Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Wide range of hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

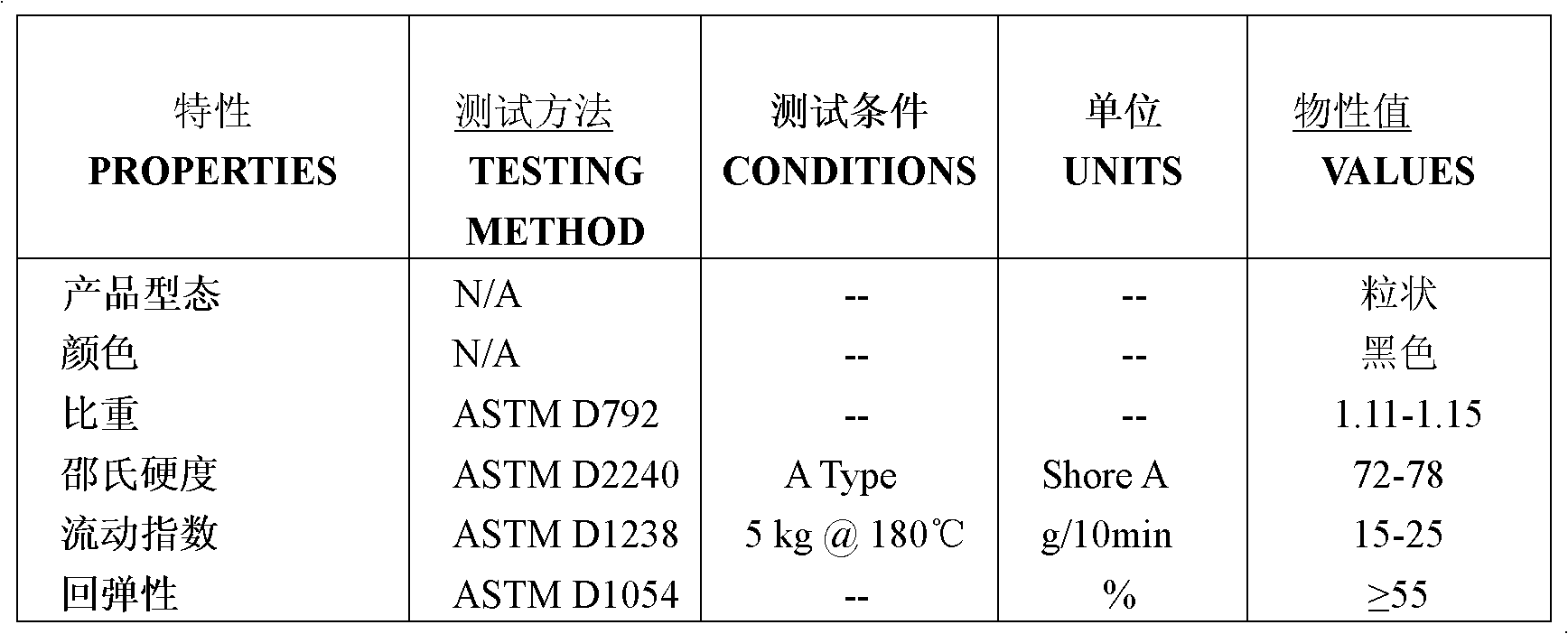

Extrusion grade thermoplastic polyurethane elastomer and manufacturing method thereof

InactiveCN105001626AImprove extrusion fluidityImprove mechanical propertiesAcrylic resinThermoplastic polyurethane

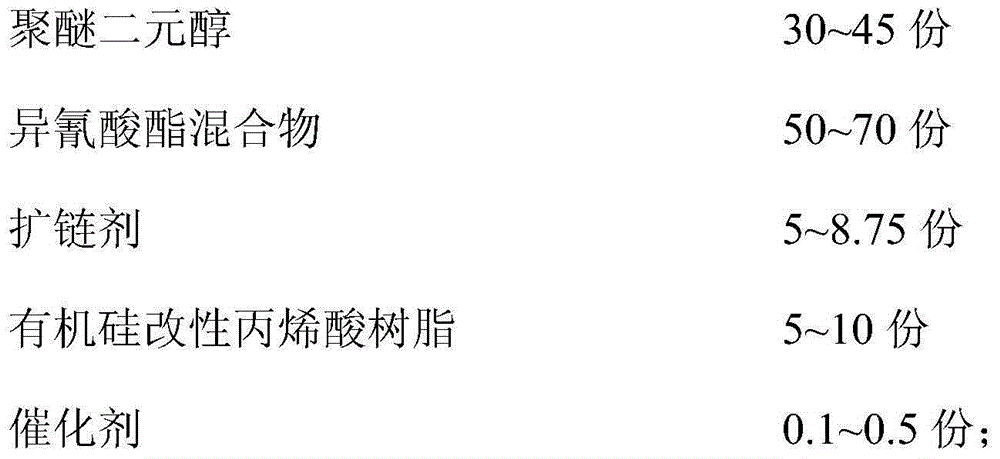

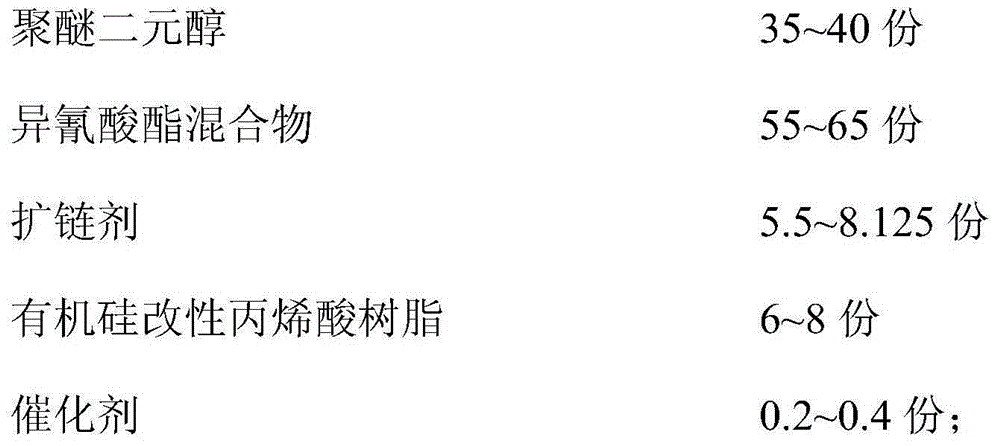

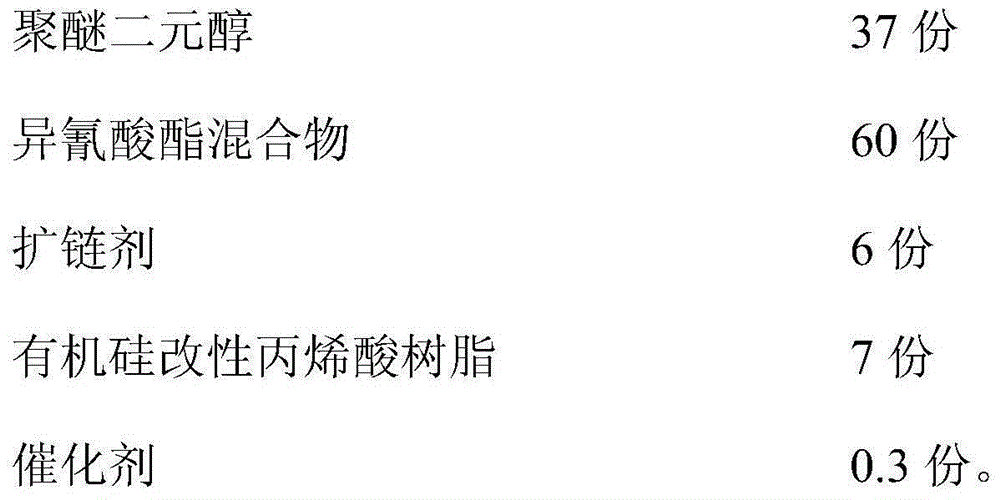

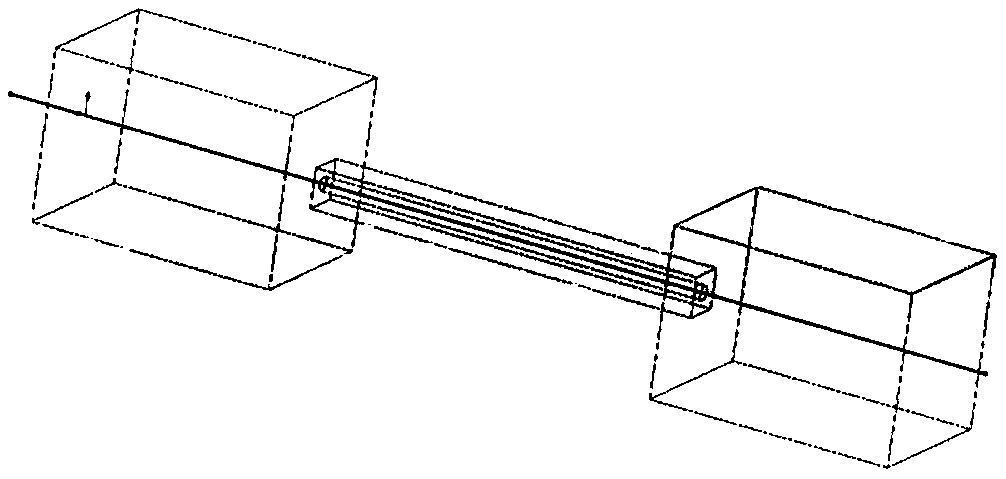

The invention provides an extrusion grade thermoplastic polyurethane elastomer and a manufacturing method thereof. The extrusion grade thermoplastic polyurethane elastomer is manufactured from, by weight, 30-45 parts of polyether diol, 50-70 parts of isocyanate mixtures, 5-8.75 parts of chain extender, 5-10 parts of silicone-modified acrylic resin and 0.1-0.5 part of catalyst. The manufacturing method includes the steps that the polyether diol and the catalyst are mixed to form a mixed material A; the isocyanate mixtures and the chain extender are fused and then mixed with the mixed material A, and the formed mixture is granulated through a double-screw extruder and then cured to manufacture the extrusion grade thermoplastic polyurethane elastomer. The manufactured thermoplastic polyurethane elastomer has high mechanical properties, the tensile strength can reach over 52 MPa, the elongation can reach over 775%, the hardness range can be 60-86A, and therefore the manufactured thermoplastic polyurethane elastomer meets the industrial requirement.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

Thermoplastic elastomer material and plastic plug made of same

InactiveCN102086287AInjection moldableIncrease elasticityPharmaceutical containersMedical packagingMarket competitionPolypropylene

The invention discloses a thermoplastic elastomer material and a plastic plug made of same. The thermoplastic elastomer material consists of the following components in percentage by weight: 40 to 60 percent of main material, 8 to 27 percent of main filler, 25 to 35 percent of toughening agent and 0 to 6.5 percent of auxiliary filler, wherein the main material is ethylene propylene rubber; the main filler contains polypropylene; and the toughening agent contains styrene, ethane, butane and styrene block copolymer (SEBS). The thermoplastic elastomer material has high elasticity, strength and resilience of rubber, and has the characteristic of capacity of being subjected to injection molding; compared with the traditional process, the method has the advantages of greatly shortening working time; and the thermoplastic elastomer material has the advantages of environmental friendliness, nontoxicity, safety, wide hardness range, good dyeing property, soft touch, weather resistance, fatigue resistance, temperature tolerance, and excellent processability, is not needed to be sulfurized, and can be recycled, so that the cost is reduced and the market competition is improved.

