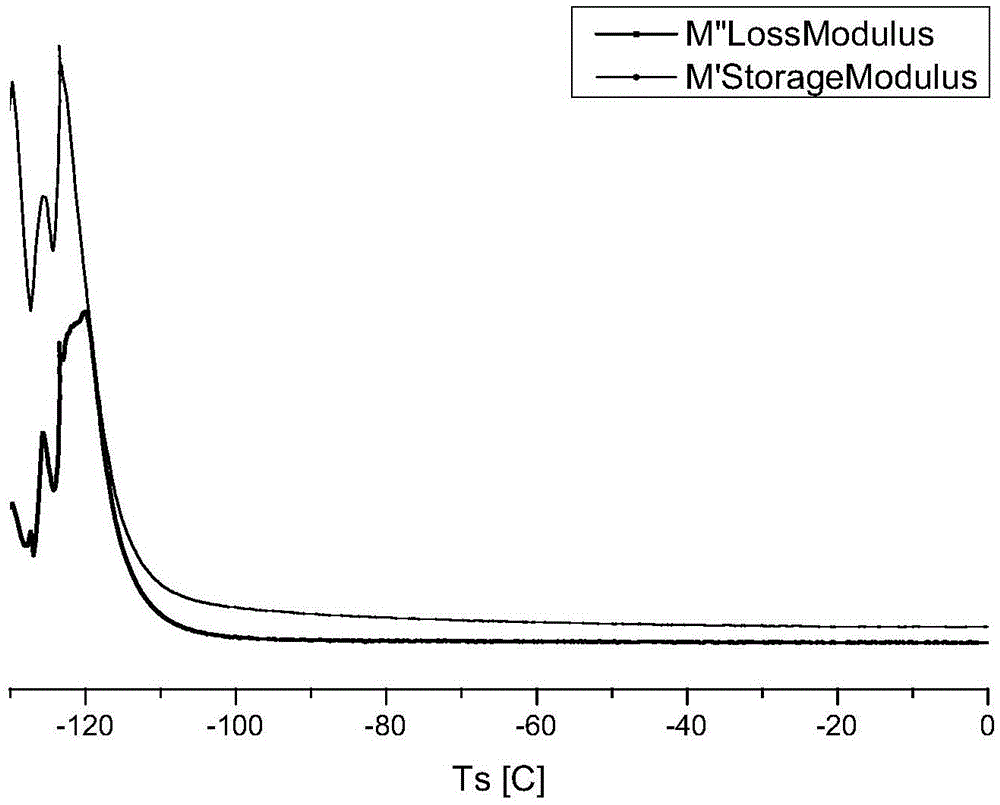

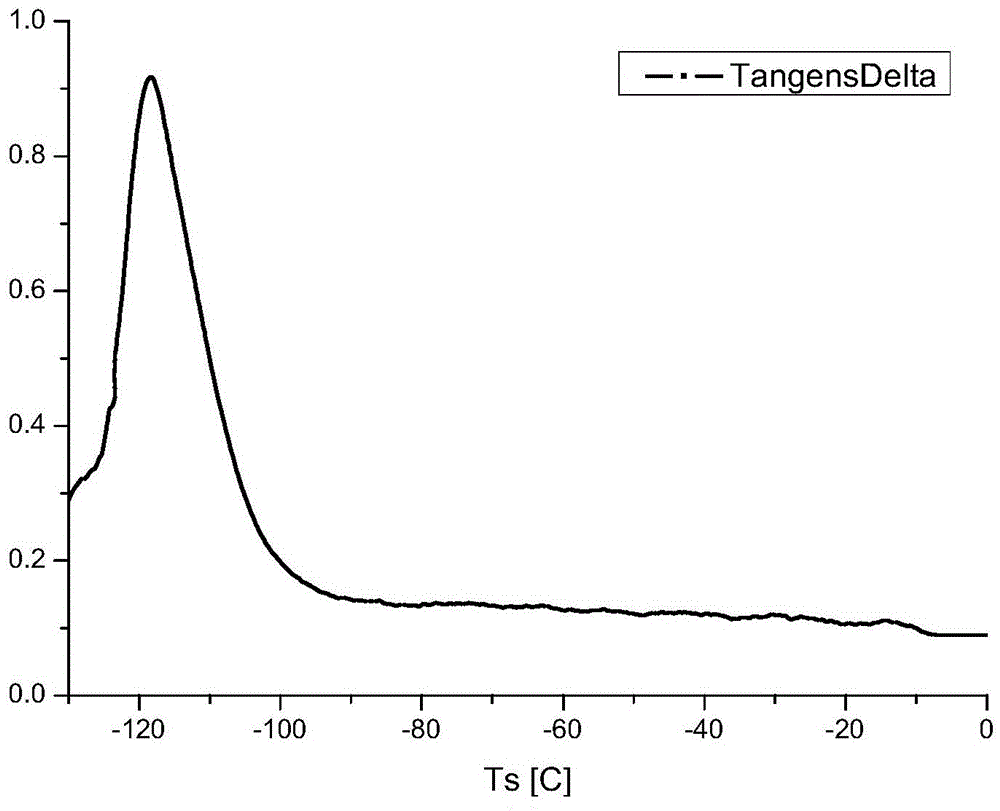

Preparation method of dealcoholized silicone sealant resistant to -110°C low temperature

A dealcoholized, silicone technology, applied in the field of fine chemicals, can solve the problems of application scope and field limitation, loss of sealing effect, material hardening and brittleness, etc., achieving long service life, eliminating low temperature resistance and eliminating crystallization temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for preparing a dealcoholized silicone O-ring with low temperature resistance of -110°C, the steps are as follows:

[0042] A. Put 80 parts by weight of α, ω-terminated hydroxyl polydiethyldimethylsiloxane (the molar content of diethylsiloxane chain unit is 17%) into the container, and stir at a speed of 50 rpm , adding 0.2 parts by weight of hexamethyldisilazane as a moisture absorber, stirring and mixing for 30 minutes to prepare a mixed solution a;

[0043] B. The surface of 12 parts by weight is hydrophobically modified with hexamethyldisilazane, and the specific surface area is 200m 2 / g of fumed white carbon black was slowly added to the mixed solution a prepared in step A under stirring conditions, and stirred for 2 hours at a stirring speed of 50 rpm to prepare mixed solution b, which was left to stand for subsequent use;

[0044] C. Add the mixed liquid b prepared in step B into the planetary mixer, and evacuate to 1×10 -3 ~10 -4 Pa, stirring at a s...

Embodiment 2

[0051] A method for preparing a dealcoholized silicone gasket resistant to low temperatures of -110°C, the steps are as follows:

