Cast polypropylene heavy packaging film

A technology of casting polypropylene and packaging film, applied in the directions of packaging, wrapping paper, transportation and packaging, etc., can solve the problems of use in the field of heavy packaging, poor low temperature resistance and impact resistance, brittle film, etc., to achieve vertical and horizontal High tear strength, high flex crack resistance, and the effect of reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

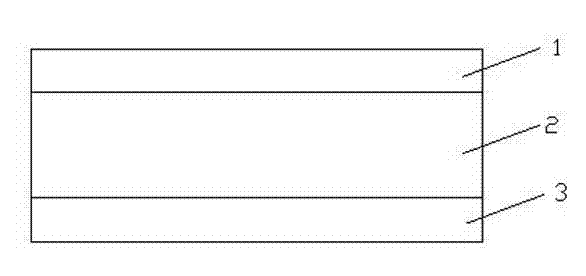

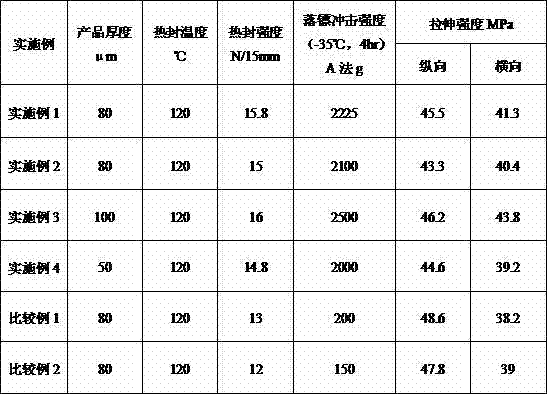

[0021] A kind of cast polypropylene heavy packaging film, its structure is as figure 1 As shown, it includes heat sealing layer 1, core layer 2 and corona layer 3. The heat-sealing layer 1 selects a ternary copolymerized polypropylene and an elastomer blend, wherein the elastomer content in the blend is 30% of the total weight; the core layer 2 selects a binary copolymerized polypropylene and an elastomer blend, wherein The content of elastomer in the blend is 40%; the corona layer 3 is a blend of binary copolymerized polypropylene and elastomer, wherein the content of elastomer in the blend is 20%. The blend of heat seal layer, core layer and corona layer is plasticized and extruded through an extruder at 240°C, and then cast through a T-shaped die head at 230°C, and then passed through a casting roll at 25°C Cold film formation, and corona spark treatment is carried out on the surface of the corona layer 3, making its surface tension greater than 38mN / m, and then winding at...

Embodiment 2

[0027] A kind of cast polypropylene heavy packaging film, its structure is as figure 1 As shown, it includes heat sealing layer 1, core layer 2 and corona layer 3. The heat-sealing layer 1 selects a ternary copolymerized polypropylene and an elastomer blend, wherein the elastomer content in the blend is 20% of the total weight; the core layer 2 selects a binary copolymerized polypropylene and an elastomer blend, wherein The content of elastomer in the blend is 30%; the corona layer 3 is a blend of binary copolymerized polypropylene and elastomer, wherein the content of elastomer in the blend is 10%. The blend of heat seal layer, core layer and corona layer is plasticized and extruded through an extruder at 240°C, and then cast through a T-shaped die head at 230°C, and then passed through a casting roll at 25°C Cold film formation, and corona spark treatment is carried out on the surface of the corona layer 3, making its surface tension greater than 38mN / m, and then winding at...

Embodiment 3

[0030] A kind of cast polypropylene heavy packaging film, its structure is as figure 1 As shown, it includes heat sealing layer 1, core layer 2 and corona layer 3. The heat-sealing layer 1 selects a ternary copolymerized polypropylene and an elastomer blend, wherein the elastomer content in the blend is 30% of the total weight; the core layer 2 selects a binary copolymerized polypropylene and an elastomer blend, wherein The content of elastomer in the blend is 40%; the corona layer 3 is a blend of binary copolymerized polypropylene and elastomer, wherein the content of elastomer in the blend is 20%. The blend of heat seal layer, core layer and corona layer is plasticized and extruded through an extruder at 240°C, and then cast through a T-shaped die head at 230°C, and then passed through a casting roll at 25°C Cold film formation, and corona spark treatment is carried out on the surface of the corona layer 3, making its surface tension greater than 38mN / m, and then winding at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com