Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

260results about How to "Tear resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

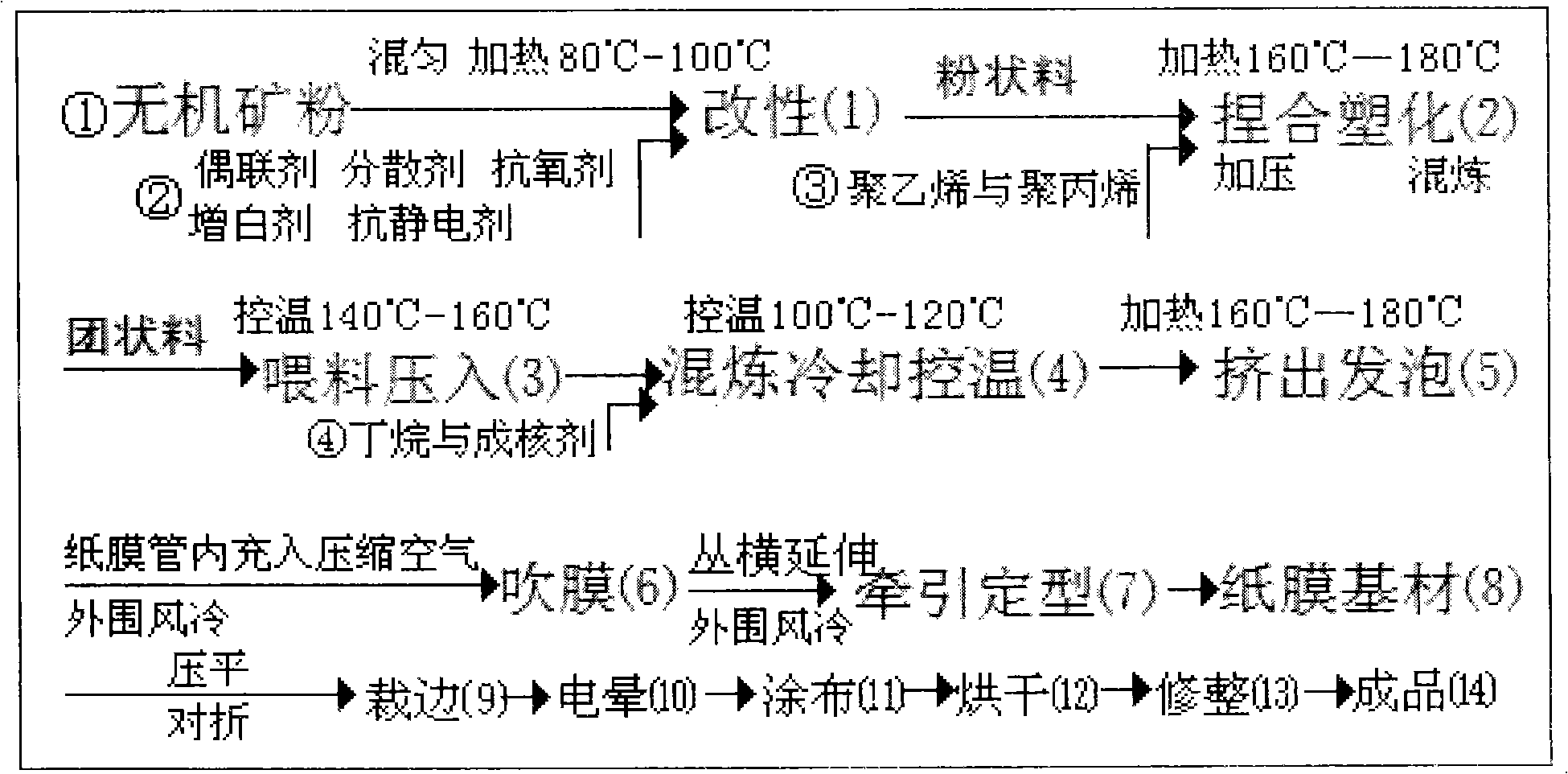

Stone papermaking method

InactiveCN101831835AControl the amount of inflationLight weightInorganic fibres/flakesSpecial paperFilm baseWhite powder

The invention discloses a stone papermaking method, which is characterized by comprising the following steps: adding 2 to 2.5 weight percent of auxiliary agent such as stearic acid and the like into 70 to 80 percent of natural inorganic ore powder such as heavy calcium, light calcium, talcpowder, titanium white powder and the like serving as main raw materials to modify the raw materials, adding 18 to 11.5 weight percent of polyethylene and 9 to 5 weight percent of polypropylene into the raw materials, and mixing, plasticizing and kneading the mixture to form a bulk material; and performing double-fold feed on the bulk material, pressing the bulk material into a paper film extruder, injecting 0.5 weight percent of butane and 0.5 weight percent of nucleating agent into the extruder, mixing and heating the mixture, extruding a paper film, then foaming, blowing, drawing, cooling and shaping the paper film to form a paper film base material, and forming a stone paper finished product through corona, coating, drying and finishing. The gram weight of stone paper is reduced by physical micro-foaming technology. The method has the advantages of simple manufacturing process, low cost, dry production, use of few water circulating cooling machines, no three-waste discharge and pollution avoidance.

Owner:山西典石晨晶科技有限公司

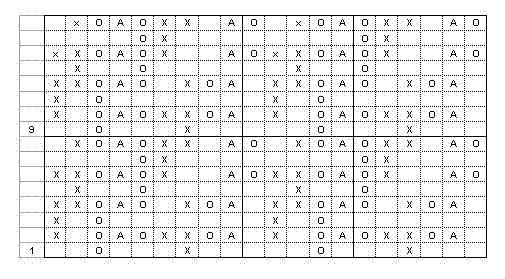

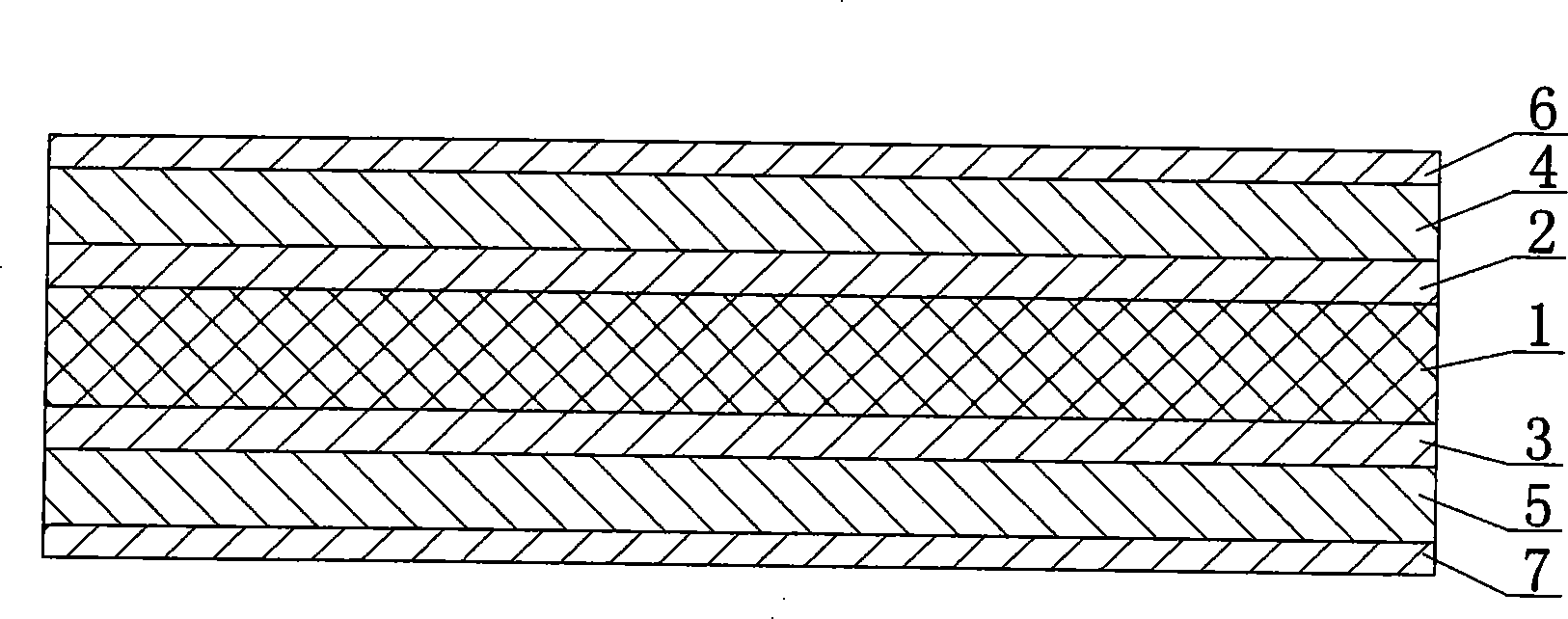

Aramid rubber canvas fabric structure for high-strength conveyor belts and production process of aramid rubber canvas fabric structure

InactiveCN104611819AEasy to weaveGood physical and mechanical propertiesConveyorsMulti-ply fabricsYarnEngineering