Owner:JIANGSU RUNDE MEDICAL MATERIALS

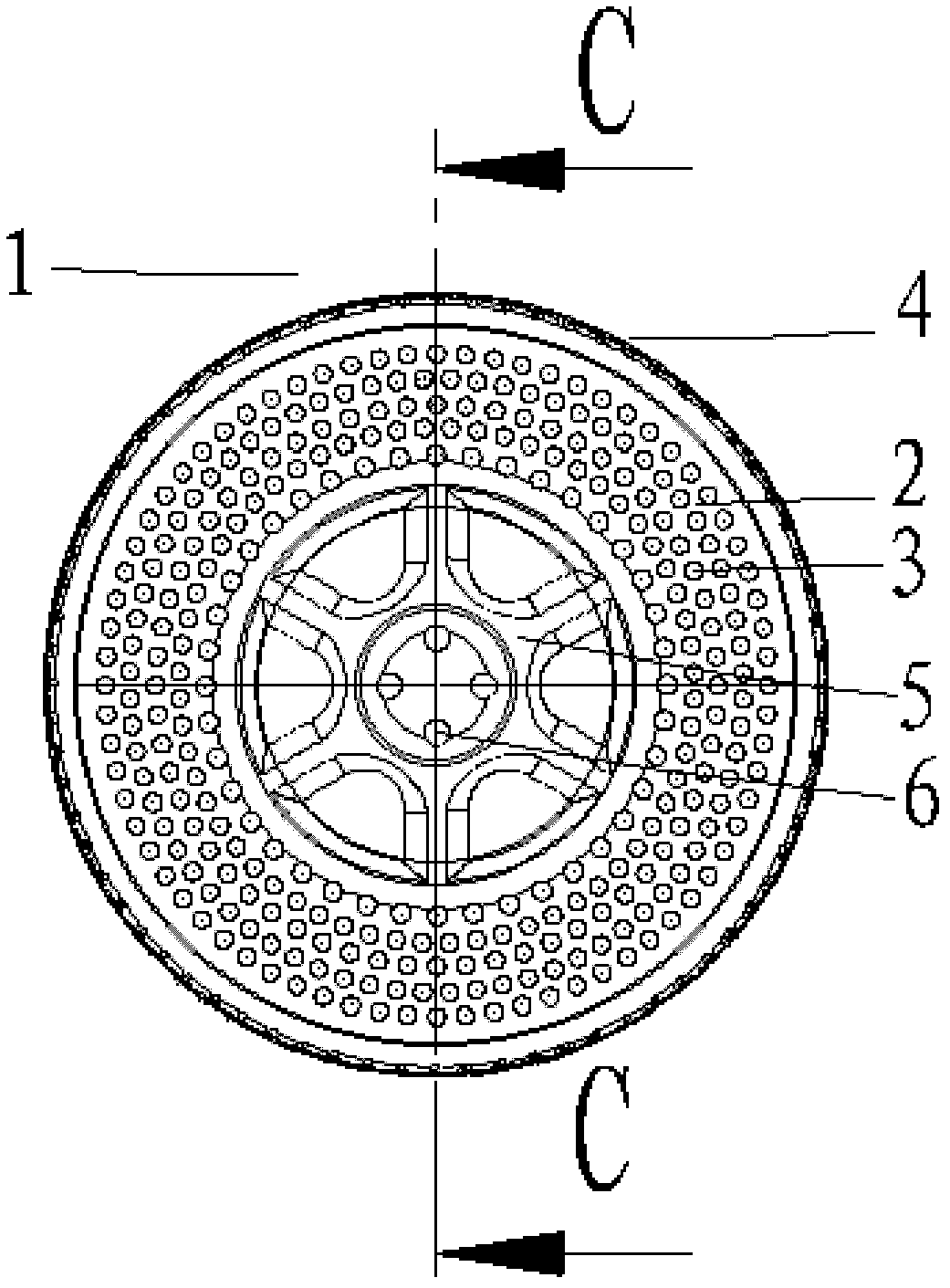

Non-pneumatic tire with rigid and flexible structure

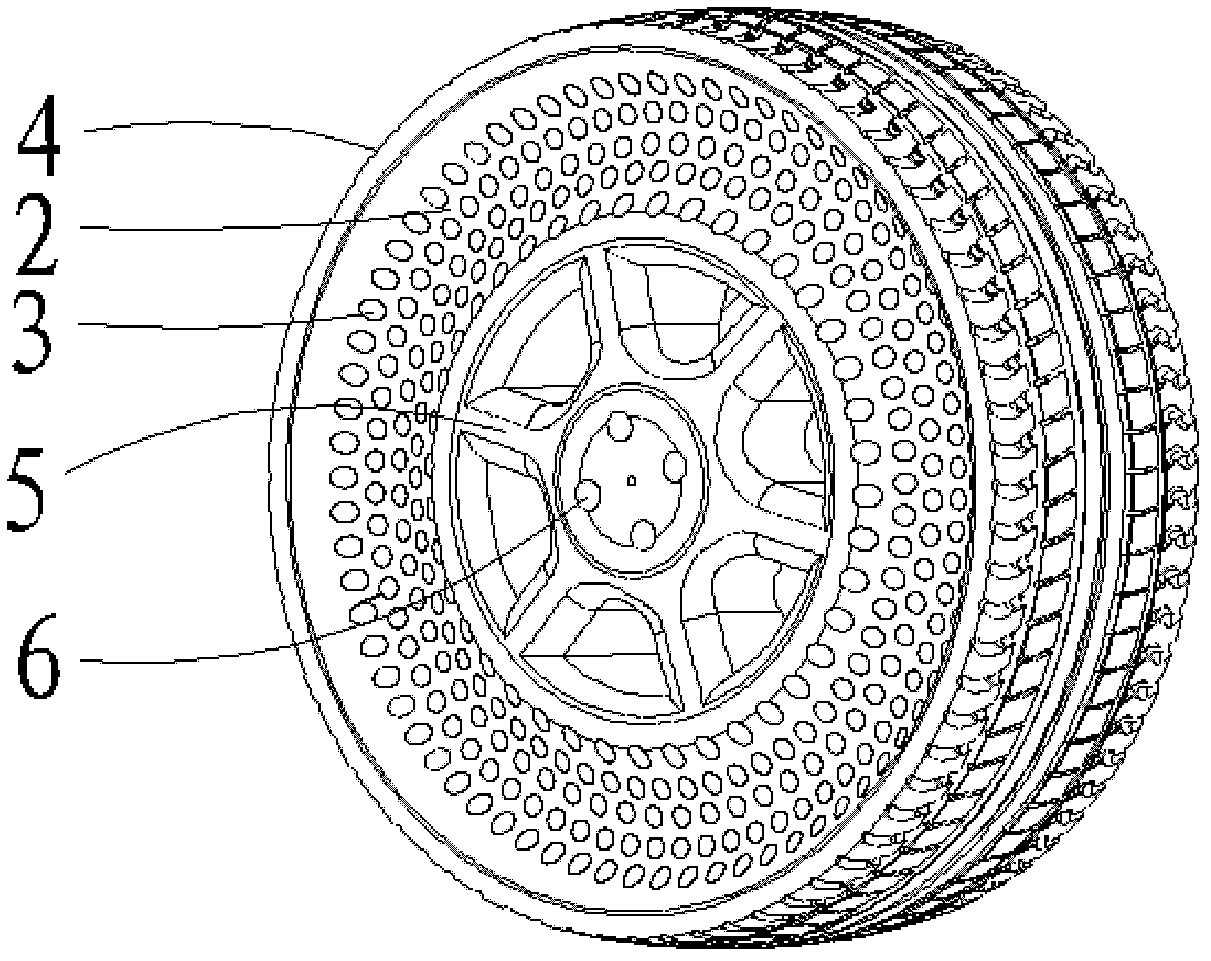

InactiveCN102582365AStrong comfortSave raw materialsNon-inflatable tyresSpecial tyresMaximum diameterThermoplastic elastomer

The invention provides a non-pneumatic tire with a rigid and flexible structure. The non-pneumatic tire mainly comprises two parts, namely a tire tread and a casing structure, wherein the tread part is mainly made of a thermoplastic elastomer, and the casing structure always extends from an inner surface of the tread to the center of a rim along the radial direction, so that the rim and the casing are combined into a whole; and the whole part is made of tough and elastic engineering plastics, an inverted conical through hole is formed in the casing part in the axial direction, and the inverted conical through hole is structurally characterized in that: holes positioned on two sides of the tire have the maximum diameter and a hole in the middle of the tire has the minimum diameter. The non-pneumatic tire with the rigid and flexible structure has the advantages of other non-pneumatic tires and is endowed with excellent structural performance and safety performance. In addition, because the casing and the rim are made of thermoplastic polymer materials, the mass of the tire is greatly reduced, and the non-pneumatic tire has a great significance for energy conservation, emission reduction and oil consumption reduction.

Owner:BEIJING UNIV OF CHEM TECH

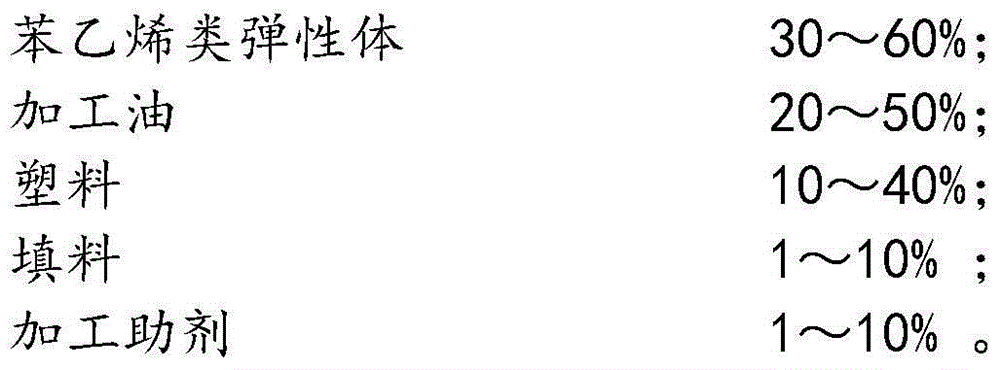

Thermoplastic elastomer medical film material

The invention provides a thermoplastic elastomer medical film material. The thermoplastic elastomer medical film material is characterized by being manufactured from the following substances in percentage by mass: 30-60% of styrene elastomers, 20-50% of processing oil, 10-40% of plastic, 1-10% of fillers and 1-10% of processing aids. Compared with the traditional medical film material, the thermoplastic elastomer medical film material provided by the invention is novel in material and excellent in performances, has the excellent performances of being capable of being recycled, simple in processing procedures, non-toxic, good in low-temperature resistance, ageing resistance and medicine resistance, wide in hardness range, light in weight, comfortable in hand feel, dry and comfortable, and the like, as well as is favoured by lots of customers.

