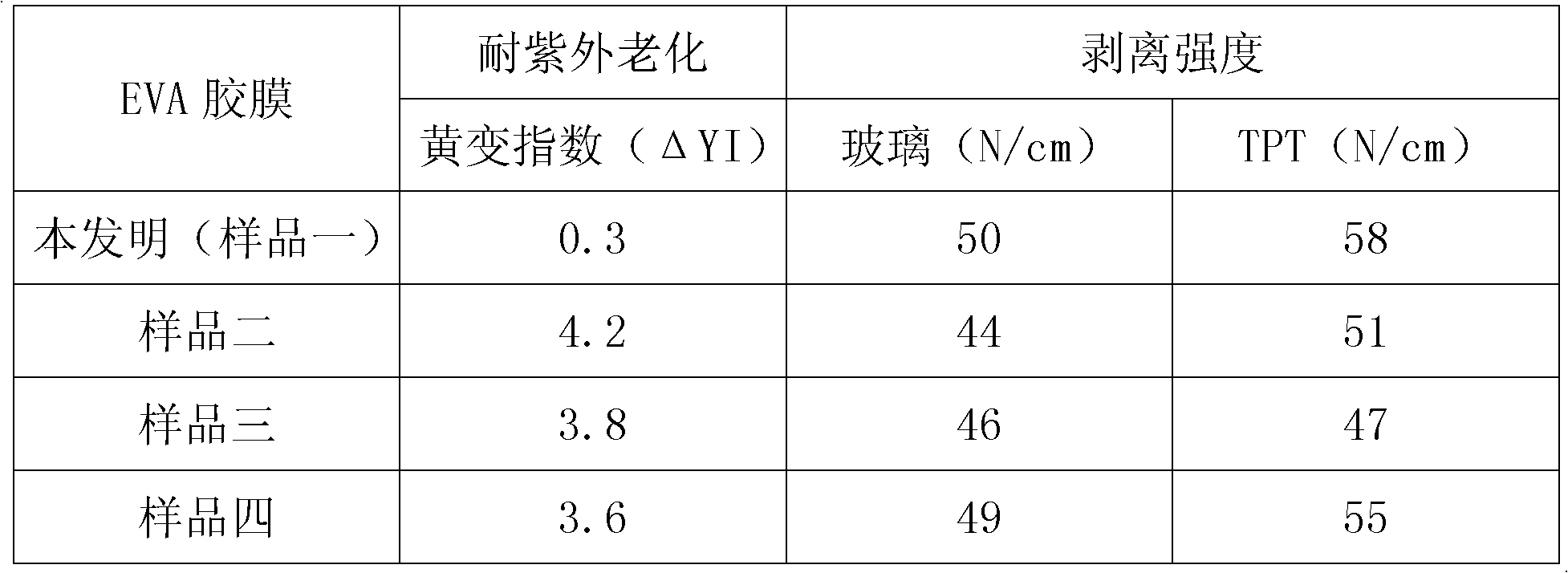

Novel ultraviolet-resistant EVA (Ethylene-Vinyl Acetate) glue film

InactiveCN102504713AExcellent UV aging resistanceLow yellowing indexNon-macromolecular adhesive additivesFilm/foil adhesivesTert butyl phenolSuperoxide

The invention discloses a novel EVA (Ethylene-Vinyl Acetate) glue film for a solar battery; the EVA glue film has excellent characteristics of ultraviolet adsorption and anti-ultraviolet aging; when the EVA glue film is applied to a solar component, a solar backplane is protected from being damaged by ultraviolet lights, and the service life of the backplane material of the component with the EVA glue film is greatly prolonged. The EVA in the EVA glue film mainly comprises the following components: 90-100 parts of ethylene-vinyl acetate, 0.05-5 parts of superoxide crosslinking agent, 5-10 parts of lipid antioxidant, 5-10 parts of hindered amine light stablizer and 0.005-5 parts of thickening agent. The EVA glue film has strong intense light energy to absorb ultraviolet by adding a novel ultraviolet light absorbing agent 2-(2'-hydroxy-3', 5'- di-tert-butyl phenol) and greatly prolongs the service life of packaging material.

Owner:CHANGSHU CANADIAN SOLAR ELECTRIC POWER TECHCO +1

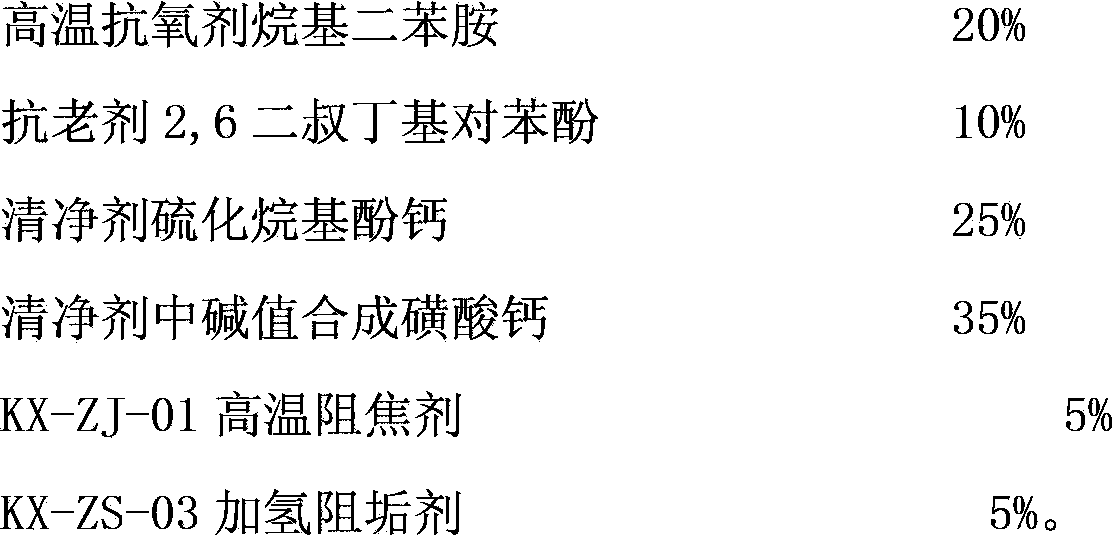

Hydrogenation synthesis heat transfer liquid and preparation method thereof

ActiveCN103387821AMolecular components are pureImprove product qualityHeat-exchange elementsSulfonateTert butyl phenol

The invention relates to a hydrogenation synthesis heat transfer liquid and a preparation method thereof. The invention belongs to the field of chemical heat transfer oil preparation. The heat transfer liquid is characterized in that the heat transfer liquid is prepared by adding a functional additive to deep hydrogenation base oil. The functional additive is prepared from the raw materials of, by mass: 20% of a high-temperature antioxidant alkyldiphenylamine, 10% of an anti-aging agent 2,6-di-tert-butyl-phenol, 25% of a detergent sulfurized alkylphenol calcium, 35% of a detergent medium-base-value synthetic calcium sulfonate, 5% of a KX-ZJ-01 high-temperature decoking agent, and 5% of a KX-ZS-03 hydrogenation scale inhibitor. The molecular components are pure, and organic impurities such as S, N, O, and heavy metals influencing the quality and service life of the heat transfer oil are not introduced. The product quality is excellent, heat transfer performance is good, and the heat transfer liquid is safe and environment-friendly.

Owner:SHANDONG ENKLI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com