Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169results about How to "Good demulsibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

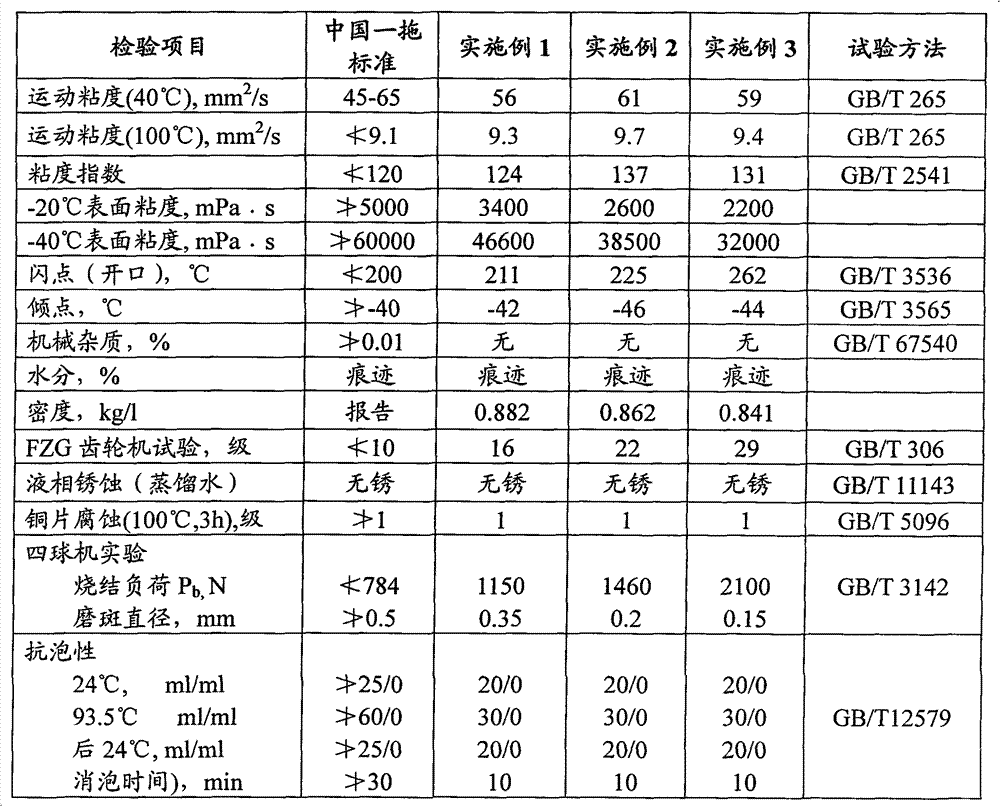

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

Ship steam turbine lubricating oil composition

InactiveCN102676279AImprove rust resistanceAnti-emulsification time is smallLubricant compositionAntioxidantWear resistant

The invention relates to a ship steam turbine lubricating oil composition. The ship steam turbine lubricating oil composition is characterized by comprising the following components in weight percent: 0.3-1.5% of antioxidant, 0.03-0.2% of rust inhibitor, 0.03-1% of wear-resistant agent, 0.003-0.1% of demulsifier, 0.001-0.1% of anti-foaming agent, 0.02-0.1% of metal deactivator and base oil in balancing amount. Through a direct liquid rustiness test (synthetic seawater, 24 h), the ship steam turbine lubricating oil composition is rustless; after distilled water is added at 90 DEG C and stirred for half an hour, the direct liquid rustiness test (synthetic seawater, 24 h) is further performed on a separated oil layer, and the ship steam turbine lubricating oil composition is still rustless; the anti-emulsification time in a steam method is less than 180 s; the FZG invalid level is greater than 12; the viscosity level is ISOVG68, anti-foaming performance is less than 65-65-65 / 0 (mL / mL); air is released for less than 8min; and the TOST oxidation life is longer than 10,000 h.

