Rubber for electric-generator shock pads and preparation method of rubber

A shock absorber and generator technology, applied in the field of rubber, can solve the problems of poor noise reduction effect, low tensile strength and tear strength of rubber shock absorber, so as to improve service life, easy processing and blending, and beneficial to noise the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

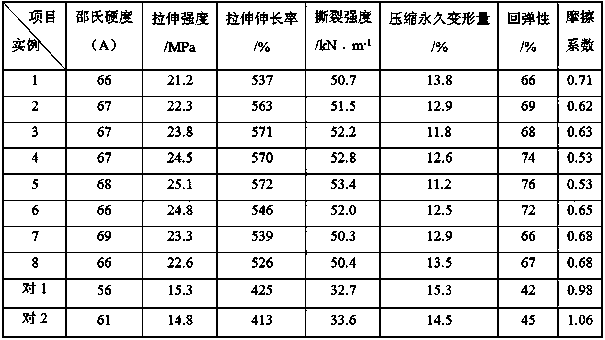

Examples

Embodiment 1

[0021] A kind of rubber for generator shock absorber, made of the following raw materials in parts by weight: 32 parts of acrylate rubber, 15 parts of polyurethane rubber, 10 parts of epichlorohydrin rubber, 10 parts of glass fiber, 5 parts of polytetrafluoroethylene fiber, 1 part of carbon black N330, 3 parts of white carbon black VN-3, 0.5 parts of stearic acid, 2 parts of liquid paraffin, 10 parts of dibutyl phthalate, 1 part of antioxidant DNP, 4 parts of dicumyl peroxide , 1 part of N, N'-m-phenylene bismaleimide, 1 part of silane coupling agent K550 and 5 parts of accelerator CZ.

[0022] The preparation method of above-mentioned generator shock pad rubber, comprises the following steps:

[0023] (1) Add acrylic rubber, polyurethane rubber, and epichlorohydrin rubber into the open mixer, and knead for 3 minutes at 80°C, then add glass fiber, polytetrafluoroethylene fiber and silane coupling agent K550, and continue kneading for 10 minutes. get glue;

[0024] (2) Add ca...

Embodiment 2

[0027] A kind of rubber for generator shock absorber, made of the following raw materials in parts by weight: 35 parts of acrylate rubber, 15 parts of polyurethane rubber, 11 parts of epichlorohydrin rubber, 12 parts of glass fiber, 5.5 parts of polytetrafluoroethylene fiber, 1.2 parts of carbon black N330, 3.5 parts of white carbon black VN-3, 0.5 parts of stearic acid, 2.5 parts of liquid paraffin, 11 parts of dibutyl phthalate, 1.2 parts of anti-aging agent DNP, 4.3 parts of dicumyl peroxide , 1.2 parts of N, N'-m-phenylene bismaleimide, 1.2 parts of silane coupling agent KH560 and 5.5 parts of accelerator CZ.

[0028] The preparation method of above-mentioned generator shock pad rubber, comprises the following steps:

[0029] (1) Add acrylic rubber, polyurethane rubber, and epichlorohydrin rubber into the open mixer, and knead for 2 minutes at 90°C, then add glass fiber, polytetrafluoroethylene fiber and silane coupling agent KH560, and continue kneading for 12 minutes. g...

Embodiment 3

[0033]A kind of rubber for generator shock absorber, made of the following raw materials in parts by weight: 36 parts of acrylate rubber, 16 parts of polyurethane rubber, 12 parts of epichlorohydrin rubber, 12 parts of glass fiber, 6 parts of polytetrafluoroethylene fiber, Carbon black N330 1.5 parts, white carbon black VN-34 parts, stearic acid 0.6 parts, liquid paraffin 3 parts, dibutyl phthalate 11 parts, antioxidant DNP 1.5 parts, dicumyl peroxide 5 parts, 1.5 parts of N, N'-m-phenylene bismaleimide, 1.7 parts of silane coupling agent Si69 and 6 parts of accelerator CZ.

[0034] The preparation method of above-mentioned generator shock pad rubber, comprises the following steps:

[0035] (1) Add acrylic rubber, polyurethane rubber, and epichlorohydrin rubber into the open mixer, and knead for 1 min at 100°C, then add glass fiber, polytetrafluoroethylene fiber and silane coupling agent Si69, and continue kneading for 15 min. get glue;

[0036] (2) Add carbon black N330, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com