Owner:TSRC SHANGHAI INDAL

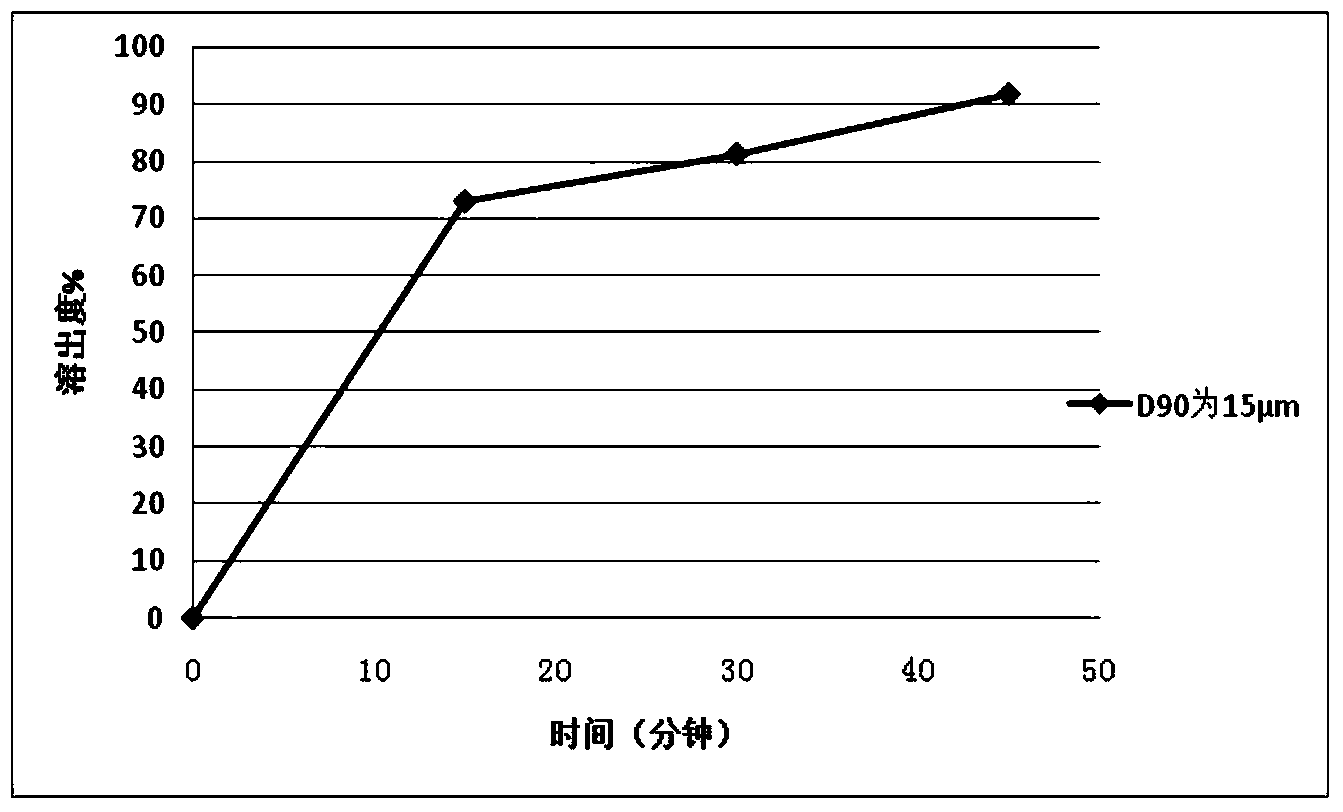

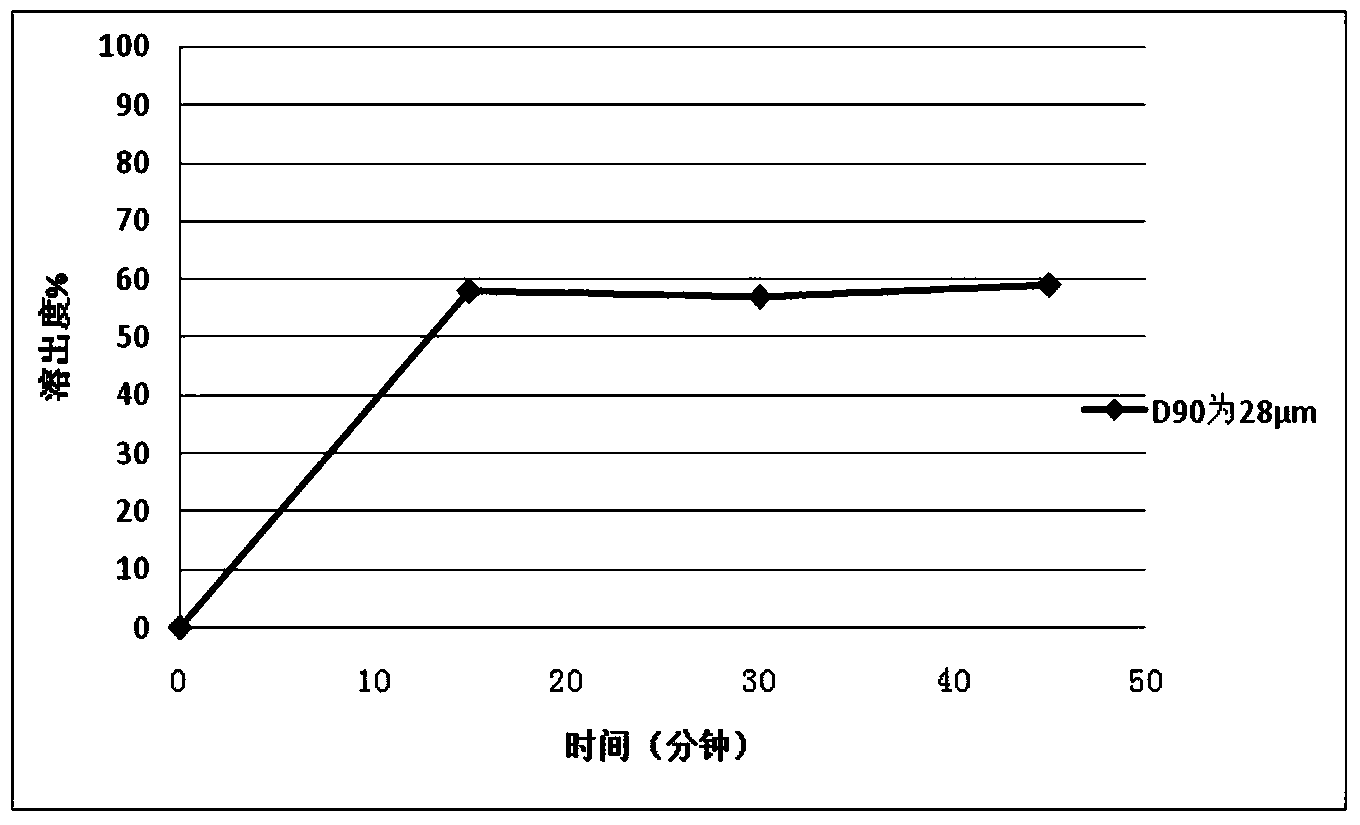

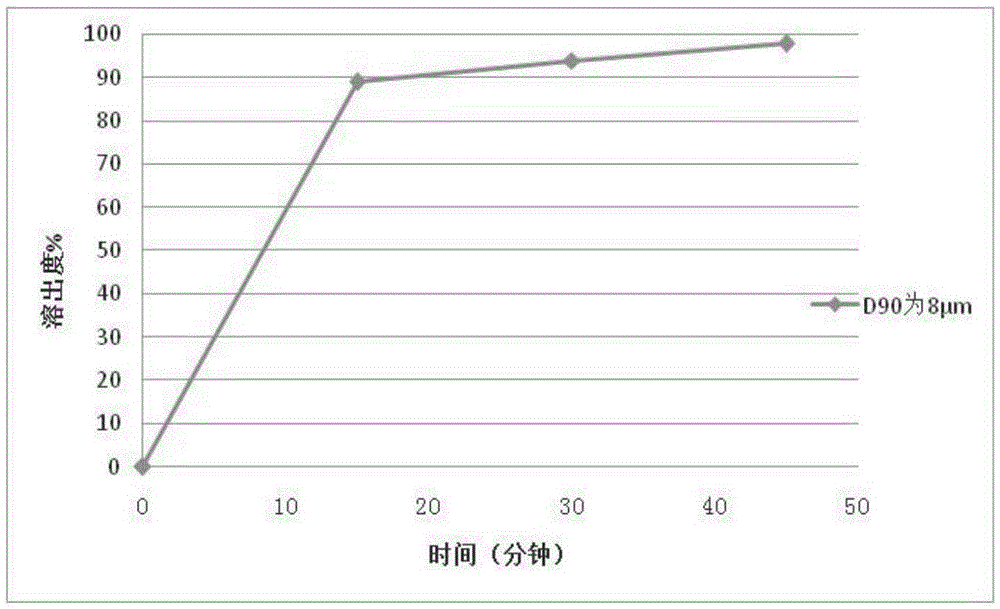

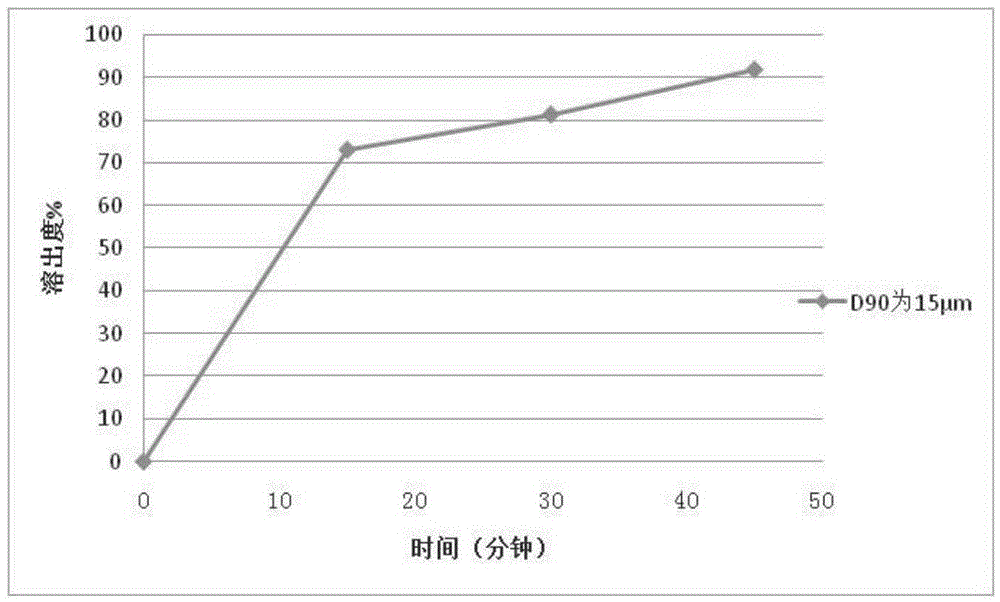

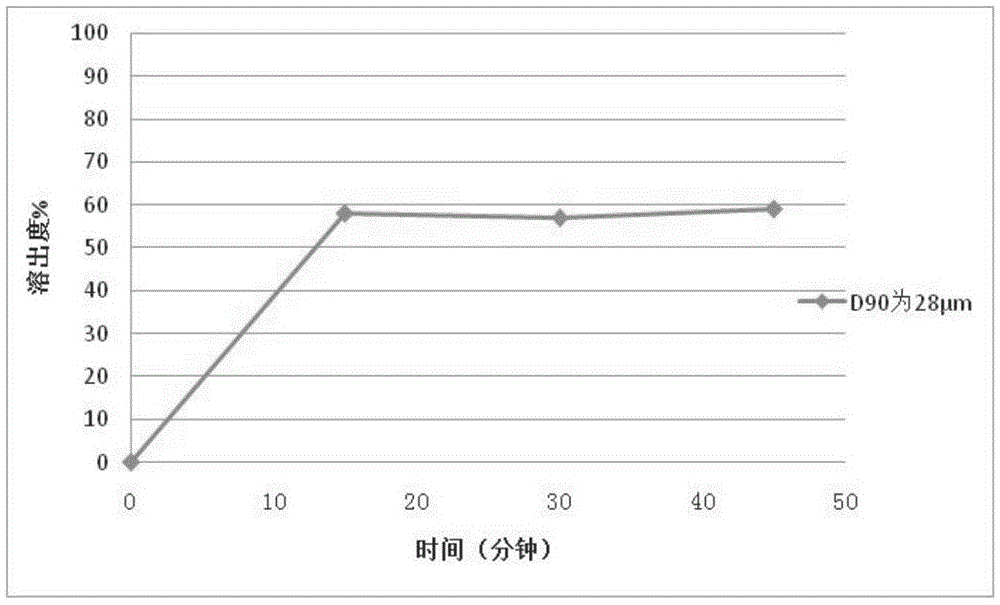

Repaglinide troche and preparation method thereof

ActiveCN103610677AAvoid stickingGood dispersionOrganic active ingredientsMetabolism disorderMedicineDissolution

The invention relates to an oral troche which contains repaglinide or pharmaceutically acceptable derivatives of repaglinide as well as a preparation method of the oral troche. According to the preparation method, powder of repaglinide or pharmaceutically acceptable derivatives of repaglinide is directly pressed into troche, so that the production cost is remarkably lowered, and the disintegration and the dissolution rate are greatly improved. The bioavailability and the stability of the medicine can be improved, and the problem of low content uniformity of existing small-dose medicines formed by the direct pressing method is overcome, so that the quality of the troche is better guaranteed.

