High-performance fully-synthetic wind-power gear oil and preparation method thereof

A fully synthetic, gear oil technology, used in the petroleum industry, lubricating compositions, etc., can solve the problems of chemical stability, lubricity thermal stability and poor oxidation stability, and achieve good chemical stability and oxidation stability. The effect of good, good shear stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

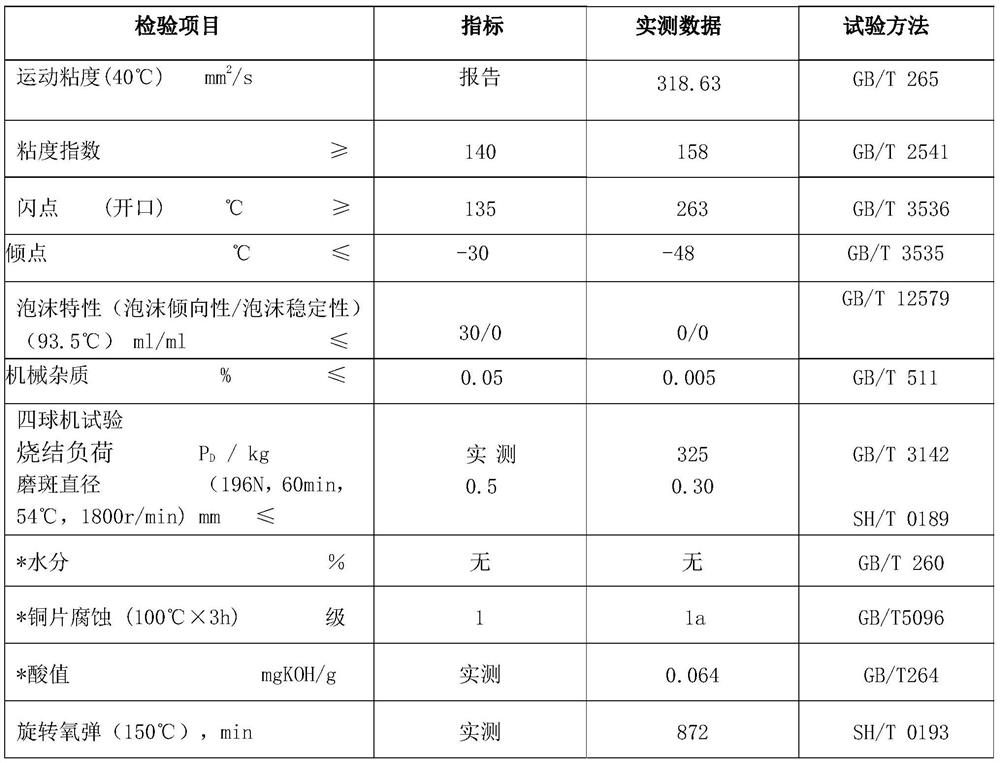

Embodiment 1

[0066] The present invention also provides a preparation method of the above-mentioned fully synthetic wind power gear oil, comprising the steps of:

[0067] (1) Add the trimellitic anhydride, the mixed base oil trimellitate obtained by the esterification reaction of monohydric alcohol and polyhydric alcohol into the reaction kettle, heat to the liquid temperature of 50-60°C, and stir at this temperature for 40-50min;

[0068] 2) Warm up the trimellitate obtained in step 1) to 60-70°C, add a pour point depressant, and stir at this temperature for 30-40min;

[0069] 3) Add the mixed liquid of extreme pressure antiwear agent A and B into the reaction kettle of step 2), raise the temperature of the obtained mixed liquid to 55-60°C, and stir at this temperature for 20-30 minutes;

[0070] 4) Add the metal deactivator and the detergent and dispersant to the mixing reactor in step 3) to obtain a mixed liquid, keep the temperature of the mixed liquid at 55-60°C, and stir at this temp...

