Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129results about How to "Good viscosity temperature performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transmission liquid composition for stepless speed gear

ActiveCN101007982AHigh viscosity indexHigh traction coefficientAdditivesAlkaline earth metalAlicyclic Hydrocarbons

The invention provides a stepless variable device transmission fluide compound. It comprises following components with their percentage on base oil weight: (1) bicyclo alicyclic hydrocarbon base oil, (2) alkali metal salt detersive, 0.05- 3%, (3) ashless dispersant 1- 15%, (4) phenol or amine anti- oxidant, 0.01- 1%, (5) antiwear agent, 0.05- 2%, (6) friction improver. 0.05- 3%, (7) viscosity index improver, 0-20%, (8) antifoam agent, 0- 1000ppm. The transmission fluide is characterized by good viscosity-temperature characteristic and low- temperature flowability, high drag coefficient at normal temperature, good comprehensive performance, and satification for CVT use requirement.

Owner:CHINA PETROLEUM & CHEM CORP +1

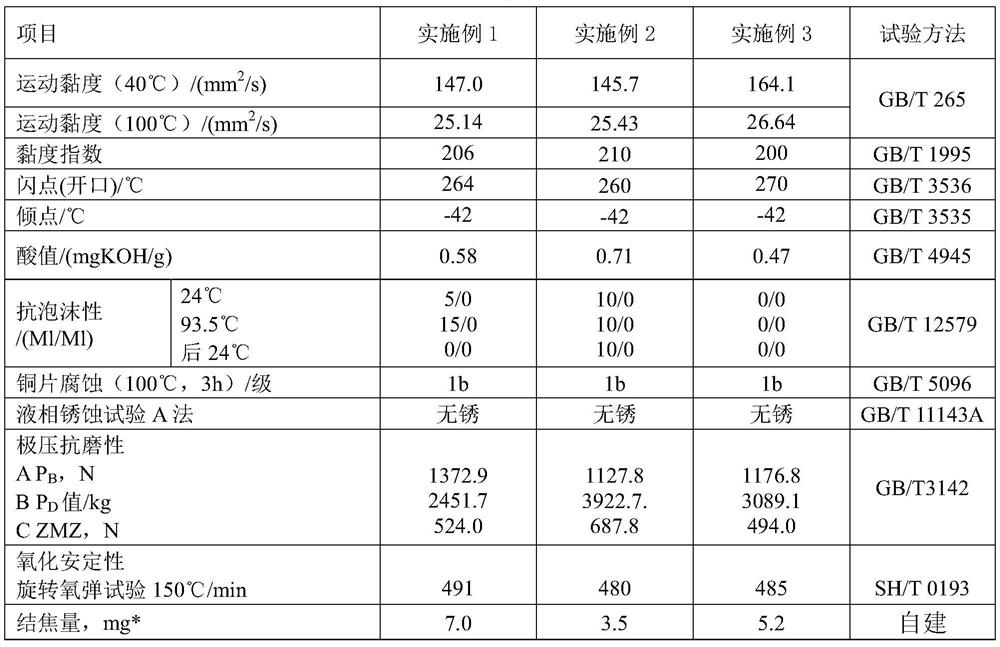

Hydraulic oil

ActiveCN104987942AGood low temperature performanceGood viscosity and film thicknessLubricant compositionOxidation stabilityAntioxidant

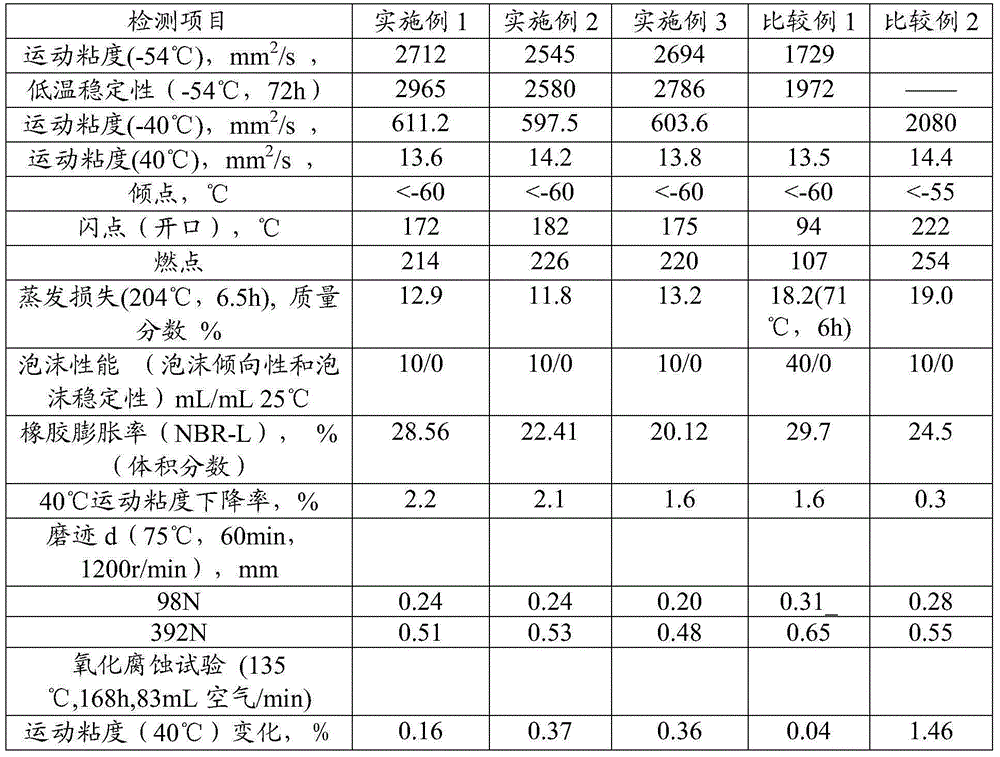

The invention provides a hydraulic oil. The hydraulic oil comprises, by weight, 70-90 parts of poly-alpha-olefin, 10-30 parts of a diester compound, 0.1-3 parts of an antioxidant, 0.1-0.5 parts of an antirust agent, 0.1-5 parts of an extreme pressure anti-wear agent, 0.0005-0.05 parts of an antifoaming agent, 0.001-0.1 parts of a coloring agent and 5-20 parts of a viscosity improver. The use amounts of all components and the comprehensive effects of all the components are controlled to make the hydraulic oil have good low-temperature performances and high flash point. Experiment results that the hydraulic oil can be used at -50DEG C, and the flash point of the hydraulic oil is 172-182DEG C. The hydraulic oil provided by the invention has the advantages of good viscosity-temperature properties, high burning point, good anti-foaming performance and good oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP

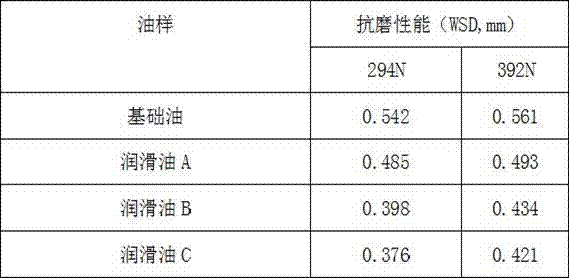

Environment-friendly semisynthetic cutting fluid for titanium alloys as well as preparation method and application of cutting fluid

InactiveCN105176656AImprove processing efficiencyExtend your lifeLubricant compositionMetalworking fluidActive agent

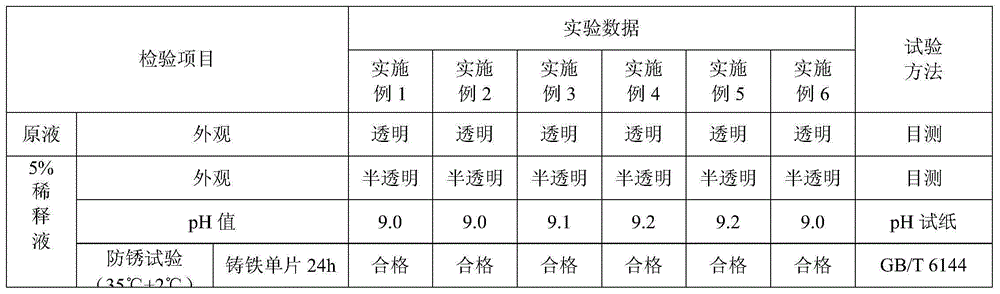

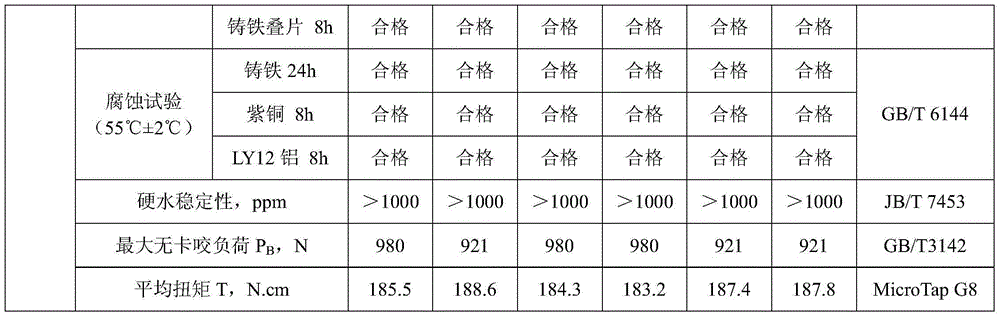

The invention belongs to the field of metal processing fluids and discloses an environment-friendly semisynthetic cutting fluid for titanium alloys as well as a preparation method and an application of the cutting fluid. The cutting fluid comprises components in percentage by mass as follows: 20%-30% of base oil, 4%-6% of a lubricant, 6%-10% of an extreme pressure agent, 10%-15% of mixed alcohol amine, 4%-8% of an anti-rusting agent, 2%-4% of a pH (potential of hydrogen) stabilizer, 15%-25% of a surfactant, 1%-2% of a hard water stabilizer, 1%-3% of a coupling agent, 2%-4% of a sterilizing mildew preventive and the balance of water. The cutting fluid doesn't contain mineral oil, sulfur, phosphorus, chlorine, boron, phenol, formaldehyde, secondary amine, heavy metals, sodium nitrite and other poisonous and harmful substances and is environment-friendly. The cutting fluid has excellent extreme pressure performance for lubrication, rust prevention and corrosion prevention performance and hard water stability and long service life, and can meet requirements of cutting processing including turning, milling, boring, drilling, tapping and the like of various titanium alloys, the titanium alloy processing efficiency can be improved by 40%, and the service life of a cutting is prolonged by 30%.