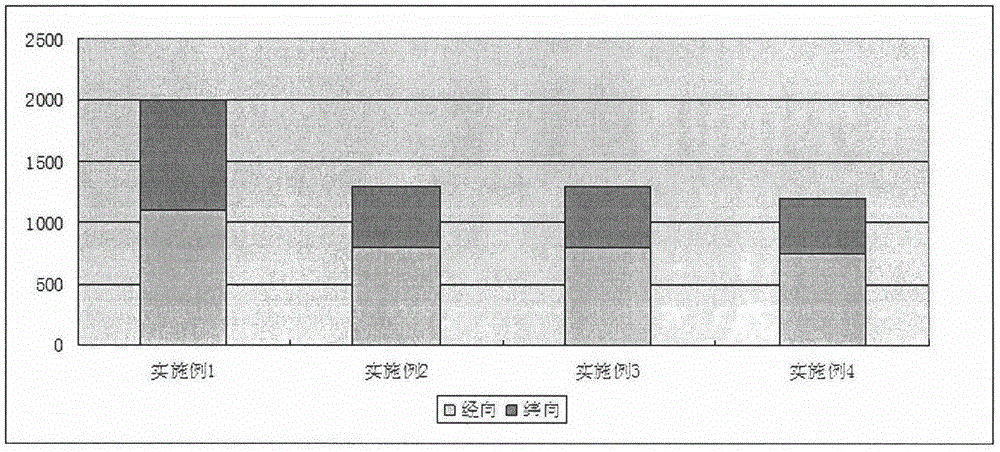

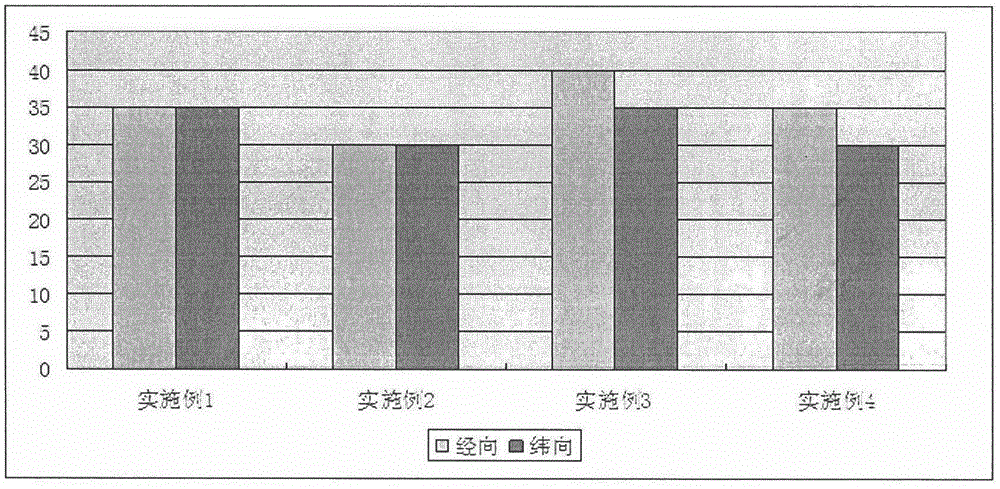

The invention discloses an aramid rubber canvas fabric structure for high-strength conveyor belts and a production process of the aramid rubber canvas fabric structure. The aramid rubber canvas fabric structure comprises warps and wefts, aramid materials are adopted in the warps, at least four warps are paved in the belt length direction, nylon industrial yarns are adopted in the wefts which are crisscrossly paved on upper end faces and lower end faces of the warps, the wefts on upper and lower layers are tightly crisscrossly bonded to the warps by adopting bundling yarns, and a canvas fabric structure is obtained after secondary bath gum dipping; the production process includes single-layer canvas knitting, secondary bath gum dipping and reeling. Single-layer structures of the warps adopting the aramid materials and the weft adopting the nylon materials are knitted through bundling yarns, the high-strength conveyor belts with the strength higher than 2500N / mm are produced after secondary bath gum dipping, mechanical physical properties of the conveyor belts are improved, layer reduction and weight reduction of the conveyor belts are realized during the production process, the conveyor belts are adaptively high strengthened, less layered and lightweight, energy consumption is reduced, the production process is further simplified, and production efficiency is higher.

Owner:浙江尤夫科技工业有限公司

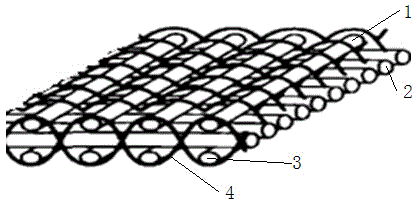

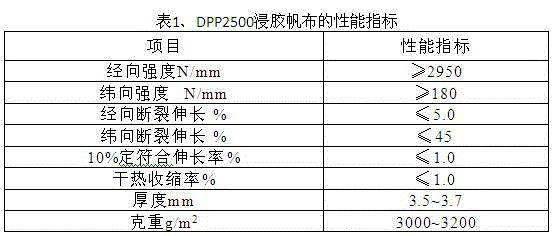

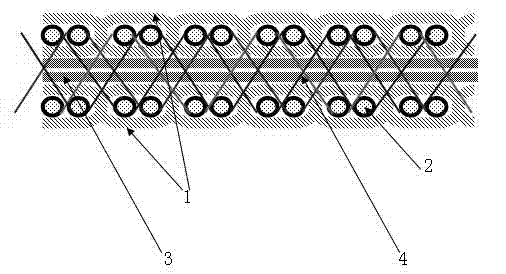

Dipped canvas fabric structure in three-dimensional structure for heavy-duty conveyor belt and production process thereof

ActiveCN102212917ASolve production technical problemsGood physical and mechanical propertiesFibre treatmentTwo or more solvent application treatmentPolyesterEngineering