Owner:华益泰康药业股份有限公司

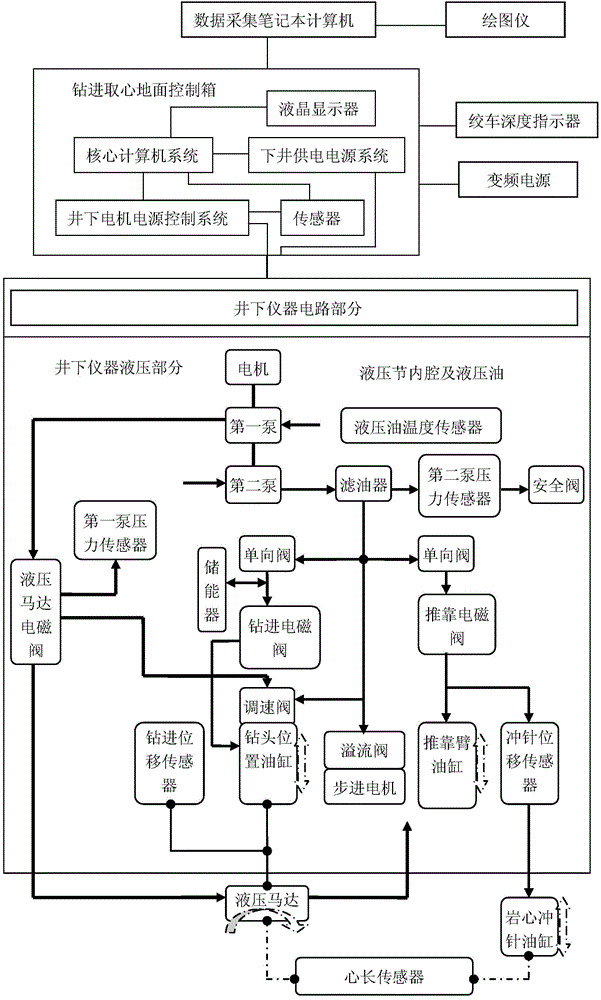

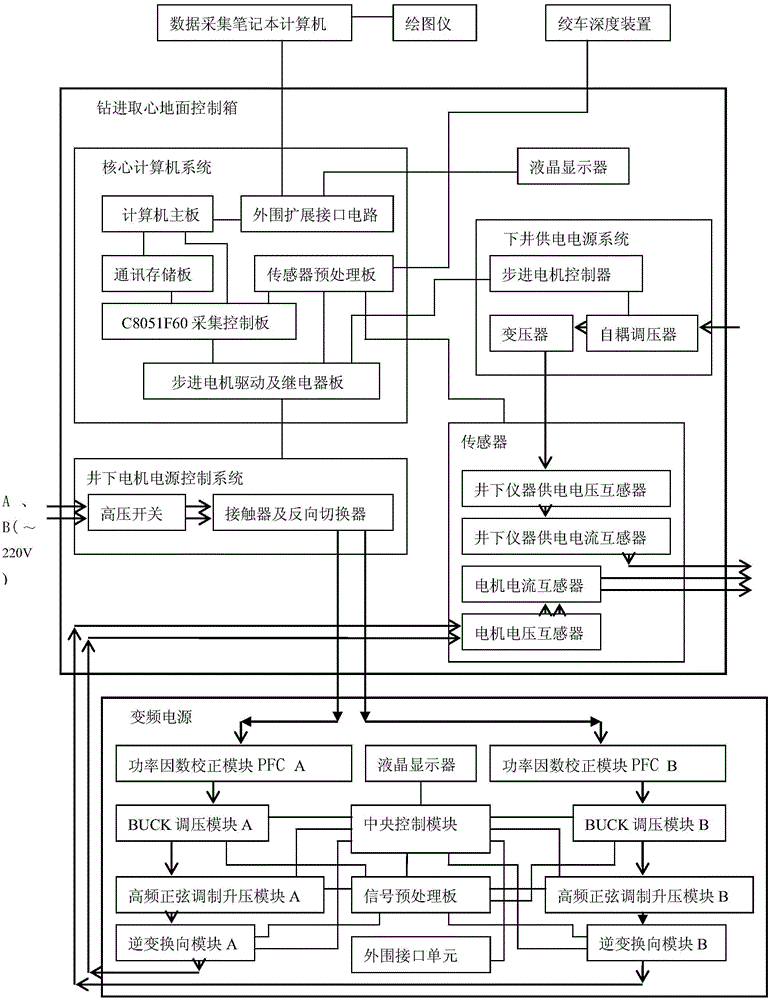

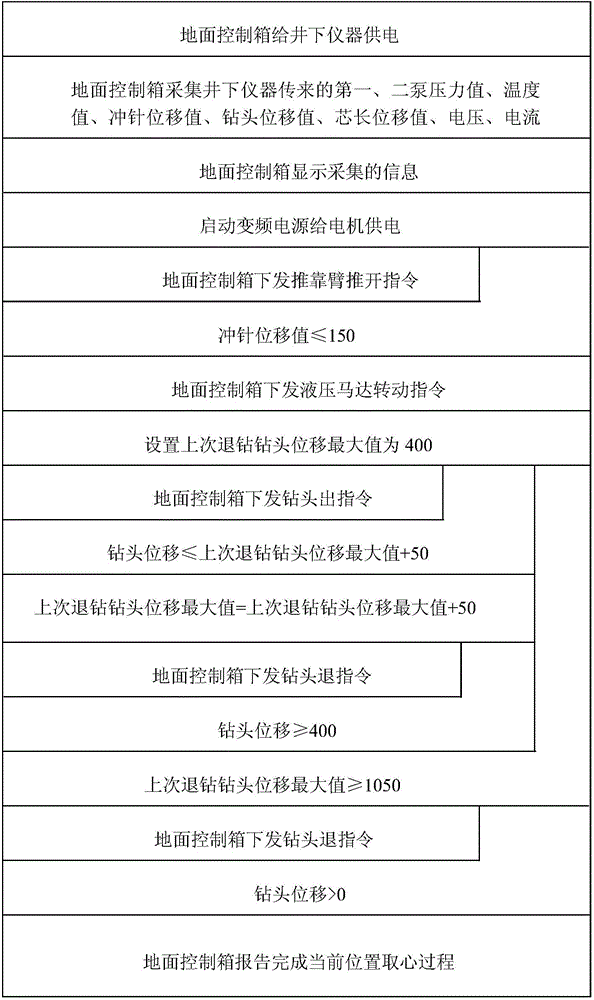

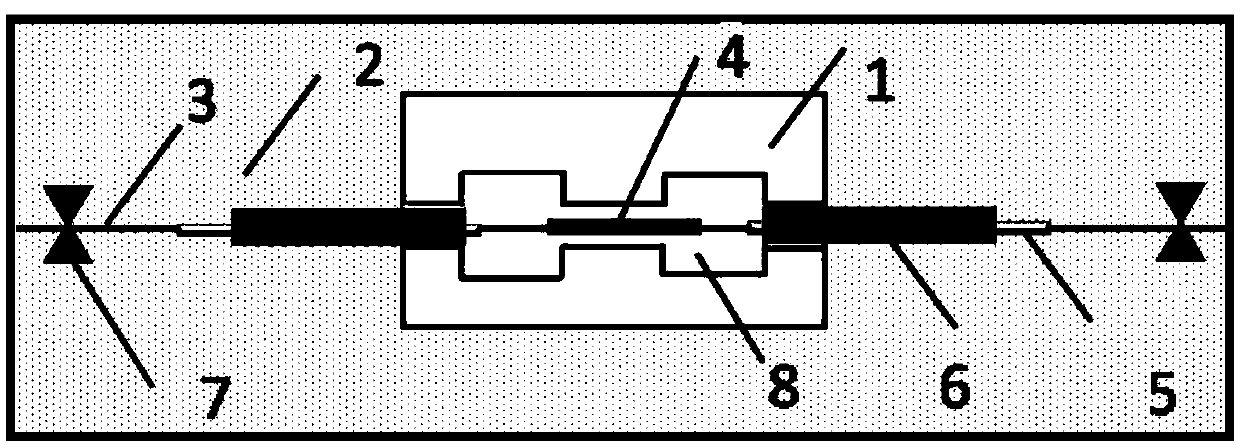

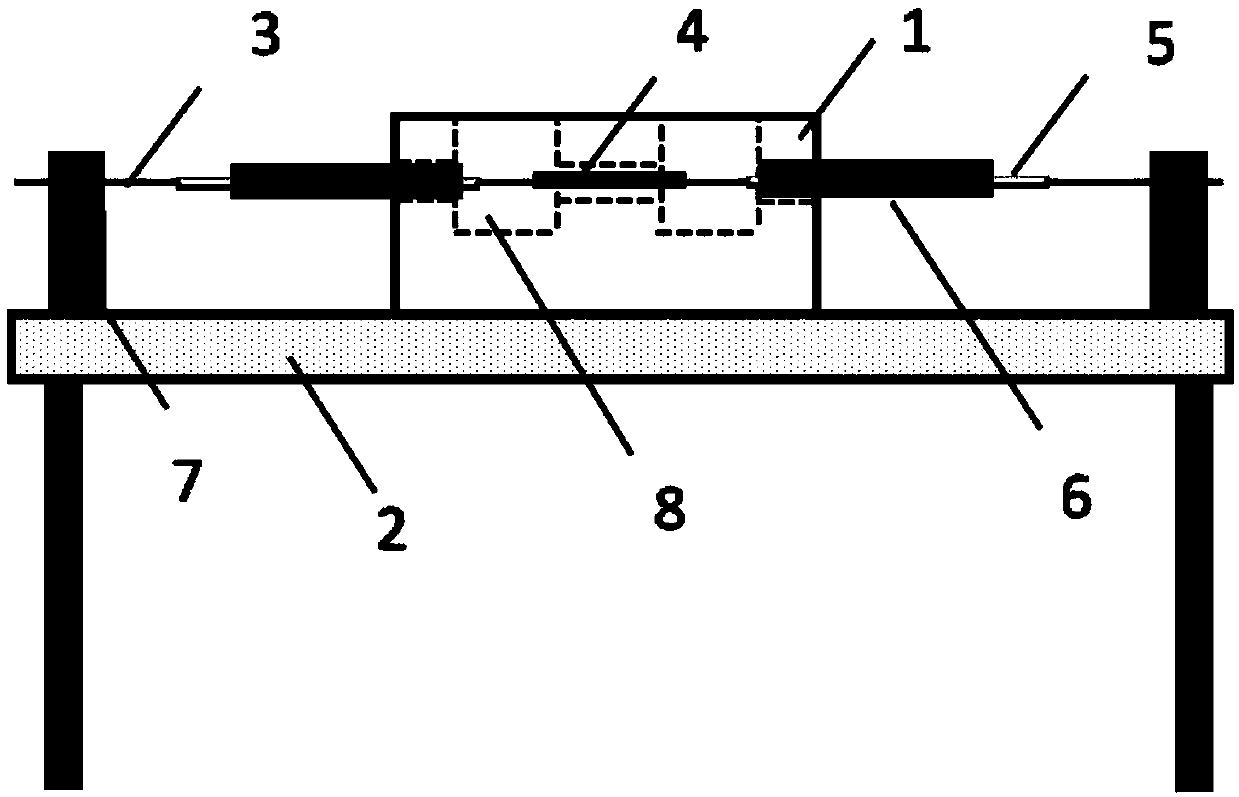

Control system and control method of logging drilling sidewall coring tool

ActiveCN104373120AWill not affect working statusFulfill control requirementsBorehole/well accessoriesHydraulic motorAutomatic control

The invention discloses a control system of a logging drilling sidewall coring tool. The control system comprises a drilling coring ground control box, a winch depth device, a variable frequency power source, a downhole instrument circuit part and a downhole instrument hydraulic part, wherein data acquisition and feedback control are performed on the coring tool through the drilling coring ground control box, various states of a downhole instrument can be detected in time through the downhole instrument circuit part, the power supply state of a downhole motor and the power supply state of the downhole instrument are monitored through a sensor, and the downhole motor can be adjusted and controlled by processing acquired data and controlling the variable frequency power source. According to a control method, automatic control over coring of the coring tool is achieved through the ground control box, an execution motor can be continuously started, a backup arm expands, the stretching displacement of a punch pin is minimal, the pressure of a second pump is maximal, a hydraulic motor rotates, a drill bit stretches out, the hydraulic motor stops rotating when the drilling displacement reaches the core breaking position, and a series of continuous actions that the core breaking drill bit retreats and is taken back is completed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

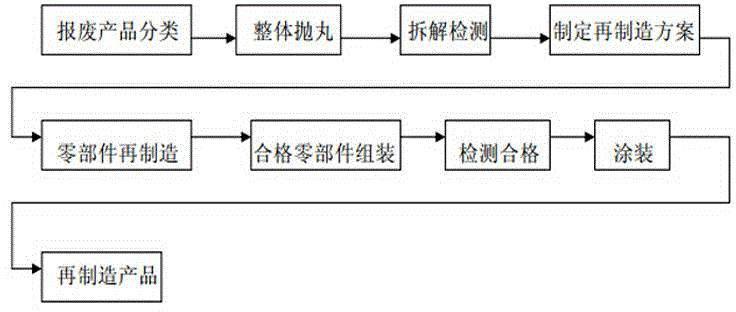

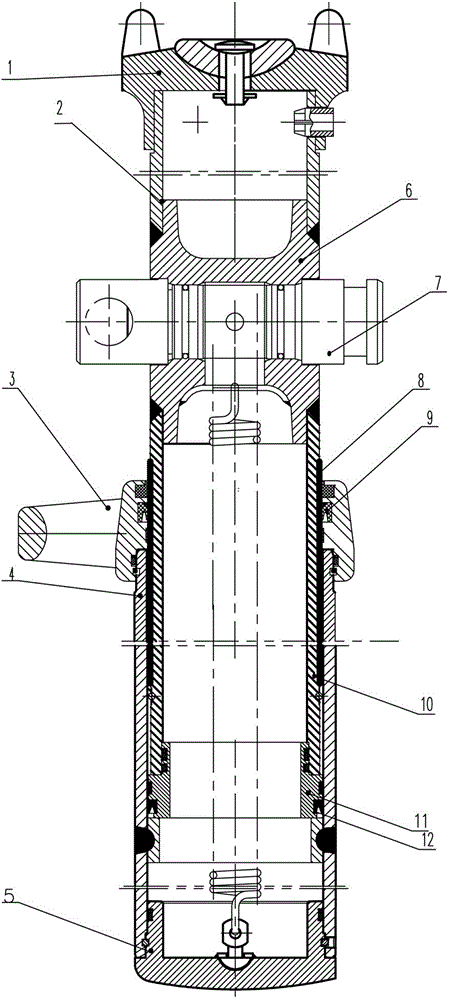

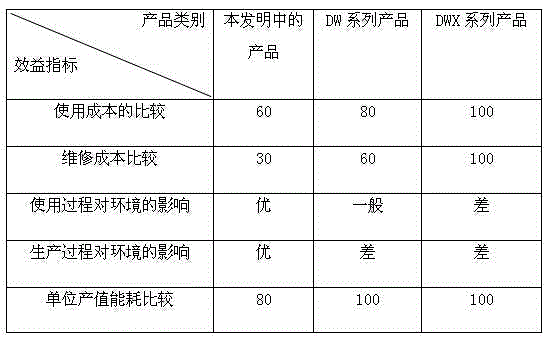

Technology method for re-manufacturing individual hydraulic prop

InactiveCN105215620AWide range of hardnessIncrease elasticityProps/chocksElastomerThermoplastic elastomer

The invention belongs to the field of an individual hydraulic prop in mineral supporting and protecting equipment, and particularly relates to a technology method for re-manufacturing an individual hydraulic prop. The technology method is characterized by comprising the following steps: (1) carrying out integral shot-blasting processing on scrapped mineral individual hydraulic props; (2) classifying, according to specifications and models, the individual hydraulic props subjected to shot-blasting; (2) dismounting classified products into parts, cleaning the parts and classifying the cleaned parts; (3) inspecting and detecting the dismounted parts; (4) making, according to the inspected and detected results, a re-manufacturing technical scheme; (5) re-manufacturing or replacing the parts, particularly replacing a handle body with a novel handle body which can be sealed between an oil cylinder and the outer surface of a plunger; and carrying out surface composite treatment on the outer surface of the plunger by use of thermoplastic elastomer and taking the plunger as a sealing surface; and (6) assembling the parts which meet the quality requirements to form an individual hydraulic prop product which meets the product quality requirements. The technology method for re-manufacturing the individual hydraulic prop can sufficiently utilize waste to reduce the manufacturing cost. The individual hydraulic prop has the advantages of being long in service life, resistant to corrosion and resistant to cracking.