Owner:GUANGZHOU MECHANICAL ENG RES INST +1

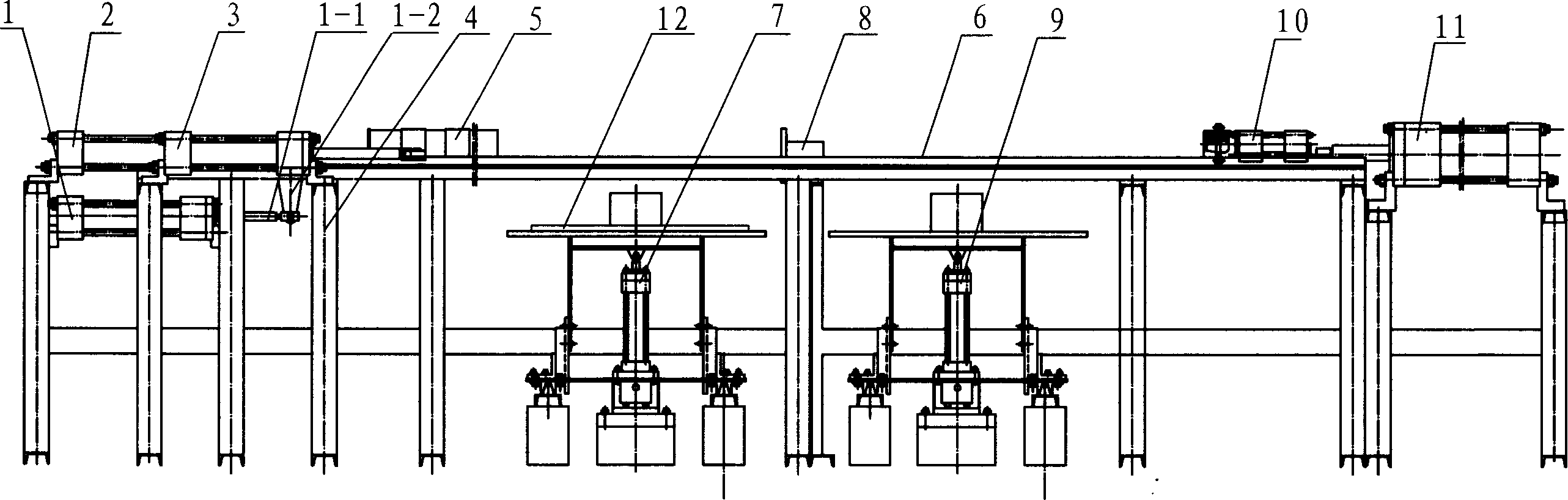

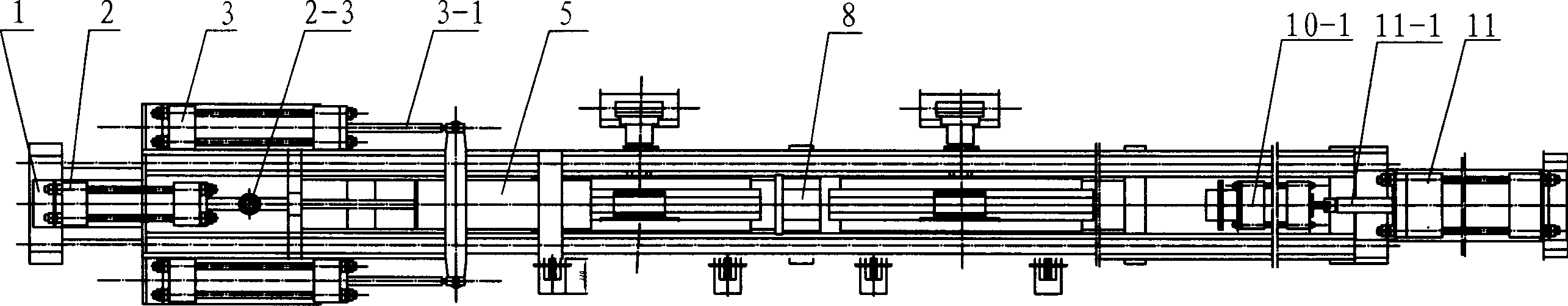

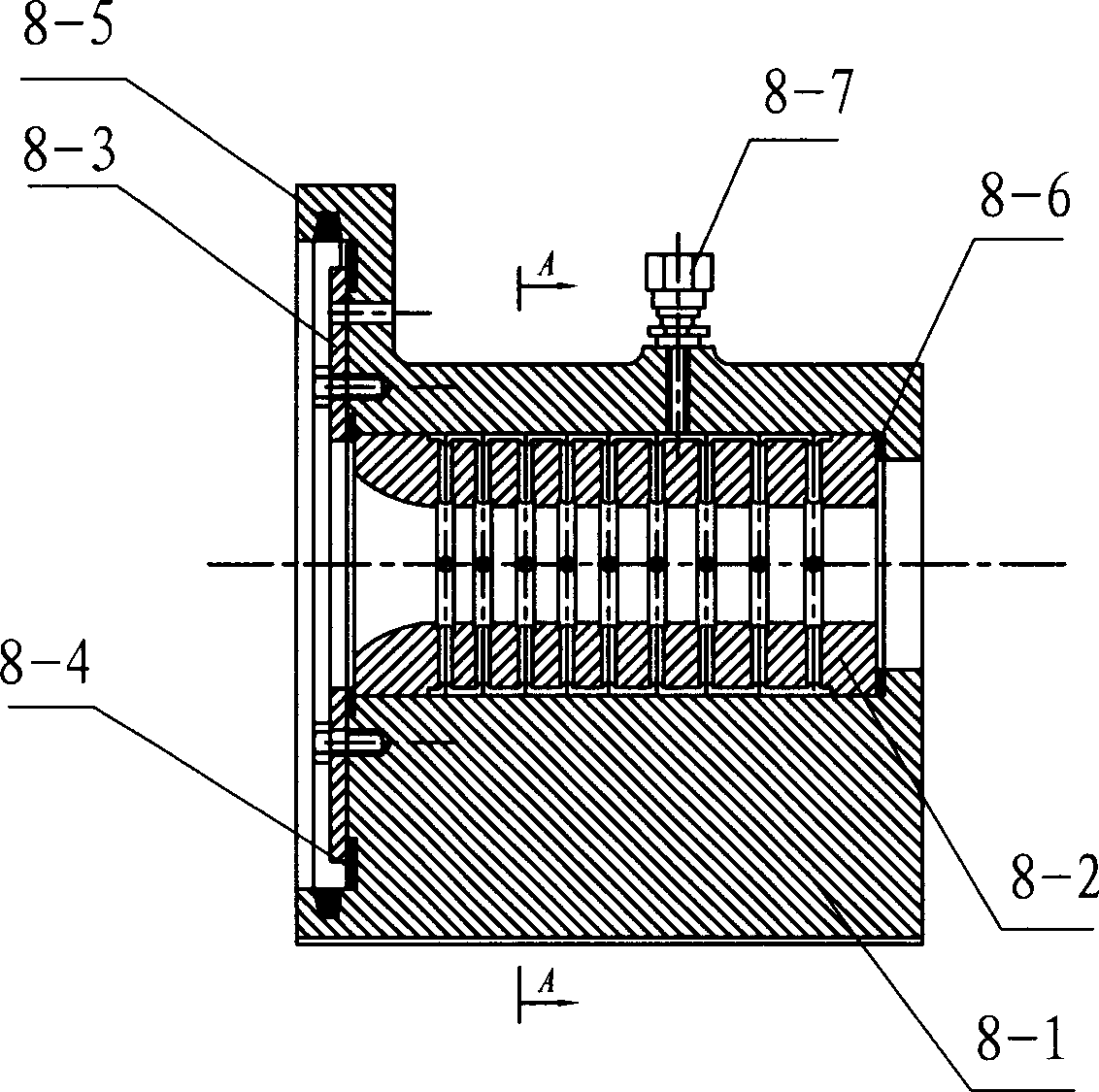

Hydraulic flexible method for producing cold-drawn pipe and apparatus

InactiveCN1803328ALow manufacturing costAvoid vibrationDrawing mandrelsDrawing diesPiston cylinderLubricant

The invention discloses a hydraulic flexible cold-drawing method and equipment in the metallurgical mechanic pipe moulding technique, which comprises the following parts: pushing piston cylinder, pushing core bar cylinder, pushing assembly cylinder, assembly, rail, feeding structure, mould, blanking structure, clamp structure and drawing cylinder. The mould doesn't touch the deformation metal to form the flexible deformation state of mould-hydraulic oil-hollow billet-hydraulic oil-core head, which improves the precision of cold-drawing pipe.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