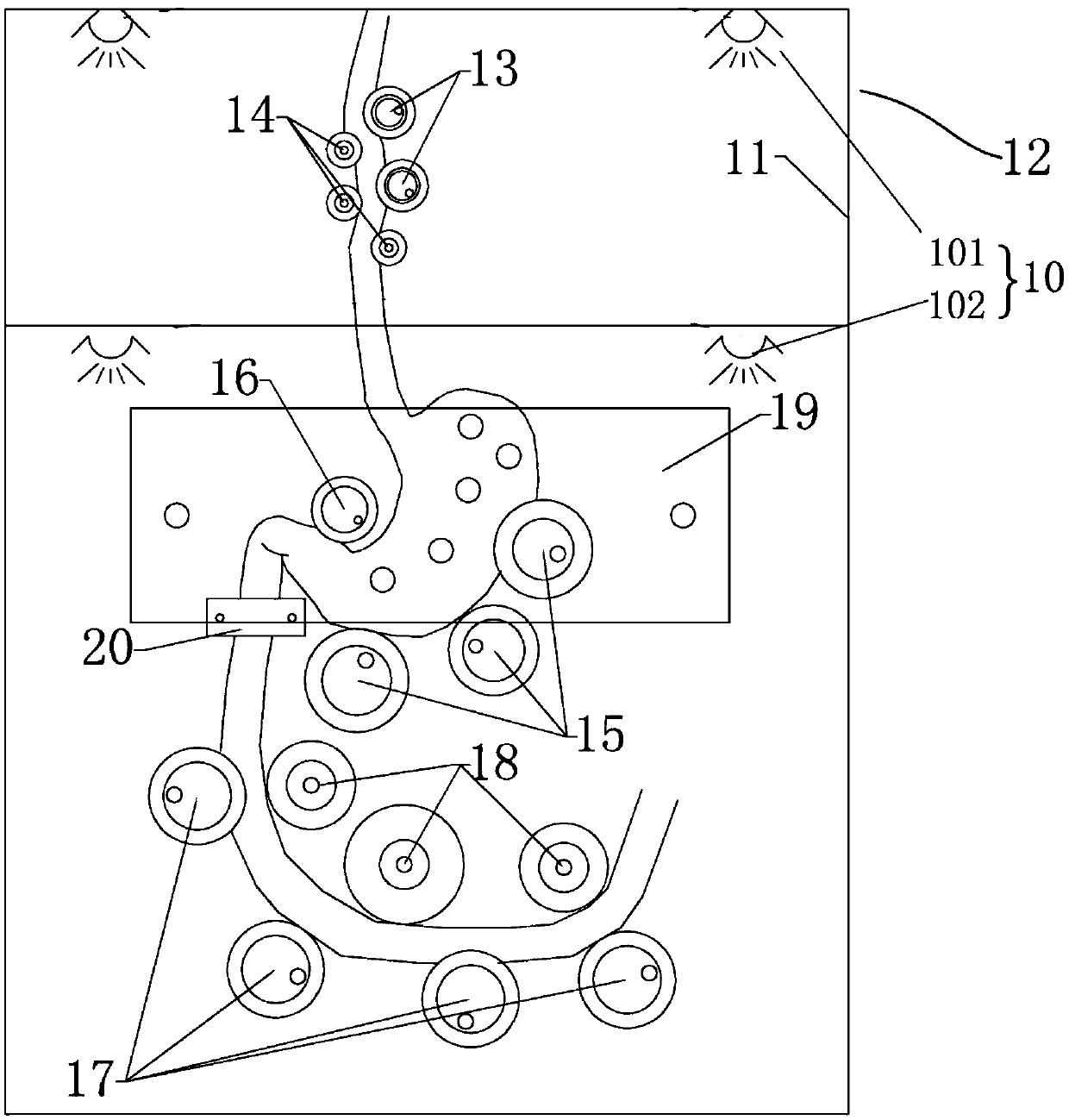

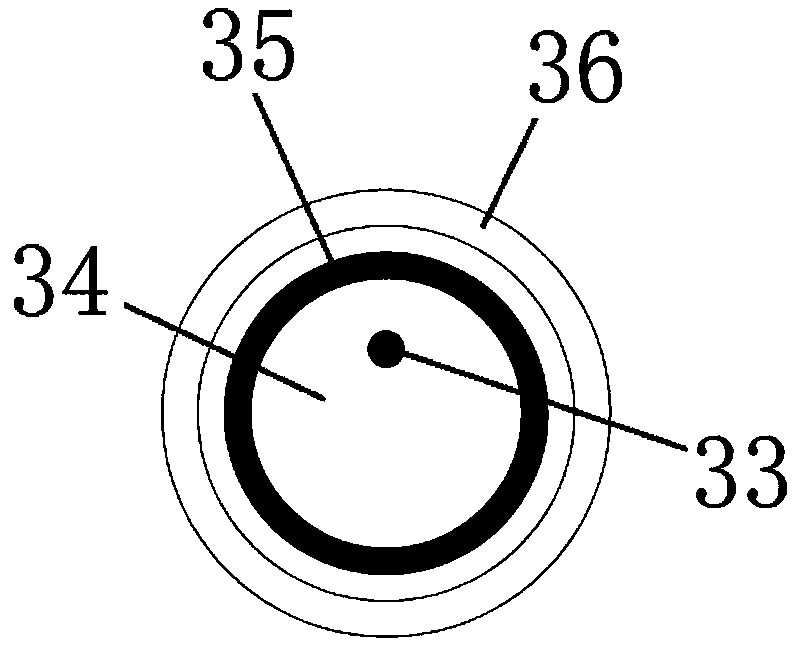

The invention discloses a dipped canvas fabric structure in a three-dimensional structure for a heavy-duty conveyor belt and a production process thereof. The dipped fabric structure is characterized in that an upper layer and a bottom layer adopt ground-facing warps (1) in the plain weave structure and weft (2) interwoven with the ground-facing warp, a straight warp (3) in the straight warp structure is utilized as an intermediate layer, a bundling warp (4) is connected with the weft (2), and the upper layer, the intermediate layer, the bottom layer and the bundling warp form the three-dimensional structure. The production process comprises the following processes: the process of weaving a fabric on a machine: adopting double warp shafts to send a warp woven cloth; and the process of stipulating a dipping formula and preparing, wherein a dipping solution is a mixture of an RF (resorcinol-formaldehyde) resin water solution generated by virtue of condensation polymerization of hydroxyphenol and formaldehyde and VP (vinyl pyridine) latex (L), the total content of solids is 18-22%, the pH value is 9-11, and the ratio of the RF to the L is (1:5)-(1:7). Polyester dipped canvas in the three-dimensional structure is especially applicable to production of the heavy-duty rubber conveyor belts and has the characteristics of tear resistance, puncture resistance and impact resistance.

Owner:浙江尤夫科技工业有限公司

Method for preparing polytetrafluoroethylene spatial structure building film material

The invention relates to a producing method of a teflon spatial structure membrane comprising following steps: fiberglass cloth low temperature genapping treatment, fiberglass cloth bottom layer dipping treatment, structure layer dipping treatment, surface layer dipping treatment and sintering treatment. Low temperature high speed genapping, multitime coating low-temperature treatment, and once hyperthermia flash sintering effectively reduce tensile strength descending caused by high-sintering treatment. Since fiberglass cloth is used as backing material, dipping treatment is not needed to be performed on the fiberglass yarn, the procedure is simplified to facilitate the production thereof, and shortcomings in prior art are overcome which are modified fiberglass yarn weaving difficulty and intensity and plasticity descending caused by multitime sintering. The teflon spatial structure membrane produced by using the invented method has a bottom layer, a structure layer and a surface layer, is provided with high pulling-against intensity, high tearing-against intensity, anti-aging property, good flexibility, good light-admitting quality and a long service life, and can be used widely in air stations, gymnasiums, exhibition halls, large-scale factory buildings and factory building warehouses.

Owner:JIANGSU VEIK TECH & MATERIALS CO LTD

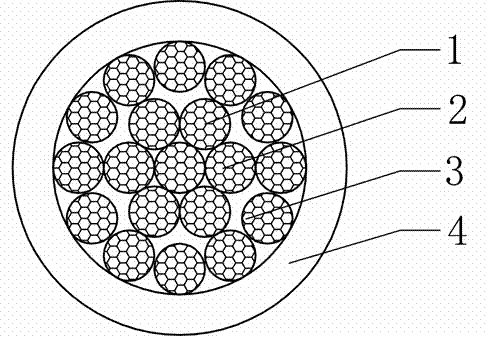

Elevator cable with high safety factor

InactiveCN102087889AGood chemical stabilityImprove aging performanceBiocidePest repellentsProtection layerElectrical and Electronics engineering

The invention provides an elevator cable with a high safety factor. A sheath of the elevator cable comprises an outer sheath, a safety protection layer and an inner sheath, wherein the raw material formula of the outer sheath contains 0.5-5wt% of antibacterial ratproof drug components; and the matrix resin of the outer sheath is fluororubber. In the invention, the high safety factor operating condition is provided in the aspect of non-electrical property design capability, so the elevator cable is suitable for working continuously and uninterruptedly in any extremely harsh environment.

Owner:江苏河阳线缆有限公司 +1

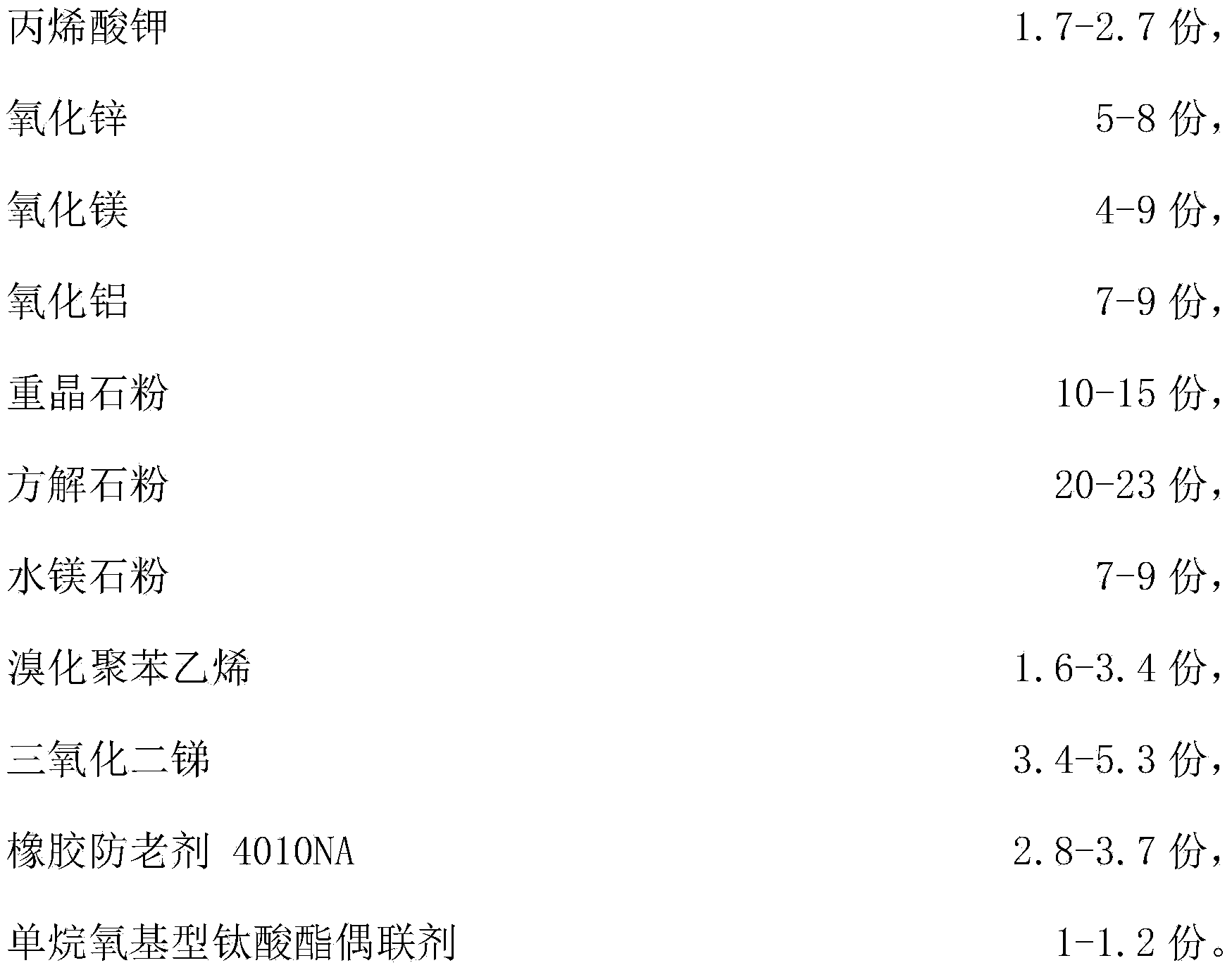

Water-tolerant oil-resistant rubber material

The invention discloses a water-tolerant oil-resistant rubber material which is prepared from the following raw materials in parts by weight: 20-30 parts of fluororubber TP (Tetrafluoroethylene-Propylene), 30-35 parts of nitrile silicone rubber, 45-50 parts of hydrogenated butyl rubber, 2-3 parts of a vulcanizing agent DCP (Dicalcium Phosphate), 2.3-3.4 parts of sulfur, 1.2-1.6 parts of epoxy resin, 1.7-2.7 parts of potassium acrylate, 5-8 parts of zinc oxide, 4-9 parts of magnesium oxide, 7-9 parts of aluminum oxide, 10-15 parts of baryte powder, 20-23 parts of calcite in powder, 7-9 parts of brucite powder, 1.6-3.4 parts of brominated polystyrene, 3.4-5.3 parts of brominated polystyrene, 2.8-3.7 parts of a rubber antioxidant 4010NA and 1-1.2 parts of a monoalkoxy titanate coupling agent. The water-tolerant oil-resistant rubber material disclosed by the invention has an excellent oil-resistant water-tolerant performance as well as flame retardant and heat resistant performances and ageing-resistant performance and further has high elasticity, high hardness and high strength.