Owner:王学伟

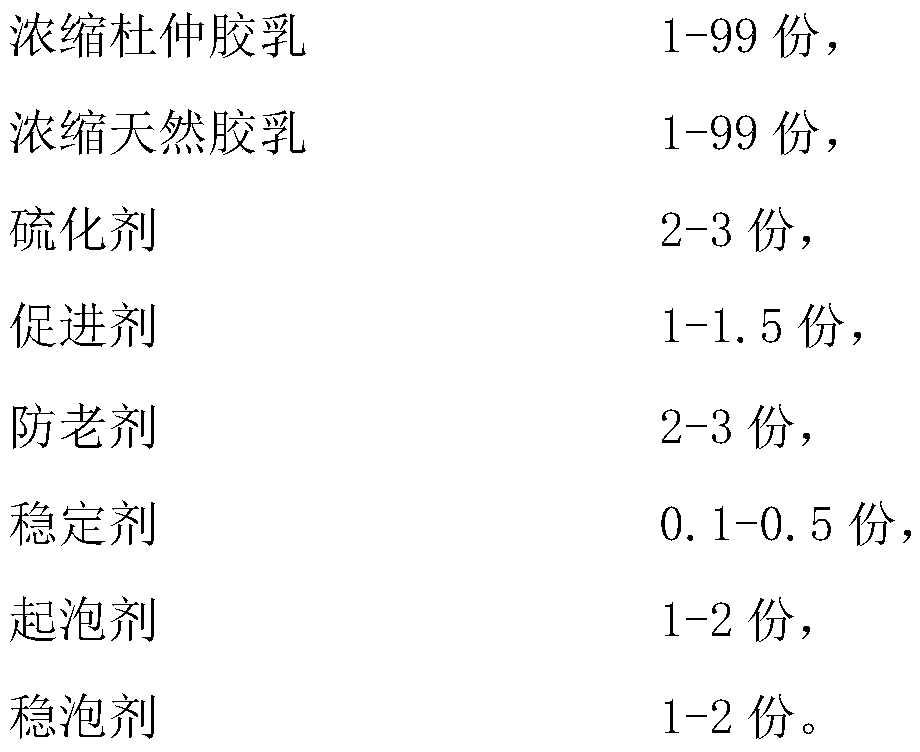

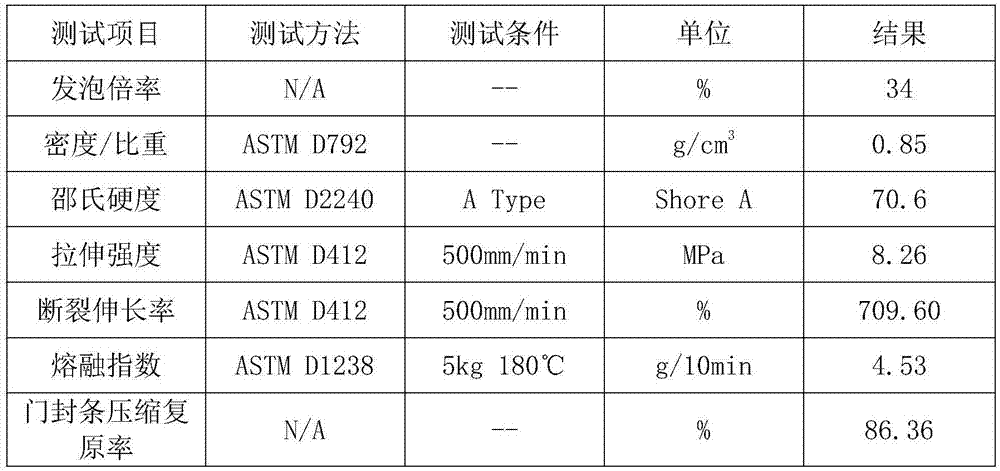

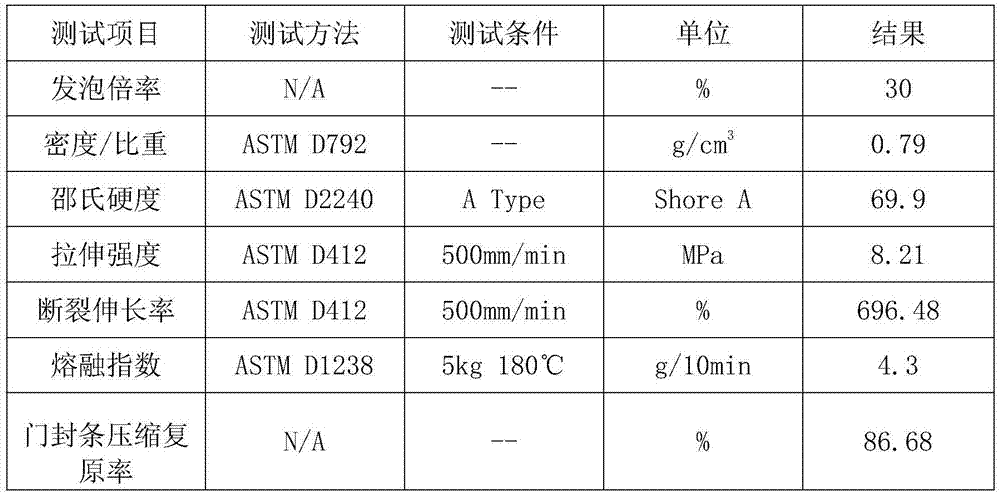

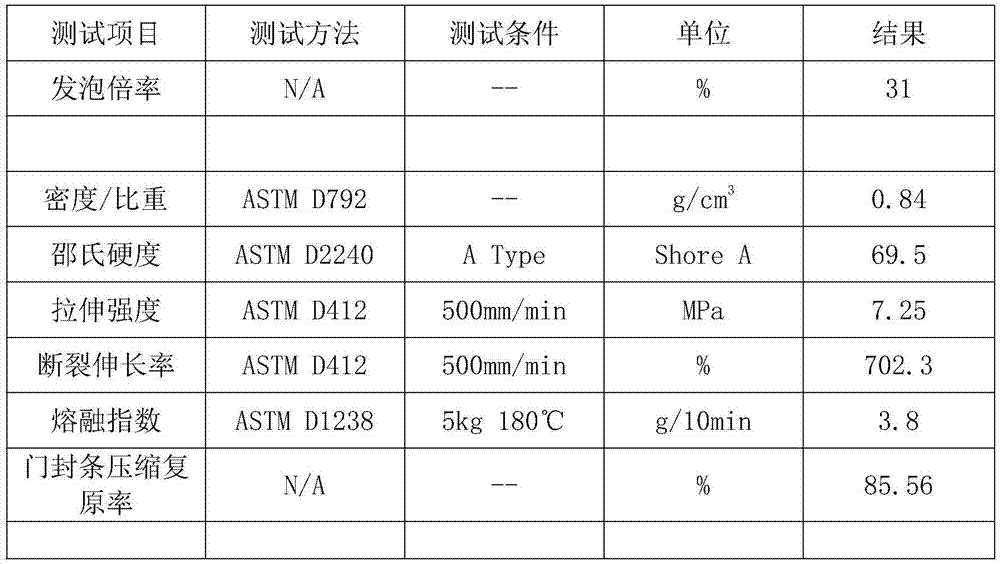

Gutta-percha/natural latex sponge product and preparation method thereof

ActiveCN110437510ASignificant technological progressHigh total solid contentFoaming agentGutta-percha

The invention provides a gutta-percha / natural latex sponge product. The gutta-percha / natural latex sponge product is prepared from the following components: gutta-percha emulsion, natural latex, a vulcanizing agent, an active agent, an accelerant, an antiager, a filler, a stabilizer, a PH value adjust, a gelatinizer, a foaming agent, a foam stabilizer, and a blowing agent in proportion, and the gutta-percha emulsion and the natural latex are correspondingly concentration emulsion. A preparation method of the gutta-percha / natural latex sponge product comprises the steps that first, the gutta-percha emulsion and the natural latex are mixed in proportion, deammoniation is conducted through a simultaneous ongoing method of mechanical stirring and air drafting, thenvarious kinds of powder typeauxiliaries and emulsifying oil auxiliaries which are grinded into dispersoid are added into a mixture latex material, after ripening, air is inflated under the mechanical stirring, foam is generatedto expand foam, after foaming, the foam is solidified with the gelatinizer, after vulcanization, washing and dewatering and drying of the solidified foam, the gutta-percha / natural latex sponge is obtained. According to the gutta-percha / natural latex sponge product and the preparation method thereof, successfully development of the gutta-percha / natural latex sponge product expands application prospects of gutta-percha, and promotes the technical progress of the gutta-percha.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

Ultrahigh-resilience wear-resistant durable TPR trundle material and preparation method thereof

InactiveCN110483937AIncreased tensile strength and elongation at breakGood wear resistancePolypropyleneChemistry

The invention relates to an ultrahigh-resilience wear-resistant durable TPR trundle material and a preparation method thereof, and belongs to the technical field of preparation of new materials. The trundle material is prepared from the following components of hydrogenated styrene-ethylene-butylene-styrene elastomer, white oil, polypropylene, polyolefin elastomer, thermoplastic polyester elastomerTPC-ET, polyolefin PE and a processing aid. The preparation method comprises the following steps of a, weighing the raw materials according to ingredients; b, adding the weighed hydrogenated styrene-ethylene-butylene-styrene elastomer SEBS into a high-speed mixer, and uniformly spraying the white oil onto the surface of the SEBS elastomer to enable the white oil to be absorbed by the SEBS elastomer; c, sequentially adding the weighed polypropylene, polyolefin elastomer, thermoplastic polyester elastomer, polyolefin and processing aid into a mixer, and uniformly stirring to obtain a mixture; and d, pouring the prepared mixture into a twin-screw extruder, and carrying out melt extrusion granulation. The trundle material prepared by the invention has a relatively wider hardness range.

Owner:廊坊诚通高分子材料科技有限公司

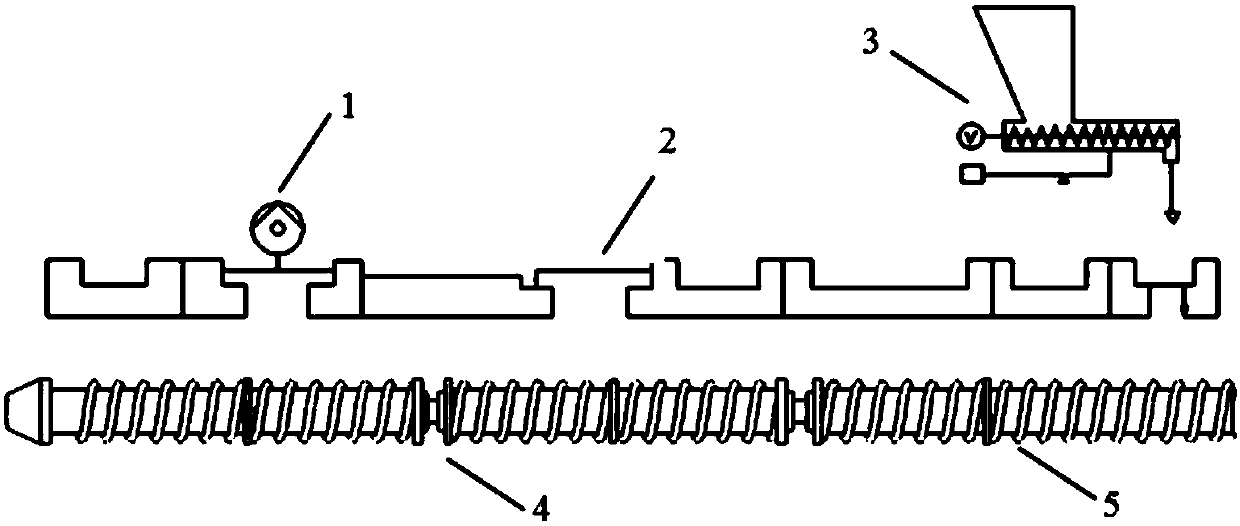

Thermoplastic elastomer foamed door seal strip and preparation method thereof

The invention discloses a thermoplastic elastomer foamed door seal strip and a preparation method thereof. The thermoplastic elastomer foamed door seal strip is characterized by being prepared from the following materials for preparation in parts by weight: 60 to 110 parts of styrene elastomer, 10 to 30 parts of high-density polyethylene, 10 to 40 parts of polypropylene, 60 to 110 parts of filling oil, 30 to 80 parts of mineral filler, 1 to 5 parts of lubricant, 1 to 5 parts of coupling agent, 0.1 to 2 parts of antioxidant, 0 to 5 parts of crosslinking agent and 1 to 8 parts of foaming agent. The preparation method is as follows: the styrene elastomer and the filling oil among the materials according to parts by weight are first sufficiently mixed for absorption, the other components are then added and uniformly mixed, the uniformly mixed materials are extruded by a double-screw extruder for pelletization, and the pelletized material is sent into a single-screw extruder and extruded out to be shaped. According to the preparation method, in the process of production, no wastewater and waste gas are produced, no solvents are discharged, halogen is not contained, scraps can be recycled, and a product has the advantages of good elasticity, high strength, good compressive resilience, low specific gravity, adjustable density, smooth surface and good welding effect.

Owner:ANHUI HIGASKET PLASTICS CO LTD

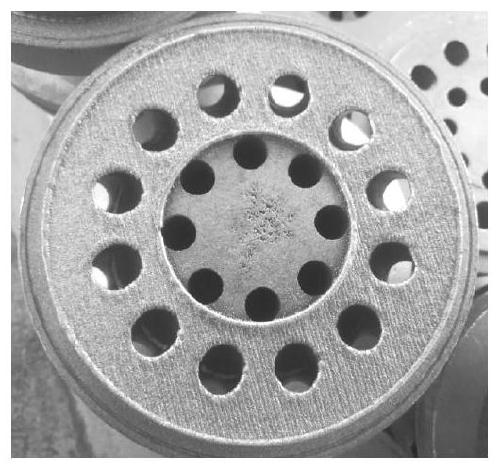

Nano modified urethane elastomer tyre material for tracked vehicle road wheel and moulding technique thereof

The invention discloses a nanometer modified PU Elastomers tyre carcass material for the loading wheel of a caterpillar and is characterized in that a nanometer modified prepolymer is made from polytetrahydrofuran dihydric alcohol, PPDI, surface modified inorganic nano-powder silicon dioxide or titanium oxide and epoxide resin / phenolic resin and is then thermally cross-linked with methylene di-ortho-chloro aniline to form the nanometer modified PU Elastomers tyre carcass material. A finished loading wheel can be formed by pouring the tyre carcass material on a metallic wheel body. The invention has the advantages of reducing the internal dynamic heat generation of PU Elastomers by modification, improving the heat-proof aging and anti-hydrolysis performances of the tyre carcass of the loading wheel, giving full play to excellent performances such as high strength, good wear resistance, wide hardness range and the like, and endowing the loading wheel with superior property.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

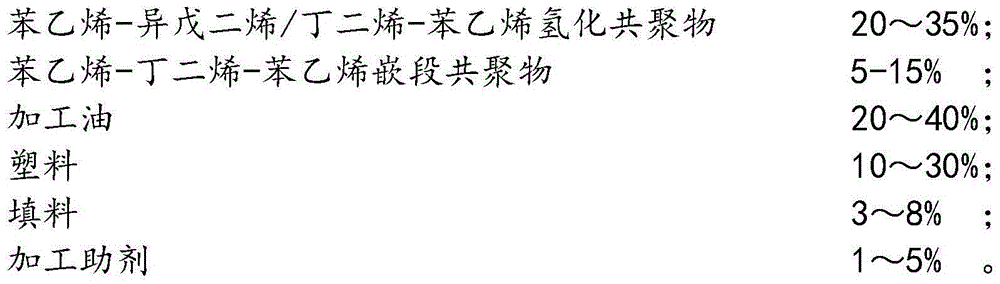

Thermoplastic elastomer material for industrial/medical caster

The invention belongs to the technical field of rubber, and particularly relates to a thermoplastic elastomer material for an industrial / medical caster. The thermoplastic elastomer material comprises, in weight percent, 30%-60% of styrene block copolymer, 20%-50% of paraffin oil, 14%-30% of polypropylene, 0.1%-2% of silicone, 0.05%-0.5% of antioxidant and 0.1%-2% of sound absorption substances. Compared with the prior art, the thermoplastic elastomer material prepared by a formula and a process has various excellent performances such as high elasticity, high strength, high resilience, high wear resistance, aging resistance, oil resistance, weather resistance and fine sound absorption effect of traditional cross-linked vulcanized rubber, so that the caster produced by the formula and the process has excellent bearing capacity, wear resistance, higher elastic shockproof property and better mute effects.