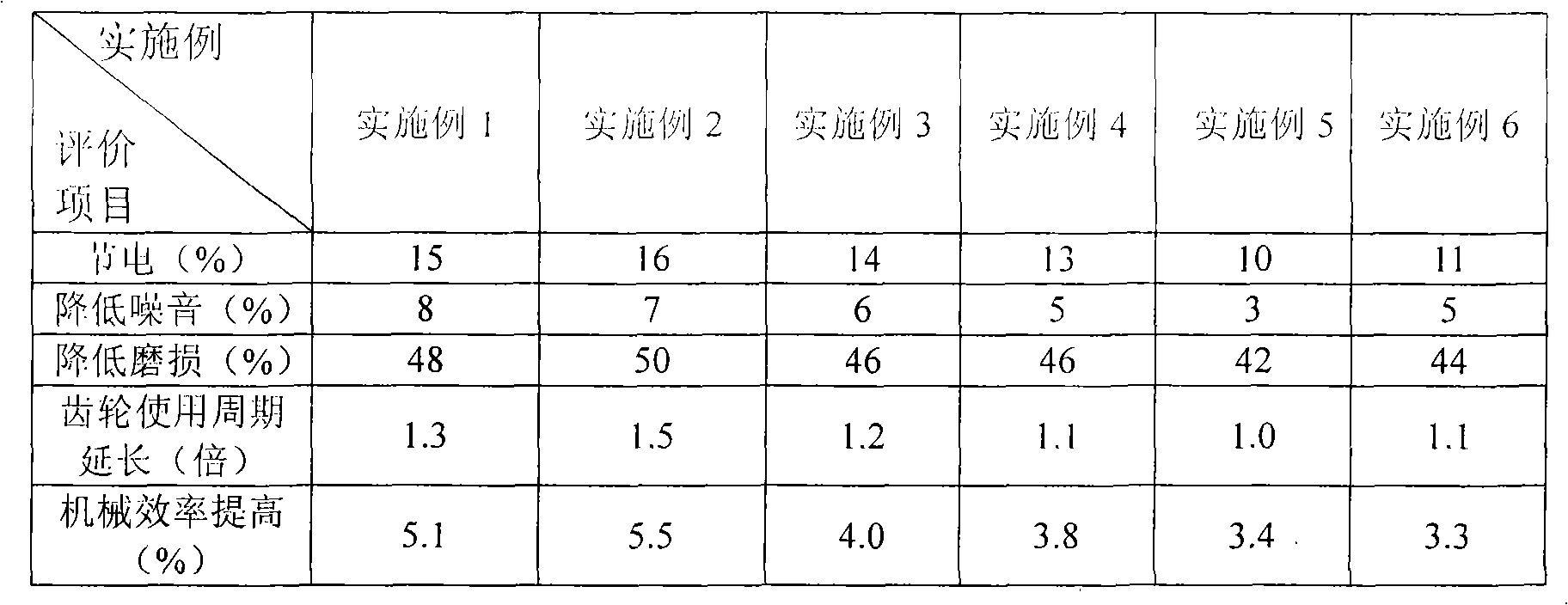

Composite gear oil additive

InactiveCN101333474ALow costGood extreme pressure and anti-wear propertiesAdditivesOil additiveGraphite

The invention relates to a compound gear oil additive containing graphite, borate, a dispersant, a stabilizer and base oil, the composition of materials includes, in weight percent, graphite 10 to 20 percent, dispersant 5 to 9 percent, stabilizer 5 to 10 percent, borate 10 to 20 percent, balance base oil, and the sum of all percents of materials is equal to a hundred percent. The compound gear oil additive has the advantage of low cost, and has properties of obviously improved anti-wear performance under extreme pressure, noise reduction, energy saving, environmental protection, anti-attrition and synergism, etc. by only adding a small amount of additive when in use.

Owner:威海橡胶化工进出口有限公司

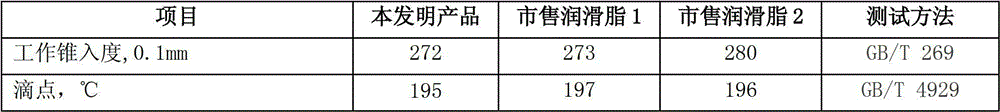

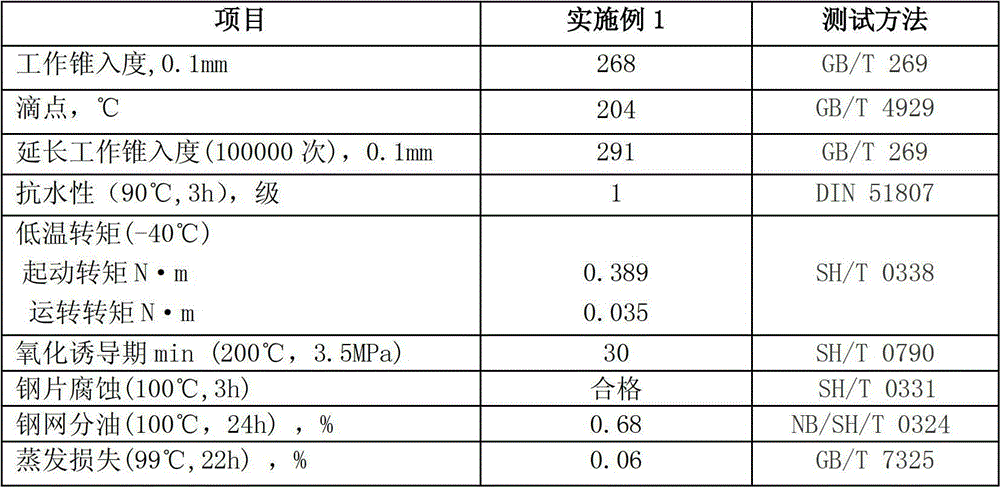

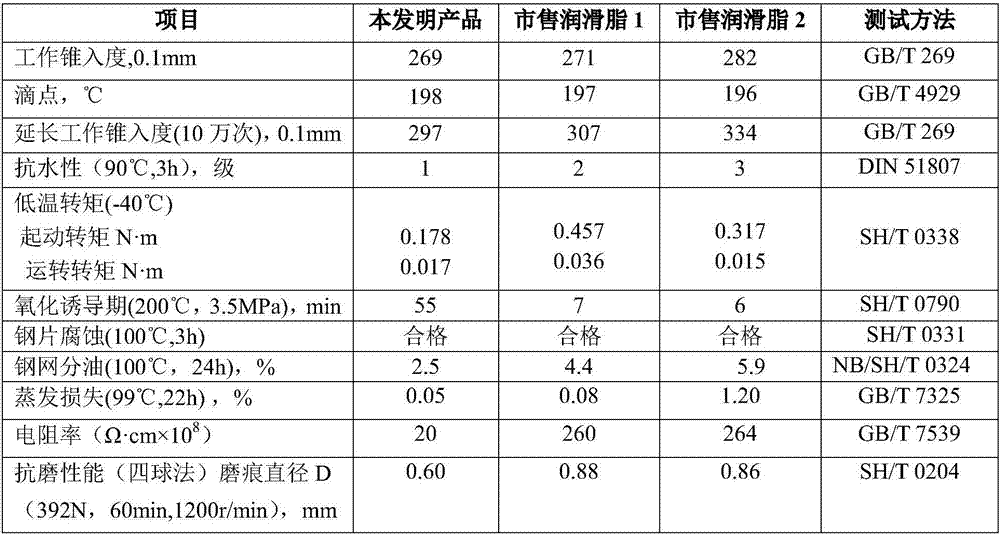

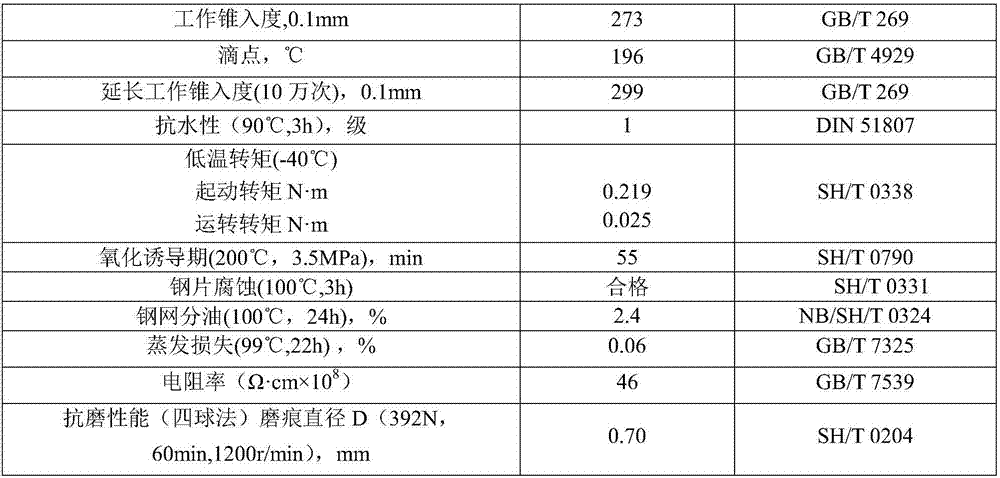

Lubricating grease composition for automobile glass lifter and preparation method of lubricating grease composition