Owner:宁国日格美橡塑股份有限公司

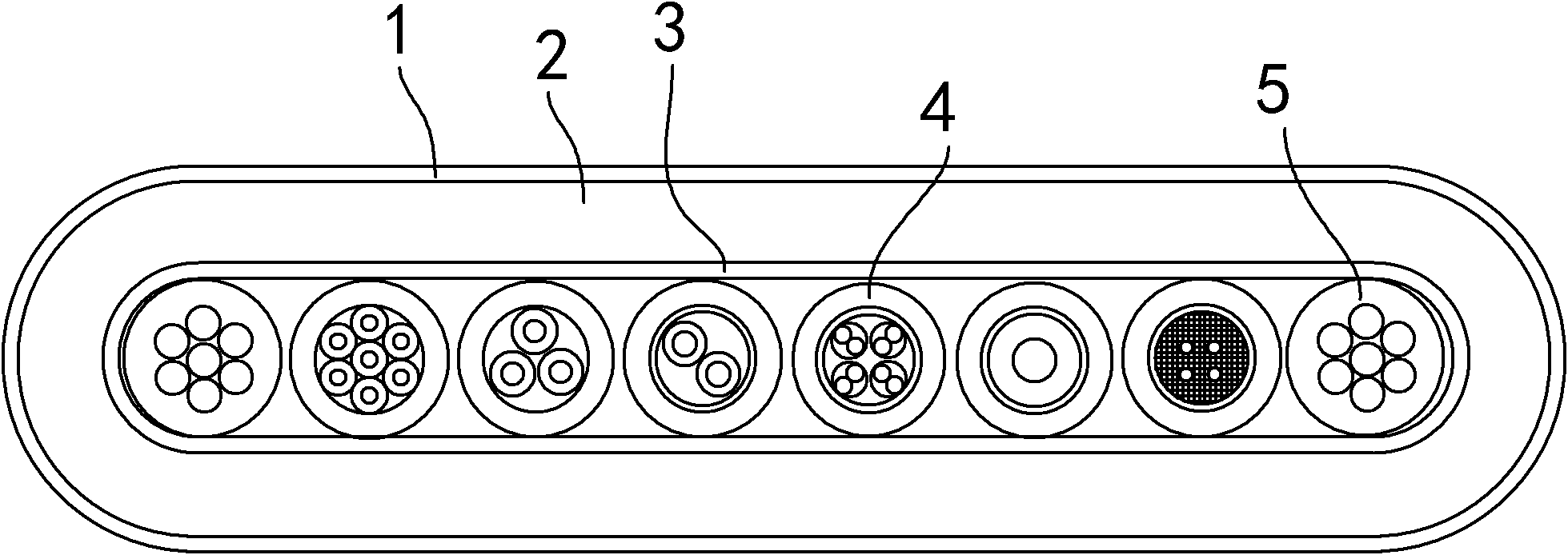

Cleaning-type oil-resistant cable

InactiveCN102082004ALarge leakage currentWear-resistantClimate change adaptationInsulated cablesCopper conductorCross-link

The invention belongs to the technical field of electrical wire and cable production processes, and particularly relates to a cleaning-type oil-resistant cable. Conductors (1) are copper conductors, the structures of the conductors adopt a first type or a second type, a cross-linked polyethylene insulating layer (2) is extruded on the conductors (1) respectively by applying a warm water cross-linking technology to serve as a cable core, an inner lining layer (3) is arranged outside the cable core, an armor layer (4) is armored by back-twist type galvanized fine steel wires, aluminum-plastic composite tapes are longitudinally coated and welded outside the armor layer (4) to form a water and tide blocking layer (5), and a flame-retardant jacket layer (6) made of a butyronitrile material is arranged at the outermost layer. With a double-layer co-extrusion mode to extrude, the arrangement of the high-strength water and tide blocking layer capable of longitudinally preventing tension in the overall cable and a process of double-layer co-extrusion protection layers, the cleaning-type oil-resistant cable has not only very strong resistance to abrasion and oil, but also better resistance to cleaning, thereby the quality stability of the oil-resistant cable is improved and a new technical field is developed for the development of the cleaning-type oil-resistant cable.

Owner:HENAN HUATAI SPECIAL CABLE

Biodegradable film and preparation method thereof

The invention provides a biodegradable film and a preparation method thereof, which belongs to the field of biodegradable polymer materials. The biodegradable film takes terephthalic acid, oxalic acid and 1,4 butanediol copolyester as base materials, and after thermoplastic starch, modified nano-silica and other raw materials are added, a blown film produced is a fully biodegradable product and can be decomposed by microorganisms in a specific environment. The biodegradable film also has moisture resistance as well as high tensile strength, toughness and hardness, and can resist oil, moisture and temperature change. The biodegradable film can be widely used in a plurality of industries as a daily packaging film, a vest bag, a food packaging bag and the like, and plays an extremely important role in protecting environment and resources. Tests prove that packing materials made from the base materials or blends containing the base materials can be completely decomposed and only need four weeks to be thoroughly decomposed under composting conditions with no residue. The preparation method of the biodegradable film has the advantages of simple process, easy control and suitability for industrial production.