Owner:DONGGUAN LIHONG PLASTIC CO LTD

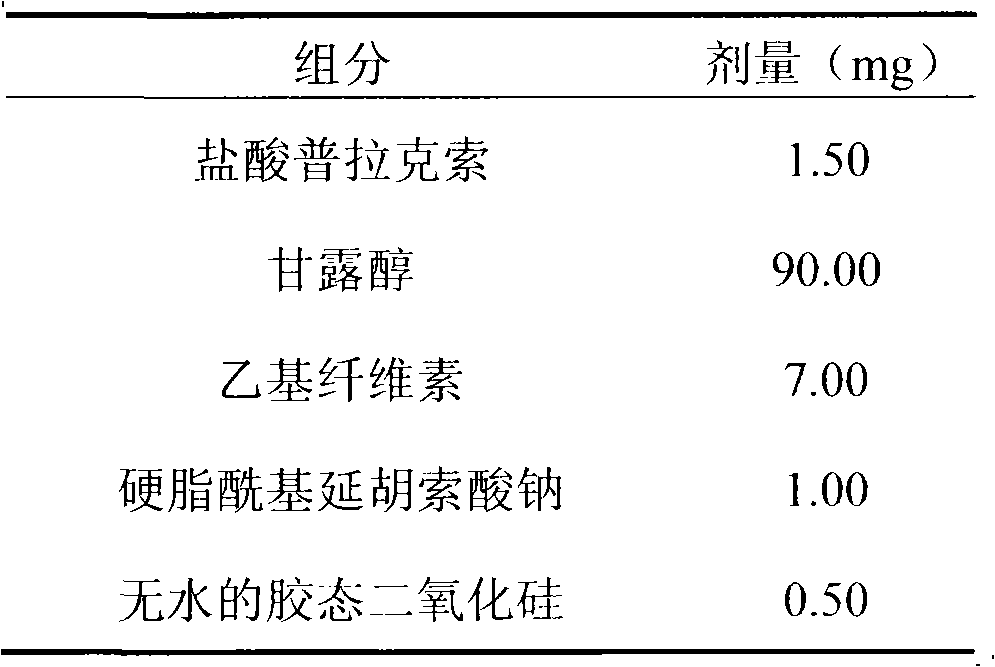

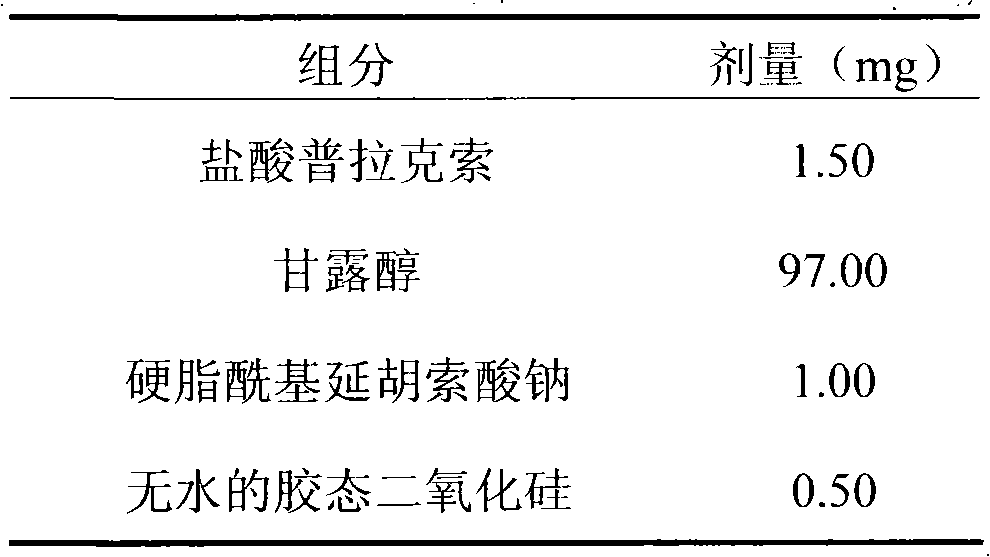

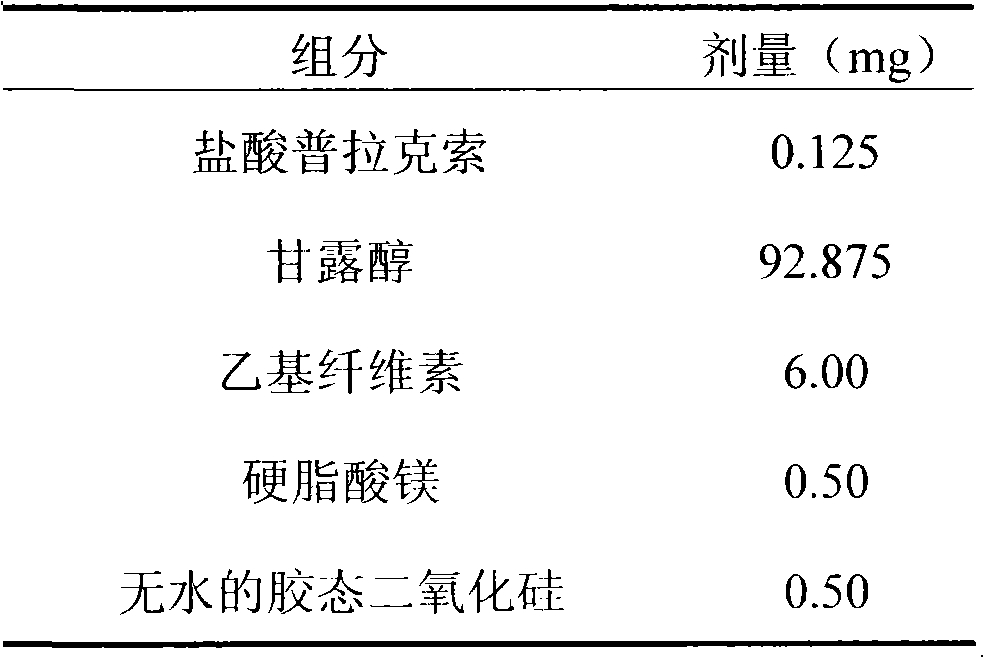

Pramipexole-contained pharmaceutical composition capable of being dispersed in mouth

InactiveCN101766605AWide range of hardnessLow friabilityOrganic active ingredientsPill deliveryMedicinePramipexole

The invention relates to a pramipexole-contained pharmaceutical composition capable of being dispersed in a mouth, which is characterized by containing pramipexole or medicinal salt thereof or pharmaceutically acceptable auxiliary materials. The invention is used for the technical field of medicines.

Owner:BEIJING D VENTUREPHARM TECH DEV

Novel material for needled carpet of car

ActiveCN102464853AImprove low temperature resistanceImprove wear resistanceFloor carpetsElastomerEnvironmental resistance

The invention discloses a novel material for a needled carpet of a car. The novel material is prepared by the following steps of: taking 38-42wt% of styrol elastomer (SBS) as a main formula; adding auxiliary materials including 8-1wt% of processing oil, 24-26% of polyethylene, 22-26wt% of filler and 1wt% of processing aid, mixing, and then extruding and pelleting. In the invention, the novel styrol elastomer is taken as a main material, therefore, the novel material has excellent performances such as recyclability, simple processing process, environment friendliness, favorable low-temperature resistance, wide hardness, light weight, comfortable handfeel, no stickiness on hands, sound-adsorption and shock-adsorption properties and the like.

Owner:TSRC SHANGHAI INDAL

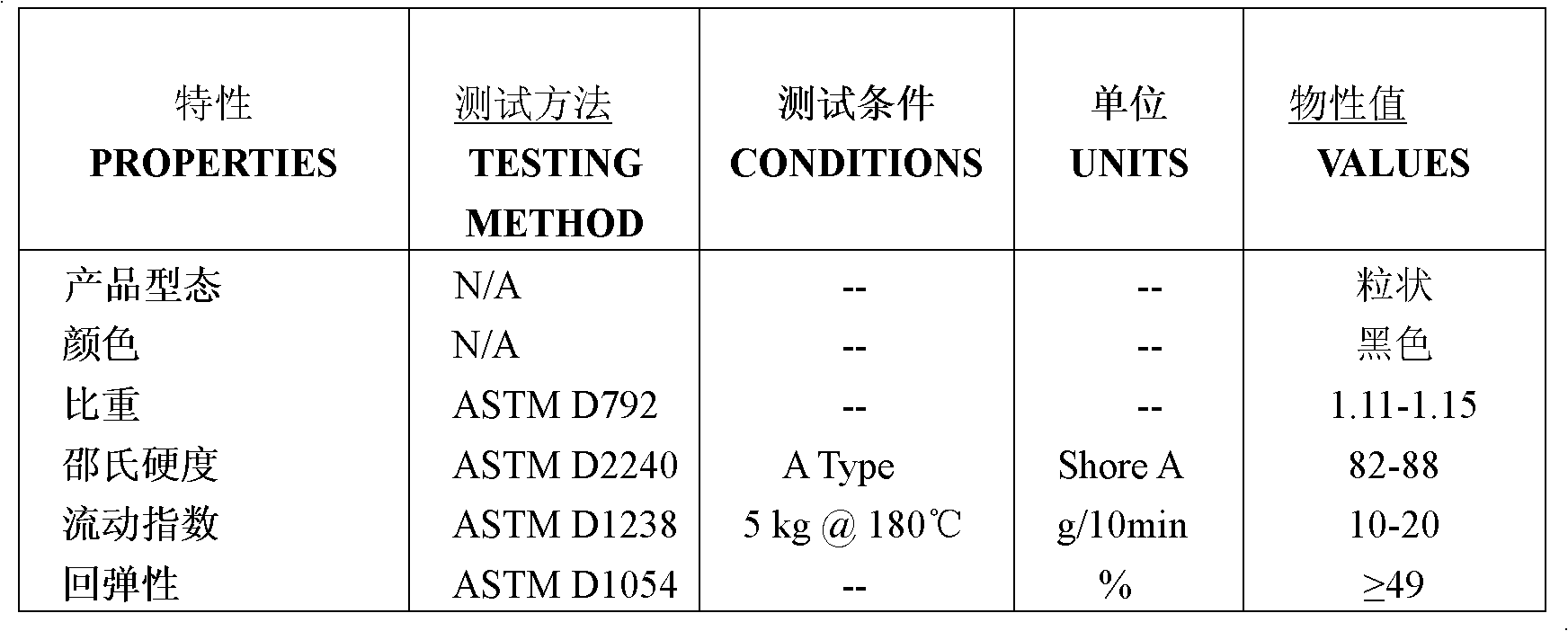

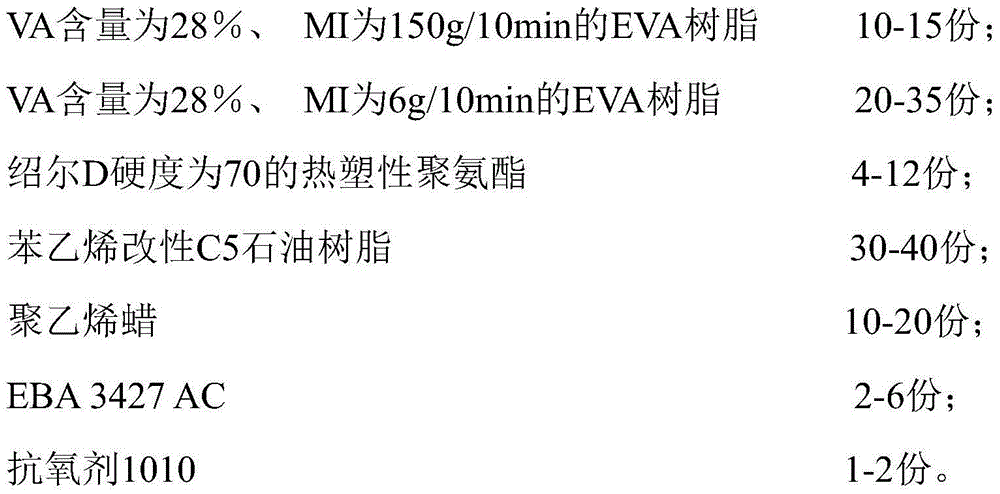

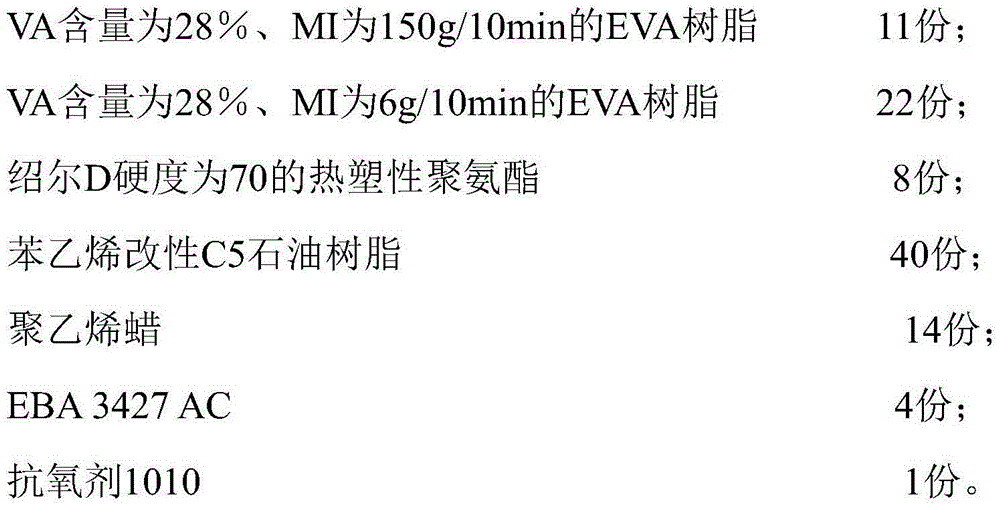

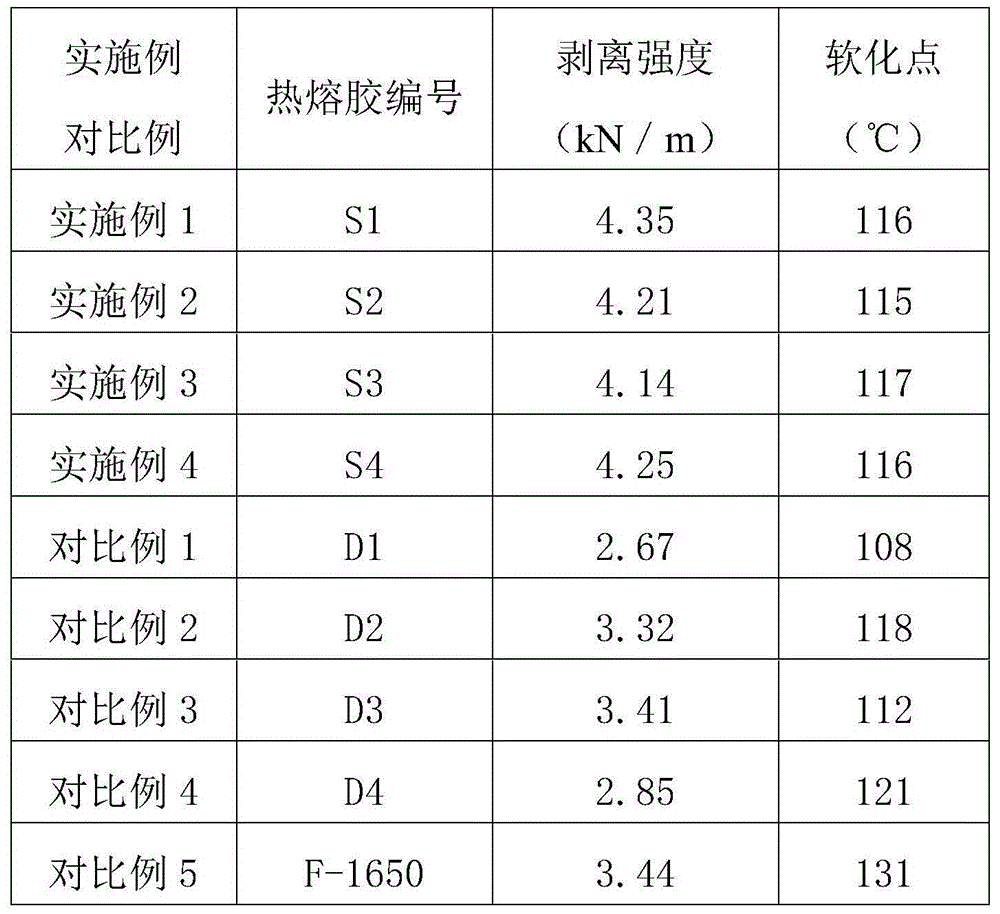

Hot melt adhesive for acrylic hot-fix rhinestone and preparation method thereof

ActiveCN105273669AAdjust melt viscosityReduce crystallinityMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesPetroleum resinThermoplastic polyurethane