Owner:PETROCHINA CO LTD

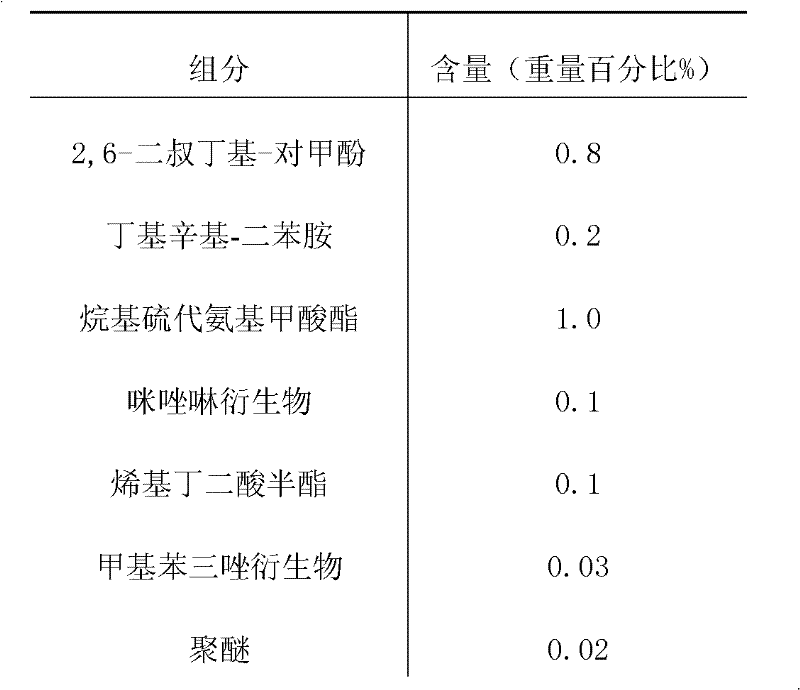

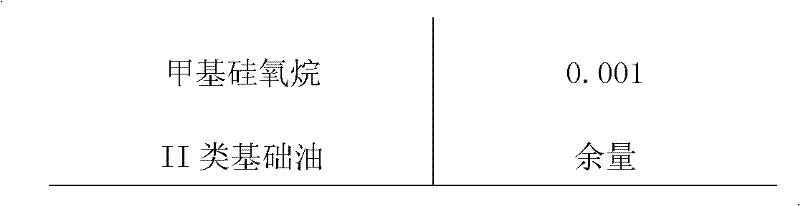

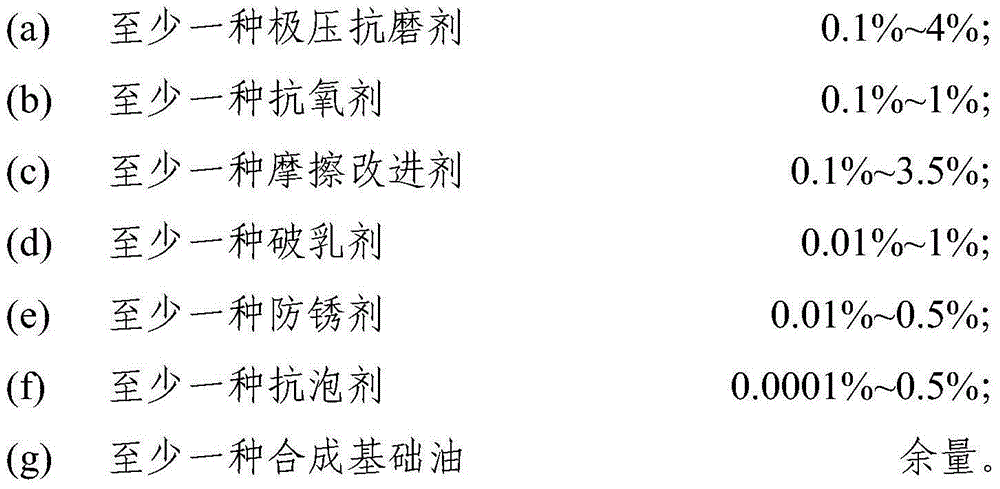

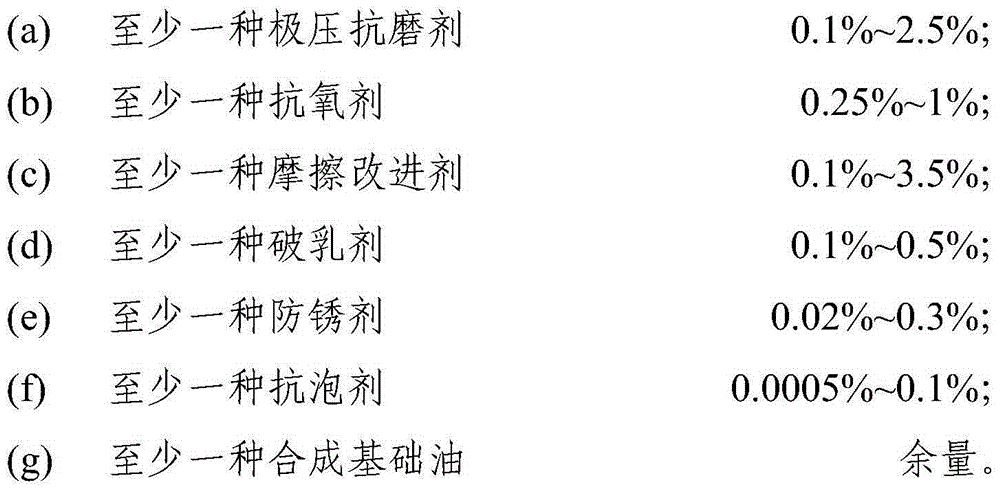

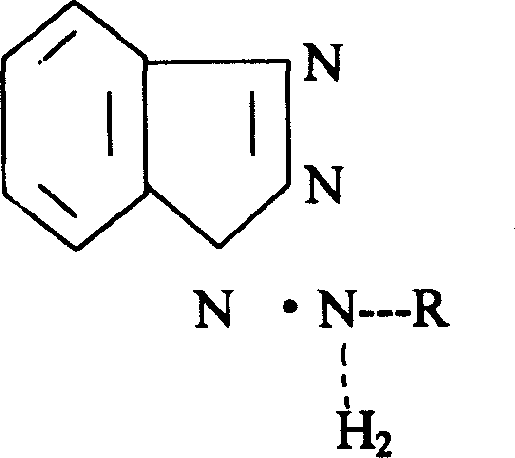

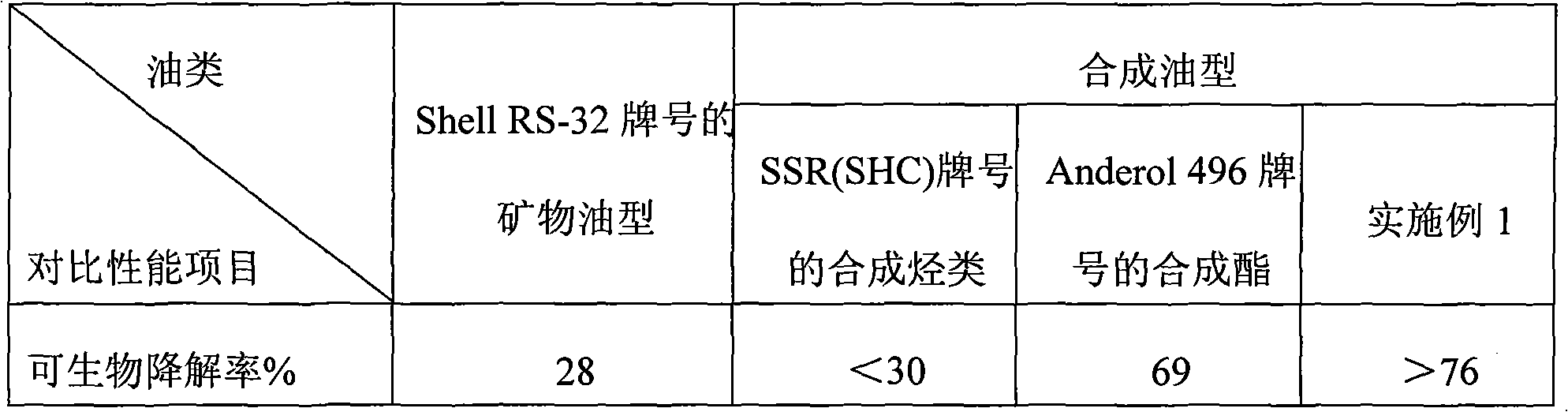

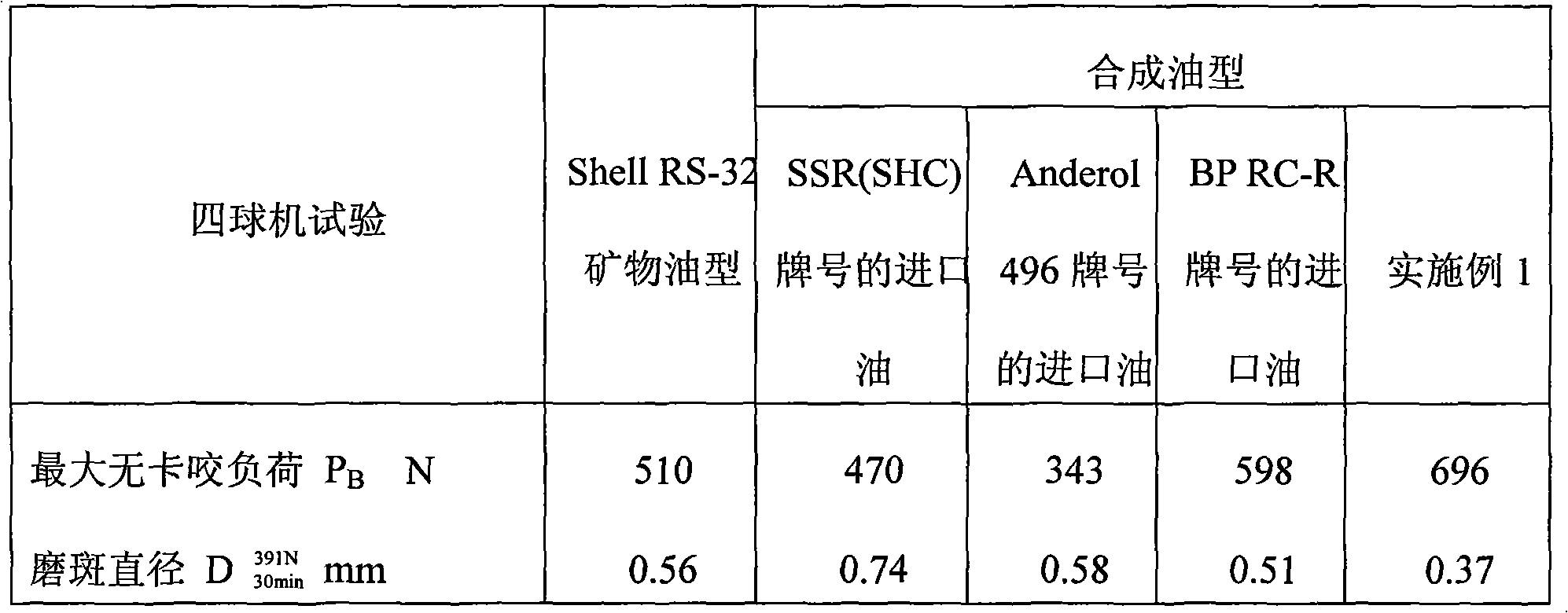

Biodegradable industrial gear oil composition

ActiveCN105132104AImprove performanceImprove compatibilityLubricant compositionEmulsionFoaming agent

The invention relates to a biodegradable industrial gear oil composition which is composed of at least one extreme pressure wear-resistant agent (a), at least one antioxidant (b), at least one friction improver (c), at least one demulsifying agent (d), at least one antirust agent (e), at least one anti-foaming agent (f) and at least one synthesis base oil (g). Biodegradable industrial gear oil has outstanding biodegradable performance, outstanding extreme pressure wear-resistant performance, excellent sealing material compatibility, excellent emulsion resistance, good oxidation stability and good corrosion resistant performance. The composition can be used for lubricating various gear devices comprising spur gears, helical gears, bevel gears and the like in environmentally sensitive areas, and can completely meet the requirement of environmental protection for the biodegradable performance of oil products.

Owner:CHINA PETROLEUM & CHEM CORP

Rotary jetting air-compressor lubricating oil and its production

InactiveCN1982423AGood thermo-oxidative stabilityImprove rust resistanceAdditivesPhosphateDicarboxylic acid

Rotary oil-jet air compressor lube oil and its production are disclosed. The formula consists of aromatic amine high-temperature antioxidant 0.1-0.6wt%, phenol antioxidant 0.1-1.0wt%, organic phosphate oil solution 0.1-0.6wt%, tinuvin fatty salt synergistic 0.01-0.1wt%, alkenyl ethylene dicarboxylic acid antirust agent VO.01-0.1wt% and base oil residue. It can be used at 100-200degree and has long antioxidant life.

Owner:抚顺远红润滑油制造有限公司

Composite synthetic air compressor oil

The invention discloses composite synthetic air compressor oil comprising the following components: a promoter, diisoalkyl (C8 to C13) linear dibasic ester, poly-alpha-olefin synthetic oil and diisoalkyl (C8 to C13) phthalate esters, wherein, the composite synthetic air compressor oil contains 15% to 20% of diisoalkyl (C8 to C13) linear dibasic ester by weight, 5% to 10% of poly-alpha-olefin synthetic oil by weight and 72% to 74% of diisoalkyl (C8 to C13) phthalate esters by weight. The composite synthetic air compressor oil of the invention can meet the requirements that the carbon residue value thereof is low and the biodegradation rate is higher than 70%; the composite synthetic air compressor oil has high high-temperature anti-oxidation stability, lubricating properties, rust-preventing properties, foam resistance and emulsion resistance; and the invention has the advantages that the energy is saved, the environmental pollution is reduced and the service life is prolonged, therefore, the invention can fully satisfy the operating requirements for rotary-type screw compressors.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Lubricating oil composition for wide steel strip hot continuous mill rolling process

A lubricating oil composition for hot tandem rolling of wide steel band contains a component (d) composed of a surface layer which is dialkylbithiophosphoric acid or monocarboxy fatty acid, and a kernel which is the nano TiO2 particle. Its advantages are excellent lubricating performance, high resistance to emulsifying, and no deposition and demixing.

Owner:CHINA PETROCHEMICAL CORP +1

Preparation of rosen modified mixed alkyl phenolic resin