Owner:林存革

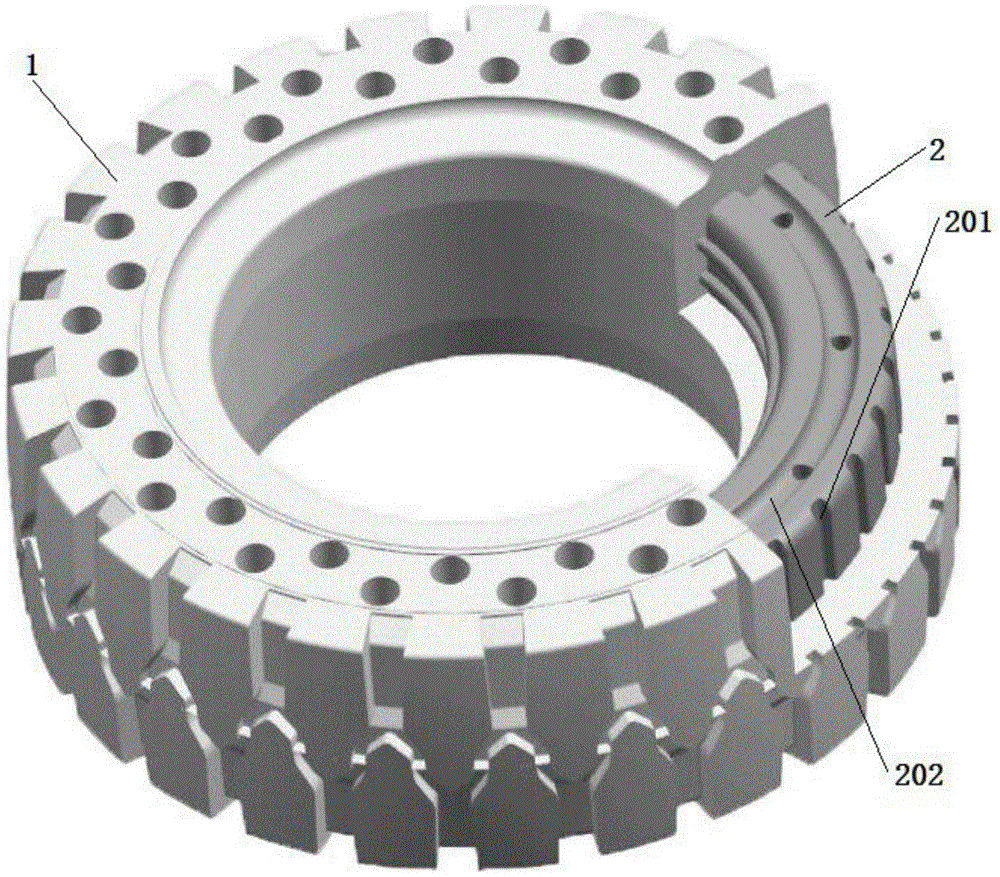

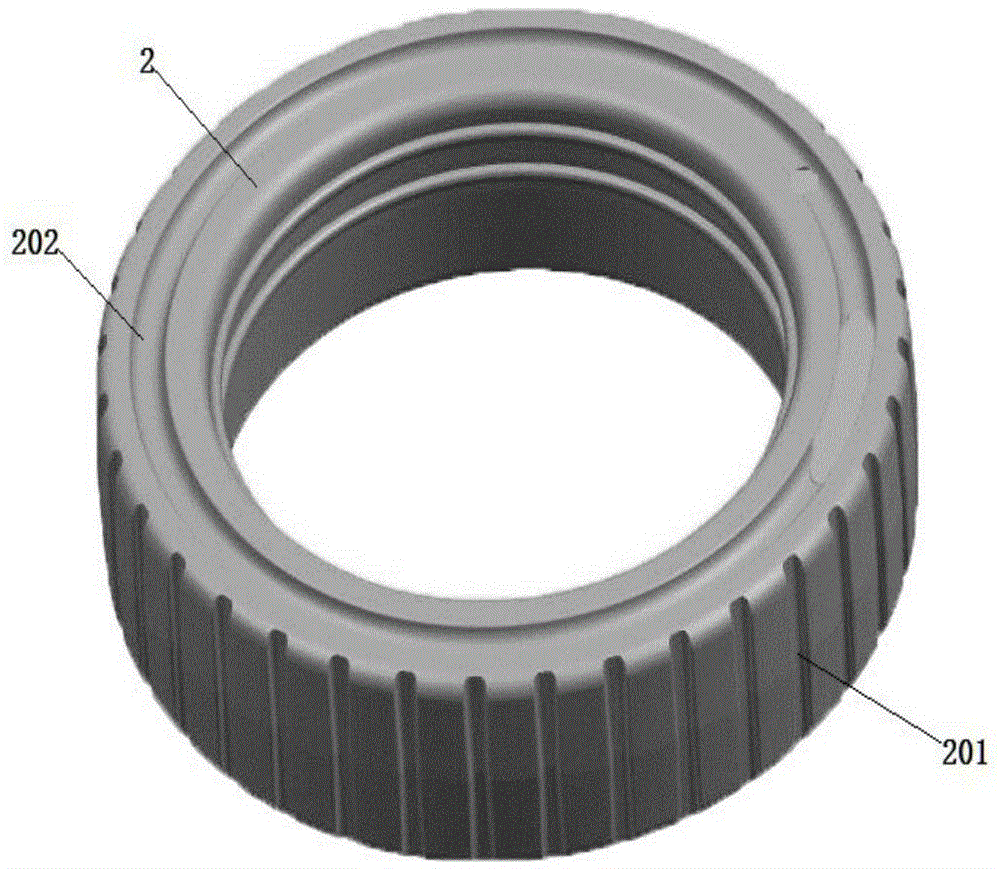

Polyurethane sandwiched tire and preparation method thereof

The invention discloses a polyurethane sandwiched tire. The polyurethane sandwiched tire comprises an outer tire and an inner tire wrapped in the outer tire. The shore hardness of the outer tire is higher than that of the inner tire. The outer tire surface of the inner tire is provided with a circle of grooves which are through in the left and right direction, wherein the direction of the grooves is perpendicular to the tire running direction, and the cross section of each groove is semicircular. The inner tire surface of the outer tire is provided with convex edges which correspond to the grooves, wherein the number of the convex edges is equal to that of the grooves, the length of the convex edges is equal to that of the grooves, and the cross section of each convex edge is also semicircular. The convex edges of the outer tire are arranged in the grooves of the inner tire in a bonding mode. The invention further discloses a preparation method of the polyurethane sandwiched tire. According to the preparation method, the inner tire and the outer tire are formed through a two-time liquid injection method. The prepared polyurethane sandwiched tire has the advantages of being high in resilience, resistant to tear and nail puncture and the like; especially, the high resilience is excellent and is incomparable for that of rubber, and the overall performance approximates the resilience of a pneumatic tire.

Owner:李明

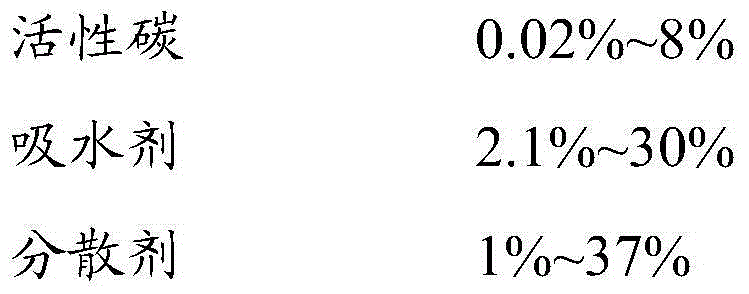

Food antistaling agent with double absorbing function

InactiveCN104886716ASafeEnsure safetySynthetic resin layered productsBagsCalcium hydroxideActivated carbon

A food antistaling agent with a double absorbing function includes a packaging bag and antistaling agent raw materials placed in the packaging bag, and the antistaling agent consists of iron powder, salt, water, activated carbon, a pH adjusting agent, a water-absorbing agent, and dispersants; a food antistaling agent with a double absorbing function includes a packaging bag and antistaling agent raw materials placed in the packaging bag, and the antistaling agent consists of iron powder, NaCl, water, activated carbon, sodium bromide. and diatomaceous earth; and a food antistaling agent with a double absorbing function includes a packaging bag and antistaling agent raw materials placed in the packaging bag, and the antistaling agent consists of iron powder, sodium bromide, calcium hydroxide, water, activated carbon, a water-absorbing agent, and silicon dioxide. The food antistaling agent with a double absorbing function can remove oxygen and protect against moisture at the same time and ensure that food is placed in a dry and oxygen-free environment, has significant antistaling effect, high practicality and good antistaling effect.

Owner:GUANGDONG GUANGYI TECH IND

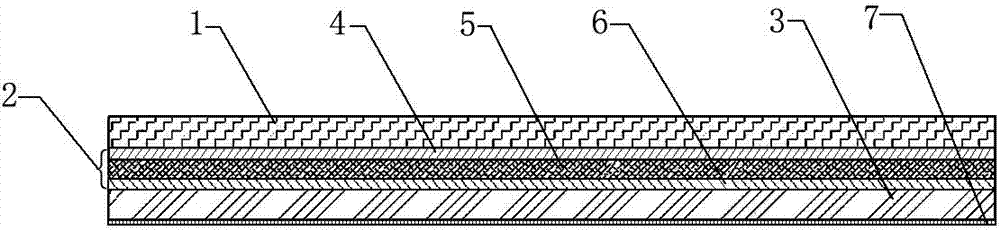

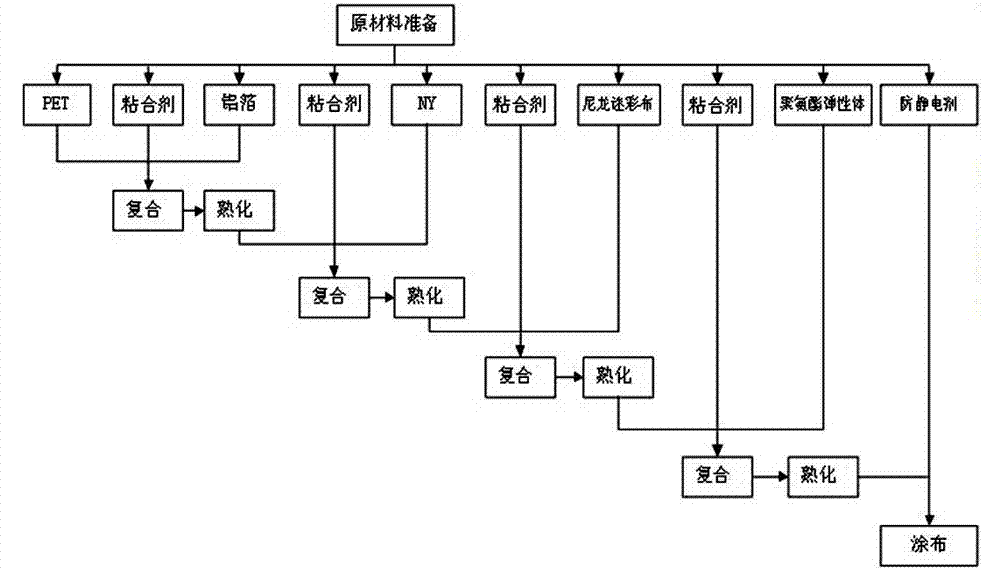

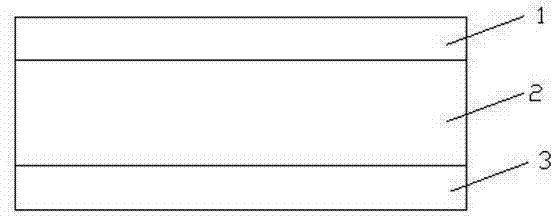

Military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite and preparation method thereof

ActiveCN103029386AImprove mechanical propertiesGood antistatic functionSynthetic resin layered productsLaminationPolyurethane elastomerAntistatic agent

The invention discloses a military puncture-proof, tear-resistant, anti-static and high-barrier camouflage painting composite which sequentially comprises a nylon camouflage cloth camouflage layer, a high-barrier layer taking aluminum foil as a substrate, and a heat sealing layer of a polyurethane elastomer film from the outside in. A preparation method of the composite comprises the steps of A preparing the high-barrier layer, and compositing polyethylene glycol terephthalate film and a polyamide film on the upper and the lower surfaces of the substrate, namely the aluminum foil, B compositing the upper surface of the high-barrier layer with a camouflage layer and curing, C compositing the lower surface of the high-barrier layer with the heat sealing layer of the thermoplastic polyurethane elastomer film and curing, and D coating the internal surface of the heat sealing layer with an antistatic agent, and obtaining the camouflage composite. According to the composite and the method, with the adoption of specific compositing and curing processes, the prepared camouflage composite has puncture-proof, tear-resistant, anti-static and high-barrier functions and the like, a protection envelope prepared by the material can effectively prevent army materials from being damp during long-term field storage and transportation, and the storage and transportation quality of the materials is improved.

Owner:中国人民解放军32181部队

Elastic mud ground wal ceramic tile and manufacturing method

InactiveCN101045640AMeet the requirements of environmentally friendly green building materialsGood weather resistanceCeramic shaping apparatusBuilding componentsFoaming agentEmulsion

An elastic clay tile for floor and wall is prepared from ordinary clay, emulsion of acrylic acid and optional assistant including disperser, softening agent, foaming agent, coloring agent and water through pulverizing clay, sieving, mixing it with said emulsion of acrylic acid and assistant, stirring, coating it on formwork, baking and removing formwork. It has high elasticity, and high antiskid, antiwear, water-proof flame-retarding and thermal insulating performance.

