Triethylene tetramine modified resin film and preparation method thereof

A technology of triethylenetetramine and resin film, applied in the field of polymer materials, can solve the problems of low production efficiency, high production difficulty and high production cost, and achieve the effects of less equipment, increased area and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with specific embodiments.

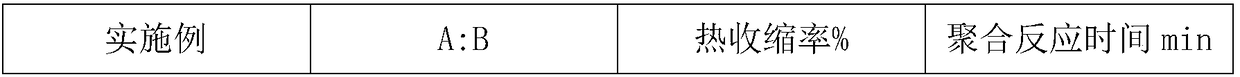

[0018] Embodiments 1 to 11, based on 100 parts of terephthalic acid: 150 parts of ethylene glycol, 30 parts of dicyclohexylcarbodiimide, 0.02 parts of 1-hydroxybenzotriazole, and 10 parts of nano silicon dioxide , mixed catalyst is 0.04 part, and take terephthalic acid and triethylenetetramine according to the weight ratio of terephthalic acid and triethylenetetramine in table 1, then carry out the preparation of resin film according to the following steps: first weigh After the terephthalic acid, dicyclohexylcarbodiimide, 1-hydroxybenzotriazole and ethylene glycol are stirred evenly, they are added to the reaction kettle for reaction, and then triethylenetetramine and nano silicon dioxide are added into the reaction kettle, continue to stir until the mixture is uniform, then add the mixed catalyst to carry out the polymerization reaction, and obtain the polymerization reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com