The present invention belongs to the field of resin preparation technology that is a kind of connecting material to printing ink. It is obtained with processed by the following steps: arbitrarily mixing p-methyl hydroxybenzene, p-tert-butylphenol, p-tex-octylphenol and p-nonylphenol, making them produce reaction with formaldehyde to synthesize A-stage mixed alkyl phenolic resin, then using rosin to make modification and using polyhydric alcohol to make esterification. Said invention is easy to operate, safe, and its resin oil-solubility and fatty hydrocarbon solubility are good. Its colour islight and softening point is high. The printing ink made up by using said invented product does not skin, and possesses good printing property.

Owner:山西省应用化学研究所

Heavy-duty antiemulsifying oil film bearing oil

InactiveCN1346874AGuaranteed normal operationImprove the lubrication effectAdditivesWire rodDemulsifier

A heavy-duty antiemulsifying oil film type bearing oil for high-speed wire rolling mill contains demulsifier, antiwear agent, antifoaming agent, alkylnaphthalene, antioxidant and mineral oil. Its advantages are excellent antiemulsifying, antiwear, anti-extreme-pressure, anticorrosion, antirust, antifoaming and antioxidizing performance, and better viscosity-temp characteristic.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI

Full-synthetic gear/bearing oil for four seasons and preparation method thereof

ActiveCN101531947ASignificant positive effectWide temperature rangeBase-materialsViscosity gradeOil additive

The invention discloses full-synthetic gear / bearing oil for four seasons and a preparation method thereof. The full-synthetic gear / bearing oil for four seasons is prepared by blending synthetic oil taken as base oil and an additive; the selected base oil is one of ester oil, synthetic hydrocarbon-type oil and a mixture of the ester oil and the synthetic hydrocarbon-type oil; the selected additive is a high-performance complexing agent, which is one of gear oil compound additive, wind turbine oil additive, industrial lubricant friction modifier, general gear oil complexing agent and multifunction gear oil additive; and the blending ratio of the base oil to the additive is 1.0 to 5.0 weight percent of the high-performance complexing agent and the balance of the base oil. According to viscosity grades of the gear oil, the synthetic oil with one or more compositions is added to a blending kettle with a stirrer in required proportion, is stirred for 0.5 to 1.5 hours at a temperature of between 30 and 60 DEG C, and is blended into the base oil of the gear oil; and the base oil is added with the high-performance complexing agent in a certain proportion and stirred for 1 to 3 hours at a temperature of between 30 and 60 DEG C to form the gear lubricant of the invention.

Owner:精锐化学(上海)有限公司

Oil-soluble polyether oil for screw-type air compressor

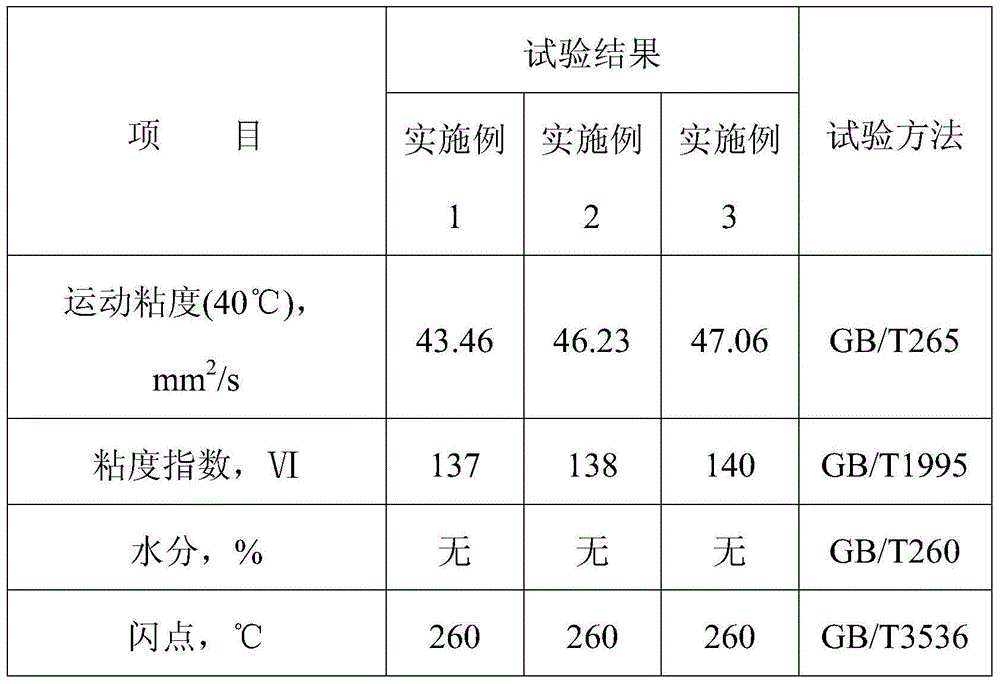

InactiveCN104130842AExcellent antioxidant stabilityGood demulsibilityLubricant compositionPerformance indexMechanical equipment

The invention discloses oil-soluble polyether oil for a screw-type air compressor. The oil-soluble polyether oil is prepared from 20-40 parts or 10-20 parts by mass of oil-soluble polyether base oil, 60-80 parts or 80-90 parts by mass of poly(alpha-olefin), 0.1-1.4 parts by mass of benzenamine, 0.8-2 parts by mass of a borate anti-oxidant, 1.2-2.2 parts by mass of a high-temperature ashless antiwear agent, 0.5-1.8 parts by mass of polyoxyethylene sorbitan fatty acid ester and 0.001-0.05 parts by mass of an acrylate-ether copolymer. The oil-soluble polyether oil for a screw-type air compressor is environmentally friendly, has the advantages of excellent antioxidation stability, emulsification resistance, corrosion and rusting resistance, very good defoaming performance and excellent viscosity-temperature performance, has performance indexes satisfying standards of air compressor oil 46 and can be used for mechanical equipment of an air compressor system.

