Preparation and application method of polyvinyl chloride (PVC) resin terminator

A technology of polyvinyl chloride and terminator, which is applied in the preparation of polyvinyl chloride resin terminator, both in 2 fields, can solve the problems of insignificant thermal and oxidative aging resistance of resin, relatively toxic ATSC substances, large ATSC substances, etc. Achieve good synergistic effect, facilitate industrial application, high whiteness and aging whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

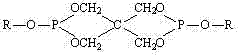

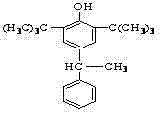

[0052] Add 750 grams of 2,6-di-tert-butylphenol, 60 grams of dodecylbenzenesulfonic acid, 2.5 grams of polymerization inhibitor, start stirring, feed nitrogen as nitrogen protection, slowly heat up to 110~112°C, start to add styrene dropwise at this temperature, the amount of styrene is 455g, add dropwise at a uniform speed and Complete within ~200 minutes, keep warm at 110~112°C for 60 minutes. After the reaction is over, lower the temperature to 80°C, add 46 grams of neutralizing and decolorizing agent diethylhydroxylamine, and keep stirring at this temperature for 20 minutes, add 843 grams of styrene, stir for 30 minutes, and mix thoroughly to make HKY-10; maintain the temperature At 60~65°C, add 68 grams of benzofuranone antioxidant and 253 grams of phosphite antioxidant, and stir thoroughly for 30 minutes to obtain 1# oil-soluble composite liquid terminator product (1# terminator) .

Embodiment 2

[0054] Add 750 grams of 2,6-di-tert-butylphenol, 53 grams of dodecylbenzenesulfonic acid, 6.0 grams of polymerization inhibitor, start stirring, feed nitrogen as nitrogen protection, slowly heat up to 80~85°C, start to add styrene dropwise at this temperature, the amount of styrene is 340g, add dropwise at a constant speed and Complete within ~240 minutes, keep warm at 80~85°C for 80 minutes. After the reaction is over, cool down to 60°C, add 38 grams of neutralizing and decolorizing agent diethylhydroxylamine, and keep stirring at this temperature for 20 minutes, add 807 grams of isododecane, stir for 30 minutes, and mix thoroughly to make HKY-10; Maintain the temperature at 75~80°C, add 60 grams of benzofuranone antioxidant and 322 grams of phosphite antioxidant, and stir thoroughly for 50 minutes to obtain 2# oil-soluble composite liquid terminator product (2# Termination agent).

Embodiment 3

[0056] Add 750 grams of 2,6-di-tert-butylphenol, 67 grams of dodecylbenzenesulfonic acid, 4.5 grams of polymerization inhibitor, start stirring, feed nitrogen as nitrogen protection, slowly heat up to 117~120°C, start to add styrene dropwise at this temperature, the amount of styrene is 378g, add dropwise at a uniform speed and Complete within ~215 minutes, keep warm at 117~120°C for 60 minutes. After the reaction is over, cool down to 70°C, add 60 grams of neutralizing and decolorizing agent diethylhydroxylamine, and keep stirring at this temperature for 30 minutes, add 800 grams of α-methylstyrene, stir for 30 minutes, and mix thoroughly to make HKY- 10. Keep the temperature at 50~55°C, add 80 grams of benzofuranone antioxidants, 400 grams of phosphite antioxidants, and stir thoroughly for 60 minutes to obtain 3# oil-soluble composite liquid terminator products (3# terminator).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com