Rotary jetting air-compressor lubricating oil and its production

A technology for air compressors and lubricating oils, applied in lubricating compositions, petroleum industry, additives, etc., which can solve the problems of high prices and achieve excellent thermal oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

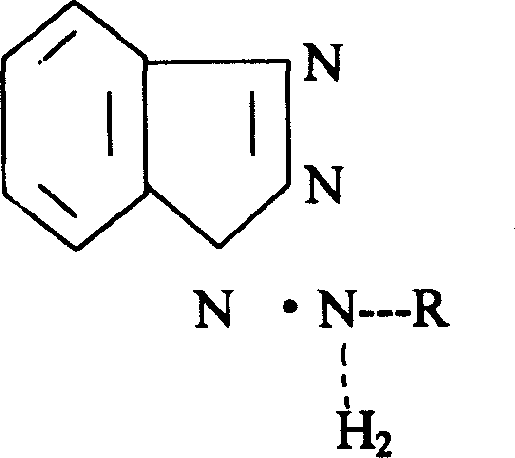

Image

Examples

Embodiment 1

[0047] No. 32 light-duty rotary (vane and screw) air compressor oil

[0048] Base oil: No. 32 white oil 99.04%

[0049] Additive: N-phenyl-α-naphthylamine (T531) 0.3%

[0050] 2.6-di-tert-butyl-p-cresol (T501) 0.3%

[0051] Tricresyl Phosphate (T306) 0.3%

[0052] Benzotriazole fatty amine salt (T406) 0.02%

[0053] Alkenyl succinic acid rust inhibitor (T746) 0.02%

[0054] The above-mentioned additives and the above-mentioned base oil are mixed, stirred and dissolved at 60°C to 80°C, then 0.02% of composite antioxidant T1001 and 10PPM simethicone defoamer are added and stirred evenly. Its performance meets the requirements of 32 in the GB5904 standard, as shown in Table 1.

Embodiment 2

[0056] No. 46 light-duty rotary (vane and screw) air compressor oil

[0057] Base oil: No. 46 white oil 99.04%

[0058] Additive: with additive and add-on in embodiment 1

[0059] Blending process: the same as the blending process in Example 1

[0060] The performance meets the requirements of 46 in the GB5904 standard, as shown in Table 1.

Embodiment 3

[0062] No. 68 light-duty rotary (vane and screw) air compressor oil

[0063] Base oil: 5 centistokes white oil 9.90%

[0064] 10 centistos white oil 89.14%

[0065] Additive: with additive and add-on in embodiment 1

[0066] Blending process: the same as the blending process in Example 1

[0067] The performance meets the requirements of 68 in the GB5904 standard, as shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com