ActiveCN102876434AOutstanding water resistanceOutstanding shear performanceLubricant compositionAntioxidantEvaporation

The invention provides a lubricating grease composition for an automobile glass lifter and a preparation method of the lubricating grease composition. The lubricating grease for the automobile glass lifter comprises the following ingredients in percentage by weight: 87 to 91.5 percent of basic oil, 7.5 to 12 percent of thickening agents, 0.5 percent of antioxidants, 0.03 percent of anti-rust agents and 0.5 percent of structure improving agents. The unique mixed thickening agent type is adopted, so the water-resistance and shearing performance of the lubricating grease are excellent, good low-temperature and viscosity-temperature performance is given to the lubricating agent through the proper basic oil type and mixture ratio, and the wide temperature use requirement being minus 40 DEG C to 70 DEG C of the automobile glass lifter accessories can be perfectly met. The prepared lubricating grease has the characteristics that the water resistance and the oxidation resistance are excellent, the oil rate is low, the evaporation loss is small, the shearing stability is high, the high-low temperature performance and the anti-corrosion protection effect are good, and the like, the use requirements of the automobile glass lifter can be perfectly met, and the use temperature range of the lubricating grease is minus 40 DEG C to 130 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

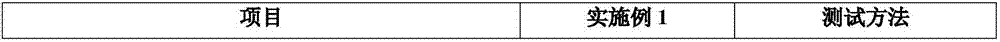

Asphalt composition particle and preparation method thereof

ActiveCN103804926AHigh oxidation reactivity and reaction self-exothermic abilityImprove product softening pointDrilling compositionBuilding insulationsLignosulfonatesWater soluble

The invention discloses an asphalt composition particle and a preparation method thereof. The asphalt composition particle comprises the following components by weight percentage: 80wt%-95wt% of high-softening point asphalt, 4.9wt%-15wt% of modified starch and / or water soluble fiber, and 0.1wt%-5wt% of a promoter. Specifically, the high-softening point asphalt is the asphalt with a softening point at 120-220DEG C, the promoter is one or more of sulfate, quaternary ammonium salt or lignosulfonate. The preparation method includes: mixing and crushing the high-softening point asphalt, the modified starch and / or water soluble fiber and the promoter to obtain the asphalt composition particle. With high softening point and excellent high temperature performance, the asphalt composition particle provided by the invention can be used under high temperature drilling operation conditions. The preparation method is simple and is convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Asphalt composition granule suitable for wider temperature drilling and preparation method thereof

ActiveCN103804922AHigh softening pointGood high temperature performanceDrilling compositionBuilding insulationsFiberSulfate

The invention discloses an asphalt composition granule suitable for wider temperature drilling and a preparation method thereof. The asphalt composition granule comprises the following components by weight percentage: 80wt%-95wt% of a high-softening point asphalt composition, 4.9wt%-15wt% of modified starch and / or water soluble fiber, and 0.1wt%-5wt% of a promoter. Specifically, the high-softening point asphalt composition is a mixture of two or more of high-softening point asphalt with a softening point of 120-220DEG C, and the softening point difference between adjacent high-softening point asphalt ranged according to the softening point from low to high is 5-50DEG C. The promoter is one or several of sulfate, quaternary ammonium salt, or lignosulfonate. The preparation method includes: mixing and crushing the high-softening point asphalt composition, the modified starch, the water soluble fiber and the promoter to obtain the asphalt composition granule. The asphalt composition granule provided by the invention has high softening point and excellent high temperature performance, and can continuously play a part under wide-temperature range drilling operation conditions. And the preparation method is simple, and is convenient to operate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Engine oil composition for improving oil loss or engine oil combustion of German automobiles

The invention provides an engine oil composition for improving oil loss or engine oil combustion of German automobiles. The engine oil composition comprises 63 to 78 weight percent of dodecyl carbon poly alpha-olefin base oil, 2 to 15 weight percent of ester base oil, 0.1 to 0.3 weight percent of pour point depressant, 8 to 10 percent of viscosity index improver and 10 to 13 weight percent of synthetic oil composite additive. The engine oil composition provided by the invention has low Noah gram value and low consumption in use, is not easy to produce 'engine oil combustion', reduces the adding times of engine oil, and reduces the maintenance expense at the same time of bring convenience to a driver. Proved by experiments, the Noah gram value of the engine oil composition is less than 4; and when the engine oil composition is used for an Audi series automobile with serious 'engine oil combustion', the engine oil is kept above the middle line by examination with an engine oil scale after the automobile runs for 5,000 kilograms.

Owner:大庆劳特润滑油有限公司

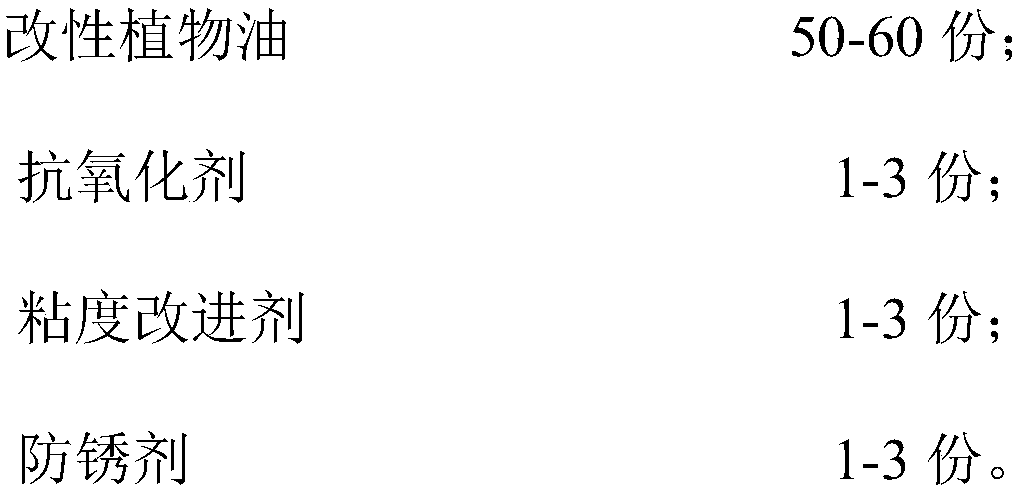

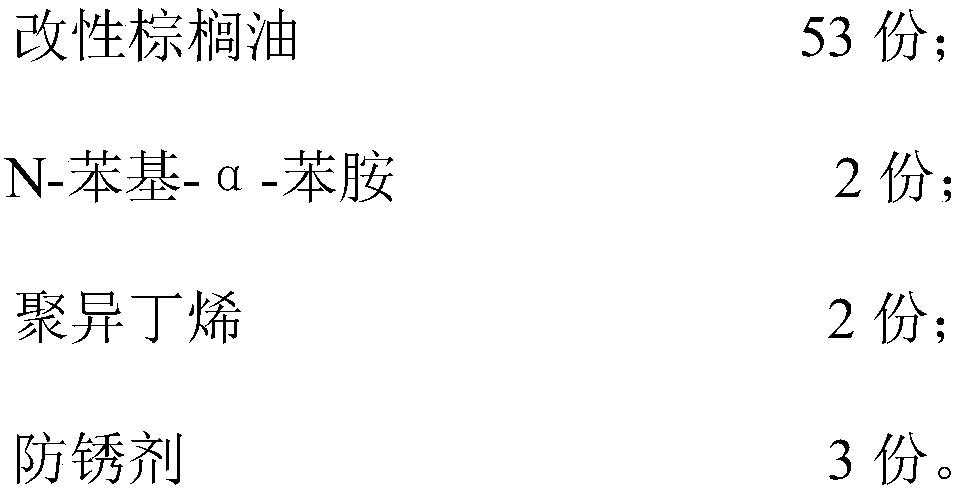

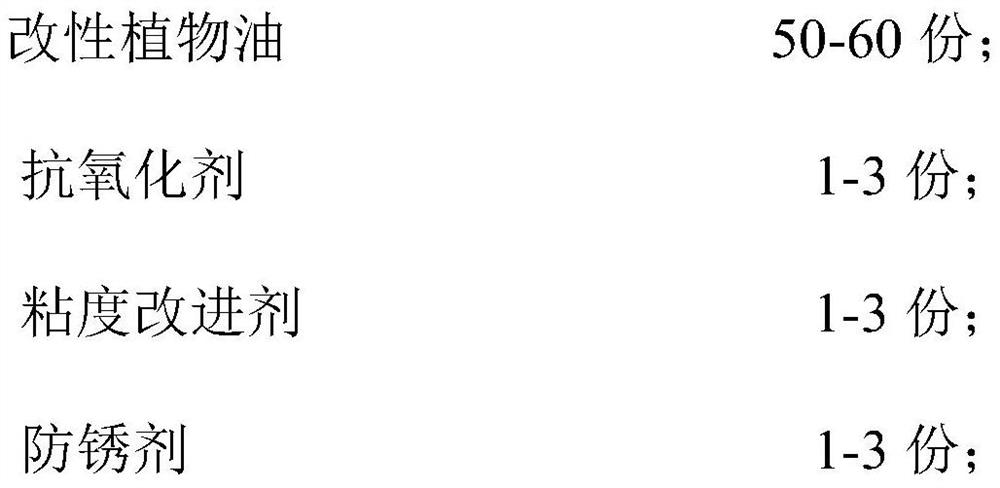

Biodegradable environmentally-friendly lubricating oil and preparation method thereof

ActiveCN108130172ASimple manufacturing methodRaw materials are easy to getLubricant compositionVegetable oilPhosphate

The invention discloses biodegradable environmentally-friendly lubricating oil. The lubricating oil is characterized by comprising the following raw materials in parts by weight: 50-60 parts of modified vegetable oil, 1-3 parts of an antioxidant, 1-3 parts of a viscosity modifier, and 1-3 parts of a rust inhibitor; the modified vegetable oil is prepared by performing hydrosilylation on methyl hydrogen silicone oil and vegetable oil and performing interesterification on the methyl hydrogen silicone oil modified vegetable oil and a phosphate ester compound; and the rust inhibitor is obtained byperforming an esterification reaction on polylactic acid and dodecenylsuccinic acid. The biodegradable environmentally-friendly lubricating oil disclosed by the invention has better viscosity-temperature performance, a more remarkable lubricating effect and more excellent oxidation stability than those of lubricating oil disclosed in the prior art, is biodegradable, and causes less pollution to the environment.