The invention provides a hot melt adhesive for an acrylic hot-fix rhinestone. The hot melt adhesive comprises the following components by weight: 10 to 15 parts of EVA resin with the VA content of 28% and the MI of 150 g / 10min, 0 to 35 parts of EVA resin with the VA content of 28% and the MI of 6 g / 10min, 4 to 12 parts of thermoplastic polyurethane with Shore D hardness of 70, 30 to 40 parts of styrene modified C5 petroleum resin, 10 to 20 parts of polyethylene wax, 2 to 6 parts of EBA3427AC and 1 to 2 parts of an antioxidant 1010. The hot melt adhesive for the acrylic hot-fix rhinestone provided by the invention has a hot-press temperature of 115 to 120 DEG C, is not prone to scalding the acrylic hot-fix rhinestone and fabrics, and has peeling strength of no less than 4.0kN / m , thereby having high bonding strength at the same time; meanwhile, the hot melt adhesive has the advantage of good adhesive force with a variety of fabrics and acrylic hot-fix rhinestones, and is an ideal hot melt adhesive for the acrylic hot-fix rhinestone.

Owner:HUANGSHAN XINDECHENG GLUE IND CO LTD

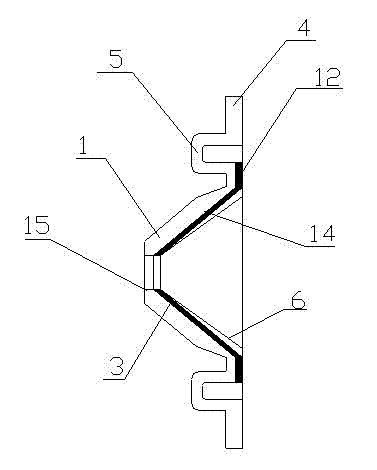

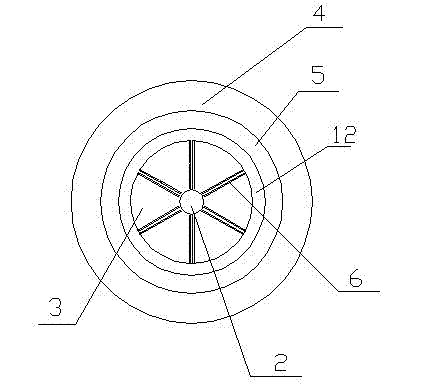

Seal ring and puncture cannula with same

Owner:佛山特种医用导管有限责任公司

Method for preparing sensor by using polyurethane package fiber grating

InactiveCN108680289AWith wear resistanceWide range of hardnessForce measurement by measuring optical property variationPolyurethane elastomerFiber

The invention provides a method for preparing a sensor by using a polyurethane package fiber grating and belongs to the technical field of optical fiber communication and light sensing. According to the method, polyurethane is used as a packaging material. The method comprises a step of fixing a package mold on a fiber platform, peeling a coating of a grating region and allowing the grating regionto enter a capillary steel pipe, fixing a bare fiber on the fiber platform with a clamp to ensure that the fiber is placed at an axis center of the mold, a step of sleeving two ends of the bare fiberwith protective sleeves in order, and a step of pouring the polyurethane into the mold which is coated with a release agent in advance, placing the mold into a vacuum box to be dried and solidified.The fiber grating and a fiber core with the removal of a coating are packaged with polyurethane elastomers to avoid the incompatibility of different materials. The package method of the invention is simple, reliable and portable, the prepared sensor can be monitored by changing the stress, temperature and the like of equipment, the method can be suitable for various industrial applications, and the stability, reliability and sensitivity of the packaged fiber grating are significantly improved.

Owner:DALIAN UNIV OF TECH

Material used for 3D printing and preparation method thereof

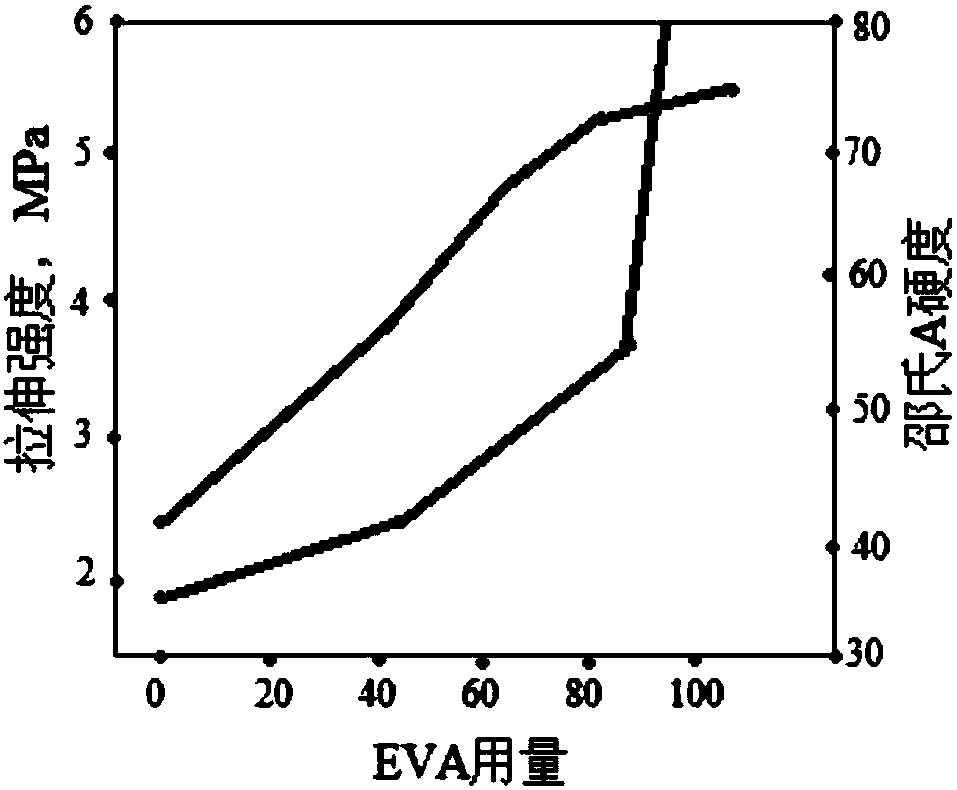

ActiveCN107746501AMeet the molding processWide range of hardnessAdditive manufacturing apparatusEmulsionPolymer science

The invention discloses a material used for 3D printing. The material used for 3D printing comprises 60-96.5% of an ethylene-vinyl acetate copolymer, 1-6% of emulsion polymerized butadiene styrene rubber, 1-6% of solution polymerized styrene butadiene rubber, and 2-6% of auxiliary modified materials, the auxiliary modified materials mainly comprise 5-22% of a cross-linking agent, 38-57% of a compounding agent, 8-17% of an anti-oxidant, 4-7% of a flexibilizer, 8-17% of an anti-hydrolysis agent, and 5-20% of a melt fusion reinforcing agent. In addition, the invention also relates to a preparation method of the material. The material used for 3D printing has wider printing hardness scope, can realize a plurality of hardness gradients, has the characteristics of high fluidity, high toughness,low shrinking percentage, and high printing precision, is suitable for fused deposition for 3D printing rapid molding, and can better satisfy a moulding processing technology of the material used for3D printing.

Owner:王臻 +1

Wet and dry dual use powder puff and preparing method thereof

InactiveCN107232734AImprove impact resistanceImprove shock absorptionSynthetic resin layered productsLaminationMetallurgyAdhesive

The invention discloses a wet and dry dual use powder puff and a preparing method thereof. The powder puff comprises a dry powder puff layer and a wet powder puff layer, wherein the dry powder puff layer comprises a thin film layer (1), a silica gel layer (2) and a thin film layer (3), the thin film layer (1), the silica gel layer (2) and the thin film layer (3) are connected with and fixed to each other, and the thin film layer (3) is connected with the wet powder puff layer by using an adhesive. The wet and dry dual use powder puff has the functions of a dry powder puff and a wet powder puff at the same time, is convenient to use, can be switched randomly when the dry powder puff and the wet powder puff are used, and is small in occupation space and convenient to carry.

Owner:江门建欢化妆用品有限公司

TPU/TPE composite modified material

The invention discloses a TPU / TPE composite modified material, which comprises: a polymer, polyurethane, a compatibilizer, a laser carving auxiliary agent and processing oil according to a certain weight part ratio, and is specifically prepared from the following raw materials by weight: 50-100% of SEBS, 50-100% of TPU, 30-50% of processing oil, 8-15% of MAH-G-SEBS, 8-15% of NH2-G-SEBS, 0.5-2% ofa laser engraving auxiliary agent, 0.1-0.5% of an antioxidant, 0.1-0.5% of an anti-ultraviolet absorber, 0.5-2% of an antibacterial agent, and 0.5-5% of organic silicone. According to the present invention, the obtained TPU / TPE composite modified material has strong adhesion with ABS, PC, POM, ASA, AS, SAN and other materials, can be subjected to secondary molding injection, can be recycled, meetsthe FDA food hygiene requirements, and further has advantages of no toxicity, no odor, excellent elasticity, high unit weight utilization rate, wide hardness range and easy processing.

Owner:上海鼎事新材料科技有限公司

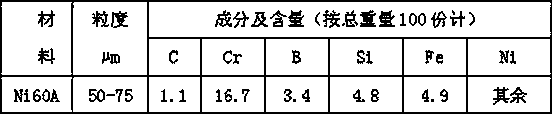

Surface composite treatment method of valve workpiece

InactiveCN110306183AUniform performancePerformance is easy to controlSolid state diffusion coatingValve housingsAfter treatmentAlloy

The invention provides a surface composite treatment method of a valve workpiece. The method includes the following steps that firstly, a laser cladding technology is adopted for performing surface treatment on the sealing face of the valve workpiece, and a laser cladding layer in a preset thickness is formed on the sealing face; secondly, an alloy atom permeating technology is adopted for treating other surfaces, except the sealing face, of the valve workpiece, and alloy atom permeating coatings are formed on the other surfaces; and thirdly, after-treatment is performed on the laser claddinglayer formed in the first step. According to the method, based on long-time industrial practice and application experience, directing at the current condition that different portions of a valve are different in abrasion resisting and corrosion resisting requirements under different using work conditions, the surface treatment technology that laser cladding treatment and alloy atom permeating treatment are combined is put forwards firstly, the abrasion resisting and corrosion resisting requirements of valve type products under different using work conditions are met, the comprehensive requirements of manufacturability and economical efficiency are both taken into consideration very well, important reference significance is provided for treatment of the surface of the workpiece under other similar requirements, and the market prospect is broad.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