Owner:张家港市胜宇石油化工制品有限公司

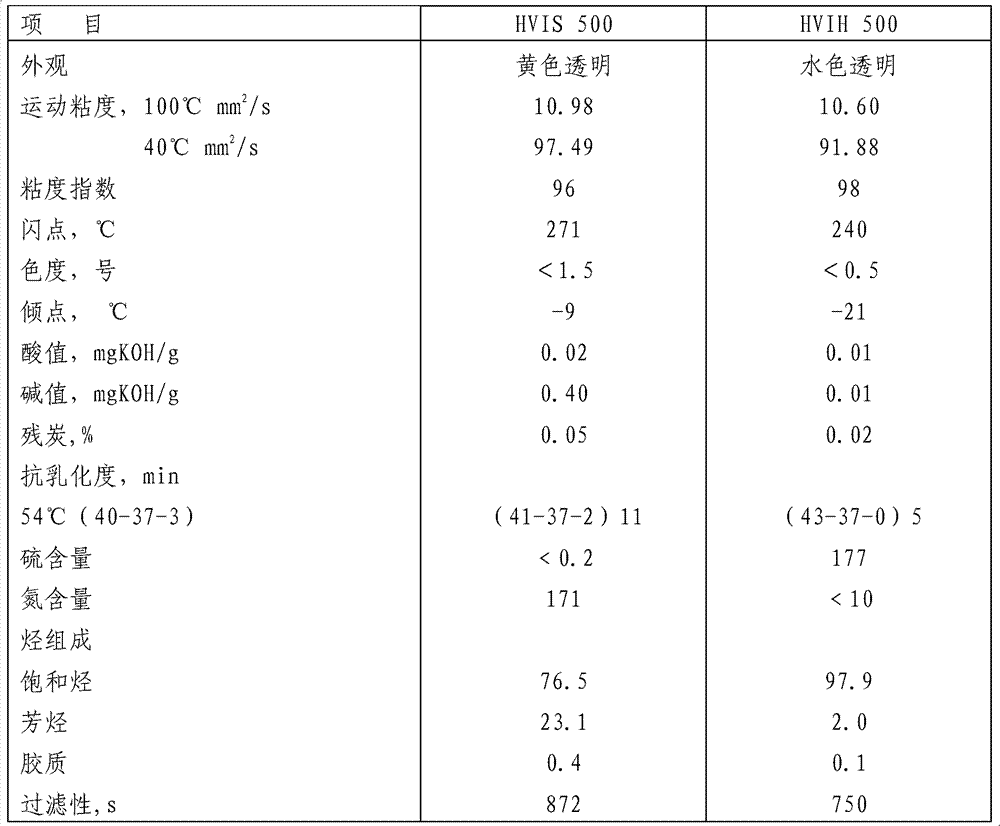

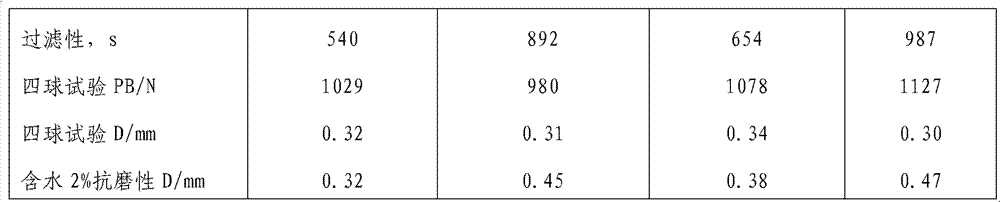

Ashless antiwear oil film bearing lubricant composition

ActiveCN102766505AImprove filtering effectGood demulsibilityLubricant compositionWire rodFoaming agent

The invention provides an ashless antiwear oil film bearing lubricant composition, which comprises: (A) at least a highly refined mineral oil with high viscosity index; (B) at least an emulsifier; (C) at least an anti-foaming agent; (D) at least an ashless phosphorus-containing antiwear additive; (E) at least an anti-oxidant; and (F) at least a metal passivator. The above lubricant component has excellent demulsibility, filterability, anti-foaming property, air release property, abrasion resistance and oxidation resistance, passes through FAG FE-8 bearing wear experiments, SKFEMCOR bearing corrosion experiments and FLENDER anti-foaming experiments, and is suitable for lubricating various bearings and industrial gears, especially lubricating highspeed wire rod oil film bearings.

Owner:PETROCHINA CO LTD

Water-expelling production process for offset printing magenta printing ink

The invention relates to a wringing process for producing offset printing fuchsine ink. The process comprises the following steps that: firstly, hydrous fuchsine paint, wet pulp causticize calcium, a bonding material and a water resisting agent which are not dried are put to a kneading machine and kneaded till water is clear; secondly, moisture is extracted under the conditions of vacuum and high-temperature; thirdly, a based ink obtained is rolled on a three-roller machine for once or twice; fourthly, ink oil and an addition agent are added and the oil is adjusted to a preset index scope; finally, the ink is filled and packaged by a racking machine. The ink made by the wringing process of the invention is more exquisite than the ink made of dry powder, has larger colour density, good transparence, high luster, strong tinctorial strength and good emulsification resistance and can save man-hour.

Owner:SHANGHAI PEONY PRINTING INK

High-pressure anti-wear hydraulic oil

InactiveCN111363608AGood demulsibilityImprove rust resistanceLubricant compositionFoaming agentThermal stability

The invention discloses high-pressure anti-wear hydraulic oil, and belongs to the hydraulic oil field. The hydraulic oil comprises the following components in percentage by mass: 95-99% of base oil, 1.0%-1.5% of an extreme pressure anti-wear agent, 0.1-0.3% of a friction modifier; 0.4-1.0% of an antioxidant, 0.1-0.5% of an antirust agent, 0.1-0.5% of a metal deactivator, 0.02-0.1% of a detergent dispersant, 0.001-0.005% of an anti-foaming agent, and 0.1-0.5% of a demulsifying agent. Compared with the prior art, the hydraulic oil has the advantages of good viscosity-temperature performance, extreme pressure abrasion resistance, oxidation resistance stability, hydrolysis stability and thermal stability, and is not prone to aging and deterioration; the service life is prolonged, a friction pair can be normally lubricated under high-pressure and high-speed harsh conditions, and abrasion is reduced. The foam generated under the condition of violent mechanical stirring in the operation process can be quickly eliminated; air mixed in the oil can be released in a short time, and a static pressure can be accurately, sensitively and stably transmitted.

Owner:无锡中石油润滑脂有限责任公司

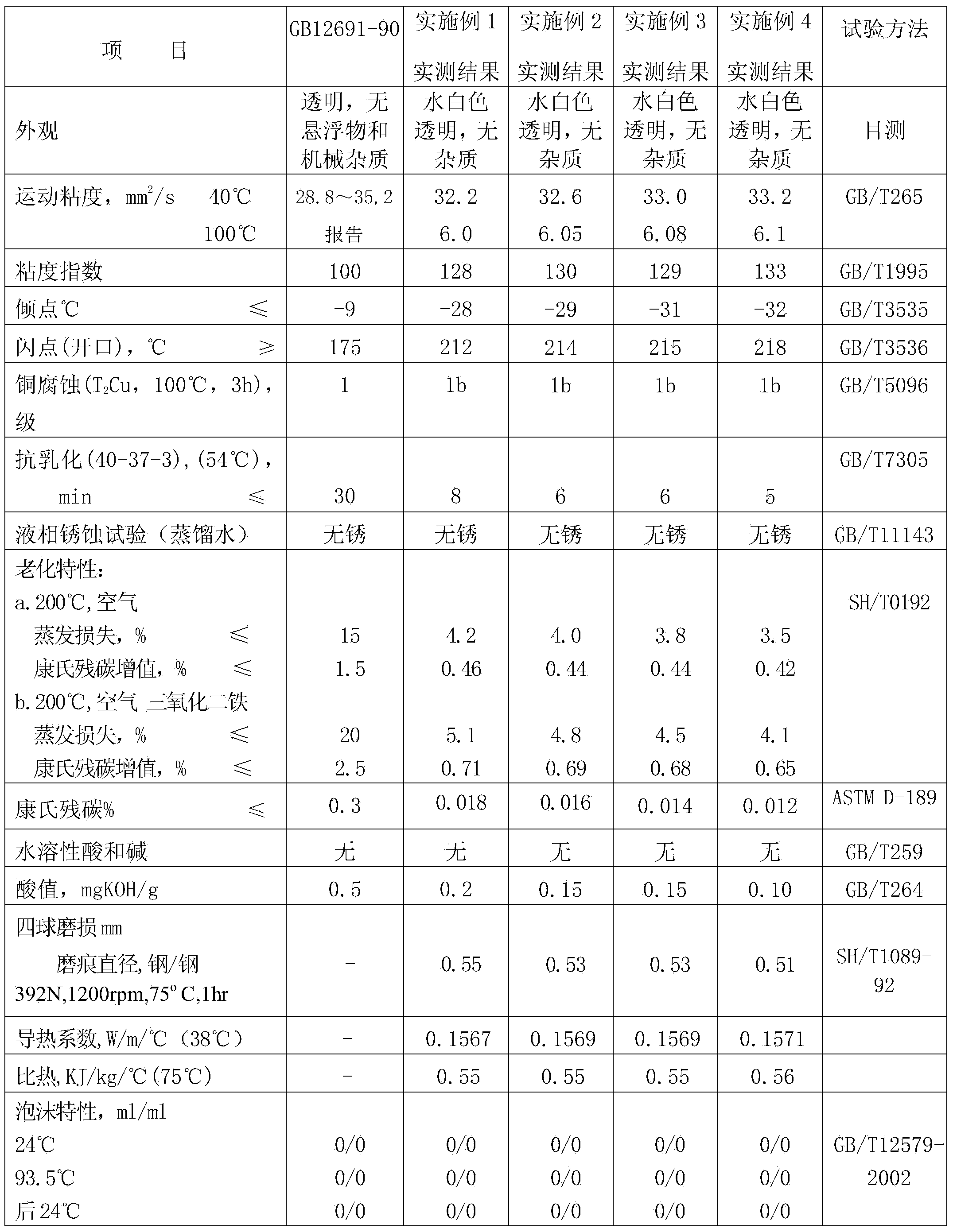

Hydraulic oil composition and uses thereof

ActiveCN103710082ALow kinematic viscosityImprove Oxidation StabilityLubricant compositionNitrogenViscosity index

The invention relates to a hydraulic oil composition and uses thereof, mainly solves the problems that in the prior art, HM anti-wear hydraulic oil is poor in low temperature performance, and cannot meet the requirements of low temperature operation equipment. The hydraulic oil composition comprises the following components: by weight, a) 100 parts of mineral base oil; and b) 0.1-2 parts of an anti-wear hydraulic oil compound agent; wherein the characteristics of the mineral base oil are that: a1) the kinematic viscosity at 40 DEG C is 28.8-35.2mm<2> / s; a2) the pour point is below -30 DEG C; a3) the viscosity index is higher than 100; a4) the sulfur content is less than or equal to 0.03 wt.%; a5) the nitrogen content is less than or equal to 0.005 wt.%; the anti-wear hydraulic oil compound agent is selected from at least one from HiTEC521 and HiTEC543 of AFTON corporation, LZ5703 of LUBRIZOL corporation, OLA4994 of CHEVRON corporation, and IR5010 of BASF corporation, and the technical scheme well solves the problems, and can be used in industrial production of low pour point anti-wear hydraulic oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Continuous regeneration adsorption purification process of trimethylolpropane trioleate

ActiveCN104387271AEffectively remove antioxidantEffective removal of demulsibilityPreparation by ester-hydroxy reactionOrganic compound preparationSorbentOxidation stability

The invention discloses a continuous regeneration adsorption purification process of trimethylolpropane trioleate. The process comprises the following operation steps: (1) putting an adsorbing agent into an adsorption tower or a plurality of adsorption towers which are connected in series; (2) enabling a trimethylolpropane trioleate crude product to continuously pass through the adsorption tower filled with the adsorbing agent at certain flow velocity and temperature to ensure that impurities such as micro solid particles, gelatine and the like which can influence the oxidation resistance and emulsification resistance of the product are adsorbed by the adsorbing agent; and (3) continuously regenerating the adsorbing agent: performing circulating washing by using low carbon alcohol to remove organic impurities such as the gelatine and the like adsorbed by the adsorbing agent, then purging by using inert gas, and performing vacuum drying and regeneration to obtain a regenerated adsorbing agent which can be recycled. Trimethylolpropane trioleate prepared by virtue of the process disclosed by the invention has excellent oxidation stability and emulsification resistance, and can be better used as base oil of various lubricating oil.

