Lubricating grease composition for automobile glass lifter and preparation method of lubricating grease composition

A grease composition and technology for automotive glass, applied in the field of grease, can solve problems such as poor lubrication, low oxidation resistance, low evaporation loss, shear stability, poor performance, etc., and achieve outstanding water resistance and excellent low temperature and viscosity-temperature performance, and the effect of low oil separation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

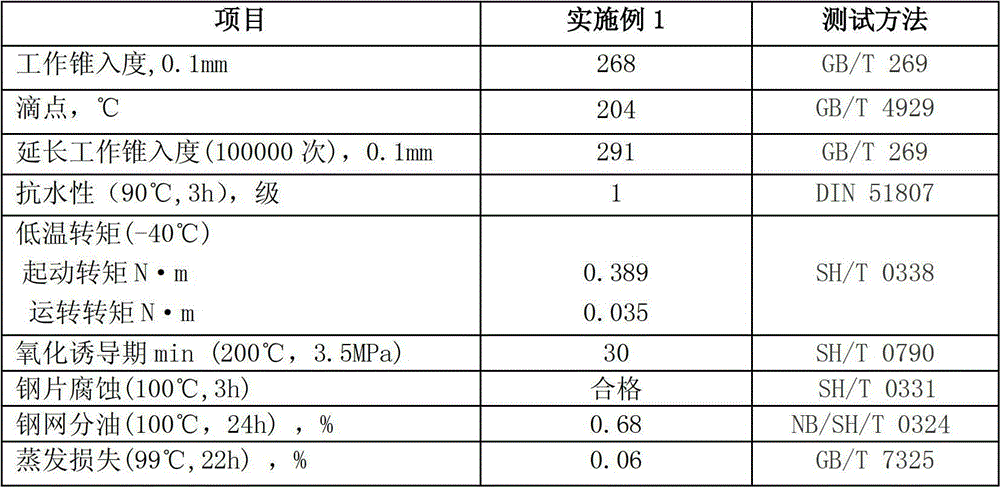

Embodiment 1

[0026] Embodiment 1: each component comprises by the total weight of composition:

[0027] (1) Base oil 89.5%;

[0028] (2) Thickener 9.5%;

[0029] (3) Antioxidant 0.5%;

[0030] (4) Antirust agent 0.03%;

[0031] (5) 0.5% tackifier.

[0032] Mix 80 grams of 12-hydroxystearic acid, 20 grams of hexadecanoic acid and 430 grams of base oil (the freezing point is -30°C, the viscosity at 100°C is 8mm 2 / s) into the reaction kettle, heated to 80-85°C, and added an aqueous solution of 11.2 grams of lithium hydroxide monohydrate and 2.2 grams of calcium hydroxide. Heat to 90-105°C to start timing saponification. After saponification, heat up to 200-220°C and cool with 215g of base oil in the reactor. After cooling, when the temperature is controlled at 160-190°C, add 6.5g of poly Methacrylate and the remaining 430g of base oil, after the temperature drops to 80°C, add 3.75 grams of 4,4-methylene bis-2,6-di-tert-butyl p-cresol, 3.75 grams of dibutyloctyldithioamino Zinc formate ...

Embodiment 2

[0035] Embodiment 2: each component comprises by the total weight of composition:

[0036] (1) Base oil 88.0%;

[0037] (2) Thickener 11.0%;

[0038] (3) Antioxidant 0.5%;

[0039] (4) Antirust agent 0.03%;

[0040] (5) 0.5% tackifier.

[0041] Mix 90 grams of 12-hydroxystearic acid, 15 grams of hexadecanoic acid and 378 grams of base oil (the freezing point is -40°C, and the viscosity at 100°C is 6mm 2 / s) into the reaction kettle, heated to 80-85°C, and added an aqueous solution of 11.5 grams of lithium hydroxide monohydrate and 2.3 grams of calcium hydroxide. Heat up to 90-105°C to start timing saponification. After saponification, heat up. After the temperature rises to 200-220°C, use 189g of base oil to cool in the reactor. After cooling, when the temperature is controlled at 160-190°C, add 5.3 grams of ethyl alcohol. Propylene copolymer and the remaining 378g of base oil, after the temperature reaches 80°C, add 2.65 grams of 2,6-di-tert-butyl-p-cresol and 2.65 grams...

Embodiment 3

[0044] Embodiment 3: each component comprises by the total weight of composition:

[0045] (1) Base oil 91.5%;

[0046] (2) Thickener 7.5%;

[0047] (3) Antioxidant 0.5%;

[0048] (4) Antirust agent 0.03%;

[0049] (5) 0.5% tackifier.

[0050] Mix 80 grams of 12-hydroxystearic acid, 10 grams of hexadecanoic acid and 508 grams of base oil (the freezing point is 42°C, the viscosity at 100°C is 8mm 2 / s) into the reaction kettle, heated to 80-85°C, and added 13.41 grams of lithium hydroxide monohydrate aqueous solution. Heat up to 90-105°C to start timing saponification. After saponification, heat up. After the temperature rises to 200-220°C, cool with 254g of base oil in the reactor. After cooling, when the temperature is controlled at 160-190°C, add 6.94g of polyform base acrylate and remaining 508g of base oil. After the temperature drops to 80°C, add 3.47 grams of 2,6-di-tert-butyl-p-cresol and 3.47 grams of zinc dibutyloctyldithiocarbamate additives and 0.42 grams of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com