Owner:JIANGSU SHUANGJIANG ENERGY TECH CO LTD

Ester lubricant base oil and synthesis method thereof

InactiveCN105368537ALow costNovel processOrganic compound preparationCarboxylic acid esters preparationOrganic acidAlcohol

The invention relates to ester lubricant base oil and a synthesis method thereof. The synthesis method comprises that acidic solid as a catalyst is added into an organic acid and an organic alcohol in a reactor, the raw materials undergo a reaction at a temperature of 150-180 DEG C for 2-6h to produce a crude ester, the excess organic acid or organic alcohol is separated by a reduced pressure distillation or molecular distillation method, the acid is further removed by an anion exchange resin so that an acid value is reduced to 0.1mg KOH / g or less and the high-quality ester lubricating base oil is obtained, and the separated organic acid or organic alcohol can be recycled and be used as raw materials for the next same reaction system so that a cost is effectively reduced.

Owner:克拉玛依理工学院筹建办公室

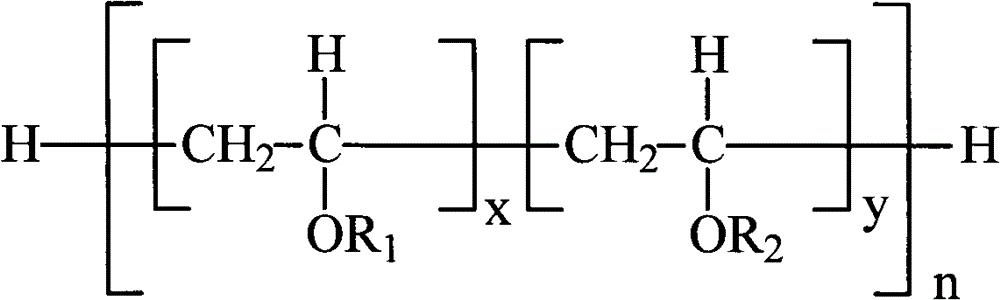

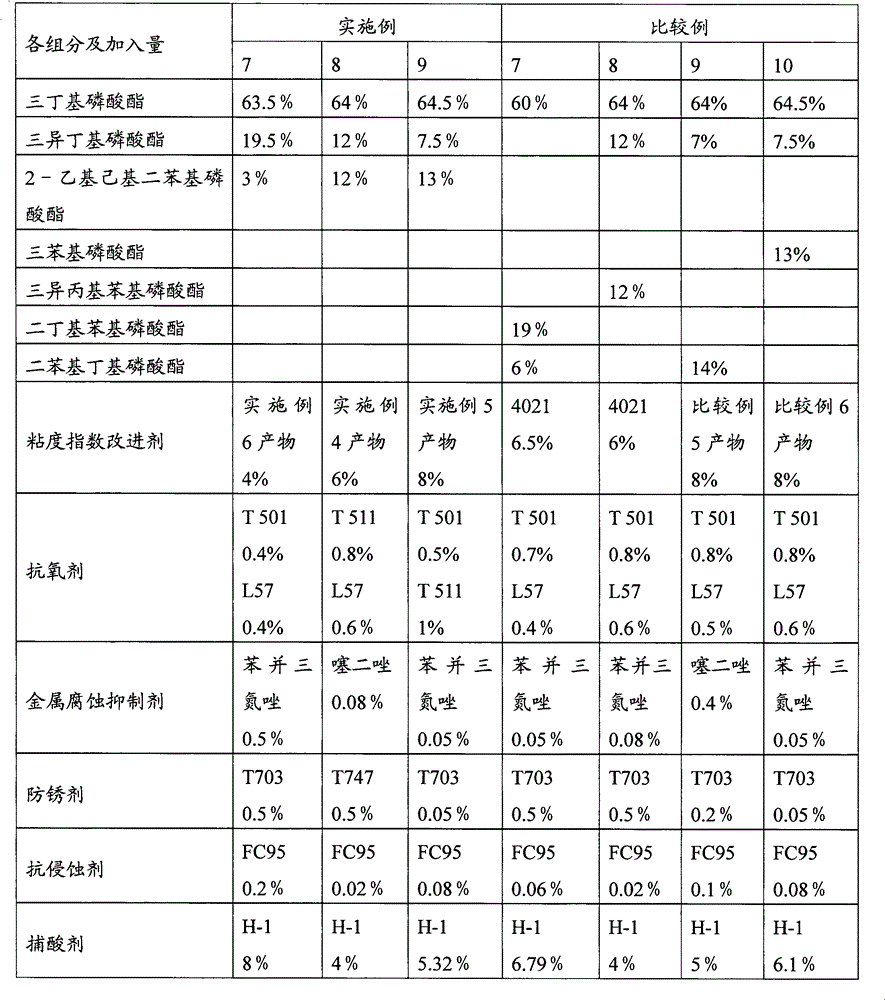

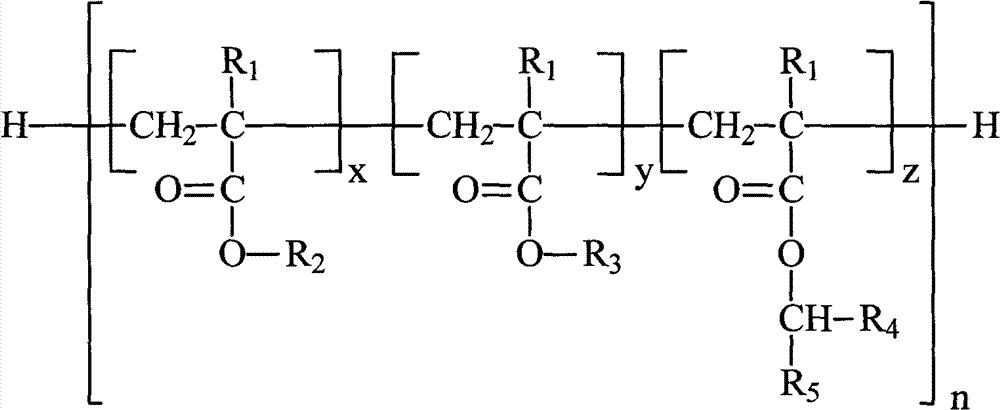

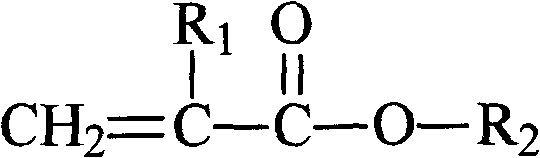

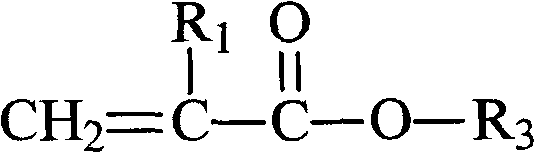

Phosphate-hydraulic oil composition

ActiveCN103060056AImprove flame resistanceGood viscosity temperature performanceBase-materialsPhosphateViscosity index

The invention provides a phosphate-hydraulic oil composition. The phosphate-hydraulic oil composition comprises tributyl phosphate, trisisobutyl phosphate and alkyl diaryl phosphate, wherein the tributyl phosphate occupies 60-90% of a total mass of a base solution; the trisisobutyl phosphate occupies 1-35% of the total mass of the base solution and the alkyl diaryl phosphate occupies 1-30% of the total mass of the base solution. A viscosity index improver prepared by polymerization of alkyl (alkyl)acrylate monomers and alkyl (isomeric alkyl)acrylate monomers can also be added in the composition. The phosphate-hydraulic oil composition provided by the invention has excellent flame resistant properties, low-temperature fluidity, shearing stability properties, antioxidant performance, metal corrosion inhibition performance, electrical erosion resistance and anti-corrosion performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