Owner:NANJING WELL BIOCHEM

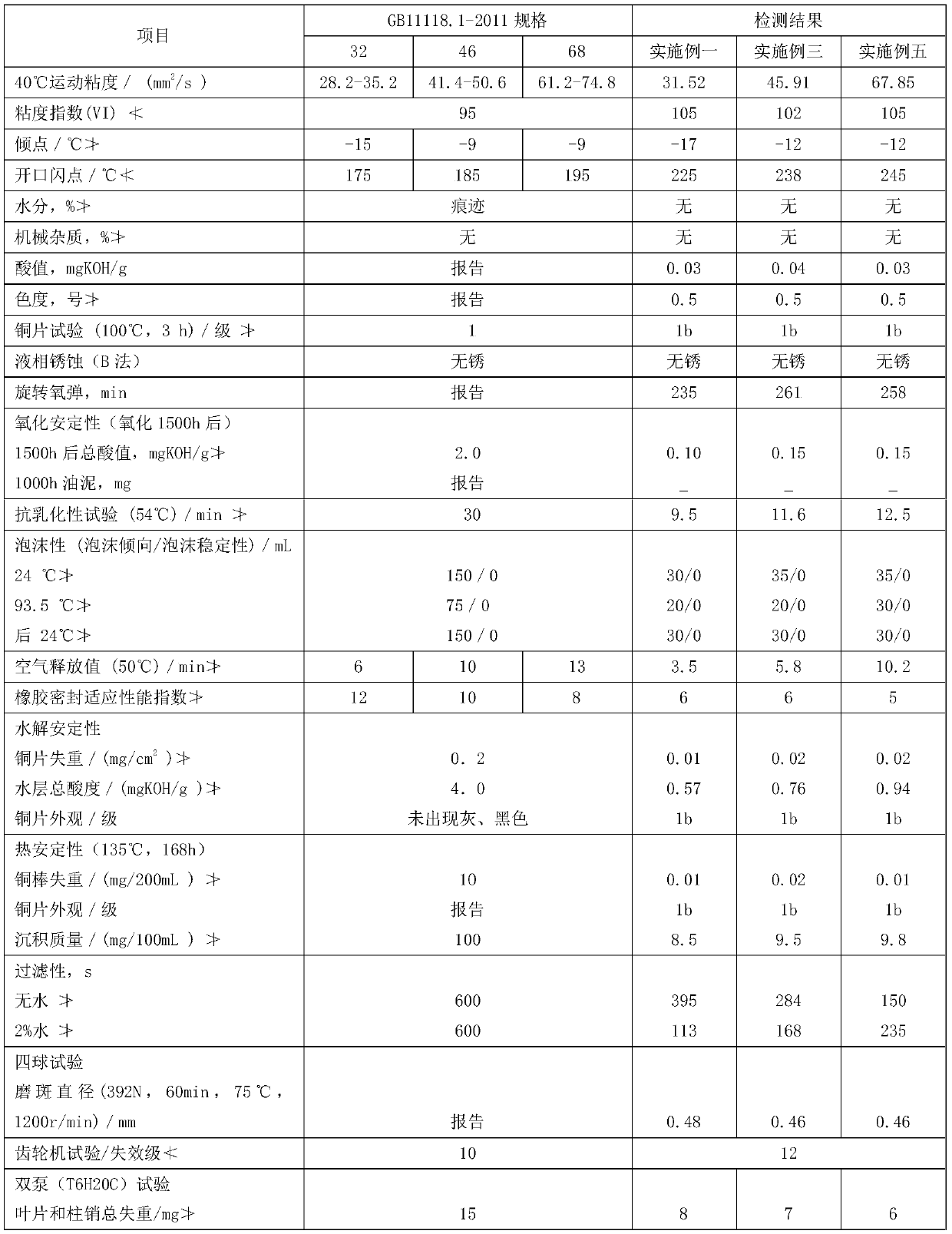

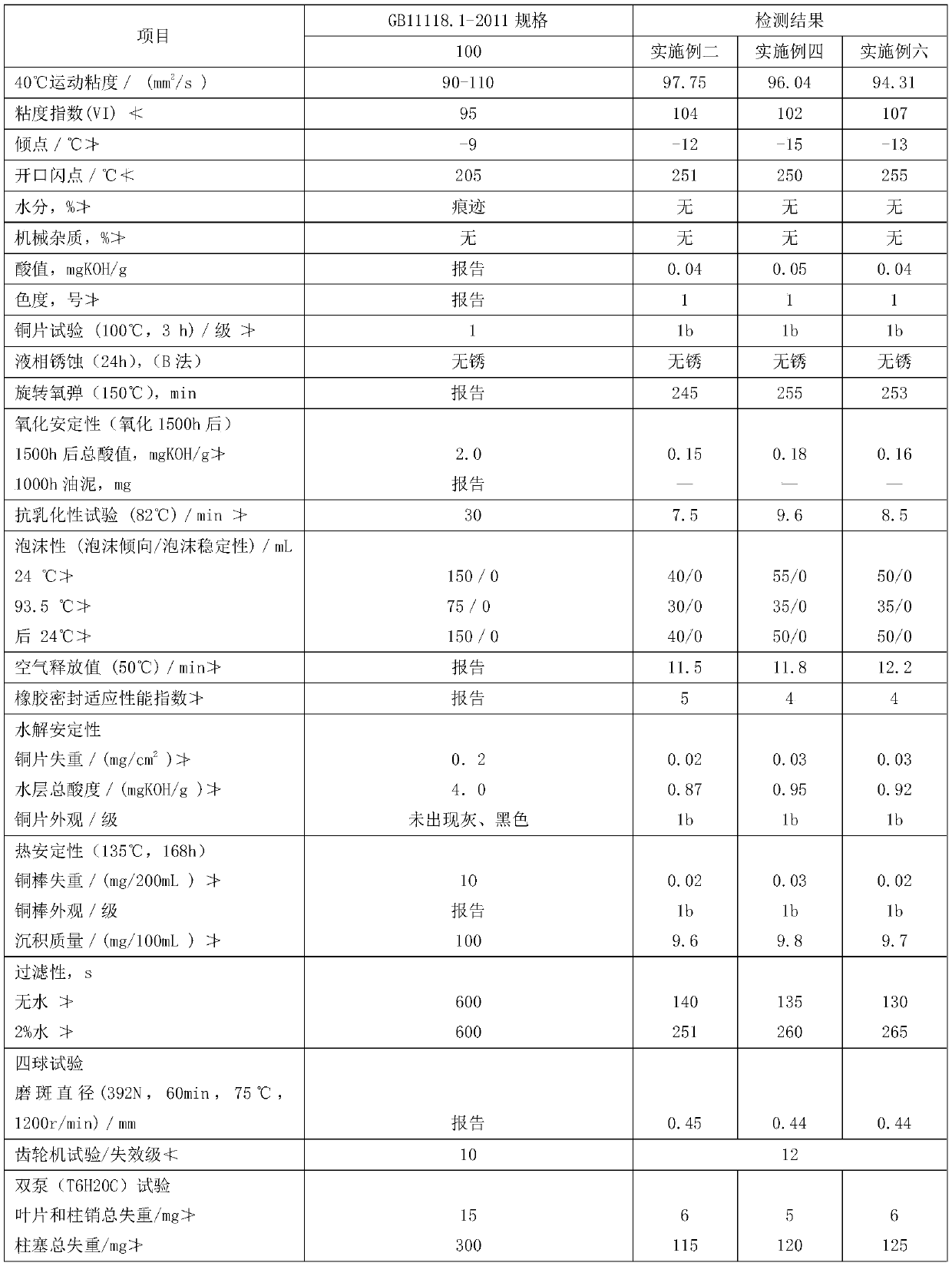

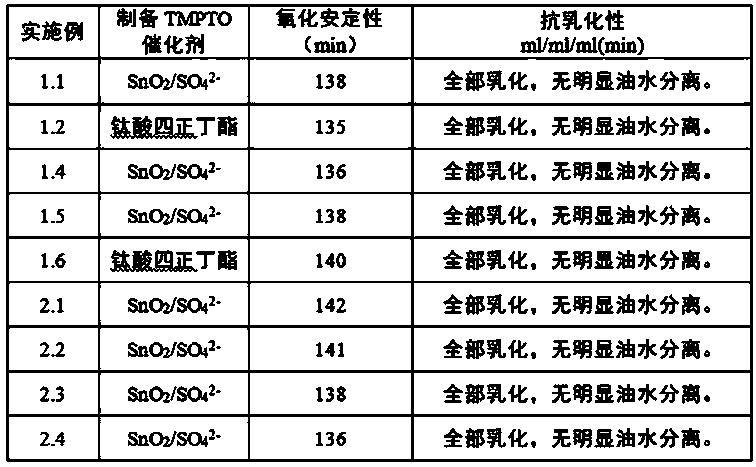

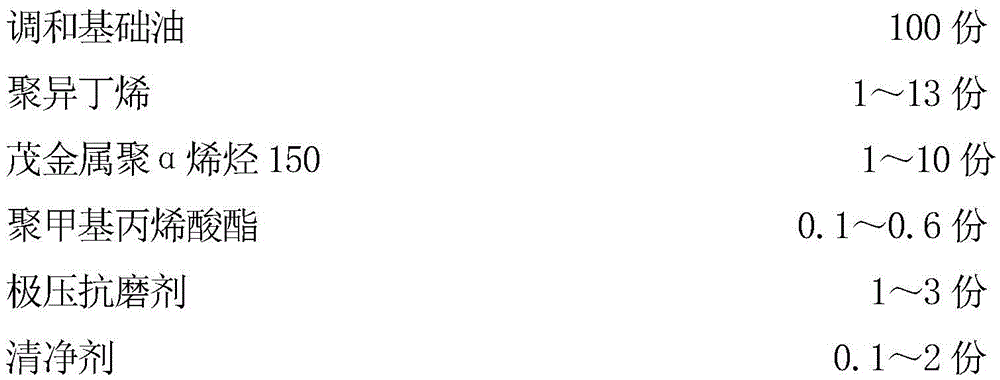

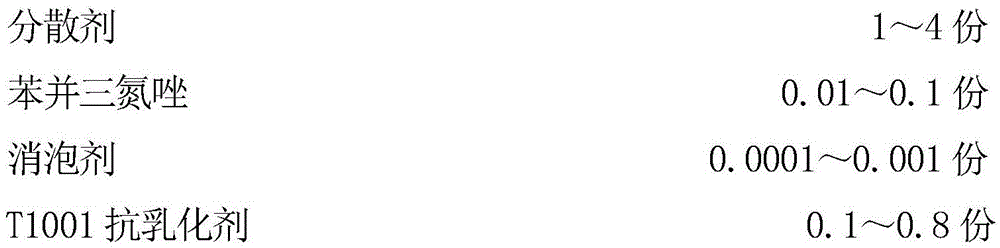

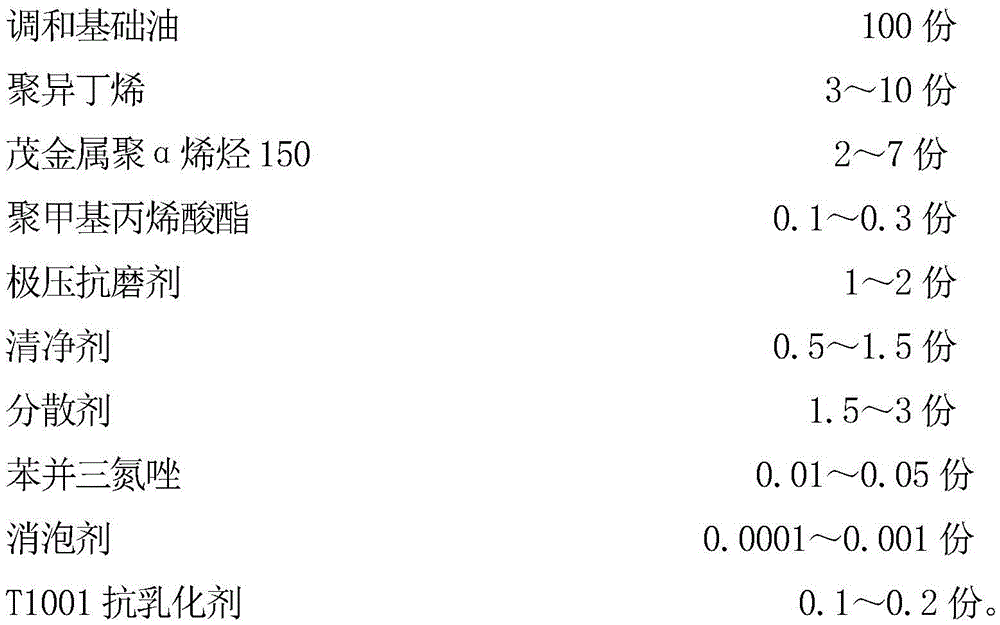

Gear oil special for reduction gearbox of pumping unit

The invention discloses gear oil special for a reduction gearbox of a pumping unit. The gear oil is prepared from, by mass, blend base oil, metallocene polyisobutene, metallocene polymerized alpha olefin 150, polymethacrylate, an extreme pressure anti-wear agent, a cleaning gent, a dispersing agent, benzotriazole, a defoaming agent and a demulsifying agent T1001, wherein the blend base oil is prepared from paraffin-base base oil 600 SN, residual oil 150 BS and hydrofined oil 250 N, and a mixture of thiophosphoric acid amine salt, bisoctyl dithiophosphate zinc and / or oil-soluble molybdenum is adopted as the extreme pressure anti-wear agent. The gear oil for the reduction gearbox is better in physical and chemical index and using performance than industrial closed gear oil, has the good extreme pressure anti-wear performance, thermal oxidation stability, corrosion resistance and anti-emulsification performance and meets the using requirements of oil pumping unit oil of an oil field.

Owner:郑生宏

Lubricating oil composition and method for improving detergency of lubricating oil

ActiveCN107987920AExcellent high temperature detergencyImprove Oxidation StabilityAdditivesDemulsifierAntioxidant

The invention provides lubricating oil composition and a method for improving detergency of lubricating oil. The lubricating oil composition is prepared from a compound detergent, a dispersant, an antioxidant, an anti-wear agent, a demulsifier and the balance of lubricating base oil, wherein the compound detergent is a mixture of alkylsalicylate, sulfurized alkyphenate and sulfonate. The lubricating oil composition has excellent high-temperature detergency, oxidation stability and antiwear and antifriction properties, particularly has excellent high-temperature detergency and emulsion resistance and is rapid and thorough in water separation and applicable to lubrication of diesel engines for ships and particularly, lubrication of crank cases of two-stroke and low-speed crosshead type diesel engines for ships and medium-speed piston type diesel engines.

Owner:CHINA PETROLEUM & CHEM CORP +1

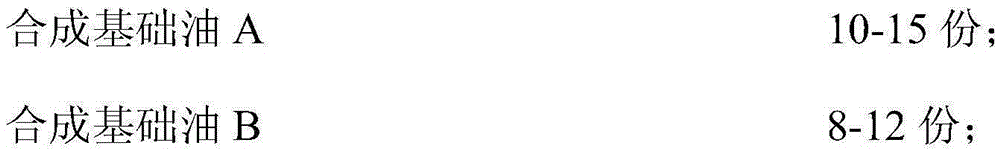

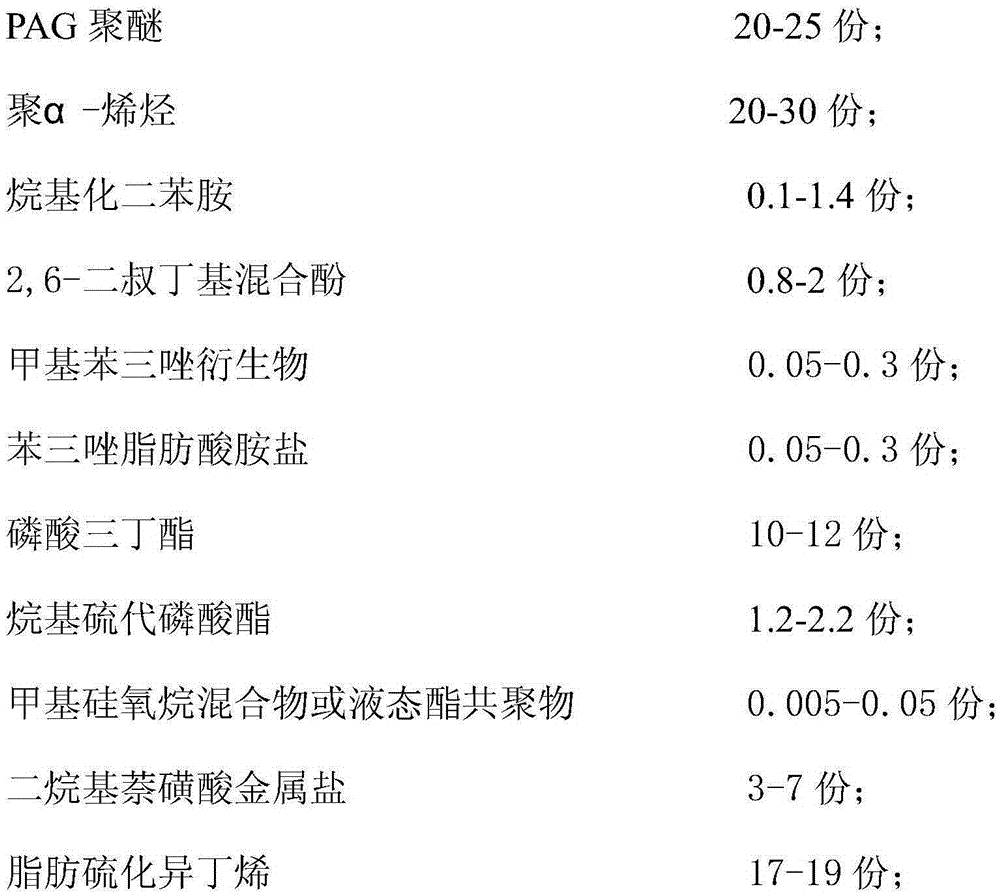

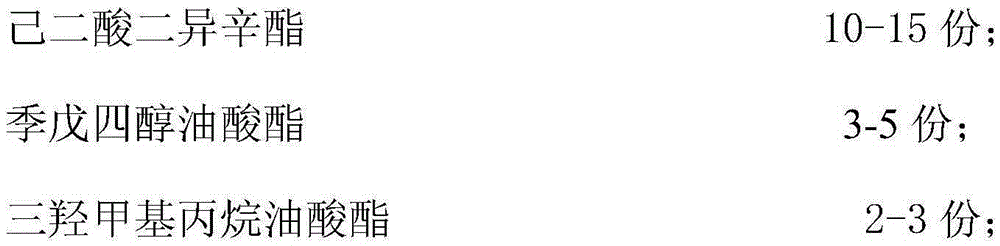

Composite screw type air compressor oil

ActiveCN105296107AEnvironmentally friendlyExcellent antioxidant stabilityLubricant compositionGreek letter alphaPhenols

The invention discloses composite screw type air compressor oil which comprises, by mass, 10-15 parts of raw material synthesis base oil A, 8-12 parts of synthesis base oil B, 20-25 parts of PAG polyether, 20-30 parts of poly-alpha-olefins, 0.1-1.4 parts of alkylated diphenylamine, 0.8-2 parts of 2,6-di-tert-butyl mixed phenols, 0.05-0.3 part of methyl benzene triazole derivative, 0.05-0.3 part of benzene triazole fatty acid amine salt, 10-12 parts of tributyl phosphate, 1.2-2.2 parts of dialkyl dithiophosphate, 0.005-0.05 part of methylsiloxane mixture or liquid ester copolymer, 3-7 parts of dialkyl group naphthalene metal organic sulfonate and 17-19 parts of fat sulphide isobutene. The composite screw type air compressor oil has the advantages of good antioxidation stability, demulsibility and anti-corrosion and anti-rust property, extremely good defoaming performance, excellent viscosity-temperature property and the like. Compared with mineral compressor oil, the energy is saved, oil consumption is lowered, environment pollution is reduced, the service life is prolonged, the performance index reaches the standard of 46# compressor oil, and the compressor oil is used for air compression system mechanical equipment.

