Refrigerating engine oil composition and application thereof

A technology for refrigerating machine oil and composition, applied in the direction of lubricating composition and the like, can solve the problems of affecting the refrigeration performance of compressors, and achieve the effects of excellent thermal stability, excellent economic performance and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

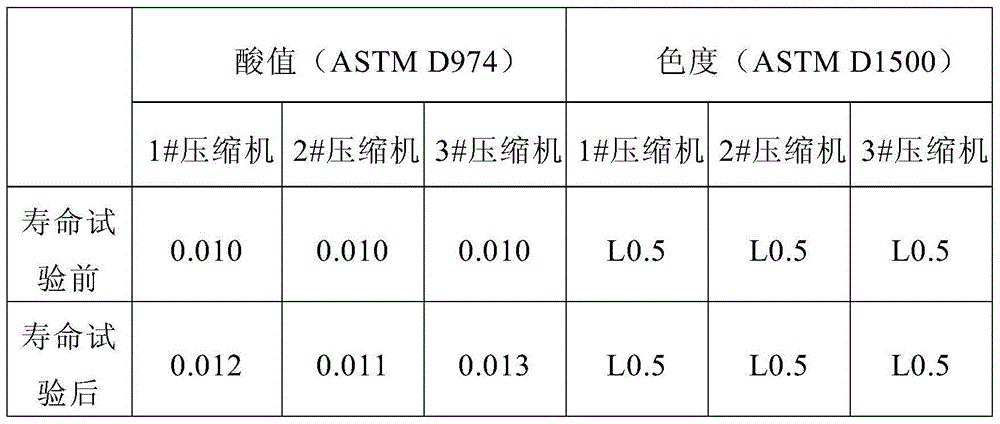

Examples

Embodiment 1

[0031] Based on the total weight of the refrigerating machine oil combination, select 65 parts of linear alkylbenzene with a molecular weight between 215 and 230 and a distillation range between 260 and 300, and select 33.47 parts of C P (paraffin) content not less than 50% of the total weight, C A (aromatic hydrocarbons) content not more than 2% of the total weight, C N (cycloalkane) or cyclic hydrocarbon content of 35% to 47% of the total weight, a mixture of alkanes with a distillation range of 220°C to 350°C, 1.5 parts of phosphate ester extreme pressure antiwear agent; 0.03 part of methyl benzo For the metal deactivator of triazole derivatives, the above raw materials are mixed evenly, heated to 40-50°C, and high-purity nitrogen or other inert gases with a moisture content of 0.5ppm are introduced at the same time for about 2-4 hours. Test the water content of the refrigerating machine oil. If the water content is lower than 25ppm, the sample is qualified and sealed to m...

Embodiment 2

[0033] Based on the total weight of the refrigerating machine oil combination, select 50 parts of linear alkylbenzene with a molecular weight between 220 and 240 and a distillation range between 270 and 320, and select 48.5 parts of C P (paraffin) content not less than 50% of the total weight, C A (aromatic hydrocarbons) content not more than 1% of the total weight, C N (cycloalkane) or cyclic hydrocarbon content of 35% to 47% of the total weight, a mixture of alkanes with a distillation range of 220°C to 350°C, 1.5 parts of phosphate ester extreme pressure antiwear agent; mix the above raw materials evenly, Heating to 40-50°C, while passing high-purity nitrogen or other inert gas with a moisture content of 0.5ppm, for about 2-4 hours. Test the water content of the refrigerating machine oil. If the water content is lower than 25ppm, the sample is qualified and sealed to make sample 2.

Embodiment 3

[0035] Based on the total weight of the refrigerating machine oil combination, select 40 parts of linear alkylbenzene with a molecular weight between 230 and 260 and a distillation range between 270 and 320, and select 58.3 parts of C P (paraffin) content not less than 50% of the total weight, C A (aromatic hydrocarbons) content not more than 1% of the total weight, C N (cycloalkane) or cyclic hydrocarbon content of 35% to 47% of the total weight, a mixture of alkanes with a distillation range of 220°C to 400°C, 0.2 parts of phenolic antioxidant BHT, 1.5 parts of phosphate ester extreme pressure resistance Grinding agent: Mix the above raw materials evenly, heat to 40-50°C, and at the same time pass high-purity nitrogen or other inert gas with a moisture content of 0.5ppm for about 2-4 hours. Test the water content of the refrigerating machine oil. If the water content is lower than 25ppm, the sample is qualified and sealed to make sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com