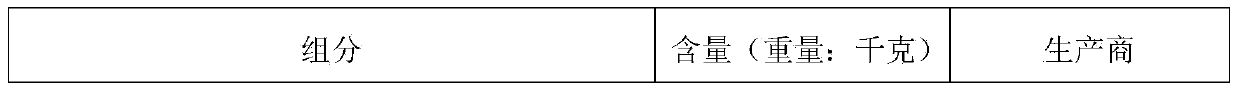

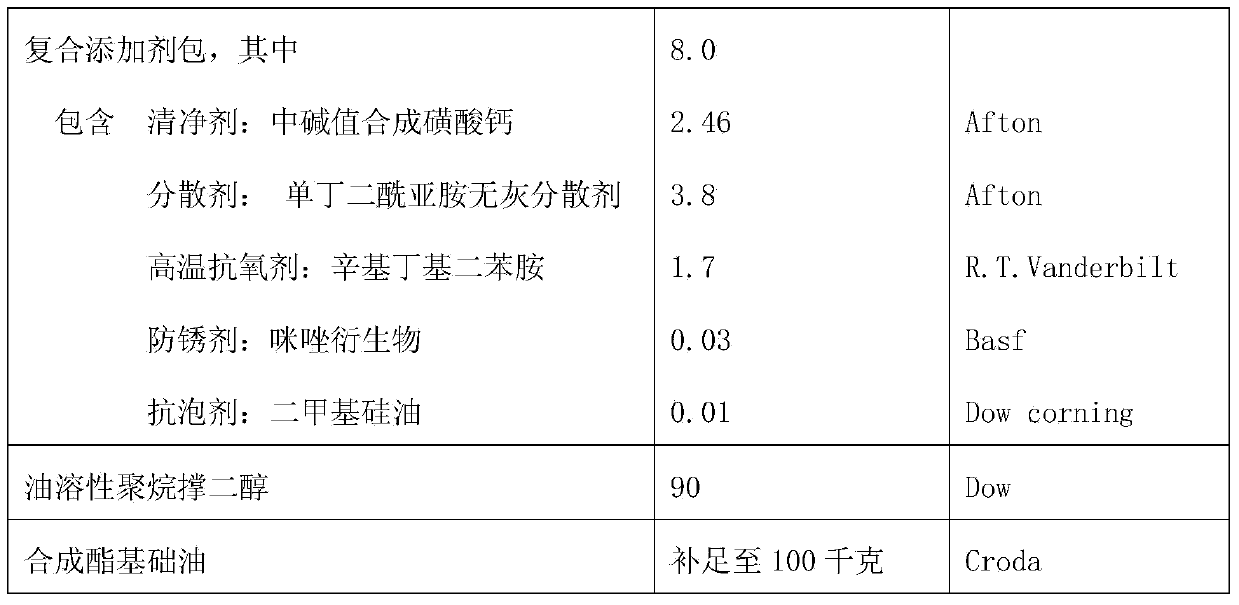

Synthetic cleaning oil for engine and gearbox, and preparation method of synthetic cleaning oil

ActiveCN103695134AWide range of viscosity gradesHigh viscosity indexLubricant compositionOil sludgeBase oil

The invention relates to the field of lubricating oil, and particularly discloses a synthetic cleaning oil for an engine and a gearbox, and a preparation method of the synthetic cleaning oil. The synthetic cleaning oil for the engine and the gearbox comprises the following components by weight: 3.01-13% of composite additive package, 70-90% of oil-soluble polyalkylene glycol, and the balance of synthetic ester base oil. The synthetic cleaning oil for the engine and the gearbox has the beneficial effects that the synthetic cleaning oil for the engine and the gearbox is safe and convenient to use, is good in mobility, extremely low in volatility, and excellent in viscosity-temperature characteristic and cleaning performance, has excellent compatibility with an engine oil and a gearbox oil, and can be directly added into the old oil and cleaned after the engine and the gearbox are opened, a low quantity of synthetic oil left in the engine and the gearbox after cleaning can also well protect the engine and the gearbox, the settlings like oil sludge and carbon deposition in the engine and the gearbox are effectively cleaned, metal pieces in the engine and the gearbox are protected against corrosion and wear, the working efficiency of the engine is improved, and gear shift is smoothly and stably conducted.

Owner:中科研创(山东)新材料有限公司

Phosphate-hydraulic oil composition

The invention provides a phosphate-hydraulic oil composition, comprising the following ingredients: A, 1-15wt% of viscosity index improver; B, 0.1-2wt% of antioxidant; C, 0.01-0.5wt% of metal corrosion inhibitor; D, 0.01-1wt% of antirust agent; and E, the balance of phosphate basic solution, wherein the viscosity index improver used herein is prepared by polymerization of alkyl acrylic acid alkyl ester monomer and alkyl acrylic acid isomeric alkyl ester monomer. The composition disclosed herein has excellent viscosity control performance and low temperature performance, simultaneously has good shear stability, and is suitable for aviation hydraulic fluids.

Owner:CHINA PETROLEUM & CHEM CORP +1

Degradable hydraulic oil added with oil-soluble nano titanium dioxide

InactiveCN105482880AImprove the shortcoming of easy oxidationHigh biodegradation rateBase-materialsBoron carbideChlorinated paraffins

The invention discloses degradable hydraulic oil added with oil-soluble nano titanium dioxide. The degradable hydraulic oil is prepared from the following raw materials in parts by weight: 280 to 285 parts of industrial oleic acid, 12.6 to 13 parts of iodine, 72 to 74 parts of acrylic acid, 134 to 135 parts of trimethylolpropane, 15 to 16 parts of toluenesulfonic acid, 15 to 17 parts of nano boron carbide particles, 0.8 to 1 part of Span 80, 2 to 3 parts of sodium carboxymethylcellulose, 30 to 32 parts of deionized water, 3.2 to 3.5 parts of hydroxyethyl imidazoline, 10 to 12 parts of polymethacrylate, 3.5 to 4 parts of zinc dialkyl dithiophosphate, 10 to 12 parts of nano titanium dioxide, 10 to 12 parts of dodecyltrimethoxysilane, 1.5 to 2 parts of sorbide oleate and 5 to 6 parts of chlorinated paraffin. The degradable hydraulic oil disclosed by the invention has good viscosity-temperature characteristic, such that the hydraulic oil has better viscosity and oil film thickness when used in a relatively wide temperature range.

Owner:WUHU CHUANGYUAN NEW MATERIALS CO LTD

Modified vegetable oil and preparation method thereof

InactiveCN111675810APromote degradationImprove thermal stabilityLubricant compositionTrans esterificationVegetable oil

The invention discloses a preparation method of modified vegetable oil. The method comprises the following steps: 1) modifying vegetable oil with methyl hydrogen-containing silicone oil: adding methylhydrogen-containing silicone oil into a flask provided with a constant-temperature feeding funnel and a condensation pipe, replacing air in the flask with nitrogen or inert gas, opening condensate water, adding a catalyst, vegetable oil and isopropanol, stirring, heating to 80-85 DEG C, keeping the temperature for 6-7 hours, and performing reduced pressure distillation to remove low-volatility substances, thereby obtaining hydrogen-containing silicone oil modified vegetable oil; and 2) ester exchange: adding methyl hydrogen-containing silicone oil modified vegetable oil prepared in the step 1) and (2R,3S)-2,3,4-trihydroxyl-3-methylbutyl dihydrogen phosphate into an organic solvent, heating to 95-105 DEG C within 30-40 minutes under a vacuum pressure of 200 mbar; making the mixture carry out reactions for 2-3 hours under stirring at a stirring speed of 800-1000 rpm, and then carrying out rotary evaporation at 50-60 DEG C to remove low-volatility substances. The lubricating oil preparedfrom the modified vegetable oil is good in chemical stability, has an extreme pressure anti-wear effect, does not need to be added with an extreme pressure anti-wear agent additionally, is economicaland environment-friendly, and avoids the problem of overlarge viscosity caused by using a large amount of auxiliaries.

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

High-softening-point asphalt particles for drilling fluid and preparation method for asphalt particles

ActiveCN104559956AHigh affinityGood deformabilityDrilling compositionBuilding insulationsPolymer scienceAsphalt

The invention discloses high-softening-point asphalt particles for drilling fluid. The high-softening-point asphalt particles comprise the following components in percentage by weight: 80-95 % of a high-softening-point asphalt composition, and 5-20 % of rubber latex, wherein the high-softening-point asphalt composition is a mixture of two or more than two kinds of high-softening-point asphalt of which the softening point ranges from 120 DEG C to 240 DEG C; the difference between softening points of adjacent high-softening-point asphalt of which the softening points are from low to high is 5-50 DEG C. The high-softening-point asphalt particles have a relatively high softening point and deformation capability, and can play function continuously under drilling operation condition with a relatively wide temperature range.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automotive wiper motor electrical contact grease composition and preparation method

InactiveCN107474922AImprove water resistanceImprove colloidal stabilityLubricant compositionAntioxidantEvaporation

The invention relates to an automotive wiper motor electrical contact grease composition and a preparation method. The grease is prepared from the following materials: 77 to 85% of base oil; 9 to 14% parts of thickener; 1% of antioxidant; 0.03% of rust inhibitor; 1 to 2% of anti-wear agent; 1 to 3 % of conductive agent; and 1 to 3% of filler. The unique hybrid thickener type of the invention enables the grease to have outstanding water resistance. The suitable base oil type and ratio give the grease excellent low temperature and viscosity-temperature properties, and can well meet -40 to 75 DEG C wide temperature use requirements of a automotive wiper motor itself; the prepared grease not only has good electrical conductivity, copper material arc resistance, outstanding water resistance and low temperature performance, but also has the characteristics of a low oil separation rate, low evaporation loss, good anti-oxidation, good shear stability, high and low temperature performance and good anti-corrosion protection effects, can better meet use requirements of the automotive wiper motor, and the use temperature range of the grease is -40 to 140 DEG C.

