Air compressor oil and preparation method

A technology of air compressor oil and oily agent, applied in the field of lubricating oil, can solve the problems of bad influence of lubricating oil performance, short life of air compressor oil, cumbersome types of additives, etc., achieve good viscosity-temperature performance and anti-pollution performance, prolong the The effect of service life and less carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a kind of preparation method of air compressor oil, comprises the following steps:

[0032] Mix 85-93% of methyl silicone oil, 2-10% of methylphenyl silicone oil, 1-10% of oily agent and 0.1-3% of corrosion inhibitor, and heat to obtain air compressor oil.

[0033] In the present invention, preferably, methyl silicone oil and methylphenyl silicone oil are mixed to obtain a base oil mixture, and the obtained base oil mixture is mixed with an oiliness agent and a corrosion inhibitor, and heated to obtain an air compressor oil. In the present invention, the type, source and dosage of the methyl silicone oil and methylphenyl silicone oil are consistent with those of the methyl silicone oil and methylphenyl silicone oil in the above technical solution, and will not be repeated here. In the present invention, the mixing method of methyl silicone oil and methylphenyl silicone oil is a method commonly used by those skilled in the art.

[003...

Embodiment 1

[0049] In terms of mass fraction, mix 5% tolyl silicone oil and 89% methyl silicone oil, then add 5.8% fatty acid ester and 0.2% benzotriazole, stir and heat to 50°C until the product is homogeneous, to obtain Air compressor oil.

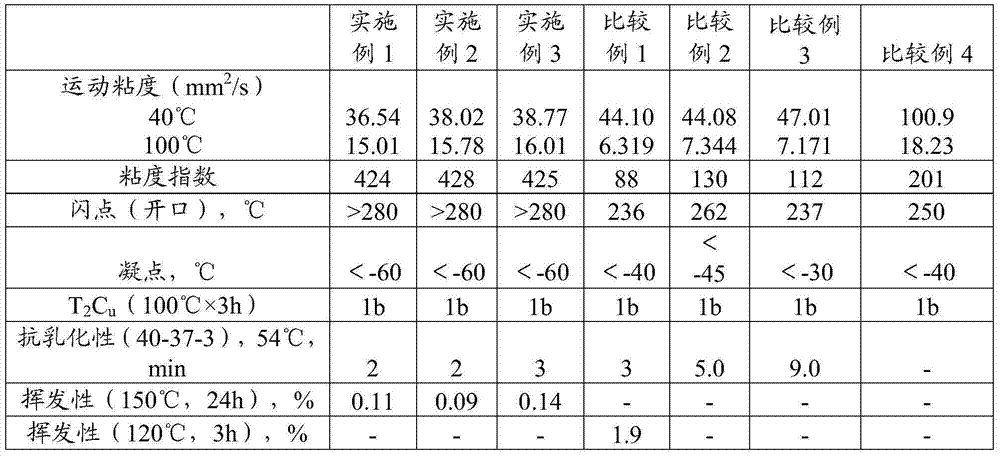

[0050] The present invention has measured the kinematic viscosity of the air compressor oil obtained in this embodiment according to the above-mentioned technical scheme, and the results are as shown in Table 1, and Table 1 is the air compressor oil obtained in Examples 1 to 3 of the present invention and Comparative Examples 1 to 4 performance data.

[0051] The present invention has measured the viscosity index of the air compressor oil that the present embodiment obtains according to above-mentioned technical scheme, and the result is shown in Table 1.

[0052] The present invention measures the flash point of the air compressor oil obtained in the present embodiment according to the above-mentioned technical scheme, and the results are shown in...

Embodiment 2

[0058] In terms of mass fraction, mix 2% methylphenyl silicone oil and 93% methyl silicone oil, then add 4.6% fatty acid ester and 0.4% benzotriazole, stir and heat to 80°C until the product is homogeneous, and get Air compressor oil.

[0059] The present invention has measured the kinematic viscosity of the air compressor oil obtained in this embodiment according to the above-mentioned technical scheme, and the results are as shown in Table 1, and Table 1 is the air compressor oil obtained in Examples 1 to 3 of the present invention and Comparative Examples 1 to 4 performance data.

[0060] The present invention has measured the viscosity index of the air compressor oil that the present embodiment obtains according to above-mentioned technical scheme, and the result is shown in Table 1.

[0061] The present invention measures the flash point of the air compressor oil obtained in the present embodiment according to the above-mentioned technical scheme, and the results are sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com