Aramid rubber canvas fabric structure for high-strength conveyor belts and production process of aramid rubber canvas fabric structure

A technology of dipping canvas and fabric structure, which is applied in the field of industrial fabrics, can solve the problems of poor flexibility of conveyor belts, difficult recycling and processing, body weight and other problems, and achieves improved mechanical and physical properties, high production efficiency, and light weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of production technology of aramid fiber dipped canvas fabric structure for high-strength conveyor belt, comprises the following steps:

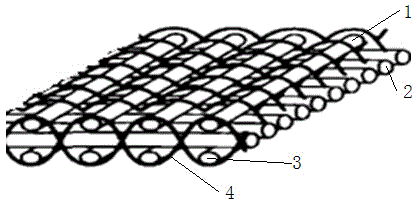

[0030](1) Machine weaving process of the fabric: the warp-feeding weaving fabric with double warp beams is adopted, and the weft yarns of the upper and lower layers and the warp yarns of the middle layer are bundled by the straight warp and straight weft weaving method, so that the three-layer structure is tightly compounded and fixed together , the weaving uses a Dornier loom with a double warp beam device, and the warp yarn passes through a split rod, draws in healds, and reeds. The machine tension is 15~30KN, and the weaving speed is 150~300rpm / min;

[0031] (2) Dipping process: decoupling, dipping in one bath, drying, heat treatment, dipping in two baths, drying, heat treatment, coiling, packaging;

[0032] a) Decoupling: after the canvas is put on the machine, the decoupling tension is 100-150 kg, after pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com