Owner:石磊

Anti-flaming aging-resistant rubber material

The invention discloses an anti-flaming aging-resistant rubber material which comprises the following constituents in parts by weight: 40 parts to 45 parts of butadiene styrene rubber, 30 parts to 36 parts of polyurethane elastomer, 10 parts to 15 parts of chlorinated butyl rubber, 2 parts to 3 parts of vulcanizing agent BPO, 1.2 parts to 1.8 parts of sulphur, 2 parts to 4 parts of divinyl carboxylic acid sodium, 20 parts to 30 parts of calcite powder, 9 parts to 11 parts of kieselguhr, 5 parts to 7 parts of aluminum silicate, 14 parts to 15 parts of carbon black N660, 14 parts to 15 parts of carbon black N330, 10 parts to 12 parts of magnesium hydroxide, 3 parts to 5 parts of quartz powder, 5 parts to 7 parts of zinc oxide, 2 parts to 4 parts of calcium stearate, 5 parts to 8 parts of barium stearate, 5 parts to 7 parts of diphenyl phosphate ester, 2 parts to 4 parts of melamine, and 1.5 parts to 2.5 parts of silane coupling agent KH450. The anti-flaming aging-resistant rubber material has an excellent anti-flaming aging-resistant performance, so that smog is effectively prevented from generating during a combustion process; besides, the ozone resistance and the weather resistance of the anti-flaming aging-resistant rubber material are excellent; moreover, the anti-flaming aging-resistant rubber material further has the advantages of high elasticity, high hardness and high strength.

Owner:南通鹏达体育用品有限公司

A shock-absorbing treadmill

ActiveCN109350909BRelieve pressureImprove comfortMovement coordination devicesCardiovascular exercising devicesClassical mechanicsEngineering

Owner:浙江力玄运动科技股份有限公司

Polylactic acid resin composition

The present invention relates to one kind of polylactic acid resin composition. The polylactic acid resin composition consists of polylactic acid resin 50-85 wt%, glycecol triacetate 15-50 wt% and lubricant 0.01-1 wt%. The plasticized polylactic acid resin composition is especially suitable for making polylactic acid film, and has the features of low cost, high toughness, high tear resistance and high transparency.

Owner:ZHEJIANG UNIV OF TECH

Sturgeon leather production method and sturgeon leather produced using same

InactiveCN102154529AImprove wrinkle resistanceFeel goodSpecial leather manufactureEngineeringSturgeon

The invention provides a sturgeon leather production method and a sturgeon leather produced using same. The sturgeon leather production method comprises the following steps of: 1) pretreating a sturgeon leather raw material with a bone deck by means of cleaning, soaking and degreasing; 2) sequentially performing primary softening, pickle softening and tanning to the bone deck of the pretreated sturgeon leather by means of cleaning, soaking and degreasing, so that the bone deck is softened; and 3) treating the sturgeon leather with the softened bone deck by means of neutral retanning, dyeing, greasing and drying to obtain the sturgeon leather with the softened bone deck after the bone deck is treated by means of the primary softening, the pickle softening and the tanning. The sturgeon leather produced by the method is soft and ventilate, and has good tear-resistant performance and buckling-resistant performance, so that the special bone deck of the sturgeon is firmly adhered to the surface of the leather without falling off, the bone deck can be bended at 45-90 degrees without breaking off, and each bone deck is distinct in gradation, natural in decorative pattern, beautiful and fashionable.

Owner:李宏强

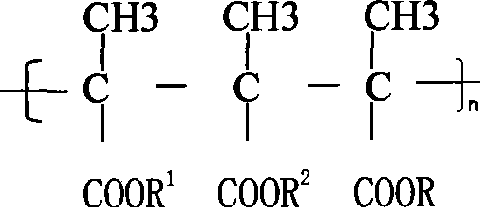

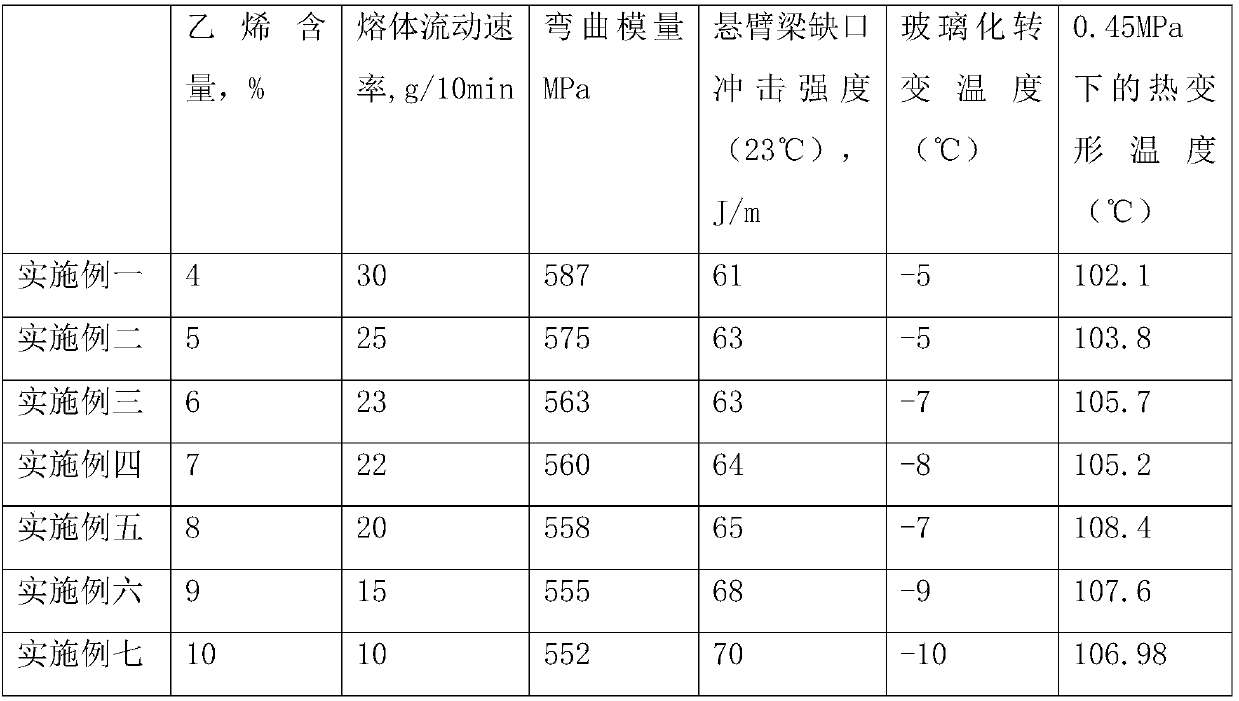

High-toughness polypropylene resin and production method thereof

The invention discloses high-toughness polypropylene resin and a production method thereof. The high-toughness polypropylene resin is mainly prepared from high-toughness polypropylene base materials,antioxidants 1, antioxidants 2 and halogen absorbing agents, and the base materials are produced by a two-step compounding method in a Spheripol process. A production method of the base materials particularly includes the steps: taking propylene and hydrogen as raw materials in a first loop reactor, adding a catalyst, an electron donor and a promoter, controlling the concentration of the hydrogento be 4245-4300mg / kg, controlling loop density to be 460kg / m<3>, controlling ethylene content to be 0.5-6wt%, and producing polypropylene random copolymers; performing gas-phase copolymerization reaction on propylene homopolymers and ethylene monomers in the polypropylene random copolymers acquired in the first step in a second loop reactor, controlling the concentration of the hydrogen to be 4245-4260mg / kg, controlling loop density to be 460kg / m<3>, controlling loop density to be 470kg / m<3>, controlling ethylene content to be 4-10wt%, controlling gas phase ratio to be 0.2-0.5, preparing polypropylene powder, and namely, preparing the base materials. The bending modulus is 600MPa or more, the impact strength of a cantilever beam gap is 60J / m (23 DEG C) or more, haze is smaller than 10, andthe polypropylene resin is provided with good-transparency soft impact-resistant polypropylene.

Owner:CHINA PETROLEUM & CHEM CORP

Method for processing waste leather into top-layer leather

ActiveCN105500804AGood weather resistanceImprove impact resistancePolyureas/polyurethane adhesivesSynthetic resin layered productsEngineeringPolyresin

The invention relates to the technical field of leather processing, in particular to a method for processing waste leather into top-layer leather. The method comprises steps as follows: selection: the waste leather produced after furniture production processing is selected for standby application; spraying of a hot-melt adhesive: the waste leather is laid flatly as one layer, and then a hot-melt adhesive material layer is sprayed on the waste leather; attachment of a resin film: the resin film is attached to the hot-melt adhesive material layer; attachment of cloth: a layer of cloth is attached to the resin film, and a finished leather product is prepared. The leather prepared with the method has good tensile strength and breaking resistance, and the added value of the finished leather product is high.

Owner:DONGGUAN TIANYI LEATHER TECH CO LTD

Preparation method of super-soft cable and external coating material of super-soft cable

ActiveCN104761909AWill not deformSmall bending radiusFlexible cablesCable/conductor manufactureYarnSesquioxide

The invention discloses a preparation method of a super-soft cable and an external coating material of the super-soft cable. The super-soft cable comprises a conductive core stranded by 7-61 groups of folded yarns and the external coating material of the conductive core, wherein each of the folded yarns is stranded by a plurality of tinned copper wires; the conductive core is coated with super-soft high-strength silicon rubber for insulation; the high-strength silicon rubber comprises the following components: methyl vinyl silicone rubber, precipitated white carbon, iron sesquioxide, chlorinated paraffin, magnesium hydrate, an anti-aging agent N-isopropyl benzene-N'-phenyl p-phenylenediamine, hydroxyl silicone oil, silicone oil containing hydrogen, dioctyl phthalate, a surfactant gamma-thiopropyl triethoxy silane, a silane coupling agent and a bis-2, 5 vulcanizing agent. The super-soft cable has the characteristics of bending resistance, corrosion resistance, wear resistance and the like, is relatively high in using temperature and relatively long in service life, and can be used for various types of equipment which is small in cable laying space and great in number of round trips.