Owner:CHINA PETROLEUM & CHEM CORP

Synthetic lubricating oil composition

PendingCN113956910AExcellent performanceTechnically difficultLubricant compositionChemistryAntifoam agent

The invention relates to a synthetic lubricating oil composition. The composition comprises the following components: 82.0 to 96.33 wt% of base oil, 3 to 10 wt% of ester oil, 0.1 to 3.0 wt% of an extreme pressure anti-wear additive, 0.02 to 1.0 wt% of a metal deactivator, 0.05 to 1.0 wt% of an antirust corrosion inhibitor, 0.5 to 3.0 wt% of an antioxidant additive and 10 to 200 [mu] g / g of an antifoaming agent; wherein the base oil is water-insoluble polyether polyalkylene glycol, and the ester oil is saturated polyol ester and / or polybasic acid ester. The lubricating oil composition has the advantages of excellent viscosity-temperature performance, excellent low-temperature performance, excellent oxidation stability, excellent high-temperature cleaning performance, excellent extreme pressure antiwear property, good rust and corrosion resistance and good foam resistance, and can quickly form an oil film, reduce the operation temperature, reduce the high-temperature coking property and reduce the wear between bearing tooth surfaces.

Owner:PETROCHINA CO LTD

Air compressor oil and preparation method

InactiveCN104327923AGood viscosity and temperatureWon't spoilLubricant compositionOil viscosityAir compressor

The invention provides air compressor oil, which comprises the following components by mass: 85-93% of methyl silicone oil, 2-10% of tolyl silicone oil, 1-10% of an oily agent, and 0.1-3% of a corrosion inhibitor. The air compressor oil uses the methyl silicone oil and the tolyl silicone oil in a certain proportion as base oil, so that the air compressor oil has good viscosity temperature properties, even after repeated heating and cooling, air compressor oil metamorphism may not be caused, and the service life of the air compressor oil is prolonged. The experimental results show that, the air compressor oil viscosity index can reach more than 420. In addition, the air compressor oil has good oxidation stability, small volatile and less carbon deposit, can guarantee the viscosity, antioxidant, anti foam, anti corrosion performances required for the normal work of compressors, and has excellent viscosity temperature performance and anti pollution performance.

Owner:CHINA PETROLEUM & CHEM CORP

Composition for lubricating oil production and preparation method thereof

InactiveCN112980556AGood viscosity temperature performanceReduce apparent viscosityLubricant compositionDemulsifierFoaming agent

The invention relates to the technical field of lubricating oil compositions and preparation methods thereof, and discloses a composition for lubricating oil production. The composition comprises the following raw materials in parts by weight: 100-150 parts of base oil, 10-15 parts of a detergent dispersant, 5-10 parts of a viscosity index improver, 10-15 parts of a pour point depressant, 10-15 parts of an antioxidant, 7-9 parts of a friction moderator, 5-8 parts of an oiliness agent, 12-15 parts of an extreme pressure agent, 10-15 parts of an anti-foaming agent, 5-15 parts of a metal deactivator, 5-8 parts of an emulsifier, 7-9 parts of an anticorrosive agent, 10-15 parts of an antirust agent and 12-15 parts of a demulsifier. According to the composition for lubricating oil production and the preparation method thereof, the overall stability is good, the storage stability is good, the storage stability is improved by at least 10%, the problem that the performance of an oil product is changed and the performance exertion of the oil product in the using process is affected due to precipitation of an additive is avoided, and the composition is convenient to use. The lubricating oil composition is prepared through four steps, the stability of the prepared lubricating oil composition is further improved, and meanwhile the preparation method is simple and convenient.

Owner:刘新宽

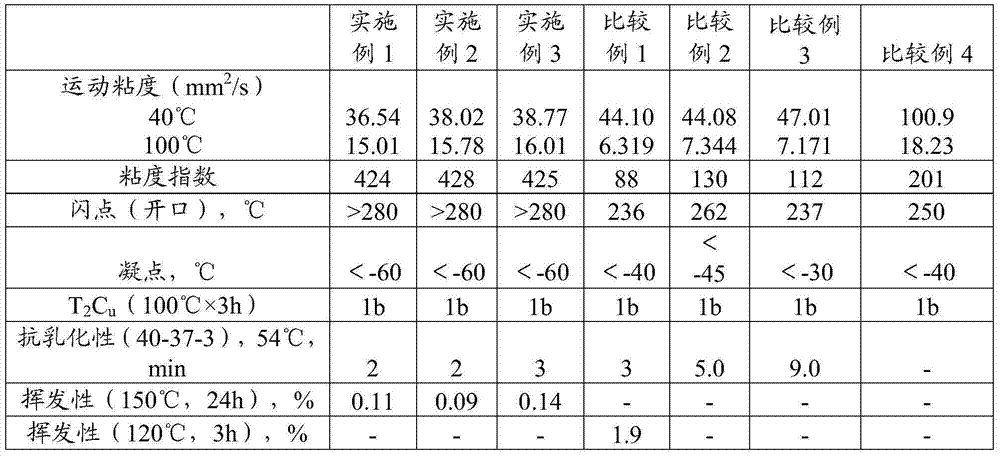

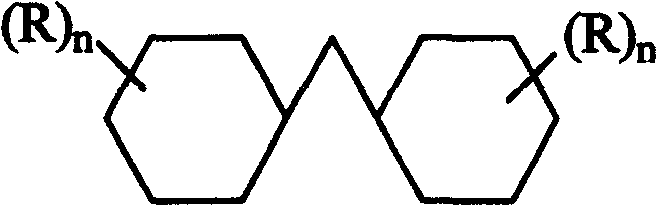

Transmission liquid composition for stepless speed gear

ActiveCN100448964CGood viscosity temperature performanceImprove low temperature fluidityAdditivesAlkaline earth metalAlicyclic Hydrocarbons

The invention provides a stepless variable device transmission fluide compound. It comprises following components with their percentage on base oil weight: (1) bicyclo alicyclic hydrocarbon base oil, (2) alkali metal salt detersive, 0.05- 3%, (3) ashless dispersant 1- 15%, (4) phenol or amine anti- oxidant, 0.01- 1%, (5) antiwear agent, 0.05- 2%, (6) friction improver. 0.05- 3%, (7) viscosity index improver, 0-20%, (8) antifoam agent, 0- 1000ppm. The transmission fluide is characterized by good viscosity-temperature characteristic and low- temperature flowability, high drag coefficient at normal temperature, good comprehensive performance, and satification for CVT use requirement.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature-resistant lubricating oil composition

InactiveCN103602419AGood viscosity temperature performanceHigh viscosity indexLubricant compositionNitrobenzoic acidLubrication

The invention discloses a high temperature-resistant lubricating oil composition which is prepared by the following raw materials by weight: 2.5-4.3 parts of vinyl chloride, 1.5-2.2 parts of nitrobenzoic acid, 15-25 parts of Turkey oil, 2.5-4.1 parts of pentaerythritol tetracrylate, 1.5-2.2 parts of nanometer zirconia, and 3-6 parts of silica. The lubricating oil composition for gears provided in the invention has excellent viscosity-temperature property and a high viscosity index; when used in a wide temperature range, the oil product still has proper viscosity and oil film thickness, and a low condensation point; the oil product has good fluidity at low temperature, which facilitates pumping or carrying to lubrication points, guarantees the safety indexes for the application of the oil product, and facilitates the transport, storage and application of the oil product. Common gear oil emulsifies when mixed with a little water, which may cause lubricating oil film breakup and failure, while the synthetic gear oil provided in the invention still has good lubricity when mixed with 20% water.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

Monel alloy plate strip cold rolling lubricant composition

InactiveCN105038929AImprove adhesionImprove wear resistanceLubricant compositionSurface finishShear stress

The invention discloses a monel alloy plate strip cold rolling lubricant composition. The monel alloy plate strip cold rolling lubricant composition adopts No.15 total loss system oil as base oil which is matched with multiple additives such as an extreme pressure agent, an antiwear agent, an oiliness agent, a friction modifier, an anti-foaming agent, an antioxidant, a metal deactivating agent and a reinforcing agent. The monel alloy plate strip cold rolling lubricant composition has the advantages that the good lubricity, cooling property, wettability, liquidity and anti-rust property are achieved, the strength and thickness of an oil film in a deformation zone are improved, the friction coefficients are decreased, and the oil film strength and thickness properties are kept stable; the adhesivity is high, and the antiwear property, the viscosity-temperature property and the washing property are good; the extreme pressure property is high, and adhesion and wear of cold rolling equipment and rollers are reduced; smaller flow shear stress exists, therefore, the cold rolling surface finish and specification precision of a machined monel alloy plate strip are improved, and oil spots and defects on the surface of the cold rolling plate strip are reduced.

Owner:GUANGXI UNIV

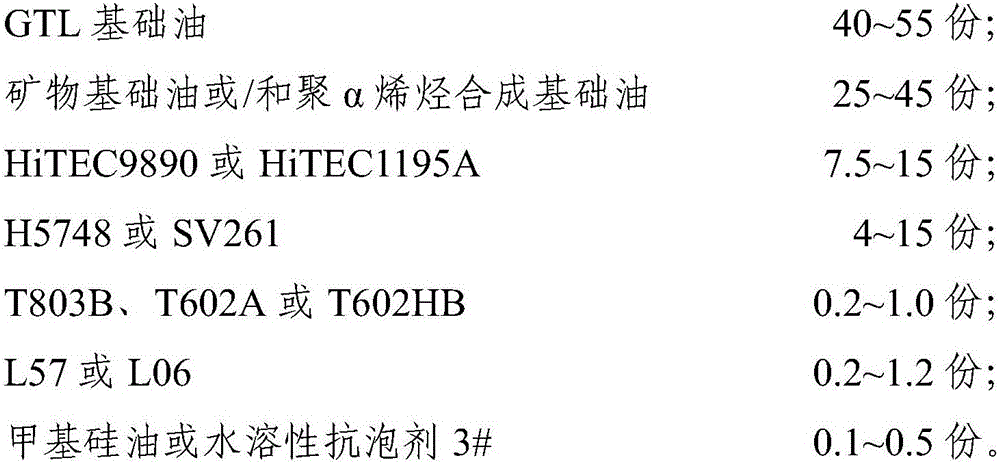

High-end lubricating oil

InactiveCN106147964AGood viscosity temperature performanceImprove low temperature fluidityLubricant compositionFoaming agentGas to liquids

The invention relates to high-end lubricating oil. The high-end lubricating oil is prepared from components in parts by weight as follows: 65-90 parts of base oil, 7.5-15 parts of a reinforcing agent, 4-15 parts of a viscosity index improver, 0.2-1.0 part of a pour point depressant, 0.2-1.2 parts of an antioxidant and 0.1-0.5 parts of an anti-foaming agent, wherein the base oil contains 40-55 parts of GTL (gas to liquid) based oil. The specific components and the relative use amount of the components of the lubricating oil are optimized, so that the lubricating oil has the advantages of good viscosity-temperature characteristics, low-temperature flowability, engine protection property, cleanability and high-temperature oxidation resistance, low cost and good using economical performance.