[0052] A. Put 73 parts by weight of α, ω-terminated hydroxyl polydiethyldimethylsiloxane (the molar content of diethylsiloxane chain unit is 24%) into the container, and stir at a speed of 50 rpm , adding 0.2 parts by weight of isocyanate as a moisture absorber, stirring and mixing for 15 minutes to prepare a mixed solution a;

[0053] B, 19 parts by weight surface has been D 4 Hydrophobically modified, with a specific surface area of 150m 2 / g of fumed white carbon black was slowly added to the mixed solution a prepared in step A under stirring conditions, and stirred for 3.5 hours at a stirring speed of 30 rpm to prepare the mixed solution b, which was left to stand for subsequent use;

[0054] C. Add the mixed liquid b prepared in step B into the planetary mixer, and evacuate to 1×10 -3 ~10 -4 Pa, stirring at a speed of 30 rpm for 30 minut...

Embodiment 3

[0060] A method for preparing a dealcoholized silicone sealing block resistant to low temperatures of -110°C, the steps are as follows:

[0061] A. Put 66 parts by weight of α, ω-terminated hydroxyl polydiethyldimethylsiloxane (the molar content of diethylsiloxane chains is 30%) into the container, and stir at a speed of 50 rpm Next, add 0.3 parts by weight of hexamethyldisilazane as a water absorbent, and stir and mix for 15 minutes to prepare a mixed solution a;

[0062] B. The surface of 25 parts by weight has been hydrophobically modified with dimethyldichlorosilane, and the specific surface area is 120m 2 / g of fumed white carbon black was slowly added to the mixed solution a prepared in step A under stirring conditions, and stirred for 3 hours at a stirring speed of 30 rpm to prepare mixed solution b, which was left to stand for subsequent use;

[0063] C. Add the mixed liquid b prepared in step B into the planetary mixer, and evacuate to 1×10 -3 ~10 -4 Pa, stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com