Steam turbine oil composition and preparation method thereof

A technology of turbine oil and composition, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems that various properties cannot be effectively balanced, cooling performance and anti-emulsification performance are affected, oil performance is unstable, etc. And the effect of excellent anti-oxidation performance, moderate viscosity and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

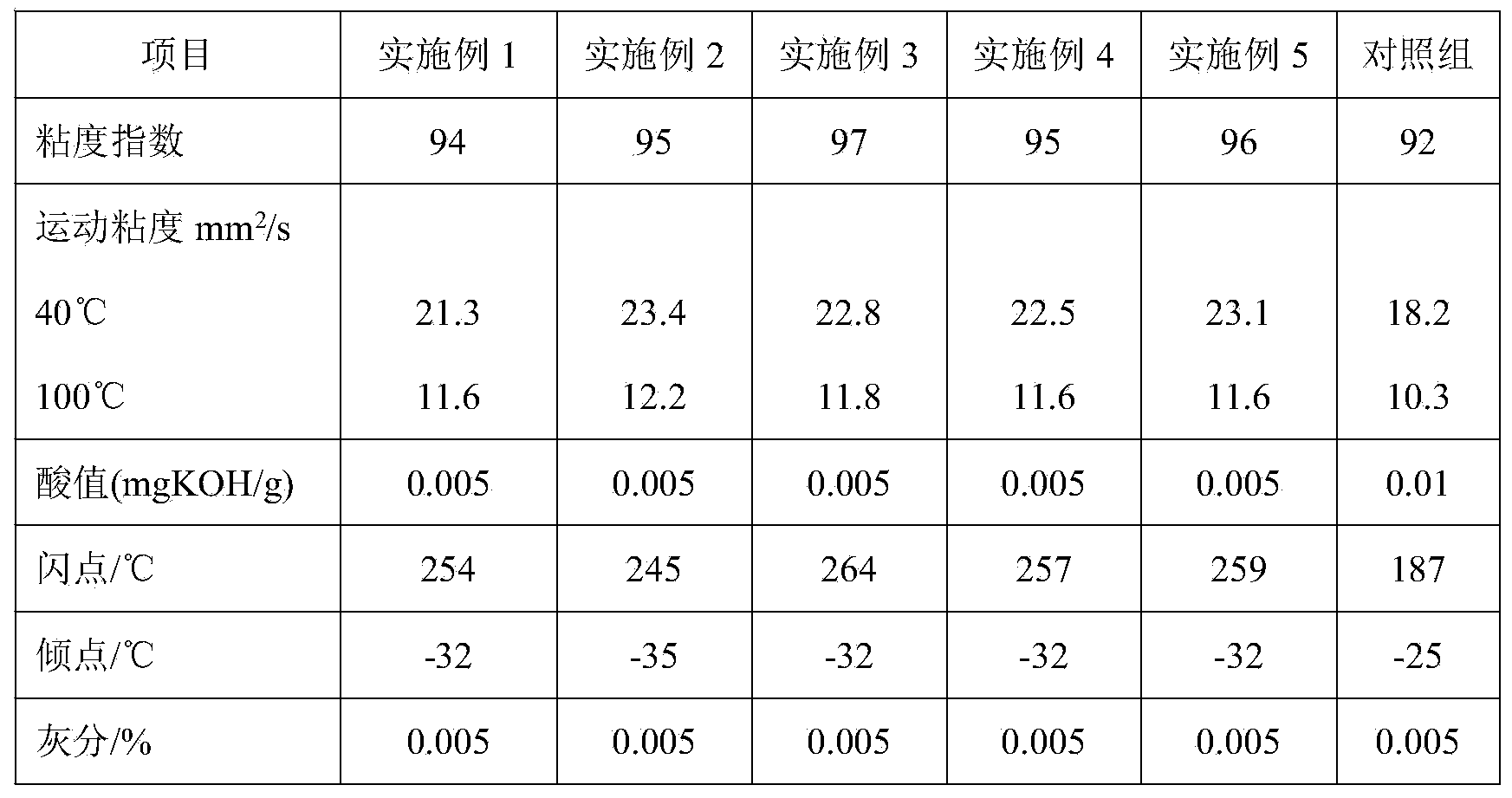

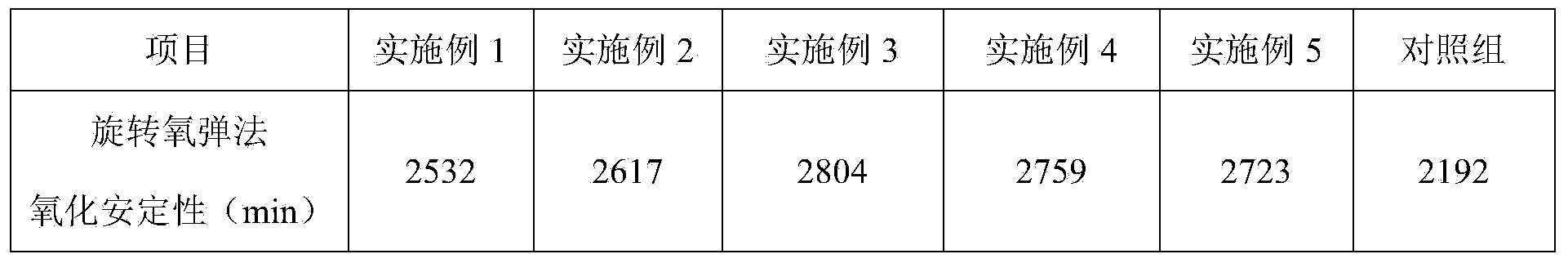

Examples

Embodiment 1

[0033] A steam turbine oil composition, comprising the following components in parts by mass:

[0034] (1) Group III and Group IV base oils, including 17 parts of Group III base oils and 38 parts of Group IV base oils, a total of 55 parts;

[0035] (2) Antioxidant is lauryl selenium, and its mass fraction is 0.5 part;

[0036] (3) anticorrosion antioxidant, is phosphoalkylphenol zinc salt, and its parts by weight are 1.2 parts;

[0037] (4) antirust agent is synthetic sodium sulfonate, and its mass fraction is 2.5 parts;

[0038] (5) extreme pressure and anti-wear composite agent, its mass parts are 5 parts, wherein in the composite agent, sulfurized isobutylene is 1.5 parts, and borated oleamide is 3.5 parts;

[0039] (6) sulfonated phenolic resin, its mass fraction is 3 parts;

[0040] (7) antifoaming agent is castor oil polyoxyethylene ether, and its mass fraction is 1.5 parts;

[0041] (8) anti-emulsifying agent is ethylene oxide, and its mass fraction is 1.3 parts;

...

Embodiment 2

[0049] A steam turbine oil composition, comprising the following components in parts by mass:

[0050] (1) Group III and Group IV base oils, including 30 parts of Group III base oils and 45 parts of Group IV base oils, a total of 75 parts;