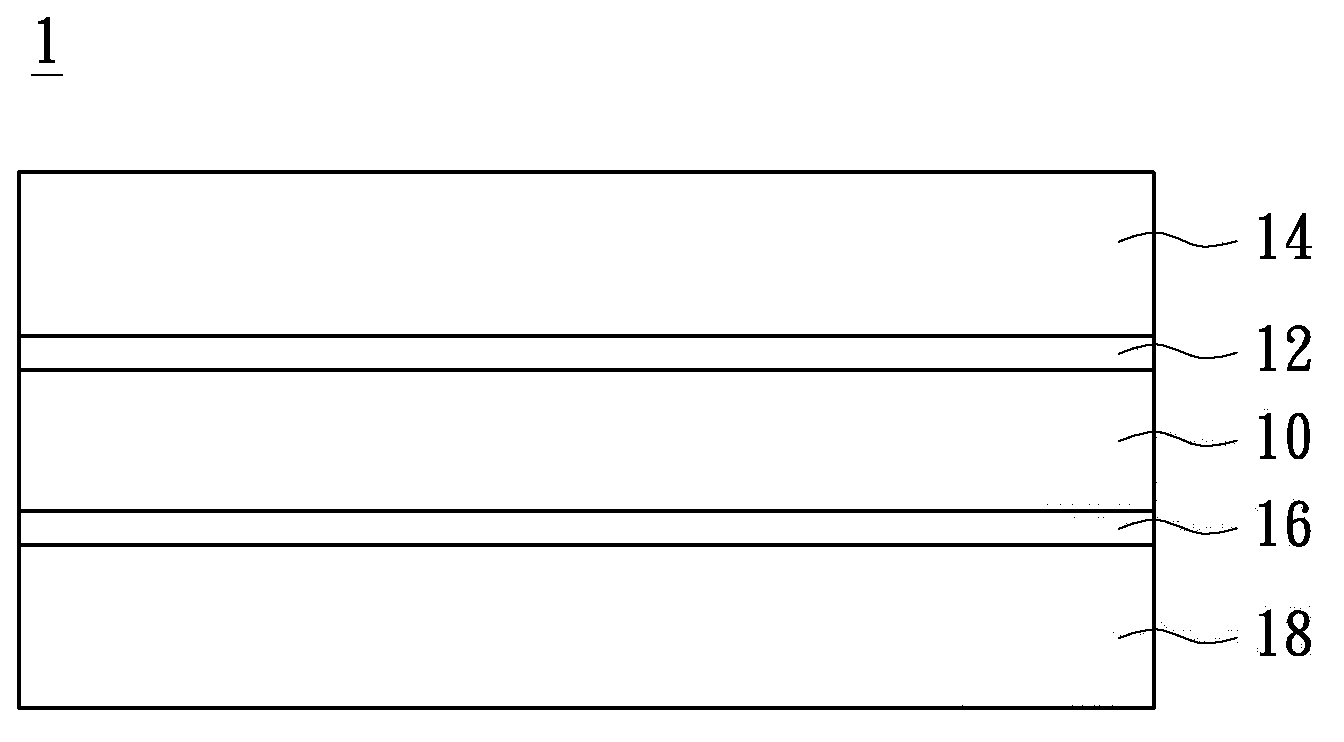

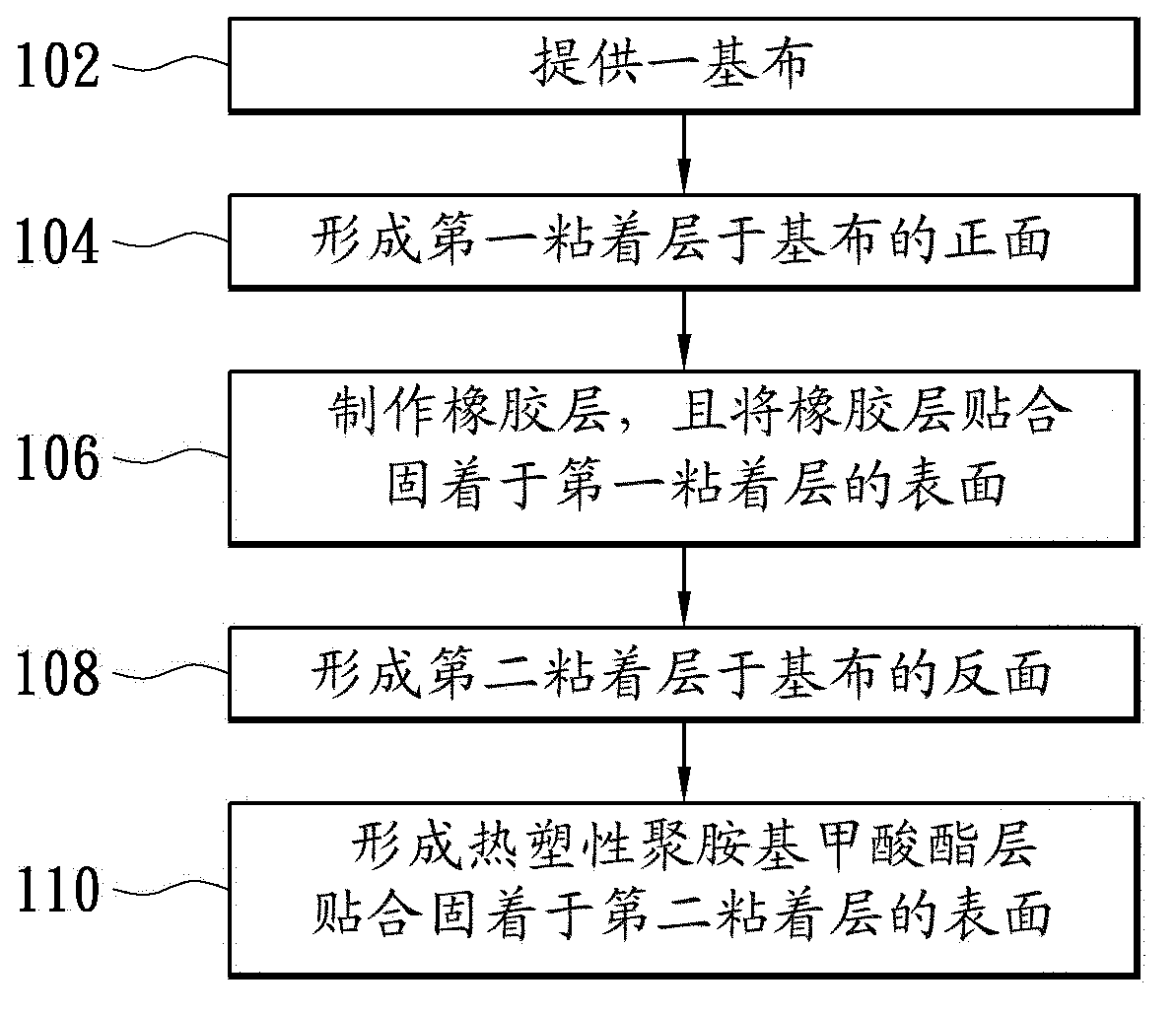

Composite rubberized fabric of rubber and thermoplasticity polyamine formic ether and manufacturing method thereof

InactiveCN103660450AImprove performanceWide range of hardnessSynthetic resin layered productsRubber layered productsEngineering

The invention provides a composite rubberized fabric of rubber and thermoplasticity polyamine formic ether and a manufacturing method thereof. The manufacturing method includes steps of providing substrate fabric, forming a front face of a first adhering layer on the substrate fabric, manufacturing a rubber layer and fitting the rubber layer on the surface of the first adhering layer; forming a back face of a second adhering layer on the substrate fabric, forming a thermoplastic polyamine formic ether layer and enabling the thermoplastic polyamine formic ether layer to be fitted on the surface of the second adhering layer.

Owner:FORMOSAN RUBBER GRP

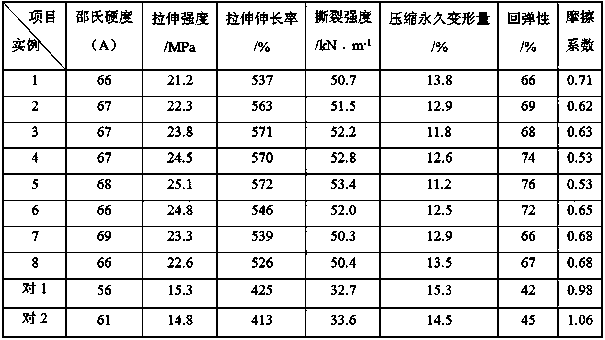

Rubber for electric-generator shock pads and preparation method of rubber

The invention belongs to the technical field of rubber, and particularly relates to rubber for electric-generator shock pads and a preparation method of the rubber. The rubber is prepared from the following raw materials in parts by weight: 32-45 parts of acrylate rubber, 15-25 parts of polyurethane rubber, 10-16 parts of epichlorohydrin rubber, 10-18 parts of glass fibers, 5-10 parts of polytetrafluoroethylene fibers, 1-3 parts of carbon black N330, 3-6 parts of white carbon black VN, 0.5-1.5 parts of stearic acid, 2-6 parts of liquid paraffin, 10-15 parts of dibutyl phthalate, 1-2.2 parts ofantiagers DNP, 4-8 parts of dicumyl peroxide, 1-3 parts of N,N'-meta phenylene bismaleimide, 1-3 parts of silane coupling agents and 5-10 parts of accelerators CZ. The rubber has the advantages of appropriate hardness, high strength, small compression set deformation, high elasticity, high wear resistance, good shock absorption effect and suitability for preparation of the electric-generator shock pads.

Owner:国网河南省电力公司西峡县供电公司

Preparation method of polyurethane elastomer with adjustable hardness

The invention belongs to the technical field of polyurethane application, and particularly relates to a preparation method of a polyurethane elastomer with adjustable hardness. The polyurethane elastomer with adjustable hardness is prepared from the following three components: a component A which is formed by mixing polytetrahydrofuran ether polyol with a catalyst; a component B which is a prepolymer obtained by reacting polytetrahydrofuran ether polyol with diisocyanate; and a component C obtained after a chain extender is dehydrated until the moisture content is less than or equal to 0.03%.The component A and the component C are premixed to serve as a curing agent component, then the component B and the curing agent component are mixed and poured into a mold, the mold is opened, and vulcanization is conducted to obtain the polyurethane elastomer. The hardness-adjustable polyurethane elastomer prepared by the method overcomes the defects that the existing polyurethane elastomer is high in viscosity, a catalyst is easy to layer with an alcohol curing agent and the like, has obvious advantages in the aspects of resilience, wear resistance and mechanical properties, and further widens the hardness range of the polyurethane elastomer.

Owner:SHANDONG INOV POLYURETHANE

Preparation method of casting polyurethane tire

InactiveCN108859198ASimplify tedious stepsSimplify problems that are greatly affected by human factorsTyresElastomerOperability

The invention discloses a preparation method of a casting polyurethane tire. The preparation method of the casting polyurethane tire comprises the specific steps that a release agent is evenly spreadinside a mold, the mold is preheated, a traveler in a framework material is fixed by a magnetic element in the mold, and internal locating of the framework material is achieved; the framework materialand the magnetic element of the mold form tension to complete shaping and locating of the framework material; a rubber elastomer is heated and poured into the tire mold, after the mold is filled andkeeps the temperature and pressure, a tire matrix is taken out of the mold, a lining layer of the prepared tire matrix is coated with a thermoplastic film or a anti-puncturing coating, and then the polyurethane tire is obtained. After the tire is worn during use, the surface of the tire is coated with a composite white carbon blank elastomer material to complete repair. According to the preparation method of the casting polyurethane tire, the technology is simple, a tire preparation technology is simplified through a magnetic locating technology, the tire is prepared in a casting formation manner, the operability is high, and industrialization is easy to achieved; and the obtained polyurethane tire is good in wear resistance and saves oil, the surface coating can be repaired in real time,the purpose that the tire is long in service life is achieved, resources are saved, and environmental protection is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Modified TPU (thermoplastic polyurethane) material and manufacturing method thereof

The invention relates to a modified TPU (thermoplastic polyurethane) material which comprises the following components in parts by weight: 30-130 parts of polyester polyol, 30-110 parts of diisocyanate, 8-45 parts of dibasic alcohol, 3-11 parts of perforating agent, 5-15 parts of polyurethane foaming agent, 3-11 parts of chain extender and 20-110 parts of magnetic powder. The invention provides a modified TPU material and a manufacturing method thereof. The modified TPU material has the properties in the traditional TPU, and also has the function of magnetic therapy. The manufacturing method is simple and convenient to operate, can easily obtain the product, and thus, is applicable to the fields of home furnishing and the like.

Owner:HEYE HEALTH TECH CO LTD

Composite fireproof insulation board and preparation method thereof

InactiveCN105948692AWide range of hardnessImprove shock absorptionSolid waste managementCeramicwareCelluloseInsulation layer

The invention discloses a composite fireproof insulation board and a preparation method thereof. The composite fireproof insulation board can be selected from a two-layer structure including an insulation layer and an inorganic fireproof insulation layer or a three-layer structure including an insulation layer, an inorganic fireproof insulation layer and a mortar protection layer; the insulation layer is selected from one of a polyurethane plate, an extruded plate, an expanded polystyrene plate and a thermosetting polystyrene foamed plastic; the inorganic fireproof insulation layer is prepared by selecting 80 parts by mass of magnesium oxide, 60 parts by mass of magnesium chloride, 40 parts by mass of water, 80 parts by mass of a mineral powder, 1 part by mass of a modifier, 8 parts by mass of a hydrophobic agent, 2 parts by mass of a hydrophobic powder, 8-10 parts by mass of expanded polystyrene particles, and 25 parts by mass of a foaming agent and water; the mortar protection layer is prepared from 350 parts by mass of cement, 650 parts by mass of quartz sand or washed-out sand, 1 part by mass of hydroxypropyl methyl cellulose, 1 part by mass of cellulose ether, 20 parts by mass of a rubber powder, and 7 parts by mass of a hydrophobic agent. The composite fireproof insulation layer provided by the invention has the advantages of fire prevention, thermal insulation, environmental friendliness and the like.

Owner:曹芳芹

A kind of repaglinide tablet and preparation method thereof

ActiveCN103610677BAvoid stickingGood dispersionOrganic active ingredientsMetabolism disorderMedicineDissolution

The invention relates to an oral troche which contains repaglinide or pharmaceutically acceptable derivatives of repaglinide as well as a preparation method of the oral troche. According to the preparation method, powder of repaglinide or pharmaceutically acceptable derivatives of repaglinide is directly pressed into troche, so that the production cost is remarkably lowered, and the disintegration and the dissolution rate are greatly improved. The bioavailability and the stability of the medicine can be improved, and the problem of low content uniformity of existing small-dose medicines formed by the direct pressing method is overcome, so that the quality of the troche is better guaranteed.

Owner:华益泰康药业股份有限公司

Pelleting method of aggregates used for encapsulating film, aggregates thereof and application

The invention relates to a pelleting method of aggregates used for an encapsulating film, aggregates thereof and application. On one hand, the pelleting method comprises the following steps: adding main body resin, an inorganic filler and a part of a softener into a mixing machine for stirring and mixing, then after warming to adjust the rotating speed, putting into an antioxygen and a cross-linking agent, finally putting into a stabilizer and the rest of the softener, and then carrying out extrusion pelletization on a double-screw extruder so as to obtain the aggregates used for the encapsulating film. On the other hand, the encapsulating film is obtained through curtain coating and cooling of the prepared and obtained aggregates used for the encapsulating film, and the encapsulating film has excellent mechanical property, weather resistance and water resistance and can be used for surface encapsulating of automobile foaming body materials.

Owner:CIXI LANXING PLASTIC & RUBBER IND

Fully-vulcanized polypropylene/acrylate rubber thermoplastic elastomer and preparation method thereof

The invention provides a fully-vulcanized polypropylene / acrylate rubber thermoplastic elastomer and a preparation method thereof, which relate to the technical field of thermoplastic elastomer. The fully-vulcanized thermoplastic elastomer is formed by melting and mixing the components which include polypropylene plastics and a rubber component, wherein the weight ratio of the rubber component to the polypropylene plastics is 30:70-75:25. The rubber component is a mixture of rubber particles with a cross-linked structure and a softener, wherein the content of the softener is 30-120% of the rubber particles by weight; and the rubber particles are fully-vulcanized acrylate powdered rubber, the mean particle diameter is 0.05mum-0.5mum, and the gel content is 60% by weight or higher. The softener is selected from at least one of a phthalic acid ester compound, dioctyl terephthalate, a trimellitate compound and a pyromellitic ester compound. The fully-vulcanized polypropylene / acrylate rubber thermoplastic elastomer has good comprehensive properties of oil resistance, low hardness, high elongation at break and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com