Owner:北京联飞翔科技股份有限公司

Carbon steel warm-forging lubricant composition

InactiveCN104450078AImprove liquidityImprove diffusivityLubricant compositionAntioxidantFriction modifier

The invention discloses a carbon steel warm-forging lubricant composition which adopts No.680 cylinder oil as basic oil and is matched with multiple composite additives which include an antioxidant, an antiwear additive, an oiliness agent, a metal passivator, a friction improver, a reinforcing agent, a corrosion inhibitor and a preservative agent. The carbon steel warm-forging lubricant composition disclosed by the invention is preferable in flowability and high in diffusion capacity, is capable of forming a layer of uniform and continuous oil film between a forge piece and a mould, has the advantages of good antiwear property and viscosity-temperature property, high extreme pressure property, stability in oil film thickness, good pressure-resistant property, good lubricating property, stability in component, no toxicity and no pungent smell and can be used for protecting a material from being cracked in a forging process, preventing the mould from being damaged and prolonging the service life of the mould.

Owner:GUANGXI UNIV

Multifunctional lubricating oil

The invention discloses multifunctional lubricating oil. The multifunctional lubricating oil is prepared from components in parts by mass as follows: 10-20 parts of adamantane phosphate salt, 5-7 parts of a phosphate-methyl methacrylate copolymer, 60-70 parts of base oil, 1-3 parts of a dispersant and 1-3 parts of a clearing agent. A preparation method of the adamantane phosphate salt comprises the steps of preparation of adamantane quaternary ammonium salt and ionic exchange; a preparation method of the phosphate-methyl methacrylate copolymer comprises the steps as follows: methyl methacrylate, triallyl phosphate and polyoxypropylene polyethylene glyceryl ether are mixed, and the mixture is placed in a radiation field in a nitrogen atmosphere to be radiated with a cobalt 60-gamma radiation method for 40-50 min. The multifunctional lubricating oil has excellent extrusion performance and lubricating performance, wide use ranges and multiple functions.

Owner:山东一和润滑油有限公司

Composite lubricating oil of styreneic block copolymers and graphene and preparation method of composite lubricating oil

InactiveCN107236583AGood viscosity temperature performanceLittle effect of temperature changeAdditivesViscosity indexSolvent

The invention discloses a composite lubricating oil of styreneic block copolymers and graphene and a preparation method of the composite lubricating oil, and belongs to the technical field of lubricating oil. The preparation method comprises the following steps: the graphene is added to basic oil and ultrasonic dispersion is performed for 0.5-2h, then the styreneic block copolymers are added, and ultrasonic dispersion is continued for 0.5-2h, so that the composite lubricating oil of the styreneic block copolymers and the graphene is obtained. According to the invention, a small amount of the styreneic block copolymers is added to the lubricating oil, so that the viscosity-temperature performance of the composite lubricating oil can be improved, and influence of temperature variation on the viscosity index of the composite lubricating oil influenced is lessened; and meanwhile, styreneic block copolymer molecular chains enter spaces among graphene layers, so that pi-pi stacking is formed and inhibits agglomeration of the graphene layers, and the graphene can stably disperse in a good solvent of the styreneic block copolymers, and accordingly, excellent usage performance is brought for lubricating oil used for aircraft engines and motor vehicles in cold highland areas.

Owner:SICHUAN CARBON WORLD TECH CO LTD

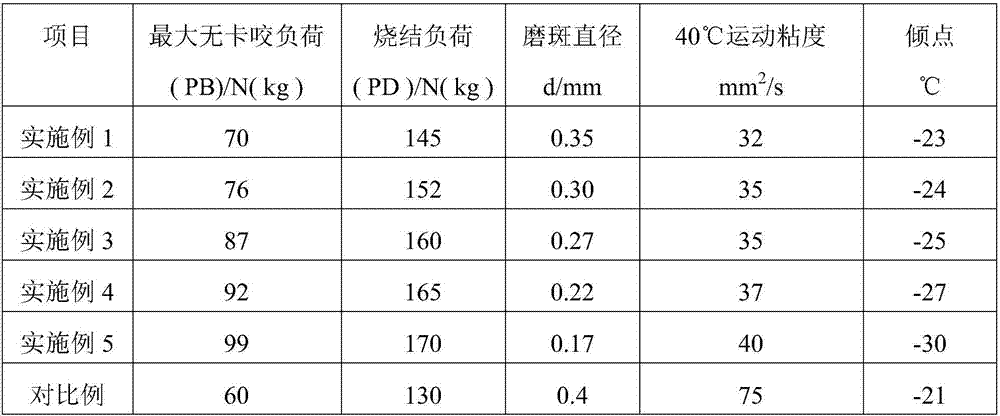

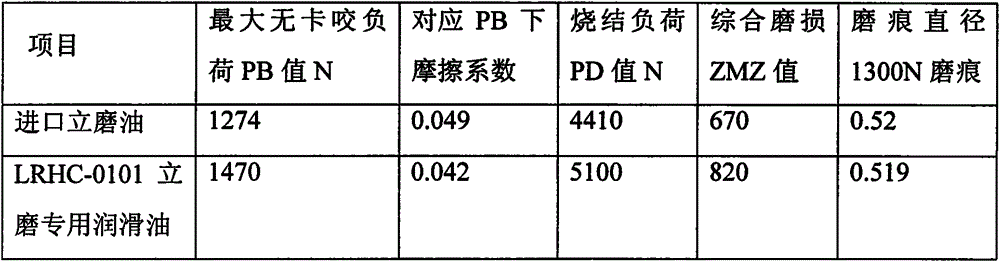

Special lubricating oil for grinding roller of vertical mill and manufacturing method of special lubricating oil

ActiveCN104450068APromote degradationGood compatibilityLubricant compositionThermal stabilityBase oil

The invention relates to special lubricating oil for a grinding roller of a vertical mill and a manufacturing method of the special lubricating oil. The special lubricating oil is prepared by taking synthetic oil as base oil, adding a variety of efficient compound additives and refining, and the special lubricating oil can fastest repair abrasion, reduce abrasion and avoid dry friction and high-temperature coking. The product is widely applied to mining, metallurgy, electric power, chemical engineering, cement and other industries for being used on vertical mills, has the advantages of good viscosity-temperature property, strong extreme pressure abrasion resistance, thermal stability, no coking at high temperature and the like, is further relatively cheap, environment-friendly and safe, and can fundamentally solve the problem that the vertical mill has a failure due to poor lubrication.

Owner:洛阳正本润滑材料有限公司

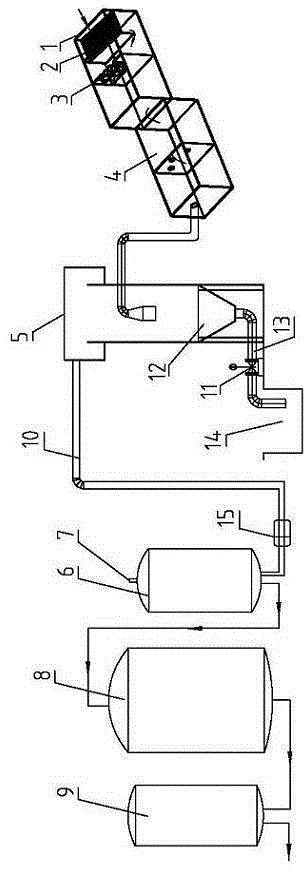

Purification method and equipment for waste hydraulic oil of extruding machine

ActiveCN104531325AGood qualityImprove purification efficiencyLubricant compositionWork productivityAutomation

The invention discloses a purification method and purification equipment for hydraulic oil of an extruding machine. The purification method is characterized in that a full-automatic washing method is adopted and comprises the steps of removing impurities, precipitating, settling by gravity, carrying out two-stage water removal, refining and purifying; and the hydraulic oil of the extruding machine is continuously operated in a stable conveying pipeline. According to the purification method and the purification equipment for the hydraulic oil of the extruding machine, the water removing rate can be up to not less than 99.99%; the hydraulic oil has no impurities and the quality of the purified hydraulic oil is good; the recycling utilization rate of the waste hydraulic oil is up to not less than 90%; and the purification method and the purification equipment have the characteristics of high automation degree, simplicity in operation, high working efficiency, high resource recycling utilization rate, safety and environmental friendliness and the like.

Owner:ALNAN ALUMINIUM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com