Owner:张家港市胜宇石油化工制品有限公司

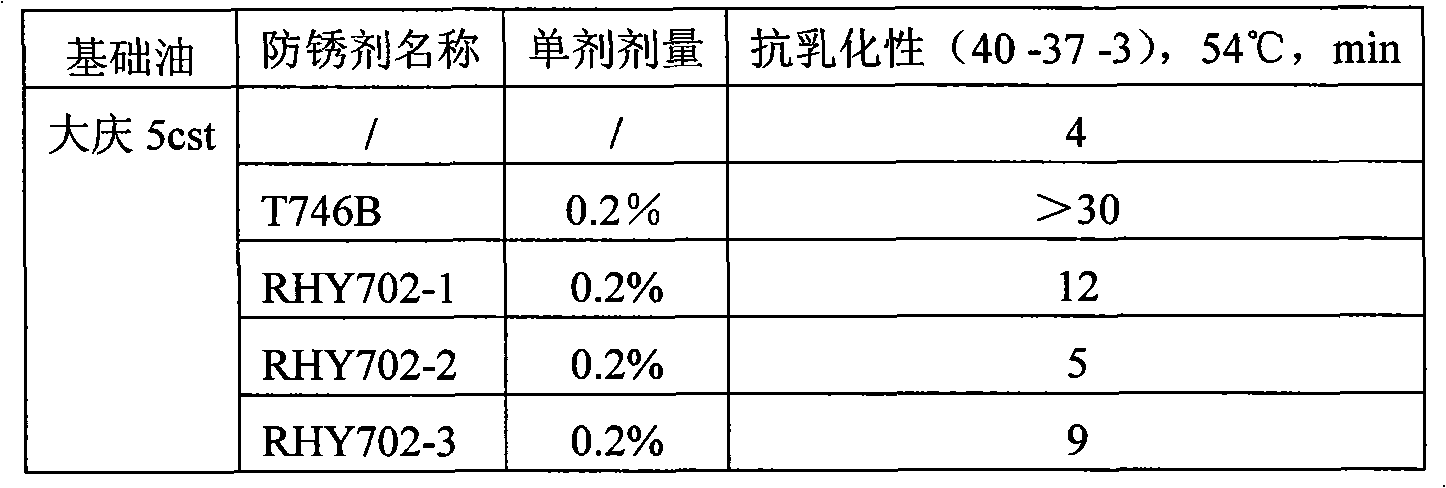

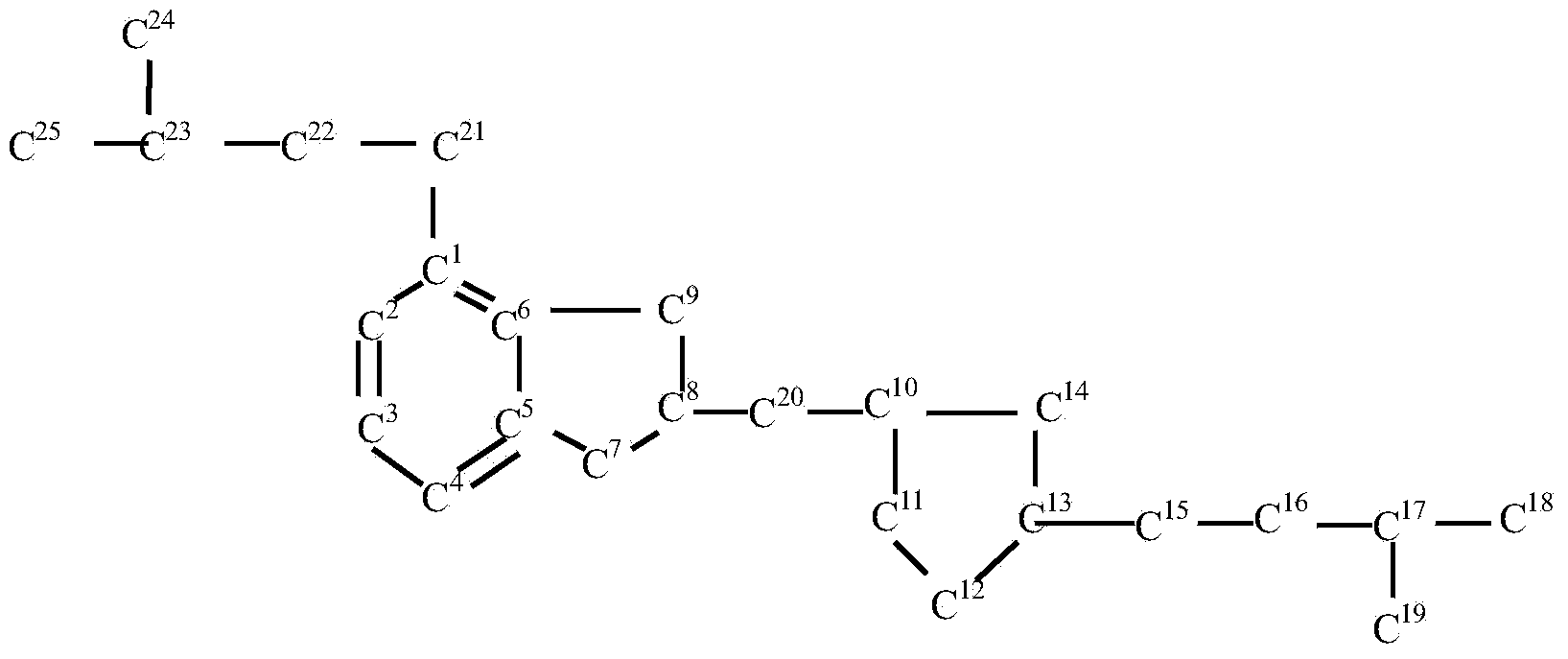

Ash-free antirust additive for industrial lubricant and preparation method thereof

InactiveCN102002415AGood oil solubilityImprove rust resistanceOrganic compound preparationAdditivesSolubilityEmulsion

The invention discloses an aliphatic ester type ash-free antirust additive, which is an aliphatic ester compound prepared from saturated or unsaturated fatty acid and a polyhydroxy organic amine compound through an esterification reaction. The method for preparing the antirust additive comprises the following steps of: mixing 1 to 2 moles of saturated or unsaturated fatty acid with 1 mole of polyhydroxy organic amine compound, adding a proper amount of No.120 or No.200 solvent oil for the esterification reaction at the temperature of between 90 and 160 DEG C until a theoretical amount of water is dehydrated; and distilling to remove the solvent oil. The ash-free antirust additive has good dissolubility, antirust property and emulsion resistance, simultaneously has a lower acid value and a certain base value, and has wide application in the industrial lubricant.

Owner:PETROCHINA CO LTD

Air compressor oil and preparation method thereof

ActiveCN103897790AThe effect is positive and obviousGood high temperature oxidation resistanceLubricant compositionAir compressionPhenolic antioxidant

The invention relates to air compressor oil, comprising a phenolic antioxidant, a phenylamino antioxidant, an olefine acid antioxidant, a metal deactivator, an ash-free antiwear agent, a defoamer, a light-sensitive agent, a hydrogenation paraffin base oil fraction, a hydrogenation naphthenic base oil and a hydrogenated alkyl high boiling substance. The invention also provides a preparation method of the air compressor oil. The air compressor oil disclosed by the invention has excellent high-temperature carbon deposit resistance, excellent high-temperature oxidation resistance, and excellent abrasion resistance, and simultaneously has excellent lubricating property, anti-foaming property and demulsibility on the product, the cost performance of the product is improved, the performances of the synthetic air compressor oil and composite synthetic air compressor oil are achieved, and the long-term work requirements of single-screw and dual-screw air compressors are completely met.

Owner:上海中孚油品集团有限公司

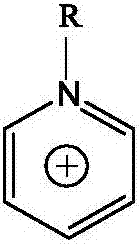

Neutralizing corrosion inhibitor

InactiveCN109518191AImprove lipophilicityBarriers gather with each otherHigh concentrationCarbon dioxide corrosion

The invention discloses a neutralizing corrosion inhibitor. The neutralizing corrosion inhibitor is prepared from the following compositions in percentage by mass: 1-5% of a dispersing agent, 20-25% of neutralizing organic amine, 4-10% of imidazolinecompounds, 1-5% of alkynol compounds, 4-15% of a nitrogenous adsorption-type corrosion inhibitor, 2-10% of a synergistic agent, and the balance of a solvent. According to the neutralizing corrosion inhibitor, high adsorption is achieved on the metal surface to prevent metal from corroding the cathode and anode conjugate process, and thus the effectof corrosion inhibition is effectively enhanced; a continuous and dense protective film can be formed on the metal surface, and corrosion of a high concentration sulfide, chloride and cyanide is inhibited; a mannich base and phosphorothioate are adopted as the synergistic agent, good thermal stabilization and chemical stability are achieved on the two-phase of water and oil, high adsorption is achieved on the metal surface, high inhibiting effect is achieved on corrosion of hydrogen sulfide and carbon dioxide, and meanwhile, good inhibition is achieved on corrosion of hyperthermia naphthenicacid; and the dosage is greatly lowered while it is ensured that the corrosion inhibition rate is greater than 90%.

Owner:JIANGSU KECHUANG PETROCHEM

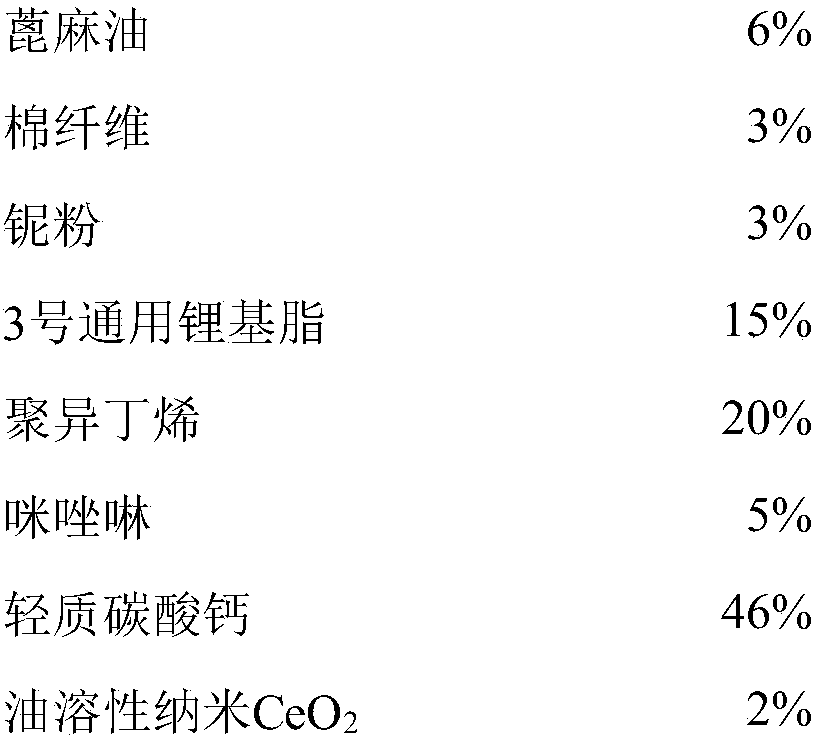

Shield machine main bearing sealing grease and preparation method thereof

ActiveCN107557114AGood demulsibilityGood wear resistanceLubricant compositionShield machineAgricultural engineering

The invention provides a shield machine main bearing sealing grease, which comprises, by mass, 4-10% of base oil, 2-6% of a fiber material, 2-7% of a solid lubricant, 14-20% of lubricating grease, 15-24% of a tackifier, 4-8% of a corrosion inhibitor, 40-50% of a powdered filler, and 0.5-3% of a nanometer rare earth oxide. The invention further provides a preparation method of the sealing grease. Compared to the existing shield machine main bearing sealing grease, the shield machine main bearing sealing grease prepared by using the formula of the present invention has good emulsification resistance, good wear resistance and good sealing property, wherein the wear resistance is excellent, the minimum diameter of the wear spot under ASTM D4172 standard is 0.49, and the emulsification resistance of the sealing grease is improved so as to easily improve the water rinsing resistance of the sealing grease of the present invention, such that the sealing grease has good sealing property.