Owner:西安飞机工业(集团)亨通航空电子有限公司

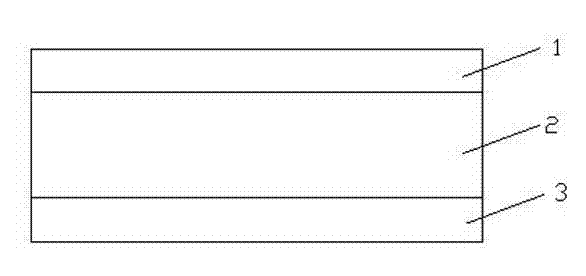

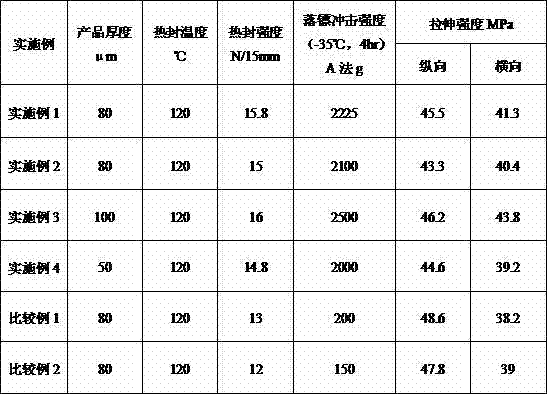

Cast polypropylene heavy packaging film

InactiveCN102501526ABreak the regularityHigh impact strengthFlexible coversWrappersElastomerPuncture resistance

The invention relates to a cast polypropylene heavy packaging film, which consists of a heat-seal layer, a core layer and a corona layer, wherein the heat-seal layer, the core layer and the corona layer are made of a polypropylene and elastomer blend; the heat-seal layer contains 20 to 30 weight percent of elastomer; the core layer contains 30 to 50 weight percent of elastomer; and the corona layer contains 10 to 20 weight percent of elastomer. The cast polypropylene heavy packaging film is convenient to prepare, product thickness is effectively reduced, the cast polypropylene heavy packaging film can be used at low temperature of -35DEG C, the dart impact strength and puncture resistance of the film can be improved, and the cast polypropylene heavy packaging film meets the requirement of heavy packaging.

Owner:任丘市京开塑业有限公司

High-strength cold-resistant rubber

The invention discloses a high-strength cold-resistant rubber which is characterized by comprising the following components in parts by weight: 100 parts of nitrile-butadiene rubber, 12 parts of natural rubber, 8 parts of melamine resin, 5 parts of polyvinyl chloride, 33 parts of carbon black, 4 parts of pine tar, 9 parts of bamboo fiber, 2.4 parts of anti-aging agent AW, 3 parts of vulcanizing agent, 0.2 part of accelerator, 5.5 parts of plasticizer, 3.7 parts of softening agent and 4 parts of stearic acid. By adding the bamboo fiber, the obtained rubber has the advantages of high strength and tear resistance; and the high-strength cold-resistant rubber can be used at low temperature for a long time, basically has the same physiochemical properties as normal temperature, and prolongs the service life of the rubber product.

Owner:ANHUI JIAMU RUBBLE & PLASTIC IND

Multifunctional inherent-flame-retardant viscose blended yarn, fabric and yarn preparation method

InactiveCN105483890ALow fabric costCost-effectiveWoven fabricsYarnTemperature resistanceElectric arc

The invention provides multifunctional inherent-flame-retardant viscose blended yarn, fabric and a yarn preparation method. The viscose blended yarn comprises 50wt%-80wt% of flame-retardant viscose fibers, 20wt%-50wt% of aromatic polyamide fibers and 0-5wt% of antistatic fibers. The multifunctional inherent-flame-retardant viscose blended yarn has the multiple advantages of electric arc resistance, high temperature resistance, heat insulation, comfort, breathability and the like; the fabric is low in cost, high in cost performance and excellent in protective performance and has the performance of high fiber strength, tearing resistance, excellent wear resistance, good flame retardance, high-temperature resistance, heat insulation and the like. Therefore, the industrial enlarged production requirement is sufficiently met, and personal safety of a worker can be sufficiently guaranteed.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Fixed-guiding non-woven fabric production method

ActiveCN106948088AThe overall thickness is thinLight in massConjugated synthetic polymer artificial filamentsNon-woven fabricsPhotosensitizerNonwoven fabric

The invention discloses a fixed-guiding non-woven fabric production method. The method comprises the following steps: preparing raw material used for non-woven fabric; heating and melting polylactide and polypropylene to obtain melts; adding photosensitizers, ammonium polyphosphates, fillers, antibacterial agents and titanate coupling agents into melts, stirring and mixing uniformly, spraying through spinneret holes and carrying out cooling solidification to form fibers; crossly arraying fibers in horizontal-vertical directions and forming a fiber net through carding; adjusting flatness of the fiber net and conveying the net into a hot milling machine for hot-press formation and finally performing trimming and examination. The fixed-guiding non-woven fabric production method has the following beneficial effects: raw material is safe and eco-friendly; the production method is easy; a production condition is mild; a product is good in formability, low in prediction cost and suitable for industrialized production; non-woven fabric is featured by being small in thickness, low in weight, good in tenacity and anti-moisture, breathable and tear-resistant; by adding ammonium polyphosphate, fillers and antibacterial agents, the non-woven fabric is antibacterial, flame-retardant, dustproof and biodegradable and worthy of promotion.

Owner:晋江市天守服装织造有限公司 +2

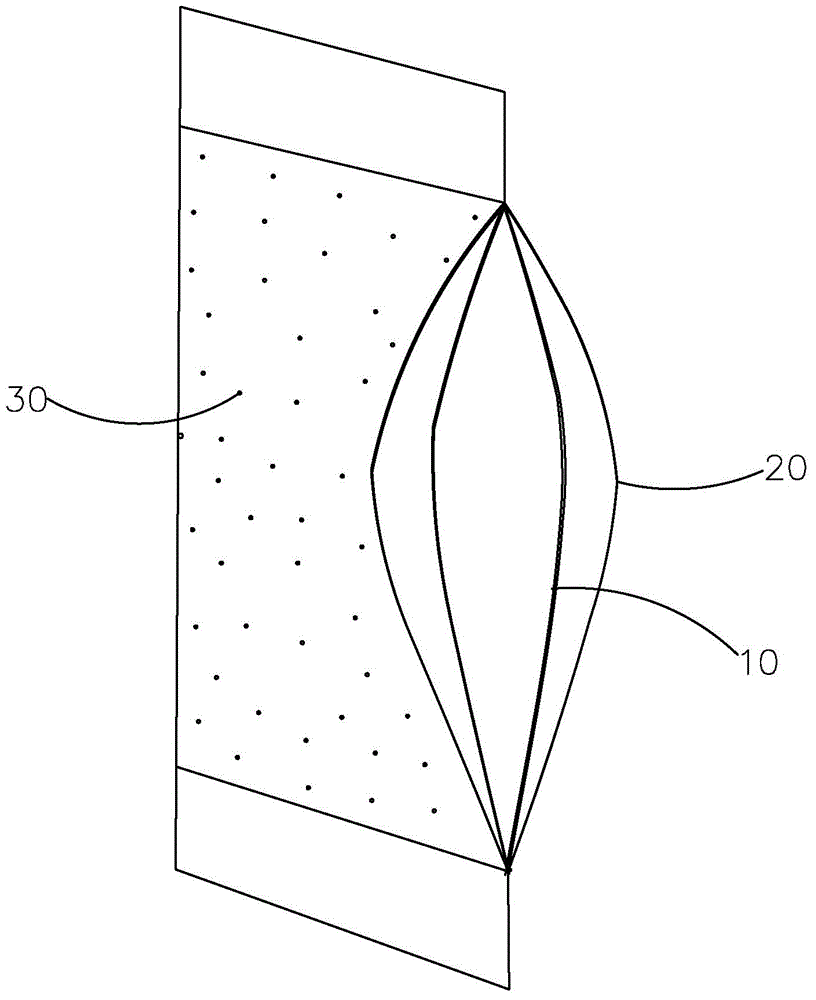

Dynamic human stomach-duodenum in-vitro bionic digestive system

The invention discloses a dynamic human stomach-duodenum in-vitro bionic digestive system comprising a heating incubator and an esophagus model, a stomach model, a duodenum model, peristaltic extrusion devices and a digestion emptying unit which are located in the heating incubator, and the esophagus model, the stomach model and the duodenum model are connected with one another; the peristaltic extrusion devices are arranged on the two sides of the esophagus model, the stomach model and the duodenum model respectively and used for achieving bionic movement of the esophagus model, the stomach model and the duodenum model; and the digestion emptying unit comprises a feeding device connected with an inlet of the esophagus model, a digestive juice adding device connected with the stomach modeland the duodenum model, and an emptying device connected with an outlet end of the duodenum model. According to the dynamic human stomach-duodenum in-vitro bionic digestive system in the invention, the digestive process of the stomach and the duodenum of a human body can be truly simulated, accurate test data is provided for researching the digestive system of the human body, and meanwhile animalexperiments and human body experiments can be properly reduced to a certain extent.

Owner:COFCO NUTRITION & HEALTH RES INST

Omni-directional metallic-coating polyolefin conductive foam and preparation method thereof

ActiveCN102963096AEffective shieldingImprove conductivitySynthetic resin layered productsPolyolefinOmni directional

The invention relates to electro-magnetic interference (EMI) protection omni-directional metallic-coating polyolefin conductive foam and a preparation method thereof. The preparation method comprises the following steps of: preparing conductive master batches, preparing flame retardant master batches, preparing foamed master batches, extruding sheets, carrying out radiation crosslinking on the sheets, foaming the sheets, bonding conductive non-woven fabrics, punching the foam and electroplating the foam. The conductive foam provides effective EMI shielding, has the advantages of high conductivity, ultra-thin type, light weight, corrosion resistance, attractive appearance and the like, is easy to shape; the surface of the conductive foam can conduct electricity, and the whole material is conducted from top to bottom; and the conductive foam has omni-directional electrical conductivity, and has the thickness of 0.10-0.50mm. The conductive foam disclosed by the invention is widely applied to electronic products such as a personal digital assistant (PDA) palm computer, a liquid crystal display (LCD), a mobile phone, a digital television, a notebook computer and a digital camera.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Polylactic acid resin composition

The present invention relates to one kind of polylactic acid resin composition. The polylactic acid resin composition consists of polylactic acid resin 50-85 wt%, glycecol triacetate 15-50 wt% and lubricant 0.01-1 wt%. The plasticized polylactic acid resin composition is especially suitable for making polylactic acid film, and has the features of low cost, high toughness, high tear resistance and high transparency.

