Multifunctional lubricating oil

A lubricating oil and multi-functional technology, applied in the field of lubricating oil, can solve the problems that the oil change period cannot reach the engine, reduce the service life of lubricating oil, and the parts cannot work normally, and achieve good thermal oxidation stability and improve wear resistance Effects of lubrication and excellent viscosity-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

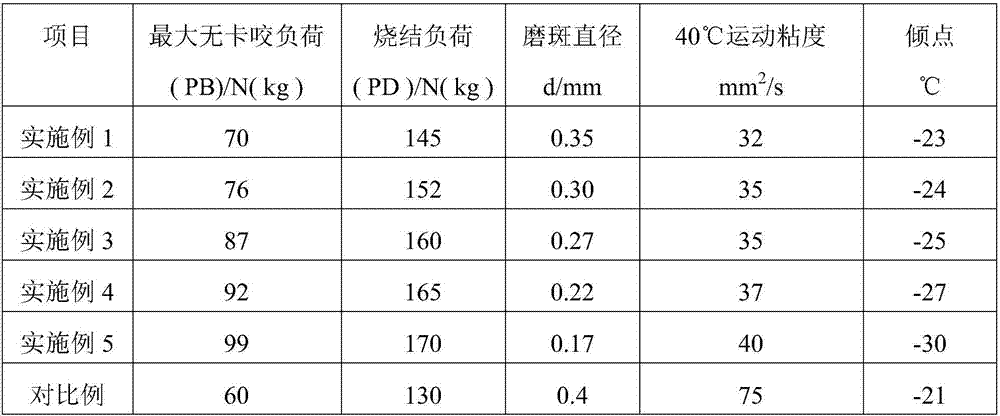

Examples

Embodiment 1

[0026] A multifunctional lubricating oil, consisting of the following components in parts by mass: 10 parts of adamantane phosphate ester salt, 5 parts of phosphate ester methyl methacrylate copolymer, 60 parts of base oil, 1 part of dispersant stearic acid, Detergent sulfurized calcium alkylphenate T115B 1 part;

[0027] Wherein, the base oil is obtained by mixing mineral oil and vegetable oil in a mass ratio of 3:5;

[0028] The vegetable oil is obtained by mixing rapeseed oil and soybean oil in a mass ratio of 2:1;

[0029] The preparation method of described adamantine phosphate, comprises the steps:

[0030] 1) Preparation of adamantane quaternary ammonium salt: Add 10 g of 1,3,5,7-tetrakis(4-aminophenyl) adamantane and 40 g of di-tert-butyl chloromethyl phosphate into 100 g of diethyl ether, at 30°C The reaction was stirred at low temperature for 6 hours, the solvent was removed by rotary evaporation at room temperature, and the product was washed with ethyl acetate th...

Embodiment 2

[0034] A multifunctional lubricating oil, consisting of the following components in parts by mass: 13 parts of adamantyl phosphate ester salt, 6 parts of phosphate methyl methacrylate copolymer, 65 parts of base oil, dispersant dodecylbenzenesulfonate 2 parts sodium acid, 2 parts sulfurized calcium alkylphenate T115B detergent;

[0035] Wherein, the base oil is formed by mixing mineral oil and polyethylene glycol in a mass ratio of 2:3;

[0036] The preparation method of described adamantine phosphate, comprises the steps:

[0037] 1) Preparation of adamantane quaternary ammonium salt: 10 g of 1,3,5,7-tetrakis(4-aminophenyl) adamantane and 40 g of di-tert-butyl chloromethyl phosphate were added to 130 g of diethyl ether, at 34°C The reaction was stirred under low temperature for 7 hours, the solvent was removed by rotary evaporation at room temperature, and the product was washed 4 times with ethyl acetate. After the solvent was removed by rotary evaporation again at room tem...

Embodiment 3

[0041] A multifunctional lubricating oil, consisting of the following components in parts by mass: 16 parts of adamantane phosphate ester salt, 7 parts of phosphate ester methyl methacrylate copolymer, 66 parts of base oil, 2 parts of dispersant fatty acid glyceride, Detergent sulfurized calcium alkylphenate T115B 3 parts;

[0042] The preparation method of described adamantine phosphate, comprises the steps:

[0043] 1) Preparation of adamantane quaternary ammonium salt: 10 g of 1,3,5,7-tetrakis(4-aminophenyl) adamantane and 40 g of di-tert-butyl chloromethyl phosphate were added to 160 g of diethyl ether, at 37°C The reaction was stirred at low temperature for 7 hours, the solvent was removed by rotary evaporation at room temperature, and the product was washed with ethyl acetate for 5 times, and the solvent was removed by rotary evaporation again at room temperature, and then put into a vacuum oven at 50°C for 8 hours;

[0044] 2) Ion exchange: 10 g of the adamantane quate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com