[0051] (2) Antioxidant is lauryl selenium, and its mass fraction is 1.2 parts;

[0052] (3) anticorrosion antioxidant, is phosphoalkylphenol zinc salt, and its parts by weight are 3.2 parts;

[0053] (4) antirust agent is synthetic barium sulfonate, and its mass fraction is 5 parts;

[0054](5) extreme pressure and anti-wear composite agent, its mass parts are 12 parts, wherein in the composite agent, sulfurized isobutylene is 5.4 parts, and borated oleamide is 6.6 parts;

[0055] (6) sulfonated phenolic resin, its mass fraction is 9 parts;

[0056] (7) antifoaming agent is methyl silicone oil, and its mass fraction is 2.2 parts;

[0057] (8) anti-emulsifying agent is ethylene oxide, and its mass fraction is 2.2 parts;

[0058] (9) Th...

Embodiment 3

[0065] A steam turbine oil composition, comprising the following components in parts by mass:

[0066] (1) Group III and Group IV base oils, including 25 parts of Group III base oils and 35 parts of Group IV base oils, a total of 60 parts;

[0067] (2) Antioxidant is lauryl selenium, and its mass fraction is 0.7 part;

[0068] (3) anticorrosion antioxidant, is phosphoalkylphenol zinc salt, and its parts by weight are 2.2 parts;

[0069] (4) antirust agent is synthetic sodium sulfonate, and its mass fraction is 3.5 parts;

[0070] (5) extreme pressure and anti-wear composite agent, its mass parts are 9 parts, wherein in the composite agent, sulfurized isobutylene is 3.5 parts, and borated oleamide is 5.5 parts;

[0071] (6) sulfonated phenolic resin, its mass fraction is 6 parts;

[0072] (7) antifoaming agent is methyl silicone oil, and its mass fraction is 1.7 parts;

[0073] (8) anti-emulsifying agent is ethylene oxide, and its mass fraction is 1.6 parts;

[0074] (9) T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com