High-temperature anti-oxidant for lubricating oil and preparation method of high-temperature anti-oxidant

An anti-oxidant and lubricating oil technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve problems such as severe oil sludge, defects in the working range of single amine antioxidants, etc., and achieve anti-oxidation ability Strong, excellent performance, easy post-processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a high-temperature antioxidant for lubricating oil, specifically: add 30ml of n-decane into a 100ml three-necked reaction bottle, add 3g of diphenylamine and 3.6g of 2,6-di-tert-butylphenol under stirring, and under the protection of nitrogen atmosphere, Slowly raise the temperature to 140°C, add 8.5ml of di-tert-butyl peroxide dropwise, after the addition is complete, continue the reaction for 3 hours, distill off the unreacted di-tert-butyl peroxide, naturally cool to room temperature, refrigerate for 30 minutes, and filter with suction. A small amount of n-decane was washed 3 times and dried to obtain 4.8g of the product of Example 1. The appearance was light yellow needle-like crystals, and the column chromatography quickly eluted the raw materials to obtain a high-purity compound (developer: V 环己烷 :V 二氯甲烷 =20:1) that is, 2,6-di-tert-butyl-4-dianilinophenol, its structural formula is as follows:

[0032] .

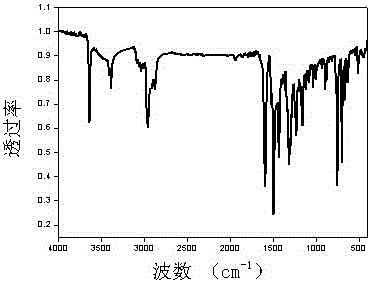

[0033] Such as figure 1 IR (KB...

Embodiment 2

[0042] A preparation method of high-temperature antioxidant for lubricating oil, specifically: add 30ml of n-decane into a 100ml three-necked reaction flask, add 3.25g of 3-methyldiphenylamine and 3.6g of 2,6-di-tert-butylphenol under stirring, nitrogen Under the protection of the atmosphere, slowly raise the temperature to 140°C, add 8.5ml of di-tert-butyl peroxide dropwise, after the addition is complete, continue the reaction for 3h, distill off the unreacted di-tert-butyl peroxide, cool naturally to room temperature, and freeze for 30min , filtered with suction, washed with a small amount of n-decane three times, and dried to obtain 5.2 g of light yellow needle crystals.

Embodiment 3

[0044] A preparation method for high-temperature antioxidants for lubricating oils, specifically: add 30ml of n-decane into a 100ml three-necked reaction flask, add 3.5g of 3-methoxydiphenylamine and 3.6g of 2,6-di-tert-butylphenol under stirring, Under the protection of nitrogen atmosphere, slowly raise the temperature to 140°C, add 8.5ml of di-tert-butyl peroxide dropwise, after the addition is complete, continue the reaction for 3h, distill off the unreacted di-tert-butyl peroxide, cool naturally to room temperature, freeze After 30 minutes, filter with suction, wash with a small amount of n-decane three times, and dry to obtain 5.6 g of powdery white solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com