Owner:ZHEJIANG UNIV OF TECH

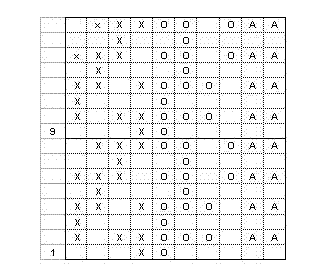

Production method of high-curliness canvas for rubber conveyer

InactiveCN103753931AEasy to curlEven by forceLamination ancillary operationsFibre typesPolyesterTear resistance

The invention discloses a production method of a high-curliness canvas for a rubber conveyer. The production method comprises the following steps: selecting high-strength polyester and nylon industry long filament as materials of products; selecting a structure with coordinated weft and warp match and using a broken twill texture structure with proper weft and warp-density; subjecting the gray fabric to gum dipping, so as to produce the framework material. The framework material produced by the method is used for producing the canvas for the rubber conveyer, and the canvas has advantages of uniform stress, high curliness, impact resistance, not easy delamination and corrugation, tear resistance, stable bonding with the rubber and high strength, so that the canvas is the ideal framework material for producing the rubber conveyer, and the rubber conveyer produced by the framework material can be used in production equipment with relatively small roller diameter or improve the warp-direction curliness in the production process of a high-layer thick rubber belt. The rubber conveyer is prevented from bending and corrugating, or being broken during the using process, and the service life of the rubber conveyer is prolonged.

Owner:SHANDONG TIANHENG CHEM FIBER

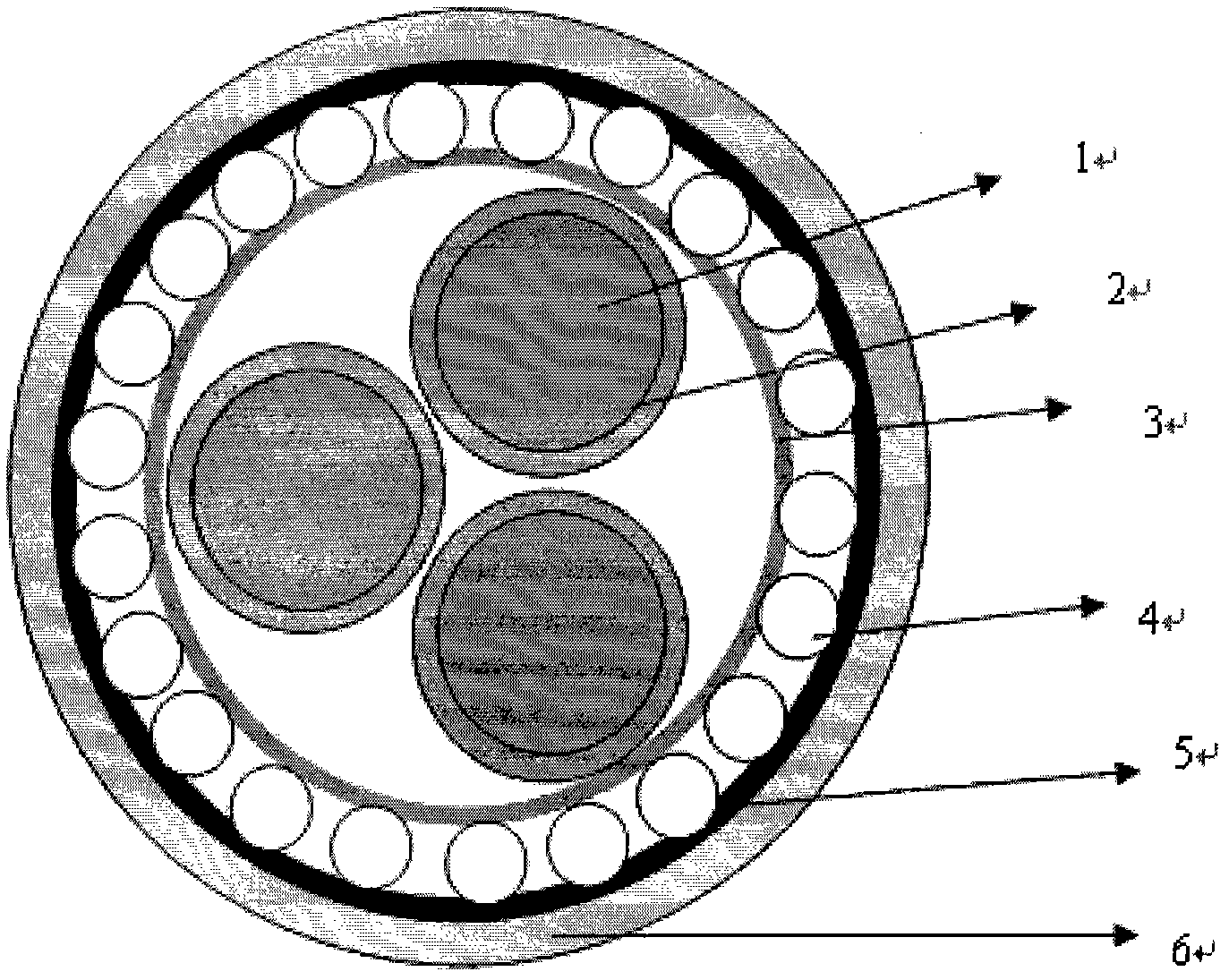

Cold-resistant, corrosion-resistant, flame-retardant and anti-interference double-sheath cable

ActiveCN110993171APrevent slippageImprove flame retardant performanceInsulated cablesCable/conductor manufactureEngineeringMoisture resistance

The invention discloses a cold-resistant, corrosion-resistant, flame-retardant and anti-interference double-sheath cable. The cable comprises an outer sheath, an anti-torsion layer, an inner sheath, awater-blocking filler and a cable core; the inner sheath is extruded on the outer side of the cable core, the anti-torsion layer is wrapped on the outer side of the inner sheath, and the outer sheathis extruded on the outer side of the anti-torsion layer; and the cable core comprises three wire cores, a tensile rope and a fixing rope. The inner sheath, the anti-torsion layer and the outer sheathare sequentially wrapped on the outer side of the cable core; double protection can be effectively performed on the cable; the cold resistance, moisture resistance and corrosion resistance of the cable are improved; the wire core can be effectively fixed and dragged through the fixing rope; the cable core is prevented from deforming and breaking due to mutual extrusion in the bending process, thefriction force between the cable core and the sheath can be effectively improved through the circularly wrapped fixing rope, the slippage between the cable core and the inner sheath is avoided, the generated stress is homogenized and eliminated through the ductility of the fixing rope, the cracking and deformation of the cable are avoided, and the service life of the cable is prolonged.

Owner:JINAN SHENGTONG POWER CABLE

Semi-hard low-temperature resistant PVC cable material and preparation method and application thereof

InactiveCN109401128AImprove low temperature resistanceWith pressurePlastic/resin/waxes insulatorsPolymer scienceStearic acid

The invention provides a semi-hard low-temperature resistant PVC cable material. The semi-hard low-temperature resistant PVC cable material is prepared from the following components in parts by weight: 100 parts of a PVC resin, 0-10 parts of dioctyl phthalate, 1-30 parts of terpolymer, 0-30 parts of calcium carbonate, 0.1-0.2 part of polyethylene wax, 0.1-0.2 part of stearic acid, 2-5 parts of a calcium-zinc composite stabilizer and 0.01-1 part of high-density oxidized polyethylene wax. The invention further provides a preparation method of the semi-hard low-temperature resistant PVC cable material. The preparation method of the semi-hard low-temperature resistant PVC cable material comprises the following steps that S1, each raw material is weighed according to the weight value of the formula, and the raw materials are added into a high-speed mixer for mixing and plasticizing; S2, the mixture is transferred to a double-screw extruder for extrusion processing, and extruding and granulating are carried out through a single-screw extrusion granulator; and S3, air-cooled conveying and packaging is carried out. The semi-hard low-temperature resistant PVC cable material can be used formanufacturing wire and cable sheathing layers and insulating layers with high product flexibility requirements, such as wind energy cables, photoelectric composite cables, elevator cables, and built-in wires of refrigeration equipment, and has good low-temperature resistance and high hardness.

Owner:SUZHOU HENGLI COMM MATERIAL

Protective paint for electric equipment

InactiveCN106519966AWear-resistantWith temperature and weather resistancePlastic/resin/waxes insulatorsAnti-corrosive paintsEpoxyElectric power equipment

The invention relates to the field of coating material for electric equipment, in particular to protective paint for electric equipment. The protective paint mainly comprises the following components in parts by weight: 30-40 parts of organosilicon glass resin, 15-20 parts of polyurethane resin, 15-30 parts of diphenol propane epoxy resin, 10-20 parts of thermosetting phenolic resin, 12-15 parts of ceramic particles, 2-3 parts of fumed silica and 1-2 parts of polyamide wax. The protective paint for the electric equipment, provided by the invention, has the properties of wear resistance, temperature resistance, weather resistance, corrosion resistance and excellent adhesiveness.

Owner:德阳瑞能电力科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com