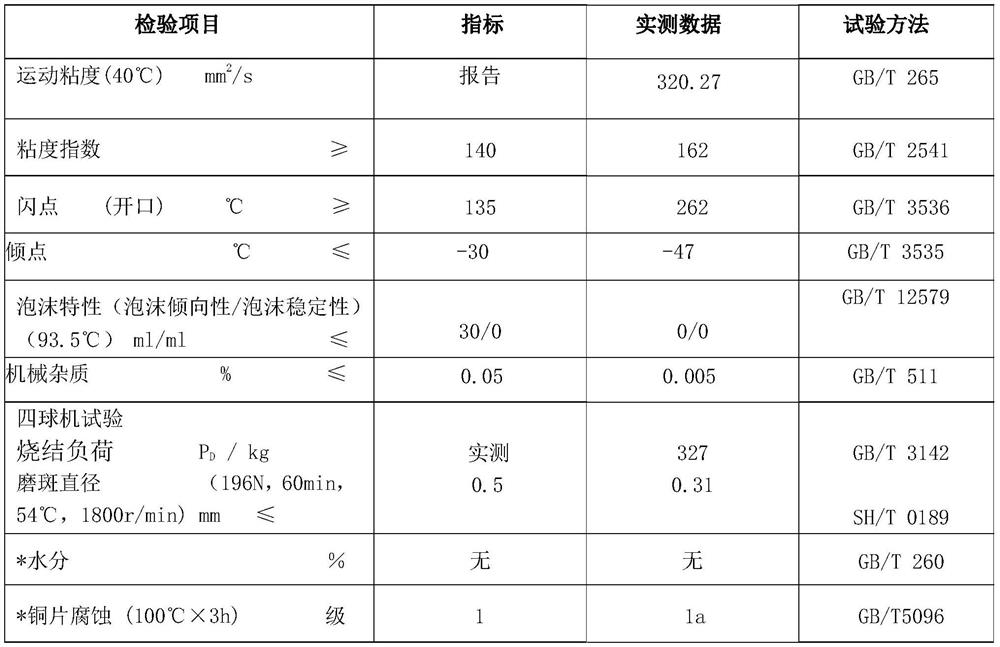

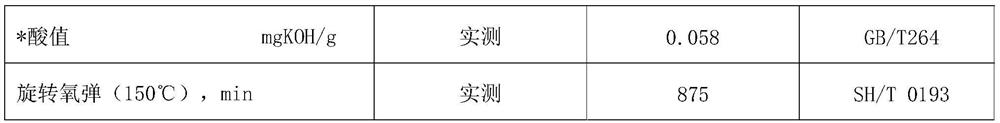

Embodiment 2

[0100] The present invention also provides a preparation method of the above-mentioned fully synthetic wind power gear oil, comprising the steps of:

[0101] (1) Add the trimellitic anhydride, the mixed base oil trimellitate obtained by the esterification reaction of monohydric alcohol and polyhydric alcohol into the reaction kettle, heat to the liquid temperature of 50-60°C, and stir at this temperature for 40-50min;

[0102] 2) Warm up the trimellitate obtained in step 1) to 60-70°C, add a pour point depressant, and stir at this temperature for 30-40min;

[0103] 3) Add the mixed liquid of extreme pressure antiwear agent A and B into the reaction kettle of step 2), raise the temperature of the obtained mixed liquid to 55-60°C, and stir at this temperature for 20-30 minutes;

[0104] 4) Add the mixed liquid of metal deactivator A and B and the detergent dispersant into the mixing reaction kettle of step 3) to obtain a mixed liquid, keep the temperature of the mixed liquid at ...

Embodiment 3

[0140] The present invention also provides a preparation method of the above-mentioned fully synthetic wind power gear oil, comprising the steps of:

[0141] (1) Add the trimellitic anhydride, the mixed base oil trimellitate obtained by the esterification reaction of monohydric alcohol and polyhydric alcohol into the reaction kettle, heat to the liquid temperature of 50-60°C, and stir at this temperature for 40-50min;

[0142] 2) Warm up the trimellitate obtained in step 1) to 60-70°C, add a pour point depressant, and stir at this temperature for 30-40min;

[0143] 3) Add the mixed liquid of extreme pressure antiwear agents A and B into the reaction kettle of step 2), raise the temperature of the obtained mixed liquid to 55-60°C, and stir at this temperature for 20-30 minutes;

[0144] 4) Add the mixed liquid of the metal deactivator and the detergent and dispersant A and B into the mixing reaction kettle of step 3) to obtain the mixed liquid, keep the temperature of the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com