Owner:GUANGZHOU AORUN SYNTHETIC MATERIAL

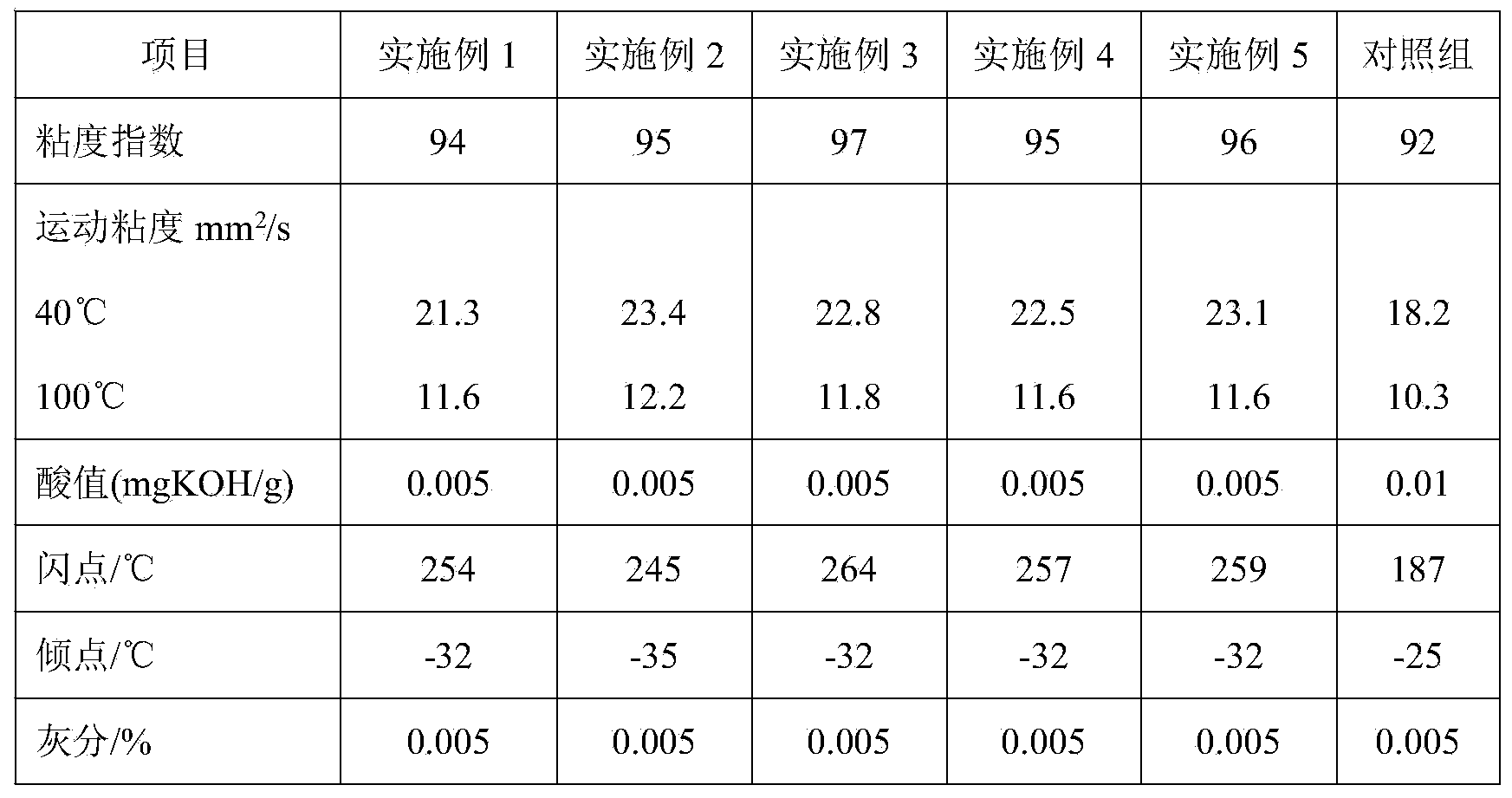

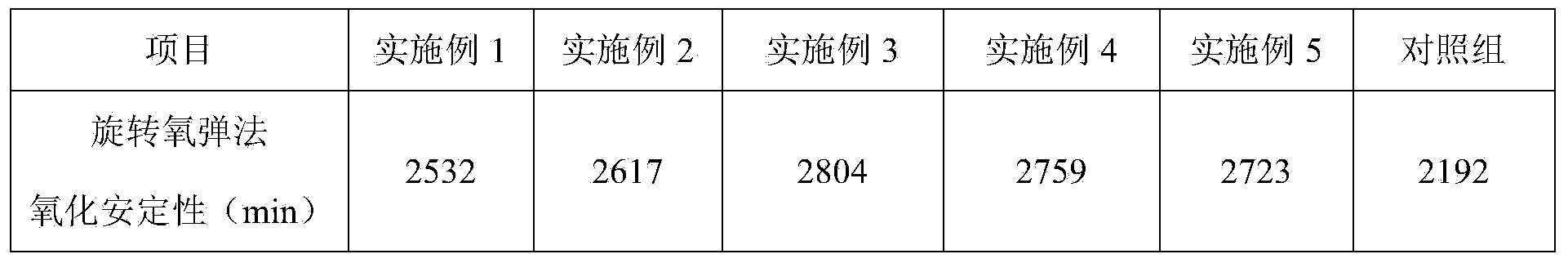

Steam turbine oil composition and preparation method thereof

InactiveCN104357183ALow viscosityHigh specific heatLubricant compositionAntioxidantSulfonated polymer

The invention discloses a steam turbine oil composition and a preparation method thereof, and relates to the field of industrial lubricants. The steam turbine oil composition comprises the following components: (1) base oil; (2) an antioxidant; (3) an anticorrosive antioxidant; (4) an antirust agent; (5) an extreme pressure wear resisting composite agent; (6) an organic sulfonated substance or organic sulfonated polymer; (7) an anti-bubbling agent; (8) a demulsifying agent; (9) a dispersing agent. The preparation method of the steam turbine oil composition comprises the following steps: (1) weighing; (2) mixing compressed air; (3) mixing by using a mixing pump; (4) performing standing. The steam turbine oil composition provided by the invention is stable in quality, moderate in viscosity and good in liquidity, has excellent lubricating performance, extreme pressure wear resistance, cooling performance, high temperature stability and oxidation stability and relatively good bubbling resistance and demulsibility, and is very ideal steam turbine oil.

Owner:SUZHOU CHANGSHENG ELECTROMECHANICAL

Surface modification nanometer copper particle and preparation method thereof

The invention relates to a surface modification nanometer copper particle and a preparation method thereof. The preparation method comprises the following steps of: firstly preparing a copper salt water solution with the concentration of 0.05-0.2 mol / L; adding an ammonia water solution; then sufficiently mixing the copper salt water solution and a mixed solution of a reducing agent, a surface modification agent with anti-emulsification property and an organic solvent to react for 1-3 hours under the condition of alkaline (pH is 8-11); and then concentrating and separating to obtain the surface modification nanometer copper particle. The preparation method has the advantages of simple preparation process, easiness for low-cost raw material obtaining, low cost, high yield and suitability for large-scale production and preparation.

Owner:NANTONG ZHONGCHENG BIOTECH

A composition used for food-grade gear oil, a preparing method thereof, gear oil including the composition and a preparing method of the gear oil including the composition

InactiveCN106947575ACaused by pollutionMeet hygiene requirementsLubricant compositionMicro pittingEngineering

The invention relates to the field of lubricating oil, and particularly discloses a composition used for food-grade gear oil, a preparing method thereof, gear oil including the composition and a preparing method of the gear oil including the composition. The composition includes, by weight, 5-10 parts of a food-grade antioxidant, 10-25 parts of a food-grade antiwear agent, 0.5-1.5 parts of a food-grade metal deactivator, 1.0-2.5 parts of a food-grade antirust agent, 0.5-1.5 parts of a food-grade corrosion inhibitor, 0.2-1.0 part of a food-grade oiliness agent, 0.1-0.5 part of a food-grade anti-emulsification agent and 0.01-0.3 part of a food-grade defoamer, with the balance being food-grade base oil A and the total weight parts being 100 parts. The composition and the gear oil including the composition have excellent waterproofness, oxidation resistance, wear resistance, extreme pressure properties, micro pitting resistance, rust resistance, emulsification resistance and foam resistance, can effectively meet requirements on heavy duty, extreme pressure properties, wear resistance, emulsification resistance, rust resistance, micro pitting resistance, and the like of gear systems in a food processing process, are nontoxic and harmless and do not contaminate foods.

Owner:TEXAS PETROCHEM YANTAI

Coal water slurry blended fuel engine oil composition

ActiveCN104087375AExcellent viscosity-temperature propertiesAvoid stickingLubricant compositionOil sludgeBlack oil

