Surface composite treatment method of valve workpiece

A treatment method and surface composite technology, applied in the field of wear-resistant and corrosion-resistant valve surface treatment, valve surface composite treatment field, can solve the problems of poor protection performance of protective layer, unenvironmental protection, low cost, etc., and achieve broad market promotion and application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

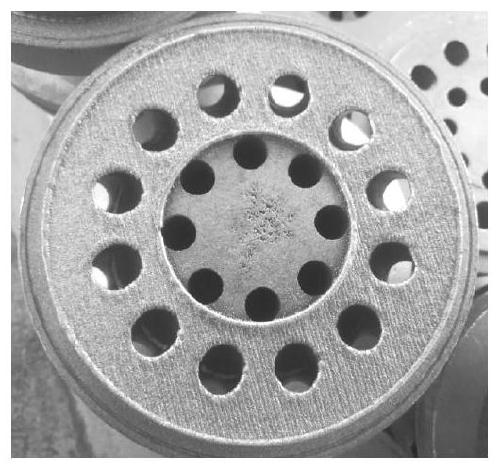

[0079] Combination valves (such as figure 1 ) is a key wearing part of the water injection pump used in oil fields. During use, the flow channel is corroded by underground water containing high concentrations of chloride ions and sulfide ions, and the sealing surface is corroded and worn. Due to the unique and complex structure of the combined valve, it is a suitable surface strengthening method to use the present invention to perform surface treatment on valves and different parts of the valves in different working conditions.

[0080] The combined valve is made of 35 steel. First, the sealing surface of the combined valve is treated with laser cladding. The main cladding process parameters are as follows: the temperature difference of the substrate during the printing process is less than 50°C, the laser power is 1000W, and the printing distance (the distance between the cladding head and the workpiece surface Distance) 15 mm, powder feeding amount 20g / min, lap rate 60%, wor...

Embodiment 2

[0090] figure 2 It is an ordinary low-pressure oil pipeline valve. The tapered sealing surface of the valve stem is treated by laser cladding to enhance its wear resistance and corrosion resistance. Require.

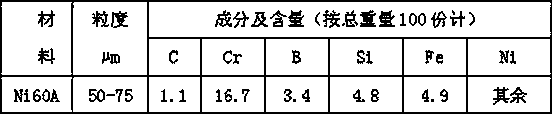

[0091] The material of the valve is carbon steel. The specific laser cladding process is as follows: the temperature difference of the substrate during the printing process is less than 50°C, the laser power is 1000W, the printing distance (the distance between the cladding head and the surface of the workpiece) is 15 mm, and the powder feeding rate is 20g / min. The layer overlap rate is 60%, the moving line speed of the workpiece is 15 mm / s, the printing angle is 90, and printing is performed 4 times. The powder used is nickel-based self-fluxing alloy Ni60A with a particle size of 50-75 microns. The specific composition is as follows:

[0092]

[0093] After the cladding is completed and the sphere is completely cooled, the thickness of the cladding layer is tested ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com