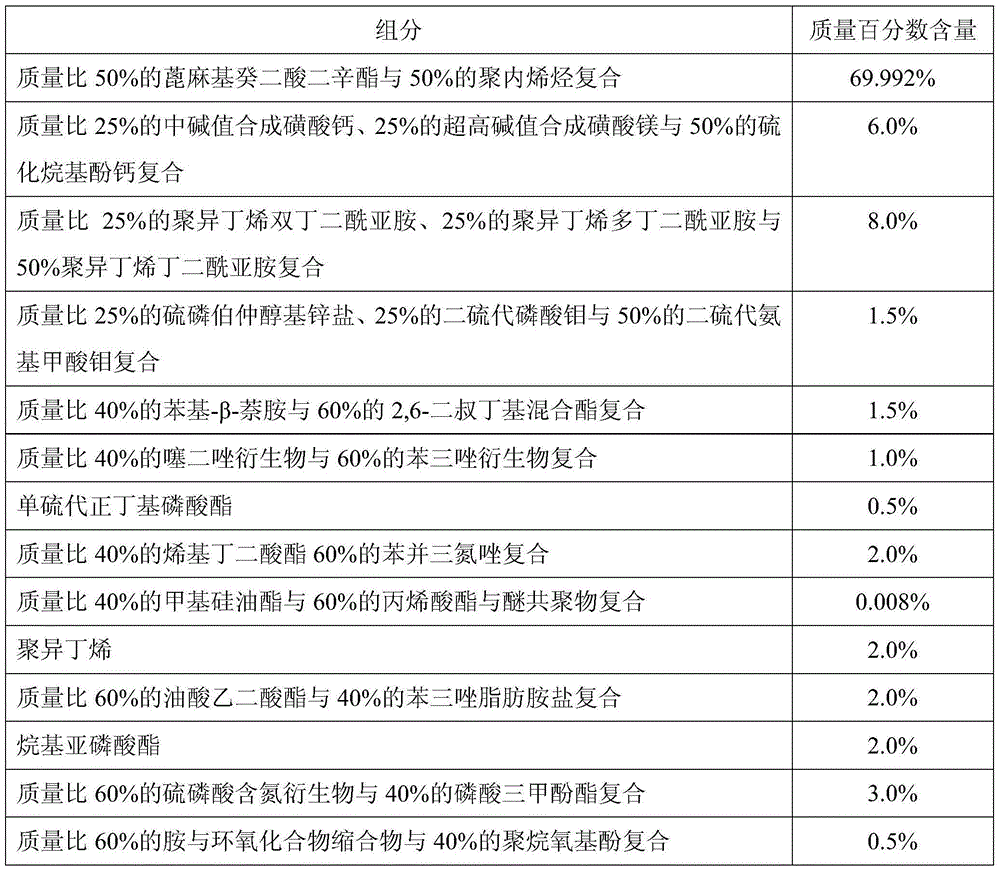

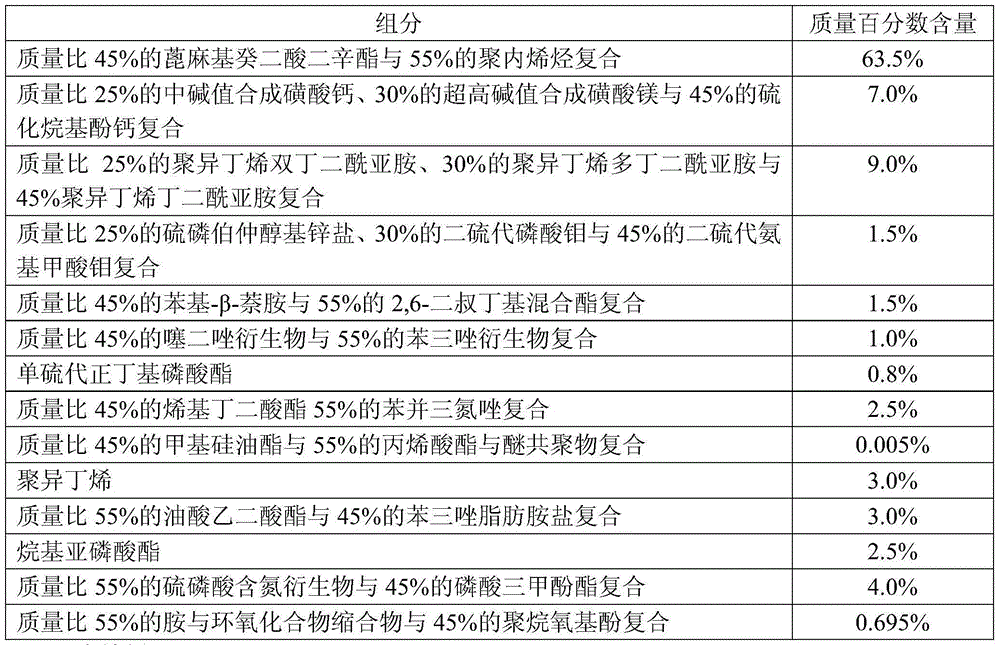

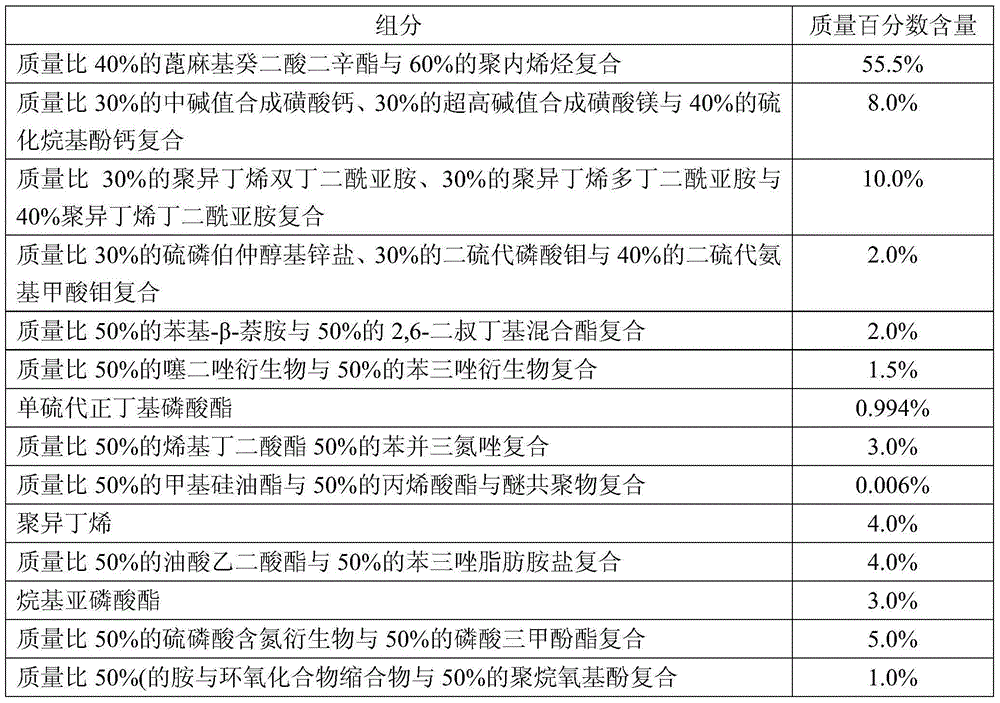

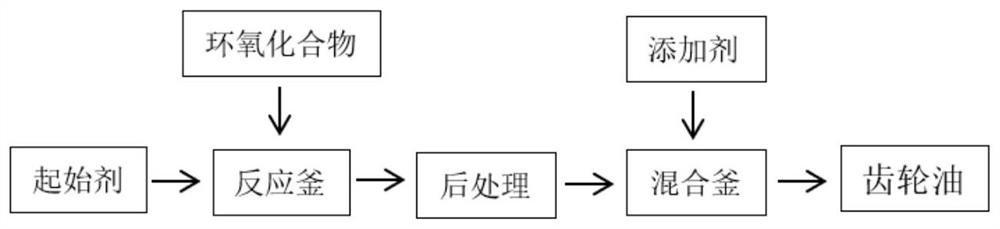

The invention discloses a coal water slurry blended fuel engine oil composition. Polyinternalolefins and castor-bsae dioctyl sebacate used as base oil are matched with multiple composite additives to obtain the composition. The composite additives comprise an antiwear additive, an antioxidant preservative, an antifoam agent, a demulsifying compound, a viscosity index improver, a metal passivator, a detergent agent, a dispersing agent, an antioxidant, an oily agent, a friction improver, a reinforcing agent and a rust inhibitor. The engine oil composition has excellent cleaning and dispersion effects, prevents the piston ring from sticking, and keeps the engine clean. Due to excellent viscosity-temperature characteristic, excellent alkali number retentivity, acid neutralizing capacity and demulsifying capacity, the engine oil composition can inhibit the black oil sludge from generation, so that the engine is cleaner. Due to favorable high-temperature oxidation stability, high shear stability, favorable rubber compatibility, favorable cold-starting property and excellent fuel economical efficiency, the engine oil composition can not corrode or tarnish the moving parts, ensures the oil product to maintain sufficient oil film strength, has better extreme-pressure abrasion resistance, and lowers the abrasion and engine oil consumption.

Owner:GUANGXI UNIV

Polyether polyol, synthetic method thereof and lubricating oil

The invention relates to the field of production of lubricating oil, in particular to polyether polyol and a synthetic method thereof and lubricating oil. The synthetic method of the polyether polyol comprises the following steps: by taking long-chain fatty alcohol as an initiator, carrying out polymerization reaction on the long-chain fatty alcohol and mixed epoxyalkane under the catalytic action of a catalyst to prepare the polyether polyol, wherein the mixed epoxyalkane comprises epoxypropane, ethylene oxide and epoxybutane according to a mass ratio of 75-95: 4-15: 1-10. The gear oil formed by adopting the specific polyether polyol as the raw material has the advantages of low viscosity, high viscosity index, high lightning and low pour point, and also has good fluidity under a low temperature condition, so that the abrasion caused in the starting process of the vehicle is greatly reduced.

Owner:上海抚佳精细化工有限公司

Method using plant oil after-cut fraction for production of green lubricating oil

ActiveCN104762121AFix stability issuesSettle the priceFatty-oils/fats separationBase-materialsVegetable oilThermal insulation

The present invention provides a method for using plant oil after-cut fraction for production of green lubricating oil, and the process comprises the following steps: various main components are separated by distillation of plant crude oil, after-cut fraction and a residue accounting for 6-15% of the total tower kettle substrate are heated to about 150 to 200 DEG C in a vacuum distillation tower device for thermal insulation distillation for more than 30-40 hours under the condition of maintaining the vacuum degree in-0.98mpa, wherein the vacuum distillation tower device has the tower height of 7-15m, and the plate number of more than 100, and use a 80-100 mesh stainless steel filler, kettle bottom residual liquid is discharged after cooling, the kettle bottom residual liquid is placed for cooling to 50 DEG C to 60 DEG C, and filter with a 150 mesh filter screen to obtain plant oil distillation kettle bottom polymer, the green lubricating oil is prepared by further addition of composite additives, and the green lubricating oil is similar with mineral base oil in density, viscosity, flash point, pour point and other indexes, and is good in thermal stability, biodegradable, low-cost, and environment friendly.

Owner:统一石油化工有限公司

Excellent-anti-corrosion-performance synthetic hydraulic oil

InactiveCN105567377AImprove the shortcoming of easy oxidationHigh biodegradation rateAdditivesBase-materialsPolyethylene glycolPotassium

The present invention discloses excellent-anti-corrosion-performance synthetic hydraulic oil made from the following raw materials in parts by weight: 280-285 parts of industrial oleic acid, 12.6-13 parts of elemental iodine, 72-74 parts of acrylic acid, 134-135 parts of trimethylolpropane, 15-16 parts of toluenesulfonic acid, 15-17 parts of nano boron carbide particles, 0.8-1 part of Span 80, 2-3 parts of sodium carboxymethyl cellulose, 30-32 parts of deionized water, 3.2-3.5 parts of hydroxyethyl imidazoline, 10-12 parts of polymethacrylate, 3.5-4 parts of zinc dialkyl dithiophosphate, 4-5 parts of oil-soluble polyalkylene glycols, 1.5-2 parts of polyethylene glycol boric acid ester, 1-1.2 parts of octadecanamide, 2-2.5 parts of nano graphene, 3-4 parts of Span 80 and 1.8-2 parts of oily potassium borate. A product prepared by the method is tasteless, environmentally-friendly, energy-saving, long in service life, suitable for industrial production, and worthy of promotion.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

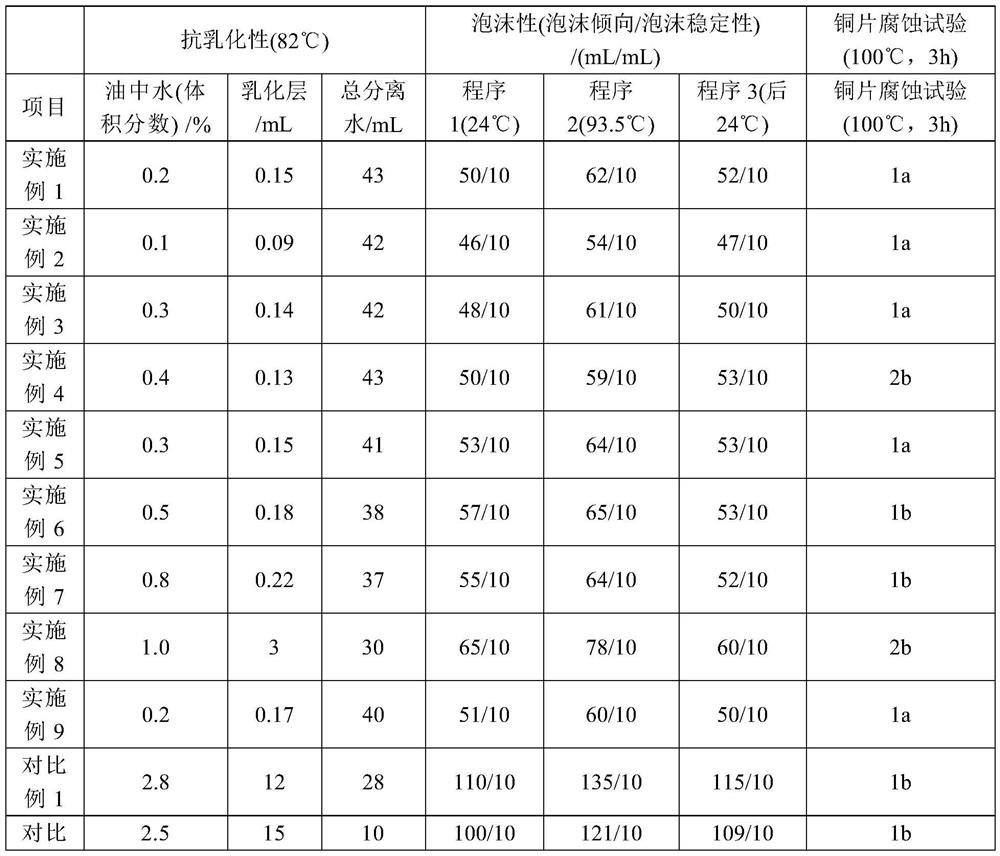

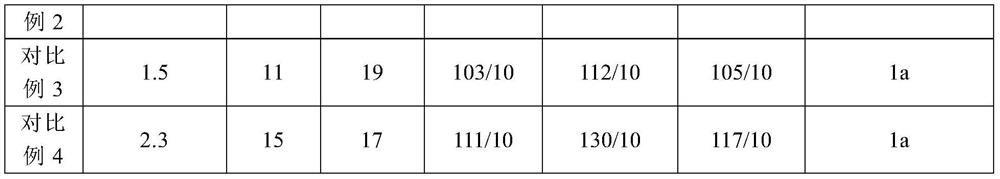

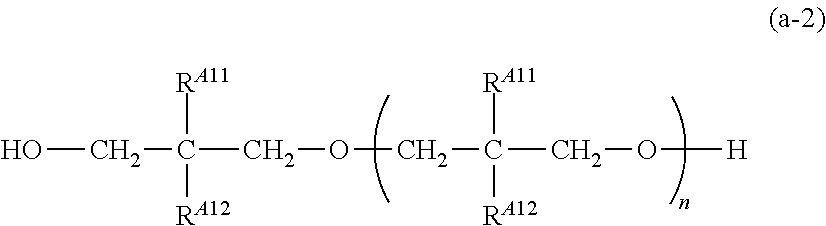

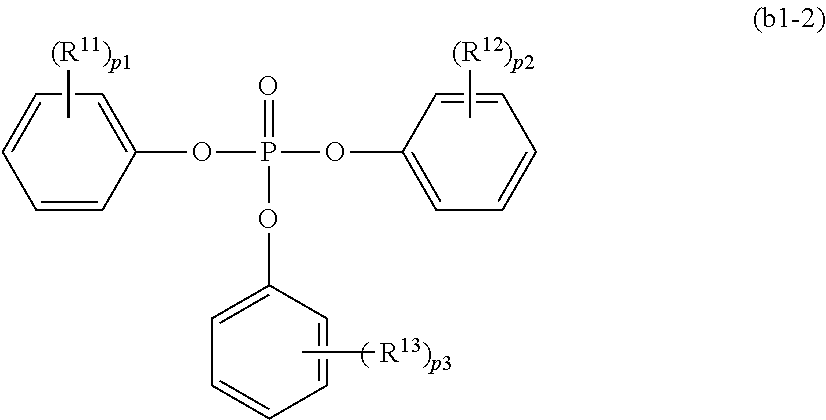

Lubricant composition

ActiveUS20190177648A1Enhanced inhibitory effectSuitable for useAdditivesBase-materialsHydraulic equipmentAntioxidant

Provided is a lubricating oil composition comprising a base oil (A) containing a polyalkylene glycol (A1) and a polyol ester (A2), a phosphorus-based rust inhibitor (B), and an antioxidant (C) containing an amine-based antioxidant (C1). The lubricating oil composition exhibits a strong effect for suppressing sludge sedimentation even when used for an extended period of time in a high-temperature environment, and has excellent demulsibility and rust preventive properties, and therefore, can be suitably used in turbomachinery, compressors, hydraulic equipment, and machine tools.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com